Page 1

Duramax™ Retrofit Torch

HRT, HRTs, and MRT for

powermax1000

powermax1650

®

, powermax1250®, and

®

Operator Manual – 807190

Revision 3

Page 2

Page 3

Duramax™ Retrofit Torch

HRT, HRTs, and MRT for

powermax1000

and powermax1650

Operator Manual

(P/N 807190)

Revision 3 – May 2012

®

, powermax1250®,

®

Hypertherm, Inc.

Hanover, NH USA

www.hypertherm.com

email: info@hypertherm.com

© 2012 Hypertherm, Inc.

All Rights Reserved

Hypertherm, Powermax, and Duramax are trademarks of Hypertherm, Inc.

andmayberegisteredintheUnited States and/or other countries.

Page 4

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

877-371-2876 Fax (Return Materials Authorization)

return.materials@hypertherm.com (RMA email)

Hypertherm Automation

5 Technology Drive, Suite 300

West Lebanon, NH 03784 USA

603-298-7970 Tel

603-298-7977 Fax

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D-63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm (S) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

65 6841 2489 (Technical Service)

Hypertherm (Shanghai) Trading Co., Ltd.

Unit A, 5th Floor, Careri Building

432 West Huai Hai Road

Shanghai, 200052

PR China

86-21 5258 3330/1 Tel

86-21 5258 3332 Fax

Hypertherm Europe B.V.

Vaartveld 9

4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP - Brasil

CEP 07115-030

55 11 2409 2636 Tel

55 11 2408 0462 Fax

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Hypertherm Korea Branch

#3904 Centum Leaders Mark B/D,

1514 Woo-dong, Haeundae-gu, Busan

Korea, 612-889

82 51 747 0358 Tel

82 51 701 0358 Fax

03/15/12

Page 5

ELECTROMAGNETIC COMPATIBILITY (EMC)

Introduction

Hypertherm’s CE‑marked equipment is built

in compliance with standard EN60974‑10.

The equipment should be installed and used

in accordance with the information be low to

achieve electromagnetic compatibility.

The limits required by EN60974‑10 may not be

adequate to completely eliminate interference

when the affected equipment is in close

proximity or has a high degree of sen sitivity.

Insuch cases it may be nec essary to use other

mea sures to further reduce interference.

This cutting equipment is designed for use only

in an in dus tri al environment.

Installation and use

The user is responsible for installing and

using the plasma equipment according to the

manufacturer’s instructions. If electromagnetic

disturbances are detected then it shall be

the responsibility of the user to resolve the

situation with the technical assistance of the

manufacturer. In some cases this remedial

action may be as simple as earthing the

cutting circuit, see Earthing of Workpiece.

Inother cases it could involve constructing an

electromagnetic screen enclosing the power

source and the work complete with associated

input filters. In all cases electromagnetic

disturbances must be reduced to the point

where they are no longer troublesome.

Assessment of area

Before installing the equipment the user

shall make an assessment of potential

electromagnetic problems in the surrounding

area. The following shall be taken into account:

a. Other supply cables, control cables,

signalling and telephone cables; above,

below and adjacent to the cutting equipment.

b. Radio and television transmitters and

receivers.

c. Computer and other control equip ment.

d. Safety critical equipment, for example

guarding of industrial equipment.

e. Health of the people around, for example the

use of pacemakers and hearing aids.

f. Equipment used for calibration or

measurement.

g. Immunity of other equipment in the

environment. User shall ensure that other

equipment being used in the environment

is compatible. This may require additional

protection measures.

h. Time of day that cutting or other activities are

to be carried out.

The size of the surround ing area to be

considered will depend on the structure of

the building and other activities that are taking

place. The surrounding area may extend beyond

the bound aries of the premises.

Methods of reducing

emissions

Mains supply

Cutting equipment must be connected to the

mains supply according to the manufacturer’s

recommendations. If interference occurs, it may

be necessary to take additional precautions

Compliance Information EMC-1

9/10

Page 6

ElEctromagnEtic compatibility (Emc)

such as filtering of the mains supply.

Consideration should be given to shielding the

supply cable of permanently installed cutting

equipment, in metallic conduit or equivalent.

