Page 1

HyPro2000 ™ Quick Disconnect

HT2000 Torch Upgrade

Field Service Bulletin

806550 – Revision 4 – September 2013

Page 2

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

877-371-2876 Fax (Return Materials Authorization)

return.materials@hypertherm.com (RMA email)

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D-63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm (S) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

65 6841 2489 (Technical Service)

Hypertherm (Shanghai) Trading Co., Ltd.

Unit 301, South Building

495 ShangZhong Road

Shanghai, 200231

PR China

86-21-60740003 Tel

86-21-60740393 Fax

Hypertherm Europe B.V.

Vaartveld 9

4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP - Brasil

CEP 07115-030

55 11 2409 2636 Tel

55 11 2408 0462 Fax

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Hypertherm Korea Branch

#3904 Centum Leaders Mark B/D,

1514 Woo-dong, Haeundae-gu, Busan

Korea, 612-889

82 51 747 0358 Tel

82 51 701 0358 Fax

© 2013 Hypertherm, Inc. All rights reserved.

HyPro2000 and Hypertherm are trademarks of Hypertherm, Inc. and may be registered in the United States and/or

other countries. All other trademarks are the property of their respective holders.

Page 3

HyPro2000 — HT2000 TORCH UPGRADE

DANGER

ELECTRIC SHOCK CAN KILL

Disconnect electrical power before performing any maintenance.

All work requiring removal of the power supply cover must be performed by a

qualified technician.

See the Safety Section of the system’s Manual for more safety precautions.

Introduction

Purpose

This document describes the steps necessary to upgrade the HT2000 with the HyPro2000 torch.

Required tools

5/16 inch, 3/8 inch, 7/16 inch, 1/2 inch, open end wrench, and 2 inch spanner wrench.

Kits

Part number Description Qty

228549 Kit: HyPro2000 Torch retrofi t with Control PCB 1

228550 Kit: HyPro2000 Torch retrofi t 1

HT2000 control PCB

Torch retrofi t kit

Field Service Bulletin 1

Page 4

HyPro2000 — HT2000 TORCH UPGRADE

Kit - 228549 Contents (PCB included)

Note: This kit includes all the parts that are in the 228550 kit , plus the following items:

Part

Number Description Qty.

141163 PCB assembly: HT2000 control board 1

223173 Jumper wire: HyPro2000/phase loss upgrade 1

Kit - 228550 Contents (PCB not included)

Part

Number Description Qty.

024249 Insulator: coolant line 1

024873 Hose 1

026009 O-ring: 0.208 inch x 0.070 inch 10

027055 Silicone lubricant: 1/4 ounce 1

044026 O-ring: 1.239 inch x 0.070 inch 2

046065 Insulator: Pilot arc 1

058224 O-ring: 1.734 inch x 0.139 inch 1

104119 Consumable tool 1

220052 Seal: 400 amp torch quick-disconnect 1

220831 Nozzle: 200 amp O

220832 Shield: 200 amp O2/air 1

220834 Swirl ring: 200 amp 1

220913 Quick-disconnect receptacle 1

220925 Electrode: 200 amp SilverPlus 3

220936 Shield: O2/air, clockwise, with IHS tab 1

220937 Electrode: 200 amp O2/air 2

220942 Torch mounting sleeve: 1-3/4 inch outside diameter 1

220943 Torch mounting sleeve: 2 inch outside diameter 1

228557 Machine torch with consumables 1

228567 Gauge: Plasma pressure 1

228571 Kit: Firmware upgrade 1

806550 Field service bulletin: HyPro2000, HT2000 Torch Upgrade 1

2

5

2 Field Service Bulletin

Page 5

HyPro2000 — HT2000 TORCH UPGRADE

Pre-installation

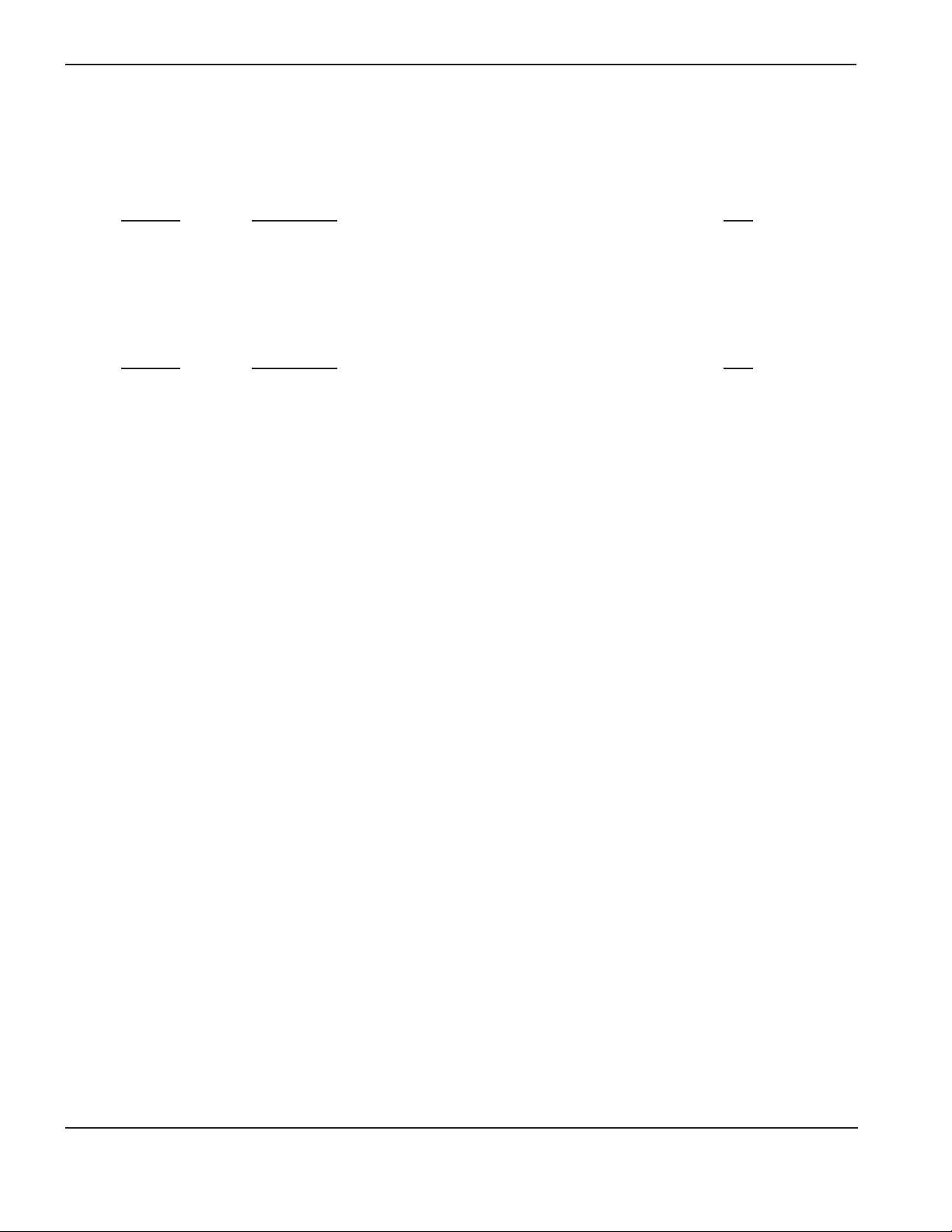

Before starting this upgrade you must determine if the system is a Local High Frequency (LHF) or a Remote High

Frequency system (RHF). You need to know this information to choose the correct firmware chip.

Inspect the gas console as described below:

1$LU

3/$60$

1

$LU

2

$LU

1

2

3/$60$

&XW)ORZ

SVL

SVL

2

3UH)ORZ3UH)ORZ

7HVW

3UHIORZ

'&

6+,(/'

SVL

5XQ

7HVW

&XWIORZ

If there is a toggle switch for the

plasma cutflow gas it is an RHF

system

If it has a knob to adjust the

plasma cutflow gas it is an LHF

system

1$LU

3/$60$

1

$LU

2

$LU

1

2

3/$60$

&XW)ORZ

SVL

SVL

2

3UH)ORZ3UH)ORZ

7HVW

3UHIORZ

'&

6+,(/'

SVL

5XQ

7HVW

&XWIORZ

The HySpeed off-valve assembly (129840) MUST be installed in an LHF system to continue with this upgrade. The offvalve assembly is marked HYSPEED, as shown below.

