600 Volt Conversion

Installation Manual

803200 - Rev. 0

600 Volt Conversion

Kit: 128312

Installation Manual

IM-320

(P/N 803200)

®

®

Revision 0 June, 1998

HYPERTHERM, Inc.

P.O. Box 5010

Hanover, New Hampshire 03755-5010

Tel.: (603) 643-3441

Fax: (603) 643-5352

http://www.hypertherm.com

email:info@hypertherm.com

© Copyright 1998 Hypertherm, Inc.

All Rights Reserved

HYPERTHERM and POWERMAX are trademarks of Hypertherm, Inc. and may be

registered in the United States and/or other countries

Hypertherm Offices Worldwide

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

Tel.: (603) 643-3441 (Main Office)

Fax: (603) 643-5352 (All Departments)

Tel.: (800) 643-9878 (Technical Service)

Tel.: (800) 737-2978 (Customer Service)

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D–63457 Hanau-Wolfgang, Germany

Tel.: 49 6181 58 2100

Fax: 49 6181 58 2134

European Technical Support Organization (ETSO)

Technologiepark Hanau

Rodenbacher Chaussee 6

D–63457 Hanau-Wolfgang, Germany

Tel.: 49 6181 58 2100

Fax: 49 6181 58 2134

:

Hypertherm Singapore Pte Ltd

No. 19 Kaki Bukit Road 2

K.B. Warehouse Complex

Singapore 417847, Republic of Singapore

Tel.: 65 841 2489

Fax: 65 841 2490

Hypertherm U.K.

9 Berkeley Court • Manor Park

Runcorn, Cheshire, England WA7 1TQ

Tel.: 44 1928 579 074

Fax: 44 1928 579 604

Hypertherm France

10, Allée de I’lsara

F-95000 Cergy-Pontoise, France

Tel.: 33 1 34 24 03 05

Fax: 33 1 34 25 09 64

Hypertherm Italy

Via Stilicone 18

20154 Milan, Italy

Tel.: 39 2 34 53 22 11

Fax: 39 2 34 53 20 18

SPECIFICATIONS

Section 1 SPECIFICATIONS

In this section:

Introduction ........................................................................................1-2

Specifications ..................................................................................... 1-2

600 Volt Powermax900 Power Supply ..........................................1-2

600V Installation Manual

1-1

SPECIFICATIONS

INTRODUCTION

The instructions in this manual will enable a qualified electronics technician to convert the

208/240/480 volt Powermax900 or 208/240/480 volt Powermax800 power supply into a 600 volt

power supply. The kit (128312) contains a transformer and case, wheels, castors, and 2 line cords one to hook up to a line disconnect box or 3-phase plug, and a shorter cord to connect from the

transformer case to the link box at the rear of the Powermax - See Figure 2-1. See also

Section 3 for a list of parts for the 600 volt conversion kit.

When installation is complete, refer to the Operator Manual for setup, operating instructions and

maintenance of the Powermax system.

SPECIFICATIONS See the operator manual for Powermax800 specifications

600 Volt Powermax900 Power Supply

Rated Open Circuit Voltage (OCV) (U0) ..............300VDC

Rated Output Current (I2) ....................................20-50 amps

Rated Output Voltage (U2) ..................................120VDC

Duty Cycle (X) @ 40°C ....................................... 50% (I2=55A, U2=120V) See data tag on power

supply for more information on duty cycle

Ambient temperature/duty cycle..........................Power supplies will operate between +14°

and 104° F (-10° and +40° C). Power

supplies operated in an ambient

temperature above 86° F (30° C) may show

some decrease in duty cycle.

