Page 1

Automation

Hypertherm Automation

5 Technology Drive, Suite 300

W. Lebanon, NH 03784 USA

Phone: 603-298-7970

Fax: 603-298-7977

HYPERTHERM SHAPE CUTTING CONTROL

OPERATOR AND INSTALLATION MANUAL

Software Version 8.0 for Touch Screen CNCs

July 2008

Page 2

D

ISCLAIMER The information in this document is subject to change without notice and should not be

construed as a commitment by Hypertherm Automation. Hypertherm Automation

assumes no responsibility for any errors that appear.

T

RADEMARKS Hypertherm Automation is a wholly owned subsidiary of Hypertherm, Inc.

Command, HT 4400, HD3070 HyDefinition Plasma and HD4070 HyDefinition Plasma

are registered trademarks of Hypertherm, Inc.

FASTLaser is a trademark of Hypertherm, Inc.

EDGE, HyperCAD, HyperNet, HyperNest, Phoenix, and ShapeWizard are registered

trademarks of Hypertherm Automation.

Align, APC, CutPro, Gemini, HPR130, HPR260 HyPerformance Plasma, Mariner,

Nester, Remote Help, Sensor, and Voyager are trademarks of Hypertherm Automation.

HASP is a registered trademark of Aladdin Knowledge Systems Ltd.

Indramat is a trademark of Bosch Rexroth.

Pacific Scientific is a trademark of Danaher Motion.

Pentium and Celeron are registered trademarks of Intel Corporation.

Virus Scan is a registered trademark of McAfee Associates, Inc.

Microsoft, the Microsoft logo, and Windows are registered trademarks of Microsoft

Corporation.

NJWIN is a registered trademark of NJStar Software Corporation.

SERCOS Interface is a trademark of SERCOS North America.

Norton AntiVirus and Norton Ghost are trademarks of Symantec Corporation.

Other trademarks are the property of their respective holders.

C

OPYRIGHT 2008 by Hypertherm Automation. All rights Reserved

Printed in USA

ii

Page 3

Contents

Safety ............................................................................................................................................ 1

Overview ...................................................................................................................................... 9

CutPro Wizard ........................................................................................................................ 9

Align Wizard ........................................................................................................................... 9

Remote Help ........................................................................................................................... 9

ShapeWizard ........................................................................................................................... 9

Teach/Trace ............................................................................................................................. 9

Shape Libraries ..................................................................................................................... 10

Program Upload and Download............................................................................................ 10

SoftMotion ............................................................................................................................ 10

Cutting Options ..................................................................................................................... 10

Programming Features .......................................................................................................... 11

Performance Features............................................................................................................ 12

Installation and Setup Features ............................................................................................. 12

Hardware Specifications ....................................................................................................... 13

Model Numbering System .................................................................................................... 13

Front Panel Layout ................................................................................................................ 14

PC Keyboard Layout ............................................................................................................. 17

Key and Menu Functions ...................................................................................................... 20

Numeric Keypad ................................................................................................................... 22

Help Screen ........................................................................................................................... 22

Main Screen .......................................................................................................................... 23

Shape Manager Screen .......................................................................................................... 26

Files ....................................................................................................................................... 28

Setups Screen ........................................................................................................................ 30

Change Consumable ............................................................................................................. 31

Remote Help .............................................................................................................................. 33

Install Shared View ............................................................................................................... 33

Use Remote Help .................................................................................................................. 34

Setups ......................................................................................................................................... 37

Cutting................................................................................................................................... 37

Process .................................................................................................................................. 43

Oxy Fuel................................................................................................................................ 44

Plasma ................................................................................................................................... 52

HD3070 Auto Gas Interface ................................................................................................. 56

HD4070 and HPR Overview ................................................................................................ 59

FineLine Overview ............................................................................................................... 65

Marker ................................................................................................................................... 71

Laser Overview ..................................................................................................................... 75

Laser Cut Chart Screen ......................................................................................................... 81

Water Jet ............................................................................................................................... 87

Watch .................................................................................................................................... 89

iii

Page 4

Shape Manager.......................................................................................................................... 93

Shape Library ........................................................................................................................ 93

Text Editor ............................................................................................................................ 94

Shape Wizard ........................................................................................................................ 95

Teach Trace ........................................................................................................................... 97

Nester .................................................................................................................................. 102

Manual Nesting ................................................................................................................... 103

Nester Setup ........................................................................................................................ 105

Using Nester........................................................................................................................ 106

HyperNest – CNC Automatic Nesting Software ................................................................ 109

Automatic Nesting Setup .................................................................................................... 110

Using HyperNest – CNC .................................................................................................... 112

HyperCAD .......................................................................................................................... 119

HyperNEST......................................................................................................................... 121

Files........................................................................................................................................... 123

Load from

Disk ................................................................................................................... 123

Resume Last Part Features .................................................................................................. 125

Save to Disk ........................................................................................................................ 126

Download from Host ........................................................................................................... 129

Upload to Host .................................................................................................................... 131

Loading Invalid Files .......................................................................................................... 132

Library Shapes ........................................................................................................................ 135

Rectangle............................................................................................................................. 136

Circle ................................................................................................................................... 138

Triangle ............................................................................................................................... 140

L-Bracket ............................................................................................................................ 142

Trapezoid ............................................................................................................................ 144

Slant Rectangle ................................................................................................................... 146

Gambrel Rectangle .............................................................................................................. 148

Roofed Rectangle ................................................................................................................ 150

4-Sided Polygon .................................................................................................................. 152

5-Sided Polygon .................................................................................................................. 154

Oval ..................................................................................................................................... 156

Circle with Flat Side ........................................................................................................... 158

Circle Slice .......................................................................................................................... 160

Straight Slots ....................................................................................................................... 162

Angled Slots ........................................................................................................................ 164

Horizontal Rip ..................................................................................................................... 166

Vertical Rip ......................................................................................................................... 168

Flange .................................................................................................................................. 170

Circle with Rectangular Hole .............................................................................................. 172

Gusset .................................................................................................................................. 174

8-Sided ................................................................................................................................ 176

Rectangle with Convex Corners ......................................................................................... 178

Rectangle with Concave Corners ........................................................................................ 180

L-Bracket with Elbow Radii ............................................................................................... 182

iv

Page 5

Slant L-Bracket with Elbow Radii ...................................................................................... 184

Flange Slice ......................................................................................................................... 188

Elbow .................................................................................................................................. 190

Flange Repair Ring ............................................................................................................. 192

Rectangle with Rectangular Hole ....................................................................................... 194

Rectangle with Circular Hole .............................................................................................. 196

Rectangle with Circular Hole and Convex Corners ............................................................ 198

Rectangle with Tab ............................................................................................................. 200

Rectangle with Convex Tab ................................................................................................ 202

Rectangle with Notch .......................................................................................................... 204

Concave Rectangle .............................................................................................................. 212

Triangle with Concave Side ................................................................................................ 214

Polygon with Concave Side ................................................................................................ 216

Slant Rectangle with Radius ............................................................................................... 218

Slant Rectangle with Circular Hole .................................................................................... 220

Slant Rectangle with Beveled Corners ............................................................................... 222

Cross ................................................................................................................................... 224

Cross with Circular Hole and Concave Inside Corners ...................................................... 226

4 Sided Convex Rectangle .................................................................................................. 228

4 Sided Concave Rectangle ................................................................................................ 230

Pipe Mount .......................................................................................................................... 232

Bolt Hole Circle .................................................................................................................. 234

Bolt Hole Flange ................................................................................................................. 236

Bolt Hole Rectangle ............................................................................................................ 238

Bolt Hole Rectangle with Convex Corners ......................................................................... 240

Bolt Hole Rectangle with Center Hole ............................................................................... 242

Bolt Hole Rectangle with Center Hole and Convex Corners ............................................. 244

