Page 1

Hypertherm Automation

5 Technology Drive, Suite 300

W. Lebanon, NH 03784 USA

Phone: 603-298-7970

Fax: 603-298-7977

Automation

HYPERTHERM SENSOR™ PHC

LASMA HEIGHT CONTROL

P

PERATION & SET UP GUIDE

O

Making people and machines more productive through process Automation

Page 2

D

ISCLAIMER The information in this document is subject to change without notice and should not be

construed as a commitment by Hypertherm Automation

®

. Hypertherm Automation®

assumes no responsibility for any errors that appear.

T

RADEMARKS Hypertherm Automation is a wholly owned subsidiary of Hypertherm

Sensor™ is a trademark of Hypertherm Automation.

HyDefinition

®

Plasma is a reg. trademark of Hypertherm®, Inc.

®

, Inc.

HyPerformance™ Plasma is a trademark of Hypertherm Automation.

Other trademarks are properties of their respective owners.

C

OPYRIGHT 2008 by Hypertherm Automation. All rights Reserved

Printed in USA

Page 3

iii

Table of Contents

Making people and machines more productive through process Automation .............................................. I

SAFETY ............................................................................................................................................................... 1

SECTION 1: OVERVIEW ................................................................................................................................. 9

PHC Control Module ......................................................................................................................................... 9

Plasma Interface Assembly .............................................................................................................................. 9

Lifter Assembly ................................................................................................................................................. 9

Sensor PHC Models .......................................................................................................................................... 9

Features ........................................................................................................................................................... 10

Features ....................................................................................................................................................... 10

Options ......................................................................................................................................................... 10

System Specifications* ................................................................................................................................... 11

Connections ..................................................................................................................................................... 12

PHC to CNC Signals ................................................................................................................................... 13

PHC to Plasma Signals ............................................................................................................................... 13

PHC to Lifter Signals .................................................................................................................................. 13

Sensor™ PHC Front Panel Indicators ....................................................................................................... 14

Sensor™ PHC Front Panel Controls .......................................................................................................... 14

Control Module ................................................................................................................................................ 15

Plasma Interface Assembly ............................................................................................................................ 16

Standard Lifter Assembly .............................................................................................................................. 17

SECTION 2: INSTALLATION AND SETUP .............................................................................................. 19

Standard components ..................................................................................................................................... 19

PHC Control Module ................................................................................................................................... 19

Optional components ...................................................................................................................................... 19

Claims .............................................................................................................................................................. 19

Claims for damage during shipment .......................................................................................................... 19

Claims for defective or missing merchandise ............................................................................................ 19

Power Requirements ....................................................................................................................................... 20

Control Unit Mounting ................................................................................................................................... 21

Control Unit Mounting from Rear ............................................................................................................. 21

Control Unit Mounting from Front ............................................................................................................ 22

Plasma Interface Assembly Mounting ........................................................................................................... 23

Lifter Assembly Mounting .............................................................................................................................. 24

Torch Breakaway Assembly ........................................................................................................................... 25

Torch Mounting Block Kit .............................................................................................................................. 26

System Cables ................................................................................................................................................. 27

Grounding Requirements ............................................................................................................................... 28

Grounding Requirements ............................................................................................................................... 28

PHC Interface Signals .................................................................................................................................... 29

CNC Interface Signals .................................................................................................................................... 30

CNC Signal Descriptions ................................................................................................................................ 30

Cycle Start ................................................................................................................................................... 30

Auto Disable / Corner Hold ......................................................................................................................... 30

IHS Sync ...................................................................................................................................................... 31

IHS Complete .............................................................................................................................................. 31

Motion .......................................................................................................................................................... 31

Retract Complete ......................................................................................................................................... 31

Error ............................................................................................................................................................. 31

Interlock ....................................................................................................................................................... 31

Plasma Interface Signals ................................................................................................................................ 33

Page 4

iv

Plasma Start ................................................................................................................................................ 37

Hold Ignition ................................................................................................................................................ 37

Transfer ........................................................................................................................................................ 37

Lifter Interface Signals ................................................................................................................................... 38

Lower Limit Switch ..................................................................................................................................... 38

Upper Limit Switch ..................................................................................................................................... 38

Breakaway Switch ....................................................................................................................................... 38

Lifter Power Connections ............................................................................................................................... 39

Motor Power ................................................................................................................................................. 39

Lifter Brake ................................................................................................................................................. 39

DIP Switch Setup ............................................................................................................................................ 40

Switch Settings ............................................................................................................................................ 40

Calibration Pot Setup ..................................................................................................................................... 44

ARC - Arc Voltage Calibration ................................................................................................................... 44

KERF - Auto Kerf Detection Level ............................................................................................................. 44

STALL - IHS Stall Sensing Level ............................................................................................................... 44

SECTION 3: OPERATION ............................................................................................................................ 45

Automatic Operation ...................................................................................................................................... 46

Manual Operation ........................................................................................................................................... 47

SECTION 4: TROUBLESHOOTING ........................................................................................................... 49

Error Codes ..................................................................................................................................................... 49

E.01 CYCLE_START at power up Error ................................................................................................... 49

E.02 Plate Contact at Home Error ............................................................................................................. 49

E.03 Lifter Timeout Error ........................................................................................................................... 50

E.04 Limit Reached during Auto Operation .............................................................................................. 50

E.05 IHS SYNC Timeout ............................................................................................................................ 50

E.06 Transfer Timeout Error ...................................................................................................................... 50

E.07 Lost Plasma Arc Error ........................................................................................................................ 50

E.08 Torch Breakaway Error ...................................................................................................................... 50

E.09 Low Input Power Error ...................................................................................................................... 51

E.10 High Input Voltage Error ................................................................................................................... 51

E.11 Over-Temperature Error .................................................................................................................... 51

E.12 Interlock Tripped Error ...................................................................................................................... 51

E.13 Excess Plate Contact Error ................................................................................................................ 51

E.99 Internal Software Error ..................................................................................................................... 51

Troubleshooting Guide ................................................................................................................................... 52

Parts and Kits ................................................................................................................................................. 55

Recommended THC Slide Maintenance ........................................................................................................ 55

Interval......................................................................................................................................................... 55

Lubricant...................................................................................................................................................... 56

APPENDIX A: INTERFACING TO A CUSTOM LIFTER ....................................................................... 57

Requirements .................................................................................................................................................. 57

Page 5

v

Table of Figures

Figure 1: Connections ......................................................................................................................................... 12

Figure 2: Control Module ................................................................................................................................... 15

Figure 3: Plasma Interface (Cover Removed) ................................................................................................... 16

Figure 4: Lifter Assembly .................................................................................................................................. 17

Figure 5: Power Connection and Fuse .............................................................................................................. 20

Figure 6: Control Unit Rear Mounting ............................................................................................................. 21

Figure 7: Control Unit Front Mounting ............................................................................................................ 22

Figure 8: Plasma Interface Mounting ............................................................................................................... 23

Figure 9: Lifter Mounting .................................................................................................................................. 24

Figure 10: Torch Breakaway ............................................................................................................................. 25

Figure 11: Torch Mounting Clamp .................................................................................................................... 26

Figure 12: System Cables................................................................................................................................... 27

Figure 13: System Grounding ............................................................................................................................ 28

Figure 14: General Interfacing Examples ......................................................................................................... 29

Figure 15: Basic CNC Interface ......................................................................................................................... 32

Figure 16: Powermax Connections using Plasma Interface Unit ................................................................... 34

Figure 17: Plasma Interface............................................................................................................................... 35

Figure 18: Plasma Interface Connections ......................................................................................................... 36

Figure 19: Interfacing to Older Plasma Systems (MAX100 or MAX200) ....................................................... 37

Figure 20: Setup DIP Switches .......................................................................................................................... 40

Figure 21: Error Indications .............................................................................................................................. 49

Page 6

vi

Page 7

Safety 1

Safety

Read this Manual

Readandunderstandthismanual,thecuttingmachinemanuals,andyouremployer’ssafetypractices.

Note:Thisproductisnotdesignedtobefieldserviceable.Returnthisproducttoanauthorizedrepaircenter

forservice.

Sensor PHC Safety Listing

Note: This product has been designed and manufactured in a c cordance with CE and UL Safety Standards.

UL has successfully tested and listed this product in accordance with the applicable U.S. and Canadian Safety

Standards. File number E307226.

Additional markings:

1) Useminimum75

0

Ccopperwireonly.

2) Usecopperconductorsonly.

3) Suitableforuseonacircuitcapableofdeliveringnotmorethan5000rmssymmetricalamperes,

230voltsmaximum.