Apparent Input Power (S1) ..................................11.4kVA (U1I1)

Input Voltage (U1)/Input Current (I1)

@ 6.6 kw Output ................................................. 600V/12A - 3φ, 60 Hz

1-2

Dimensions and Weight:

Depth...................................................................23.1" (590 mm)

Width ...................................................................15.25" (390 mm)

Height..................................................................27.7" (700 mm)

Weight .................................................................128 pounds (58 kg)

Gas Type.............................................................Air or Nitrogen

Gas Quality, Air ...................................................Clean, dry, oil-free

Gas Quality, Nitrogen..........................................99.995% pure

Gas Inlet Pressure ..............................................90 psi (6.2 bar)

Gas Flow .............................................................360 scfh/6 scfm at 90 psi (170 l/min

at 6.2 bar) supplied to power supply

pressure regulator

Power Supply pressure regulator setting ............70 psi (4.8 bar) flowing

600V Installation Manual

600V INSTALLATION

Section 2 600V INSTALLATION

In this section:

Installation .........................................................................................2-2

Installation of Wheels and Casters to Transformer Case..................2-4

Wheel Installation .........................................................................2-4

Caster Installation.........................................................................2-4

Attaching Power Supply Bracket to Powermax900 Chassis .............2-6

Attaching 600V Transformer Case Assembly to

Powermax900 Chassis .....................................................................2-8

Switching Voltage Configuration to 480V ..........................................2-9

Hooking Up the Three-Phase Transformer Secondary Power Cord

from 600V Transformer Case Assembly to Powermax900 ...............2-10

Choosing Plug, Power Cord and Line Disconnect Box Fuse ............2-11

Power Cord Plug......................................................................2-11

Power Cord - 600V ..................................................................2-11

Line Voltage Disconnect Box and Fuses .................................2-11

600V Installation Manual

2-1

600V INSTALLATION

WARNING

INSTALLATION MUST BE PERFORMED ONLY BY HYPERTHERM DISTRIBUTORS OR

QUALIFIED ELECTRONICS TECHNICIANS!!

SHOCK HAZARD: Always turn off power, unplug cord from wall and wait 5 minutes before

removing any cover of the power supply! If power unit is directly connected to a line

disconnect box, place line disconnect switch to OFF position. Lock out and tag out switch

before proceeding!

See Section 3 for a parts list of the 128312 Powermax 600V conversion kit.

Note: All graphics and text in this document refer to the Powermax900. Unless otherwise noted, all

instructions apply to either the Powermax800 or Powermax900.

INSTALLATION

The installation of the 600V kit to the 208/240/480V Powermax900 involves 6 basic steps:

1. Installation of wheels and casters to the transformer case.

2. Attaching the 600V power supply bracket to the Powermax900 chassis.

3. Attaching the 600V case assembly to the Powermax900 chassis.

4. Switching the power supply voltage configuration to 480V.

5. Hooking up the three-phase transformer secondary power cord from the 600V

transformer case assembly to the Powermax900.

6. Choosing the plug, power cord and line disconnect box fuse.

WARNING

THE 208/240/480V POWERMAX900 POWER SUPPLY IS SET UP TO OPERATE AT 240V WITH

A SINGLE-PHASE INPUT. WHEN CONVERTED TO A 600V POWER SUPPLY, THE VOLTAGE CONFIGURATION IN THE POWER SUPPLY MUST BE SWITCHED TO 480V, AND THE

POWER CORD MUST BE HOOKED UP FOR THREE-PHASE OPERATION. See pages 2-9 to

2-10.

