Page 1

FASTLaser®Cutting Heads

LH2125/LH2100

®

Instruction Manual

810250 – Revision 1

Page 2

LH2125/LH2100

FASTLaser Cutting Heads

Instruction Manual

Part Number – 810250

Revision 1 – January, 2008

© Copyright 2008 Hypertherm, Inc.

All Rights Reserved

Hypertherm and FAST Laser are trademarks of Hypertherm, Inc.

and may be registered in the United States and/or other countries

Hypertherm, Inc.

Hanover, NH USA

www.hypertherm.com

Page 3

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

Hypertherm Automation

5 Technology Drive, Suite 300

West Lebanon, NH 03784 USA

603-298-7970 Tel

603-298-7977 Fax

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D-63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm (S) Pte Ltd.

No. 19 Kaki Bukit Road 2

K.B. Warehouse Complex

Singapore 417847, Republic of Singapore

65 6 841 2489 Tel

65 6 841 2490 Fax

65 6 841 2489 (Technical Service)

Hypertherm (Shanghai) Trading Co., Ltd.

Unit 1308-09, Careri Building

432 West Huai Hai Road

Shanghai, 200052

PR China

86-21 5258 3330/1 Tel

86-21 5258 3332 Fax

France (Representative office)

15 Impasse des Rosiers

95610 Eragny, France

00 800 3324 9737 Tel

00 800 4973 7329 Fax

Hypertherm S.r.l.

Via Torino 2

20123 Milano, Italia

39 02 725 46 312 Tel

39 02 725 46 400 Fax

39 02 725 46 314 (Technical Service)

Hypertherm Europe B.V.

Vaartveld 9

4704 SE Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 165 596900 Tel (Technical Service)

00 800 49 73 7843 Tel (Technical Service)

Hypertherm Japan Ltd.

801 Samty Will Building

2-40 Miyahara 1-Chome,

Yodogawa-ku, Osaka

532-0003, Japan

81 6 6170 2020 Tel

81 6 6170 2015 Fax

HYPERTHERM BRASIL LTDA.

Avenida Doutor Renato de

Andrade Maia 350

Parque Renato Maia

CEP 07114-000

Guarulhos, SP Brasil

55 11 6409 2636 Tel

55 11 6408 0462 Fax

Hypertherm

Branch of Hypertherm, UK, UC

PO Box 244

Wigan, Lancashire, England WN8 7WU

00 800 3324 9737 Tel

00 800 4973 7329 Fax

00 800 4973 7843 (Technical Service)

1/19/07

Page 4

ELECTROMAGNETIC COMPATIBILITY (EMC)

Hypertherm i

6-07

EMC Introduction

Hypertherm’s CE-marked equipment is built in compliance

with standard EN60974-10. The equipment should be

installed and used in accordance with the information

below to achieve electromagnetic compatibility.

The limits required by EN60974-10 may not be adequate

to completely eliminate interference when the affected

equipment is in close proximity or has a high degree of

sensitivity. In such cases it may be necessary to use other

measures to further reduce interference.

This cutting equipment is designed for use only in an

industrial environment.

Installation and use

The user is responsible for installing and using the plasma

equipment according to the manufacturer’s instructions.

If electromagnetic disturbances are detected then it shall

be the responsibility of the user to resolve the situation

with the technical assistance of the manufacturer. In some

cases this remedial action may be as simple as earthing

the cutting circuit, see Earthing of Workpiece. In other

cases it could involve constructing an electromagnetic

screen enclosing the power source and the work

complete with associated input filters. In all cases

electromagnetic disturbances must be reduced to the

point where they are no longer troublesome.

Assessment of area

Before installing the equipment the user shall make an

assessment of potential electromagnetic problems in the

surrounding area. The following shall be taken into

account:

a. Other supply cables, control cables, signalling and

telephone cables; above, below and adjacent to the

cutting equipment.

b. Radio and television transmitters and receivers.

c. Computer and other control equipment.

d. Safety critical equipment, for example guarding of

industrial equipment.

e. Health of the people around, for example the use of

pacemakers and hearing aids.

f. Equipment used for calibration or measurement.

g. Immunity of other equipment in the environment. User

shall ensure that other equipment being used in the

environment is compatible. This may require additional

protection measures.

h. Time of day that cutting or other activities are to be

carried out.

The size of the surrounding area to be considered will

depend on the structure of the building and other

activities that are taking place. The surrounding area may

extend beyond the boundaries of the premises.

Methods of reducing emissions

Mains supply

Cutting equipment must be connected to the mains

supply according to the manufacturer’s recommendations.

If interference occurs, it may be necessary to take

additional precautions such as filtering of the mains supply.

Consideration should be given to shielding the supply

cable of permanently installed cutting equipment, in

metallic conduit or equivalent. Shielding should be

electrically continuous throughout its length. The shielding

should be connected to the cutting mains supply so that

good electrical contact is maintained between the conduit

and the cutting power source enclosure.

Maintenance of cutting equipment

The cutting equipment must be routinely maintained

according to the manufacturer’s recommendations. All

access and service doors and covers should be closed

and properly fastened when the cutting equipment is in

operation. The cutting equipment should not be modified

in any way except for those changes and adjustments

covered in the manufacturer’s instructions. In particular,

the spark gaps of arc striking and stabilizing devices

should be adjusted and maintained according to the

manufacturer’s recommendations.

Cutting cables

The cutting cables should be kept as short as possible

and should be positioned close together, running at or

close to the floor level.

Equipotential bonding

Bonding of all metallic components in the cutting

installation and adjacent to it should be considered.

However, metallic components bonded to the workpiece

will increase the risk that the operator could receive a

shock by touching these metallic components and the

electrode (nozzle for laser heads) at the same time.

The operator should be insulated from all such bonded

metallic components.

Page 5

0

ELECTROMAGNETIC COMPATIBILITY (EMC)

ii Hypertherm

8-06

Earthing of workpiece

Where the workpiece is not bonded to earth for electrical

safety, nor connected to earth because of its size and

position, for example, ship’s hull or building steelwork, a

connection bonding the workpiece to earth may reduce

emissions in some, but not all instances. Care should be

taken to prevent the earthing of the workpiece increasing

the risk of injury to users, or damage to other electrical

equipment. Where necessary, the connection of the

workpiece to earth should be made by a direct

connection to the workpiece, but in some countries where

direct connection is not permitted, the bonding should be

achieved by suitable capacitances selected according to

national regulations.

Note: the cutting circuit may or may not be earthed for

safety reasons. Changing the earthing arrangements

should only be authorized by a person who is competent

to assess whether the changes will increase the risk of

injury, for example, by allowing parallel cutting current

return paths which may damage the earth circuits of other

equipment. Further guidance is given in IEC/TS 62081

Arc Welding Equipment Installation and Use.

Screening and shielding

Selective screening and shielding of other cables

and equipment in the surrounding area may alleviate

problems of interference. Screening of the entire

plasma cutting installation may be considered for

special applications.