4) Integralsolidstateshortcircuitprotectiondoesnotprovidebranchcircuitprotection.Branch

circuitprotectionprovidedbyintegralLISTEDbranchcircuitprotection

fuse.

5) “Solidstatemotoroverloadprotectionisprovidedat145%offullloadcurrent”,ortheequivalent.

Page 8

8 Sensor™ PHC Operation and Setup Guide

Page 9

Section 1: Overview 9

Section 1: Overview

Hypertherm’s Sensor™ PHC (228214) is a plasma torch height control/initial height sensing (THC/IHS) system

designed for conventional plasma cutting applications on an X-Y cutting table. The system uses the plasma

arc voltage to control the physical stand-off (distance) between the torch and work piece during plasma arc

cutting. Initial Height Sense (IHS) is accomplished by ohmic contact sensing or by a limited force stall

detection method. The Sensor™ PHC has been optimized for conventional plasma at or below 200 amps.

Note: Sensor™ PHC is not recommended for HyDefinition

applications. The system is not recommended for use on a water table.

A complete Sensor™ PHC system includes the following components:

PHC Control Module

The PHC control module (228116) houses a microcontroller, an operator control panel, and a Lifter motor drive.

This unit provides initial height sensing, arc voltage control. The PHC control module interfaces with the torch

lifter, the CNC machine, and the plasma power supply through standard discrete I/O interfaces. The operator

interface includes an LED display for set and actual arc voltage as well as error codes. The control unit ma in

functions are: arc voltage control/manual position mode, end of cut retract, IHS test, pierce height, voltage

controlled cut height, pierce delay; and access to setup and calibration adjustments. See Figure 2 on page 15.

Plasma Interface Assembly

®

or HyPerformance™ cutting or for higher power

The plasma interface (228256) provides a clean, standardized connection between the PHC control module

and the plasma power supply. The assembly can be mounted either to the back of or inside the plasma power

supply. The voltage divider provides a filtered low voltage signal which is derived from the cutting arc voltage.

The interface also provides an enclosed terminal block for easy connection to the interface signals. See Figure

3 on page 16.

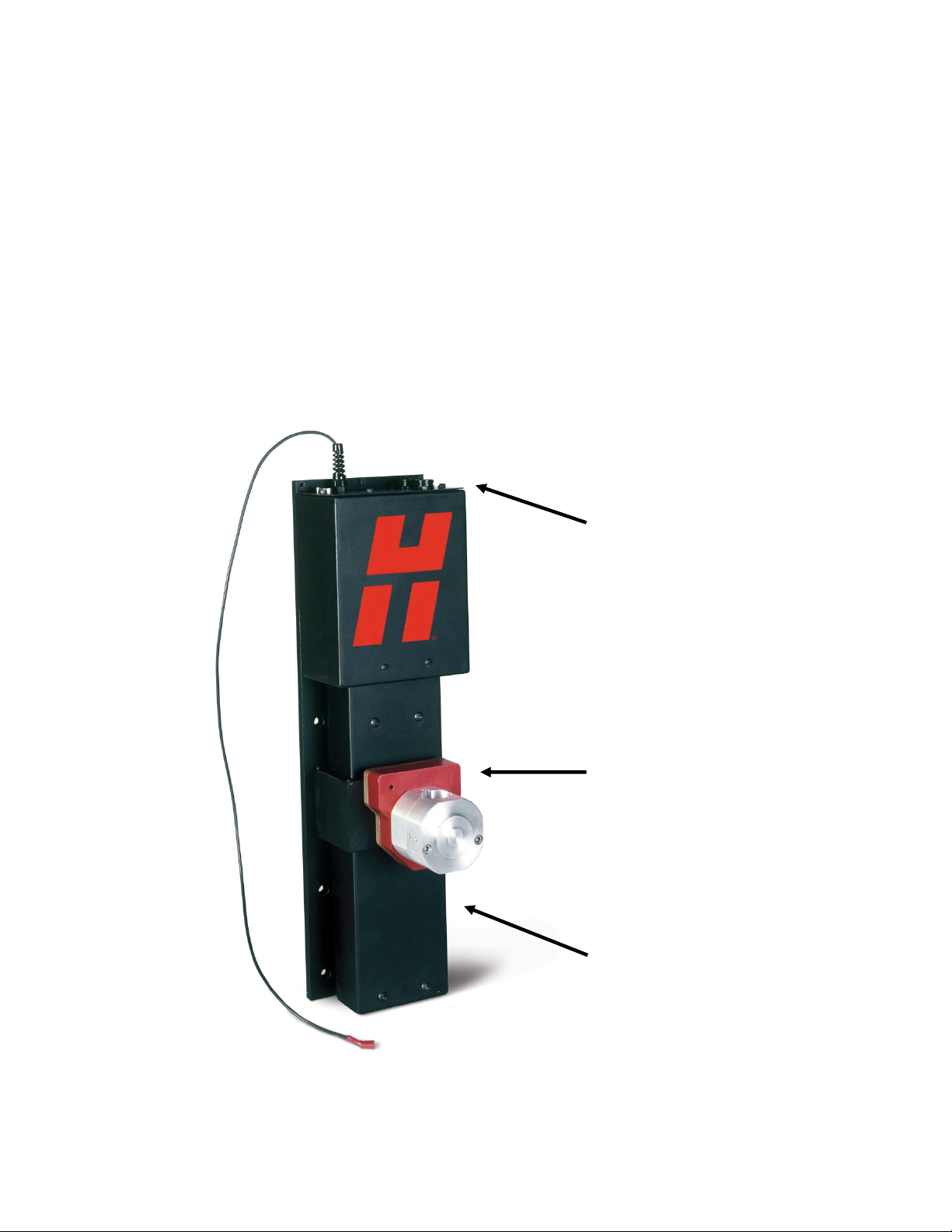

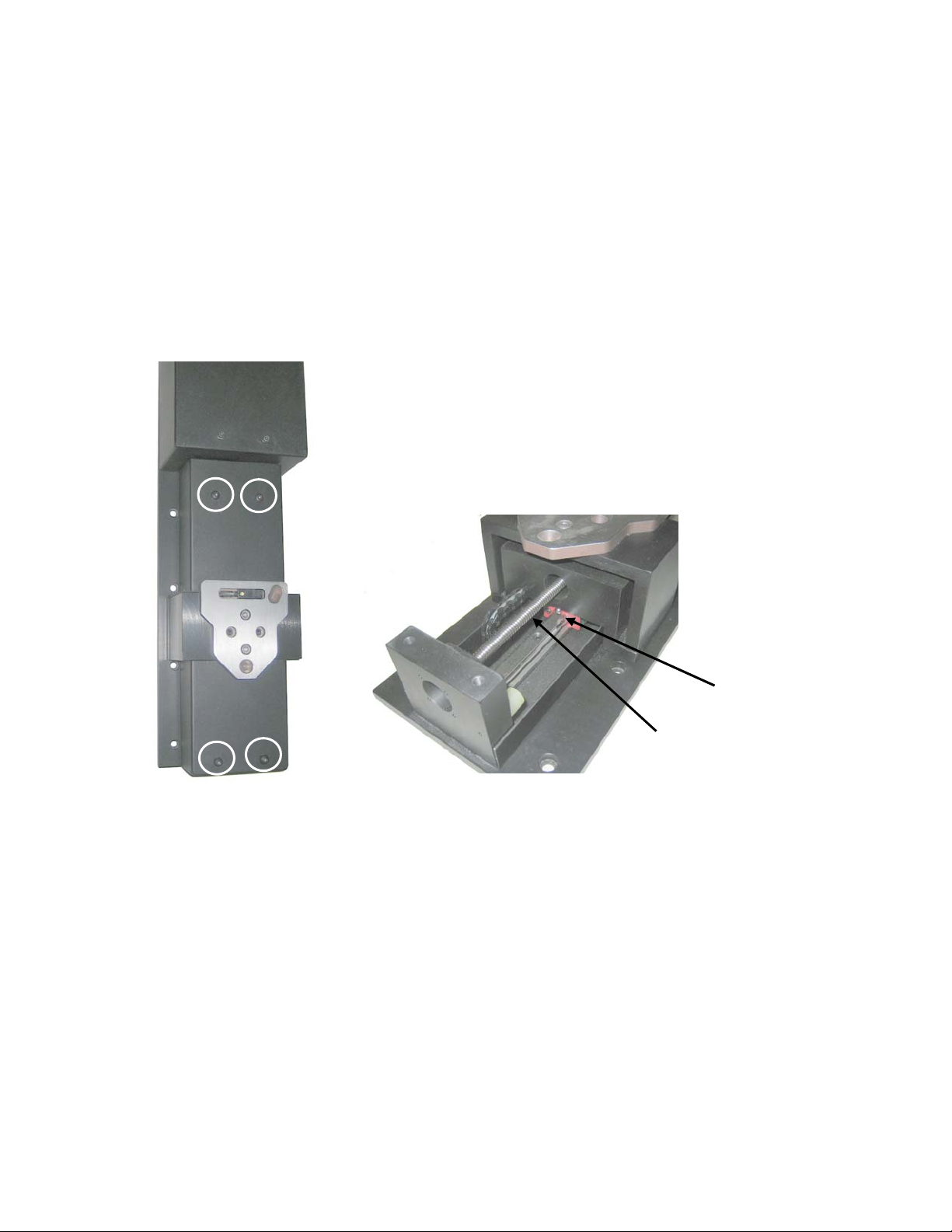

Lifter Assembly

The torch lifter station (228117) positions a torch head vertically above the work piece and is controlled by the