Field Service Bulletin 3

Page 6

HyPro2000 — HT2000 TORCH UPGRADE

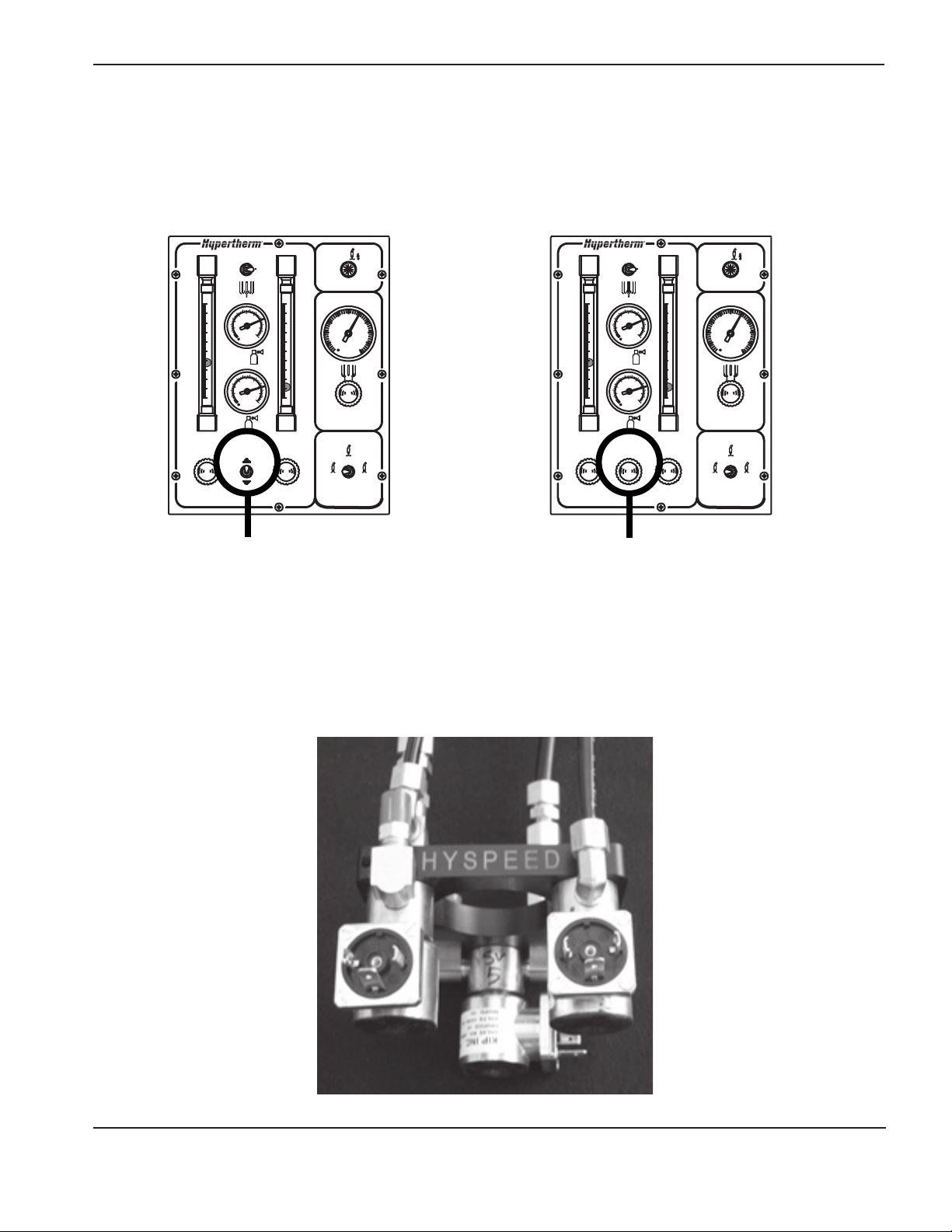

Installation of the firmware chip

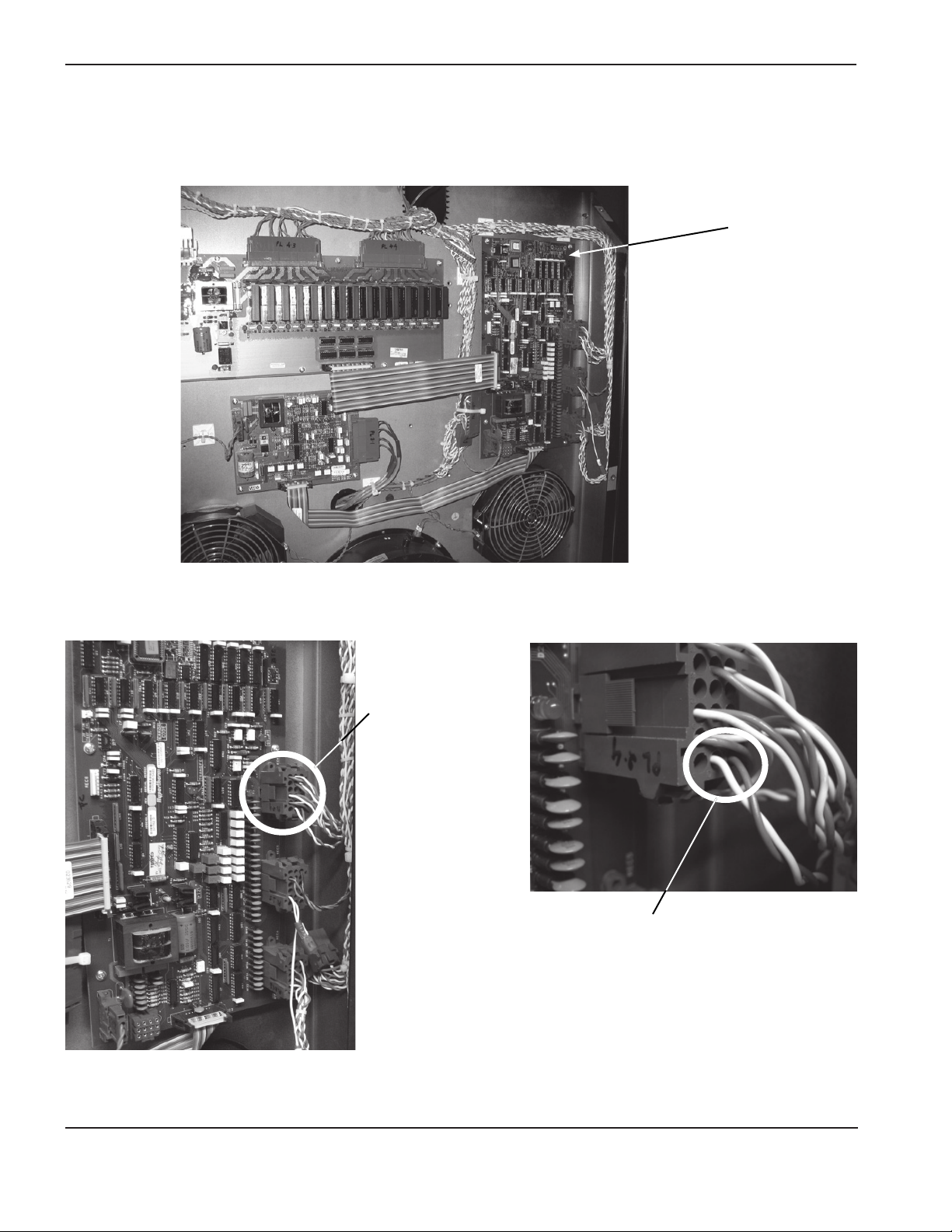

1. Access the control board (PCB2) by removing the 2 front panels. Inspect the control board. If it is a older

model, you will have to replace the board and the fi rmware chip.

Control board

location

Firmware chip

location

2. Inspect the control board. If it is a older model, you will have to replace the board and the fi rmware chip.

Older board

(replace board and chip)

Look for this

metal cover

ON the older

board

Firmware chip

location

Newer board

(replace chip)

4 Field Service Bulletin

Page 7

HyPro2000 — HT2000 TORCH UPGRADE

If you are installing a new control board skip to step 4.