Page 6

0

WARRANTY

Hypertherm iii

6-07

Attention

Genuine Hypertherm parts are the factory-recommended

replacement parts for your Hypertherm system. Any

damage caused by the use of other than genuine

Hypertherm parts may not be covered by the

Hypertherm warranty.

You are responsible for the safe use of the Product.

Hypertherm does not and cannot make any guarantee

or warranty regarding the safe use of the Product in

your environment.

General

Hypertherm, Inc. warrants that its Products shall be free

from defects in materials and workmanship, if Hypertherm

is notified of a defect (i) with respect to the power supply

within a period of two (2) years from the date of its delivery

to you, with the exception of Powermax Series power

supplies, which shall be within a period of three (3) years

from the date of delivery to you, and (ii) with respect to the

torch and leads within a period of one (1) year from its date

of delivery to you, and with respect to torch lifter

assemblies within a period of one (1) year from its date of

delivery to you, and with respect to laser heads within a

period of one (1) year from its date of delivery to you. This

warranty shall not apply to any Product which has been

incorrectly installed, modified, or otherwise damaged.

Hypertherm, at its sole option, shall repair, replace, or

adjust, free of charge, any defective Products covered by

this warranty which shall be returned with Hypertherm’s

prior authorization (which shall not be unreasonably

withheld), properly packed, to Hypertherm’s place of

business in Hanover, New Hampshire, or to an authorized

Hypertherm repair facility, all costs, insurance and freight

prepaid. Hypertherm shall not be liable for any repairs,

replacement, or adjustments of Products covered by this

warranty, except those made pursuant to this paragraph or

with Hypertherm’s prior written consent. The warranty

above is exclusive and is in lieu of all other

warranties, express, implied, statutory, or otherwise

with respect to the Products or as to the results

which may be obtained therefrom, and all implied

warranties or conditions of quality or of

merchantability or fitness for a particular purpose or

against infringement. The foregoing shall constitute

the sole and exclusive remedy for any breach by

Hypertherm of its warranty. Distributors/OEMs may

offer different or additional warranties, but Distributors/

OEMs are not authorized to give any additional warranty

protection to you or make any representation to you

purporting to be binding upon Hypertherm.

Certification test marks

Certified products are identified by one or more

certification test marks from accredited testing laboratories.

The certification test marks are located on or near the data

plate. Each certification test mark means that the product

and its safety-critical components conform to the relevant

national safety standards as reviewed by that testing

laboratory. Hypertherm places a certification test mark on

its products only after that product is manufactured with

safety-critical components that have been authorized by the

accredited testing laboratory.

Once the product has left the Hypertherm factory, the

certification test marks are invalidated if any of the following

occurs:

• The product is significantly modified in a manner that

creates a hazard or non-conformance.

• Safety-critical components are replaced with

unauthorized spare parts.

• Any unauthorized assembly or accessory that uses or

generates a hazardous voltage is added.

• There is any tampering with a safety circuit or other

feature that is designed into the product as part of the

certification.

CE marking constitutes a manufacturer’s declaration of

conformity to applicable European directives and

standards. Only those versions of Hypertherm products

with a CE Marking located on or near the data plate have

been tested for compliance with the European Low Voltage

Directive and the European EMC Directive. EMC filters

needed to comply with the European EMC Directive are

incorporated within versions of the power supply with a

CE Marking.

Patent indemnity

Except only in cases of products not manufactured by

Hypertherm or manufactured by a person other than

Hypertherm not in strict conformity with Hypertherm’s

specifications and in cases of designs, processes,

formulae, or combinations not developed or purported to

be developed by Hypertherm, Hypertherm will defend or

settle, at its own expense, any suit or proceeding brought

against you alleging that the use of the Hypertherm

product, alone and not in combination with any other

product not supplied by Hypertherm, infringes any patent of

any third party. You shall notify Hypertherm promptly upon

learning of any action or threatened action in connection

with any such alleged infringement, and Hypertherm’s

Page 7

0

WARRANTY

iv Hypertherm

6-07

obligation to indemnify shall be conditioned upon

Hypertherm’s sole control of, and the indemnified party’s

cooperation and assistance in, the defense of the claim.

Limitation of liability

In no event shall Hypertherm be liable to any person

or entity for any incidental, consequential, indirect,

or punitive damages (including but not limited to

lost profits) regardless of whether such liability is

based on breach of contract, tort, strict liability,

breach of warranties, failure of essential purpose or

otherwise and even if advised of the possibility of

such damages.

Liability cap

In no event shall Hypertherm’s liability, whether such

liability is based on breach of contract, tort, strict

liability, breach of warranties, failure of essential

purpose or otherwise, for any claim action suit or

proceeding arising out of or relating to the use of

the Products exceed in the aggregate the amount

paid for the Products that gave rise to such claim.

Insurance

At all times you will have and maintain insurance in such

quantities and types, and with coverage sufficient and

appropriate to defend and to hold Hypertherm harmless

in the event of any cause of action arising from the use of

the Products.

National and Local codes

National and Local codes governing plumbing and

electrical installation shall take precedent over any

instructions contained in this manual. In no event shall

Hypertherm be liable for injury to persons or property

damage by reason of any code violation or poor work

practices.

Transfer of rights

You may transfer any remaining rights you may have

hereunder only in connection with the sale of all or

substantially all of your assets or capital stock to a

successor in interest who agrees to be bound by all of the

terms and conditions of this Warranty.

Proper disposal of Hypertherm

products

Hypertherm plasma cutting systems, like all electronic

products, may contain materials or components, such as

printed circuit boards, that cannot be discarded with

ordinary waste. It is your responsibility to dispose of any

Hypertherm product or component part in an

environmentally acceptable manner according to national

and local codes.

• In the United States, check all federal, state, and local

laws.

• In the European Union, check the EU directives, national,

and local laws. For more information, visit

www.hypertherm.com/weee.

• In other countries, check national and local laws.

Page 8

TABLE OF CONTENTS

1

LH2125/LH2100 Laser Head Instruction Manual v

Electromagnetic Compatibility (EMC) ...................................................................................................................................i

Warranty.......................................................................................................................................................................................iii

Section 1 Safety...................................................................................................................................................................1-1

Recognize safety information...................................................................................................................................................................1-2

Follow safety instructions .........................................................................................................................................................................1-2

Cutting can cause fire or explosion........................................................................................................................................................1-2

Radiation hazard.........................................................................................................................................................................................1-2

Electric shock can kill................................................................................................................................................................................1-3

Cutting can produce toxic fumes............................................................................................................................................................1-3

A laser can cause injury and burns ........................................................................................................................................................1-3

A laser can burn eyes and skin ...............................................................................................................................................................1-4

Grounding safety........................................................................................................................................................................................1-4

Pacemaker and hearing aid operation...................................................................................................................................................1-4

Section 2 Specifications....................................................................................................................................................2-1

Cutting head................................................................................................................................................................................................2-2

Requirements ..............................................................................................................................................................................................2-2

Electrical ...........................................................................................................................................................................................2-2

Purge gas...........................................................................................................................................................................................2-2