Rounded L-Bracket ............................................................................................................. 246

Horseshoe ............................................................................................................................ 248

Convex Roof Trapezoid with Hole ..................................................................................... 250

Convex Roof Polygon with Hole ........................................................................................ 252

Convex Roof Polygon with Oval Hole and Concave Bottom ............................................ 254

Pulley Cover........................................................................................................................ 256

Paddle Blind ........................................................................................................................ 258

Water Pump Gasket ............................................................................................................ 260

Frame .................................................................................................................................. 262

Pulley .................................................................................................................................. 264

Sprocket .............................................................................................................................. 266

Text ..................................................................................................................................... 268

Test Pattern ......................................................................................................................... 270

Part Options ............................................................................................................................ 271

Repeat ................................................................................................................................. 273

Align ................................................................................................................................... 276

Align Wizard ....................................................................................................................... 276

Manual Part Alignment ....................................................................................................... 277

Automatic Plate Alignment (APA) ..................................................................................... 278

v

Page 6

Cut Operations ........................................................................................................................ 283

CutPro Wizard .................................................................................................................... 283

Cutting in Manual Mode ..................................................................................................... 283

Multitasking ........................................................................................................................ 287

Pause......................................................................................................................................... 289

Change Consumable ........................................................................................................... 295

Manual ..................................................................................................................................... 297

Manual Options ................................................................................................................... 303

Home Axes.......................................................................................................................... 305

Diagnostics ............................................................................................................................... 307

Control Information ............................................................................................................ 307

I/O ....................................................................................................................................... 309

Analog Input Diagnostics ................................................................................................... 312

Serial Port............................................................................................................................ 313

Drives and Motors............................................................................................................... 315

SERCOS Drives and Motors .............................................................................................. 317

Error Messages.................................................................................................................... 320

Norton Ghost Utility ........................................................................................................... 325

Password Setups ...................................................................................................................... 329

Machine............................................................................................................................... 330

SERCOS ............................................................................................................................. 333

Speeds ................................................................................................................................. 336

CBH Speed Setups .............................................................................................................. 339

THC Speed Setups .............................................................................................................. 339

Torch Height Disable .......................................................................................................... 341

Ports .................................................................................................................................... 343

I/O ....................................................................................................................................... 348

Speed Pot and Joystick Overview ....................................................................................... 350

Axes – Transverse or Rail ................................................................................................... 364

Axes -- Dual Gantry ............................................................................................................ 369

Axes -- CBH ....................................................................................................................... 372

Axes -- Rotate ..................................................................................................................... 375

Axes -- Tilt .......................................................................................................................... 376

Axes -- Transverse 2 ........................................................................................................... 377

Station Configuration .......................................................................................................... 378

Special ................................................................................................................................. 385

System Tools – Windows XP ............................................................................................. 391

Phoenix Link............................................................................................................................ 399

Overview ............................................................................................................................. 399

Files ..................................................................................................................................... 400

Settings ................................................................................................................................ 402

Installation........................................................................................................................... 403

Software .............................................................................................................................. 403

Hardware ............................................................................................................................. 407

Operating Phoenix Link ...................................................................................................... 408

Common Errors ................................................................................................................... 408

vi

Page 7

Error Messages.................................................................................................................... 409

Sensor THC ............................................................................................................................. 411

Overview ............................................................................................................................. 411

Cut Setups ........................................................................................................................... 412

Plasma Setups ..................................................................................................................... 413

Marker Setups ..................................................................................................................... 417

Process Watch ..................................................................................................................... 419

Main Cut Screen ................................................................................................................. 420

Sensor THC Setups ............................................................................................................. 421

Sensor THC Axis Setups .................................................................................................... 422

THC Speeds ........................................................................................................................ 424

THC I/O .............................................................................................................................. 425

Command THC ....................................................................................................................... 429

Main Cut Screen ................................................................................................................. 433

Diagnostics .......................................................................................................................... 435

Machine Interface ............................................................................................................... 435

Motion Overview ..................................................................................................................... 437

Closed Loop Servo Control ................................................................................................ 437

Encoders .............................................................................................................................. 438

Encoder Counts and Maximum Machine Speed ................................................................. 440

Motion Tuning Watch Windows ........................................................................................ 445

SERCOS Interface Overview ............................................................................................. 447

ASCII Codes ............................................................................................................................ 449

0BProgram Codes ........................................................................................................................ 451

1BEIA RS-274D ...................................................................................................................... 451

2B2BESSI .................................................................................................................................... 459

3B3BAdvanced Feature Codes ................................................................................................... 463

4BStation Selects ..................................................................................................................... 464

5BAutomatic Torch Spacing ................................................................................................... 465

6BSensor THC Part Program Support ..................................................................................... 468

7BSubparts............................................................................................................................... 469

8BMarker Font Generator ....................................................................................................... 471

9BSerial Messaging ................................................................................................................. 475

Automated Plasma Interface ................................................................................................. 485

HPR and HD4070 Interface ................................................................................................ 485

Cut Charts ........................................................................................................................... 486

Custom Cut Charts .............................................................................................................. 490

Change Consumable ........................................................................................................... 493

HD4070 Diagnostics ........................................................................................................... 494

HPR Diagnostics ................................................................................................................. 495

HD3070 Auto Gas Interface ............................................................................................... 504

FineLine Overview ............................................................................................................. 507

Serial Ports .............................................................................................................................. 515

Control RS-232C DB-9 Pinout ........................................................................................... 515

RS-232C Connections to Host PC with 9-pin D-type connector ........................................ 516

RS-232C Connections to Host PC with 25-pin D-type connector ...................................... 516

vii

Page 8

Automatic DXF Import .......................................................................................................... 517

Overview ............................................................................................................................. 517

Load DXF Files................................................................................................................... 517

Raw DXF Files ................................................................................................................... 518

Prepared DXF Files............................................................................................................. 520

Networking .............................................................................................................................. 523

Network Operating System ................................................................................................. 523

Configuring the Network Interface Card ............................................................................ 523

Connecting the CNC to a Network ..................................................................................... 524

Mapping a Connection to a Network Share ........................................................................ 524

Connecting the CNC to a Workgroup ................................................................................. 527

Hardware Considerations .................................................................................................... 529

MicroEdge ............................................................................................................................... 535

Overview ............................................................................................................................. 535

Keyboard Layout ................................................................................................................ 536

System Requirements.......................................................................................................... 536

Machine Interface ............................................................................................................... 537

I/O Configuration ................................................................................................................ 538

I/O Interface ........................................................................................................................ 539

THC and Joystick Interface ................................................................................................ 544

Calibration........................................................................................................................... 548

Edge Ti ..................................................................................................................................... 549

Overview ............................................................................................................................. 549

Machine Interface ............................................................................................................... 550

I/O Configuration ................................................................................................................ 551

I/O Interface ........................................................................................................................ 552

Lifter Interface .................................................................................................................... 555

Plasma Interface .................................................................................................................. 556

External Interlock................................................................................................................ 557

Voyager III .............................................................................................................................. 561

Overview ............................................................................................................................. 561

Setups .................................................................................................................................. 563

Common Status Messages .................................................................................................. 564

Machine Interface ............................................................................................................... 565

SERCOS to Analog Conversion Card ................................................................................ 570

Mariner .................................................................................................................................... 573

Overview ............................................................................................................................. 573

Touch Screen ...................................................................................................................... 573

THC, Joystick and Speedpots ............................................................................................. 573

AC Input Pinout .................................................................................................................. 574

E-Stop ................................................................................................................................. 574

Diagram Location Din-02 ................................................................................................... 574

SERCOS Motion and I/O.................................................................................................... 574

viii

Page 9

Safety

Product Listings

MicroEdge and Voyager III

Note: This product has been designed and manufactured in accordance with CE and UL Safety

Standards.