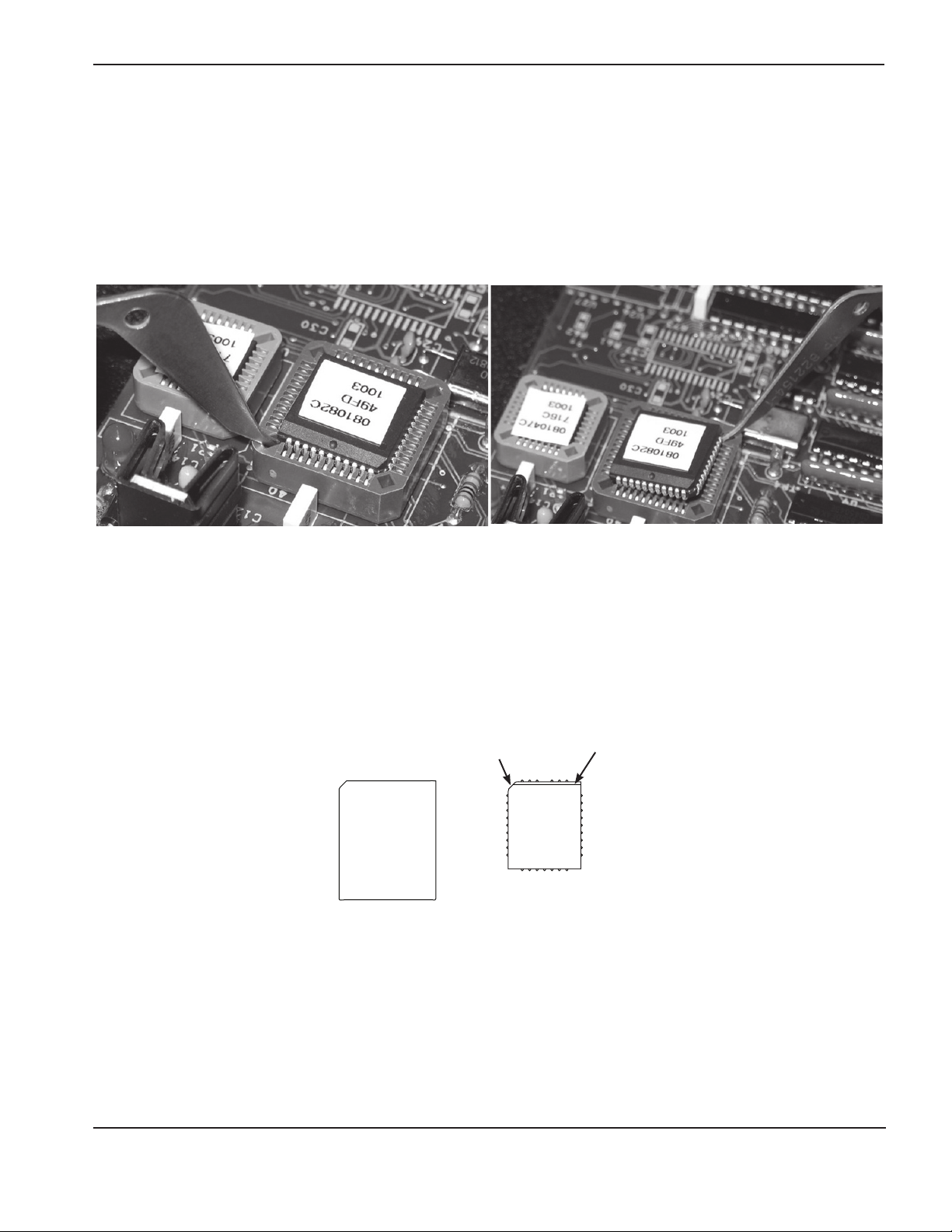

3. Remove and discard the old chip by using the tool included in this kit. See pictures below.

a. Place the straight end of the chip removal tool under one corner of the chip. Only 2 opposite corners will

accept the tool.

b. Carefully pry each of the 2 corners alternately until the chip is removed. Prying the chip out from only one

corner can damage the chip receptacle.

4. Chose the appropriate chip from fi rmware kit 228571 (located in the main kit box), and install it in the chip

receptacle on the control board.

Use the chip labeled 081192 for an RHF system.

Use the chip labeled 081194 for an LHF system.

Note: NOTE: The chip must be oriented correctly before installation. DO NOT use the orientation of the label to

orient the chip to the chip receptacle. There is a bevel on one edge of each chip and one corner is

angled (see fi gure below).

Angled corner

Firmware Chip

Chip receptacle

on PCB

Bevel

5. If you are installing a new control board see Installation of the new control board on the next page.

If you have installed the new chip on an existing control board see step 2 of Installation of the new control

board on the next page, before you replace the 2 front panels of the power supply and continue to torch and

quick-disconnect installation.

Field Service Bulletin 5

Page 8

HyPro2000 — HT2000 TORCH UPGRADE

Installation of the new control board

1. Install the appropriate fi rmware chip on the new control board by following step 4 on the previous page.

Control board

location

2. Locate plug PL 2.4 in receptacle 4 on the control board. If no wires are present in sockets 1 and 2 use the

jumper wire provided in this kit to jump the 2 sockets.

Plug PL 2.4 in

receptacle 4

Wires (blue and white)

present in sockets 1 and 2

6 Field Service Bulletin

Page 9

HyPro2000 — HT2000 TORCH UPGRADE

3. Label each connector before removing any connections to the old board. After labeling the connectors,

remove all connections to the control board. Any wires that are present but not connected to the board will

remain disconnected.

4. Remove the 6 screws that hold the control board in place, and remove the old control board. Save the screws

for reuse.

5. Install the new control board using the six screws from step 3.

6. Plug all the connectors into the appropriate receptacles on the new control board.

7. Replace the 2 front panels and continue to torch and quick-disconnect installation.

Field Service Bulletin 7

Page 10

HyPro2000 — HT2000 TORCH UPGRADE

Torch and quick-disconnect receptacle Installation

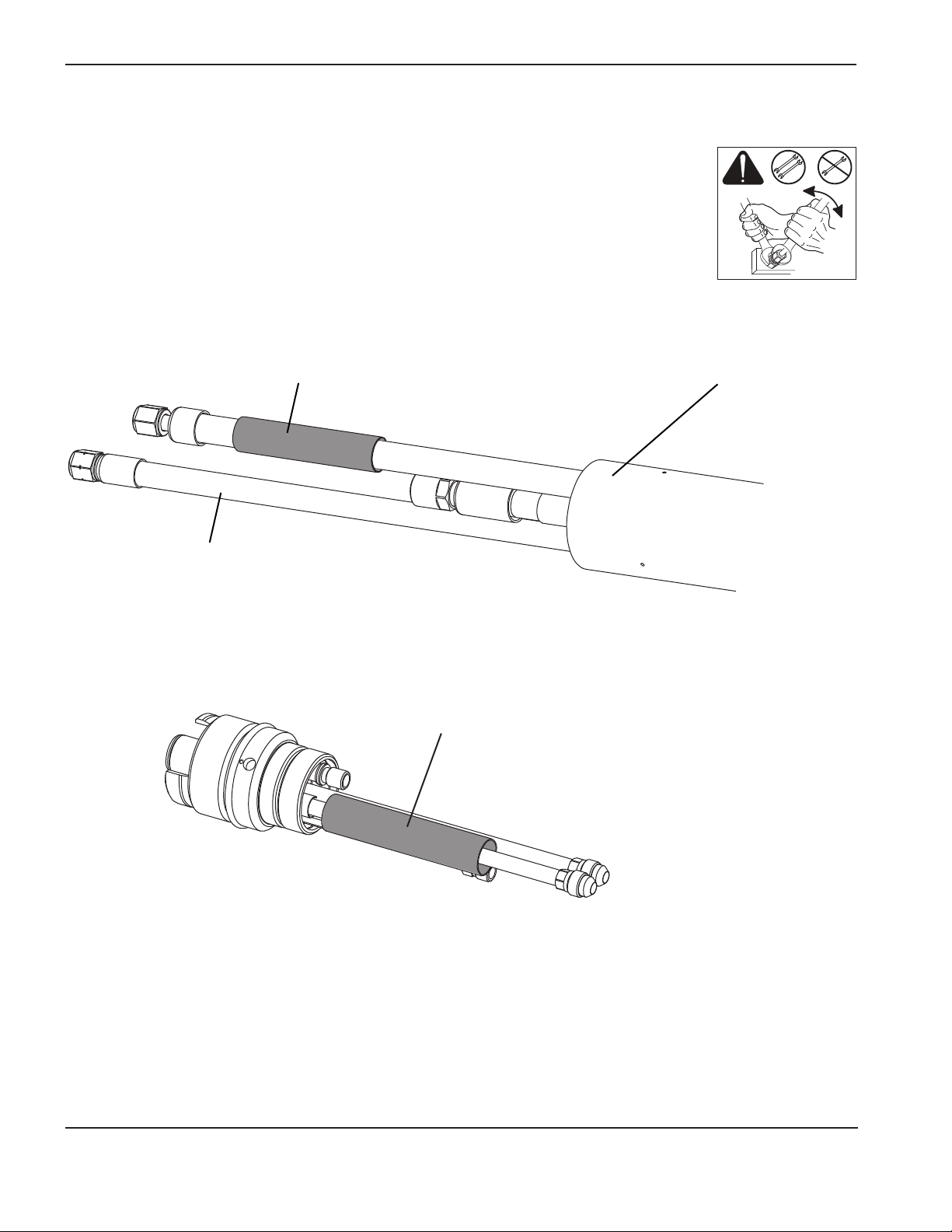

1. Remove the existing torch and mounting sleeve from the lifter.

2. Unscrew the mounting sleeve and slide it up to expose the hose fi ttings.

3. Disconnect all the hoses and the pilot arc connection from the torch and remove the sleeve.

Always use 2 wrenches to loosen or tighten the fi ttings.

