1

4

5

6

55 t

55

3550t

5

60

BAR

0

0

S

0

0

0 60

80

AS

120926 120925

120978

120927

120928

120928

120929

120977

110378ReA

6.0

BAR

5.0

4.0

PSI

80

70

50 60

60

40

AMPS

80

25

AC

+

_

2

3

1 4

5

6

15-50ft

45-15m

15-25ft

45-75 m

35-50ft

12-15m

60

BAR

50

40

PSI

80

70

50

60

80

AMPS

80

AMPS

powermax1000

Plasma Arc

Cutting System

Operator Manual

804290 – Revision 2

®

powermax1000

Operator Manual

(P/N 804290)

Revision 2 – November 2013

Hypertherm, Inc.

Hanover, NH USA

www.hypertherm.com

© Copyright 2013 Hypertherm, Inc.

All Rights Reserved

Hypertherm and Powermax are trademarks of Hypertherm, Inc.

and may be registered in the United States and/or other countries.

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

Hypertherm Automation

5 Technology Drive, Suite 300

West Lebanon, NH 03784 USA

603-298-7970 Tel

603-298-7977 Fax

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D-63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm (S) Pte Ltd.

No. 19 Kaki Bukit Road 2

K.B. Warehouse Complex

Singapore 417847, Republic of Singapore

65 6 841 2489 Tel

65 6 841 2490 Fax

65 6 841 2489 (Technical Service)

Hypertherm (Shanghai) Trading Co., Ltd.

Unit 1308-09, Careri Building

432 West Huai Hai Road

Shanghai, 200052

PR China

86-21 5258 3330/1 Tel

86-21 5258 3332 Fax

France (Representative office)

15 Impasse des Rosiers

95610 Eragny, France

00 800 3324 9737 Tel

00 800 4973 7329 Fax

Hypertherm S.r.l.

Via Torino 2

20123 Milano, Italia

39 02 725 46 312 Tel

39 02 725 46 400 Fax

39 02 725 46 314 (Technical Service)

Hypertherm Europe B.V.

Vaartveld 9

4704 SE Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 165 596900 Tel (Technical Service)

00 800 49 73 7843 Tel (Technical Service)

Hypertherm Japan Ltd.

801 Samty Will Building

2-40 Miyahara 1-Chome,

Yodogawa-ku, Osaka

532-0003, Japan

81 6 6170 2020 Tel

81 6 6170 2015 Fax

HYPERTHERM BRASIL LTDA.

Avenida Doutor Renato de

Andrade Maia 350

Parque Renato Maia

CEP 07114-000

Guarulhos, SP Brasil

55 11 6409 2636 Tel

55 11 6408 0462 Fax

Hypertherm

Branch of Hypertherm, UK, UC

PO Box 244

Wigan, Lancashire, England WN8 7WU

00 800 3324 9737 Tel

00 800 4973 7329 Fax

00 800 4973 7843 (Technical Service)

1/19/07

ELECTROMAGNETIC COMPATIBILITY (EMC)

EMC Introduction

Hypertherm’s CE-marked equipment is built in

compliance with standard EN60974-10. The

equipment should be installed and used in

accordance with the information below to achieve

electromagnetic compatibility.

The limits required by EN60974-10 may not be

adequate to completely eliminate interference

when the affected equipment is in close proximity

or has a high degree of sensitivity. In such cases

it may be necessary to use other measures to

further reduce interference.

This plasma equipment is designed for use only in

an industrial environment.

Installation and use

The user is responsible for installing and using

the plasma equipment according to the

manufacturer’s instructions. If electromagnetic

disturbances are detected then it shall be the

responsibility of the user to resolve the situation

with the technical assistance of the manufacturer.

In some cases this remedial action may be as

simple as earthing the cutting circuit, see

Earthing of Workpiece.

involve constructing an electromagnetic screen

enclosing the power source and the work

complete with associated input filters. In all cases

electromagnetic disturbances must be reduced to

the point where they are no longer troublesome.

In other cases it could

Assessment of area

Before installing the equipment the user shall

make an assessment of potential electromagnetic

problems in the surrounding area. The following

shall be taken into account:

a. Other supply cables, control cables, signalling

and telephone cables; above, below and

adjacent to the cutting equipment.

b. Radio and television transmitters and

receivers.

c. Computer and other control equipment.

d. Safety critical equipment, for example guarding

of industrial equipment.

e. Health of the people around, for example the

use of pacemakers and hearing aids.

f. Equipment used for calibration or

measurement.

g. Immunity of other equipment in the

environment. User shall ensure that other

equipment being used in the environment is

compatible. This may require additional

protection measures.

h. Time of day that cutting or other activities are

to be carried out.

The size of the surrounding area to be considered

will depend on the structure of the building and

other activities that are taking place. The

surrounding area may extend beyond the boundaries of the premises.

Methods of reducing emissions

Mains supply

Cutting equipment must be connected to the

mains supply according to the manufacturer’s

recommendations. If interference occurs, it may

be necessary to take additional precautions such

as filtering of the mains supply. Consideration

should be given to shielding the supply cable of

permanently installed cutting equipment, in

metallic conduit or equivalent. Shielding should

be electrically continuous throughout its length.

The shielding should be connected to the cutting

mains supply so that good electrical contact is

maintained between the conduit and the cutting

power source enclosure.

Maintenance of cutting equipment

The cutting equipment must be routinely

maintained according to the manufacturer’s

recommendations. All access and service doors

and covers should be closed and properly

fastened when the cutting equipment is in

operation. The cutting equipment should not be

modified in any way except for those changes and

adjustments covered in the manufacturer’s

Hypertherm Plasma Systems i

8-06

ELECTROMAGNETIC COMPATIBILITY (EMC)

instructions. In particular, the spark gaps of arc

striking and stabilizing devices should be adjusted

and maintained according to the manufacturer’s

recommendations.

Cutting cables

The cutting cables should be kept as short as

possible and should be positioned close together,

running at or close to the floor level.

Equipotential bonding

Bonding of all metallic components in the cutting

installation and adjacent to it should be

considered. However, metallic components

bonded to the workpiece will increase the risk that

the operator could receive a shock by touching

these metallic components and the electrode at

the same time. The operator should be insulated

from all such bonded metallic components.

Earthing of workpiece

Where the workpiece is not bonded to earth for

electrical safety, nor connected to earth because

of its size and position, for example, ship’s hull or

building steelwork, a connection bonding the

workpiece to earth may reduce emissions in

some, but not all instances. Care should be

taken to prevent the earthing of the workpiece

increasing the risk of injury to users, or damage to

other electrical equipment. Where necessary, the

connection of the workpiece to earth should be

made by a direct connection to the workpiece, but

in some countries where direct connection is not

permitted, the bonding should be achieved by

suitable capacitances selected according to

national regulations.

Note: the cutting circuit may or may not be

earthed for safety reasons. Changing the earthing

arrangements should only be authorized by a

person who is competent to assess whether the

changes will increase the risk of injury, for

example, by allowing parallel cutting current return

paths which may damage the earth circuits of

other equipment. Further guidance is given in

IEC/ TS 62081 Arc Welding Equipment Installation

and Use.

Screening and shielding

Selective screening and shielding of other cables

and equipment in the surrounding area may

alleviate problems of interference. Screening of

the entire plasma cutting installation may be considered for special applications.

ii Hypertherm Plasma Systems

8-06

TABLE OF CONTENTS

WARRANTY

Warning

Genuine Hypertherm parts are the factoryrecommended replacement parts for your

Hypertherm system. Any damage caused by the

use of other than genuine Hypertherm parts may

not be covered by the Hypertherm warranty.