PHC control module. Its maximum standard stroke is 6 inches (152 mm) between home and the lower limit. It

is driven by a DC motor attached to a lead screw. The control module interfaces with an optional lower limit

switch to detect maximum travel downward. The control also interfaces with an optional home switch to detect

when the lifter is in the highest position. The standard lifter does not use limit switches but has been designed

to allow for hard stop limit detection. A power-off brake disables power off motion of the torch. A torch

breakaway is an integral part of the lifter and provides a level of protection for the torch, lifter and X-Y table.

Upon impact, the breakaway releases from the locked position and allows the torch to float. A breakaway

switch detects when this protection has tripped and signals both the PHC control and the CNC machine. See

Figure 4 on page 17.

Sensor PHC Models

Kit Number Description

228214 Sensor PHC with control module, lifter, and 50-foot cables

228123 Sensor PHC (with 123896) for Powermax bundle

228242 Sensor PHC without lifter station

228243 Sensor PHC without lifter or 123895

228244 Sensor PHC without control module

228245 Sensor HPC without plasma interface

Page 10

10 Sensor™ PHC Operation and Setup Guide

Features

Sensor™ PHC Plasma Height Control is an automated height control system for plasma shape cutting

applications. This product uses microprocessor technology to automatically detect the plate and adjust torch

position to an arc voltage set point during plasma cutting operations. This reduces operator input, improves

accuracy and increases productivity. The design of the Sensor™ PHC has been optimized for lower power

conventional plasma operation.

Features

¾ Sensor™ PHC can be used with any CNC

¾ Easy setup & operation

¾ Both manual & automatic operation modes

¾ Microprocessor control for increased sensitivity and control

¾ High positioning speeds possible with up to 6 amps continuous current and linear adjustment over

full range

¾ Built-in torch breakaway protection

¾ Built-in diagnostic and fault detection features

¾ Auto retract on plate contact

¾ 7 Segment LED display for set/actual arc voltage & error displays

¾ Power on indicator

¾ Upper and lower limit indicators

¾ In Position Indicator

¾ Attention / error indicator

¾ Torch position hold indicator

¾ Plate contact indicator

Options

¾ Interface cables

¾ Torch mounting clamps -1 3/8”, 1 3/4” and 2” diameters available.

Page 11

Section 1: Overview 11

System Specifications*

Compatible motors:

DC PM 24Vdc, 2 Amps to 6 Amps

Max power output:

Standard lifter range:

Motor output:

Accuracy:

Voltage control range:

IHS range:

Operator controls:

Operator switches:

Operator display:

Calibration adjustments:

Setup DIP switches:

Measuring technology:

Interface inputs/ outputs:

150W

Linear 6” (152mm)

Full “H” bridge PWM with current & voltage sensing

0.01” (.25mm ) or 0.5 Volt **

50 Vdc to 210 Vdc

0.05 inches (1.2 mm) to 0.5 inches (12 mm) **

Arc voltage, IHS height, & pierce delay control knobs

IHS test, auto / manual, & manual up / down

3 digit 7 segment display for set volts, actual volts, & error

Arc voltage, stall force, auto kerf detect level

Max motor current, arc voltage response, IHS speed, auto delay,

int/ext pierce delay, end of cut retract height, auto kerf detect,

preflow during IHS, limit switches, breakaway switch, arc voltage

calibration

Arc voltage feedback & ohmic contact sensing

8 outputs and 6 inputs optically isolated on “D” connectors

Control dimensions:

Control weight:

Control power:

Standard lifter dimensions:

Standard lifter weight:

Operating environment:

*Information subject to change without notice.

** With Standard supplied lifter mechanics

6.2”(157mm)W x 4.3”(1.9mm)D x 10.4”(264mm)H

9 lbs

115VAC 0r 230VAC +/- 10% 50/60 Hz –selectable

6”(152mm)W x 3.15”(80mm)D x 21.5”(546mm) **

19 lbs **

0 to 50C; 95% relative humidity (non-condensing)

Page 12

12 Sensor™ PHC Operation and Setup Guide

Connections

All connections to the Sensor™ PHC are made through four connectors on the bottom of the control unit. See

Figure 1.

Lifter signal

connections

Computer

controller I/O

Input power

115/230 Vac

Figure 1: Connections

table.

Fuse and voltage

selector w/ switch

WARNING! For safety and proper operation this unit must be connected to the star ground o n the work

Lifter motor &

brake power

Plasma

system I/O

Ground

Page 13

Section 1: Overview 13

PHC to CNC Signals

All signals to the CNC are connected through the 25-pin D subconnector on the control unit. For detailed

interfacing information, see PHC Interface Signals on page 29 and CNC Interface Signals on page 30.

Outputs to CNC:

Digital IHS complete output

Digital motion output

Digital retract complete output

Digital error output/torch collision

Inputs from CNC:

Digital cycle start input

Digital corner hold input

Digital IHS sync input

Interlock

PHC to Plasma Signals

All signals to the plasma interface are connected through the 15-pin D subconnector on the control unit. These

signals are easily connected through the plasma interface unit or d irectly to a Powermax

®

G3 supply using a

G3 interface cable. For more detailed information, see Plasma Interface Assembly on page 16.

Outputs to plasma:

Digital plasma start output

Digital hold ignition output

Inputs from plasma:

Digital transfer input

Analog attenuated arc voltage

PHC to Lifter Signals

All signals to the lifter are connected through the 9-pin D subconnector on the control unit. For more detailed

information, see Standard Lifter Assembly on page 17.

Inputs from lifter:

Digital upper limit switch

Digital lower limit switch

Digital breakaway switch

Analog tip touch sense

PHC to Lifter Power Connections

All power connections to the lifter are coupled through the 7-pin circular connector on the control unit. For

more detailed information, see Standard Lifter Assembly on page 17.

Outputs to Lifter:

Motor drive 24V PWM

Power off brake 24Vdc

Page 14

14 Sensor™ PHC Operation and Setup Guide

Sensor™ PHC Front Panel Indicators

Green Power

Yellow Upper Limit

Green In Position

Yellow Lower Limit

Red Attention / Error Code

Yellow Corner / Kerf Hold

Red Plate Contact

Red 3 digit Set / Actual Arc Voltage – Error Number – Set Pierce Height & Delay

Sensor™ PHC Front Panel Controls

Multiturn Rotary Pot Set Arc Voltage

Rotary Pot Pierce Height Retract

Rotary Pot Pierce Delay Time

Momentary Toggle Switch IHS Test

Toggle Switch Auto / Manual

Momentary 3 pos Toggle Manual Up / Down

Page 15

Section 1: Overview 15

Control Module

Electrical

Input power (switch selected dual range)................................ 115 VAC or 230 VAC, 1 Phase, 50/60 Hz

Parallel digital I/O ................................................................... + 12 Vdc

Motor drive output voltage ……………………….....................24 Vdc

Motor drive output current ……………………….....................2,3,4,6 Amps max DIP switch selectable

Motor brake output ………………………………......................+24 Vdc ½ Amp

The features of the control module are highlighted in Figure 2.