4. Inspect all hoses and wires for damage.

5. Loosen the off-valve assembly to remove the existing blue plasma hose.

6. Hold the black plasma hose provided in this kit with the bundled cables and hoses and slide the HyPro2000 torch

mounting sleeve over the leads (with the threaded end closest to the torch) and install the pilot arc lead insulator onto the

pilot arc lead (dark blue hose).

Pilot arc lead insulator Threaded end of the torch mounting sleeve

Black plasma gas hose

7. Connect the torch quick-disconnect receptakce to the torch leads.

a. The coolant hose insulator is on the coolant return (red) line of the torch quick disconnect when shipped.

Make sure it is in place before making any connections.

Coolant hose

insulator

8 Field Service Bulletin

Page 11

HyPro2000 — HT2000 TORCH UPGRADE

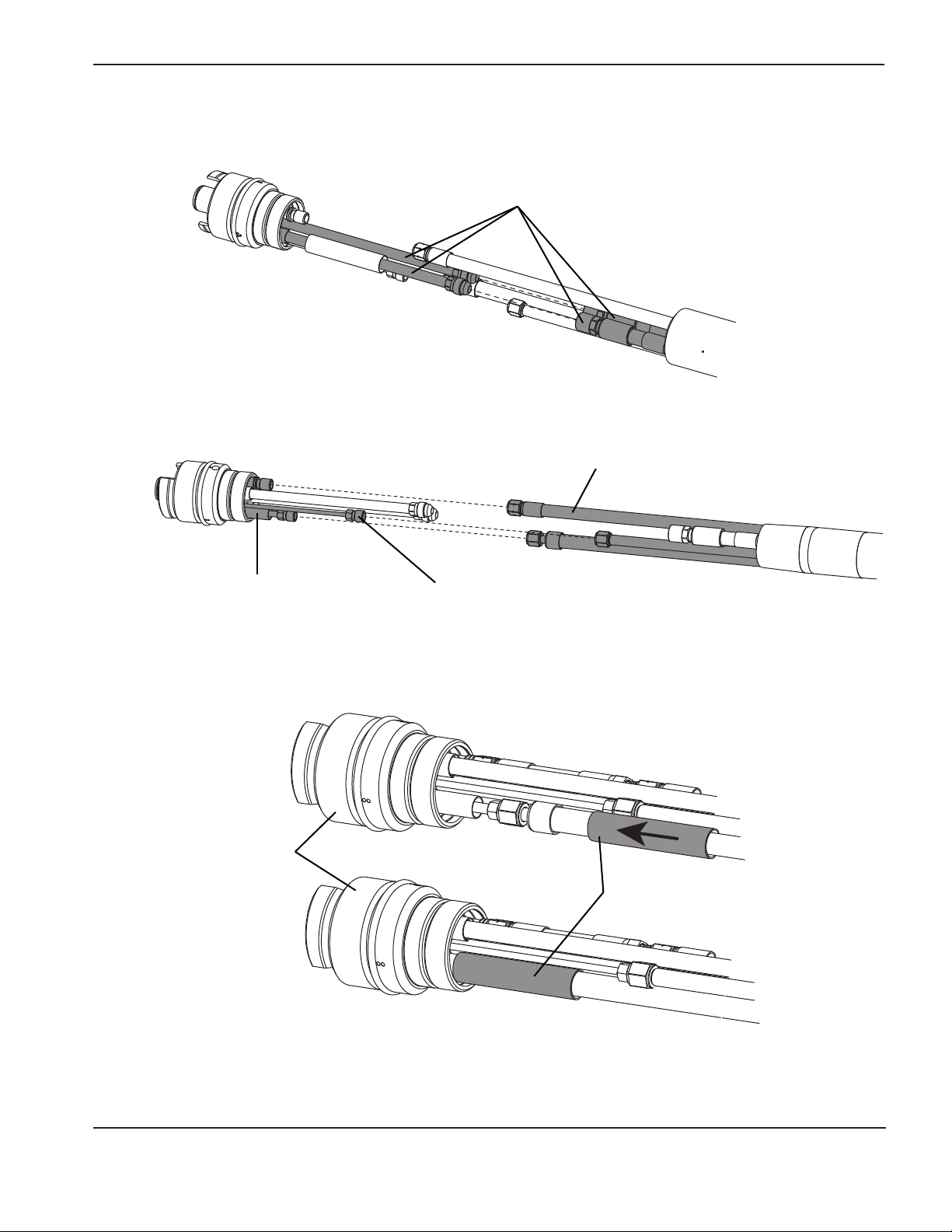

b. Connect the green and red coolant hoses to the fi tting on the torch quick-disconnect receptacle with the

corresponding color.

Coolant hoses

c. Connect the cap senor lead, the plasma gas hose, and the shield gas/pilot arc lead to the torch

quick-disconnect assembly.

Plasma gas hose

Cap sensor leadShield gas hose/pilot arc lead

8. Slide the pilot arc lead insulator over the blue shield gas/pilot arc lead until it contacts the bottom of the torch

quick-disconnect receptacle.

Torch

quick-disconnect

receptacle

Pilot arc lead insulator

Field Service Bulletin 9

Page 12

HyPro2000 — HT2000 TORCH UPGRADE

9. Slide the coolant hose insulator over the fi ttings.

10. Secure the coolant hose insulator in place by wrapping electrical tape around the lead set.

11. Slide the torch mounting sleeve over the fi ttings and screw it onto the torch quick-disconnect receptacle.

Torch mounting sleeve

10 Field Service Bulletin

Page 13

HyPro2000 — HT2000 TORCH UPGRADE

12. Install the pressure gauge included in this kit between the plasma gas line and the off-valve assembly.

Off-valve

connection

Plasma gas

hose connection

13. Install the torch onto the quick-disconnect receptacle.

a. Align any of the matching dots on the torch and quick-disconnect receptacle, and slide the torch into the

receptacle. 3 triangular dots are shown below, but there are also single dots that match and double dots

that match.

b. Turn the threaded collar on the torch clockwise until it is tight

Threaded collar

Alignment dots

Field Service Bulletin 11

Page 14

HyPro2000 — HT2000 TORCH UPGRADE

14. Verify gas pressures.

a. Turn on the power to the system and turn on the gas supplies.

b. Adjust the gas console settings for the chosen process using the cut charts in this document.

c. Verify the gas pressure reading on the gauge between the plasma gas line and the off-valve assembly with

the table below.

Note: Recommended incoming gas (supply gas) pressures are 120 psi for oxygen and nitrogen and 90 psi for air.

If the incoming gas pressure are not set correctly the back pressure reading will also

be incorrect.

15. Verify that there are no leaks at any of the connections.

16. Remove the pressure gauge that was installed in step 12 and the installation is complete.

Test pressures

Current Process

Amps Gases psi bar psi bar psi bar

50

Air/Air

Preflow pressure

(at the off-valve)

49.2 3.4 31.3 2.2 63.2 4.4

Cutflow pressure

(at the off-valve)

Pressure while cutting

(at the off-valve)

50

130

130 Air/Air 27 1.8 50 3.4 62.5 4.3

200

200

200 Air/Air 26 1.8 36 2.5 52 3.6

200 N2/Air 38.3 2.6 48.6 3.4 63.4 4.4

(SilverPlus electrode)

O2/Air

O2/Air

O2/Air

(copper electrode)

O2/Air

54.2 4.4 24.3 1.7 71 4.9

37.5 2.6 18.4 1.3 62.8 4.3

27 1.8 49 3.4 69 4.8

32 2.2 54 3.7 75 5.1

12 Field Service Bulletin

Page 15

HyPro2000 — HT2000 TORCH UPGRADE

Daily start-up

Prior to start-up, ensure that your cutting environment and that your clothing meet the safety requirements outlined in the

Safety section of the system’s instruction manual.

