Page 1

HPR800XD™ Auto Gas

Preventive Maintenance Program

Instruction Manual

808680 | Revision 2 | English

Page 2

HPR, Phoenix, XD, and Hypertherm are trademarks of Hypertherm, Inc. and may be registered in the United States and other

countries. All other trademarks are the property of their respective holders.

© 2018 Hypertherm, Inc.

Page 3

HPR800XD Auto Gas

Preventive Maintenance Program

Instruction Manual

808680

Revision 2

English

November 2018

Hypertherm, Inc.

Hanover, NH 03755 USA

Page 4

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

877-371-2876 Fax (Return Materials Authorization)

return.materials@hypertherm.com (RMA email)

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Soporte.Tecnico@hypertherm.com (Technical Service Email)

Hypertherm Plasmatechnik GmbH

Sophie-Scholl-Platz 5

63452 Hanau

Germany

00 800 33 24 97 37 Tel

00 800 49 73 73 29 Fax

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emea@hypertherm.com (Technical Service Email)

Hypertherm (Singapore) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

Marketing.asia@hypertherm.com (Marketing Email)

TechSupportAPAC@hypertherm.com (Technical Service Email)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

HTJapan.info@hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com (Technical Service Email)

Hypertherm Europe B.V.

Vaartveld 9, 4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emea@hypertherm.com

(Technical Service Email)

Hypertherm (Shanghai) Trading Co., Ltd.

B301, 495 ShangZhong Road

Shanghai, 200231

PR China

86-21-80231122 Tel

86-21-80231120 Fax

86-21-80231128 Tel (Technical Service)

techsupport.china@hypertherm.com

(Technical Service Email)

South America & Central America: Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP – Brasil

CEP 07115-030

55 11 2409 2636 Tel

tecnico.sa@hypertherm.com (Technical Service Email)

Hypertherm Korea Branch

#3904. APEC-ro 17. Heaundae-gu. Busan.

Korea 48060

82 (0)51 747 0358 Tel

82 (0)51 701 0358 Fax

Marketing.korea@hypertherm.com (Marketing Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm Pty Limited

GPO Box 4836

Sydney NSW 2001, Australia

61 (0) 437 606 995 Tel

61 7 3219 9010 Fax

au.sales@Hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm (India) Thermal Cutting Pvt. Ltd

A-18 / B-1 Extension,

Mohan Co-Operative Industrial Estate,

Mathura Road, New Delhi 110044, India

91-11-40521201/ 2/ 3 Tel

91-11 40521204 Fax

HTIndia.info@hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Page 5

ENGLISH

Copies of the manuals may accompany the product in electronic and printed

formats. You can also obtain copies of the manuals, in all languages available

for each manual, from the “Documents library” at www.hypertherm.com.

SVENSKA / SWEDISH

Kopior av manualen kan medfölja produkten i elektronisk och tryckform.

Du hittar även kopior av manualerna i alla tillgängliga språk

i dokumentbiblioteket (Documents library) på www.hypertherm.com.

DEUTSCH / GERMAN

Bedienungsanleitungen und Handbücher können dem Gerät in

elektronischer Form oder als Druckversion beiliegen. Alle Handbücher

und Anleitungen können in den jeweils verfügbaren Sprachen auch in der

„Dokumente-Bibliothek“ unter www.hypertherm.com heruntergeladen werden.

FRANÇAIS / FRENCH

Des copies de ces manuels peuvent accompagner le produit en format

électronique et papier. Vous pouvez également obtenir des copies de chaque

manuel dans toutes les langues disponibles à partir de la «Bibliothèque

de documents» sur www.hypertherm.com.

ESPAÑOL / SPANISH

Pueden venir copias de los manuales en formato electrónico e impreso

junto con el producto. También se pueden obtener copias de los manuales,

en todos los idiomas disponibles para cada manual, de la “Biblioteca

de documentos” en www.hypertherm.com.

ITALIANO / ITALIAN

Il prodotto può essere accompagnato da copie elettroniche e cartacee

del manuale. È anche possibile ottenere copie del manuale, in tutte le lingue

disponibili per ogni manuale, dall’“Archivio documenti” all’indirizzo

www.hypertherm.com.

NEDERLANDS / DUTCH

De handleidingen kunnen in elektronische en gedrukte vorm met het

product worden meegeleverd. De handleidingen, elke handleiding

beschikbaar in alle talen, zijn ook verkrijgbaar via de “Documentenbibliotheek”

op www.hypertherm.com.

DANSK / DANIS H

Kopier af manualerne kan ledsage produktet i elektroniske og trykte formater.

Du kan også få kopier af manualer, på alle sprog der er til rådighed for hver

manuel, fra “Dokumentbiblioteket” på www.hypertherm.com.

한국어 / KOREAN

전자 형식과 인쇄된 형식으로 설명서 사본이 제품과 함께 제공될

수 있습니다. www.hypertherm.com 의 'Documents library (문서라이브러리)'

에서도모든언어로이용할수있는설명서사본을얻을수있습니다.

ČESKY / CZECH

Kopie příruček a manuálů mohou být součástí dodávky produktu, a to

v elektronické i tištěné formě. Kopie příruček a manuálů ve všech jazykových

verzích, v nichž byly dané příručky a manuály vytvořeny, naleznete v „Knihovně

dokumentů“ na webových stránkách www.hypertherm.com.

POLSKI / POLISH

Do produktu mogą być dołączone kopie podręczników w formacie

elektronicznym i drukowanym. Kopie podręczników, wkażdym udostępnionym

języku, można również znaleźć w„Bibliotece dokumentów” pod adresem

www.hypertherm.com.

PУССКИЙ / RUSSIAN

Копии руководств, которые поставляются вместе с продуктом, могут быть

представлены в электронном и бумажном виде. Копии руководств на всех

языках, на которые переведено то или иное руководство, можно также

загрузить в разделе «Библиотека документов» на веб-сайте

www.hypertherm.com.

SUOMI / FINNISH

Käyttöoppaiden kopiot voivat olla tuotteen mukana elektronisessa ja

tulostetussa muodossa. Voit saada käyttöoppaiden kopiot kaikilla kielillä

”latauskirjastosta”, joka on osoitteessa www.hypertherm.com.