Warning

You are responsible for the safe use of the

Product. Hypertherm does not and cannot make

any guarantee or warranty regarding the safe use

of the Product in your environment.

General

Hypertherm, Inc. warrants that its Products shall

be free from defects in materials and

workmanship, if Hypertherm is notified of a defect

(i) with respect to the power supply within a period

of two (2) years from the date of its delivery to

you, with the exception of Powermax Series

power supplies, which shall be within a period of

three (3) years from the date of delivery to you,

and (ii) with respect to the torch and leads within a

period of one (1) year from its date of delivery to

you. This warranty shall not apply to any Product

which has been incorrectly installed, modified, or

otherwise damaged. Hypertherm, at its sole

option, shall repair, replace, or adjust, free of

charge, any defective Products covered by

this warranty which shall be returned with

Hypertherm’s prior authorization (which shall not

be unreasonably withheld), properly packed, to

Hypertherm’s place of business in Hanover,

New Hampshire, or to an authorized Hypertherm

repair facility, all costs, insurance and freight

prepaid. Hypertherm shall not be liable for any

repairs, replacement, or adjustments of Products

covered by this warranty, except those made

pursuant to this paragraph or with Hypertherm’s

prior written consent. The warranty above is

exclusive and is in lieu of all other warranties,

express, implied, statutory, or otherwise with

respect to the Products or as to the results

which may be obtained therefrom, and all

implied warranties or conditions of quality or

of merchantability or fitness for a particular

purpose or against infringement. The

foregoing shall constitute the sole and

exclusive remedy for any breach by

Hypertherm of its warranty. Distributors/OEMs

may offer different or additional warranties, but

Distributors/OEMs are not authorized to give any

additional warranty protection to you or make any

representation to you purporting to be binding

upon Hypertherm.

Certification test marks

Certified products are identified by one or more

certification test marks from accredited testing

laboratories. The certification test marks are

located on or near the data plate. Each certification

test mark means that the product and its safetycritical components conform to the relevant national

safety standards as reviewed by that testing

laboratory. Hypertherm places a certification test

mark on its products only after that product is

manufactured with safety-critical components that

have been authorized by the accredited testing

laboratory.

Once the product has left the Hypertherm factory,

the certification test marks are invalidated if any of

the following occurs:

• The product is significantly modified in a manner

that creates a hazard or non-conformance.

• Safety-critical components are replaced with

unauthorized spare parts.

• Any unauthorized assembly or accessory that

uses or generates a hazardous voltage is added.

• There is any tampering with a safety circuit or

other feature that is designed into the product as

part of the certification.

CE marking constitutes a manufacturer’s

declaration of conformity to applicable European

directives and standards. Only those versions of

Hypertherm products with a CE Marking located on

or near the data plate have been tested for

compliance with the European Low Voltage

Directive and the European EMC Directive.

powermax1000 Operator Manual iii

Hypertherm Plasma Systems iii

8-06

0

WARRANTY

EMC filters needed to comply with the European

EMC Directive are incorporated within versions of

the power supply with a CE Marking.

Patent indemnity

Except only in cases of products not

manufactured by Hypertherm or manufactured by

a person other than Hypertherm not in strict

conformity with Hypertherm’s specifications and in

cases of designs, processes, formulae, or

combinations not developed or purported to be

developed by Hypertherm, Hypertherm will

defend or settle, at its own expense, any suit or

proceeding brought against you alleging that the

use of the Hypertherm product, alone and not in

combination with any other product not supplied

by Hypertherm, infringes any patent of any third

party. You shall notify Hypertherm promptly upon

learning of any action or threatened action in

connection with any such alleged infringement,

and Hypertherm’s obligation to indemnify shall be

conditioned upon Hypertherm’s sole control of,

and the indemnified party’s cooperation and

assistance in, the defense of the claim.

Limitation of liability

In no event shall Hypertherm be liable to any

person or entity for any incidental,

consequential, indirect, or punitive damages

(including but not limited to lost profits)

regardless of whether such liability is based

on breach of contract, tort, strict liability,

breach of warranties, failure of essential

purpose or otherwise and even if advised of

the possibility of such damages.

Liability cap

In no event shall Hypertherm’s liability,

whether such liability is based on breach of

contract, tort, strict liability, breach of

warranties, failure of essential purpose or

otherwise, for any claim action suit or

proceeding arising out of or relating to the use

of the Products exceed in the aggregate the

amount paid for the Products that gave rise to

such claim.

Insurance

At all times you will have and maintain insurance

in such quantities and types, and with coverage

sufficient and appropriate to defend and to hold

Hypertherm harmless in the event of any cause of

action arising from the use of the Products.

National and Local codes

National and Local codes governing plumbing and

electrical installation shall take precedent over any

instructions contained in this manual. In no event

shall Hypertherm be liable for injury to persons or

property damage by reason of any code violation

or poor work practices.

Transfer of rights

You may transfer any remaining rights you may

have hereunder only in connection with the sale of

all or substantially all of your assets or capital

stock to a successor in interest who agrees to be

bound by all of the terms and conditions of this

Warranty.

Proper disposal of Hypertherm

products

Hypertherm plasma cutting systems, like all

electronic products, may contain materials or

components, such as printed circuit boards, that

cannot be discarded with ordinary waste. It is your

responsibility to dispose of any Hypertherm product

or component part in an environmentally

acceptable manner according to national and local

codes.

• In the United States, check all federal, state, and

local laws.

• In the European Union, check the EU directives,

national, and local laws.

• In other countries, check national and local laws.

Register your product on-line at:

www.hypertherm.com/warranty.htm

iv Hypertherm Plasma Systems

8-06

TABLE OF CONTENTS

Electromagnetic compatibility ...............................................................................................................................i

Warranty ...................................................................................................................................................................iii

Section 1 Safety

Recognize safety information ...........................................................................................................................1-2

Follow safety instructions ..................................................................................................................................1-2

Cutting can cause fire or explosion ................................................................................................................1-2

Electric shock can kill .........................................................................................................................................1-3

Static electricity can damage circuit boards ................................................................................................1-3

Toxic fumes can cause injury or death ...........................................................................................................1-4

A plasma arc can cause injury and burns ......................................................................................................1-5

Arc rays can burn eyes and skin ......................................................................................................................1-5

Grounding safety ................................................................................................................................................1-6

Compressed gas equipment safety ................................................................................................................1-6

Gas cylinders can explode if damaged ..........................................................................................................1-6

Noise can damage hearing ...............................................................................................................................1-7

Pacemaker and hearing aid operation ...........................................................................................................1-7

A plasma arc can damage frozen pipes ........................................................................................................1-7

Additional safety information ............................................................................................................................1-7

Warning label .......................................................................................................................................................1-8

Section 1a Sécurité

Identifier les consignes de sécurité ............................................................................................................. 1a-2

Suivre les instructions de sécurité ............................................................................................................... 1a-2

Danger--Avertissement--Précaution ............................................................................................................. 1a-2

Le coupage peut provoquer un incendie ou une explosion ................................................................... 1a-2

Les chocs électriques peuvent être fatals .................................................................................................. 1a-3

L’électricité statique peut endommager les cartes de circuits imprimés ............................................1a-3

Le vapeurs toxiques peuvent provoquer des blessures ou la mort ...................................................... 1a-4

L’arc plasma peut provoquer des blessures ou des brûlures ................................................................ 1a-5

Les rayons de l’arc peuvent brûler les yeux et la peau ............................................................................ 1a-5

Mise à la masse et à la terre .......................................................................................................................... 1a-6

Sécurité des bouteilles de gaz comprimé .................................................................................................. 1a-6

Les bouteilles de gaz comprimé peuvent exploser en cas de dommages ......................................... 1a-6

Le bruit peut provoquer des problèmes auditifs ........................................................................................1a-7