Check torch

WARNING

Before operating this system, you must read the Safety section thoroughly! Turn OFF the power

supply’s main disconnect switch before proceeding with the following steps.

1. Turn OFF the main disconnect switch to the power supply.

2. Remove the consumables from the torch and check for worn or damaged parts. Always place the

consumables on a clean, dry, oil-free surface after removing. Dirty consumables can cause the

torch tomalfunction.

• Refer to Install consumables on the next page for details.

• Refer to the Cut charts to choose the correct consumables for your cutting needs.

3. Replace consumable parts. Refer to Changing consumables later in this section for details.

4. Ensure that the torch is perpendicular to the workpiece.

Shield

Nozzle

retaining cap

Nozzle

Swirl ring

TorchWater tubeElectrode

Field Service Bulletin 13

Page 16

HyPro2000 — HT2000 TORCH UPGRADE

Install consumables

WARNING

Always disconnect power to the power supply before inspecting or changing torch consumable parts. Use gloves

when removing consumables. The torch might be hot.

Install consumables

Check the consumable parts daily for wear before cutting. Before removing consumables, bring the torch to the edge of

the cutting table, with the torch lifter raised to its highest point to prevent the consumables from dropping into the water

of the water table.

Note: Do not overtighten parts! Only tighten until mating parts are seated.

Apply a thin film of silicone

The o-ring should look shiny, but there should not be any excess or

built-up grease.

Tool: 104119

1. Install the

electrode

into the

torch head

lubricant on each o-ring.

2. Install the

swirl ring

into the

nozzle

3. Install the nozzle

and

swirl ring into the

nozzle

retaining cap

Wipe the internal and external surfaces of the

torch with a clean cloth or paper towel.

4. Install the

nozzle

retaining cap

onto the torch

head

5. Install the

shield onto

the nozzle

retaining cap

14 Field Service Bulletin

Page 17

HyPro2000 — HT2000 TORCH UPGRADE

Arc voltage

The arc voltage settings (v) shown in the cut charts may need to be adjusted to produce the correct cutting height.

Physically measuring the height after stopping the torch is preferred, but visual inspection during a cut is acceptable.

Over the life of a consumable set it will also be necessary to periodically adjust the arc voltage (v) up 1 to 2 volts at a

time to maintain the proper torch height and to achieve the maximum life from the consumables.

Cut charts

The following Cut charts show the consumable parts, cutting speeds, gas pressures, and the current settings required

for each process.

The numbers shown in the Cut charts are recommended to provide high-quality cuts with minimal dross. Because of

differences between installations and material composition, adjustments may be required to obtain desired results.

Digital remote

Hypertherm has produced a few versions of the digital remote. Some versions increase and decrease in 10 amp

increments, and some increase and decrease in 20 amp increments. If you have a digital remote that increases/

decreases by 20 amps, set the digital remote to 120 amps or 140 amps for a 130 amp process. The system will

automatically choose the 130 amp process.

Field Service Bulletin 15

Page 18

HyPro2000 — HT2000 TORCH UPGRADE

Estimated kerf width compensation

The widths in the chart below are for reference. Differences between installations and material composition may cause

actual results to vary from those shown in the tables.

Metric

Process Thickness (mm)

Mild steel 3468101215202532384450

50A O2/Air 1.5 1.6 –––––––––––

50A Air/Air 1.3 1.3 –––––––––––

130A O2/Air 2.4 2.5 2.7 2.8 2.9 3.1 3.3 3.6 4.0 – – – –

130A Air/Air 2.2 – 2.4 – 2.6 2.8 2.9 3.2 3.5 – – – –

200A O2/Air – – 2.8 2.9 3.0 3.3 3.4 3.7 4.1 4.6 5.0 5.4 5.9

200A Air/Air – – 2.7 – 2.9 3.1 3.4 3.6 4.0 4.5 5.0 – 5.9

Stainless steel

50A Air/Air 1.5 1.5 –––––––––––

200A N2/Air – – 2.5 2.6 2.7 2.9 3.1 3.3 3.7 4.1 4.5 – –

Aluminum

50A Air/Air 1.5 1.6 –––––––––––

200A N2/Air – – 3.2 3.3 3.4 3.6 3.8 4.1 4.6 5.1 5.6 – –

English

Process Thickness (in.)

Mild steel

50A O2/Air

50A Air/Air

130A O2/Air

130A Air/Air

200A O2/Air

200A Air/Air

Stainless steel

50A Air/Air 0.059 0.062 ––––––––

200A N2/Air – – 0.106 0.114 0.122 0.130 0.145 0.161 0.177 –

0.135 0.25 0.375 0.5 0.625 0.75 1.0 1.25 1.5 2.0

0.059 0.064 ––––––––

0.051 0.053 ––––––––

0.096 0.105 0.114 0.123 0.132 0.141 0.159 – – –

0.089 0.095 0.102 0.109 0.116 0.123 0.138 – – –

– 0.110 0.119 0.128 0.136 0.145 0.163 0.180 0.197 0.232

– 0.106 0.115 0.124 0.132 0.141 0.159 0.177 0.195 0.231

Aluminum

50A Air/Air 0.060 0.062 ––––––––

200A N2/Air – – 0.133 0.143 0.152 0.162 0.181 0.201 0.220 –

16 Field Service Bulletin

Page 19

HyPro2000 — HT2000 TORCH UPGRADE

Mild steel

Air Plasma / Air Shield

50 A Cutting

Flow rates – lpm/scfh

Preflow 123 / 259

Cutflow 114 / 241

220532 220528220529220890220936

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air mm Volts mm mm/m mm factor % seconds

39 27 40

Test Cutfl ow

Flowrates

Material

Thickness

0.5 112 1.5 9400 3.0 200 0.0

0.8 111 1.5 8510 3.0 200 0.0

1.0 111 1.5 8050 3.0 200 0.1

1.2 107 1.8 7625 3.6 200 0.1

1.5 108 1.8 7370 3.6 200 0.1

2.0 108 1.8 6735 3.6 200 0.1

2.5 109 2.0 5080 4.0 200 0.2

3.0 112 2.0 3760 4.0 200 0.3

4.0 116 2.3 2415 4.6 200 0.4

6.0 120 2.5 1600 5.0 200 0.5

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Air

Pierce Delay

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air in Volts in ipm in factor % seconds

39 27 40

Test Cutfl ow

Flowrates

Material

Thickness

0.018 112 0.06 375 0.12 200 0.0

0.024 112 0.06 350 0.12 200 0.0

0.030 111 0.06 340 0.12 200 0.0

0.036 110 0.06 325 0.12 200 0.1

0.048 107 0.07 300 0.14 200 0.1

0.060 108 0.07 290 0.14 200 0.1

0.075 108 0.07 275 0.14 200 0.1

0.105 110 0.08 180 0.16 200 0.2

0.135 114 0.08 110 0.16 200 0.3

0.188 118 0.09 75 0.18 200 0.4

0.250 121 0.10 60 0.20 200 0.5

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Pierce Delay

Time

Field Service Bulletin 17

Page 20

HyPro2000 — HT2000 TORCH UPGRADE

O2 Plasma / Air Shield

220532 220528220529220891

220936

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

35 0 21 30

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air mm Volts mm mm/m mm factor % seconds

0.5 98 1.5 7550 3.0 200 0.0

0.8 98 1.5 7050 3.0 200 0.0

1.0 98 1.5 6775 3.0 200 0.1

1.2 98 1.5 6600 3.0 200 0.1

1.5 98 1.5 6150 3.0 200 0.1

2.0 98 1.5 5400 3.0 200 0.1

2.5 100 1.8 4300 3.6 200 0.2

3.0 102 1.8 3650 3.6 200 0.3

4.0 104 2.0 2800 4.0 200 0.4

6.0 108 2.5 1750 4.0 200 0.5

Mild steel

50 A Cutting

Arc

Torch-to-Work

Voltage

Distance

Flow rates – lpm/scfh

O

Preflow 2 / 4 19 / 40 73 / 155

Cutflow 12 / 25 73 / 155

Cutting

Speed

Initial Pierce Height

2

N

2

Pierce Delay

Air

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

35 0 21 30

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air in Volts in ipm in factor % seconds