БЪЛГAPCКИ / BULGARIAN

Копия на ръководствата може да придружават продукта в електронен и в

печатен формат. Можете да получите копия на ръководствата, предлагани

на всички езици, от „Documents library“ (Библиотека за документи)

на адрес www.hypertherm.com.

PORTUGUÊS / PORTUGUESE

Cópias dos manuais podem acompanhar os produtos nos formatos eletrônico

e impresso. Também é possível obter cópias dos manuais em todos os idiomas

disponíveis para cada manual na “Biblioteca de documentos” em

www.hypertherm.com.

日本語 / JAPANESE

説明書のコピーは、電子フォーマット、または印刷物として製品に同梱さ

れています。各説明書は、 www.hypertherm.com の「ドキュメントライブラ

リ」から各言語で入手できます。

简体中文 / CHINESE (SIMPLIFIED)

随产品提供的手册可能提供电子版和印刷版两种格式。您也可从

“Documents library” (文档资料库)中获取每本手册所有可用语言的副本,

网址为 www.hypertherm.com.

NORSK / NORWEGIAN

Eksemplarer av håndbøkene kan medfølge produktet i elektroniske og trykte

utgaver. Du kan også få eksemplarer av håndbøkene i alle tilgjengelige språk

for hver håndbok fra dokumentbiblioteket på www.hypertherm.com.

ROMÂNĂ / ROMANIAN

Produsul poate fi însoțit de copii ale manualului în format tipărit și electronic.

De asemenea, dumneavoastră puteţi obţine copii ale manualelor, în toate limbile

disponibile pentru fiecare manual, din cadrul secţiunii „Bibliotecă documente”

aflată pe site-ul www.hypertherm.com.

TÜRKÇE / TURKISH

Kılavuzların kopyaları, elektronik ve basılı formatta ürünle birlikte verilebilir.

Her biri tüm dillerde yayınlanan kılavuzların kopyalarını www.hypertherm.com

adresindeki “Documents library” (Dosyalar kitaplığı) başlığından da elde

edebilirsiniz.

MAGYAR / HUNGARIAN

A termékhez a kézikönyv példányai elektronikus és nyomtatott formában

is mellékelve lehetnek. A kézikönyvek példányai (minden nyelven) a

www.hypertherm.com weboldalon a „Documents library” (Dokumentum

könyvtár) részben is beszerezhetők.

ΕΛΛΗΝΙΚΆ / GREEK

Αντίγραφα των εγχειριδίων μπορεί να συνοδεύουν το προϊόν σε ηλεκτρονική

και έντυπη μορφή. Μπορείτε, επίσης, να λάβετε αντίγραφα των εγχειριδίων σε

όλες τις γλώσσες που διατίθενται για κάθε εγχειρίδιο από την ψηφιακή

βιβλιοθήκη εγγράφων (Documents library) στη διαδικτυακή τοποθεσία

www.hypertherm.com.

Page 6

繁體中文 / CHINESE (TRADITIONAL)

手冊複本可能以電子和印刷格式隨附產品提供。您也可以在

www.hypertherm.com 的 「文檔資料庫」內獲取所有手冊的多語種複本。

SLOVENŠČINA / SLOVENIAN

Izdelku so lahko priloženi izvodi priročnikov v elektronski ali tiskani obliki. Izvode

priročnikov v vseh razpoložljivih jezikih si lahko prenesete tudi iz knjižnice

dokumentov “Documents library” na naslovu www.hypertherm.com.

SRPSKI / SERBIAN

Može se dogoditi da kopije priručnika prate proizvod u elektronskom

i štampanom formatu. Takođe možete da pronađete kopije priručnika, na svim

jezicima koji su dostupni za svaki od priručnika, u “Biblioteci dokumenata”

(“Documents library”) na www.hypertherm.com.

SLOVENČINA / SLOVAK

Kópia návodu, ktorá je dodávaná s produktom, môže mať elektronickú

alebo tlačenú podobu. Kópie návodov, vo všetkých dostupných jazykoch,

sú k dispozícii aj v sekcii z „knižnice Dokumenty“ na www.hypertherm.com.

Page 7

Contents

Preventive Maintenance Program ............................................................................................ 9

Overview ............................................................................................................................................................................................. 9

Cleaning and inspection schedule ............................................................................................................................................ 10

Daily .......................................................................................................................................................................................... 11

Do a test of the inlet pressures ................................................................................................................................... 11

Examine all of the air filters .......................................................................................................................................... 11

Do a check of the coolant level and condition ........................................................................................................ 11

Examine and lubricate O-rings .................................................................................................................................... 12

Examine the water tube and torch ............................................................................................................................. 12

Weekly ...................................................................................................................................................................................... 13

Examine hoses and torch leads .................................................................................................................................. 13

Do tests for gas leaks ................................................................................................................................................... 13

Do a check of the coolant flow ................................................................................................................................... 13

Do a check of the coolant level .................................................................................................................................. 13

Monthly ..................................................................................................................................................................................... 14

Clean inside the power supply ................................................................................................................................... 14

Clean the chiller air filter ............................................................................................................................................... 14

Clean inside the chiller ................................................................................................................................................. 15

Examine the coolant system ........................................................................................................................................ 15

Examine the main contactor ........................................................................................................................................ 16

Examine the pilot arc relay ........................................................................................................................................... 16

Do the coolant flow test ............................................................................................................................................... 16

Examine the gas line connections .............................................................................................................................. 17

Examine the hoses ......................................................................................................................................................... 17

Examine the cables ........................................................................................................................................................ 17

Examine the ground connections ............................................................................................................................... 17

Examine the table-to-workpiece connection ........................................................................................................... 17

Component replacement schedule ........................................................................................................................................... 18

HPR800XD Auto Gas Instruction Manual 808680 7

Page 8

Contents

Cutting area and operation effects .....................................................................................................................................21

External cutting area .......................................................................................................................................................21

Incoming air supply quality ............................................................................................................................................22

Metal dust inside the power supply cabinet .............................................................................................................22