Shielding should be electrically continuous

throughout its length. The shielding should be

connected to the cutting mains supply so that

good electrical contact is maintained between

the conduit and the cutting pow er source

enclosure.

Maintenance of cutting equipment

The cutting equipment must be routinely

maintained according to the manufacturer’s

recommendations. All access and service doors

and covers should be closed and properly

fastened when the cutting equipment is in

operation. The cutting equipment should not

be modified in any way except as set forth in

and in accordance with the manufacturer’s

written instructions. For example, the spark gaps

of arc striking and stabilizing devices should

be adjusted and maintained according to the

manufacturer’s recommendations.

Cutting cables

The cutting cables should be kept as short

aspossible and should be positioned close

together, running at or close to the floor level.

Equipotential bonding

Bonding of all metallic components in the

cutting installation and adjacent to it should

be considered. However, metallic com po nents

bonded to the workpiece will increase the risk

that the operator could receive a shock by

touching these metallic components and the

electrode (nozzle for laser heads) at the same

time. The operator should be insulated from all

such bonded metallic components.

Earthing of workpiece

Where the workpiece is not bonded to earth

for electrical safety, nor connected to earth

because of its size and position, for example,

ship’s hull or building steelwork, a connection

bonding the work piece to earth may reduce

emis sions in some, but not all instances.

Careshould be taken to prevent the earthing

ofthe workpiece increasing the risk of injury

to users, or damage to other electrical

equipment. Where necessary, the connection

of the workpiece to earth should be made by

a direct connection to the workpiece, but in

some countries where direct connection is not

permitted, the bonding should be achieved by

suitable capacitances selected according to

national regulations.

Note: the cutting circuit may or may not

be earthed for safety reasons. Changing

the earthing arrangements should only be

authorized by a person who is competent to

assess whether the changes will increase the

risk of injury, for example, by allowing parallel

cutting current return paths which may damage

the earth cir cuits of other equipment. Further

guidance is provided in IEC 60974‑9, Arc

Welding Equip ment, Part 9: Installation and

Use.

Screening and shielding

Selective screening and shielding of other

cables and equipment in the surrounding

area may alleviate problems of interference.

Screening of the entire plasma cutting

installation may be con sid ered for special

applications.

EMC-2 Compliance Information

9/10

Page 7

WARRANTY

Attention

Genuine Hypertherm parts are the factory‑

recommended replacement parts for your

Hypertherm system. Any damage or injury

caused by the use of other than genuine

Hypertherm parts may not be covered by the

Hypertherm warranty, and will constitute misuse

of the Hypertherm Product.

You are solely responsible for the safe use of

the Product. Hypertherm does not and cannot

make any guarantee or warranty regarding the

safe use of the product in your environment.

General

Hypertherm, Inc. warrants that its Products

shall be free from defects in materials and

workmanship for the specific periods of time

set forth herein and as follows: if Hypertherm

is notified of a defect (i) with respect to the

power supply within a period of two (2) years

from the date of its delivery to you, with the

exception of Powermax brand power supplies,

which shall be within a period of three (3) years

from the date of delivery to you, and (ii) with

respect to the torch and leads within a period

of one (1) year from its date of delivery to you,

and with respect to torch lifter assemblies

within a period of one (1) year from its date of

delivery to you, and with respect to laser heads

within a period of one (1) year from its date of

delivery to you, and with respect to Automation

products one (1) year from its date of delivery

to you, with the exception of the EDGE Pro

CNC and ArcGlide THC, which shall be within

a period of two (2) years from the date of

delivery to you.

This warranty shall not apply to any Powermax

brand power supplies that have been used with

phase converters. In addition, Hypertherm does

not warranty systems that have been damaged

as a result of poor power quality, whether from

phase converters or incoming line power. This

warranty shall not apply to any Product which

has been incorrectly installed, modified, or

otherwise damaged.

Hypertherm provides repair, replacement or

adjustment of the Product as the sole and

exclusive remedy, if and only if the warranty

set forth herein properly is invoked and

applies. Hypertherm, at its sole option, shall

repair, replace, or adjust, free of charge, any

defective Products covered by this warranty

which shall be returned with Hypertherm’s prior

authorization (which shall not be unreasonably

withheld), properly packed, to Hypertherm’s

place of business in Hanover, New Hampshire,

or to an authorized Hypertherm repair facility,

all costs, insurance and freight pre paid by

the customer. Hypertherm shall not be liable

for any repairs, replacement, or adjustments

of Products covered by this warranty, except

those made pursuant to this paragraph and

with Hypertherm’s prior written consent.