Power

Upper limit

Torch position hold

Display actual /

set arc voltage &

errors

Voltage in

control

Lower limit

Error

Set IHS

height

IHS test

Manual / auto

Plate contact LED

Set arc voltage

Set pierce

delay time

Manual up / down

for torch

Figure 2: Control Module

Calibration

and setup

Page 16

16 Sensor™ PHC Operation and Setup Guide

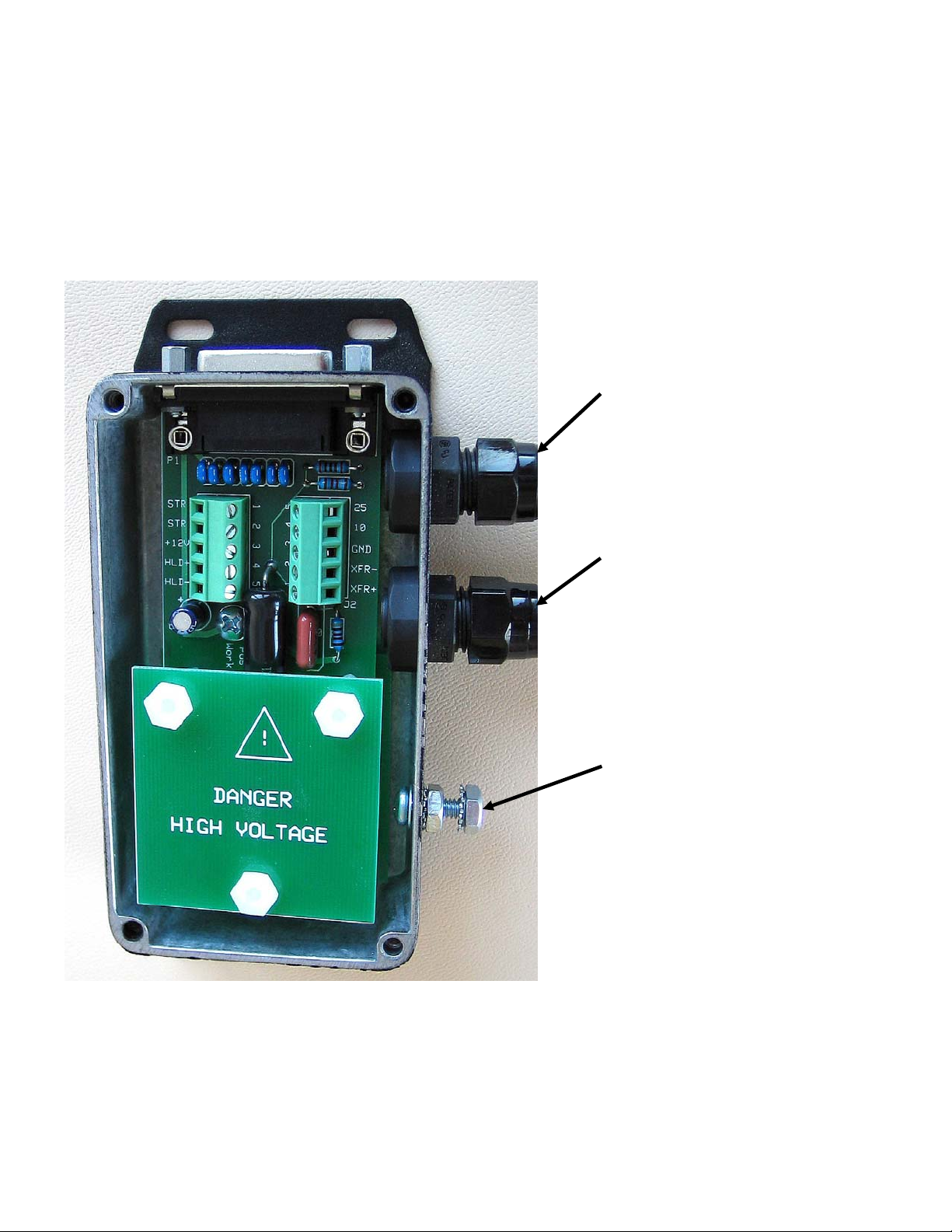

Plasma Interface Assembly

The plasma interface module is shown in Figure 3.

Electrical

Parallel digital I/O.....................................................................+12 Vdc to +24 Vdc

Interface signals……………………………………................... Plasma start, hold ignition, transfer

Voltage divider function............................................................Arc voltage (attenuated and filtered)

Plasma interface

signals

Electrode voltage

(negative)

Connection for ground

to the star ground on

the work table

Figure 3: Plasma Interface (Cover Removed)

If you are using a Sensor PHC 228245 with an HSD 130, select plasma interface assembly 22824 7 (25-foot

cable) or 228248 (50-foot cable). Refer to Field Service Bulletin 805740 for installation information.

Page 17

Section 1: Overview 17

Standard Lifter Assembly

Electrical

Motor .......................................................................................+ 24 Vdc, 3 Amps

Motor brake …………………………………………...................+ 24 Vdc ½ Amp

Limit switches...........................................................................not used – hard stop limit detection

Breakaway switch ……..……………………………..................+ 12 Vdc proximity

Lifter Control Function

Motordrive...............................................................................DC full bridge, PWM chopped current source

Lifter speed feedback.............................................................Motor voltage

Maximum lifter speed..............................................................200 inches (508 cm) per minute

Maximum lifter stroke..............................................................6- inches (152 mm)

Maximum lifter load 10 pounds

All cable connections

exit top cover

Torch magnetic

breakaway

All lifter components, including

motor and brake, are fully

enclosed

Figure 4: Lifter Assembly

Page 18

18 Sensor™ PHC Operation and Setup Guide

Page 19

Section 2: Installation and Setup 19

Section 2: Installation and Setup

The standard PHC system includes the following components:

Standard components

PHC Control Module

Power cord - 6.5 ft. (2 m)

Lifter assembly with torch breakaway

Plasma interface assembly

Interface cables

• Lifter motor drive cable

• Lifter interface cable

• Plasma interface cable

• Ohmic contact wire

• CNC interface cable

Sensor™ PHC system instruction manual

In addition, the following optional components can be ordered:

Optional components

Interface cables

Torch mounting clamps -1 3/8 ”, 1 3/4” and 2” diameters available.

Claims

Claims for damage during shipment

If your unit is damaged during shipment, you must file a claim with the carrier. Hypertherm will furnish you with

a copy of the bill of lading upon request. If you need additional assistance, please contact your Hypertherm

Customer Service agent.

Claims for defective or missing merchandise

If any of the merchandise is defective or missing, call your authorized Hypertherm distributor. If you need

additional assistance, please contact your Hypertherm Customer Service agent.

Page 20

20 Sensor™ PHC Operation and Setup Guide

Power Requirements

The PHC can be connected to either 115 Vac or 230 Vac 50/60 Hz. Depending on the input voltage, Slow

Blow fuses of the correct size should be installed. For 115 Vac, install a 2 Amp fuse and for 230 Vac, a 1 Amp

fuse should be used. The power input voltage is selected by installing the fuse block into the power input

module so that the correct voltage is displayed through the power input module window. See Figure 5 for input

voltage selection.

If the line cord plug is removed and the unit is directly wired then the connections should be made as follo ws.

• Blue wire AC neutral

• Brown wire AC hot

• Green wire ground-chassis

WARNING!

Configure for the correct

input voltage. 115V or

230V should be displayed

in the window.

Figure 5: Power Connection and Fuse

Page 21

Section 2: Installation and Setup 21

Control Unit Mounting

Before interconnecting the PHC system, mount the units as required, using customer-supplied hard wa re. Do

not allow the units to lie unsecured on top of cabinets or on the floor. The control units can be mounted from

either the rear or the front as shown in Figure 6 and Figure 7.

Control Unit Mounting from Rear

Mount the PHC control unit close to the machine operator console for easy access to the operator panel. The

unit should be mounted to provide easy access and visibility to the PHC controls and display. There are four

mounting holes for #10-32 inch or M4 mm fasteners.

NOTE: For reliable operation the ground must be connected.

Figure 6: Control Unit Rear Mounting

Page 22

22 Sensor™ PHC Operation and Setup Guide

Control Unit Mounting from Front

Mount the PHC control unit close to the machine operator console for easy access to the operator panel. The

unit should be mounted to provide easy access and visibility to the PHC controls and display. There are six

mounting holes available. See Figure 7

NOTE: For reliable operation the ground must be connected.

WARNING!

Connect ground here

Figure 7: Control Unit Front Mounting

Page 23

Section 2: Installation and Setup 23

Plasma Interface Assembly Mounting

Mount the plasma interface assembly close to the plasma power supply for easy connection of arc voltage and

signal wires between the units. The unit can be mounted in any position and can be mounted directly to the

back or inside of the power supply. The mounting holes are sized for #6 or M3 fasteners. See Figure 8.

NOTE: The plasma interface ground terminals must be connected to the plasma power supply

positive ground to provide measurement feedback for arc voltage. This feedback is essential for

optimal cutting performance.

WARNING!

Connect to the star

ground on the work

table.