Cutting gas........................................................................................................................................................................................2-2

Coolant requirements......................................................................................................................................................................2-2

Section 3 Installation..........................................................................................................................................................3-1

Mounting dimensions ................................................................................................................................................................................3-2

Right side connections .............................................................................................................................................................................3-6

Single channel interface box installation ..............................................................................................................................................3-7

Controller cable connector information.......................................................................................................................................3-7

Connect cables ................................................................................................................................................................................3-7

Capacitive height sensor (CHS) interface box installation...............................................................................................................3-8

Controller cable connector information ......................................................................................................................................3-8

Connect cables ................................................................................................................................................................................3-8

Left side connections ................................................................................................................................................................................3-9

Lens travel..........................................................................................................................................................................................3-9

Color codes.......................................................................................................................................................................................3-9

Lens installation........................................................................................................................................................................................3-10

Alignment guides .....................................................................................................................................................................................3-11

Crosshair assembly.......................................................................................................................................................................3-11

Aperture assembly ........................................................................................................................................................................3-12

Section 4 Operation............................................................................................................................................................4-1

Operation safety .........................................................................................................................................................................................4-2

FAST Laser nozzles ....................................................................................................................................................................................4-3

Principles of operation ...................................................................................................................................................................4-3

FAST nozzle installation ..................................................................................................................................................................4-3

Inspect the baffle..............................................................................................................................................................................4-3

Page 9

TABLE OF CONTENTS

1

vi LH2125/LH2100 Laser Head Instruction Manual

Piercing.........................................................................................................................................................................................................4-4

Mild steel............................................................................................................................................................................................4-4

Stainless steel and aluminum........................................................................................................................................................4-4

Single channel interface adjustments....................................................................................................................................................4-5

Cut-error monitor..............................................................................................................................................................................4-5

Precision adjustments.....................................................................................................................................................................4-5

Capacitive height sensing ........................................................................................................................................................................4-7

Introduction........................................................................................................................................................................................4-7

Operation...........................................................................................................................................................................................4-8

Adjustment.........................................................................................................................................................................................4-8

Cut charts..................................................................................................................................................................................................4-10

Mild steel .........................................................................................................................................................................................4-10

Stainless steel................................................................................................................................................................................4-10

Focal position locations..........................................................................................................................................................................4-11

Maintenance..............................................................................................................................................................................................4-12

Drive mechanism ...........................................................................................................................................................................4-12

Inspect nozzle.................................................................................................................................................................................4-12

Inspect lens.....................................................................................................................................................................................4-12

Clean lens .......................................................................................................................................................................................4-13

Lens mounting – standard and pre-mounted options ..................................................................................................................4-14

Standard..........................................................................................................................................................................................4-14

Premounted ....................................................................................................................................................................................4-15

Lens centering................................................................................................................................................................................4-15

Troubleshooting (O2 cutting).................................................................................................................................................................4-16

Troubleshooting (N2 cutting) .................................................................................................................................................................4-18

Section 5 Parts List .............................................................................................................................................................5-1

Outside view................................................................................................................................................................................................5-2

Consumables ..............................................................................................................................................................................................5-3

Parts and accessories kits .......................................................................................................................................................................5-4

Single channel optics and lens adjustment screws ...........................................................................................................................5-5

Capacitive height sensor..........................................................................................................................................................................5-6

Lenses...........................................................................................................................................................................................................5-7

Apperture, crosshair and receiver assemblies.....................................................................................................................................5-8

Motor and timing belt.................................................................................................................................................................................5-9

Appendix A ZnSe LENS SAFETY DATA .........................................................................................................................a-1

Section I product identification.........................................................................................................................................................a-2

Section 2 Hazardous Ingredients.....................................................................................................................................................a-2

Section 3 Physical data......................................................................................................................................................................a-2

Section 4 Fire and explosion hazard data ......................................................................................................................................a-2

Section 5 Health hazard data............................................................................................................................................................a-3

Section 6 Reactivity data....................................................................................................................................................................a-4

Section 7 Disposal information.........................................................................................................................................................a-4

Section 8 Special Protection information.......................................................................................................................................a-4

Section 9 Special precautions..........................................................................................................................................................a-5

Page 10

Hypertherm 1-1

10/03

Section 1

SAFETY

In this section:

Recognize safety information...................................................................................................................................................................1-2

Follow safety instructions .........................................................................................................................................................................1-2

Cutting can cause fire or explosion........................................................................................................................................................1-2

Radiation hazard.........................................................................................................................................................................................1-2

Electric shock can kill................................................................................................................................................................................1-3

Cutting can produce toxic fumes............................................................................................................................................................1-3

A laser can cause injury and burns ........................................................................................................................................................1-3

A laser can burn eyes and skin ...............................................................................................................................................................1-4

Grounding safety........................................................................................................................................................................................1-4

Pacemaker and hearing aid operation...................................................................................................................................................1-4

Page 11

SAFETY

10/03

1-2 Hypertherm

RECOGNIZE SAFETY INFORMATION

The symbols shown in this section are used

to identify potential hazards. When you see a safety symbol

in this manual or on your machine, understand the potential

for personal injury, and follow the related instructions to

avoid the hazard.

FOLLOW SAFETY INSTRUCTIONS

Read carefully all safety messages in this manual and safety

labels on your machine.

• Keep the safety labels on your machine in good

condition. Replace missing or damaged labels

immediately.

• Learn how to operate the machine and how to use

the controls properly. Do not let anyone operate it without

instruction.

• Keep your machine in proper working condition.

Unauthorized modifications to the machine may affect

safety and machine service life.

DANGER WARNING CAUTION

A signal word DANGER or WARNING is used with a

safety symbol. DANGER identifies the most serious

hazards.

• DANGER and WARNING safety labels are located

on your machine near specific hazards.

• WARNING safety messages precede related instruc tions in this manual that may result in injury or death if

not followed correctly.

• CAUTION safety messages precede related

instructions in this manual that may result in damage

to equipment if not followed correctly.

Fire Prevention

• Be sure the area is safe before doing any cutting. Keep a fire extinguisher nearby.

• Remove all flammables within 35 feet (10 m) of the cutting area.

• Quench hot metal or allow it to cool before handling or before letting it touch combustible materials.

• Never cut containers with potentially flammable materials inside – they must be emptied and properly cleaned first.

• Ventilate potentially flammable atmospheres before cutting.

Explosion Prevention

• Do not use the laser system if explosive dust or vapors may be present.

• Do not cut pressurized cylinders, pipes, or any closed container.

• Do not cut containers that have held combustible materials.

CUTTING CAN CAUSE FIRE OR EXPLOSION

• Visible or invisible radiation (class IV) can be present when the laser head door is open.

• Avoid eye and skin exposure to direct and scattered radiation.

• Never look into the laser beam.

RADIATION HAZARD

Page 12

SAFETY

10/03

Hypertherm 1-3

The laser beam will cut quickly through gloves and skin.

• Keep away from the nozzle tip.

• Do not hold metal near the cutting path.

