Page 1

Plasma arc cutting system

Operator Manual – 805160

Revision 2

Page 2

Register your new Hypertherm system

Register your product on-line at www.hypertherm.com/registration for

easier technical and warranty support. You can also receive updates on new

Hypertherm products and a free gift as a token of our appreciation.

For your records

Serial number: _____________________________________________

Purchase date: _____________________________________________

Distributor: _____________________________________________

________________________________________________________

________________________________________________________

Maintenance notes:

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

____________________________________________________________

Page 3

powermax30

Operator Manual

(P/N 805160)

Revision 2 – November 2009

Hypertherm, Inc.

Hanover, NH USA

www.hypertherm.com

email:info@hypertherm.com

© Copyright 2009 Hypertherm, Inc.

All Rights Reserved

Hypertherm and Powermax are trademarks of Hypertherm, Inc.

and may be registered in the United States and/or other countries.

Page 4

7/1/09

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

Hypertherm Automation

5 Technology Drive, Suite 300

West Lebanon, NH 03784 USA

603-298-7970 Tel

603-298-7977 Fax

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D-63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm (S) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

65 6841 2489 (Technical Service)

Hypertherm (Shanghai) Trading Co., Ltd.

Unit A, 5th Floor, Careri Building

432 West Huai Hai Road

Shanghai, 200052

PR China

86-21 5258 3330/1 Tel

86-21 5258 3332 Fax

Hypertherm Europe B.V.

Vaartveld 9

4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

Hypertherm Japan Ltd.

801 Samty Will Building

2-40 Miyahara 1-Chome,

Yodogawa-ku, Osaka

532-0003, Japan

81 6 6170 2020 Tel

81 6 6170 2015 Fax

Hypertherm Brasil Ltda.

Avenida Doutor Renato de

Andrade Maia 350

Parque Renato Maia

CEP 07114-000

Guarulhos, SP Brasil

55 11 2409 2636 Tel

55 11 2408 0462 Fax

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Page 5

ELECTROMAGNETIC COMPATIBILITY (EMC)

4-08

Hypertherm i

EMC Introduction

Hypertherm’s CE-marked equipment is built in

compliance with standard EN60974-10. The

equipment should be in stalled and used in

accordance with the information be low to

achieve elec tro mag net ic com pat i bil i ty.

The limits required by EN60974-10 may not

be adequate to com plete ly eliminate in ter fer ence when the affected equip ment is in close

proximity or has a high degree of sen si tivity.

In such cases it may be nec es sary to use other

mea sures to further re duce interference.

This cutting equipment is designed for use

only in an in dus tri al environment.

Installation and use

The user is responsible for installing and

using the plasma equipment according to the

manufacturer’s instructions. If elec tro mag net ic

disturbances are de tect ed then it shall be the

respon si bil i ty of the user to re solve the

situation with the technical as sis tance of the

man u fac tur er. In some cases this remedial

action may be as sim ple as earthing the

cutting circuit, see Earthing of Workpiece.

In other cas es it could involve constructing an

electromag net ic screen enclosing the pow er

source and the work complete with associated

input filters. In all cases elec tro mag net ic

disturbanc es must be reduced to the point

where they are no longer trou ble some.

Assessment of area

Before installing the equipment the user shall

make an assessment of po ten tial electro magnet ic problems in the sur round ing area.

The following shall be taken into account:

a. Other supply cables, control cables,

signalling and telephone ca bles; above,

below and adjacent to the cutting equipment.

b. Radio and television transmitters and

receivers.

c. Computer and other control equip ment.

d. Safety critical equipment, for example

guarding of industrial equipment.

e. Health of the people around, for example the

use of pacemakers and hear ing aids.

f. Equipment used for calibration or

measurement.

g. Immunity of other equipment in the

environment. User shall ensure that other

equipment being used in the environment is

com pat i ble. This may require ad di tion al

protection measures.

h. Time of day that cutting or other ac tiv i ties

are to be carried out.

The size of the sur round ing area to be con sidered will depend on the structure of the

building and other activities that are tak ing

place. The surrounding area may ex tend

beyond the bound aries of the pre mises.

Methods of reducing

emissions

Mains supply

Cutting equipment must be con nect ed to the

mains supply according to the man u fac tur er’s

recom men da tions. If in ter fer ence occurs, it may

be necessary to take addi tional precautions

such as fil ter ing of the mains supply.

Consideration should be given to shield ing the

supply cable of per ma nent ly installed cutting

equip ment, in metallic conduit or equiv a lent.

Shielding should be elec tri cal ly continuous

through out its length. The shielding should

be con nect ed to the cutting mains supply so

that good electrical contact is maintained

between the conduit and the cutting pow er

source enclosure.

Page 6

ELECTROMAGNETIC COMPATIBILITY (EMC)

4-08

ii Hypertherm

Maintenance of cutting equipment

The cutting equipment must be rou tine ly

maintained according to the man u fac tur er’s

recom men da tions. All ac cess and service doors

and covers should be closed and properly

fastened when the cutting equip ment is in

operation. The cutting equipment should not be

modified in any way except for those chang es

and ad just ments covered in the manufac tur er’s

instructions. In par tic u lar, the spark gaps of arc

striking and sta bi liz ing devices should be

adjusted and maintained according to the

manu fac tur er’s recommendations.

Cutting cables

The cutting cables should be kept as short

as possible and should be po si tioned close

together, running at or close to the floor level.

Equipotential bonding

Bonding of all metallic components in the

cutting installation and adjacent to it should be

considered. However, metallic com po nents

bonded to the workpiece will increase the risk

that the op er a tor could receive a shock by

touch ing these metallic compo nents and the

electrode (nozzle for laser heads) at the same

time. The op er a tor should be in su lat ed from all

such bonded metallic components.

Earthing of workpiece

Where the workpiece is not bonded to earth

for electrical safety, nor connected to earth

because of its size and position, for ex am ple,

ship’s hull or building steel work, a con nec tion

bonding the work piece to earth may reduce

emis sions in some, but not all instances.

Care should be taken to prevent the earthing

of the work piece increasing the risk of injury to

users, or damage to other elec tri cal equip ment.

Where necessary, the con nec tion of the

workpiece to earth should be made by a direct

connection to the work piece, but in some

countries where direct connection is not

permitted, the bonding should be achieved by

suit able capacitances se lect ed according to

national regulations.

Note: the cutting circuit may or may not be

earthed for safety reasons. Changing the

earthing arrangements should only be

authorized by a person who is com pe tent to

assess whether the chang es will in crease the

risk of injury, for example, by al low ing parallel

cutting cur rent return paths which may damage

the earth cir cuits of other equipment. Further

guid ance is given in IEC/ TS 62081 Arc

Welding Equip ment Installation and Use.

Screening and shielding

Selective screening and shielding of other

cables and equipment in the surrounding area

may alleviate problems of in ter fer ence.

Screening of the entire plas ma cutting

installation may be con sid ered for special

applications.

Page 7

WARRANTY

Hypertherm iii

4-08

Attention

Genuine Hypertherm parts are the factoryrecommended replacement parts for your

Hypertherm system. Any damage caused by the

use of other than genuine Hypertherm parts may

not be covered by the Hypertherm warranty.

You are responsible for the safe use of the

Product. Hypertherm does not and cannot make

any guarantee or warranty regarding the safe

use of the Product in your environment.

General

Hypertherm, Inc. warrants that its Products shall

be free from defects in materials and workman ship, if Hypertherm is notified of a defect (i) with

respect to the power supply within a period of

two (2) years from the date of its delivery to you,

with the exception of Powermax brand power

supplies, which shall be within a period of three

(3) years from the date of delivery to you, and

(ii) with respect to the torch and leads within a

period of one (1) year from its date of delivery to

you, and with respect to torch lifter assemblies

within a period of one (1) year from its date of

delivery to you, and with respect to laser heads

within a period of one (1) year from its date of

delivery to you. This warranty shall not apply to

any Powermax brand power supplies that have

been used with phase converters. In addition,

Hypertherm does not warranty systems that

have been damaged as a result of poor power

quality, whether from phase converters or

incoming line power. This warranty shall not

apply to any Product which has been incorrectly

installed, modified, or otherwise damaged.

Hypertherm, at its sole option, shall repair,

replace, or adjust, free of charge, any defective

Products covered by this warranty which shall

be returned with Hypertherm’s prior

authorization (which shall not be unreasonably

withheld), properly packed, to Hypertherm’s

place of business in Hanover, New Hampshire,

or to an authorized Hypertherm repair facility, all

costs, insurance and freight pre paid.

Hypertherm shall not be liable for any repairs,

replacement, or adjustments of Products

covered by this war ranty, except those made

pursuant to this paragraph or with Hypertherm’s

prior written consent. The warranty above is

exclusive and is in lieu of all other

warranties, express, implied, statutory, or

otherwise with respect to the Products or

as to the results which may be obtained

therefrom, and all implied war ranties or

conditions of quality or of merchantability

or fitness for a particular purpose or

against infringement. The foregoing shall

constitute the sole and exclusive remedy

for any breach by Hypertherm of its

warranty. Distributors/OEMs may offer different

or additional warranties, but Distributors/OEMs

are not authorized to give any additional

warranty protection to you or make any

representation to you purporting to be binding

upon Hypertherm.