Pacemakers et prothèses auditives ..............................................................................................................1a-7

Un arc plasma peut endommager les tuyaux gelés ..................................................................................1a-7

Étiquette de sécurité ....................................................................................................................................... 1a-8

Section 1b Seguridad

Reconocimiento de información de seguridad ......................................................................................... 1b-2

Siga las instrucciones de seguridad ........................................................................................................... 1b-2

Los cortes pueden provocar incendios o explosiones ............................................................................1b-2

El choque eléctrico puede provocar la muerte .........................................................................................1b-3

Electricidad estática puede dañar tablillas de circuito ............................................................................1b-3

Humos tóxicos pueden causar lesiones o muerte ...................................................................................1b-4

El arco de plasma puede causar lesiones y quemaduras ...................................................................... 1b-5

Los rayos del arco pueden producir quemaduras en los ojos y en la piel..........................................1b-5

powermax1000 Operator Manual v

1

TABLE OF CONTENTS

Seguridad de toma a tierra ............................................................................................................................ 1b-6

Seguridad de los equipos de gas comprimido ......................................................................................... 1b-6

Los cilindros de gas pueden explotar si están dañados .........................................................................1b-6

El ruido puede deteriorar la audición .......................................................................................................... 1b-7

Operación de marcapasos y de audífonos ................................................................................................ 1b-7

Un arco plasma puede dañar tubos congelados .....................................................................................1b-7

Etiquetas de advertencia ................................................................................................................................1b-8

Section 2 Specifications

Power supply ......................................................................................................................................................2-2

Dimensions and weight ...........................................................................................................................2-3

T60 torches .........................................................................................................................................................2-4

Dimensions ................................................................................................................................................2-5

Symbols and Markings ......................................................................................................................................2-6

Section 3 Setup

Upon receipt ........................................................................................................................................................3-2

Claims ....................................................................................................................................................................3-2

Contents of box ...................................................................................................................................................3-2

Locating power supply ......................................................................................................................................3-2

Lifting power supply ...........................................................................................................................................3-3

Power connection ...............................................................................................................................................3-4

Three-phase power cord – plug installation .................................................................................................3-4

Single-phase power cord ..................................................................................................................................3-5

Power cord installation ............................................................................................................................3-5

Plug installation .........................................................................................................................................3-5

Grounding ...........................................................................................................................................................3-6

Extension cords ...................................................................................................................................................3-6

Torch installation ..................................................................................................................................................3-7

Plasma gas supply .............................................................................................................................................3-9

Additional gas filtration ............................................................................................................................3-9

Gas supply installation ....................................................................................................................................3-10

T60M torch alignment .....................................................................................................................................3-10

ON/OFF pendant connection ............................................................................................................3-11

Machine interface connection ............................................................................................................3-11

Arc voltage .............................................................................................................................................. 3-12

Changing XFER (start machine motion) from dry contact closure to voltage signal .......................3-14

Section 4 Operation

Controls and indicators .....................................................................................................................................4-2

Indicator LEDs ..........................................................................................................................................4-2

Torch consumable configurations ...................................................................................................................4-3

Installing torch consumables ............................................................................................................................4-4

Mode switch .........................................................................................................................................................4-5

Turn power ON ....................................................................................................................................................4-5

Check indicator lights ........................................................................................................................................4-5

Adjust gas pressure and current setting .......................................................................................................4-6

Hand torch operation .........................................................................................................................................4-7

vi powermax1000 Operator Manual

1

TABLE OF CONTENTS

Safety trigger operation ..........................................................................................................................4-7

Attach the work clamp ............................................................................................................................4-8

Starting a cut from the edge of the workpiece ..................................................................................4-8

Hand torch cutting technique ................................................................................................................4-9

Piercing ....................................................................................................................................................4-10

Gouging ...................................................................................................................................................4-11

Cut charts ..........................................................................................................................................................4-12

Section 5 Maintenance and parts

Routine maintenance..........................................................................................................................................5-2

Inspect consumables .........................................................................................................................................5-3

Controls and indicators .....................................................................................................................................5-4

Basic troubleshooting ........................................................................................................................................5-5

System circuit diagram ......................................................................................................................................5-8

Technical questions ............................................................................................................................................5-9

Parts ....................................................................................................................................................................5-10

Torch consumable configurations ...................................................................................................... 5-10

Torch parts ..............................................................................................................................................5-11

Power supply parts ............................................................................................................................... 5-11

Accessories ............................................................................................................................................5-12

powermax1000 Operator Manual vii

1

TABLE OF CONTENTS

viii powermax1000 Operator Manual

0

Hypertherm Plasma Systems 1-1

8-06

Section 1

SAFETY

In this section:

Recognize safety information ...................................................................................................1-2

Follow safety instructions .........................................................................................................1-2

Cutting can cause fire or explosion ..........................................................................................1-2

Electric shock can kill ...............................................................................................................1-3

Static electricity can damage circuit boards .............................................................................1-3

Toxic fumes can cause injury or death .....................................................................................1-4

A plasma arc can cause injury and burns.................................................................................1-5

Arc rays can burn eyes and skin ..............................................................................................1-5

Grounding safety ......................................................................................................................1-6

Compressed gas equipment safety..........................................................................................1-6

Gas cylinders can explode if damaged ....................................................................................1-6

Noise can damage hearing ......................................................................................................1-7

Pacemaker and hearing aid operation .....................................................................................1-7

A plasma arc can damage frozen pipes ...................................................................................1-7

Additional safety information ....................................................................................................1-7

Warning labels..........................................................................................................................1-8

1-2 Hypertherm Plasma Systems

11-98

SAFETY

RECOGNIZE SAFETY INFORMATION

The symbols shown in this section are

used to identify potential hazards. When you see a

safety symbol in this manual or on your machine,

understand the potential for personal injury, and

follow the related instructions to avoid the hazard.

FOLLOW SAFETY INSTRUCTIONS

Read carefully all safety messages in

this manual and safety labels on your

machine.

• Keep the safety labels on your machine in good

condition. Replace missing or damaged labels

immediately.

• Learn how to operate the machine and how to

use the controls properly. Do not let anyone

operate it without instruction.

• Keep your machine in proper working condition.

Unauthorized modifications to the machine may

affect safety and machine service life.

DANGER WARNING CAUTION

A signal word DANGER or WARNING is used with

a safety symbol. DANGER identifies the most

serious hazards.

• DANGER and WARNING safety labels are

located on your machine near specific hazards.

• WARNING safety messages precede related

instructions in this manual that may result in

injury or death if not followed correctly.

• CAUTION safety messages precede related

instructions in this manual that may result in

damage to equipment if not followed correctly.

Fire Prevention

• Be sure the area is safe before doing any

cutting. Keep a fire extinguisher nearby.

• Remove all flammables within 35 feet (10 m) of

the cutting area.

• Quench hot metal or allow it to cool before

handling or before letting it touch combustible

materials.

• Never cut containers with potentially flammable

materials inside – they must be emptied and

properly cleaned first.

• Ventilate potentially flammable atmospheres

before cutting.

• When cutting with oxygen as the plasma gas, an

exhaust ventilation system is required.

Explosion Prevention

• Do not use the plasma system if explosive dust

or vapors may be present.

• Do not cut pressurized cylinders, pipes, or any

closed container.

• Do not cut containers that have held combustible

materials.

CUTTING CAN CAUSE FIRE OR EXPLOSION

WARNING

Explosion Hazard

Argon-Hydrogen and Methane

Hydrogen and methane are flammable gases that

present an explosion hazard. Keep flames away

from cylinders and hoses that contain methane or

hydrogen mixtures. Keep flames and sparks away

from the torch when using methane or argonhydrogen plasma.