• Never point the laser toward yourself or others.

A LASER CAN CAUSE INJURY AND BURNS

Electric Shock Prevention

• Never touch the laser head, while in operation.

• Install and ground this equipment according to the instruction manual and in accordance with national or

local codes.

• Inspect the input power cord frequently for damage or cracking of the cover. Replace a damaged power cord

immediately. Bare wiring can kill.

• Before checking, cleaning or changing parts, disconnect the main power or unplug the power supply.

• When making input connections, attach proper grounding conductor first.

ELECTRIC SHOCK CAN KILL

Cutting can produce toxic fumes and gases that deplete

oxygen and cause injury or death.

• Keep the cutting area well ventilated or use an

approved air-supplied respirator.

• Do not cut in locations near degreasing, cleaning or

spraying operations. The vapors from certain

chlorinated solvents decompose to form phosgene

gas when exposed to ultraviolet radiation.

• Do not cut metal coated or containing toxic materi als,

such as zinc (galvanized), lead, cadmium or beryllium,

unless the area is well ventilated and the operator

CUTTING CAN PRODUCE TOXIC FUMES

wears an air-supplied respirator. The coatings and any

metals containing these elements can produce toxic

fumes when cut.

• Never cut containers with potentially toxic materials

inside – they must be emptied and properly

cleaned first.

• This product, when used for welding or cutting,

produces fumes or gases which contain chemicals

known to the State of California to cause birth defects

and, in some cases, cancer.

Page 13

SAFETY

5/04

1-4 Hypertherm

Eye Protection Lasers produce intense visible and

invisible (ultraviolet and infrared) rays that can burn eyes

and skin.

• Use eye protection in accordance with applicable

national or local codes.

• Wear eye protection (safety glasses or goggles with

side shields) with appropriate lens shading to protect

your eyes from ultraviolet and infrared rays.

• Reference laser system manufacturer and standard

BS EN 207:1999 for proper eye protection level.

A LASER CAN BURN EYES AND SKIN

Skin Protection Wear protective clothing to protect

against burns caused by ultraviolet light, sparks and hot

metal.

• Gauntlet gloves, safety shoes and hat.

• Flame-retardant clothing to cover all exposed areas.

• Cuffless trousers to prevent entry of sparks and slag.

• Remove any combustibles, such as a butane lighter or

matches, from your pockets before cutting.

Input Power

• If installation of the laser head involves connecting the power cord to the power supply, be sure to connect the

power cord ground wire properly.

• Tighten all electrical connections to avoid excessive heating.

• Follow system recommendations for grounding the workpiece.

GROUNDING SAFETY

Pacemaker and hearing aid operation can be affected by magnetic fields from high currents.

Pacemaker and hearing aid wearers should consult a doctor before going near any cutting equipment.

PACEMAKER AND HEARING AID OPERATION

DANGER

Never put fingers or hands between the lens assembly and the laser head enclosure. Moving parts can cause

severe crush injuries.

Page 14

LH2125/LH2100 Laser Head Instruction Manual 2-1

0

Section 2

SPECIFICATIONS

In this section:

Cutting head................................................................................................................................................................................................2-2

Requirements ..............................................................................................................................................................................................2-2

Electrical ...........................................................................................................................................................................................2-2

Purge gas...........................................................................................................................................................................................2-2

Cutting gas........................................................................................................................................................................................2-2

Coolant requirements......................................................................................................................................................................2-2

Page 15

1

SPECIFICATIONS

2-2 LH2125/LH2100 Laser Head Instruction Manual

Cutting head

This manual provides the information needed to install, operate, and maintain the LH2125 and LH2100 laser cutting

heads. The LH2125/2100 is designed to process material with a CO2laser cutting system. Lens position is controlled

by a servo motor for precise and repeatable location of the focal position, relative to the cutting nozzle. The LH2100

accepts 2" (50.8 mm) diameter optics with focal lengths of 7.5" and 10" (190.5 mm and 254 mm).The LH2125 accepts

2" (50.8 mm) diameter optics with focal lengths of 7.5", 10" and 12.5" (190.5 mm, 254 mm and 317.5 mm).

Requirements

Electrical:

Motor ..................................................................................................................System dependent

Encoder..............................................................................................................System dependent

Sensor................................................................................................................9 – 36 VDC, 2 Watts

Capacitive interface.........................................................................................9 – 36 VDC, 5 Watts

Purge gas: air or nitrogen

Gas quality ........................................................................................................Clean, dry and oil-free

Flow rate ............................................................................................................2 liters/minute

The customer must provide a regulated gas supply capable of delivering at a pressure of 1.4 bar (20 psig) to the laser

head.

Cutting gas: air, oxygen, nitrogen

Maximum system pressure ............................................................................27.5 bar (400 psi)*

Coolant requirements:

Coolant type......................................................................................................Water

Water purity.......................................................................................................200 kΩ – cm

Flow rate ............................................................................................................9 liters/hour (2.4 gallons/hour)

Pressure ............................................................................................................4.8 bar (70 psi) maximum

Note: Use purified water as coolant in order to prevent corrosion in the coolant system. The hardness

of the water should be between 0.2 and 8.5 ppm. If using a conductivity meter to measure

water purity, the recommended level is between 0.5 and 5 µ Siemens/cm at 25° C (77° F).

*Maximum pressure is determined by the individual lens used. Check with the lens manufacturer for pressure rating.

Hypertherm lenses are rated for 20.7 bar (300 psi).

Page 16

LH2125/LH2100 Laser Head Instruction Manual 3-1

1

Section 3

INSTALLATION

In this section:

Mounting dimensions ................................................................................................................................................................................3-2

Right side connections .............................................................................................................................................................................3-6

Single-channel interface box installation ..............................................................................................................................................3-7

Controller cable connector information.......................................................................................................................................3-7

Connect cables ................................................................................................................................................................................3-7

Capacitive height-sensor (CHS) interface box installation...............................................................................................................3-8

Controller cable connector information ......................................................................................................................................3-8

Connect cables ................................................................................................................................................................................3-8

Left side connections ................................................................................................................................................................................3-9

Lens travel..........................................................................................................................................................................................3-9

Color codes.......................................................................................................................................................................................3-9

Lens installation........................................................................................................................................................................................3-10

Alignment guides .....................................................................................................................................................................................3-11

Cross-hair assembly .....................................................................................................................................................................3-11

Aperture assembly ........................................................................................................................................................................3-12