0.018 98 0.06 300 0.12 200 0.0

0.024 98 0.06 290 0.12 200 0.0

0.030 98 0.06 280 0.12 200 0.0

0.036 98 0.06 270 0.12 200 0.1

0.048 98 0.06 260 0.12 200 0.1

0.060 98 0.06 240 0.12 200 0.1

0.075 98 0.06 220 0.12 200 0.1

0.105 100 0.07 160 0.14 200 0.2

0.135 103 0.07 130 0.14 200 0.3

0.188 106 0.09 85 0.18 200 0.4

0.250 108 0.10 65 0.20 200 0.5

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Pierce Delay

Time

18 Field Service Bulletin

Page 21

HyPro2000 — HT2000 TORCH UPGRADE

O2 Plasma / Air Shield

220491 220488220893

220936

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

25 30 34 35

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air mm Volts mm mm/m mm factor % seconds

3 128 2.6 5900 5.2 200 0.1

4 129 2.7 5325 5.4 200 0.2

6 129 2.8 3925 5.6 200 0.3

10 133 3.0 2680 6.0 200 0.4

12 135 3.0 2200 6.0 200 0.5

15 139 3.6 1665 7.2 200 0.7

20 141 3.9 1195 7.8 200 1.0

25 151 4.1 685 8.2 200 1.5

32 155 4.6 515

38 160 4.6 310

Mild steel

130 A Cutting

Arc

Torch-to-Work

Voltage

Distance

Flow rates – lpm/scfh

O

Preflow 16 / 33 21 / 44 86 / 183

Cutflow 20 / 42 86 / 183

2

N

220487

or

420185 SliverPlus

Cutting

Speed

Initial Pierce Height

Edge Start

2

Pierce Delay

Air

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

25 30 34 35

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air in Volts in ipm in factor % seconds

0.135 128 0.10 240 0.20 200 0.1

3/16 129 0.11 190 0.22 200 0.2

1/4 129 0.11 150 0.22 200 0.3

3/8 133 0.12 110 0.24 200 0.3

1/2 135 0.12 80 0.24 200 0.5

5/8 140 0.15 60 0.30 200 0.7

3/4 141 0.15 50 0.30 200 1.0

1.0 151 0.16 25 0.32 200 1.5

1-1/4 155 0.18 20

1-1/2 160 0.18 12

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start

Pierce Delay

Time

Field Service Bulletin 19

Page 22

HyPro2000 — HT2000 TORCH UPGRADE

Flow rates – lpm/scfh

Preflow 26 / 56 68 / 145

Cutflow 44 / 93 68 / 145

220536 220487220936

Mild steel

Air Plasma / Air Shield

130 A Cutting

220488220892

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air mm Volts mm mm/m mm factor % seconds

45 77 24

Test Cutfl ow

Flowrates

Material

Thickness

3 139 3.0 5350 6.0 200 0.1

4 137 3.0 4630 6.0 200 0.2

6 142 3.4 3865 6.8 200 0.3

10 148 4.1 2445 8.2 200 0.5

12 149 4.1 2045 8.2 200 0.5

15 153 4.4 1445 8.8 200 0.8

20 159 4.6 815 10.5 230 1.2

25 167 4.6 415

32 174 5.1 250

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start

Air Air

Pierce Delay

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air in Volts in ipm in factor % seconds

45 77 24

Test Cutfl ow

Flowrates

Material

Thickness

0.135 140 0.12 220 0.24 200 0.1

3/16 136 0.12 160 0.24 200 0.2

1/4 144 0.14 150 0.28 200 0.3

3/8 148 0.16 100 0.32 200 0.5

1/2 149 0.16 75 0.32 200 0.5

5/8 154 0.18 50 0.36 200 0.8

3/4 158 0.18 35 0.42 230 1.2

1.0 167 0.18 15

1-1/4 174 0.20 10

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start

Pierce Delay

Time

20 Field Service Bulletin

Page 23

HyPro2000 — HT2000 TORCH UPGRADE

O2 Plasma / Air Shield

Copper electrode

220832 220937220834220831

220936

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

12 38 70 53

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air mm Volts mm mm/m mm factor % seconds

6 145 1.5 6210 3.00 200 0.30

8 154 3.4 4850 5.10 150 0.35

10 160 4.6 3735 6.90 150 0.40

12 157 3.8 3415 9.50 250 0.60

15 156 3.1 2845 7.80 250 0.70

20 157 3.0 1920 7.50 250 0.80

25 163 3.2 1430 8.00 250 1.00

32 170 3.1 805 7.80 250 1.25

38 179 4.4 570 11.0 250 1.50

44 185 4.4 395

50 191 4.4 270

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

12 38 70 53

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air in Volts in ipm in factor % seconds

1/4 147 0.075 235 0.150 200 0.30

3/8 161 0.188 150 0.280 150 0.30

1/2 156 0.140 130 0.280 200 0.30

5/8 156 0.115 105 0.280 250 0.50

3/4 157 0.115 80 0.280 250 0.60

7/8 162 0.125 65 0.312 250 0.70

1.0 163 0.125 55 0.312 250 0.80

1-1/4 170 0.125 32 0.312 250 1.25

1-1/2 179 0.175 22 0.437 250 1.50

1-3/4 185 0.175 15

2.0 192 0.175 10

Mild steel

200 A Cutting

Arc

Torch-to-Work

Voltage

Arc

Voltage

Distance

Torch-to-Work

Distance

Cutting

Speed

Cutting

Speed

Flow rates – lpm/scfh

O

Preflow 7 / 15 27 / 57 123 / 260

Cutflow 32 / 67 123 / 260

Initial Pierce Height

Initial Pierce Height

2

Edge Start

Edge Start

N

2

Pierce Delay

Air

Time

Pierce Delay

Time

Field Service Bulletin 21

Page 24

HyPro2000 — HT2000 TORCH UPGRADE

O2 Plasma / Air Shield

SilverPlus electrode

220832 220925220834220831

220936

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

12 38 77 53

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air mm Volts mm mm/m mm factor % seconds

6 145 1.5 6210 3.0 200 0.30

8 154 3.4 4850 5.1 150 0.35

10 160 4.6 3735 6.9 150 0.40

12 157 3.8 3415 9.5 250 0.60

15 156 3.1 2845 7.8 250 0.70

20 158 3.0 1920 7.5 250 0.80

25 163 3.2 1430 8.0 250 1.00

32 170 3.1 805 7.8 250 1.25

38 179 4.4 565 11.0 250 1.50

44 185 4.4 395

50 191 4.4 270

Mild steel

200 A Cutting

Arc

Torch-to-Work

Voltage

Distance

Cutting

Speed

Flow rates – lpm/scfh

O

Preflow 7 / 15 27 / 57 123 / 260

Cutflow 34 / 72 123 / 260

Initial Pierce Height

2

Edge Start

N

2

Pierce Delay

Air

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

12 38 77 53

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air in Volts in ipm in factor % seconds

1/4 147 0.075 235 0.150 200 0.30

3/8 161 0.188 150 0.280 150 0.30

1/2 156 0.140 130 0.280 200 0.30

5/8 156 0.115 105 0.280 250 0.50

3/4 157 0.115 80 0.280 250 0.60

7/8 162 0.125 65 0.312 250 0.70

1.0 163 0.125 55 0.312 250 0.80

1-1/4 170 0.125 32 0.312 250 1.25

1-1/2 179 0.175 22 0.437 250 1.50

1-3/4 185 0.175 15

2.0 192 0.175 10

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start

Pierce Delay

Time

22 Field Service Bulletin

Page 25

HyPro2000 — HT2000 TORCH UPGRADE

Mild steel

Air Plasma / Air Shield

200 A Cutting

420045 220937220488420044

220936

Flow rates – lpm/scfh

Preflow 26 / 56 123 / 220

Cutflow 31 / 65 123 / 220

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air mm Volts mm mm/m mm factor % seconds