Consumable use .............................................................................................................................................................23

Cut-cycle time .................................................................................................................................................................24

Find arc hour data on a Hypertherm CNC ...............................................................................................................................25

Part numbers for HPR800XD Auto Gas cables and leads ..................................................................................................26

Primary power supply to secondary power supply cables ............................................................................................26

Interface cable .................................................................................................................................................................26

Communication cable ....................................................................................................................................................26

Power supply to ignition console leads .............................................................................................................................26

Pilot arc lead ....................................................................................................................................................................26

Negative lead ...................................................................................................................................................................26

Ignition console power cable .......................................................................................................................................27

Coolant hoses .........................................................................................................................................................................27

Chiller-interface console to ignition console ............................................................................................................27

Chiller to chiller-interface console ..............................................................................................................................27

Power supply to chiller cables .............................................................................................................................................27

Control cable ...................................................................................................................................................................27

Power cable .....................................................................................................................................................................27

Power supply to selection console cables .......................................................................................................................28

Control cable ...................................................................................................................................................................28

Power cable .....................................................................................................................................................................28

Cable and gas hose assembly (selection console to metering console) ..................................................................28

Power supply to CNC interface cable ...............................................................................................................................28

Torch lead .................................................................................................................................................................................29

Work lead .................................................................................................................................................................................29

Ohmic contact wire ................................................................................................................................................................29

Supply gas hoses ...................................................................................................................................................................30

Air hose .............................................................................................................................................................................30

Argon-hydrogen (H35) or nitrogen-hydrogen (F5) hose .......................................................................................30

Nitrogen or argon hose .................................................................................................................................................30

Oxygen hose ....................................................................................................................................................................30

System information .........................................................................................................................................................................31

Model number ..........................................................................................................................................................................31

Serial number ...........................................................................................................................................................................31

System voltage ........................................................................................................................................................................31

Coolant requirements ............................................................................................................................................................31

Notes .................................................................................................................................................................................................32

Maintenance log for HPR800XD Auto Gas plasma systems ..............................................................................................33

8 HPR800XD Auto Gas Instruction Manual 808680

Page 9

Preventive Maintenance Program

Overview

Congratulations on the purchase of your Hypertherm plasma system.

Hypertherm plasma systems can operate in harsh conditions for many years. To maintain system performance, minimize

operating costs, and lengthen system life, follow the maintenance procedures given in this Preventative Maintenance

Program (PMP).

Hypertherm made this PMP specifically for your plasma system. The PMP has two parts: a cleaning and inspection

schedule and a component replacement schedule.

If you have questions about how to maintain your plasma system, contact your OEM or regional Hypertherm Technical

Service team. You can find contact information for each regional office at www.hypertherm.com

page.

This document refers to your system’s instruction manual. If you do not have your instruction manual, you can find it at

www.hypertherm.com/docs

HPR800XD Auto Gas Instruction Manual: 806500

.

on the “Contact us”

HPR800XD Auto Gas Instruction Manual 808680 9

Page 10

Preventive Maintenance Program

Cleaning and inspection schedule

This is a daily, weekly, and monthly schedule for cleaning and inspections. The PMP has instructions for each task. These

instructions help your personnel understand what to do and what to look for during each task. In general, an operator can

do the daily and weekly tasks, while maintenance personnel usually do the monthly tasks.

A monthly maintenance log is in the back of this manual. You can make photocopies of the maintenance log to record

tasks.