Page 17

0

INSTALLATION

3-2 LH2125/LH2100 Laser Head Instruction Manual

9.1 Kgs

20 Lbs

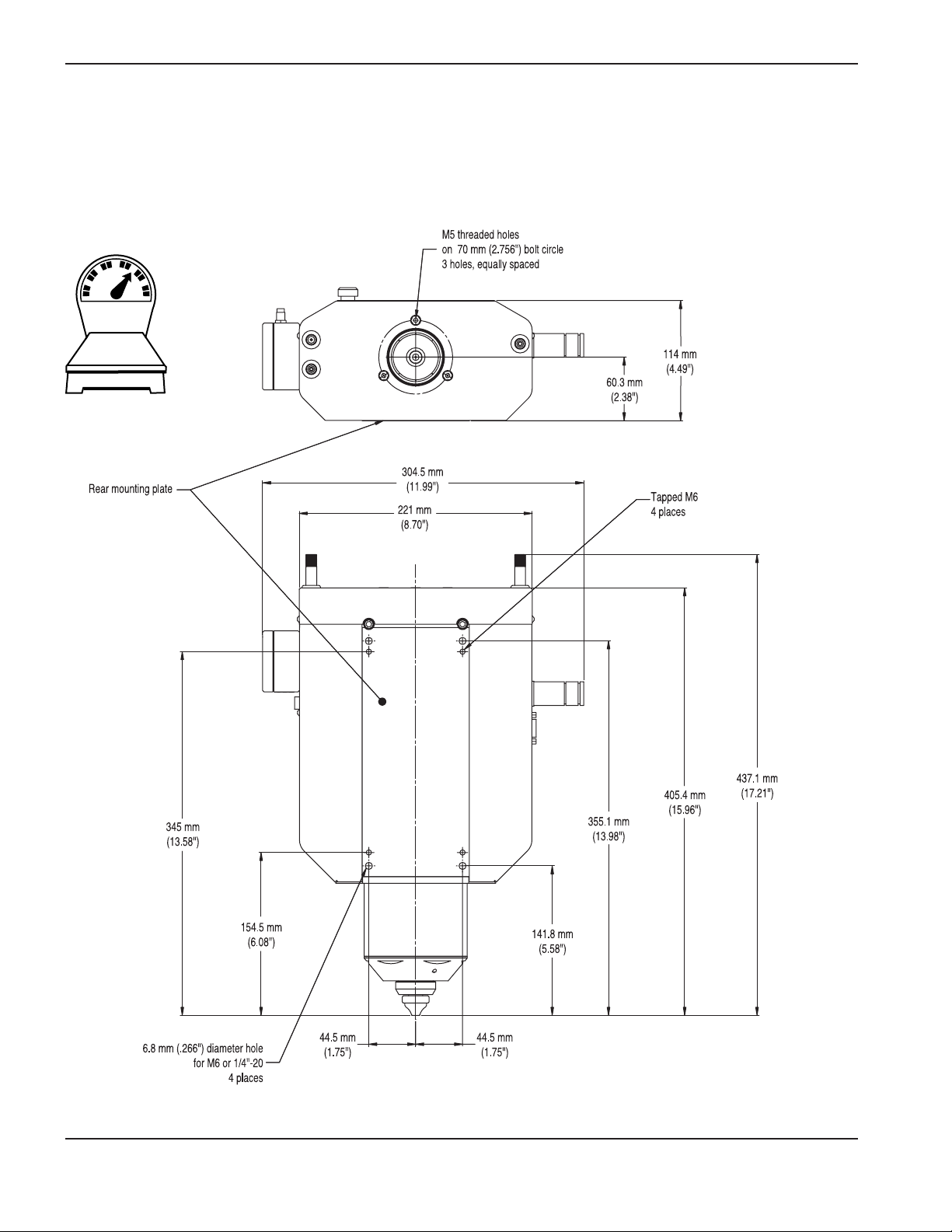

Mounting dimensions

Note: Customer is responsible for breakaway collision protection.

LH2125

Page 18

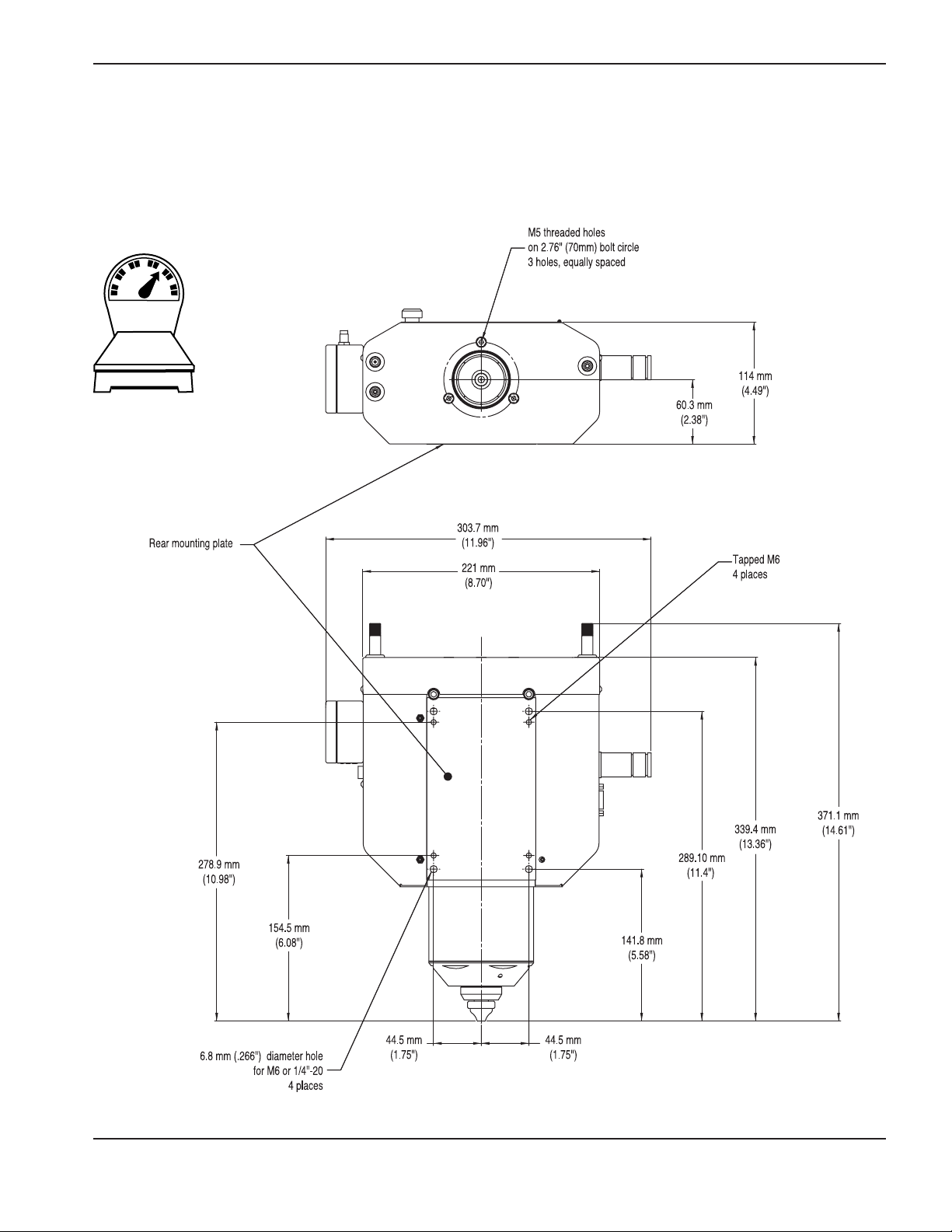

LH2100

7.7 Kgs

17 Lbs

0

INSTALLATION

LH2125/LH2100 Laser Head Instruction Manual 3-3

Page 19

1

INSTALLATION

3-4 LH2125/LH2100 Laser Head Instruction Manual

0.54 Kgs

1.2 Lbs

Capacitive height sensor – interface box

Page 20

1

INSTALLATION

LH2125/LH2100 Laser Head Instruction Manual 3-5

0.64 Kgs

1.4 Lbs

single-channel interface box

Page 21

1

INSTALLATION

3-6 LH2125/LH2100 Laser Head Instruction Manual

Right side connections

single-channel interface (SC):

box and cable

Capacitive height-sensing

amplifier

Coolant water OUT:

1/8" NPT, internal thread

Coolant water IN:

1/8" NPT, internal thread

Anti-spatter IN:

1/8" NPT, external thread

Pressure port:

1/8" NPT, external thread

Capacitive height sensing interface (CHS):

box and cable

Page 22

single-channel interface box installation

The single-channel interface box provides 3 independent optically isolated outputs. Outputs can be used by the

controller to detect piercing and cutting operations.

Controller cable connector information (9 pin D-Sub)

J1 pin-outs (Output To Controller)

Output Circuit

+ Output

+ Output

MOC8050

If = 2mA

Connect cables

Controller cable – 9 pin cable to controller

Sensor cable – interface box to laser head

Pin Wire

Number Color Description

1 Red Voltage in+ (9-36 VDC, 2 watts maximum)

2 Black Voltage in3 White Cut error +

4 Green Cut error 5 Blue Continuous wave pierce complete +

6 Brown Continuous wave Pierce complete 7 Orange Pulsed pierce complete +

8 Yellow Pulsed pierce complete 9 Shield Electromagnetic protection (earth ground)

1

INSTALLATION

LH2125/LH2100 Laser Head Instruction Manual 3-7

Note: Nominal voltage drop across output (+/-) is 1.2 volts. Current must be limited by input

resistance.

Page 23

Connect cables

Interface box (CHS) 15-pin cable to controller

Amplifier module to interface box (CHS)

1

INSTALLATION

3-8 LH2125/LH2100 Laser Head Instruction Manual

Capacitive height sensor (CHS) interface box installation

The amplifier module will be mounted to the laser head if the capacitive height sensing option was ordered. Choose a

suitable location for the CHS interface box.

Controller cable connector information (15 pin D-Sub)

Pin-outs (Output To Controller)

Note: Outputs are dry-contact relay outputs.

Pin Wire

Number Color Description

1 Blue Not used

2 Purple Not used

3 Brown Over-range +

4 Grey Over-range 5 Yellow Tip-touch +

6 Green Tip-touch 7 White Distance signal +

8 Orange Distance signal 9 Red + Volt input (9-36 VDC)

10 Black - Volt input

11-14 Not used

15 Shield Electromagnetic Protection (earth ground)

Power indicator

Over-range indicator

Under-range indicator

(not shown)

Page 24

Left side connections

Cutting gas:

1/8" NPT, internal thread

Purge gas:

1/8" NPT, external thread

1

INSTALLATION

LH2125/LH2100 Laser Head Instruction Manual 3-9

M12 thread

Interlock and limit switch connector

Pin 1

Pin 4 Pin 3

Pin 2

Pin # Description Wire color

1 Limit switch, home position Brown

2 Limit switch, home position White

3 Door interlock Blue

4 Door interlock Black

Lens travel

The lens travels 0.706 mm for each revolution of the motor.

Color codes

12.5" lens door and cartridge – Green*

10" lens door and cartridge – Blue

7.5" lens door and cartridge – Gold

Blanks – Black

*LH2125 only

Green

Blue

Gold

Page 25

0

INSTALLATION

3-10 LH2125/LH2100 Laser Head Instruction Manual

Lens installation

햲 Check condition of the lens seal before insertion. If there are any cuts or abrasions, replace seal. See Parts List.

햳 Orient lens tab in upward position, seal downward. Door will not close if lens is incorrectly oriented.

햴 Align lens tab with cut out in lens door to allow lens door to close.

햵 Close and latch lens door securely.

Note 1: Seal is designed to operate dry. Do not lubricate.

Note 2: Only 1 lens can be used at a time for a process. Empty lens bays must have a lens blank

installed before cutting. See Parts List for part number.

Lens tab in upward position

Seal (not shown)

햲햳

Lens door

Lens tab

Cut-out

햴

햵

12.5" lens bay

(LH2125 only)

10" lens bay

7.5" lens bay

Page 26

Alignment guides

Two alignment guides will help align the laser beam with the mechanical axis of the cutting head.

DANGER

Visible and invisible radiation (class IV) can be present when the laser head door is open. Avoid eye

and skin exposure to direct and scattered radiation. Always follow safety precautions set by the

manufacturer of the laser system.

1

INSTALLATION

LH2125/LH2100 Laser Head Instruction Manual 3-11

Cross-hair assembly

1. Insert the crosshair assembly into the upper lens bay.

Orient the tab straight out the front of the lens bay. The

diameter of crosshair assembly prevents the lens bay

door from closing all the way.

2. Insert a beam card or heavy paper into the lower lens

bay and pulse the laser beam to form an imprint. Be

careful not to ignite the card or the cavity will become

dirty and reduce the life of the lens.

3. Adjust beam delivery mirrors to center the beam with

the cross-hair.

Page 27

1

INSTALLATION

3-12 LH2125/LH2100 Laser Head Instruction Manual

Nozzle Adapter

Aperture assembly

1. Insert the aperture assembly into the upper lens bay.

Orient the tab straight out the front of the lens bay. The

diameter of the aperture assembly prevents the lens

bay door from closing all the way.

2. Remove the nozzle and place a beam card or tape over

the nozzle adapter opening. Pulse the beam to cause an

imprint but do not ignite the material. Check that the

imprint and the nozzle adapter opening are concentric.

If not, the beam axis and mechanical axis are incorrectly

aligned and need to be adjusted.

3. Make necessary adjustments and repeat the procedure

until the beam pattern is centered with the cross-hair

and the aperture imprint is concentric with the nozzle

adapter’s opening.