UL has successfully tested and listed these products in accordance with the applicable U.S. and

Canadian Safety Standards. File number E178333. Note: Suitable for pollution degree 2

environment only.

This appliance has been successfully tested and listed by CE under the following standards; EN

500081-2 1994, EN 61000-6-2 1999, and EN 55011:1998. Certificate number: Retlif R-3909N

Edge TI

Note: This product has been designed and manufactured in accordance with CE and UL Safety

Standards.

UL has successfully tested and listed these products in accordance with the applicable U.S. and

Canadian Safety Standards. File number E307226.

Additional markings:

1. Use minimum 75° C copper wire only.

2. Use copper conductors only.

3. Suitable for use on a circuit capable of delivering not more than 5000rms symmetrical

amperes, 230 volts maximum.

4. Solid state motor overload protection is not provided on this device.

5. Integral solid state short circuit protection does not provide branch circuit protection.

Branch circuit protection provided by integral LISTED branch circuit protection fuse.

This appliance has been successfully tested and listed by CE under the following standards; EN 5000812 1994, EN 61000-6-2 1999, and EN 55011:1998. Certificate number: Retlif R-3909N

Please contact Hypertherm Automation for further safety listing information.

1

Page 10

2 Safety

RECOGNIZE SAFETY INFORMATION

The symbols shown in this section are used to

identify potential hazards. When you see a safety

symbol in this manual or on your machine, understand

the potential for personal injury, and follow the related

instructions to avoid the hazard.

FOLLOW SAFETY INSTRUCTIONS

Read carefully all safety messages in this manual and

safety labels on your machine.

• Keep the safety labels on your machine in good

condition. Replace missing or damaged labels

immediately.

• Learn how to operate the machine and how to use

the controls properly. Do not let anyone operate it

without instruction.

• Keep your machine in proper working condition.

Unauthorized modifications to the machine may

affect safety and machine service life.

DANGER WARNING CAUTION

A signal word DANGER or WARNING is used with a

safety symbol. DANGER identifies the most serious

hazards.

• DANGER and WARNING safety labels are located

on your machine near specific hazards.

• WARNING safety messages precede related

instruc tions in this manual that may result in injury

or death if not followed correctly.

• CAUTION safety messages precede related

instructions in this manual that may result in

damage to equipment if not followed correctly.

Fire Prevention

• Be sure the area is safe before doing any cutting.

Keep a fire extinguisher nearby.

• Remove all flammables within 35 feet (10 m) of the

cutting area.

• Quench hot metal or allow it to cool before handling

or before letting it touch combustible materials.

• Never cut containers with potentially flammable

materials inside – they must be emptied and

properly cleaned first.

• Ventilate potentially flammable atmospheres before

cutting.

• When cutting with oxygen as the plasma gas, an

exhaust ventilation system is required.

Explosion Prevention

• Do not use the plasma system if explosive dust or

vapors may be present.

• Do not cut pressurized cylinders, pipes, or any

closed container.

• Do not cut containers that have held combustible

materials.

CUTTING CAN CAUSE FIRE OR EXPLOSION

WARNING

Explosion Hazard

Argon-Hydrogen and Methane

Hydrogen and methane are flammable gases that

present an explosion hazard. Keep flames away from

cylinders and hoses that contain methane or hydrogen

mixtures. Keep flames and sparks away from the torch

when using methane or argon-hydrogen plasma.

WARNING

Hydrogen Detonation with Aluminum Cutting

• When cutting aluminum underwater, or with the

water touching the underside of the aluminum, free

hydrogen gas may collect under the workpiece and

detonate during plasma cutting operations.

• Install an aeration manifold on the floor of the water

table to eliminate the possibility of hydrogen

detonation. Refer to the Appendix section of this

manual for aeration manifold details.

Page 11

Safety 3

Touching live electrical parts can cause a fatal shock

or severe burn.

• Operating the plasma system completes an

electrical circuit between the torch and the

workpiece. The workpiece and anything touching

the workpiece are part of the electrical circuit.

• Never touch the torch body, workpiece or the water

in a water table when the plasma system is

operating.

Electric Shock Prevention

All Hypertherm plasma systems use high voltage

in the cutting process (200 to 400 VDC are

common). Take the following precautions when

operating this system:

• Wear insulated gloves and boots, and keep your

body and clothing dry.

• Do not stand, sit or lie on – or touch – any wet

surface when using the plasma system.

• Insulate yourself from work and ground using dry

insulating mats or covers big enough to prevent any

physical contact with the work or ground. If you must

work in or near a damp area, use extreme caution.

• Provide a disconnect switch close to the power

supply with properly sized fuses. This switch allows

the operator to turn off the power supply quickly in

an emergency situation.

• When using a water table, be sure that it is correctly

connected to earth ground.

ELECTRIC SHOCK CAN KILL

• Install and ground this equipment according to the

instruction manual and in accordance with national

and local codes.

• Inspect the input power cord frequently for damage

or cracking of the cover. Replace a damaged power

cord immediately. Bare wiring can kill.

• Inspect and replace any worn or damaged torch

leads.

• Do not pick up the workpiece, including the waste

cutoff, while you cut. Leave the workpiece in place

or on the workbench with the work cable attached

during the cutting process.

• Before checking, cleaning or changing torch parts,

disconnect the main power or unplug the power

supply.

• Never bypass or shortcut the safety interlocks.

• Before removing any power supply or system

enclosure cover, disconnect electrical input power.

Wait 5 minutes after disconnecting the main power

to allow capacitors to discharge.

• Never operate the plasma system unless the power

supply covers are in place. Exposed power supply

connections present a severe electrical hazard.

• When making input connections, attach proper

grounding conductor first.

• Each Hypertherm plasma system is designed to be

used only with specific Hypertherm torches. Do not

substitute other torches which could overheat and

present a safety hazard.

Use proper precautions when handling printed

circuit boards.

STATIC ELECTRICITY CAN DAMAGE CIRCUIT BOARDS

• Store PC boards in anti-static containers.

• Wear a grounded wrist strap when handling

PC boards.

Page 12

4 Safety

The plasma arc by itself is the heat source used for

cutting. Accordingly, although the plasma arc has not

been identified as a source of toxic fumes, the

material being cut can be a source of toxic fumes or

gases that deplete oxygen.

Fumes produced vary depending on the metal that is

cut. Metals that may release toxic fumes include, but

are not limited to, stainless steel, carbon steel, zinc

(galvanized), and copper.

In some cases, the metal may be coated with a

substance that could release toxic fumes. Toxic

coatings include, but are not limited to, lead (in some

paints), cadmium (in some paints and fillers), and

beryllium.

Gases produced by plasma cutting vary based on the

material to be cut and the method of cutting, but may

include ozone, oxides of nitrogen, hexavalent

chromium, hydrogen, and other substances if such

are contained in or released by the material being cut.

Caution should be taken to minimize exposure to

fumes produced by any industrial process. Depending

upon the chemical composition and concentration of

the fumes (as well as other factors, such as

ventilation), there may be a risk of physical illness,

such as birth defects or cancer.

It is the responsibility of the equipment and site owner

to test the air quality in the area where the equipment

is used and to ensure that the air quality in the

workplace meets all local and national standards

and regulations.

TOXIC FUMES CAN CAUSE INJURY OR DEATH

The air quality level in any relevant workplace

depends on site-specific variables such as:

• Table design (wet, dry, underwater).

• Material composition, surface finish, and

composition of coatings.

• Volume of material removed.

• Duration of cutting or gouging.

• Size, air volume, ventilation and filtration of the

work area.

• Personal protective equipment.

• Number of welding and cutting systems in

operation.

• Other site processes that may produce fumes.

If the workplace must conform to national or local

regulations, only monitoring or testing done at the site

can determine whether the site is above or below

allowable levels.

To reduce the risk of exposure to fumes:

• Remove all coatings and solvents from the metal

before cutting.