Certification test marks

Certified products are identified by one or more

certification test marks from accredited testing

laboratories. The certification test marks are

located on or near the data plate. Each

certification test mark means that the product

and its safety-critical components conform to

the relevant national safety standards as

reviewed by that testing laboratory. Hypertherm

places a certification test mark on its products

only after that product is manufactured with

safety-critical components that have been

authorized by the accredited testing laboratory.

Once the product has left the Hypertherm

factory, the certification test marks are

invalidated if any of the following occurs:

• The product is significantly modified

in a manner that creates a hazard or

non-conformance.

• Safety-critical components are replaced with

unauthorized spare parts.

Page 8

WARRANTY

4-08

iv Hypertherm

• Any unauthorized assembly or accessory that

uses or generates a hazardous voltage is

added.

• There is any tampering with a safety circuit or

other feature that is designed into the product

as part of the certification.

CE marking constitutes a manufacturer’s

declaration of conformity to applicable European

directives and standards. Only those versions of

Hypertherm products with a CE Marking located

on or near the data plate have been tested for

compliance with the European Low Voltage

Directive and the European EMC Directive.

EMC filters needed to comply with the European

EMC Directive are incorporated within versions

of the power supply with a CE Marking.

Differences in National Standards

Differences in standards include, but are not

limited to:

• Voltages

• Plug and cord ratings

• Language requirements

• Electromagnetic compatibility requirements

These differences in national standards may

make it impossible or impractical for all

certification test marks to be placed on the

same version of a product. For example, the

CSA versions of Hypertherm’s products do not

comply with European EMC requirements and

they do not have a CE marking on the data

plate.

Countries that require CE marking or have

compulsory EMC regulations must use CE

versions of Hypertherm products with the CE

marking on the data plate. These include:

• Australia

• New Zealand

• Countries in the European Union

• Russia

It is important that the product and its

certification test mark be suitable for the enduse installation site. When Hypertherm

products are shipped to one country for export

to another country, the product must be

configured and certified properly for the enduse site.

Higher-level systems

When a system integrator adds additional

equipment; such as cutting tables, motor drives,

motion controllers or robots; to a Hypertherm

plasma cutting system, the combined system

may be considered a higher-level system. A

higher-level system with hazardous moving parts

may constitute industrial machinery or robotic

equipment, in which case the OEM or end-use

customer may be subject to additional

regulations and standards than those relevant to

the plasma cutting system as manufactured by

Hypertherm.

It is the responsibility of the end-use customer

and the OEM to perform a risk assessment for

the higher-level system and to provide

protection against hazardous moving parts.

Unless the higher-level system is certified when

the OEM incorporates Hypertherm products

into it, the installation also may be subject to

approval by local authorities. Seek advice from

legal counsel and local regulatory experts if

uncertain about compliance.

External interconnecting cables between

component parts of the higher level system

must be suitable for contaminants and

movement as required by the final end-use

installation site. When the external inter connecting cables are subject to oil, dust, or

water contaminants, hard usage ratings may be

required. When external interconnecting cables

are subject to continuous movement, constant

flexing ratings may be required. It is the

responsibility of the end-use customer or the

OEM to ensure the cables are suitable for the

application. Since there are differences in the

Page 9

TABLE OF CONTENTS

Electromagnetic compatibility................................................................................................................................i

Warranty....................................................................................................................................................................iii

Section 1 Safety

Recognize safety information ...........................................................................................................................1-2

Follow safety instructions..................................................................................................................................1-2

Cutting can cause fire or explosion ................................................................................................................1-2

Electric shock can kill.........................................................................................................................................1-3

Static electricity can damage circuit boards ................................................................................................1-3

Toxic fumes can cause injury or death............................................................................................................1-4

A plasma arc can cause injury and burns......................................................................................................1-5

Arc rays can burn eyes and skin......................................................................................................................1-5

Grounding safety.................................................................................................................................................1-6

Compressed gas equipment safety................................................................................................................1-6

Gas cylinders can explode if damaged..........................................................................................................1-6

Noise can damage hearing ...............................................................................................................................1-7

Pacemaker and hearing aid operation............................................................................................................1-7

A plasma arc can damage frozen pipes.........................................................................................................1-7

Additional safety information.............................................................................................................................1-7

Warning labels.....................................................................................................................................................1-8

Section 1a Sécurité

Identifier les consignes de sécurité..............................................................................................................1a-2

Suivre les instructions de sécurité................................................................................................................1a-2

Danger Avertissement Précaution..............................................................................................................1a-2

Le coupage peut provoquer un incendie ou une explosion....................................................................1a-2

Les chocs électriques peuvent être fatals ..................................................................................................1a-3

Le coupage peut produire des vapeurs toxiques......................................................................................1a-3

L’arc plasma peut provoquer des blessures ou des brûlures.................................................................1a-4

Les rayons de l’arc peuvent brûler les yeux et la peau.............................................................................1a-4

Mise à la masse et à la terre...........................................................................................................................1a-4

Sécurité des bouteilles de gaz comprimé...................................................................................................1a-5

Les bouteilles de gaz comprimé peuvent exploser en cas de dommages..........................................1a-5

Le bruit peut provoquer des problèmes auditifs........................................................................................1a-5

Pacemakers et prothèses auditives..............................................................................................................1a-5

Un arc plasma peut endommager les tuyaux gelés ..................................................................................1a-5

Étiquette de sécurité........................................................................................................................................1a-6

Section 1b Seguridad

Reconocimiento de información de seguridad..........................................................................................1b-2

Siga las instrucciones de seguridad............................................................................................................1b-2

Los cortes pueden provocar incendios o explosiones ............................................................................1b-2

El choque eléctrico puede provocar la muerte..........................................................................................1b-3

Electricidad estática puede dañar tablillas de circuito ............................................................................1b-3

Humos tóxicos pueden causar lesiones o muerte....................................................................................1b-4

powermax30 Operator Manual v

1

Page 10

TABLE OF CONTENTS

El arco de plasma puede causar lesiones y quemaduras.......................................................................1b-5

Los rayos del arco pueden producir quemaduras en los ojos y en la piel..........................................1b-5

Seguridad de toma a tierra.............................................................................................................................1b-6

Seguridad de los equipos de gas comprimido..........................................................................................1b-6

Los cilindros de gas pueden explotar si están dañados .........................................................................1b-6

El ruido puede deteriorar la audición ...........................................................................................................1b-7

Operación de marcapasos y de audífonos.................................................................................................1b-7

Un arco plasma puede dañar tubos congelados ......................................................................................1b-7

Etiquetas de advertencia ................................................................................................................................1b-8

Section 2 Specifications

System description.............................................................................................................................................2-2

Power supply dimensions and weight ..........................................................................................................2-2

Power supply ratings..........................................................................................................................................2-3

Torch dimensions ................................................................................................................................................2-4

T30v torch ratings...............................................................................................................................................2-4

Symbols and markings.......................................................................................................................................2-5

mark......................................................................................................................................................2-5

CE mark ......................................................................................................................................................2-5

IEC symbols...............................................................................................................................................2-5

Section 3 Setup

Unpack the Powermax30..................................................................................................................................3-2

Claims .........................................................................................................................................................3-2

Contents.....................................................................................................................................................3-2

Position the power supply.................................................................................................................................3-3

Voltage configurations .......................................................................................................................................3-3

Requirements for grounding.............................................................................................................................3-3

Power cord considerations...............................................................................................................................3-4

Power cord and plugs for CSA power supplies ...............................................................................3-4

Power cord for CE power supplies......................................................................................................3-5

Extension cord recommendations ........................................................................................................3-6

Generator recommendations.................................................................................................................3-6

Gas supply............................................................................................................................................................3-7

Connection.................................................................................................................................................3-7

Additional gas filtration............................................................................................................................3-8

Section 4 Operation

Controls and indicators .....................................................................................................................................4-2

Front controls and LEDs.........................................................................................................................4-2

Rear controls .............................................................................................................................................4-2