Page 28

LH2125/LH2100 Laser Head Instruction Manual 4-1

1

Section 4

OPERATION AND MAINTENANCE

In this section:

Operation safety .........................................................................................................................................................................................4-2

FAST Laser nozzles ....................................................................................................................................................................................4-3

Principles of operation ...................................................................................................................................................................4-3

FAST nozzle installation ..................................................................................................................................................................4-3

Inspect the baffle..............................................................................................................................................................................4-3

Piercing.........................................................................................................................................................................................................4-4

Mild steel............................................................................................................................................................................................4-4

Stainless steel and aluminum........................................................................................................................................................4-4

Single channel interface adjustments....................................................................................................................................................4-5

Cut-error monitor..............................................................................................................................................................................4-5

Precision adjustments.....................................................................................................................................................................4-5

Capacitive height sensing ........................................................................................................................................................................4-7

Introduction........................................................................................................................................................................................4-7

Operation...........................................................................................................................................................................................4-8

Adjustment.........................................................................................................................................................................................4-8

Cut charts..................................................................................................................................................................................................4-10

Mild steel .........................................................................................................................................................................................4-10

Stainless steel................................................................................................................................................................................4-10

Focal position locations..........................................................................................................................................................................4-11

Maintenance..............................................................................................................................................................................................4-12

Drive mechanism ...........................................................................................................................................................................4-12

Inspect nozzle.................................................................................................................................................................................4-12

Inspect lens.....................................................................................................................................................................................4-12

Clean lens .......................................................................................................................................................................................4-13

Lens mounting – standard and pre-mounted options ..................................................................................................................4-14

Standard..........................................................................................................................................................................................4-14

Premounted ....................................................................................................................................................................................4-15

Lens centering................................................................................................................................................................................4-15

Troubleshooting (O2cutting).................................................................................................................................................................4-16

Troubleshooting (N2cutting) .................................................................................................................................................................4-18

Page 29

WARNING

It is the users responsibility to know what materials are being cut. Do not cut metal or other

materials coated or containing toxic substances, such as zinc (galvanized), lead, cadmium, beryllium

or asbestos unless the area is well ventilated and the operator wears an air-supplied respirator. The

coatings and any metals containing these elements can produce toxic fumes when cut.

DANGER

Lenses for cutting with CO2lasers contain Zinc Selenide (ZnSe) which can be very poisonous as dust

or vapor. If a lens breaks, proper cleanup and disposal must be immediately initiated.

0

OPERATION

4-2 LH2125/LH2100 Laser Head Instruction Manual

DANGER

Visible or invisible radiation (class IV) can be present when the laser head door is open. Avoid eye

and skin exposure to direct and scattered radiation. Always follow safety precautions set by the

manufacturer of the laser system.

DANGER

Never put fingers or hands in the path of the beam. Visible and invisible radiation is emitted from the

nozzle aperture.

Operation safety

DANGER

Never put fingers or hands between the lens assembly and the laser head enclosure. Moving parts

can cause severe crush injuries.

Page 30

1

OPERATION

LH2125/LH2100 Laser Head Instruction Manual 4-3

FAST Laser nozzles

Principles of operation

FAST Laser nozzles achieve increased performance in oxygen-assisted mild steel cutting by modification of the cuttinggas flow as it passes through the baffle at the nozzle exit. The laser beam forms a hole in the baffle that is the the same

diameter as the beam and approximately the same width as the kerf in the plate. The gas flow through this hole is

unrestricted and forms a small-diameter jet that couples efficiently into the kerf. The gas flow through the surrounding

baffle is restricted and exits with a lower velocity. This low-velocity jet shields the high-velocity central jet and controls

the reaction between the gas and workpiece. The FAST Laser nozzles operate at a plenum pressure that is 1.5 to 2

times higher than traditional laser cutting nozzles.

The reaction between the oxygen and the mild steel is influenced by many factors, including oxygen purity, oxygen

pressure, chemical composition of the plate, microstructure of the grains in the steel, surface condition of the steel and

laser mode (quality). It is also important to verify that the nozzle is in good condition, and essential that the hole in the

baffle remains approximately the same size as the kerf, to prevent excessive burning. FAST laser nozzles are intended for

low pressure 3.0 bar (45 psi) O2cutting.

Take these precautions to prevent enlargement of the hole:

1. Maintain a nozzle-to-workpiece distance of 6 mm (0.24") or more during a pierce. If the nozzle is too close to the

workpiece, a reflection during the first 50 milliseconds can damage the baffle.

2. Use a pressure of 1.4 bar (20 psi) or higher during a continuous wave (blast) pierce, to protect the nozzle from molten

metal that is blown back from the pierce.

3. The relative position of the lens in its piercing and cutting position must be kept within 2% of the lens’ focal length to

ensure the hole in the baffle does not grow to an unacceptable level.

Note: Do not use Hypertherm’s FAST Laser nozzles for cutting stainless steel, aluminum or laser

alignment. Use only the “standard” nozzles listed in the Parts List of this manual for cutting

stainless steel and during laser alignment.

FAST nozzle installation

When a new nozzle is installed it must be conditioned by using the following procedure:

Move the focus about + 3.5 mm (0.14") from the normal cutting location and irradiate the nozzle with the laser

beam for about 10 seconds at full power. This will ensure that the baffle will not interfere with laser beam when the

focus is returned to the cutting location and gives optimal piercing and cutting performance.

Inspect the baffle

The nozzle should be replaced when the central (conditioned) hole becomes large enough to break into the next

array of holes.

Baffle with central (conditioned) hole

The nozzle needs to be replaced

Baffle with a marginal hole

Page 31

1

OPERATION

4-4 LH2125/LH2100 Laser Head Instruction Manual

Piercing

Mild steel

To prevent damage or spatter adhesion to the nozzle, the nozzle-to-workpiece height must be a minimum of 6 mm (.24")

and the cutting gas pressure must be 1.4 bars (20 psi) or higher. For continuous wave piercing, most pierce times are

less than 2 seconds and create a hole that is approximately 1.5 times larger than the nozzle orifice diameter. When the

pulse pierce mode is chosen, the nozzle-to-workpiece height needs to be 6 mm for at least 0.5 seconds to allow the

formation of a small pit in the material surface. This prevents damage to the baffle from the laser beam reflections from

the workpiece. After the formation of a pit, the nozzle-to-workpiece height can be lowered to 4 mm and the focal

position can shift to the workpiece surface. The focal position cannot deviate from the cutting position by more than 2%

of the focal length or excessive damage to the baffle will occur.

Stainless steel and aluminum

Cutting gas pressures for piercing stainless steel are typically lower than pressures used during cutting to prevent the

formation of a plasma cloud, which will interrupt cutting. 2 to 3 bar (29 to 43 psi) is a typical pressure for piercing

stainless. Additionally, the lead in for thicker stainless material must be slow until the kerf is well established or a plasma

cloud will form.

Highly reflective material can present a problem during piercing. If inert gas is used, the material will not oxidize and can

remain highly reflective. See caution below.

CAUTION

Highly reflective material can cause the beam to be reflected back through the beam delivery system

when the focus is near the surface of the workpiece, causing a significant increase in laser power

that can cause catastrophic failure of components.

Page 32

1

OPERATION

LH2125/LH2100 Laser Head Instruction Manual 4-5

Single-channel interface adjustments

Cut-error monitor: (continuously monitors the cutting process.)

The cut-error monitor is intended for steady-state cutting. An error condition may be recorded in transient operations,

such as near a sharp corner, and should be ignored. Set the error-compensation adjustment for the specific cutting

conditions.

Material Thickness, 6 mm (1/4") or more, Setting = 18Material Thickness, 6 mm (1/4") or less, Setting = 09

General error-compensation settings

Precision adjustments

The cut error monitor sensitivity can be changed with potentiometer R1 (E). If false error signals 1are seen consistently

during good cutting, turn R1 clockwise to increase the sensitivity limit.