2-2

600V Installation Manual

600V INSTALLATION

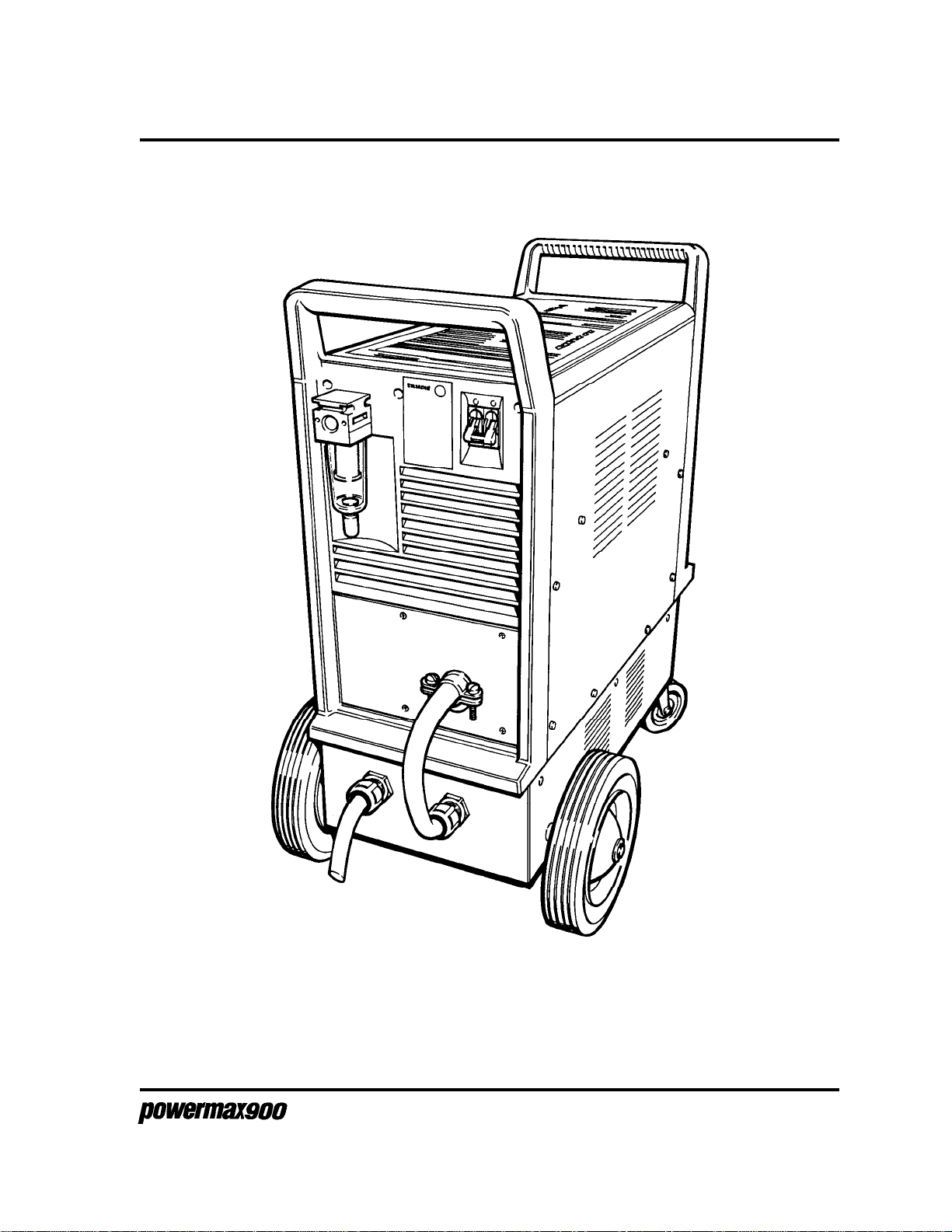

Figure 2-1 Powermax900 600V Power Supply Assembled

600V Installation Manual

2-3

600V INSTALLATION

INSTALLATION OF WHEELS AND CASTERS TO TRANSFORMER

CASE

Wheel Installation

1. Carefully turn transformer case assembly upside down.

2. Snap an 027249 retaining ring on one end of the 004672 wheel axle.

3. Slide one 027057 wheel on the axle.

4. Slide 008973 shoulder washer over the end of the axle with the larger diameter end of

the washer facing the mounted wheel.

5. Slide the axle through both holes in the rear of the transformer case assembly.

6. Slide the second 008973 shoulder washer over the end of the axle with the smaller

diameter end of the washer facing the transformer case.

7. Slide the second 027057 wheel onto the axle.

8. Snap the second 027249 retaining ring on the end of the axle to secure the second

wheel.

Caster Installation

1. Attach the 027299 casters to the case with the 075470 10-32 screws and 075174 star

washers as shown in Figure 2-2.

2. Turn transformer case back over on to wheels - Figure 2-3.

Wheel and caster installation complete.