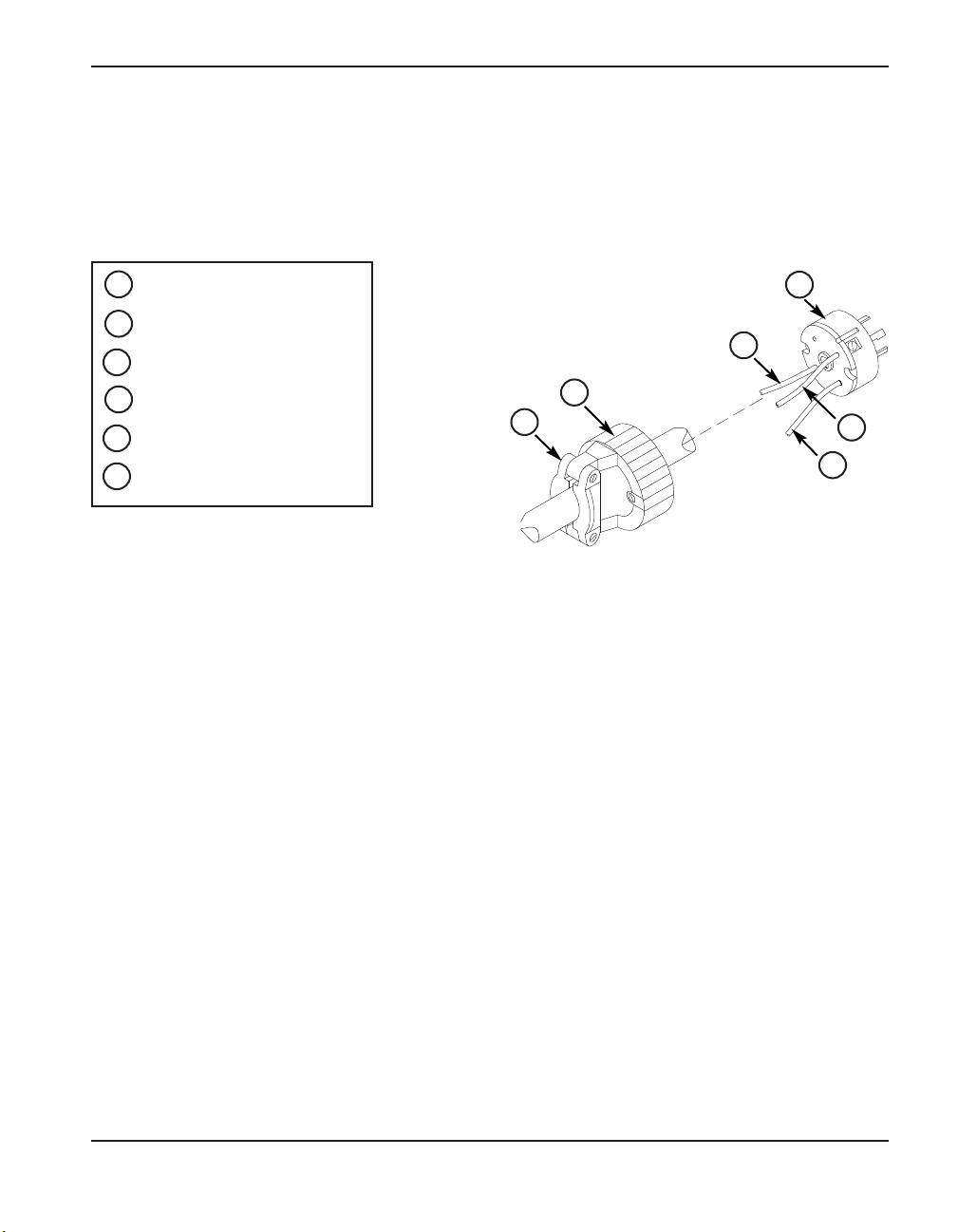

Install the consumables .....................................................................................................................................4-3

Attach the work clamp.......................................................................................................................................4-4

Power ON the system........................................................................................................................................4-4

Hand torch operation .........................................................................................................................................4-6

vi powermax30 Operator Manual

1

Page 11

TABLE OF CONTENTS

Safety trigger operation ..........................................................................................................................4-6

Hand torch cutting hints..........................................................................................................................4-7

To start a cut from the edge of the workpiece...................................................................................4-8

To pierce a workpiece..............................................................................................................................4-9

Cut chart.............................................................................................................................................................4-10

Duty cycle and overheating............................................................................................................................4-11

Common cutting faults....................................................................................................................................4-11

Section 5 Maintenance and parts

Routine maintenance..........................................................................................................................................5-2

Inspect the consumables ..................................................................................................................................5-3

Basic troubleshooting........................................................................................................................................5-4

Repairs...................................................................................................................................................................5-7

Remove and replace the cover and Nomex® barrier.......................................................................5-7

Remove an endcap ..................................................................................................................................5-9

Disconnect the torch lead....................................................................................................................5-11

Replace the work lead ..........................................................................................................................5-13

Replace the power cord (CSA)..........................................................................................................5-15

Replace the power cord (CE) .............................................................................................................5-17

Replace the air filter element...............................................................................................................5-19

Replacement and accessory parts...............................................................................................................5-20

Power cords and adapters...................................................................................................................5-20

Accessory parts......................................................................................................................................5-20

T30v hand torch assembly ..................................................................................................................5-21

Consumables..........................................................................................................................................5-21

Filter regulator.........................................................................................................................................5-22

Work clamp.............................................................................................................................................5-22

Powermax30 labels ...............................................................................................................................5-23

powermax30 Operator Manual vii

1

Page 12

TABLE OF CONTENTS

viii powermax30 Operator Manual

Page 13

Hypertherm 1-1

11/08

Section 1

SAFETY

In this section:

Recognize safety information ...........................................................................................................................1-2

Follow safety instructions..................................................................................................................................1-2

Cutting can cause fire or explosion ................................................................................................................1-2

Electric shock can kill.........................................................................................................................................1-3

Static electricity can damage circuit boards ................................................................................................1-3

Toxic fumes can cause injury or death............................................................................................................1-4

A plasma arc can cause injury and burns......................................................................................................1-5

Arc rays can burn eyes and skin......................................................................................................................1-5

Grounding safety.................................................................................................................................................1-6

Compressed gas equipment safety................................................................................................................1-6

Gas cylinders can explode if damaged..........................................................................................................1-6

Noise can damage hearing ...............................................................................................................................1-7

Pacemaker and hearing aid operation............................................................................................................1-7

A plasma arc can damage frozen pipes.........................................................................................................1-7

Additional safety information.............................................................................................................................1-7

Symbols and markings.......................................................................................................................................1-8

Warning labels.....................................................................................................................................................1-9

Dry dust collection information......................................................................................................................1-11

Page 14

1-2 Hypertherm

11/08

SAFETY

RECOGNIZE SAFETY INFORMATION

The symbols shown in this section are used to

identify potential hazards. When you see a

safety symbol in this manual or on your machine,

understand the potential for personal injury, and follow

the related instructions to avoid the hazard.

FOLLOW SAFETY

INSTRUCTIONS

Read carefully all safety messages in this

manual and safety labels on your machine.

• Keep the safety labels on your machine in good

condition. Replace missing or damaged labels

immediately.

• Learn how to operate the machine and how to use

the controls properly. Do not let anyone operate it

without instruction.

• Keep your machine in proper working condition.

Unauthorized modifications to the machine may

affect safety and machine service life.

DANGER WARNING CAUTION

Hypertherm uses American National Standards

Institute guidelines for safety signal words and

symbols. A signal word DANGER or WARNING is

used with a safety symbol. DANGER identifies the

most serious hazards.

• DANGER and WARNING safety labels are

located on your machine near specific hazards.

• DANGER safety messages precede related

instructions in the manual that will result in serious

injury or death if not followed correctly.

• WARNING safety messages precede related

instructions in this manual that may result in injury

or death if not followed correctly.

• CAUTION safety messages precede related

instructions in this manual that may result in

minor injury or damage to equipment if not

followed correctly.

Fire Prevention

• Be sure the area is safe before doing any cutting.

Keep a fire extinguisher nearby.

• Remove all flammables within 35 feet (10 m) of

the cutting area.

• Quench hot metal or allow it to cool before

handling or before letting it touch combustible

materials.

• Never cut containers with potentially flammable

materials inside – they must be emptied and

properly cleaned first.

• Ventilate potentially flammable atmospheres

before cutting.

• When cutting with oxygen as the plasma gas,

an exhaust ventilation system is required.

Explosion Prevention

• Do not use the plasma system if explosive dust

or vapors may be present.

• Do not cut pressurized cylinders, pipes, or any

closed container.

• Do not cut containers that have held combustible

materials.

CUTTING CAN CAUSE FIRE OR EXPLOSION

WARNING

Explosion Hazard

Argon-Hydrogen and Methane

Hydrogen and methane are flammable gases that

present an explosion hazard. Keep flames away from

cylinders and hoses that contain methane or hydrogen

mixtures. Keep flames and sparks away from the torch

when using methane or argon-hydrogen plasma.

WARNING

Hydrogen Detonation with

Aluminum Cutting

• When cutting aluminum underwater, or with the

water touching the underside of the aluminum,

free hydrogen gas may collect under the workpiece

and detonate during plasma cutting operations.

• Install an aeration manifold on the floor of the water

table to eliminate the possibility of hydrogen

detonation. Refer to the Appendix section of this

manual for aeration manifold details.

Page 15

Hypertherm 1-3

SAFETY

11/08

Touching live electrical parts can cause a fatal shock

or severe burn.

• Operating the plasma system completes an

electrical circuit between the torch and the

workpiece. The workpiece and anything touching

the workpiece are part of the electrical circuit.

• Never touch the torch body, workpiece or the

water in a water table when the plasma system

is operating.

Electric Shock Prevention

All Hypertherm plasma systems use high

voltage in the cutting process (200 to 400 VDC

are common). Take the following precautions

when operating this system:

• Wear insulated gloves and boots, and keep your

body and clothing dry.

• Do not stand, sit or lie on – or touch – any wet

surface when using the plasma system.

• Insulate yourself from work and ground using dry

insulating mats or covers big enough to prevent

any physical contact with the work or ground.

If you must work in or near a damp area, use

extreme caution.

• Provide a disconnect switch close to the power

supply with properly sized fuses. This switch allows

the operator to turn off the power supply quickly in

an emergency situation.

• When using a water table, be sure that it is

correctly connected to earth ground.

ELECTRIC SHOCK CAN KILL

• Install and ground this equipment according to the

instruction manual and in accordance with national

and local codes.