Test and fine-tune the sensitivity levels of each output for error parameters. The cut error monitor is intended for steady

state cutting operations. Any error reported during transient operations, such as near a sharp corner, should be ignored.

Blast pierce/continuous wave (strong): (laser on, with the cutting gas at maximum power)

Blast pierce sensitivity can be changed with potentiometer R2 (B). If the circuit is giving a late pierce complete signal 2,

turn R2 clockwise to increase the sensitivity limit 3. If the blast piercing method is utilized, the pulse pierce output

should be ignored.

Note 1: A false error signal represents an error reported during acceptable cutting..

Note 2: Output is not switching within 1/2 second of when pierce is complete. This can be observed

visualy

Note 3: Use 1/2 turn increments when adjusting sensitivity

R2 (B)

R1 (E)

Gain adjustment knob

Pierce pulse LED indicator

Page 33

1

OPERATION

4-6 LH2125/LH2100 Laser Head Instruction Manual

Pulse pierce (fine): The laser beam is modulated to pierce a small diameter hole

A 10-turn gain adjustment knob is provided to optimize the pulse pierce sensor over a wide range of operating

conditions. It is located on the top of the single channel interface enclosure and has a locking lever. The knob adjusts

the sensitivity for the optical sensor inside the laser head. It is important that the sensitivity be set to a proper range. If

the sensitivity is too low, the circuit will signal a pierce complete before the hole is completely through the material. If the

sensitivity is too high, the sensor will detect the beam striking the sides of the pierce hole even after the pierce is

completed.

In general a higher gain setting will be required with lower laser powers and smaller diameter nozzles because these

conditions will produce lower levels of optical emission. Higher laser powers and larger diameter nozzles will necessitate

a change to a lower gain setting.

Gain adjustment procedure:

1. Set the gain adjustment knob to the mid-range (5.0)

2. Set piercing conditions for 6 mm material with a 2 mm standard nozzle.

3. Open the end door of the interface box and locate the green LED (pulse pierce indicator)

4. Initiate a pulse pierce sequence while monitoring the pulse pierce indicator.

a. The indicator is normally green and will turn red during a pulse pierce sequence.

b. If the LED changes from red to green at the same time the material is completely pierced, record the setting

and continue to step 5.

c. If the LED changes before the material is completely pierced, the gain needs to be increased. Turn the gain

adjustment knob clockwise one full turn and repeat step 4.

d. If the LED changes more than 2 seconds after the material is pierced, the gain needs to be decreased. Turn

the gain adjustment knob counter-clockwise one full turn and repeat step 4.

5. Set piercing conditions for 16 mm material with a 2 mm standard nozzle.

6. Initiate a pulse pierce sequence while monitoring the pulse pierce indicator.

a. If the LED changes to green at the same time the material is completely pierced, record the setting and

continue to step 7.

b. If the LED changes before the material is completely pierced, the gain needs to be increased. Turn the knob

clockwise one full turn and repeat step 6.

c. If the LED changes more than 2 seconds after the material is pierced, the gain needs to be decreased. Turn

the knob counter-clockwise one full turn and repeat step 6.

i. If the gain knob is at zero and the LED is not changing back to green, the internal gain setting needs

to be decreased.

ii. Set the external adjustment knob to 1.0.

iii. Open the end door on the interface box and use a small screwdriver to turn R25 counter-clockwise

one full turn.

iv. Repeat pierce test.

v. If the LED does not change when pierce is complete, repeat steps iii and iv.

vi. If pierce complete output state does change at the correct time, close the end door and continue to

step 7.

7. Repeat the conditions in step 2 with the setting determined in step 6.

a. If the LED changes from red to green at the same time the material is completely pierced, no further

adjustments are necessary. Record the setting and use for all operating conditions.

b. If the LED changes before the material is completely pierced, reset the pierce gain knob to the value

determined from step 4. This will make sure a complete pierce is achieved over the range of material

conditions but will delay the output signal in the thicker material conditions.

c. If the delay is unacceptable, different pierce gain settings are required for different material thicknesses.

Make adjustments as necessary.

Note: Contact Hypertherm if you are still having problems after followig the procedure above.

Technical service 1-800-643-9878.

Page 34

1

OPERATION

LH2125/LH2100 Laser Head Instruction Manual 4-7

Capacitive height sensing

Introduction

The capacitive height sensor measures the relative capacitance between the cutting head nozzle and the work piece.

The lower part of the cutting head is electronically excited and acts as a guard against any stray capacitance from other

sources including the moving components in the cutting head. The signal to the nozzle is carried by the center

conductor of the internal coaxial cable. The signal to the lower part of the cutting head is carried on the shield of the

internal coaxial cable.

Note: It is important that the lower part of the cutting head is not shorted to ground, and that there is

electrical isolation between the nozzle and the lower part of the cutting head. Isolation is

provided by the insulating washer and a ceramic coating on the top side of the nozzle adapter

and prevents a false tip-touch error signal.

Lower part of the cutting head

If a false tip-touch error is suspected:

Remove nozzle and retaining ring. Inspect for particles between parts, damage and cleanliness. Replace as necessary.

Nozzle

Retaining nut

Insulating washer

Nozzle adapter

Shown with spatter shield and spatter shield retaining nut

Retaining nut wrench (104222)

Retaining nut wrench (104223)

Spatter shield

Spatter shield

retaining nut

Page 35

1

OPERATION

4-8 LH2125/LH2100 Laser Head Instruction Manual

Adjustment

The capacitive height sensor interface box (051008) provides digital outputs for the tip-touch, over-range, and underrange signals. It also provides an analog signal that measures the distance from the nozzle to the material.

1. Set the gain knob to mid range (5.0).

2. Position the cutting head so the distance between the nozzle and the work piece is 10 mm.

a. If the over-range LED is illuminated, decrease the Offset knob until the LED is extinguished and then slowly

increase the knob until the LED illuminates again. Lock the knob and record the setting.

b. If the over-range LED is extinguished, increase the Offset knob setting until the LED illuminates. Lock the

knob and record the setting.

c. If the over-range LED is still illuminated when the offset knob is set to 0.0, remove the nozzle and the nozzle

adapter retaining ring. Inspect the condition of the o-ring and the ceramic layer on the nozzle adapter.

Replace if necessary. Reinstall the nozzle adapter and nozzle, tighten both appropriately. Repeat steps 1

and 2.

d. If the over-range LED is still illuminated, decrease the R2-Gain knob until the over-range LED is extinguished.

e. If both R1 and R2 knobs are set to 0.0 and the over-range LED is still illuminated the nozzle adapter may be

damaged. Replace with new a nozzle adapter and repeat steps 1 and 2.

Continued on next page

Power LED

Over range LED

Under range LED

Gain knob

Offset knob

Operation

The capacitive height sensor interface has gain and offset adjustments. It is calibrated to have a signal of 0.0V at a