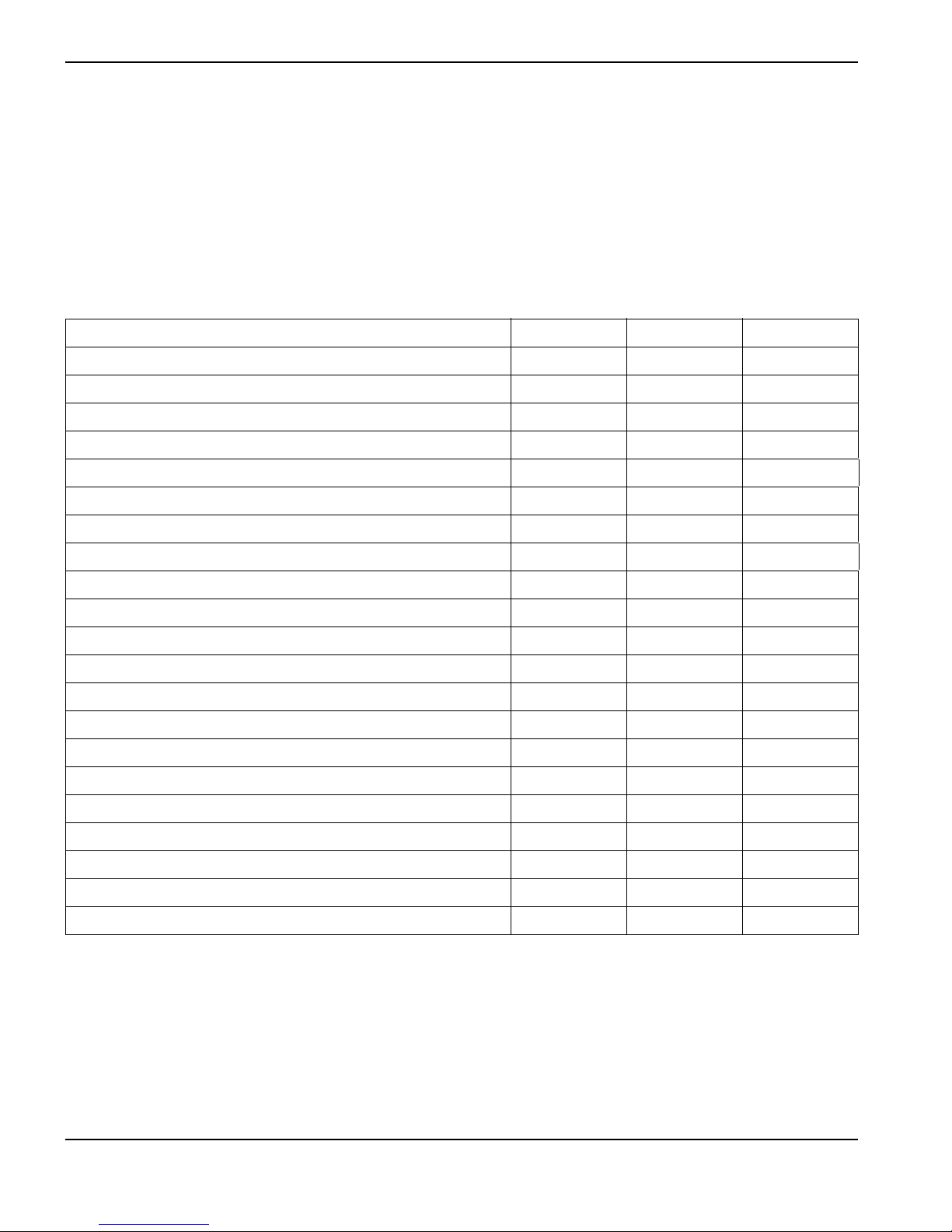

Table 1

Maintenance task or activity Daily Weekly Monthly

Do a test of the inlet pressures X

Examine all of the air filters X

Do a check of the coolant level and condition X

Examine and lubricate O-rings X

Examine the water tube and torch X

Examine hoses and torch leads X

Do tests for gas leaks X

Do a check of the coolant flow* X

Do a check of the coolant level* X

Clean inside the power supply* X

Clean the chiller air filter* X

Clean inside the chiller* X

Examine the coolant system* X

Examine the main contactor X

Examine the pilot arc relay X

Do the coolant flow test X

Examine the gas line connections X

Examine the hoses X

Examine the cables X

Examine the ground connections X

Examine the table-to-workpiece connection X

*See the chiller manufacturer manual for guidance on chiller maintenance. Chiller manufacturer specifications override Hypertherm’s

recommendations for chiller maintenance.

10 HPR800XD Auto Gas Instruction Manual 808680

Page 11

Preventive Maintenance Program

1

3

4

Daily

Do a test of the inlet pressures

1. With the gas flowing in test preflow mode, make sure that the pressure at the

regulator is set to 8 bar (115 psi).

2. Repeat the test in cutflow mode, and make sure that the regulator is set to 8 bar

(115 psi).

For instructions about setting supply regulators, see Setting the supply

regulators in your system’s instruction manual.

Examine all of the air filters

Examine all of the air filters for contamination.

If you find moisture or oil, replace the air filter.

If you find a moderate quantity of solid contamination, such as

dust, blow air through it or use suction to clean the filter.

If you find a large quantity of solid contamination, replace the air

filter.

See Air filter element replacement in your system’s instruction

manual for replacement instructions.

Do a check of the coolant level and condition

Make sure that the coolant tank in the chiller is full:

1. Remove the panel from the left rear side of the chiller.

2. Look at the coolant tank.

3. If the level is more that 5.1 cm (2 inches) from the top of the tank, add coolant (028872) to this level.

4. Record the number of gallons your system requires in Coolant requirements on page 31.

Examine the coolant tank for contamination. If you find any contamination, drain the tank and replace the coolant. See

Draining the coolant system in your system’s instruction manual for instructions.

Examine the inline coolant strainers in the chiller. See the DuraChill 5 HP Air-Cooled Chiller For Hypertherm Instruction

Manual (806600) for details.

HPR800XD Auto Gas Instruction Manual 808680 11

Page 12

Preventive Maintenance Program

1

2

3

Examine and lubricate O-rings

1. Examine all of the O-rings on the torch and consumables for

damage.

2. If you find damage, replace the O-ring.

Receptacle O-rings and torch O-rings for the torch main body

are available as part of kit 428252. Other O-rings are included

with the consumables.

3. Apply a thin film of silicone lubricant (027055) to all O-rings.

The O-rings should look shiny. Too much lubricant can prevent

gas flow.

4. Install all O-rings so they fit snugly.

5. Examine all threaded consumables, and remove any dirt from the

threads.

Examine the water tube and torch

1. Examine the water tube for bends and pitting.

2. Examine the nozzle and electrode mating surfaces on the torch main body for

damage or pitting.

3. Use a clean cloth to clean the internal and external surfaces of the torch. Use a

cotton swab to clean internal surfaces that are not easy to get to.

Make sure that you do not leave any cotton fibers on the inner surfaces of the

torch main body.

4. Use compressed air to remove any remaining particles from the torch main body.

12 HPR800XD Auto Gas Instruction Manual 808680

Page 13

Preventive Maintenance Program

Weekly

Examine hoses and torch leads

1. Examine all air hoses, coolant hoses, and torch leads for:

Scrapes, cuts, or holes

Chemical spills or burns

Kinks or bends

2. Replace any hoses or leads that have damage.

See Part numbers for HPR800XD Auto Gas cables and leads on page 26 for lengths and part numbers.

Do tests for gas leaks

For more information, see Gas leak tests in the Maintenance section of your system’s instruction manual.

Do the following gas system tests:

Inlet Leak test

System Leak test

Proportional valve test – Make sure that you use the 130 A O

/Air consumables and that you select the 30 A O2/O2

2

plasma process.

Do a check of the coolant flow

Find the flow rate shown on the CNC’s diagnostic screen. Record the coolant flow.

If the information on the CNC indicates a problem with the coolant flow, do the tests described in Coolant flow tests in

the Maintenance section of your system’s instruction manual.

If the flow rate is below 2.9 L/min (0.75 g/min), contact your maintenance department to service the coolant system.

Do a check of the coolant level

Make sure that the coolant tank in the chiller is full:

1. Remove the panel from the rear left side of the chiller.

2. Look at the coolant tank.

3. If the level is more that 5.1 cm (2 inches) from the top of the tank, add coolant (028872) to this level.

4. Record the number of gallons your system requires in Coolant requirements on page 31.

HPR800XD Auto Gas Instruction Manual 808680 13

Page 14

Preventive Maintenance Program

Monthly

Disconnect electric power before performing any maintenance.

All work requiring removal of the power supply cover must be performed by

a qualified technician.