Figure 8: Plasma Interface Mounting

Page 24

24 Sensor™ PHC Operation and Setup Guide

Lifter Assembly Mounting

Mount the lifter assembly on the cutting table to take maximum advantage of the vertical travel range. Typically

the bottom of the lifter should be between 6 and 8 inches above the cutting table.

NOTE: The lifter ground terminal must be connected to the cutting table ground to provide

measurement feedback for tip touch sensing. This feedback is essential for optimal cutting

performance. See Figure 9.

Figure 9: Lifter Mounting

WARNING!

Connect to the star

ground on the work

table.

Page 25

Section 2: Installation and Setup 25

Torch Breakaway Assembly

The torch breakaway (229164) should be mounted to the lifter as shown in Figure 10.

CAUTION: The breakaway uses extremely strong magnets to clamp the two halves of the

breakaway unit together. Use extra care when you mate the two halves of the breakaway.

Hold the breakaway at a 45 degree angle to the mounting plate and carefully place the lower alignment pin into

the mating depression on the breakaway back plate. Slowly angle the breakaway toward the back plate. Use

care to avoid pinching your fingers between the two halves. After installation, it is almost impossible to

separate the two halves without the leverage of the mounting block and torch.

Figure 10: Torch Breakaway

WARNING!

Pinch Point: Use

Caution when mating

two halves of torch

breakaway assembly.

Page 26

26 Sensor™ PHC Operation and Setup Guide

Torch Mounting Block Kit

Mount the torch mounting block kit to the lifter torch breakaway assembly. See Figure 11.

The mounting blocks are available in three sizes as listed.

• 128277 Torch mounting block 1 3/8” diameter

• 128278 Torch mounting block 1 3/4” diameter

• 128279 Torch mounting block 2” diameter

Breakaway

mounting plate

Gap adjustment

set screw

Torch breakaway

Torch mounting clamp

Figure 11: Torch Mounting Clamp

Page 27

Section 2: Installation and Setup 27

System Cables

Install system cables as shown in Figure 12. All cables should be properly shielded with shield connections at

both ends of the cables. If possible, route all PHC cables away from high power plasma cables. If both the

plasma high power and PHC cables must share a cable track, it is recommended that they are se parated as

much as possible in the cable track. For reliable operation, all grounds must be connected to machine grounds

as directly as possible.

Tip touch sense

high voltage cable

Lifter signal cable

PN = 123897

CNC interface cable

PN = 123895

See Figure 15

Plasma signal wiring,

user supplied

Lifter power cable

PN = 123898

Plasma interface

cable

PN = 228249

High voltage wiring,

user supplied

See Figure 16

Figure 12: System Cables

Note: If you are using a Powermax with a built-in voltage divider, use the Powermax interface cable 123896.

Page 28

28 Sensor™ PHC Operation and Setup Guide

Grounding Requirements

WARNING!

To ensure personal safety and reduce electromagnetic interference (EMI), the PHC system must be

properly grounded.

NOTE: For reliable operation, the lifter ground terminals must be connected to the ground on the

cutting table ground to provide measurement feedback for tip touch sensing. The plasma interface

ground terminals must be connected to the plasma power supply positive ground to provide

measurement feedback for arc voltage. Both types of feedback are essential for optimal cutting

performance.

Power cord grounding

The PHC control module must be properly grounded through the power cord according to national or local

electrical codes.

Protective earth ground

Install protective earth (PE) grounding cables to the three PHC components (control unit, lifter, and plasma

interface,) as shown in Figure 13. Grounding must comply with national or local electrical requirements.

Note: The PE (Ground) cables must be supplied by the customer.

Connect lifter

assembly to star

ground on work

table.

Connect control

unit to star ground

on work table.

Connect plasma

interface to star

ground on work

table.

Figure 13: System Grounding

Page 29

Section 2: Installation and Setup 29

PHC Interface Signals

Most of the PHC interface signals are through optoisolators. Figure 14 shows the details of connecting the IO

to external switches, relays, transistors, and other circuitry. The figure shows examples using both the

internally available isolated +12V source and using an external voltage source. Do not use an external voltage

higher than +24V with inputs without adding some additional series resistance.

Note: The “Plasma Start” output to the plasma power supply is a relay dry contact closure.

WARNING!

Do not exceed 24V or 30mA in or out of any optoisolator. Observe correct signal polarity to prevent damage.

Example Inputs

External Circuitry

Use Internal PHC +12V Supply

SWITCH RESISTOR LED

Use External +24V Supply

OPTO ISOLATOR

Use External +24V Supply

+

24V

GND_External

+

24V

RELAY

GND_External

Sensor PHC Internal Circuitry

Inputs

+12V Field

+IN

-IN

+IN

-IN

+IN

-IN

3300

3300

3300

Outputs External Circuitry

+12V Field

+OUT

-OUT

+OUT

-OUT

+OUT

-OUT

Example Outputs

Use Internal PHC +12V Supply

Use External +24V Supply

Use External +24V Supply

RELAY

Figure 14: General Interfacing Examples

RESISTOR

OPTO ISOLATOR

DIODE

GND_External

+

24V

GND_External

+

24V

Page 30

30 Sensor™ PHC Operation and Setup Guide

CNC Interface Signals

See Figure 14 on page 29 for an illustration.

CNC Interface Signals 25-pin D Subconnector

Name Pair ~ Pin #s (wire color) Signal Type

Cycle Start

Auto Disable / Corner Hold In + 10 (red) ~ In - 22 (green) Isolator input

IHS Sync In + 9 (red) ~ In - 21 (white) Isolator input

IHS Complete Out + 18 (black) ~ Out - 5 (yellow) Isolator output

Motion

Retract Complete Out + 16 (black) ~ Out - 3 (green) Isolator output

Error or Breakaway

(DIP switch selectable)

Interlock

Field +12V

Field Common

Note: All required signals are shown in bold. All other signals are optional for multiple torch operation,

improved performance, or reduction in cycle times.

In + 11 (red) ~ In - 23 (blue) Isolator input

Out + 17 (black) ~ Out - 4 (blue) Isolator o utput

Out + 15 (black) ~ Out - 2 (white) Isolator output

14 (black) ~ 1 (red)

contact closure required

12 (red), 24 (yellow), 13 (yellow),

25(brown)

6 (brown), 19 (black), 8 (black), 20

(orange)

Isolator & relay coil

Field power output

Field power

common

WARNING:

Observe optoisolator signal polarities to prevent damage to the control unit.

CNC Signal Descriptions

Use a customer supplied mating 25-pin D subconnector or cut off the unused connector and wire directly to the

appropriate signals.

Cycle Start

This signal is an output from the CNC and an input to the PHC. The CNC activates this signal to begin the

Initial Height Sensing and start a plasma cut.

Auto Disable / Corner Hold

This output from the CNC is activated to turn off the automatic voltage control and freeze the position of the

torch. This signal is optional but improves performance and is usually used to prevent diving in corners. This

signal is required if PHC pierce delay has been disabled and the CNC is controlling the pierce delay time. In

this case, the “Auto Disable” is activated during the “Pierce Delay Time” as well as the subsequent “Accel

Delay” to allow machine motion to reach a steady cutting speed.

Page 31

Section 2: Installation and Setup 31

IHS Sync

This optional CNC output is used to synchronize torches in a multiple torch installation. The CNC issues this

signal to delay plasma torch ignition until all torches in a multiple torch configuration have completed their IHS

sequence and are in position and ready to fire. When the CNC releases (de-activates) this signal, the torch

ignites and the plasma torch begins piercing.

For single torch installations, this signal is not required and can be left unconnected.

IHS Complete

This optional signal is an output from the PHC and an input to the CNC. This signal is used to indicate that

initial height sensing is complete and that a torch is in position and ready to fire. For multiple torch installations,

the CNC waits for all active torches to indicate IHS COMPLETE before simultaneously releasing all IHS SYNC

signals to allow the torches to ignite.

For single torch installations, this signal is not required.

Motion

This signal is an output from the PHC and an input to the CNC. The signal is issued after plasma ignition and

the PHC set pierce delay time. It indicates to the CNC that the pierce delay is complete and the cut motion

should begin. If the CNC performs all pierce delay timing, the EXT_PIERCE_DELAY - DIP switch on the PHC

should be turned ON which forces the PHC pierce delay to be zero and disables the front panel pierce delay

control. If the CNC is controlling the pierce delay, the CNC uses the AUTO_DISABLE / HOLD signal to delay

the arc voltage control until the pierce and accel times have elapsed.