• Inspect the input power cord frequently for damage

or cracking of the cover. Replace a damaged

power cord immediately. Bare wiring can kill.

• Inspect and replace any worn or damaged torch

leads.

• Do not pick up the workpiece, including the waste

cutoff, while you cut. Leave the workpiece in place

or on the workbench with the work cable attached

during the cutting process.

• Before checking, cleaning or changing torch parts,

disconnect the main power or unplug the power

supply.

• Never bypass or shortcut the safety interlocks.

• Before removing any power supply or system

enclosure cover, disconnect electrical input power.

Wait 5 minutes after disconnecting the main power

to allow capacitors to discharge.

• Never operate the plasma system unless the power

supply covers are in place. Exposed power supply

connections present a severe electrical hazard.

• When making input connections, attach proper

grounding conductor first.

• Each Hypertherm plasma system is designed to be

used only with specific Hypertherm torches. Do not

substitute other torches which could overheat and

present a safety hazard.

Use proper precautions when handling printed

circuit boards.

STATIC ELECTRICITY CAN DAMAGE CIRCUIT BOARDS

• Store PC boards in anti-static containers.

• Wear a grounded wrist strap when handling

PC boards.

Page 16

1-4 Hypertherm

SAFETY

11/08

The plasma arc by itself is the heat source used for

cutting. Accordingly, although the plasma arc has

not been identified as a source of toxic fumes, the

material being cut can be a source of toxic fumes

or gases that deplete oxygen.

Fumes produced vary depending on the metal that

is cut. Metals that may release toxic fumes include,

but are not limited to, stainless steel, carbon steel,

zinc (galvanized), and copper.

In some cases, the metal may be coated with a

substance that could release toxic fumes. Toxic

coatings include, but are not limited to, lead (in

some paints), cadmium (in some paints and fillers),

and beryllium.

Gases produced by plasma cutting vary based on

the material to be cut and the method of cutting,

but may include ozone, oxides of nitrogen,

hexavalent chromium, hydrogen, and other

substances if such are contained in or released

by the material being cut.

Caution should be taken to minimize exposure

to fumes produced by any industrial process.

Depending upon the chemical composition and

concentration of the fumes (as well as other factors,

such as ventilation), there may be a risk of physical

illness, such as birth defects or cancer.

It is the responsibility of the equipment and site

owner to test the air quality in the area where the

equipment is used and to ensure that the air quality

in the workplace meets all local and national

standards and regulations.

The air quality level in any relevant workplace

depends on site-specific variables such as:

• Table design (wet, dry, underwater).

• Material composition, surface finish, and

composition of coatings.

• Volume of material removed.

TOXIC FUMES CAN CAUSE INJURY OR DEATH

• Duration of cutting or gouging.

• Size, air volume, ventilation and filtration of the

work area.

• Personal protective equipment.

• Number of welding and cutting systems

in operation.

• Other site processes that may produce fumes.

If the workplace must conform to national or local

regulations, only monitoring or testing done at the

site can determine whether the site is above or

below allowable levels.

To reduce the risk of exposure to fumes:

• Remove all coatings and solvents from the metal

before cutting.

• Use local exhaust ventilation to remove fumes

from the air.

• Do not inhale fumes. Wear an air-supplied

respirator when cutting any metal coated with,

containing, or suspected to contain toxic

elements.

• Assure that those using welding or cutting

equipment, as well as air-supplied respiration

devices, are qualified and trained in the proper

use of such equipment.

• Never cut containers with potentially toxic

materials inside. Empty and properly clean the

container first.

• Monitor or test the air quality at the site as

needed.

• Consult with a local expert to implement a site

plan to ensure safe air quality.

Page 17

Hypertherm 1-5

SAFETY

11/08

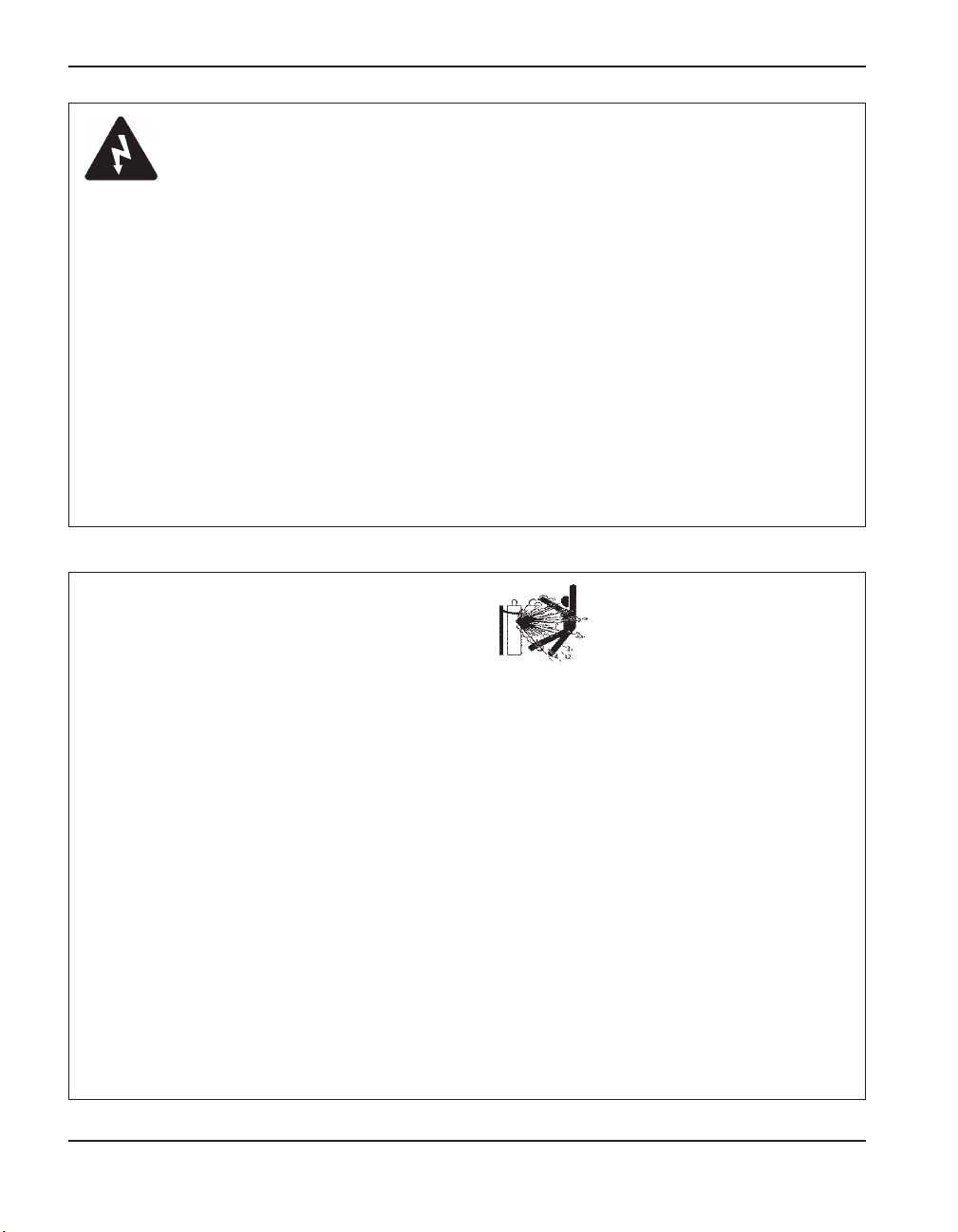

Instant-On Torches

Plasma arc comes on immediately when the torch

switch is activated.

A PLASMA ARC CAN CAUSE INJURY AND BURNS

The plasma arc will cut quickly through gloves

and skin.

• Keep away from the torch tip.

• Do not hold metal near the cutting path.

• Never point the torch toward yourself or others.