45 57 44

Test Cutfl ow

Flowrates

Material

Thickness

6 134 1.0 4885 3.0 300 0.3

8 138 1.3 4515 3.9 300 0.5

10 142 2.6 2975 5.2 200 0.8

12 145 3.0 2655 6.0 200 0.9

15 152 4.3 2265 8.6 200 1.0

20 160 4.8 1415 9.6 200 1.1

25 165 6.4 940 12.8 200 1.2

32 172 6.4 630 12.8 200 1.8

38 176 6.4 510

50 186 6.4 215

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start44 180 6.4 320

Air Air

Pierce Delay

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air in Volts in ipm in factor % seconds

45 57 44

Test Cutfl ow

Flowrates

Material

Thickness

1/4 134 0.040 190 0.120 300 0.3

5/16 138 0.050 180 0.150 300 0.5

3/8 142 0.100 120 0.200 200 0.8

1/2 145 0.125 100 0.250 200 0.9

5/8 152 0.188 85 0.375 200 1.0

3/4 155 0.188 60 0.375 200 1.1

7/8 160 0.188 50 0.375 200 1.2

1.0 165 0.250 35 0.500 200 1.2

1-1/4 172 0.250 25 0.500 200 1.8

1-1/2 176 0.250 20

2.0 186 0.250 8

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start1-3/4 180 0.250 12

Pierce Delay

Time

Field Service Bulletin 23

Page 26

HyPro2000 — HT2000 TORCH UPGRADE

Mild steel – 3 inch under water

O2 Plasma / Air Shield

Copper electrode

220832 220937220834220831

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

O

12 38 70 53

220936

220935

(No IHS tab)

Test Cutfl ow

Flowrates

2

Material

Thickness

Air mm Volts mm mm/m mm factor % seconds

6 142 0.7 6235 1.4 200 0.3

10 166 3.8 3460 7.6 200 0.3

12 159 2.9 3060 5.8 200 0.3

15 159 2.8 2555 5.6 200 0.5

20 163 3.0 1700 7.5 250 0.6

22 164 3.2 1545 8.0 250 0.7

25 165 3.2 1300 8.0 250 0.8

200 A Cutting

Arc

Torch-to-Work

Voltage

Distance

Cutting

Speed

Flow rates – lpm/scfh

O

Preflow 7 / 15 27 / 57 123 / 260

Cutflow 32 / 67 123 / 260

Initial Pierce Height

2

N

2

Pierce Delay

Air

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

12 38 70 53

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air in Volts in ipm in factor % seconds

1/4 145 0.040 235 0.080 200 0.3

3/8 168 0.157 140 0.312 200 0.3

1/2 157 0.100 115 0.200 200 0.3

5/8 160 0.115 95 0.230 200 0.5

3/4 163 0.115 70 0.290 250 0.6

7/8 164 0.125 60 0.312 250 0.7

1.0 165 0.125 50 0.312 250 0.8

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Pierce Delay

Time

24 Field Service Bulletin

Page 27

HyPro2000 — HT2000 TORCH UPGRADE

Mild steel – 3 inch under water

O2 Plasma / Air Shield

SilverPlus electrode

220832 220925220834220831

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

O

12 38 77 53

220936

220935

(No IHS tab)

Test Cutfl ow

Flowrates

2

Material

Thickness

Air mm Volts mm mm/m mm factor % seconds

6 142 0.7 6235 1.4 200 0.3

10 166 3.8 3460 7.6 200 0.3

12 159 2.9 3060 5.8 200 0.3

15 159 2.8 2555 5.6 200 0.5

20 163 3.0 1700 7.5 250 0.6

22 164 3.2 1545 8.0 250 0.7

25 165 3.2 1300 8.0 250 0.8

200 A Cutting

Arc

Torch-to-Work

Voltage

Distance

Cutting

Speed

Flow rates – lpm/scfh

O

Preflow 7 / 15 27 / 57 123 / 260

Cutflow 34 / 72 123 / 260

Initial Pierce Height

2

N

2

Pierce Delay

Air

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

O

2

N

2

12 38 77 53

Test Cutfl ow

Flowrates

O

2

Material

Thickness

Air in Volts in ipm in factor % seconds

1/4 145 0.040 235 0.080 200 0.3

3/8 168 0.157 140 0.312 200 0.3

1/2 157 0.100 115 0.200 200 0.3

5/8 160 0.115 95 0.230 200 0.5

3/4 163 0.115 70 0.290 250 0.6

7/8 164 0.125 60 0.312 250 0.7

1.0 165 0.125 50 0.312 250 0.8

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Pierce Delay

Time

Field Service Bulletin 25

Page 28

HyPro2000 — HT2000 TORCH UPGRADE

Stainless steel

Air Plasma / Air Shield

50 A Cutting

220532 220528220529220890

220936

Flow rates – lpm/scfh

Preflow 123 / 259

Cutflow 114 / 241

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air mm Volts mm mm/m mm factor % seconds

39 27 40

Test Cutfl ow

Flowrates

Material

Thickness

0.5 103 1.5 7620 3.0 200 0.0

0.8 104 1.5 6730 3.0 200 0.0

1.0 104 1.5 6350 3.0 200 0.1

1.2 105 1.8 5715 3.6 200 0.1

1.5 108 1.8 4830 3.6 200 0.1

2.0 110 1.8 4190 3.6 200 0.1

2.5 113 2.0 3175 4.0 200 0.2

3.0 114 2.0 2160 4.0 200 0.3

4.0 118 2.3 1400 4.6 200 0.4

6.0 122 2.5 1145 5.0 200 0.5

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Air

Pierce Delay

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air in Volts in ipm in factor % seconds

39 27 40

Test Cutfl ow

Flowrates

Material

Thickness

0.018 103 0.06 300 0.12 200 0.0

0.024 103 0.06 275 0.12 200 0.0

0.030 104 0.06 265 0.12 200 0.0

0.036 104 0.06 250 0.12 200 0.1

0.048 105 0.07 225 0.14 200 0.1

0.060 108 0.07 190 0.14 200 0.1

0.075 109 0.07 165 0.14 200 0.1

0.105 114 0.08 125 0.16 200 0.2

0.135 115 0.08 85 0.16 200 0.3

0.188 121 0.09 55 0.18 200 0.4

0.250 122 0.10 45 0.20 200 0.5

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Pierce Delay

Time

26 Field Service Bulletin

Page 29

HyPro2000 — HT2000 TORCH UPGRADE

Flow rates – lpm/scfh

Preflow 26 / 56 68 / 145

Cutflow 44 / 93 68 / 145

220536 220487220936

Stainless steel

Air Plasma / Air Shield

130 A Cutting

220488220892

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air mm Volts mm mm/m mm factor % seconds

45 77 24

Test Cutfl ow

Flowrates

Material

Thickness

6 142 3.5 2625 7.0 200 0.3

10 149 4.1 1700 8.2 200 0.5

12 152 4.1 1380 8.2 200 0.8

15 160 4.4 900

20 165 4.6 430

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start

Air Air

Pierce Delay

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air in Volts in ipm in factor % seconds

45 77 24

Test Cutfl ow

Flowrates

Material

Thickness

1/4 143 0.14 100 0.28 200 0.3

3/8 148 0.16 70 0.32 200 0.5

1/2 153 0.16 50 0.32 200 0.8

5/8 162 0.18 30

3/4 164 0.18 20

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start

Pierce Delay

Time

Field Service Bulletin 27

Page 30

HyPro2000 — HT2000 TORCH UPGRADE

Flow rates – lpm/scfh

Preflow 26 / 56 123 / 220

Cutflow 31 / 65 123 / 220

420045 220937220936

Stainless steel

Air Plasma / Air Shield

200 A Cutting

220488420044

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air mm Volts mm mm/m mm factor % seconds

45 57 44

Test Cutfl ow

Flowrates

Material

Thickness

5 140 2.7 5695 5.4 200 0.40

6 144 3.0 3105 6.0 200 0.40

10 144 3.2 2485 6.4 200 0.50

12 147 3.2 2245 6.4 200 0.75

15 152 3.8 1700 7.6 200 0.80

20 156 4.9 1155 9.8 200 1.00

25 162 5.6 670

38 180 5.6 310

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start32 172 5.6 515

Air Air

Pierce Delay

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air in Volts in ipm in factor % seconds