Retract Complete

This signal is an output from the PHC that is active when a cut has been completed and the torch has been

retracted to the selected retract height. The CNC can use this signal to delay rapid transit to the next cut until

the torch has been raised and cleared any tip-ups. The use of this signal is optional.

Error

This signal is output by the PHC for errors. The actual error number displays on the PHC front panel LED

display.

Interlock

This is a normally closed contact closure provided by the CNC to allow PHC motion. If this contact is opened,

the PHC motor drive does not receive power.

NOTE: This signal is required for operation of the PHC. If this signal is not used as an external interlock,

use a jumper to satisfy the input.

Page 32

32 Sensor™ PHC Operation and Setup Guide

t

t

CNC I/O

Start Output

Motion Input

OPTO

Interlock Output

RELAY

+

jumper if

not used

RELAY

+24V

Sensor PHC I/O

11

23

17

4

14

1

+Out

+

- Out

+Ou

+

-Ou

+

3300

Common

OPTO

+12V

OPTO

Motion Output

Interlock

RELAY

Start Input

25 Pin D Sub

Figure 15: Basic CNC Interface

Page 33

Section 2: Installation and Setup 33

Plasma Interface Signals

WARNING: HAZARDOUS VOLTAGE & ENERGY The plasma interface signals from

plasma cutting equipment without an internal voltage divider are directly connected to

the plasma cutting circuit output. To prevent electrical shock and energy hazards,

wiring from the plasma cutting circuit of the power supply to the plasma interface

(228256) must be enclosed or protected.

Hypertherm Powermax systems are equipped with a factory-installed intern al voltage divider which is designed

to be safely connected without tools to the Sensor™ PHC plasma interface using the standard PHC to

Powermax cable provided by Hypertherm.

The plasma interface (228256) includes the arc voltage divider for connection to Hypertherm Powermax

plasma supplies not equipped with a factory installed internal voltage divider and other plasma sup plies.

However, the wiring from the plasma cutting circuit to the 228256 must be enclosed or protected for safe

operation and use. The plasma cutting circuit output ratings are printed on the data plate and vary by

manufacturer and model up to 500 VDC and 400 ADC, such that contact with metal live parts of this connection

under normal operating and fault conditions can result in death or burns.

To make connections between the plasma cutting circuit and 228256:

- Use qualified service personnel only.

- Turn OFF and disconnect all power.

- Mount the 228256 as close as is practical to the entry point to the power supply. Permanent

connection is recommended.

- If cord connected, use jacketed cables suitable for the environment.

o Verify that the outer jacket of each interconnecting cable is protected from damage at the entry

point to the power supply. A strain relief is recommended.

o Verify that the outer diameter of the interconnecting cable fits the strain relief with provided

228256:

Plasma start, transfer grip: .114" - .250" diameter

Plasma interface grip: .064" -.210" diameter

o Strip back the outer jacket and individual conductor insulation as needed.

o Insert the outer jacket cable through the strain relief and make co nnections as shown in Figure

16 on page 34.

o Verify the outer jacket is a min. of 1 inch (2.54 cm) inside the 228256 and tighten the strain

relief(s).

- Before operating the equipment, verify that the connections are correct and that all live parts are

enclosed and that all jacket/conductor insulation is protected against damage.

Page 34

34 Sensor™ PHC Operation and Setup Guide

Plasma Interface Signals

Name

Plasma start 2, 10

15-pin D Subconnector

Pin #s

Plasma Interface Signal Type

J1-1, J1-2 (dry

contact)

Relay contact output

Hold iIgnition Pos 3 Neg 11 J1-4 (+), J1-5 (-) Isolator output

Transfer Out + 4 Out - 12 J3-1 (+), J3-2 (-) Isolator input

Arc voltage Out + 8 Out - 15

Ground stud (+),

Term (-)

Attenuated filtered analog

Field +12V 1, 9 J1-3 Field power output

Field common 5, 6, 7, 13, 14 J3-3 Field power common

Start-

Start +

15 D-Sub

J19J3J1

1

2

3

4

5

5

4

3

2

1

Xfer-

Xfer+

1

2

3

4

5

6

PowerMax

WHT

G3 Series

RED

PowerMax

YEL

G3 Series

BLK

+24Vdc

Com

Positive Ground

Work (pos GND)

J15

Arc Volts (neg)

Electrode (neg)

J16

Sensor PHC

Plasma Interface

Figure 16: Powermax Connections using Plasma Interface Unit

For a diagram of circuits on the plasma interface, see Figure 18 on page 36.

Page 35

Section 2: Installation and Setup 35

Start output

(contact closure)

+12V output

50mA max

Hold output +

Hold output -

Common for

12V output

Signals

enter here

High voltage

enter here

Figure 17: Plasma Interface

-Transfer input

+Transfer input

Connection to star

ground on work

table

Connect negative

electrode voltage

here.

Page 36

36 Sensor™ PHC Operation and Setup Guide

WARNING! For safety and proper operation this unit must be connected to positive ground.

RELAY

OPTO

OPTO

Sensor PHC Plasma

Interface I/O

J1

1

2

3

4

5

J3

1

2

3

4

5

Electrode (N eg)

Figure 18: Plasma Interface Connections

3300

+12V Field

1

2

STR

STR

HLD+

HLD-

XFR+

XFR-

External Plasma Supply

(using External +24V)

+24V Exte rnal

GND_External

PLASMA START (+24V)

DIODE

GND_External

Electrode (Neg)

Work

Positive Ground

HOLD

IGNITION

RELAY 24V c oil

TRANSFER

RELAY

WARNING:

Observe signal polarities when connecting to optocouplers. Do not exceed 24Vdc on any signal lines. Do not

exceed 30mA current from any input or output. Do not exceed 50mA total current drawn from Sensor™

internal +12V field supply. Failure to observe these warnings could damage the unit.

Page 37

Section 2: Installation and Setup 37

Plasma Start

This signal is a relay contact output from the PHC and an input the plasma power supply. The PHC activates

this signal by closing the contact to start the plasma power supply.

WARNING: An interface to older plasma systems, such as the MAX100 or MAX200 must be

implemented with a customer-supplied relay (see Figure 19). Older plasma systems draw large current

levels through the PLASMA START input that are far in excess of the capability of the Sensor PHC

START output.

Figure 19: Interfacing to Older Plasma Systems (MAX100 or MAX200)

Hold Ignition

This output from the PHC and input to the plasma power supply should be activated to delay the high

frequency ignition of mechanized torches. This signal is usually issued to synchronize the ignition of multiple

plasma torches. This signal can also be used to save cycle time by performing preflow during IHS. The use of

this signal is optional but improves performance on plasma systems that can use it. This signal is not used for

contact start torches installed on Powermax

Transfer

This signal is an output from the plasma power supply and an input the PHC. The plasma power supply

activates this output to signal that arc transfer has occurred.

®

plasma units.

Page 38

38 Sensor™ PHC Operation and Setup Guide

Lifter Interface Signals

These signals can be directly connected to a Sensor™ PHC standard lifter using the supplie d cable.

Lifter Interface Signals 9-Pin D Subconnector

Name Pin #s Signal Type

Lower limit switch *

Upper limit switch *

Torch breakaway switch 7 - Switch to common Isolator input

Torch tip touch sense 4, 5, 9 Attenuated filtered analog

Field +12V 1 Field power output

Field common 3, 8 Field power common

6 - Switch to common Isolator input

2 - Switch to common Isolator input

* The PHC standard lifter does not include limit switches and the PHC detects the hard stop limits by

monitoring motor speed.

Lower Limit Switch

This signal is an output from the lifter and an input to the PHC. The lifter can activate this signal to indicate that

the lifter has reached the lower range of motion. The normally open/closed sense of this signal can be

changed through setup DIP switch #14. The use of a limit switch is optional.

Upper Limit Switch

This signal is an output from the lifter and an input to the PHC. The lifter can activate this signal to indicate that

the lifter has reached the upper range of motion. The normally open/closed sense of this signal can be

changed through setup DIP switch #14. The use of a limit switch is optional.

Breakaway Switch

This signal is an output from the lifter and an input to the PHC. The lifter can activate this signal to indicate that

the mechanical torch breakaway has tripped. The normally open/closed sense of this signal can be changed

through setup DIP switch #15. The use of a torch breakaway switch is optional.

Page 39

Section 2: Installation and Setup 39

Lifter Power Connections

These connections can be made directly to a Sensor™ PHC standard lifter using the supplied cabl e.