Read the Safety and Compliance Manual (80669C) for important safety

information.

Clean inside the power supply

1. Turn OFF the power to the power supply.

2. Remove the top and side panels of the power supply.

WARNING!

ELECTRIC SHOCK CAN KILL

3. Use low pressure air or a vacuum to remove any accumulation of dust and particles from:

The top and side panels

The inside of the power supply

The fans

4. Remove dust and particles from circuit boards.

Be careful not to damage the circuit boards.

5. Install the top and side panels before you turn ON the power.

Clean the chiller air filter

These instructions are only for the PolyScience chiller. If you do not use a PolyScience chiller, refer to the chiller

manufacturer manual for air filter replacement and more information on how to clean the air filter.

Chillers have 3 reusable air filters. Chillers in dusty environments need their filters cleaned more frequently.

Do not let the air filters become clogged with dust. This reduces air flow and can decrease cooling efficiency. It can also

lead to filter breakthrough, allowing dust to get into the condenser coils.

To remove and clean the chiller’s air filters:

1. Hold the strap at the bottom center of the filter and carefully lift it up and away from the chiller housing.

2. Use a water or high pressure air stream directed through the back of the air filter (the downstream side) to remove

dust from the filter. Let the filter dry, as required.

3. Position the top edge of filter in the upper channel of the chiller housing.

4. Carefully lift on the bottom strap while pushing the bottom edge of the filter toward the housing.

14 HPR800XD Auto Gas Instruction Manual 808680

Page 15

Preventive Maintenance Program

Clean inside the chiller

1. Turn OFF the power to the chiller.

2. Remove the top and side panels.

3. Blow out or vacuum any accumulation of dust and particulates from:

The top and side panels

The inside of the chiller

The fans

4. Remove dust and particulates from circuit boards.

Be careful not to damage the circuit boards.

5. Install the top and side panels before you turn ON the power.

Examine the coolant system

Examine the coolant system for coolant leaks at all connections. Make sure you examine:

The ignition console

The torch main body

The internal connection in the power supply

All of the connections in the chiller

HPR800XD Auto Gas Instruction Manual 808680 15

Page 16

Preventive Maintenance Program

1

2

Examine the main contactor

1. Examine the contacts in the main contactor for black or rough surfaces.

2. If you find too much of this condition, replace the main contactor.

Examine the pilot arc relay

1. Remove the cover of the pilot

arc relay.

2. Examine the contacts inside the

relay for black or rough

surfaces.

3. If you find too much of this

condition, replace the pilot arc

relay.

4. Install the cover of the pilot arc

relay.

Be careful that you do not pinch the wires between the cover and the center panel.

Do the coolant flow test

Do the coolant flow test and record the coolant flow rate. You can find the coolant flow rate on the diagnostic screen

on the CNC. For more information, see Do a check of the coolant flow on page 13.

If the flow rate is below 2.9 L/min (0.75 g/min), do the coolant flow test in Coolant flow tests in the Maintenance

section of your system’s instruction manual. You may need to service the coolant system or replace the coolant pump

or motor.

The flow alarm turns on when the flow rate is below 2.3 L/min (0.6 g/min). For more information, see Testing the flow

sensor in the Maintenance section of your system’s instruction manual.

Examine the coolant tank for contamination. If you find any contamination, flush the tank. See Do a check of the

coolant level and condition on page 11 for instructions.

Make sure that you use the correct Hypertherm coolant (028872) or use water that meets the requirements in Water

purity requirements in the Installation section of your system’s instruction manual.

16 HPR800XD Auto Gas Instruction Manual 808680

Page 17

Preventive Maintenance Program

Examine the gas line connections

Spray all of the gas line connections with soapy water. If bubbles appear on a gas line, tighten or replace it as necessary.

See Part numbers for HPR800XD Auto Gas cables and leads on page 26 for lengths and part numbers.

CAUTION!

Do not clean brass connections with ammonia-based cleaners. Ammonia causes brass to crack and

become brittle.

Examine the hoses

Examine each hose for kinks or sharp bends that can restrict gas flow or cause damage to the hose.

If the cutting table uses a power track system to support the leads that go from the power supply to the gas console or

torch, look at the position of the leads in the track. Make sure the leads do not twist or kink. This can cause a restriction.

Examine the cables

Examine all cables for scratches or unusual wear. If the outside insulation is cut or has any other damage, replace the

cable. See Part numbers for HPR800XD Auto Gas cables and leads on page 26 for lengths and part numbers.

Examine the ground connections

Make sure that all components of the system are individually grounded to a driven earth ground. See the Installation and

Grounding section of your system’s instruction manual.

Examine the table-to-workpiece connection

Examine the work lead (+) connection where the work lead (+) connects to the cutting table.

Make sure that there is no paint, oil, dirt, or rust on the workpiece. This type of contamination prevents a clean

metal-to-metal contact between the work lead and the cutting table or workpiece. It can also cause arc-transfer

problems.

HPR800XD Auto Gas Instruction Manual 808680 17

Page 18

Preventive Maintenance Program

Component replacement schedule

This is a list of components and their recommended replacement schedules. The schedule uses total arc hours to

estimate when to replace a component. The use of cumulative arc hours is the most accurate method to estimate when

you need to replace a component.

If you have a Hypertherm CNC, you can find the total number of arc hours on the CNC. See Find arc hour data on a

Hypertherm CNC on page 25. You can also find cumulative arc hours on a serial communication link between your CNC

and power supply.

If you do not have a Hypertherm CNC and your CNC cannot track arc hours, use the guide below to estimate arc hours

per year. This guide uses the average number of 8-hour shifts that the system operates on an average work day. For more

information about calculating arc hours, contact your table manufacturer.

Average shifts per day Estimated arc hours per year

1500

2 1,000

31,500

Your cutting area and operations can have an effect on this schedule. See Cutting area and operation effects on page 21.