WARNING

Hydrogen Detonation with

Aluminum Cutting

• When cutting aluminum underwater, or with the

water touching the underside of the aluminum,

free hydrogen gas may collect under the

workpiece and detonate during plasma cutting

operations.

• Install an aeration manifold on the floor of the

water table to eliminate the possibility of hydrogen

detonation. Refer to the Appendix section of this

manual for aeration manifold details.

Hypertherm Plasma Systems 1-3

8-06

SAFETY

Touching live electrical parts can cause a fatal

shock or severe burn.

• Operating the plasma system completes an

electrical circuit between the torch and the

workpiece. The workpiece and anything touching

the workpiece are part of the electrical circuit.

• Never touch the torch body, workpiece or the

water in a water table when the plasma system is

operating.

Electric Shock Prevention

All Hypertherm plasma systems use high

voltage in the cutting process (200 to 400 VDC

are common). Take the following precautions

when operating this system:

• Wear insulated gloves and boots, and keep your

body and clothing dry.

• Do not stand, sit or lie on – or touch – any wet

surface when using the plasma system.

• Insulate yourself from work and ground using dry

insulating mats or covers big enough to prevent

any physical contact with the work or ground. If

you must work in or near a damp area, use

extreme caution.

• Provide a disconnect switch close to the power

supply with properly sized fuses. This switch

allows the operator to turn off the power supply

quickly in an emergency situation.

• When using a water table, be sure that it is

correctly connected to earth ground.

ELECTRIC SHOCK CAN KILL

• Install and ground this equipment according to

the instruction manual and in accordance with

national and local codes.

• Inspect the input power cord frequently for

damage or cracking of the cover. Replace a

damaged power cord immediately. Bare wiring

can kill.

• Inspect and replace any worn or damaged torch

leads.

• Do not pick up the workpiece, including the

waste cutoff, while you cut. Leave the workpiece

in place or on the workbench with the work cable

attached during the cutting process.

• Before checking, cleaning or changing torch

parts, disconnect the main power or unplug the

power supply.

• Never bypass or shortcut the safety interlocks.

• Before removing any power supply or system

enclosure cover, disconnect electrical input

power. Wait 5 minutes after disconnecting the

main power to allow capacitors to discharge.

• Never operate the plasma system unless the

power supply covers are in place. Exposed

power supply connections present a severe

electrical hazard.

• When making input connections, attach proper

grounding conductor first.

• Each Hypertherm plasma system is designed to

be used only with specific Hypertherm torches.

Do not substitute other torches which could

overheat and present a safety hazard.

Use proper precautions when handling printed

circuit boards.

STATIC ELECTRICITY CAN DAMAGE CIRCUIT BOARDS

• Store PC boards in anti-static containers.

• Wear a grounded wrist strap when handling

PC boards.

1-4 Hypertherm Plasma Systems

8-06

SAFETY

The plasma arc by itself is the heat source

used for cutting. Accordingly, although the

plasma arc has not been identified as a

source of toxic fumes, the material being cut

can be a source of toxic fumes or gases that

deplete oxygen.

Fumes produced vary depending on the

metal that is cut. Metals that may release

toxic fumes include, but are not limited to,

stainless steel, carbon steel, zinc

(galvanized), and copper.

In some cases, the metal may be coated

with a substance that could release toxic

fumes. Toxic coatings include, but are not

limited to, lead (in some paints), cadmium

(in some paints and fillers), and beryllium.

Gases produced by plasma cutting vary

based on the material to be cut and the

method of cutting, but may include ozone,

oxides of nitrogen, hexavalent chromium,

hydrogen, and other substances if such are

contained in or released by the material

being cut.

Caution should be taken to minimize

exposure to fumes produced by any

industrial process. Depending upon the

chemical composition and concentration of

the fumes (as well as other factors, such as

ventilation), there may be a risk of physical

illness, such as birth defects or cancer.

It is the responsibility of the equipment and

site owner to test the air quality in the area

where the equipment is used and to ensure

that the air quality in the workplace meets all

local and national standards and regulations.

The air quality level in any relevant

workplace depends on site-specific variables

such as:

TOXIC FUMES CAN CAUSE INJURY OR DEATH

• Table design (wet, dry, underwater).

• Material composition, surface finish, and

composition of coatings.

• Volume of material removed.

• Duration of cutting or gouging.

• Size, air volume, ventilation and filtration

of the work area.

• Personal protective equipment.

• Number of welding and cutting systems in

operation.

• Other site processes that may produce

fumes.

If the workplace must conform to national or

local regulations, only monitoring or testing

done at the site can determine whether the

site is above or below allowable levels.

To reduce the risk of exposure to fumes:

• Remove all coatings and solvents from the

metal before cutting.

• Use local exhaust ventilation to remove

fumes from the air.

• Do not inhale fumes. Wear an air-supplied

respirator when cutting any metal coated

with, containing, or suspected to contain

toxic elements.

• Assure that those using welding or cutting

equipment, as well as air-supplied

respiration devices, are qualified and

trained in the proper use of such

equipment.

• Never cut containers with potentially toxic

materials inside. Empty and properly clean

the container first.

• Monitor or test the air quality at the site as

needed.

• Consult with a local expert to implement a

site plan to ensure safe air quality.

Hypertherm Plasma Systems 1-5

5-02

SAFETY

Instant-On Torches

Plasma arc comes on immediately when the

torch switch is activated.

A PLASMA ARC CAN CAUSE INJURY AND BURNS

The plasma arc will cut quickly through gloves

and skin.

• Keep away from the torch tip.

• Do not hold metal near the cutting path.

• Never point the torch toward yourself or others.

Eye Protection Plasma arc rays produce intense

visible and invisible (ultraviolet and infrared) rays

that can burn eyes and skin.

• Use eye protection in accordance with applicable

national or local codes.

• Wear eye protection (safety glasses or goggles

with side shields, and a welding helmet) with

appropriate lens shading to protect your eyes

from the arc’s ultraviolet and infrared rays.

Lens Shade

Arc Current AWS (USA) ISO 4850

Up to 100 A No. 8 No. 11

100-200 A No. 10 No. 11-12

200-400 A No. 12 No. 13

Over 400 A No. 14 No. 14

ARC RAYS CAN BURN EYES AND SKIN

Skin Protection Wear protective clothing to

protect against burns caused by ultraviolet light,

sparks and hot metal.

• Gauntlet gloves, safety shoes and hat.

• Flame-retardant clothing to cover all exposed

areas.

• Cuffless trousers to prevent entry of sparks

and slag.

• Remove any combustibles, such as a butane

lighter or matches, from your pockets before

cutting.

Cutting Area Prepare the cutting area to reduce

reflection and transmission of ultraviolet light:

• Paint walls and other surfaces with dark colors to

reduce reflection.

• Use protective screens or barriers to protect

others from flash and glare.

• Warn others not to watch the arc. Use placards

or signs.

1-6 Hypertherm Plasma Systems

11-98

SAFETY

• Never lubricate cylinder valves or regulators

with oil or grease.

• Use only correct gas cylinders, regulators,

hoses and fittings designed for the specific

application.

• Maintain all compressed gas equipment and

associated parts in good condition.

• Label and color-code all gas hoses to identify

the type of gas in each hose. Consult applicable

national or local codes.

GAS CYLINDERS CAN

EXPLODE IF DAMAGED

COMPRESSED GAS EQUIPMENT SAFETY

Gas cylinders contain gas under high pressure.

If damaged, a cylinder can explode.

• Handle and use compressed gas cylinders in

accordance with applicable national or local

codes.

• Never use a cylinder that is not upright and

secured in place.

• Keep the protective cap in place over valve

except when the cylinder is in use or connected

for use.