• Use local exhaust ventilation to remove fumes from

the air.

• Do not inhale fumes. Wear an air-supplied

respirator when cutting any metal coated with,

containing, or suspected to contain toxic elements.

• Assure that those using welding or cutting

equipment, as well as air-supplied respiration

devices, are qualified and trained in the proper use

of such equipment.

• Never cut containers with potentially toxic materials

inside. Empty and properly clean the container first.

• Monitor or test the air quality at the site as needed.

• Consult with a local expert to implement a site plan

to ensure safe air quality.

Page 13

Safety 5

Instant-On Torches

Plasma arc comes on immediately when the torch

switch is activated.

A PLASMA ARC CAN CAUSE INJURY AND BURNS

The plasma arc will cut quickly through gloves and

skin.

• Keep away from the torch tip.

• Do not hold metal near the cutting path.

• Never point the torch toward yourself or others.

Eye Protection Plasma arc rays produce intense

visible and invisible (ultraviolet and infrared) rays that

can burn eyes and skin.

• Use eye protection in accordance with applicable

national or local codes.

• Wear eye protection (safety glasses or goggles with

side shields, and a welding helmet) with appropriate

lens shading to protect your eyes from the arcʼs

ultraviolet and infrared rays.

Lens Shade

Arc Current AWS (USA) ISO 4850

Up to 100 A No. 8 No. 11

100-200 A No. 10 No. 11-12

200-400 A No. 12 No. 13

Over 400 A No. 14 No. 14

ARC RAYS CAN BURN EYES AND SKIN

Skin Protection Wear protective clothing to protect

against burns caused by ultraviolet light, sparks and

hot metal.

• Gauntlet gloves, safety shoes and hat.

• Flame-retardant clothing to cover all exposed areas.

• Cuffless trousers to prevent entry of sparks and

slag.

• Remove any combustibles, such as a butane lighter

or matches, from your pockets before cutting.

Cutting Area Prepare the cutting area to reduce

reflection and transmission of ultraviolet light:

• Paint walls and other surfaces with dark colors to

reduce reflection.

• Use protective screens or barriers to protect others

from flash and glare.

• Warn others not to watch the arc. Use placards or

signs.

Work Cable Attach the work cable securely to the

workpiece or the work table with good metal-to-metal

contact. Do not connect it to the piece that will fall

away when the cut is complete.

Work Table Connect the work table to an earth

ground, in accordance with appropriate national or

local electrical codes.

GROUNDING SAFETY

Input Power

• Be sure to connect the power cord ground wire to

the ground in the disconnect box.

• If installation of the plasma system involves

connecting the power cord to the power supply, be

sure to connect the power cord ground wire

properly.

• Place the power cord's ground wire on the stud first,

then place any other ground wires on top of the

power cord ground. Fasten the retaining nut tightly.

• Tighten all electrical connections to avoid excessive

heating.

Page 14

6 Safety

ADDITIONAL SAFETY INFORMATION

1. ANSI Standard Z49.1,

Safety in Welding and Cutting,

American

Welding Society, 550 LeJeune Road

P.O. Box 351020, Miami, FL 33135

2. ANSI Standard Z49.2,

Fire Prevention in the Use of Cutting and

Welding Processes,

American National Standards Institute

1430 Broadway, New York, NY 10018

3. ANSI Standard Z87.1,

Safe Practices for Occupation and

Educational Eye and Face Protection,

American National

Standards Institute, 1430 Broadway, New York, NY 10018

4. AWS F4.1,

Recommended Safe Practices for the Preparation for

Welding and Cutting of Containers and Piping That Have Held

Hazardous Substances,

American Welding Society

550 LeJeune Road, P.O. Box 351040, Miami, FL 33135

5. AWS F5.2,

Recommended Safe Practices for Plasma Arc

Cutting,

American Welding Society

550 LeJeune Road, P.O. Box 351040, Miami, FL 33135

6. CGA Pamphlet P-1,

Safe Handling of Compressed Gases in

Cylinders,

Compressed Gas Association

1235 Jefferson Davis Highway, Arlington, VA 22202

7. CSA Standard W117.2,

Code for Safety in Welding and Cutting,

Canadian Standards Association Standard Sales

178 Rexdale Boulevard, Rexdale, Ontario M9W 1R3, Canada

8. NFPA Standard 51B,

Cutting and Welding Processes,

National

Fire Protection Association

470 Atlantic Avenue, Boston, MA 02210

9. NFPA Standard 70–1978,

National Electrical Code,

National Fire

Protection Association, 470 Atlantic Avenue, Boston, MA 02210

10. OSHA,

Safety and Health Standards,

29FR 1910

U.S. Government Printing Office, Washington, D.C. 20402

• Never lubricate cylinder valves or regulators with oil

or grease.

• Use only correct gas cylinders, regulators, hoses

and fittings designed for the specific application.

• Maintain all compressed gas equipment and

associated parts in good condition.

• Label and color-code all gas hoses to identify the

type of gas in each hose. Consult applicable

national or local codes.

GAS CYLINDERS CAN

EXPLODE IF DAMAGED

COMPRESSED GAS EQUIPMENT SAFETY

Gas cylinders contain gas under high pressure. If

damaged, a cylinder can explode.

• Handle and use compressed gas cylinders in

accordance with applicable national or local codes.

• Never use a cylinder that is not upright and secured

in place.

• Keep the protective cap in place over valve except

when the cylinder is in use or connected for use.

• Never allow electrical contact between the plasma

arc and a cylinder.

• Never expose cylinders to excessive heat, sparks,

slag or open flame.

• Never use a hammer, wrench or other tool to open

a stuck cylinder valve.

Prolonged exposure to noise from cutting or gouging

can damage hearing.

• Use approved ear protection when using plasma

system.

• Warn others nearby about the noise hazard.

NOISE CAN DAMAGE HEARING

Pacemaker and hearing aid operation can be affected

by magnetic fields from high currents.

Pacemaker and hearing aid wearers should consult a

doctor before going near any plasma arc cutting and

gouging operations.

To reduce magnetic field hazards:

• Keep both the work cable and the torch lead to one

side, away from your body.

• Route the torch leads as close as possible to the

work cable.

• Do not wrap or drape the torch lead or work cable

around your body.

• Keep as far away from the power supply as

possible.

PACEMAKER AND HEARING

AID OPERATION

A PLASMA ARC CAN

DAMAGE FROZEN PIPES

Frozen pipes may be damaged or can burst if you

attempt to thaw them with a plasma torch.

Page 15

Safety 7

WARNING LABEL

This warning label is affixed to some power supplies. It is

important that the operator and maintenance technician

understand the intent of these warning symbols as described.

The numbered text corresponds to the numbered boxes on

the label.

1. Cutting sparks can cause explosion or fire.

1.1 Keep flammables away from cutting.

1.2 Keep a fire extinguisher nearby, and have

a watchperson ready to use it.

1.3 Do not cut on any closed containers.

2. The plasma arc can cause injury and

burns.

2.1 Turn off power before disassembling torch.

2.2 Do not hold the material near cutting path.

2.3 Wear complete body protection.

3. Electric shock from torch or wiring can kill.

Protect yourself from electric shock.

3.1 Wear insulating gloves. Do not wear wet or

damaged gloves.

3.2 Insulate yourself from work and ground.

3.3 Disconnect input plug or power before

working on machine.

4. Breathing cutting fumes can be hazardous

to your health.

4.1 Keep your head out of the fumes.

4.2 Use forced ventilation or local exhaust to

remove the fumes.

4.3 Use ventilating fan to remove the fumes.

5. Arc rays can burn eyes and injure skin.

5.1 Wear hat and safety glasses. Use ear

protection and button shirt collar. Use

welding helmet with correct shade of filter.

Wear complete body protection.

6. Become trained and read the instructions

before working on the machine or cutting.