Record information about your system and its replacement requirements in the following places:

Part numbers for HPR800XD Auto Gas cables and leads on page 26

System information on page 31

Notes on page 32

18 HPR800XD Auto Gas Instruction Manual 808680

Page 19

HPR800XD Auto Gas Instruction Manual 808680 19

Preventive Maintenance Program

Tabl e 2

Item

Number

Quantity Component

Cumulative number of arc hours

500 1,000 1,500 2,000 2,500 3,000 3,500 4,000 4,500 5,000 5,500 6,000

428263 1 Torch rebuild and filter kit without coolant* X X X X X X X X X X X X

428264 1 Torch rebuild and filter kit with coolant* X X X X X X X X X X X X

028872 4–6Coolant (in gallons)** XXXXXXXXXXXX

Kit: Electronics***

428270

428272

2 200 V – 240 V

380 V – 600 V

XXXXXX

003249 2 Inrush contactor XXXX X

220705 1 Quick-disconnect torch receptacle X X X

1Torch lead

†

XXX

006113 1 Coolant check valve X X

006077 2 Gas check valve X X

027079 6 10-inch fan X X

127039 16 6-inch fan XX

229235 1 Coolant flow switch X X

229345 1 Coolant solenoid valve X X

1Gas lead

†

XX

1 Pilot arc lead

†

XX

041802 1 Power board (PCB2) X

041817 1 Ignition board (PCB IGN) X

006109 3

Gas solenoid valve

‡

X

228984 2 X

129854 1 High-frequency transformer (T1) X

005263 8 Gas pressure sensor X

229213 2 I/O board X

Chiller coolant pump

040296

040297

1 200 V – 460 V

575 V – 600 V

X

129792 8 Chopper X

Page 20

Preventive Maintenance Program

* This kit includes the air filter (011110), coolant filter (027664), and torch rebuild kit (428252).

** The number of gallons you need depends on the length of the leads. See your system’s instruction manual for more information, then

record this number in Coolant requirements on page 31.

*** Kit 428270 includes a pilot arc relay (003149), contactor (003218), and torch main body (220706). Kit 428272 includes a pilot arc

relay (003149), contactor (003233), and torch main body (220706). See your system’s instruction manual for the correct voltage,

then record this number in System voltage on page 31.

†

Record the part numbers for cables and leads in Part numbers for HPR800XD Auto Gas cables and leads on page 26 so you can

refer to this information when you replace these components.

‡

The gas solenoid valves that are connected to the air lines must be maintained. The quantity of gas solenoid valves given is the

quantity of valves connected to the air lines not the total quantity of valves in the system.

20 HPR800XD Auto Gas Instruction Manual 808680

Page 21

Preventive Maintenance Program

Cutting area and operation effects

The component replacement schedule is for reference only. Your cutting area conditions and operations can have an

effect on your component replacement schedule.

These topics give the most common conditions and operations that increase the wear on some components in your

plasma system. This wear decreases system performance and component life. If any of these conditions or operations

apply, change your replacement schedule as suggested.

How much you need to change your schedule depends on how bad the condition is. If you have questions about your

replacement schedule, contact your OEM or regional Hypertherm Technical Service team.

External cutting area

Consumables and torch assemblies stored in dirty cutting areas with no protection can collect contamination, such as dirt

and metal dust. If this contamination gets into the torch or coolant, it can cause the following problems:

Prevent O-rings and seals on the torch heads and receptacles from sealing

Increase wear on torch heads and receptacles

Increase wear on the coolant pump

Cause unsatisfactory operation of the coolant flow switch

It can help to flush the coolant system or clean the flow switch. But, it can be necessary

to replace the coolant switch to fully repair the operation of the coolant loop system.

The best solution is to store consumables and torch assemblies in a clean, protective space. Another solution is to use

compressed air to clean these parts before you use them.

If you cannot store your consumables and torch heads in a protective space, you can replace the following components

more frequently.

Description Part number

HPRXD quick-disconnect torch receptacle 220705

HPRXD quick-disconnect torch 220706

Coolant flow switch 229235

HPR800XD Auto Gas Instruction Manual 808680 21

Page 22

Preventive Maintenance Program

Incoming air supply quality

To maintain system performance, it is important that the incoming air supply is clean. If the air supply has dirt, oil, or water

in it, components can become clogged or defective. An air supply of bad quality can cause the following problems:

Decrease air flow

Increase system errors (044, 053, 057, or 058)

Decrease cut quality and performance

Oil in the torch head can cause a fire when the oil reacts with the oxygen cutting process. Also, unwanted material in

pressure sensors can cause false pressure readings.

The best solution, if possible, is to improve the quality of the air supply. Contact your OEM or regional Hypertherm

Technical Service team if you need advice on how to improve the quality of your air supply.

If you cannot change your air supply quality, you can replace the following components more frequently.

Description Part number

Air filter element 011110

HPRXD quick-disconnect torch 220706

Gas check valve 006077

Gas solenoid valve 006109

Kit: Gas solenoid valve 228984

Gas pressure sensor 005263

Metal dust inside the power supply cabinet

Plasma cutting makes metal dust. If metal dust collects inside the plasma power supply, it can decrease the life of the

fans and coolant pump motor.

The main power supply, chopper, or heat exchanger fans can operate more slowly, or failure of the fans can occur. This

can cause temperature-related errors (065, 066, 067, or 071). The coolant pump motor can become too hot and operate

incorrectly.

The best solution to extend the life of the fans and coolant pump motor is to clean inside of the power supply. For

instructions, see Clean inside the power supply on page 14.

If metal dust has collected inside your power supply, you can replace the following components more frequently.

Description Part number

6-inch fan 127039

10-inch fan 027079

Heat-exchange fan 027658

Coolant pump motor 200 V – 460 V 040296

Coolant pump motor 575 V – 600 V 040297

22 HPR800XD Auto Gas Instruction Manual 808680

Page 23

Preventive Maintenance Program

Consumable use

If you let consumables reach complete failure, they can melt. Copper pieces can then break off and go into the coolant. In

the coolant, these pieces can cause the following problems:

Decrease coolant flow

Increase coolant flow errors (093)

Cause damage to the consumables

Cause coolant to leak at the check valve when you change the consumables

Cause inaccurate coolant flow readings

Decrease the life of the coolant pump

Decrease the life of the check valve

When you do maintenance, examine the coolant filter for copper pieces. If you find copper pieces in the coolant filter,

replace both the filter and coolant. If a coolant flow error (093) occurs after you replace the filter and coolant, use the

troubleshooting procedure in your system’s instruction manual to find the correct action.