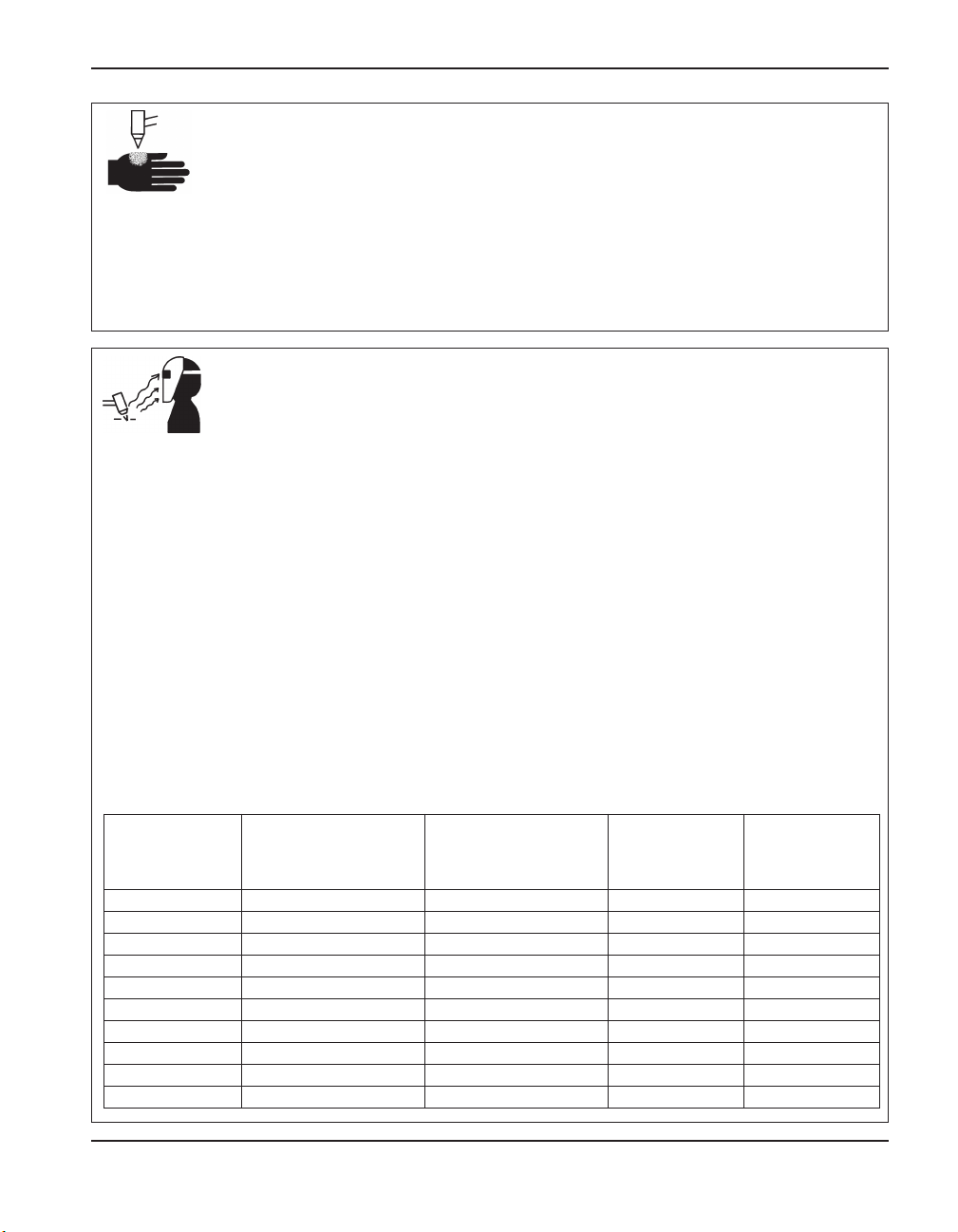

Eye Protection Plasma arc rays produce intense visible and invisible (ultraviolet and infrared) rays that can

burn eyes and skin.

• Use eye protection in accordance with applicable national or local codes.

• Wear eye protection (safety glasses or goggles with side shields, and a welding helmet) with appropriate

lens shading to protect your eyes from the arc’s ultraviolet and infrared rays.

Skin Protection Wear protective clothing to protect against burns caused by ultraviolet light, sparks and

hot metal.

• Gauntlet gloves, safety shoes and hat.

• Flame-retardant clothing to cover all exposed areas.

• Cuffless trousers to prevent entry of sparks and slag.

• Remove any combustibles, such as a butane lighter or matches, from your pockets before cutting.

Cutting Area Prepare the cutting area to reduce reflection and transmission of ultraviolet light:

• Paint walls and other surfaces with dark colors to reduce reflection.

• Use protective screens or barriers to protect others from flash and glare.

• Warn others not to watch the arc. Use placards or signs.

ARC RAYS CAN BURN EYES AND SKIN

Arc current

(amps)

Minimum protective

shade number

(ANSI Z49.1:2005)

Suggested shade

number for comfort

(ANSI Z49.1:2005)

OSHA 29CFR

1910.133(a)(5)

Europe

EN168:2002

Less than 40 A 5 5 8 9

41 to 60 A 6 6 8 9

61 to 80 A 8 8 8 9

81 to 125 A 8 9 8 9

126 to 150 A 8 9 8 10

151 to 175 A 8 9 8 11

176 to 250 A 8 9 8 12

251 to 300 A 8 9 8 13

301 to 400 A 9 12 9 13

401 to 800 A 10 14 10

Page 18

1-6 Hypertherm

SAFETY

11/08

• Never lubricate cylinder valves or regulators with

oil or grease.

• Use only correct gas cylinders, regulators, hoses

and fittings designed for the specific application.

• Maintain all compressed gas equipment and

associated parts in good condition.

• Label and color-code all gas hoses to identify

the type of gas in each hose. Consult applicable

national or local codes.

GAS CYLINDERS CAN

EXPLODE IF DAMAGED

COMPRESSED GAS EQUIPMENT

SAFETY

Gas cylinders contain gas under high pressure.

If damaged, a cylinder can explode.

• Handle and use compressed gas cylinders in

accordance with applicable national or local

codes.

• Never use a cylinder that is not upright and

secured in place.

• Keep the protective cap in place over valve

except when the cylinder is in use or connected

for use.

• Never allow electrical contact between the

plasma arc and a cylinder.

• Never expose cylinders to excessive heat, sparks,

slag or open flame.

• Never use a hammer, wrench or other tool to

open a stuck cylinder valve.

Work Cable Attach the work cable securely to the

workpiece or the work table with good metal-to-metal

contact. Do not connect it to the piece that will fall

away when the cut is complete.

Work Table Connect the work table to an earth

ground, in accordance with appropriate national or

local electrical codes.

Input Power

• Be sure to connect the power cord ground wire

to the ground in the disconnect box.

• If installation of the plasma system involves

connecting the power cord to the power supply,

be sure to connect the power cord ground wire

properly.

• Place the power cord's ground wire on the stud

first, then place any other ground wires on top

of the power cord ground. Fasten the retaining

nut tightly.

• Tighten all electrical connections to avoid

excessive heating.

GROUNDING SAFETY

Page 19

Hypertherm 1-7

SAFETY

11/08

Prolonged exposure to noise from cutting or

gouging can damage hearing.

• Use approved ear protection when using

plasma system.

• Warn others nearby about the noise hazard.

Frozen pipes may be damaged or can burst if you

attempt to thaw them with a plasma torch.

NOISE CAN DAMAGE

HEARING

A PLASMA ARC

CAN DAMAGE

FROZEN PIPES

Pacemaker and hearing aid operation can be

affected by magnetic fields from high currents.

Pacemaker and hearing aid wearers should

consult a doctor before going near any plasma arc

cutting and gouging operations.

To reduce magnetic field hazards:

• Keep both the work cable and the torch lead

to one side, away from your body.

• Route the torch leads as close as possible to

the work cable.

• Do not wrap or drape the torch lead or work

cable around your body.

• Keep as far away from the power supply

as possible.

PACEMAKER AND

HEARING AID OPERATION

ADDITIONAL SAFETY INFORMATION

1. ANSI Standard Z49.1, Safety in Welding and Cutting,

American Welding Society, 550 LeJeune Road, P.O. Box

351020, Miami, FL 33135

2. ANSI Standard Z49.2, Fire Prevention in the Use of

Cutting and Welding Processes, American National

Standards Institute, 1430 Broadway, New York, NY

10018

3. ANSI Standard Z87.1, Safe Practices for Occupation

and Educational Eye and Face Protection, American

National Standards Institute, 1430 Broadway, New York,

NY 10018

4. AWS F4.1, Recommended Safe Practices for the

Preparation for Welding and Cutting of Containers and

Piping That Have Held Hazardous Substances,

American Welding Society, 550 LeJeune Road, P.O. Box

351040, Miami, FL 33135

5. AWS F5.2, Recommended Safe Practices for Plasma

Arc Cutting, American Welding Society, 550 LeJeune

Road, P.O. Box 351040, Miami, FL 33135

6. CGA Pamphlet P-1, Safe Handling of Compressed

Gases in Cylinders, Compressed Gas Association,

1235 Jefferson Davis Highway, Arlington, VA 22202

7. CSA Standard W117.2, Code for Safety in Welding

and Cutting, Canadian Standards Association

Standard Sales, 178 Rexdale Boulevard, Rexdale,

Ontario M9W 1R3, Canada

8. NFPA Standard 51B, Cutting and Welding

Processes, National Fire Protection Association,

470 Atlantic Avenue, Boston, MA 02210

9. NFPA Standard 70–1978, National Electrical Code,

National Fire Protection Association, 470 Atlantic

Avenue, Boston, MA 02210

10. OSHA, Safety and Health Standards, 29FR 1910

U.S. Government Printing Office, Washington, D.C.

20402

11. AWS Safety and Health Fact Sheets, American

Welding Society 550 LeJeune Road, P.O. Box

351040, Miami, FL 33135

www.aws.org/technical/facts/

Page 20

1-8 Hypertherm

SAFETY

11/08

SYMBOLS AND MARKINGS

Your Hypertherm product may have one or more of the following markings on or near the data plate. Due to

differences and conflicts in national regulations, not all marks are applied to every version of a product.

S mark symbol

The S mark symbol indicates that the power supply and torch are suit able for operations carried out

in en vi ron ments with in creased hazard of elec tri cal shock per IEC 60974-1.

CSA mark

Hypertherm products with a CSA mark meet the United States and Canadian regulations for

product safety. The products were evaluated, tested, and certified by CSA-International. Alternatively

the product may have a mark by one of the other Nationally Recognized Testing Laboratories (NRTL)

accredited in both the United States and Canada, such as Underwriters Laboratories, Incorporated

(UL) or TÜV.