7. Do not remove or paint over (cover)

warning labels.

www.hypertherm.com/weee

110647 Rev. A

Page 16

8 Safety

Page 17

Overview

The following sections highlight the features of the Hypertherm Automation CNC and version

8.0 of the Phoenix® software.

CutPro Wizard

The CutPro™ wizard is an interactive tool that simplifies the steps of cutting a part. The CutPro

wizard helps you:

• Load a part program

• Select a cut process

• Align a plate and adjust for skew

• Set scrap clearance

• Select cut mode

• Start the cut directly from the wizard or by pressing the green Start button on the console

The wizard opens automatically from the Main screen after 10 seconds. Automatic activation

can be disabled on the Special password setup screen. However, the wizard is always

accessible by pressing the CutPro Wizard soft key on the Main screen.

Align Wizard

The Align™ wizard is an interactive tool that guides you through the process of aligning a plate

and adjusting for a skewed plate. This wizard can be accessed from the CutPro Wizard or from

the Align screen.

Remote Help

The Remote Help™ facility is an easy-to-use and reliable means of remotely connecting the

Hypertherm Automation CNC to up to 15 users for:

• Observing an operator at the machine

• Reviewing settings and software configurations

• Transferring setup files, part programs, software updates, etc.

• Performing HPR diagnostics

• Training users

ShapeWizard

The ShapeWizard

on the internal hard disk present in the control.

®

tool allows you to graphically create simple part programs and store them

Teach/Trace

9

Page 18

Overview

If your system is configured with a tracing head, you can use the control to digitize almost any

pattern, store it on the internal hard disk, and further customize the program with ShapeWizard.

The control has both smart-arc and smart-line translators to provide you with optimum program

resolution.

Shape Libraries

Graphically select the desired shape from the parts library. Then you simply add the dimensions

you want, and the scaled part, with your entered dimensions, will be displayed. There is even a

Help Icon to step you through the data entry.

Program Upload and Download

Communication is an integral part of today’s fabricating shop. All part programs that have

been entered in the control can be uploaded to a remote computer or file server with an

integrated RS-232C/ RS-422 communications link. CAD generated programs can be

downloaded at baud rates of up to 115K baud and visually previewed on the color LCD display.

Visual representation of part programs, along with full alpha-numeric file name support, gives

you the flexibility to manage your data as you see fit. Use of the optional Network Card allows

us to bring the latest in communication technology for increased speed and productivity to your

shape cutting controller. Additionally, built-in Control monitoring features allow current

operational status to be displayed at the host Link screen.

SoftMotion

SoftMotion is a proprietary data buffer and interrupt structure that allows the control to generate

all of its motion control algorithms from the main Pentium® Processor. This architecture allows

SoftMotion to tightly couple the motion control and I/O logic to the operator interface.

Cutting Options

Flexibility in your cutting operation is the key to success. The control comes standard with the

following cutting functions to help you optimize material and plate usage. These functions

work on any program. After selecting one of these functions, the new part will be graphically

displayed.

Mirror function

The mirror function can be used to create a mirror image of the part along either the X or Yaxis.

Rotate function

The rotate function can be used to rotate the current part.

Scale function

The scale function can be used to increase or decrease the current part by a programmed ratio.

Repeat function

10

Page 19

Overview

The repeat function duplicates the part shape in either a straight, staggered or nested grid

patterns.

Programming Features

• English and metric operation for worldwide use. Each axis can have its own encoder-to-

unit edge rate.

• Dynamic kerf compensation with programmable kerf value.

• Automatic corner and plate alignment with programmable scrap clearance.

• Shape Repeat with three grid patterns (straight, stagger, and nested) allows fast cutting of

multiple pieces.

• Part mirroring in both X and Y axes.

• Part rotation.

• Scaling allows quick part resizing to original size.

• Virtually no limit to the number of program names or work file folders that can be stored on

the internal hard disk drive.

• Punch or powder marker control with twelve programmable offsets.

• Choice of industry-standard EIA RS-274D or ISO 6582 ESSI part programming languages.

Manual Data Input (MDI)

• Full screen ASCII text editor.

• Allows writing, editing, and graphical review of part programs at the machine.

Communications Link

• Preview Mode allows machine operator to graphically review and select programs for

download.

• Download part programs from CAD system, remote host computer, or other storage device

via built-in RS-232C/ RS-422 port.

• Can accept EIA RS-274D or ESSI part programs.

• Baud Rates of up to 115K Baud. Communication baud rates of 230K are obtainable using

the communication link software provided with the control.

• Optional network card for connecting directly to a PC Network for part file allocation.

Graphical program display

• Visually display any part program.

• Display of real-time position and I/O information.

• Display of actual cut path while cutting.

Built-in Parametric Shape Library

• Contains 68 commonly used shapes.

• Simple Graphical prompts for entering all part dimensions.

11

Page 20

Overview

Teach/Trace

• Smart-arc and Smart-Line algorithms for optimum program size and contouring

smoothness.

• Converts your existing optical tracer templates to EIA RS-274D programs, and stored on

the internal hard disk drive.

• Automatic part closure detection.

• Allows multiple pierce points, lead-ins, lead-outs, and rapid traverse segments.

• Upload taught part programs to CAD system, remote host computer, or other storage

device.

• Requires a separate optical tracer control system.

Performance Features

• Digital servo positioning control for any cutting machine. An optional SERCOS Interface

allows expansion of motion axes and distributed I/O.

• Control dynamic accuracy of 0.002 inch (0.051 mm) with 1000 edge/inch encoders.

• Programmable cut speeds up to 3000 IPM (76,200 mmpm).

• Variable segment length look-ahead for optimum contouring performance.

• Automatic corner slowdown and torch height disable for clean, sharp corners.

• Speed Increase/Decrease buttons for optimizing machine cut speed.

• Automatic Plate and Corner Alignment corrects for skewed plates.

• Complete cut-loss recovery with backup and forward along path, off-path re-pierce and

return-to-path, and move pattern functions.

• Rip Mode for straight-line cutting. Jog control cutting.

• Punch, powder or Plasma marker capability.

• Manual jog control with position read-out for positioning torches.

• Nester™ and optional HyperNest

productivity and increased plate utilization.

• Automated Torch Spacing feature to position torch station spacing automatically through

the part program for standard and mirrored multi-torch cutting.

• Rush Job Interrupt and Automated Power Loss Recovery features.

®

– CNC Automatic Nesting features for increased

Installation and Setup Features

• Selectable axis orientation for compatibility with all cutting machines.

• Built in oxy-fuel interface with programmable pre-heat time, ignition, and creep speed.

• Built in plasma interface with programmable purge time, ignition time, arc-off delay time,

and arc-transferred feedback.

• Built in Laser interface with programmable shutter time, power ramp time and pierce time.

• Built in Water Jet interface with programmable abrasive output and pierce time.

12

Page 21

Overview

• Programmable servo gains, speeds, Watch Window, machine parameters, and com-

munication parameters for flexible application.

• Interfaces easily to most optical tracing systems for integrated control.

• Complete built-in diagnostics for checkout and test.

Hardware Specifications

• 15” TFT Touch Screen with 1024 x 768 resolution.

• ≥60Gbyte hard disk

• ≥1.3 GHz Processor.

• 512 Mbytes of RAM.

• Up to 96 lines of interface signals for cutting and motion logic (gas control, tracing system,

markers, homing, etc.) depending on I/O configuration. An optional SERCOS Interface™

allows expansion of I/O configuration.

• Industrial grade enclosure and keypad designed to minimize RFI/EMI interference.

• Surface mount printed circuit board technology.

• Two axes optically isolated ±10VDC drive outputs and incremental encoder inputs which

are expandable to 6 axes of motion. Up to twelve axes of motion and 1024 I/O available

with optional SERCOS Interface. Optional axes available for dual gantry, dual transverse,

contoured bevel head, two rotate, two tilt angle and eight Sensor™ THC applications..