The best solution is to follow the usage guidelines for your consumables. However, if overuse occurs, you can replace the

following components more frequently.

Description Part number

Coolant 028872

HPRXD quick-disconnect torch receptacle 220705

HPRXD quick-disconnect torch 220706

Coolant filter element 027664

Coolant check valve 006113

Coolant flow switch 229235

HPR800XD Auto Gas Instruction Manual 808680 23

Page 24

Preventive Maintenance Program

Cut-cycle time

When the cut-cycle is very short, relays operate more frequently. The system also pierces more frequently. Examples of

this type of cycle are when you cut many small holes or make markings for numbers and letters. These types of operations

can cause the following problems:

Increase wear on pilot arc relay contact pads

Increase wear on the starting components, such as the high-frequency transformer and the high-frequency ignition

board

Increase misfires and error codes (020 or 021)

If your cut-cycle is short, you can replace the following components more frequently.

Description Part number

Pilot arc relay 003149

Contactor (200 V – 240 V) 003218

Contactor (380 V – 600 V) 003233

HPRXD quick-disconnect torch 220706

High-frequency transformer 129854

High-frequency ignition board (PCB) 041817

24 HPR800XD Auto Gas Instruction Manual 808680

Page 25

Preventive Maintenance Program

Find arc hour data on a Hypertherm CNC

To find arc hour data with Phoenix™ software (versions 7.0, 8.0, and 9.0),

from the CNC Main screen, go to Setups > Diagnostics > HPR System.

If you do not see the HPR System softkey, make sure that the HPR

and station selection switch are ON.

If a control board in the plasma system is replaced, the Arc On

Statistics values are reset to 0.

An HPR system with a Manual Gas console but without serial

communication does not have this screen.

Make sure that you have the latest Phoenix software and plasma system

software so that you have the most accurate Arc On Time information.

To find the Phoenix software version number go to Setups > Diagnostics.

To find the plasma system software version number go to Setups >

Diagnostics > HPR System.

HPR800XD Auto Gas Instruction Manual 808680 25

Page 26

Preventive Maintenance Program

Part numbers for HPR800XD Auto Gas cables and leads

Primary power supply to secondary power supply cables

Interface cable

Part number Length

223071 4.5 m (15 ft)

223098 7.5 m (25 ft)

Communication cable

Part number Length

123839 4.5 m (15 ft)

123691 7.5 m (25 ft)

Power supply to ignition console leads

Pilot arc lead

Part number Length Part number Length

123683* 1.5 m (5 ft) 123823 20 m (65 ft)

123820 3 m (10 ft) 123735 25 m (82 ft)

123821 4.5 m (15 ft) 123668 35 m (115 ft)

123666 7.5 m (25 ft) 123669 45 m (150 ft)

123822 10 m (35 ft) 123824 60 m (200 ft)

123667 15 m (50 ft) 123825 75 m (250 ft)

* This cable is for use with systems that have the ignition console mounted on the power supply.

Negative lead

Part number Length Part number Length

123418 3 m (10 ft) 123996 25 m (82 ft)

023382 4.5 m (15 ft) 123997 35 m (115 ft)

023078 7.5 m (25 ft) 023081 45 m (150 ft)

123994 10 m (35 ft) 023188 60 m (200 ft)

023079 15 m (50 ft) 023815 75 m (250 ft)

123995 20 m (65 ft)

26 HPR800XD Auto Gas Instruction Manual 808680

Page 27

Preventive Maintenance Program

Ignition console power cable

Part number Length Part number Length

123865* 2.1 m (7 ft) 123836 20 m (65 ft)

123419 3 m (10 ft) 123425 22.5 m (75 ft)

123834 4.5 m (15 ft) 123736 25 m (82 ft)

123420 6 m (20 ft) 123426 30 m (100 ft)

123670 7.5 m (25 ft) 123672 35 m (115 ft)

123422 9 m (30 ft) 123938 37.5 m (125 ft)

123835 10 m (35 ft) 123673 45 m (150 ft)

123423 12 m (40 ft) 123837 60 m (200 ft)

123671 15 m (50 ft) 123838 75 m (250 ft)

* This cable is for use with systems that have the ignition console mounted on the power supply.

Coolant hoses

Chiller-interface console to ignition console

Part number Length Part number Length

128499 1.5 m (5 ft) 128078 25 m (82 ft)

028652 3 m (10 ft) 028444 30 m (100 ft)

028440 4.5 m (15 ft) 028896 35 m (115 ft)

028441 7.5 m (25 ft) 028445 45 m (150 ft)

128173 10 m (35 ft) 028637 60 m (200 ft)

028442 15 m (50 ft) 128985 75 m (250 ft)

128984 20 m (65 ft)

Chiller to chiller-interface console

Part number Length Part number Length

228540 4.5 m (15 ft) 228542 15 m (50 ft)

228541 7.5 m (25 ft)

Power supply to chiller cables

Control cable

Part number Length Part number Length

123844 1.5 m (5 ft) 123839 4.5 m (15 ft)

123784 3 m (10 ft)

Power cable

Part number Length Part number Length

123979 1.5 m (5 ft) 123981 4.5 m (15 ft)

123980 3 m (10 ft)

HPR800XD Auto Gas Instruction Manual 808680 27

Page 28

Preventive Maintenance Program

Power supply to selection console cables

Control cable

Part number Length Part number Length

123784* 3 m (10 ft) 123841 20 m (65 ft)

123839 4.5 m (15 ft) 123737 25 m (82 ft)

123963 6 m (20 ft) 123738 35 m (115 ft)

123691 7.5 m (25 ft) 123739 45 m (150 ft)

123840 10 m (35 ft) 123842 60 m (200 ft)

123711 15 m (50 ft) 123843 75 m (250 ft)

* This cable is for use with systems that have the selection console mounted on the power supply.