45 57 44

Test Cutfl ow

Flowrates

Material

Thickness

3/16 140 0.110 230 0.22 200 0.40

1/4 144 0.120 200 0.24 200 0.40

3/8 144 0.125 160 0.25 200 0.50

1/2 147 0.125 110 0.25 200 0.75

5/8 152 0.157 85 0.315 200 0.80

3/4 156 0.188 60 0.375 200 1.00

7/8 160 0.210 50 0.420 200 1.20

1.0 162 0.220 40

1-1/2 180 0.220 12

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start1-1/4 172 0.220 20

Pierce Delay

Time

28 Field Service Bulletin

Page 31

HyPro2000 — HT2000 TORCH UPGRADE

420045 020415220936

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

N

2

Test Cutfl ow

Flowrates

N

2

45 55 44

Stainless steel

N2 Plasma / Air Shield

200 A Cutting

Flow rates – lpm/scfh

N

Preflow 26 / 56 123 / 220

Cutflow 31 / 65 123 / 220

2

220529420044

Material

Thickness

Air mm Volts mm mm/m mm factor % seconds

5 154 3.0 3505 6.0 200 0.40

6 155 3.0 3355 6.0 200 0.40

10 156 3.0 2670 6.0 200 0.50

12 158 3.0 2210 6.0 200 0.75

15 160 4.0 1930 8.0 200 0.80

20 162 4.8 1180 9.6 200 1.00

22 167 4.8 1035 9.6 200 1.20

25 172 6.2 890 12.4 200 1.30

32 180 6.2 610

38 188 6.2 380

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start

Pierce Delay

Time

Air

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

N

2

45 55 44

Test Cutfl ow

Flowrates

N

2

Material

Thickness

Air in Volts in ipm in factor % seconds

3/16 154 0.125 230 0.25 200 0.40

1/4 155 0.125 200 0.25 200 0.40

3/8 156 0.125 160 0.25 200 0.50

1/2 158 0.125 110 0.25 200 0.75

5/8 160 0.157 75 0.315 200 0.80

3/4 162 0.188 60 0.375 200 1.00

7/8 167 0.188 40 0.375 200 1.20

1.0 172 0.250 35 0.50 200 1.30

1-1/4 180 0.250 25

1-1/2 188 0.250 15

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start

Pierce Delay

Time

Field Service Bulletin 29

Page 32

HyPro2000 — HT2000 TORCH UPGRADE

Aluminum

Air Plasma / Air Shield

50 A Cutting

220532 220528220529220890

220936

Flow rates – lpm/scfh

Preflow 123 / 259

Cutflow 114 / 241

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air mm Volts mm mm/m mm factor % seconds

39 27 40

Test Cutfl ow

Flowrates

Material

Thickness

0.5 110 1.5 8000 3.0 200 0.0

0.8 111 1.6 7750 3.2 200 0.0

1.0 112 1.8 7115 3.6 200 0.1

1.2 112 1.8 6350 3.6 200 0.1

1.5 113 1.8 5335 3.6 200 0.1

2.0 118 2.0 4200 4.0 200 0.1

2.5 121 2.0 3300 4.0 200 0.2

3.0 122 2.0 2800 4.0 200 0.3

4.0 123 2.2 2300 4.4 200 0.4

6.0 128 2.5 1400 5.0 200 0.5

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Air

Pierce Delay

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air in Volts in ipm in factor % seconds

39 27 40

Test Cutfl ow

Flowrates

Material

Thickness

0.018 110 0.06 325 0.12 200 0.0

0.020 110 0.06 315 0.12 200 0.0

0.024 110 0.06 305 0.12 200 0.0

0.030 111 0.06 295 0.12 200 0.1

0.036 112 0.07 280 0.14 200 0.1

0.048 112 0.07 230 0.14 200 0.2

0.060 113 0.07 195 0.14 200 0.2

0.075 118 0.08 160 0.16 200 0.2

0.105 121 0.08 120 0.16 200 0.3

0.125 122 0.08 100 0.16 200 0.3

3/16 124 0.09 75 0.18 200 0.4

1/4 129 0.10 50 0.20 200 0.5

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Pierce Delay

Time

30 Field Service Bulletin

Page 33

HyPro2000 — HT2000 TORCH UPGRADE

Flow rates – lpm/scfh

Preflow 26 / 56 68 / 145

Cutflow 44 / 93 68 / 145

220536 220487220936

Aluminum

Air Plasma / Air Shield

130 A Cutting

220488220892

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air mm Volts mm mm/m mm factor % seconds

45 77 24

Test Cutfl ow

Flowrates

Material

Thickness

6 152 2.8 2370 5.6 200 0.2

10 155 3.0 1470 6.0 200 0.3

12 157 3.0 1230 6.0 200 0.5

15 161 3.2 1050 6.4 200 0.8

20 164 3.6 725 7.9 220 1.3

25 172 4.0 525 Edge Start

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Air Air

Pierce Delay

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air in Volts in ipm in factor % seconds

45 77 24

Test Cutfl ow

Flowrates

Material

Thickness

1/4 152 0.11 90 0.22 200 0.2

3/8 155 0.12 60 0.24 200 0.3

1/2 157 0.12 45 0.24 200 0.5

5/8 162 0.13 40 0.26 200 0.8

3/4 163 0.14 30 0.31 220 1.3

1.0 173 0.16 20 Edge Start

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Pierce Delay

Time

Field Service Bulletin 31

Page 34

HyPro2000 — HT2000 TORCH UPGRADE

Flow rates – lpm/scfh

Preflow 26 / 56 123 / 220

Cutflow 31 / 65 123 / 220

420045 220937220936

Aluminum

Air Plasma / Air Shield

200 A Cutting

220488420044

220935

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air mm Volts mm mm/m mm factor % seconds

45 57 44

Test Cutfl ow

Flowrates

Material

Thickness

5 145 2.2 6215 4.4 200 0.5

6 148 3.0 5195 6.0 200 0.5

10 151 3.3 3930 6.6 200 0.5

12 154 3.7 3370 7.4 200 0.5

15 157 4.0 2625 8.0 200 0.8

20 161 4.9 1625 9.8 200 1.0

25 174 5.6 1050

38 196 5.6 310

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start32 186 5.6 515

Air Air

Pierce Delay

Time

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

Air Air Air in Volts in ipm in factor % seconds

45 57 44

Test Cutfl ow

Flowrates

Material

Thickness

3/16 145 0.100 230 0.200 200 0.50

1/4 148 0.125 200 0.250 200 0.50

3/8 151 0.125 160 0.250 200 0.50

1/2 154 0.150 125 0.300 200 0.50

5/8 157 0.160 95 0.320 200 0.80

3/4 161 0.188 70 0.375 200 1.00

7/8 166 0.210 50 0.420 200 1.20

1.0 174 0.220 40

1-1/2 196 0.220 12

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start1-1/4 186 0.220 20

Pierce Delay

Time

32 Field Service Bulletin

Page 35

HyPro2000 — HT2000 TORCH UPGRADE

420045 020415220936

(No IHS tab)

Metric

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

N

2

Test Cutfl ow

Flowrates

N

2

45 55 44

Aluminum

N2 Plasma / Air Shield

200 A Cutting

Flow rates – lpm/scfh

N

Preflow 26 / 56 123 / 220

Cutflow 31 / 65 123 / 220

2

220529420044

220935

Material

Thickness

Air mm Volts mm mm/m mm factor % seconds

5 150 2.2 4750 4.4 200 0.5

6 153 3.0 4345 6.0 200 0.5

10 156 3.3 3050 6.6 200 0.5

12 159 3.7 2490 7.4 200 0.5

15 165 4.0 2010 8.0 200 0.8

20 170 4.9 1450 9.8 200 1.0

22 176 5.6 1295 11.2 200 1.2

25 184 5.6 1040

38 200 5.6 510

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start32 194 5.6 740

Pierce Delay

Time

Air

English

Test Prefl ow

Flowrates

Prefl ow % Plasma % Shield (psi)

N

2

45 55 44

Test Cutfl ow

Flowrates

N

2

Material

Thickness

Air in Volts in ipm in factor % seconds

3/16 150 0.125 190 0.25 200 0.5

1/4 153 0.125 200 0.25 200 0.5

3/8 156 0.125 160 0.25 200 0.5

1/2 159 0.125 125 0.25 200 0.5

5/8 165 0.157 95 0.314 200 0.8

3/4 170 0.188 70 0.375 200 1.0

7/8 176 0.250 50 0.50 200 1.2

1.0 184 0.250 40

1-1/2 200 0.250 12

Arc

Voltage

Torch-to-Work

Distance

Cutting

Speed

Initial Pierce Height

Edge Start1-1/4 194 0.250 20

Pierce Delay

Time

Field Service Bulletin 33

Page 36

HyPro2000 — HT2000 TORCH UPGRADE

34 Field Service Bulletin

Loading...

Loading...