2-4

600V Installation Manual

027299

Caster

600V INSTALLATION

075470

10-32 screws (8)

075174

10-32 star washers (8)

027057

Wheel

027249

Retaining

ring

008973

Shoulder

washer

004672

Axle

027057

Wheel

Figure 2-2 Wheel and Caster Installation

Figure 2-3 Wheels and Casters Installed on 600V Transformer Case

600V Installation Manual

2-5

600V INSTALLATION

ATTACHING POWER SUPPLY BRACKET TO POWERMAX900

CHASSIS.

1. If torch is connected to power supply, disconnect it.

WARNING

INSTALLATION MUST BE PERFORMED ONLY BY HYPERTHERM DISTRIBUTORS OR

QUALIFIED ELECTRONICS TECHNICIANS!!

SHOCK HAZARD: Always turn off power, unplug cord from wall and wait 5 minutes before

removing any cover of the power supply! If power unit is directly connected to a line

disconnect box, place line disconnect switch to OFF position and remove power cord from

line disconnect box.

2. Remove power cord from line disconnect box or from receptacle.

3. Remove power cord from power supply. See Figure 2-4.

3.1.Loosen the 2 screws on the power cord strain relief.

3.2.Remove the screws securing the line cord rear panel.

3.3.Slide rear panel down on power cord to expose link box.

3.4.Disconnect power cord from link box.

3.5.Remove power cord from rear panel.

Link Box

Loosen 2 screws

on power cord

strain relief.

Remove screws to

remove line cord

rear panel and

expose link box.

Figure 2-4 Removal of Power Cord from Powermax900 Power Supply

Green

Red (3φ)

White

Black

Remove power

cord wires from

link box.

2-6

600V Installation Manual

600V INSTALLATION

4. Remove the power supply cover (Powermax900 only).

5. Carefully tilt Powermax over onto its front handle as shown in Figure 2-5.

6. Place the 001568 power supply bracket against the bottom of the power supply as shown

in Figure 2-5 and fasten with the 075470 10-32 screws, 075174 star washers and

075160 kepnuts in 12 locations.

Note: The Powermax800 chassis does not require the 075160 kepnuts.

075160

Kepnuts (on inside)

(12)

075174

Star washers (12)

075470

Screws (12)

Figure 2-5 Attaching 600V Power Supply Bracket to Powermax Chassis

001568

Power supply

bracket

600V Installation Manual

2-7

600V INSTALLATION

ATTACHING 600V TRANSFORMER CASE ASSEMBLY TO

POWERMAX900 CHASSIS

1. Replace the power supply cover.

2. Lift Powermax over transformer case assembly with the rear of the power supply lined up

over the power cord side of the transformer case.

3. Carefully set down the Powermax onto the transformer case assembly.

4. Fasten the Powermax to the transformer case assembly by screwing in the 075467

8-32 screws in 10 locations.

5. Thread the transformer secondary power cord (shorter cord) through the strain relief of

the line cord rear panel.

Transformer

Secondary

Power Cord

Figure 2-6 Attaching 600V Transformer Case Assembly to Powermax900 Chassis

2-8

075467

8-32 screw

600V Installation Manual

600V INSTALLATION

SWITCHING VOLTAGE CONFIGURATION TO 480V

1. Configure TB2 by moving the voltage link wire (Black) to the position shown in Figure 2-7.

Link Box

TB3

TB2

Jumper

480V (Black)

GND (White)

Figure 2-7 Switching Voltage Configuration to 480V

2. Configure TB3 with one jumper linked in the position shown in Figure 2-7.

3. Secure unused link jumper in the clip located in the link box,

600V Installation Manual

2-9

600V INSTALLATION

HOOKING UP THE THREE-PHASE TRANSFORMER SECONDAR Y

POWER CORD FROM 600V TRANSFORMER CASE ASSEMBLY TO

POWERMAX900

1. Connect L1 (Black), L2 (White) and L3 (Red) of the three-phase transformer secondary

power cord to TB1 of the link box as shown in Figure 2-8.

2. Connect the ground (Green) wire to the stud marked above the terminal block .

Conductor Color

L1 Black

L2 White

Link Box

Green

TB1

Red

L3 Red

Ground Green

White

Black

Figure 2-8 Connecting the Transformer Secondary Power Cord

from 600V Transformer Case to Powermax900

3. Connect the rear panel to the Powermax900 power supply and secure with screws.

4. Tighten the strain relief screws around the power cord. Be certain that the strain relief

grips the outer insulation of the power cord and not the individual wires. See completed

assembly in Figure 2-1.