• Never allow electrical contact between the

plasma arc and a cylinder.

• Never expose cylinders to excessive heat,

sparks, slag or open flame.

• Never use a hammer, wrench or other tool to

open a stuck cylinder valve.

Work Cable Attach the work cable securely to the

workpiece or the work table with good metal-tometal contact. Do not connect it to the piece that

will fall away when the cut is complete.

Work Table Connect the work table to an earth

ground, in accordance with appropriate national or

local electrical codes.

GROUNDING SAFETY

Input Power

• Be sure to connect the power cord ground wire

to the ground in the disconnect box.

• If installation of the plasma system involves

connecting the power cord to the power supply,

be sure to connect the power cord ground wire

properly.

• Place the power cord's ground wire on the stud

first, then place any other ground wires on top

of the power cord ground. Fasten the retaining

nut tightly.

• Tighten all electrical connections to avoid

excessive heating.

Hypertherm Plasma Systems 1-7

8-01

SAFETY

Prolonged exposure to noise from cutting or

gouging can damage hearing.

• Use approved ear protection when using

plasma system.

• Warn others nearby about the noise hazard.

Frozen pipes may be damaged or can burst if

you attempt to thaw them with a plasma torch.

NOISE CAN DAMAGE HEARING

A PLASMA ARC

CAN DAMAGE

FROZEN PIPES

Pacemaker and hearing aid operation can be

affected by magnetic fields from high currents.

Pacemaker and hearing aid wearers should

consult a doctor before going near any plasma

arc cutting and gouging operations.

To reduce magnetic field hazards:

• Keep both the work cable and the torch lead

to one side, away from your body.

• Route the torch leads as close as possible to

the work cable.

• Do not wrap or drape the torch lead or work

cable around your body.

• Keep as far away from the power supply as

possible.

PACEMAKER AND

HEARING AID OPERATION

ADDITIONAL SAFETY INFORMATION

1. ANSI Standard Z49.1,

Safety in Welding and Cutting,

American Welding Society, 550 LeJeune Road

P.O. Box 351020, Miami, FL 33135

2. ANSI Standard Z49.2,

Fire Prevention in the Use of Cutting

and Welding Processes,

American National Standards

Institute, 1430 Broadway, New York, NY 10018

3. ANSI Standard Z87.1,

Safe Practices for Occupation and

Educational Eye and Face Protection,

American National

Standards Institute, 1430 Broadway, New York, NY 10018

4. AWS F4.1,

Recommended Safe Practices for the Preparation

for Welding and Cutting of Containers and Piping That Have

Held Hazardous Substances,

American Welding Society,

550 LeJeune Road, P.O. Box 351040, Miami, FL 33135

5. AWS F5.2,

Recommended Safe Practices for Plasma Arc

Cutting,

American Welding Society, 550 LeJeune Road, P.O.

Box 351040, Miami, FL 33135

6. CGA Pamphlet P-1,

Safe Handling of Compressed Gases in

Cylinders,

Compressed Gas Association, 1235 Jefferson

Davis Highway, Arlington, VA 22202

7. CSA Standard W117.2,

Code for Safety in Welding and

Cutting,

Canadian Standards Association Standard Sales

178 Rexdale Boulevard, Rexdale, Ontario M9W 1R3,

Canada

8. NFPA Standard 51B,

Cutting and Welding Processes,

National Fire Protection Association, 470 Atlantic Avenue,

Boston, MA 02210

9. NFPA Standard 70–1978,

National Electrical Code,

National

Fire Protection Association, 470 Atlantic Avenue, Boston, MA

02210

10. OSHA,

Safety and Health Standards,

29FR 1910

U.S. Government Printing Office, Washington, D.C. 20402

1-8 Hypertherm Plasma Systems

SAFETY

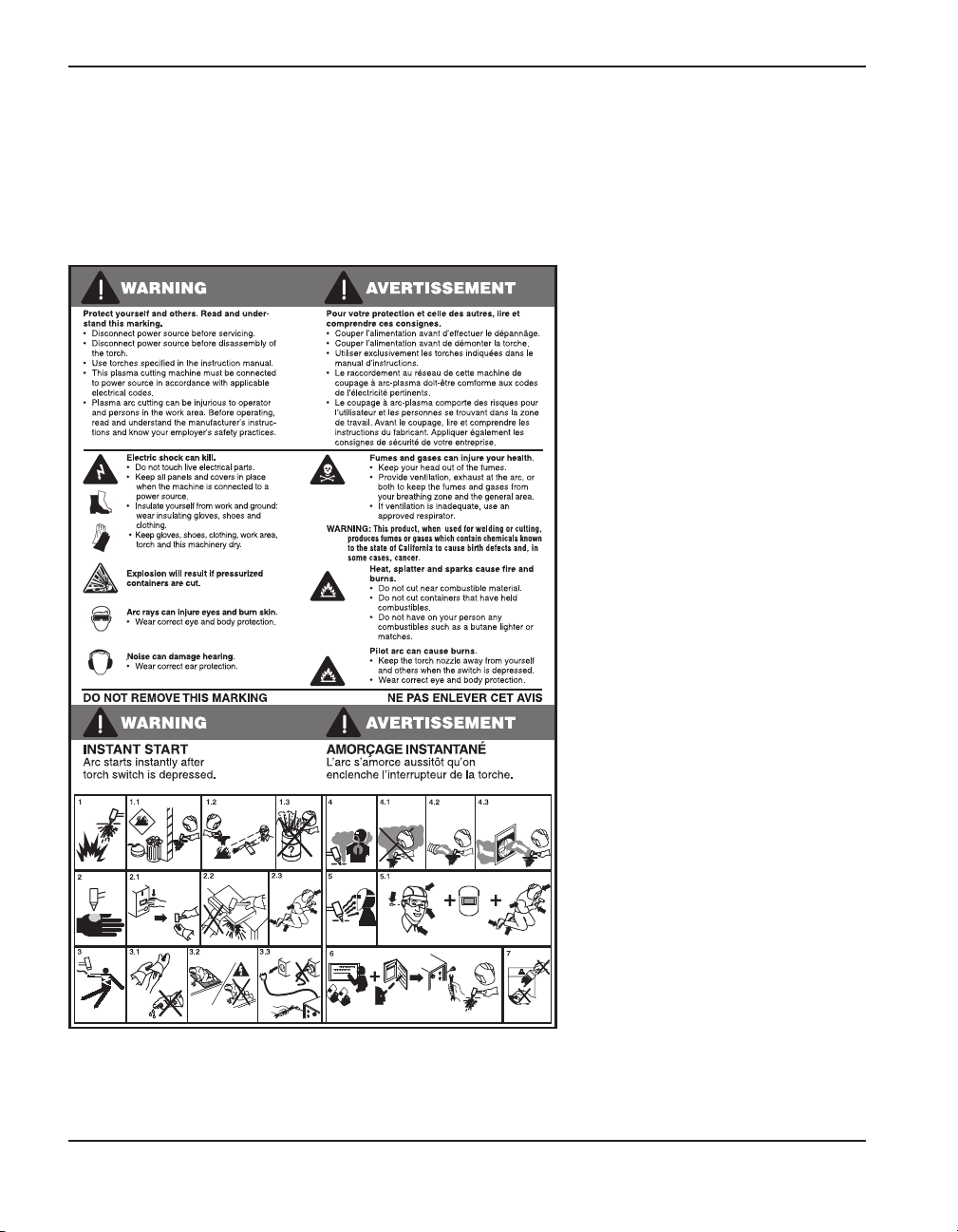

WARNING LABEL

This warning label is affixed to some power supplies. It is

important that the operator and maintenance technician

understand the intent of these warning symbols as

described. The numbered text corresponds to the numbered

boxes on the label.