Lifter Power Connections 7-Pin Circular Connector

Name Pin #s Signal Type

Motor power – up direction Positive 1 Negative 2 PWM H bridge output

Lifter brake Positive 4 Negative 5 +24Vdc output

Chassis ground 6

Motor Power

This signal is an output from the PHC. It is output from a PWM controlled “H” bridge motor drive. The

maximum current level can be set using DIP switches #1 and #2. This output is intended to drive a 24Vdc

permanent magnet motor.

Lifter Brake

This output from the PHC is a 24Vdc signal to an electromagnetic brake. When this signal is energized, the

brake is released to allow lifter motion.

Page 40

40 Sensor™ PHC Operation and Setup Guide

DIP Switch Setup

Arc voltage

calibrate

SW1 SW8

Auto kerf

detect level

Stall force

level

Switch on

Switch off

Figure 20: Setup DIP Switches

Switch Settings

Switch settings for control module operation and setup outlined below. Note*: Default switch settings (as

shipped) are indicated in BOLD text.

As shown in the figure above, the setup DIP switches are divided into two groups of eight switches. The top

set of switches is numbered SW1 through SW8 and the bottom set of switches is numbered SW9 through

SW16.

SW1

SW2 Maximum Motor Current / Power

on on Max Current = 2 Amps, 50 Watts

on off Max Current = 3 Amps, 75 Watts *

off on Max Current = 4 Amps, 100 Watts

off off Max Current = 6 Amps, 150 Watts

Set DIP switches SW1 and SW2 to the rating for the current of the lifter motor. This is the maximum current

that is applied and is directly related to the motor power rating. This setting is also used to determine the

minimum applied current for stall sensing and to calculate the motor speed based on the measured motor

voltage.

SW9

SW16

NOTE: For optimum performance it is important that these switches are set correctly. For the standard

lifter, these switches should be set for 3 Amps

Page 41

Section 2: Installation and Setup 41

SW3

SW4 Voltage Control Response / Gain

on on Gain = Low = +/- 4V In Position Range

on off Gain = Med Low = +/- 2V In Position Range *

off on Gain = Med High = +/- 1V In Position Range

off off Gain = High = +/- 0.5V In Position Range

Set DIP switches SW3 and SW4 to select the closed loop voltage control response. The DIP switches should

be set for the highest gain possible that yields an acceptable control response. An acceptable response should

be stable and should have a minimum overshoot. These settings are a function of the lifter and motor

combination. For faster lifters use a lower gain setting. Faster settings can require the use of the “Corner Hold”

signal from the CNC to prevent diving in the corners. This setting affects control.

SW5

IHS Slow Approach / Retract Speed

on Speed = Low = 15% of Max Speed *

off Speed = High = 30% of Max Speed

The setting of SW5 affects the speed of the torch when it approaches the plate during an IHS cycle. This

speed is also used when the torch retracts from plate contact to the pierce height and during the first seconds

of low speed manual motion. This setting is a compromise between positioning accuracy and cycle time. Set a

speed that is as fast as possible and still provides the required IHS range and fine manual motion accuracy.

SW6

CNC Error Select

on Normal – Error output on all errors *

off Error output on Torch Breakaway only

The SW6 allows the user to select logic for error conditions. Select On to provide an output for all errors.

Select Off to provide an output only when the torch breakaway input is active.

SW7

Auto Voltage Control Acceleration Delay

on Low – Enable Voltage Control 0.5 Second after Pierce delay *

off High – Enable Voltage Control 2.5 Second after Pierce delay

The SW7 delay setting is used to allow the cutting machine to accelerate to steady state speed before starting

the closed loop voltage control of torch height. The shorter delay should be used for most machines. For very

large cutting machines, use the longer delay to avoid diving into the plate during machine acceleration.

SW8

External Pierce Delay

on CNC controls pierce delay – Front panel Pierce delay is disabled

off Normal – Internal Pierce Delay *

SW8 should be turned ON if the CNC controls the time for the pierce delay. When this switch is ON, the front

panel control for pierce time is disabled and the PHC uses a pierce time of zero. The CNC issues the AUTO /

CORNER HOLD command, waits for the MOTION signal, and begins timing the pierce delay. After the Pierce

Time has elapsed, the CNC can begin the actual cutting machine motion and start to time the acceleration

delay. After the acceleration delay time has elapsed, the CNC can remove the AUTO / CORNER HOLD and

allow the PHC to control the torch height.

Page 42

42 Sensor™ PHC Operation and Setup Guide

SW9 SW10 End of Cut Retract Time

on on Retract = Low = 0.25 Sec @ Max Speed (0.8” std lifter)

on off Retract = Med Low = 0.5 Sec @ Max Speed (1.6” std lifter)*

off on Retract = Med High = 1.0 Sec @ Max Speed (3.3” std lifter)

off off Retract = High = 1.5 Sec @ Max Speed (5.0” std lifter)

SW9 and SW10 control the end of cut retract. This setting should be set as low as possible to achieve

optimum cycle times and still clear worst case tip-ups. The end of cut retract moves at the maximum lifter

speed.

SW11

Automatic Kerf Detect

on Normal – PHC the detects Kerf crossings and auto HOLD

off Automatic Kerf Detection is disabled*

For the automatic kerf detection to operate properly, the kerf threshold pot must be adjusted to the correct

level. The correct level is low enough to trip the kerf detection when crossing a kerf, but high enough that

nuisance trips are avoided during normal cutting. This pot should be adjusted by viewing the yellow “corner /

kerf hold LED” during a test cut.

SW12

Preflow During IHS

on Plasma Start and Preflow during IHS with capable plasma systems

off Normal – Plasma Start and Preflow after IHS – Contact Start Torch *

Note: This function must be disabled for Powermax

®

contact start torches.

This function is only used with high frequency start mechanized torches. With mechanized torches, this

function can save cycle time by performing IHS and torch preflow during the same period of time. When

“Preflow During IHS” is active, the “Start” and “Ignition Hold” output signals are applied to the plasma system

during the IHS process. This allows the plasma system to begin the gas preflow requirement during the same

period of time when the PHC lifter is positioning the torch at the correct pierce height. After the PHC lifter has

been positioned at the correct pierce height, the Ignition Hold output is removed to allow the torch to start and

the cutting process to begin.

SW13

Reserved

on Normal

off Special operation

SW14

Lifter Limit Switches

on (Sw NC) Open on Limit – Use normally closed lifter inputs

off (Sw NO) Close on Limit – or switches not used, lifter hard stops *

For the standard lifter, limit switches are not used. The PHC senses the lifter upper and lower limits by sensing

when the lifter hard stops at the travel limits.

Page 43

Section 2: Installation and Setup 43

SW15

Torch Breakaway Switch

on (Sw NO) Open on Breakaway – Use normally open s witch input *

off (Sw NC) Close on Breakaway – or switch not used

For the standard lifter, the torch breakaway uses a normally open proximity switch. When the breakaway is

installed, the switch closes. When the breakaway is tripped, the switch opens again.

SW16

Arc Voltage Calibration Mode

on Display actual arc voltage during idle state for calibration

off Normal – Display set arc voltage during Idle state *

For normal operation, this switch should be set to OFF.

This switch is used to display the actual arc voltage on the PHC display. This allows the arc voltage to be

calibrated by adjusting the Arc Voltage adjustment pot. When the calibration mode is active, the PHC displays

“X.X.X.” with the X’s indicating the measured arc voltage and all the decimal points on to indicate calibration

mode.

When calibration mode is active the display can be temporarily overridden by adjusting either the kerf detect

level or the stall force. If you adjust either the kerf detect or stall force, a 0 to 10 reference level displays

temporarily. After one second of inactivity the display reverts to the measured arc voltage.

NOTE: The arc voltage calibration procedure should be performed on all new installations

because the actual measured arc voltage accuracy is a combination of the indiv idual plasma interface

and control units.

Page 44

44 Sensor™ PHC Operation and Setup Guide

Calibration Pot Setup

ARC - Arc Voltage Calibration

This trim pot is used to calibrate the actual arc voltage used for arc voltage control feedback. To calibrate the

arc voltage, place the PHC into the arc voltage calibration mode by turning ON DIP switch #16. This causes

the actual arc voltage to display on the 3 digit LED display. The user can either perform a test cut with a meter

connected to the plasma supply output or connect a known voltage (250 Vdc max.) to the plasma interface arc

voltage terminals (negative electrode and positive ground). Adjust the arc voltage pot until the display is equal

to the applied voltage on the meter.

NOTE: For accurate operation, this procedure should be done for all new installations since the

measured arc voltage accuracy is combination of the specific plasma interface and control units.