WARNING

BE CERTAIN THAT WIRES ARE CONNECTED EXACTLY AS SHOWN ABOVE. AS A

PRECAUTION, CHECK CONTINUITY FROM POWER SUPPLY ENCLOSURE TO INCOMING

GROUND WIRE BEFORE CONNECTING TO POWER.

2-10

600V Installation Manual

600V INSTALLATION

CHOOSING PLUG, POWER CORD AND LINE DISCONNECT BOX

FUSE

Power Cord Plug

The 600V Powermax900 kit is shipped with a three-phase power cord and no plug. The user

must obtain a plug that is certified by national or local electrical codes. The plug should be connected

to the power cord by a licensed electrician.

Power Cord - 600V

If the three-phase power cord length needs to be changed, use the table below to choose the proper

gauge size for the appropriate length. Use a 4-conductor SO type cord for three-phase power

supplies. The cord should be installed only by a licensed electrician.

Input Input Recommended Power Cord Gauge Size (AWG)

Voltage Current to 10 ft 10 – 25 ft 25 – 50 ft 50 – 100 ft 100 –150 ft

600 VAC 8 amps 12 12 12 12 10

Line Voltage Disconnect Box and Fuse

Use a line disconnect box for each power supply. This disconnect box allows the operator to turn the

power supply off quickly in an emergency situation. The switch should be located on a wall near the

power supply, and should be easily accessible to the operator. The interrupt level of the switch must

be equal to or exceed the continuous rating of the fuses. Use slow-blow fuses according to the power

requirements listed below.

Input Input Current Recommended

Voltage Phase @ 6.6 kw Output Slow-Blow Fuse Size

600 VAC 3 12 amps 20 amp

The 600Volt conversion is now complete. See the Powermax Operator Manual for further instructions

to setup, operate and maintain the Powermax system.

600V Installation Manual

2-11

600V INSTALLATION

2-12

600V Installation Manual

PARTS LIST

Section 3 PARTS LIST

In this section:

Powermax900 600 Volt Conversion Kit - 128312..............................3-2

600V Installation Manual

3-1

PARTS LIST

POWERMAX900 600 VOLT CONVERSION KIT - 128312

Index No. Part No. Description Quantity

1 001568 Panel:Powermax800 600V 1

2 004672 Axle:Powermax800 Power Unit 1

3 008973 Shoulder Washer:1/2" X 27/64 Nylon 2

4 027057 Wheel:8" X 1.75" 2

5 027249 Retaining Ring:1/2" Shaft Extension 2

6 027299 Caster:MAX70 Swivel 2

7 075467 M/S:8-32 X 3/8 Phillips Head Round SSB 10

8 075470 M/S:10-32 X 3/4 Phillips Head Pan 20

9 075174 Lockwasher :#10 Internal 20

075160 Kepnut:10-32 S/Z 12

129364 Powermax900 600V Conversion SA 1

10 001672 Cover:Powermax900 600V 1

11 001570 Bracket:Powermax800 600V 2

12 008752 Fuseblock:3Position 30A600V 13/32X1-1/2 1

13 008949 Terminal board:3-Terminal 1

14 008962 Fuse:20A 600V .406X1.5 Slow 3

15 008963 Strain relief:3/4" X .625-.750 2

16 014235 Transformer:Powermax900 600V Input 1

17 123060 Cable:Powermax800 600V Conv. Fuses 1

18 123061 Cable:Powermax800 600V Conv. Term. Block 1

1

5

10

Figure 3-1 Powermax900 600V Panel, Wheels and Casters

8

4

3

2

9

6

3

6

4

5

3-2

600V Installation Manual

PARTS LIST

12

14

16

10

11

7

13

17

15

18

Figure 3-2 Powermax900 600V Conversion Subassembly - 129364

600V Installation Manual

3-3

Wiring Diagram: Powermax900 600V Transformer - 014235

Loading...

Loading...