CE marking

The CE marking signifies the manufacturer’s declaration of conformity to applicable European

directives and standards. Only those versions of Hypertherm products with a CE marking located on

or near the data plate have been tested for compliance with the European Low Voltage Directive and

the European Electromagnetic Compatibility (EMC) Directive. EMC filters needed to comply with the

European EMC Directive are incorporated within versions of the product with a CE marking.

GOST-R mark

CE versions of Hypertherm products that include a GOST-R mark of conformity meet the product

safety and EMC requirements for export to the Russian Federation.

c-Tick mark

CE versions of Hypertherm products with a c-Tick mark comply with the EMC regulations required

for sale in Australia and New Zealand.

CCC mark

The China Compulsory Certification (CCC) mark indicates that the product has been tested and

found compliant with product safety regulations required for sale in China.

Page 21

Hypertherm 1-9

SAFETY

11/08

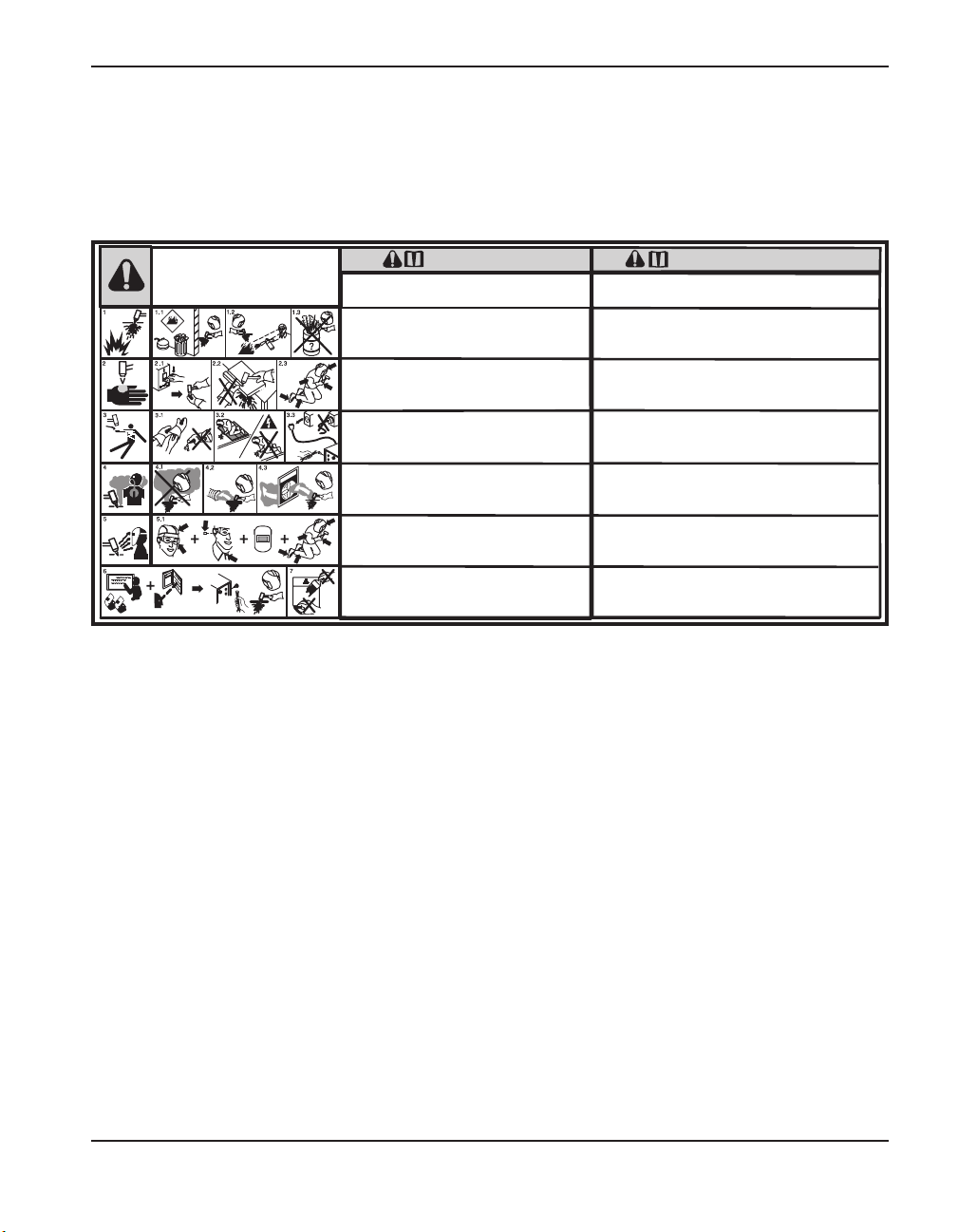

WARNING LABEL

This warning label is affixed to some power supplies. It is important that the operator

and maintenance technician understand the intent of these warning symbols as

described. The numbered text corresponds to the numbered boxes on the label.

1. Cutting sparks can cause explosion or fire.

1.1 Do not cut near flammables.

1.2 Have a fire extinguisher nearby and ready to use.

1.3 Do not use a drum or other closed container as

a cutting table.

2. Plasma arc can injure and burn; point the nozzle

away from yourself. Arc starts instantly when

triggered.

2.1 Turn off power before disassembling torch.

2.2 Do not grip the workpiece near the cutting path.

2.3 Wear complete body protection.

3. Hazardous voltage. Risk of electric shock or

burn.

3.1 Wear insulating gloves. Replace gloves when

wet or damaged.

3.2 Protect from shock by insulating yourself from

work and ground.

3.3 Disconnect power before servicing. Do not

touch live parts.

4. Plasma fumes can be hazardous.

4.1 Do not inhale fumes.

4.2 Use forced ventilation or local exhaust to remove

the fumes.

4.3 Do not operate in closed spaces. Remove fumes

with ventilation.

5. Arc rays can burn eyes and injure skin.

5.1 Wear correct and appropriate protective

equipment to protect head, eyes, ears, hands,

and body. Button shirt collar. Protect ears from

noise. Use welding helmet with the correct

shade of filter.

6. Become trained. Only qualified personnel should

operate this equipment. Use torches specified in

the manual. Keep non-qualified personnel and

children away.

7. Do not remove, destroy, or cover this label.

Replace if it is missing, damaged, or worn.

Read and follow these instructions, employer safety

practices, and material safety data sheets. Refer to

ANS Z49.1, “Safety in Welding, Cutting and Allied

Processes” from American Welding Society

(http://www.aws.org) and OSHA Safety and Health

Standards, 29 CFR 1910 (http://www.osha.gov).

Plasma cutting can be injurious to operator and persons

in the work area. Consult manual before operating. Failure

to follow all these safety instructions can result in death.

1. Cutting sparks can cause explosion or fire.

1.1 Do not cut near flammables.

1.2 Have a fire extinguisher nearby and ready to use.

1.3 Do not use a drum or other closed container as a cutting table.

2. Plasma arc can injure and burn; point the nozzle away

from yourself. Arc starts instantly when triggered.

2.1 Turn off power before disassembling torch.

2.2 Do not grip the workpiece near the cutting path.

2.3 Wear complete body protection.

3. Hazardous voltage. Risk of electric shock or burn.

3.1 Wear insulating gloves. Replace gloves when wet or damaged.

3.2 Protect from shock by insulating yourself from work and ground.

3.3 Disconnect power before servicing. Do not touch live parts.

4. Plasma fumes can be hazardous.

4.1 Do not inhale fumes.

4.2 Use forced ventilation or local exhaust to remove the fumes.

4.3 Do not operate in closed spaces. Remove fumes with ventilation.

5. Arc rays can burn eyes and injure skin.

5.1 Wear correct and appropriate protective equipment to protect

head, eyes, ears, hands, and body. Button shirt collar. Protect ears

from noise. Use welding helmet with the correct shade of filter.

6. Become trained.

equipment. Use torches specified in the manual. Keep non-qualified

personnel and children away.

7. Do not remove, destroy, or cover this label.

Replace if it is missing, damaged, or worn (PN 110584 Rev C).

WARNING

Only qualified personnel should operate this

Le coupage plasma peut être préjudiciable pour l’opérateur et les personnes qui se

trouvent sur les lieux de travail. Consulter le manuel avant de faire fonctionner. Le

non respect des ces instructions de sécurité peut entraîner la mort.

1. Les étincelles de coupage peuvent provoquer une explosion

ou un incendie.

1.1 Ne pas couper près des matières inflammables.

1.2 Un extincteur doit être à proximité et prêt à être utilisé.

1.3 Ne pas utiliser un fût ou un autre contenant fermé comme table de coupage.

2. L’arc plasma peut blesser et brûler; éloigner la buse de soi.

Il s’allume instantanément quand on l’amorce;

2.1 Couper l’alimentation avant de démonter la torche.

2.2 Ne pas saisir la pièce à couper de la trajectoire de coupage.

2.3 Se protéger entièrement le corps.

3. Tension dangereuse. Risque de choc électrique ou de brûlure.

3.1 Porter des gants isolants. Remplacer les gants quand ils sont humides ou

endommagés.