• +5VDC single ended or differential encoder inputs.

• Optically isolated serial ports with programmable baud rates to 115 K baud.

Communication baud rates of 230K are obtainable using the communication link software

provided with the control. Optional Network Card for connecting directly to a PC Network.

• Universal power input (100-240 VAC; 47-63Hz). Individual models may vary. Refer to

machine interface information for details.

• Operating environment: 0 to 50°C (32 to 122°F); 95% relative humidity (non-condensing).

• An optional Chiller for Mariner style controls is available.

Model Numbering System

The control is available with the following hardware and software configurations. Features and

control configuration options in software are based on the I/O configuration of the control.

Generally, the information presented in this guide is based on the I/O configuration as outlined

below. Please refer to your control I/O configuration for available features and product

information. The specific configuration is determined by the Model Number, as shown below:

13

Page 22

Overview

H

Axis Configuration

2 = 2 Servo Axes

3 = 3 Servo Axes

4 = 4 Servo Axes

5 = 5 Servo Axes

6 = 6 Servo Axes

7 = 7 Servo Axes

8 = 8 Servo Axes

9 = 9 Servo Axes

A = 10 Servo Axes

B = 11 Servo Axes

C = 12 Servo Axes

S = Sercos

I / O Configuration

B = Burny 3 / 5

M = MicroPath

P = PicoPath

V = Voyager

S = Sercos

D = Edge Ti - DC amps

Power Supplies

0 = Standard Logic Supply

2 = Standard Logic Supply &

Auxiliary Supply with

+5, +/-12 & +24 vdc

Pointing Device

0 = None

1 = Industrial Mouse

LCD Type

X = None

0 = 10.4" Dual Scan DSTN

1 = 10.4" Active Matrix TFT

2 = 15" Active Matrix TFT

3 = 15" Touch Screen

4 = 12.1" Active Matrix TFT

-

Memory

0 = 16 MBytes

1 = 32 MBytes

2 = 64 MBytes

3 = 128 MBytes

4 = 256 MBytes

5 = 512 MBytes

--

Operating System

0 = Windows 95 / 98

1 = Windows NT

2 = Windows XP

APC

0 = None

1 = Laser

2 = Plasma

THC

0 = None

1 = 1 THC

2 = 2 THC's

Speed Pots

0 = None

1 = 1 Speed Pot

2 = 2 Speed Pots

Joystick

0 = None

1 = Joystick

Backup Hard Drive

0 = None

1 = Installed

Processor

0 = 166 MHz

1 = 200 MHz

2 = 266 MHz

3 = 433 MHz

4 = 566 MHz

5 = 1.2 GHz

6 = 2.4 GHz

7 = 3.06 GHz

8 = 1.3 GHz M

Front Panel Layout

This software is designed specifically for 15” TFT Touch Screen operation with 1024 x 768 or

higher resolution and is used on all CNC models. Individual man machine interface (MMI) and

front panels may vary.

Power Switch

Hypertherm Automation controls are equipped with a momentary contact power switch. Press

briefly and release for controlled power on and power off the control. Pressing the power

switch for 10 seconds will force a hard system shutdown of Windows and the control.

Generally, a hard shutdown is not recommended.

Touch Screen

14

Page 23

Overview

The touch screen software interface allows direct key input on the screen through the use of

check boxes, radial boxes, drop down selections and data input. Data input boxes will

automatically display a numeric or alphanumeric keypad depending on data type.

Front Panel (selected models)

ICON Legend

Emergency Stop

Start

Stop

Forward and Backward on Path

Torch Up / Down

Manual

Speed Pot (Manual Feedrate)

Front Panel Keypad (Voyager III model)

The yellow key labeled with a question mark (?) is for online documentation and help. Simply

press this key at any time and this document will be displayed.

The keys to the lower right of the front panel comprise the alpha numeric keypad, which is used

for entering data. To the far left are keys which control manual motion and cursor location

during data input. These include the MANUAL key (for Manual Mode jogs) and the eight

arrow keys (for jog and cursor direction).

The two keys in the center of the keypad are for program start and stop.

15

Page 24

Overview

The two keys to the right of the yellow help key are for Forward on Path and Backup on Path

while in the Pause screen.

Key Functions

The alpha–numeric keypad is used to enter numeric data or

text. To enter a number, simply press the key. To enter a

word, press and hold the matching colored shift key (up arrow)

while pressing the desired letter key. The + (plus) and –

(minus) keys are used to add and delete features at selection

and check boxes.

An alternate (ALT) soft key indicates that more

soft keys and features are available by pressing

this soft key on screen.

When the alternate soft key is displayed, the

purple shift can also be used to view additional

soft keys.

These keys activate jogging using the arrow keys when in the manual

mode. Manual key functions (indicated in green) are available at the

Manual, Pause and Align Screens. This keypad is also used for

navigating through a multi-variable dialog box (indicated in yellow).

The Prev/Next buttons are used to move through the field boxes, Page

Up/Down is used to scroll and the arrow keys are used to select items

in a dialog box.

16

Page 25

Pressing the space key inserts a space into the current data entry field. The space key is also

used to toggle between fixed logic settings ( i.e. setups - preheat sense input open/closed ).

The space key may also be used to add and delete features at selection and check boxes.

Deletes the current character in the data entry field and backs up one position in the field.

Located above the Back Space key are the * and ? characters which are used as wild cards

to search for files.

Can be pressed at any time (except during cut) to return to the previous menu without

saving any changes. Located above the Cancel key are the \ and : characters which are

used for mapping network drives.

Causes the last number entered/toggled to be accepted. Located above the enter key are

the < and > characters which are used for mapping network drives.

PC Keyboard Layout

Overview

Available as standard on selected models but may be added to all controls.

17

Page 26

Overview

Keyboard Functions

Function Keys F1-F8 are equivalent to the soft keys on the display screen.

Function Key F9 is equivalent to the START key.

Function Key F10 and Pause Key are equivalent to the STOP key.

Function Key F11 is equivalent to the MANUAL MODE key.

Function Key F12 is equivalent to the HELP key.

Arrow direction keys are used for manual motion.

The HOME key is equivalent to the PREV field key.

The END key is equivalent to the NEXT field key.

The [ key is equivalent to the purple arrow shift key.

The ] key is equivalent to the blue arrow shift key.

The Esc key is equivalent to the CANCEL key.

To exit the control software press Alt F4. Warning: This will terminate the current application.

To switch between applications press Alt Tab. Warning: The selected application window to be

on top of the desktop and may cover or hide the control software application window.

Operation Summary

The programming and operation of the control is menu-driven. The following diagram shows

the Screen Hierarchy for the menu structure.

The menu that appears in the display when the unit is first turned on is referred to throughout

this manual as the Main Menu. All other menus and functions are accessed at some level under

Main Menu, or else appear as part of a special operational sequence, such as when the cutting

process is interrupted during the middle of a part.

18

Page 27

Overview

The OK and CANCEL keys have special functions in relation to the menu structure. The OK

soft key returns to the menu from which the present selection was entered and retains any

changes that were made. The CANCEL key returns to the menu from which it was entered and

deletes/discards any changes that were made. There are, however, some operations during

which CANCEL is not active.