1. Cutting sparks can cause

explosion or fire.

1.1 Keep flammables away from

cutting.

1.2 Keep a fire extinguisher nearby,

and have a watchperson ready to

use it.

1.3 Do not cut on any closed

containers.

2. The plasma arc can cause injury

and burns.

2.1 Turn off power before

disassembling torch.

2.2 Do not hold the material near

cutting path.

2.3 Wear complete body protection.

3. Electric shock from torch or wiring

can kill. Protect yourself from

electric shock.

3.1 Wear insulating gloves. Do not

wear wet or damaged gloves.

3.2 Insulate yourself from work and

ground.

3.3 Disconnect input plug or power

before working on machine.

4. Breathing cutting fumes can be

hazardous to your health.

4.1 Keep your head out of the fumes.

4.2 Use forced ventilation or local

exhaust to remove the fumes.

4.3 Use ventilating fan to remove the

fumes.

5. Arc rays can burn eyes and injure

skin.

5.1 Wear hat and safety glasses. Use

ear protection and button shirt

collar. Use welding helmet with

correct shade of filter. Wear

complete body protection.

6. Become trained and read the

instructions before working on the

machine or cutting.

7. Do not remove or paint over

(cover) warning labels.

110391 Rev A

8-06

Hypertherm Systèmes plasma 1a-1

Section 1a

SÉCURITÉ

Dans cette section :

Identifier les consignes de sécurité ........................................................................................1a-2

Suivre les instructions de sécurité..........................................................................................1a-2

Le coupage peut provoquer un incendie ou une explosion....................................................1a-2

Les chocs électriques peuvent être fatals ..............................................................................1a-3

L’électricité statique peut endommager les cartes de circuits imprimés.................................1a-3

Les vapeurs toxiques peuvent provoquer des blessures ou la mort ......................................1a-4

L’arc plasma peut provoquer des blessures ou des brûlures.................................................1a-5

Les rayons de l’arc peuvent brûler les yeux et la peau ..........................................................1a-5

Mise à la masse et à la terre ..................................................................................................1a-6

Sécurité des bouteilles de gaz comprimé...............................................................................1a-6

Les bouteilles de gaz comprimé peuvent exploser en cas de dommages .............................1a-6

Le bruit peut provoquer des problèmes auditifs .....................................................................1a-7

Pacemakers et prothèses auditives .......................................................................................1a-7

Un arc plasma peut endommager les tuyaux gelés ...............................................................1a-7

Étiquettes de sécurité.............................................................................................................1a-8

11-98

1a-2 Hypertherm Systèmes plasma

SÉCURITÉ

IDENTIFIER LES CONSIGNES

DE SÉCURITÉ

Les symboles indiqués dans cette section sont

utilisés pour identifier les risques éventuels. Si vous trouvez

un symbole de sécurité, que ce soit dans ce manuel ou sur

l’équipement, soyez conscient des risques de blessures et

suivez les instructions correspondantes afin d’éviter ces

risques.

SUIVRE LES INSTRUCTIONS

DE SÉCURITÉ

Lire attentivement toutes les consignes de

sécurité dans le présent manuel et sur les étiquettes de

sécurité se trouvant sur la machine.

• Les étiquettes de sécurité doivent rester lisibles.

Remplacer immédiatement les étiquettes manquantes ou

abîmées.

• Apprendre à faire fonctionner la machine et à utiliser

correctement les commandes. Ne laisser personne utiliser

la machine sans connaître son fonctionnement.

• Garder la machine en bon état. Des modifications non

autorisées sur la machine peuvent engendrer des

problèmes de sécurité et raccourcir la durée d’utilisation

de l’équipement.

DANGER AVERTISSEMENT PRÉCAUTION

Les signaux DANGER ou AVERTISSEMENT sont utilisés

avec un symbole de sécurité, DANGER correspondant aux

risques les plus sérieux.

• Les étiquettes de sécurité DANGER et AVERTISSEMENT

sont situées sur la machine pour signaler certains dangers

spécifiques.

• Les messages d’AVERTISSEMENT précèdent les

instructions d’utilisation expliquées dans ce manuel et

signalent les risques de blessures ou de mort au cas où

ces instructions ne seraient pas suivies correctement.

• Les messages de PRÉCAUTION précèdent les

instructions d’utilisation contenues dans ce manuel et

signalent que le matériel risque d’être endommagé si les

instructions ne sont pas suivies correctement.

Prévention des incendies

• Avant de commencer, s’assurer que la zone de coupage

ne présente aucun danger. Conserver un extincteur à

proximité.

• Éloigner toute matière inflammable à une distance d’au

moins 10 m du poste de coupage.

• Tremper le métal chaud ou le laisser refroidir avant de le

manipuler ou avant de le mettre en contact avec des

matériaux combustibles.

• Ne jamais couper des récipients pouvant contenir des

matières inflammables avant de les avoir vidés et

nettoyés correctement.

• Aérer toute atmosphère potentiellement inflammable

avant d’utiliser un système plasma.

• Lors de l’utilisation d’oxygène comme gaz plasma, un

système de ventilation par aspiration est nécessaire.

Prévention des explosions

• Ne pas couper en présence de poussière ou de vapeurs.

• Ne pas couper de bouteilles, de tuyaux ou autres

récipients fermés et pressurisés.

• Ne pas couper de récipients contenant des matières

combustibles.

LE COUPAGE PEUT PROVOQUER

UN INCENDIE OU UNE EXPLOSION

AVERTISSEMENT

Risque d’explosion

argon-hydrogène et méthane

L’hydrogène et le méthane sont des gaz inflammables et

potentiellement explosifs. Conserver à l’écart de toute

flamme les bouteilles et tuyaux contenant des mélanges à

base d’hydrogène ou de méthane. Maintenir toute flamme et

étincelle à l’écart de la torche lors de l’utilisation d’un plasma

d’argon-hydrogène ou de méthane.

AVERTISSEMENT

Détonation de l’hydrogène lors du

coupage de l’aluminium

• Lors du coupage de l’aluminium sous l’eau, ou si l’eau

touche la partie inférieure de la pièce d’aluminium, de

l’hydrogène libre peut s’accumuler sous la pièce à couper

et détonner lors du coupage plasma.

• Installer un collecteur d’aération au fond de la table à eau

afin d’éliminer les risques de détonation de l’hydrogène.

Se référer à l’annexe du manuel pour plus de

renseignements sur les collecteurs d’aération.

8-06

Toucher une pièce électrique sous tension peut provoquer

un choc électrique fatal ou des brûlures graves.

• La mise en fonctionnement du système plasma ferme un

circuit électrique entre la torche et la pièce à couper. La

pièce à couper et tout autre élément en contact avec

cette pièce font partie du circuit électrique.

• Ne jamais toucher le corps de la torche, la pièce à

couper ou l’eau de la table à eau pendant le

fonctionnement du système plasma.

Prévention des chocs électriques

Tous les systèmes plasma Hypertherm utilisent des hautes

tensions pour le coupage (souvent de 200 à 400 V). On

doit prendre les précautions suivantes quand on utilise le

système plasma :

• Porter des bottes et des gants isolants et garder le corps

et les vêtements au sec.

• Ne pas se tenir, s’asseoir ou se coucher sur une surface

mouillée, ni la toucher quand on utilise le système

plasma.

• S’isoler de la surface de travail et du sol en utilisant des

tapis isolants secs ou des couvertures assez grandes

pour éviter tout contact physique avec le travail ou le sol.

S’il s’avère nécessaire de travailler dans ou près d’un

endroit humide, procéder avec une extrême prudence.