3.2 Se protéger contre les chocs en s’isolant de la pièce et de la terre.

3.3 Couper l’alimentation avant l’entretien. Ne pas toucher les pièces sous tension.

4. Les fumées plasma peuvent être dangereuses.

4.1 Ne pas inhaler les fumées

4.2 Utiliser une ventilation forcée ou un extracteur local pour dissiper les fumées.

4.3 Ne pas couper dans des espaces clos. Chasser les fumées par ventilation.

5. Les rayons d’arc peuvent brûler les yeux et blesser la peau.

5.1 Porter un bon équipement de protection pour se protéger la tête, les yeux, les

oreilles, les mains et le corps. Boutonner le col de la chemise. Protéger les oreilles

contre le bruit. Utiliser un masque de soudeur avec un filtre de nuance appropriée.

6. Suivre une formation. Seul le personnel qualifié a le droit de faire

fonctionner cet équipement. Utiliser exclusivement les torches indiquées dans le

manual. Le personnel non qualifié et les enfants doivent se tenir à l’écart.

7. Ne pas enlever, détruire ni couvrir cette étiquette.

La remplacer si elle est absente, endommagée ou usée (PN 110584 Rev C).

AVERTISSEMENT

Page 22

1-10 Hypertherm

SAFETY

11/08

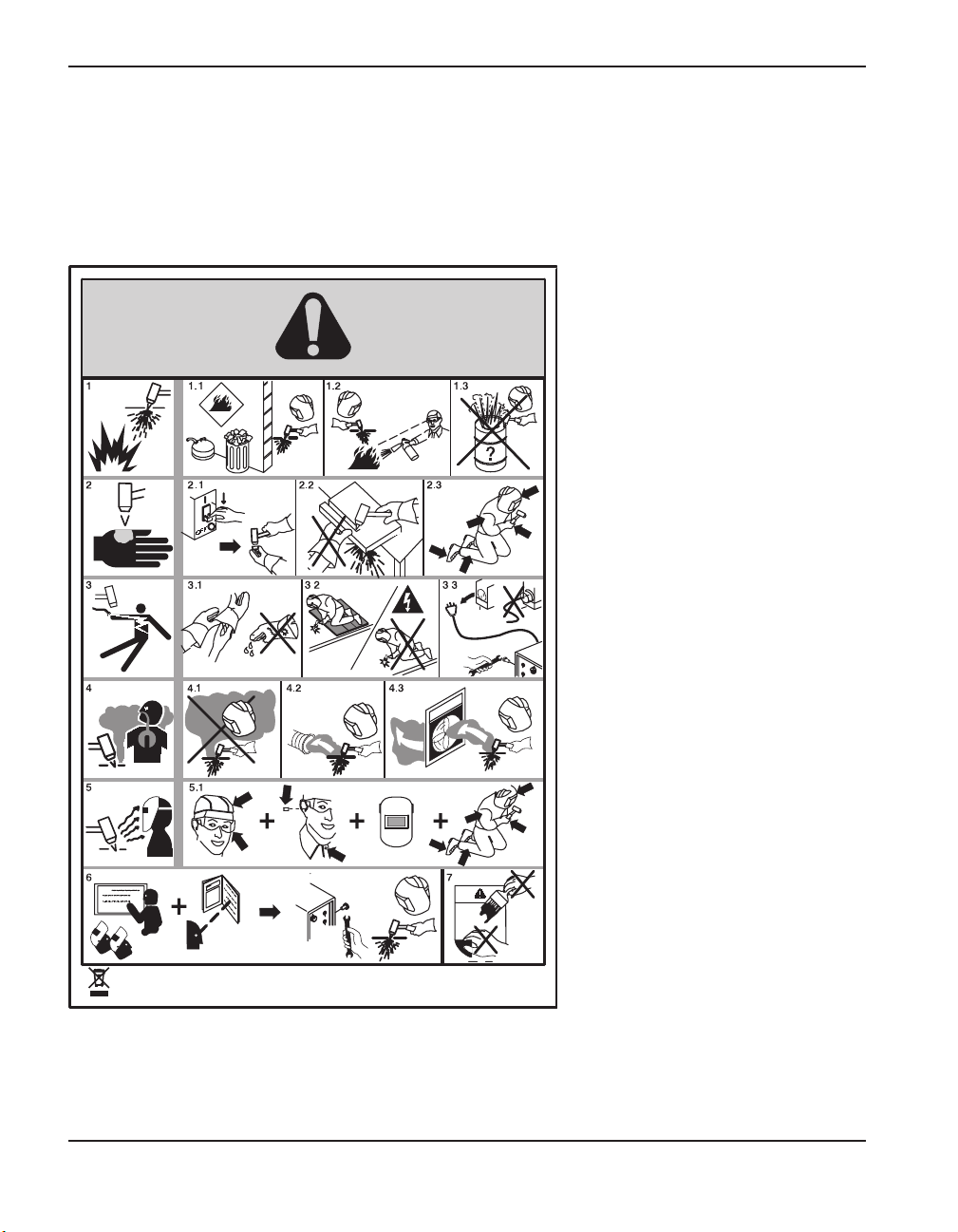

WARNING LABEL

This warning label is affixed to some power supplies. It is

important that the operator and maintenance technician

understand the intent of these warning symbols as described.

The numbered text corresponds to the numbered boxes on

the label.

1. Cutting sparks can cause explosion

or fire.

1.1 Do not cut near flammables.

1.2 Have a fire extinguisher nearby and

ready to use.

1.3 Do not use a drum or other closed

container as a cutting table.

2. Plasma arc can injure and burn;

point the nozzle away from yourself.

Arc starts instantly when triggered.

2.1 Turn off power before disassembling

torch.

2.2 Do not grip the workpiece near the

cutting path.

2.3 Wear complete body protection.

3. Hazardous voltage. Risk of electric

shock or burn.

3.1 Wear insulating gloves. Replace

gloves when wet or damaged.

3.2 Protect from shock by insulating

yourself from work and ground.

3.3 Disconnect power before servicing.

Do not touch live parts.

4. Plasma fumes can be hazardous.

4.1 Do not inhale fumes.

4.2 Use forced ventilation or local

exhaust to remove the fumes.

4.3 Do not operate in closed spaces.

Remove fumes with ventilation.

5. Arc rays can burn eyes and injure

skin.

5.1 Wear correct and appropriate

protective equipment to protect

head, eyes, ears, hands, and body.

Button shirt collar. Protect ears from

noise. Use welding helmet with the

correct shade of filter.

6. Become trained. Only qualified

personnel should operate this

equipment. Use torches specified in

the manual. Keep non-qualified

personnel and children away.

7. Do not remove, destroy, or cover

this label. Replace if it is missing,

damaged, or worn.

www.hypertherm.com/weee

110647 Rev. A

Page 23

Hypertherm 1-11

11/08

SAFETY

DRY DUST COLLECTION INFORMATION

At some sites, dry dust can represent a potential explosion hazard.

The U.S. National Fire Protection Association’s 2007 edition of NFPA standard 68, “Explosion Protection by

Deflagration Venting,” provides requirements for the design, location, installation, maintenance, and use of

devices and systems to vent combustion gases and pressures after any deflagration event. Consult with the

manufacturer or installer of any dry dust collection system for applicable requirements before you install a new

dry dust collection system or make significant changes in the process or materials used with an existing dry

dust collection system.

Consult your local “Authority Having Jurisdiction” (AHJ) to determine whether any edition of NFPA 68 has

been “adopted by reference” in your local building codes.

Refer to NFPA68 for definitions and explanations of regulatory terms such as deflagration, AHJ, adopted by

reference, the Kst value, deflagration index, and other terms.

Note 1 – Hypertherm’s interpretation of these new requirements is that unless a site-specific evaluation has

been completed to determine that all dust generated is not combustible, the 2007 edition of NFPA 68

requires the use of explosion vents designed to the worst-case Kst value (see annex F) that could be

generated from dust so that the explosion vent size and type can be designed. NFPA 68 does not specifically

identify plasma cutting or other thermal cutting processes as requiring deflagration venting systems, but it

does apply these new requirements to all dry dust collection systems.

Note 2 – Users of Hypertherm manuals should consult and comply with all applicable federal, state, and local

laws and regulations. Hypertherm does not, by the publication of any Hypertherm manual, intend to urge

action that is not in compliance with all applicable regulations and standards, and this manual may never be

construed as doing so.