Power cable

Part number Length Part number Length

123785* 3 m (10 ft) 123848 20 m (65 ft)

123846 4.5 m (15 ft) 123740 25 m (82 ft)

123964 6 m (20 ft) 123676 35 m (115 ft)

123674 7.5 m (25 ft) 123677 45 m (150 ft)

123847 10 m (35 ft) 123849 60 m (200 ft)

123675 15 m (50 ft) 123850 75 m (250 ft)

* This cable is for use with systems that have the selection console mounted on the power supply.

Cable and gas hose assembly (selection console to metering console)

Part number Length Part number Length

128992 3 m (10 ft) 128994 10 m (35 ft)

128993 4.5 m (15 ft) 128930 15 m (50 ft)

228338 6 m (20 ft) 128995 20 m (65 ft)

128952 7.5 m (25 ft)

Power supply to CNC interface cable

Part number Length Part number Length

123210 3 m (10 ft) 123851 20 m (65 ft)

123211 4.5 m (15 ft) 123217 22.5 m (75 ft)

123212 6 m (20 ft) 123741 25 m (82 ft)

123022 7.5 m (25 ft) 123218 30 m (100 ft)

123213 9 m (30 ft) 123742 35 m (115 ft)

123214 10 m (35 ft) 123219 37.5 m (125 ft)

123215 12 m (40 ft) 123220 45 m (150 ft)

123216 13.5 m (45 ft) 123852 60 m (200 ft)

123023 15 m (50 ft) 123853 75 m (250 ft)

123494 16.5 m (55 ft)

28 HPR800XD Auto Gas Instruction Manual 808680

Page 29

Preventive Maintenance Program

Torch lead

Part number Length Part number Length

228291 2 m (6 ft) 228295 7.5 m (25 ft)

228292 3 m (10 ft) 228296 10 m (35 ft)

228293 4.5 m (15 ft) 228297 15 m (50 ft)

228294 6 m (20 ft)

Work lead

Part number Length Part number Length

123418 3 m (10 ft) 123996 25 m (82 ft)

023382 4.5 m (15 ft) 123997 35 m (115 ft)

023078 7.5 m (25 ft) 023081 45 m (150 ft)

123994 10 m (35 ft) 023188 60 m (200 ft)

023079 15 m (50 ft) 023815 75 m (250 ft)

123995 20 m (65 ft)

Ohmic contact wire

Part number Length Part number Length

123983 3 m (10 ft) 123988 15 m (50 ft)

123984 6 m (20 ft) 123989 23 m (75 ft)

123985 7.5 m (25 ft) 123990 30 m (100 ft)

123986 9 m (30 ft) 123991 45 m (150 ft)

123987 12 m (40 ft)

HPR800XD Auto Gas Instruction Manual 808680 29

Page 30

Preventive Maintenance Program

Supply gas hoses

Air hose

Part number Length Part number Length

024671 3 m (10 ft) 024740 25 m (82 ft)

024658 4.5 m (15 ft) 024676 30 m (100 ft)

024659 7.5 m (25 ft) 024744 35 m (115 ft)

024765 10 m (35 ft) 024678 45 m (150 ft)

024660 15 m (50 ft) 024680 60 m (200 ft)

024766 20 m (65 ft) 024767 75 m (250 ft)

Argon-hydrogen (H35) or nitrogen-hydrogen (F5) hose

Part number Length Part number Length

024768 3 m (10 ft) 024741 25 m (82 ft)

024655 4.5 m (15 ft) 024742 35 m (115 ft)

024384 7.5 m (25 ft) 024743 45 m (150 ft)

024769 10 m (35 ft) 024771 60 m (200 ft)

024656 15 m (50 ft) 024772 75 m (250 ft)

024770 20 m (65 ft)

Nitrogen or argon hose

Part number Length Part number Length

024210 3 m (10 ft) 024739 25 m (82 ft)

024203 4.5 m (15 ft) 024116 30 m (100 ft)

024134 7.5 m (25 ft) 024451 35 m (115 ft)

024211 10 m (35 ft) 024120 45 m (150 ft)

024112 15 m (50 ft) 024124 60 m (200 ft)

024763 20 m (65 ft) 024764 75 m (250 ft)

Oxygen hose

Part number Length Part number Length

024607 3 m (10 ft) 024738 25 m (82 ft)

024204 4.5 m (15 ft) 024206 30 m (100 ft)

024205 7.5 m (25 ft) 024450 35 m (115 ft)

024760 10 m (35 ft) 024159 45 m (150 ft)

024155 15 m (50 ft) 024333 60 m (200 ft)

024761 20 m (65 ft) 024762 75 m (250 ft)

30 HPR800XD Auto Gas Instruction Manual 808680

Page 31

Preventive Maintenance Program

System information

Model number Serial number

System voltage

200 V/208 V

220 V

240 V

380 V (CCC)

400 V (CE)

415 V (CE)

440 V

480 V (CSA)

600 V (CSA)

Coolant requirements

11.4 L (3 gal)

15.1 L (4 gal)

18.9 L (5 gal)

22.7 L (6 gal)

26.5 L (7 gal)

Other:

HPR800XD Auto Gas Instruction Manual 808680 31

Page 32

Preventive Maintenance Program

Notes

32 HPR800XD Auto Gas Instruction Manual 808680

Page 33

Maintenance log for HPR800XD Auto Gas plasma systems

Daily tasks 12345678910111213141516171819202122232425262728293031

Do a test of the inlet pressures

Examine all of the air filters

Do a check of the coolant level and

condition

Examine and lubricate O-rings

Examine the water tube and torch

Weekly tasks Week beginning: Week beginning: Week beginning: Week beginning: Week beginning:

Examine hoses and torch leads

Do tests for gas leaks

Do a check of the coolant flow

Do a check of the coolant level

Monthly tasks

circle one: January February March April May June July August September October November December

Clean inside the power supply Notes:

Clean the chiller air filter

Clean inside the chiller

Examine the coolant system

Examine the main contactor

Examine the pilot arc relay

Do the coolant flow test

Examine the gas line connections

Examine the hoses

Examine the cables

Examine the ground connections

Examine the table-to-workpiece connection

Loading...

Loading...