KERF - Auto Kerf Detection Level

This adjustment pot sets the auto kerf detection level. The auto kerf function must be enabled by turning ON

the automatic kerf detect DIP switch #11. When this pot is adjusted with the PHC in calibration mode, the

display temporarily shows a 0 to 10 reference level display. The auto kerf detection works by looking for a

rapid change in the arc voltage. When the pot is adjusted toward the lower settings, the PHC looks for smaller

voltage changes and the kerf detection is more sensitive. At higher settings, the kerf detection is less sensitive.

The pot should be set sensitive enough to reliably detect kerf crossings but not so sensitive that false nuisance

trips occur and degrade the height control performance. The operation of auto kerf detect can be checked by

monitoring the yellow Hold LED on the PHC front panel during a plasma cut. If the threshold is properly se t,

the yellow Hold LED lights whenever a Kerf is crossed. Note that this LED also lights when an active

Auto/Corner input is present on the CNC Interface or when the unit is set for Manual operation.

STALL - IHS Stall Sensing Level

This adjustment is used to set the Stall force sensing level during Initial Height Sense (IHS). When this pot is

adjusted with the PHC in calibration mode, the display temporarily shows a 0 to 10 reference level display.

The stall force is always used as a backup to the ohmic contact sensing in automatic mode. When it is set to

the lower settings (turn counter-clockwise), the maximum applied force i s lower d uring IHS. Higher settings

(turn clockwise) increase the maximum applied force. If this setting is too high, the torch or consumables can

be damaged or can deflect the work piece or trip the torch breakaway. Set this adjustment as low as possible

but high enough so that false stalled plate detects do not occur in mid air. The adjustment can be checked by

executing an IHS Test with the nozzle ohmic wire disconnected.

Page 45

Section 3: Operation 45

Section 3: Operation

Automated torch height control (THC) systems used in mechanized plasma cutting are used to provide the

optimum height for the desired metal cutting process. The appropriate cut height is crucial to the pla sma

process to provide the ability to transfer the Arc to the work piece for piercing / cutting and for optimum cut

quality (bevel angle, etc).

With the plasma process there is a direct relationship between the cut voltage and the torch height (g ap

between the metal work surface and the torch electrode). By using the automated control to monitor the

working arc (cut) voltage, it can then control the THC to maintain a specific voltage set point.

Page 46

46 Sensor™ PHC Operation and Setup Guide

Automatic Operation

Automatic voltage control operation is selected by placing the lower center toggle switch in the upper auto

position. In this mode, the unit automatically performs IHS to the set pierce height, ignite the plasma torch, wait

for the torch to pierce the plate, and begin the cutting machine motion.

The basic Sensor™ PHC auto operation setup consists of three steps:

1. Set arc voltage

Use the larger multi-turn adjustment, to set the arc voltage on the display. The starting point for this

voltage should be included in the cut charts supplied with your plasma system. It is important to remember

that this voltage is just a starting point since the actual arc voltage depends on consumable wear, torch

lead lengths, gas flow rates, and machine motion. For optimal cut quality you must make small

adjustments to the nominal arc voltage that is specified in the cut charts. The important item to control is

the torch-tip to work height during a cut. The arc voltage is just an indirect method to control this height.

2. Set IHS retract or pierce height

Use the lower left rotary control to set the IHS retract height. As this control is adjusted, the display is

temporarily overridden with a 0 to 10 reference level. This represents the desired pierce height. The actual

height should be available in the cut charts supplied with the plasma system. This setting is approximate

because it depends on whether the unit can sense the plate using ohmic contac t or must rely on the

backup limited force stall sensing.

Check this setting by performing an IHS test and check for the correct pierce height. Each time the lower

left IHS test switch is pressed, the torch alternates between the set IHS height and the end of cut retract

height. Continue testing and fine tuning this adjustment until the desired IHS height is achieved.

If the IHS speed (DIP SW #5) has been set to the normal low speed setting, then the IHS retract

adjustment range should be between about 50 thousandths and 1/2 inch. If the IHS speed was set to the

high speed setting, then the IHS retract adjustment range should be between about 1/10

3. Set pierce delay time

Use the lower right rotary control to set the pierce time delay. As this control is adjusted, the display is

temporarily overridden with a 0 to 4.0 second delay time. This is the time delay between igniting the torch

and beginning the cut motion. The pierce delay is the time required for the plasma torch to initially cut

through the plate. This time delay should be included in the cut charts provided with your plasma system.

To provide more accuracy for the short delay settings, this rotary control is divided into two ranges. The

first range covers the first ½ rotation of the control and provides a linear delay between 0 and 1 second.

The second ½ rotation provides a linear delay of between 1 and 4 seconds.

th

inch and 1 inch.

Page 47

Section 3: Operation 47

Manual Operation

Manual lifter operation is selected by placing the lower center toggle switch in the lower manual position. In

this mode, the unit manually jogs or slews slow or fast in the desired direction. If a cut is started while in the

manual mode, the torch moves only in response to the front panel manual move commands. The IHS, voltage

control, and end-of-cut retract functions are all disabled during manual mode.

Use your cut chart and the following steps to set up operations in manual mode:

1. Select manual mode with the toggle switch.

2. Set cut height with the up/down toggle switch.

The three types of manual motion are jog, slow and fast. Note that slow and fast types of manual motion are

time-based.

Manual Jog

Manual jog motion is useful for fine-tuning the torch height in manual mode. When the lower right manual

motion switch is momentarily switched into either the up or down position, the torch jogs approximately 20

thousandths in the desired direction. Repeat the momentary depression of the switch up or down to create a

series of discrete jog motions in the desired direction. This is useful for fine-tuning the torch height in manual

mode.

Slow Manual Motion

Continue to hold the manual motion switch for about ½ second after the jog has completed to create slow

manual motion in the desired direction. This motion should be at the IHS speed as determined by DIP SW #5.

Fast Manual Motion

Hold the manual motion switch for about one second after the start of slow manual motion to create fast

manual motion. The fast manual motion continues for as long as the manual motion switch is depressed.

Page 48

48 Sensor™ PHC Operation and Setup Guide

Page 49

Section 4: Troubleshooting 49

Section 4: Troubleshooting

Error Codes

Error code

Displays here

Red error

LED

Figure 21: Error Indications

The red ERROR LED indicates abnormal conditions. The error code is displayed in the PHC 3 digit LED

display as E.XX where XX represents the error number. The meanings are listed below. Most errors are

cleared by either removing the abnormal condition or with the application of the next “Cycle Start” from the

CNC.

E.01 CYCLE_START at power up Error

Reason: The CNC CYCLE_START input was active when the PHC was powered up.

Solution: Deactivate the CYCLE_START input on the CNC interface to clear the error.

E.02 Plate Contact at Home Error

Reason: Ohmic contact sensed the work piece when the torch was at the maximum retract position.

Possible causes:

• A short circuit in either the nozzle connection wire or the torch consumables.

Page 50

50 Sensor™ PHC Operation and Setup Guide

• A coolant leak on a liquid cooled torch.

Solution: This error is reset on the next CYCLE_START.

E.03 Lifter Timeout Error

Reason: Lifter motion was commanded but the lifter destination was not sensed within the timeout period.

Possible causes:

• A mechanical problem in the lifter such as the motor coupling to the lifter mechanics has loosened.

• The torch lead set is binding and limiting the lifter motion.

• A problem with the motor wiring, motor drive, or with the motor itself.

Solution: The error is reset on the next CYCLE_START.

E.04 Limit Reached during Auto Operation

Reason: The lifter reaches a travel limit during arc voltage controlled operation.

Possible causes:

• The lifter does not have the range of travel to accommodate the thickness of the material being cut.

• Improper operation of either the limit switches or the limit switch wiring.

Solution: Adjust the lifter or torch mounting to make more effective use of the lifter travel range.

This error is reset on the next CYCLE_START.

E.05 IHS SYNC Timeout

Reason: The torch reaches the IHS pierce position and is waiting for the IHS_SYNC input from the CNC to be

released.

Solution: Check the wiring of the IHS_SYNC input and the CNC programming for this signal. This error is

reset on the next CYCLE_START.

The HIS_SYNC signal is usually only used for multiple torch installations.

E.06 Transfer Timeout Error

Reason: The Plasma torch was fired but that the TRANSFER signal was not received within 5 seconds

Possible causes:

• A faulty IHS sequence that resulted in an improperly high pierce height.

• Failure to transfer due to bad consumables.

• Improper plasma gas settings.

• Bad work piece grounding.

• The TRANSFER signal on the power supply interface is missing or improperly connected to the PHC

Plasma Interface

Solution: The next CYCLE_START resets this error.

E.07 Lost Plasma Arc Error