Page 24

1-12 Hypertherm

11/08

SAFETY

Page 25

11/08

Hypertherm 1a-1

Section 1a

SÉCURITÉ

Dans cette section :

Identifier les consignes de sécurité..............................................................................................................1a-2

Suivre les instructions de sécurité................................................................................................................1a-2

Le coupage peut provoquer un incendie ou une explosion....................................................................1a-2

Les chocs électriques peuvent être fatals ..................................................................................................1a-3

L’électricité statique peut endommager les cartes de circuits imprimés .............................................1a-3

Les vapeurs toxiques peuvent provoquer des blessures ou la mort.....................................................1a-4

L’arc plasma peut provoquer des blessures ou des brûlures.................................................................1a-5

Les rayons de l’arc peuvent brûler les yeux et la peau.............................................................................1a-5

Mise à la masse et à la terre...........................................................................................................................1a-6

Sécurité des bouteilles de gaz comprimé...................................................................................................1a-6

Les bouteilles de gaz comprimé peuvent exploser en cas de dommages..........................................1a-6

Le bruit peut provoquer des problèmes auditifs........................................................................................1a-7

Pacemakers et prothèses auditives ..............................................................................................................1a-7

Un arc plasma peut endommager les tuyaux gelés...................................................................................1a-7

Symboles et marquage....................................................................................................................................1a-8

Étiquettes de sécurité......................................................................................................................................1a-9

Information sur le dépoussiérage ...............................................................................................................1a-11

Page 26

11/08

1a-2 Hypertherm

SÉCURITÉ

IDENTIFIER LES CONSIGNES

DE SÉCURITÉ

Les symboles indiqués dans cette section sont utilisés

pour identifier les risques éventuels. Si vous trouvez un symbole

de sécurité, que ce soit dans ce manuel ou sur l’équipement,

soyez conscient des risques de blessures et suivez les

instructions correspondantes afin d’éviter ces risques.

SUIVRE LES INSTRUCTIONS

DE SÉCURITÉ

Lire attentivement toutes les consignes de sécurité

dans le présent manuel et sur les étiquettes de sécurité se

trouvant sur la machine.

• Les étiquettes de sécurité doivent rester lisibles. Remplacer

immédiatement les étiquettes manquantes ou abîmées.

• Apprendre à faire fonctionner la machine et à utiliser

correctement les commandes. Ne laisser personne utiliser

la machine sans connaître son fonctionnement.

• Garder la machine en bon état. Des modifications non

autorisées sur la machine peuvent engendrer des problèmes

de sécurité et raccourcir la durée d’utilisation de l’équipement.

DANGER AVERTISSEMENT ATTENTION

Hypertherm adopte les lignes directrices de l’American

National Standards Institute relativement aux termes, aux

symboles et à la signalisation de sécurité. Les signaux

DANGER ou AVERTISSEMENT sont utilisés avec un symbole

de sécurité, DANGER correspondant aux risques les plus

sérieux.

• Les étiquettes de sécurité DANGER et AVERTISSE MENT

sont situées sur la machine pour signaler certains dangers

spécifiques.

• Les messages de sécurité DANGER précèdent les

directives associées dans le manuel qui, si elles ne sont pas

suivies scrupuleusement, entraînent des blessures graves

voire mortelles.

• Les messages d’AVERTISSEMENT précèdent les

instructions d’utilisation expliquées dans ce manuel et

signalent les risques de blessures ou de mort au cas où ces

instructions ne seraient pas suivies correctement.

• Les messages de sécurité ATTENTION précèdent les

directives associées dans le manuel qui, si elles ne sont pas

suivies scrupuleusement, peuvent entraîner des blessures

secondaires ou endommager l’équipement.

Prévention des incendies

• Avant de commencer, s’assurer que la zone de coupage

ne présente aucun danger. Conserver un extincteur

à proximité.

• Éloigner toute matière inflammable à une distance

d’au moins 10 m du poste de coupage.

• Tremper le métal chaud ou le laisser refroidir avant

de le manipuler ou avant de le mettre en contact avec

des matériaux combustibles.

• Ne jamais couper des récipients pouvant contenir

des matières inflammables avant de les avoir vidés

et nettoyés correctement.

• Aérer toute atmosphère potentiellement inflammable

avant d’utiliser un système plasma.

• Lors de l’utilisation d’oxygène comme gaz plasma, un

système de ventilation par aspiration est nécessaire.

Prévention des explosions

• Ne pas couper en présence de poussière ou de vapeurs.

• Ne pas couper de bouteilles, de tuyaux ou autres

récipients fermés et pressurisés.

• Ne pas couper de récipients contenant des matières

combustibles.

LE COUPAGE PEUT PROVOQUER

UN INCENDIE OU UNE EXPLOSION

AVERTISSEMENT

Risque d’explosion

argon-hydrogène et méthane

L’hydrogène et le méthane sont des gaz inflammables

et potentiellement explosifs. Conserver à l’écart de toute

flamme les bouteilles et tuyaux contenant des mélanges

à base d’hydrogène ou de méthane. Maintenir toute

flamme et étincelle à l’écart de la torche lors de l’utilisation

d’un plasma d’argon-hydrogène ou de méthane.

AVERTISSEMENT

Détonation de l’hydrogène lors du

coupage de l’aluminium

• Lors du coupage de l’aluminium sous l’eau, ou si l’eau

touche la partie inférieure de la pièce d’aluminium, de

l’hydrogène libre peut s’accumuler sous la pièce à couper

et détonner lors du coupage plasma.

• Installer un collecteur d’aération au fond de la table à eau

afin d’éliminer les risques de détonation de l’hydrogène.

Se référer à l’annexe du manuel pour plus de

renseignements sur les collecteurs d’aération.

Page 27

11/08

Toucher une pièce électrique sous tension peut provoquer

un choc électrique fatal ou des brûlures graves.

• La mise en fonctionnement du système plasma ferme

un circuit électrique entre la torche et la pièce à couper.

La pièce à couper et tout autre élément en contact avec

cette pièce font partie du circuit électrique.

• Ne jamais toucher le corps de la torche, la pièce à couper

ou l’eau de la table à eau pendant le fonctionnement du

système plasma.

Prévention des chocs électriques

Tous les systèmes plasma Hypertherm utilisent des hautes

tensions pour le coupage (souvent de 200 à 400 V). On

doit prendre les précautions suivantes quand on utilise le

système plasma :

• Porter des bottes et des gants isolants et garder le corps

et les vêtements au sec.

• Ne pas se tenir, s’asseoir ou se coucher sur une surface

mouillée, ni la toucher quand on utilise le système plasma.

• S’isoler de la surface de travail et du sol en utilisant des

tapis isolants secs ou des couvertures assez grandes

pour éviter tout contact physique avec le travail ou le sol.

S’il s’avère nécessaire de travailler dans ou près d’un

endroit humide, procéder avec une extrême prudence.

• Installer un sectionneur avec fusibles appropriés, à

proximité de la source de courant. Ce dispositif permet à

l’opérateur d’arrêter rapidement la source de courant en

cas d’urgence.

• En cas d’utilisation d’une table à eau, s’assurer que cette

dernière est correctement mise à la terre.

LES CHOCS ÉLECTRIQUES PEUVENT ÊTRE FATALS

• Installer et mettre à la terre l’équipement selon les

instructions du présent manuel et conformément aux

codes électriques locaux et nationaux.

• Inspecter fréquemment le cordon d’alimentation primaire

pour s’assurer qu’il n’est ni endommagé, ni fendu.

Remplacer immédiatement un cordon endommagé.

Un câble dénudé peut tuer.

• Inspecter et remplacer les câbles de la torche qui sont

usés ou endommagés.

• Ne pas saisir la pièce à couper ni les chutes lors du

coupage. Laisser la pièce à couper en place ou sur la

table de travail, le câble de retour connecté lors du

coupage.

• Avant de vérifier, de nettoyer ou de remplacer les pièces

de la torche, couper l’alimentation ou débrancher la prise

de courant.

• Ne jamais contourner ou court-circuiter les verrouillages

de sécurité.

• Avant d’enlever le capot du système ou de la source de

courant, couper l’alimentation électrique. Attendre ensuite

5 minutes pour que les condensateurs se déchargent.

• Ne jamais faire fonctionner le système plasma sans que

les capots de la source de courant ne soient en place.

Les raccords exposés de la source de courant sont

extrêmement dangereux.

• Lors de l’installation des connexions, attacher tout

d’abord la prise de terre appropriée.

• Chaque système plasma Hypertherm est conçu pour

être utilisé uniquement avec des torches Hypertherm

spécifiques. Ne pas utiliser des torches inappropriées

qui pourraient surchauffer et présenter des risques pour

la sécurité.

On doit prendre les précautions qui s’imposent quand on

manipule les circuits imprimés.

L’ÉLECTRICITÉ STATIQUE PEUT ENDOMMAGER

LES CARTES DE CIRCUITS IMPRIMÉS

• On doit ranger les cartes de circuits imprimés dans des

contenants antistatiques.

• On doit porter un bracelet antistatique quand on

manipule les cartes de circuits imprimés.

Hypertherm 1a-3

SÉCURITÉ

Page 28

11/08

1a-4 Hypertherm

SÉCURITÉ

L’arc plasma est lui-même la source de chaleur utilisée

pour le coupage. Par conséquent, bien que l’arc plasma

n’ait pas été reconnu comme une source de vapeurs

toxiques, le matériau coupé peut être une source de

vapeurs ou de gaz toxiques qui épuisent l’oxygène.

Les vapeurs produites varient selon le métal coupé.

Les métaux qui peuvent dégager des vapeurs toxiques

comprennent, entre autres, l’acier inoxydable, l’acier au

carbone, le zinc (galvanisé) et le cuivre.

Dans certains cas, le métal peut être revêtu d’une

substance susceptible de dégager des vapeurs toxiques.

Les revêtements toxiques comprennent entre autres,

le plomb (dans certaines peintures), le cadmium (dans

certaines peintures et enduits) et le béryllium.

Les gaz produits par le coupage plasma varient selon

le matériau à couper et la méthode de coupage, mais

ils peuvent comprendre l’ozone, les oxydes d’azote,