• Installer un sectionneur avec fusibles appropriés, à

proximité de la source de courant. Ce dispositif permet à

l’opérateur d’arrêter rapidement la source de courant en

cas d’urgence.

• En cas d’utilisation d’une table à eau, s’assurer que cette

dernière est correctement mise à la terre.

LES CHOCS ÉLECTRIQUES PEUVENT ÊTRE FATALS

• Installer et mettre à la terre l’équipement selon les

instructions du présent manuel et conformément aux

codes électriques locaux et nationaux.

• Inspecter fréquemment le cordon d’alimentation primaire

pour s’assurer qu’il n’est ni endommagé, ni fendu.

Remplacer immédiatement un cordon endommagé.

Un câble dénudé peut tuer.

• Inspecter et remplacer les câbles de la torche qui sont

usés ou endommagés.

• Ne pas saisir la pièce à couper ni les chutes lors du

coupage. Laisser la pièce à couper en place ou sur la

table de travail, le câble de retour connecté lors du

coupage.

• Avant de vérifier, de nettoyer ou de remplacer les pièces

de la torche, couper l’alimentation ou débrancher la prise

de courant.

• Ne jamais contourner ou court-circuiter les verrouillages

de sécurité.

• Avant d’enlever le capot du système ou de la source de

courant, couper l’alimentation électrique. Attendre ensuite 5 minutes pour que les condensateurs se

déchargent.

• Ne jamais faire fonctionner le système plasma sans que

les capots de la source de courant ne soient en place.

Les raccords exposés de la source de courant sont

extrêmement dangereux.

• Lors de l’installation des connexions, attacher tout

d’abord la prise de terre appropriée.

• Chaque système plasma Hypertherm est conçu pour

être utilisé uniquement avec des torches Hypertherm

spécifiques. Ne pas utiliser des torches inappropriées

qui pourraient surchauffer et présenter des risques pour

la sécurité.

On doit prendre les précautions qui s’imposent quand on

manipule les circuits imprimés.

L’ÉLECTRICITÉ STATIQUE PEUT ENDOMMAGER

LES CARTES DE CIRCUITS IMPRIMÉS

• On doit ranger les cartes de circuits imprimés dans des

contenants antistatiques.

• On doit porter un bracelet antistatique quand on

manipule les cartes de circuits imprimés.

Hypertherm Systèmes plasma 1a-3

SÉCURITÉ

8-06

1a-4 Hypertherm Systèmes plasma

SÉCURITÉ

L’arc plasma est lui-même la source de chaleur utilisée

pour le coupage. Par conséquent, bien que l’arc plasma

n’ait pas été reconnu comme une source de vapeurs

toxiques, le matériau coupé peut être une source de

vapeurs ou de gaz toxiques qui épuisent l’oxygène.

Les vapeurs produites varient selon le métal coupé. Les

métaux qui peuvent dégager des vapeurs toxiques

comprennent, entre autres, l’acier inoxydable, l’acier au

carbone, le zinc (galvanisé) et le cuivre.

Dans certains cas, le métal peut être revêtu d’une

substance susceptible de dégager des vapeurs toxiques.

Les revêtements toxiques comprennent entre autres, le

plomb (dans certaines peintures), le cadmium (dans

certaines peintures et enduits) et le béryllium.

Les gaz produits par le coupage plasma varient selon le

matériau à couper et la méthode de coupage, mais ils

peuvent comprendre l’ozone, les oxydes d’azote, le

chrome hexavalent, l’hydrogène et autres substances

présentes dans le matériau coupé ou en émanent.

On doit prendre les précautions qui s’imposent pour

réduire au minimum l’exposition aux vapeurs produites par

tout processus industriel. Selon la composition chimique et

la concentration des vapeurs (ainsi que d’autres facteurs

comme la ventilation), il peut y avoir un risque de maladie

physique, comme des malformations ou le cancer.

Il incombe au propriétaire du matériel et du site de vérifier

la qualité de l’air dans le secteur où l’on utilise le matériel

et de s’assurer que la qualité de l’air sur les lieux de travail

répond aux normes et réglementation locales et nationales.

LES VAPEURS TOXIQUES PEUVENT PROVOQUER

DES BLESSURES OU LA MORT

Le niveau de qualité de l’air dans tout lieu de travail

dépend des variables propres au site comme :

• Type de table (humide, sèche, sous l’eau).

• Composition du matériau, fini de la surface et

composition des revêtements.

• Volume de matériau enlevé.

• Durée du coupage ou du gougeage.

• Dimensions, volume d’air, ventilation et filtration de la

zone de travail.

• Équipement de protection individuelle.

• Nombre de systèmes de soudage et de coupage en

fonctionnement.

• Autres procédés du site qui peuvent produire des

vapeurs.

Si les lieux de travail doivent être conformes aux

règlements nationaux ou locaux, seuls les contrôles ou les

essais effectués au site peuvent déterminer si celui-ci se

situe au-dessus ou au-dessous des niveaux admissibles.

Pour réduire le risque d’exposition aux vapeurs :

• Éliminer tout revêtement et solvant du métal avant le

coupage.

• Utiliser la ventilation d’extraction locale pour éliminer les

vapeurs de l’air..

• Ne pas inhaler les vapeurs. Porter un respirateur à

adduction d’air quand on coupe des métaux revêtus

d’éléments toxiques ou qui en contiennent ou sont

susceptibles d’en contenir.

• S’assurer que les personnes qui utilisent un matériel de

soudage ou de coupage ainsi que les dispositifs de

respiration par adduction d’air sont qualifiés et ont reçu

la formation sur la bonne utilisation d’un tel matériel.

• Ne jamais couper les contenants dans lesquels il peut y

avoir des matériaux toxiques. En premier lieu, vider et

nettoyer correctement le contenant.

• Contrôler ou éprouver la qualité de l’air au site selon les

besoins.

• Consulter un expert local pour mettre en œuvre un plan

du site afin d’assurer une qualité de l’air sûre.

5-02

Torches à allumage instantané

L’arc plasma s’allume immédiatement après que la torche

soit mise en marche.

L’ARC PLASMA PEUT PROVOQUER DES BLESSURES OU DES BRÛLURES

L’arc plasma coupe facilement les gants et la peau.

• Rester éloigné de l’extrémité de la torche.

• Ne pas tenir de métal près de la trajectoire de coupe.

• Ne jamais pointer la torche vers soi ou d’autres

personnes.

Protection des yeux Les rayons de l’arc plasma

produisent de puissants rayons visibles ou invisibles

(ultraviolets et infrarouges) qui peuvent brûler les yeux et

la peau.

• Utiliser des lunettes de sécurité conformément aux

codes locaux ou nationaux en vigueur.

• Porter des lunettes de protection (lunettes ou masque

muni d’écrans latéraux et encore masque de soudure)

avec des verres teintés appropriés pour protéger les

yeux des rayons ultraviolets et infrarouges de l’arc.

Puissance des

verres teintés

Courant de l’arc AWS (É.-U.) ISO 4850

Jusqu’à 100 A N

o

8N

o

11

100-200 A N

o

10 No11-12

200-400 A N

o

12 No13

Plus de 400 A N

o

14 No14

LES RAYONS DE L’ARC PEUVENT BRÛLER LES YEUX ET LA PEAU

Protection de la peau Porter des vêtements de sécurité

pour se protéger contre les brûlures que peuvent causer

les rayons ultraviolets, les étincelles et le métal brûlant :

• Gants à crispin, chaussures et casque de sécurité.

• Vêtements ignifuges couvrant toutes les parties

exposées du corps.

• Pantalon sans revers pour éviter que des étincelles ou

des scories puissent s’y loger.

• Avant le coupage, retirer de ses poches tout objet

combustible comme les briquets au butane ou les

allumettes.