Screen Hierarchy

Main Screen

Cut Chart

Load from Disk

Save to Disk

Save Log to Disk

Download from Host

Upload to Host

Setups

Cut Types Password 1Diagnostics

Oxy Fuel

Timing Diagram

Water Jet

Timing Diagram

Plasma

Timing Diagram

Cut Chart

Marker

Timing Diagram

Cut Chart

Laser

Timing Diagram

Cut Chart

Process Monitoring

Change Consumable

Manual

Control Information

I / O

Oscilloscope

Serial Port

Drives and Motors

Plasma System

Manual Options

Manual Options

Home Axes

Inputs

Outputs

Analog Inputs

Inputs

Outputs

Supply Information

Part OptionsFiles

Repeat

Align

Manual Options

Speeds

Link

I/O

Sercos

Axes

Transverse

Rail

Dual Gantry

CBH

Tilt

Rotate

THC

Lens

Cut

Pause

Change Consumable

Manual Options

Cutting

WatchMachine

Password 3

Station Configuration

Password 2

System Tools

Backup Hard Drive

Scan Hard Disk

Defrag Hard Disk

Format Floppy Disk

Network Tools

Remote Assistant

Shape Manager

Shape Library

Simple Shape

View Text

Part Options

Repeat

Align

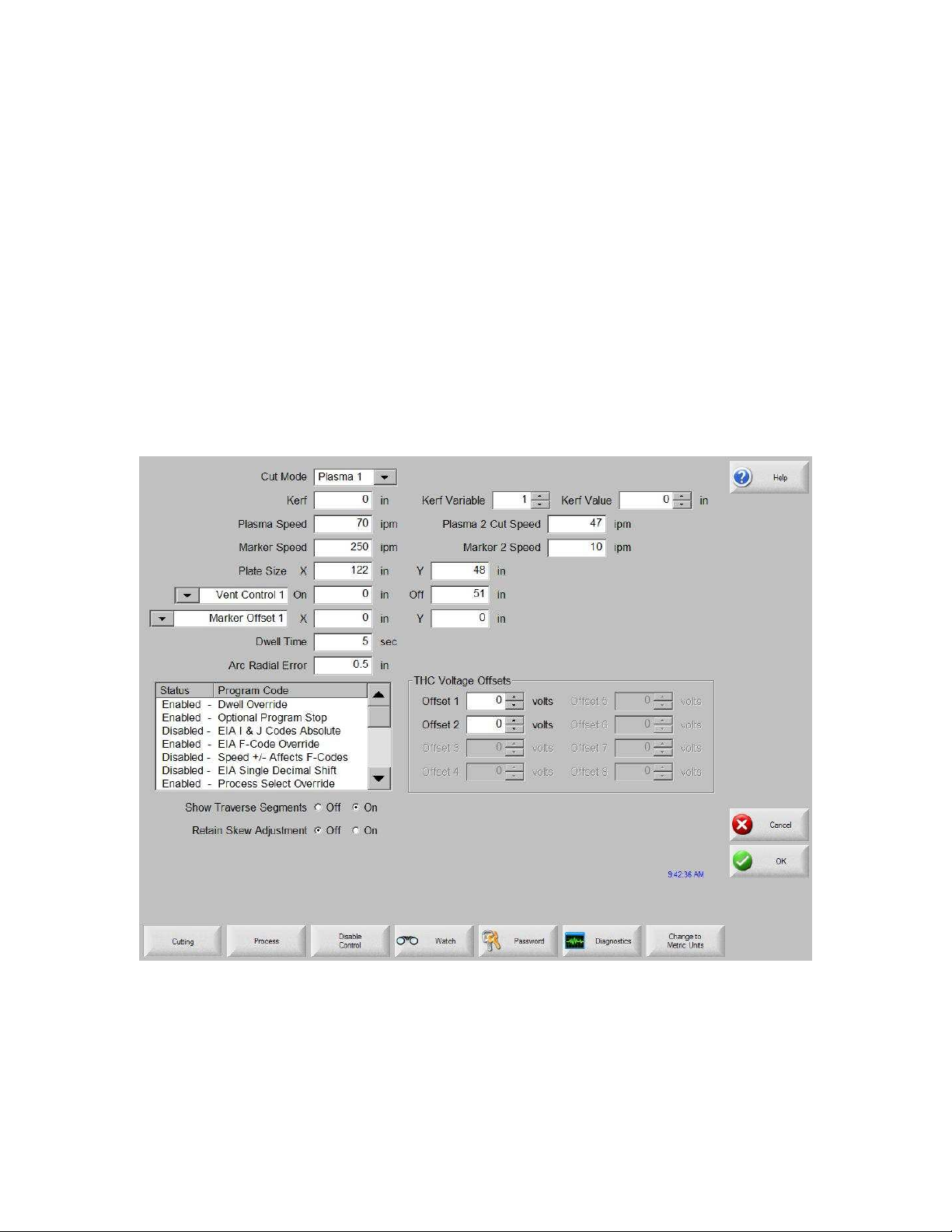

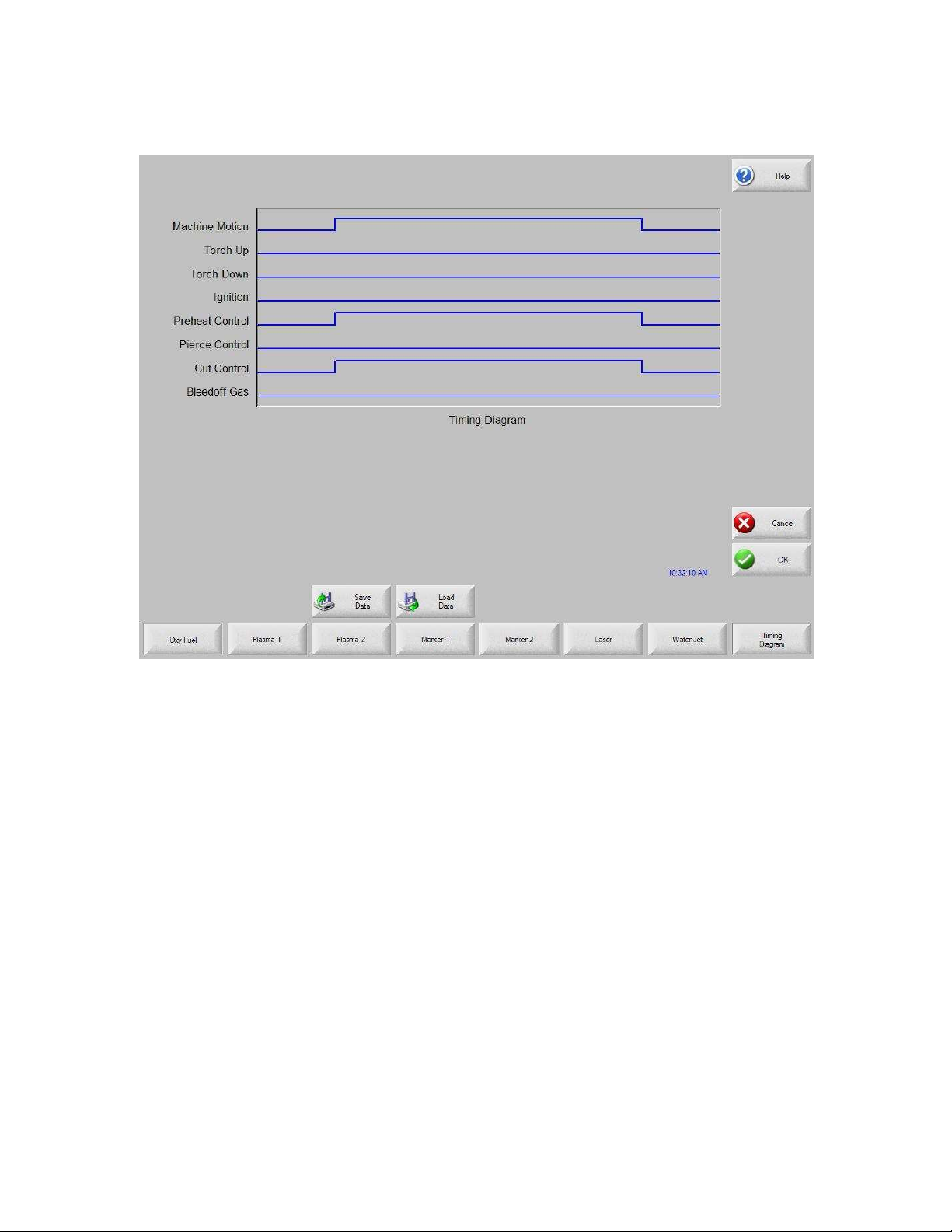

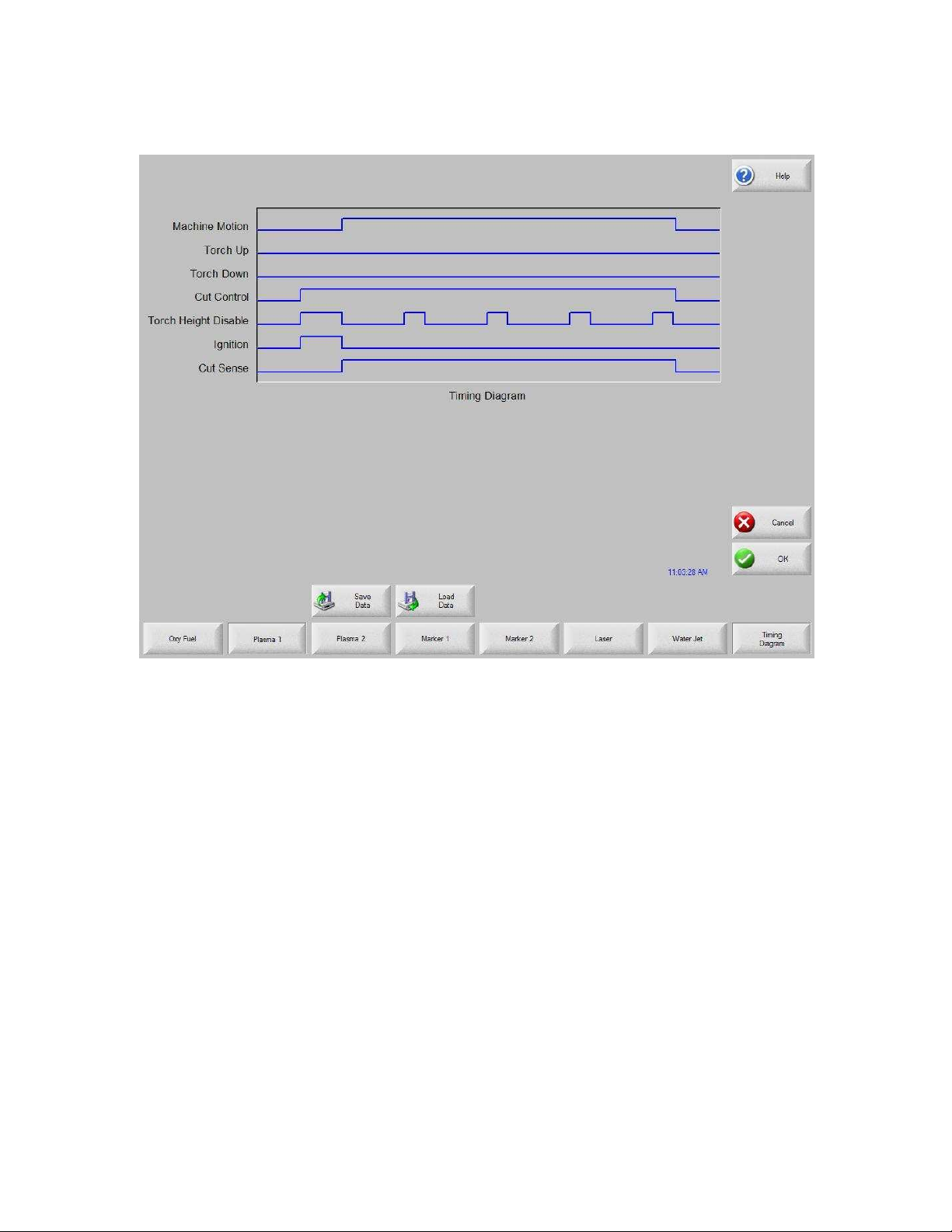

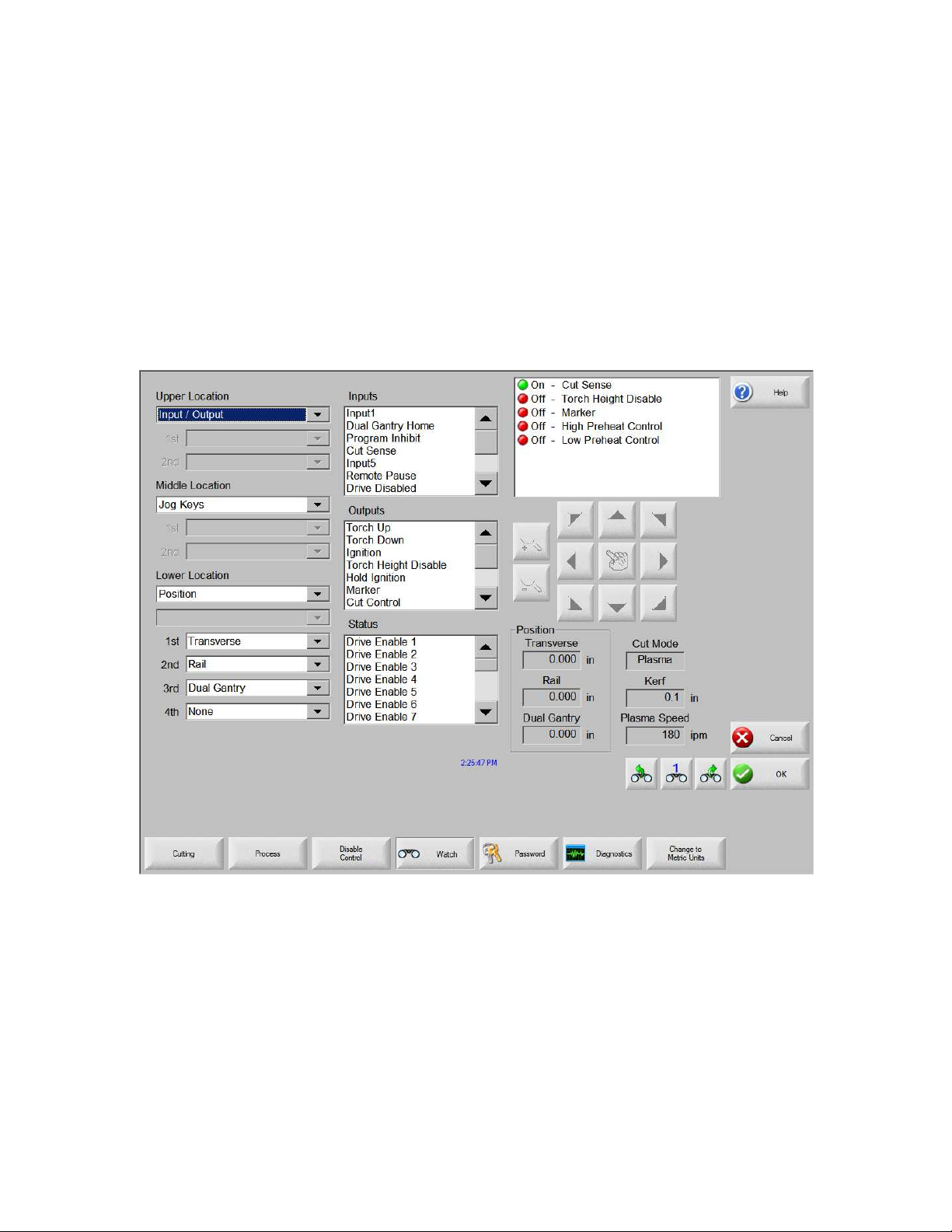

Manual Options