Zone de coupage Préparer la zone de coupage afin de

réduire la réverbération et la transmission de la lumière

ultraviolette :

• Peindre les murs et autres surfaces de couleur sombre

pour réduire la réflexion de la lumière.

• Utiliser des écrans et autres dispositifs de protection afin

de protéger les autres personnes de la lumière et de la

réverbération.

• Prévenir les autres personnes de ne pas regarder l’arc.

Utiliser des affiches ou des panneaux.

Hypertherm Systèmes plasma 1a-5

SÉCURITÉ

11-98

1a-6 Hypertherm Systèmes plasma

SÉCURITÉ

• Ne jamais lubrifier les robinets des bouteilles ou les

régulateurs avec de l’huile ou de la graisse.

• Utiliser uniquement les bouteilles, régulateurs, tuyaux et

accessoires appropriés et conçus pour chaque

application spécifique.

• Entretenir l’équipement et les pièces d’équipement à gaz

comprimé afin de les garder en bon état.

• Étiqueter et coder avec des couleurs tous les tuyaux de

gaz afin d’identifier le type de gaz contenu dans chaque

tuyau. Se référer aux codes locaux ou nationaux en

vigueur.

LES BOUTEILLES DE

GAZ COMPRIMÉ

PEUVENT EXPLOSER

EN CAS DE DOMMAGES

SÉCURITÉ DES BOUTEILLES

DE GAZ COMPRIMÉ

Les bouteilles de gaz contiennent du gaz à haute pression.

Si une bouteille est endommagée, elle peut exploser.

• Manipuler et utiliser les bouteilles de gaz comprimé

conformément aux codes locaux ou nationaux.

• Ne jamais utiliser une bouteille qui n’est pas placée à la

verticale et bien assujettie.

• Le capuchon de protection doit être placé sur le robinet

sauf si la bouteille est en cours d’utilisation ou connectée

pour utilisation.

• Éviter à tout prix le contact électrique entre l’arc plasma

et une bouteille.

• Ne jamais exposer des bouteilles à une chaleur

excessive, aux étincelles, aux scories ou aux flammes

nues.

• Ne jamais utiliser des marteaux, des clés ou d’autres

outils pour débloquer le robinet des bouteilles.

Câble de retour Bien fixer le câble de retour (ou de

masse) à la pièce à couper ou à la table de travail de

façon à assurer un bon contact métal-métal. Ne pas fixer

le câble de retour à la partie de la pièce qui doit se

détacher.

Table de travail Raccorder la table de travail à la terre,

conformément aux codes de sécurité locaux ou nationaux

appropriés.

MISE À LA MASSE ET À LA TERRE

Alimentation

• S’assurer que le fil de terre du cordon d’alimentation est

connecté à la terre dans le coffret du sectionneur.

• S’il est nécessaire de brancher le cordon d’alimentation

à la source de courant lors de l’installation du système,

s’assurer que le fil de terre est correctement branché.

• Placer tout d’abord le fil de terre du cordon

d’alimentation sur le plot de mise à la terre puis placer

les autres fils de terre par-dessus. Bien serrer l’écrou de

retenue.

• S’assurer que toutes les connexions sont bien serrées

pour éviter la surchauffe.

8-01

Une exposition prolongée au bruit du coupage ou du

gougeage peut provoquer des problèmes auditifs.

• Utiliser un casque de protection homologué lors de

l’utilisation du système plasma.

• Prévenir les personnes aux alentours des risques

encourus en cas d’exposition au bruit.

Les tuyaux gelés peuvent être endommagés ou éclater si

l'on essaie de les dégeler avec une torche plasma.

LE BRUIT PEUT PROVOQUER

DES PROBLÈMES AUDITIFS

UN ARC PLASMA PEUT

ENDOMMAGER LES

TUYAUX GELÉS

Les champs magnétiques produits par les courants à

haute tension peuvent affecter le fonctionnement des

prothèses auditives et des pacemakers. Les personnes

portant ce type d’appareil doivent consulter un médecin

avant de s’approcher d’un lieu où s’effectue le coupage

ou le gougeage plasma.

Pour réduire les risques associés aux champs

magnétiques :

• Garder loin de soi et du même côté du corps le câble

de retour et le faisceau de la torche.

• Faire passer le faisceau de la torche le plus près

possible du câble de retour.

• Ne pas s’enrouler le faisceau de la torche ou le câble

de retour autour du corps.

• Se tenir le plus loin possible de la source de courant.

PACEMAKERS ET

PROTHÈSES AUDITIVES

Hypertherm Systèmes plasma 1a-7

SÉCURITÉ

1a-8 Hypertherm Systèmes plasma

SÉCURITÉ

Étiquette de sécurité

Cette étiquette est affichée sur la source de courant. Il est important que

l’utilisateur et le technicien de maintenance comprennent la signification

des symboles de sécurité. Les numéros de la liste correspondent aux

numéros des images.

1. Les étincelles produites par le coupage

peuvent provoquer une explosion ou un

incendie.

1.1 Pendant le coupage, éloigner toute

matière inflammable.

1.2 Conserver un extincteur à proximité et

s’assurer qu’une personne soit prête à

l’utiliser.

1.3 Ne jamais couper de récipients fermés.

2. L’arc plasma peut provoquer des

blessures et des brûlures.

2.1 Couper l’alimentation avant de démonter

la torche.

2.2 Ne pas tenir la surface à couper près de

la trajectoire de coupe.

2.3 Porter des vêtements de protection

couvrant tout le corps.

3. Un choc électrique causé par la torche

ou les câbles peut être fatal. Se protéger

contre les risques de chocs électriques.

3.1 Porter des gants isolants. Ne pas porter

de gants mouillés ou abîmés.

3.2 S’isoler de la surface de travail et du sol.

3.3 Débrancher la prise ou la source de

courant avant de manipuler

l’équipement.

4. L’inhalation des vapeurs produites par le

coupage peut être dangereuse pour la

santé.

4.1 Garder le visage à l’écart des vapeurs.

4.2 Utiliser un système de ventilation par

aspiration ou d’échappement localisé

pour dissiper les vapeurs.

4.3 Utiliser un ventilateur pour dissiper les

vapeurs.

5. Les rayons de l’arc peuvent brûler les

yeux et provoquer des lésions de la

peau.

5.1 Porter un casque et des lunettes de

sécurité. Se protéger les oreilles et

porter une chemise dont le col peut être

déboutonné. Porter un casque de

soudure dont la protection filtrante est

suffisante. Porter des vêtements

protecteurs couvrant la totalité du corps.

6. Se former à la technique du coupage et

lire les instructions avant de manipuler

l’équipement ou de procéder au

coupage.

7. Ne pas retirer ou peindre (recouvrir) les

étiquettes de sécurité.

110391 Rev A

8-06

Hypertherm Sistemas plasma 1b-1

Seccíon 1b

SEGURIDAD

En esta sección:

Reconocimiento de información de seguridad .......................................................................1b-2

Siga las instrucciones de seguridad.......................................................................................1b-2

Los cortes pueden provocar incendios o explosiones............................................................1b-2

El choque eléctrico puede provocar la muerte .......................................................................1b-3

Electricidad estática puede dañar tablillas de circuito............................................................1b-3

Humos tóxicos pueden causar lesiones o muerte..................................................................1b-4

El arco de plasma puede causar lesiones y quemaduras......................................................1b-5

Los rayos del arco pueden producir quemaduras en los ojos y en la piel..............................1b-5

Seguridad de toma a tierra.....................................................................................................1b-6

Seguridad de los equipos de gas comprimido .......................................................................1b-6

Los cilindros de gas pueden explotar si están dañados.........................................................1b-6