The warranty set forth above is exclusive and is

in lieu of all other warranties, express, implied,

statutory, or otherwise with respect to the

Products or as to the results which may be

obtained therefrom, and all implied warranties

or conditions of quality or of merchantability

or fitness for a particular purpose or against

infringement. The foregoing shall constitute the

sole and exclusive remedy for any breach by

Hypertherm of its warranty.

Compliance Information W-1

9/10

Page 8

Warranty

WARRANTY

Distributors/OEMs may offer different or

additional warranties, but Distributors/OEMs

are not authorized to give any additional

warranty protection to you or make any

representation to you purporting to be binding

upon Hypertherm.

Patent indemnity

Except only in cases of products not

manufactured by Hypertherm or manufactured

by a person other than Hypertherm not in strict

conformity with Hypertherm’s specifications

and in cases of designs, processes, formulae,

or combinations not developed or purported

to be developed by Hypertherm, Hypertherm

will have the right to defend or settle, at

its own expense, any suit or proceeding

brought against you alleging that the use

of the Hypertherm product, alone and not

in combination with any other product not

supplied by Hypertherm, infringes any patent

of any third party. You shall notify Hypertherm

promptly upon learning of any action or

threatened action in connection with any

such alleged infringement (and in any event

no longer than fourteen (14) days after

learning of any action or threat of action), and

Hypertherm’s obligation to defend shall be

conditioned upon Hypertherm’s sole control

of, and the indemnified party’s cooperation and

assistance in, the defense of the claim.

Limitation of liability

In no event shall Hypertherm be liable to

any person or entity for any incidental,

consequential direct, indirect, punitive

or exemplary damages (including but

not limited to lost profits) regardless of

whether such liability is based on breach

of contract, tort, strict liability, breach of

warranty, failure of essential purpose,

or otherwise, and even if advised of the

possibility of such damages.

National and local codes

National and local codes governing plumbing

and electrical installation shall take precedence

over any instructions contained in this manual.

In no event shall Hypertherm be liable for injury

to persons or property damage by reason of

any code violation or poor work practices.

Liability cap

In no event shall Hypertherm’s liability,

if any, whether such liability is based on

breach of contract, tort, strict liability,

breach of warranties, failure of essential

purpose or otherwise, for any claim,

action, suit or proceeding (whether in

court, arbitration, regulatory proceeding

or otherwise) arising out of or relating

to the use of the Products exceed in

the aggregate the amount paid for the

Products that gave rise to such claim.

Insurance

At all times you will have and maintain

insurance in such quantities and types, and

with coverage sufficient and appropriate to

defend and to hold Hypertherm harmless in the

event of any cause of action arising from the

use of the products.

W-2 Compliance Information

9/10

Page 9

Transfer of rights

You may transfer any remaining rights you may

have hereunder only in connection with the

sale of all or substantially all of your assets or

capital stock to a successor in interest who

agrees to be bound by all of the terms and

conditions of this Warranty. Within thirty (30)

days before any such transfer occurs, you

agree to notify in writing Hypertherm, which

reserves the right of approval. Should you

fail timely to notify Hypertherm and seek its

approval as set forth herein, the Warranty set

forth herein shall be null and void and you will

have no further recourse against Hypertherm

under the Warranty or otherwise.

Warranty

Compliance Information W-3

9/10

Page 10

Warranty

W-4 Compliance Information

9/10

Page 11

Safety information

Before operating any Hypertherm equipment, read the separate Safety and Compliance Manual

(80669C) included with your product for important safety information.

Page 12

Page 13

Table of ConTenTs

ELECTROMAGNETIC COMPATIBILITY (EMC) ....................................................................EMC-1

WARRANTY ........................................................................................................................................W-1

Safety information ................................................................................................................................. 1

Section 1

Specifications ......................................................................................................................................1-1

Component weights .......................................................................................................................................... 1‑2

Duramax HRT hand torch dimensions .......................................................................................................... 1‑2

Duramax HRTs hand torch dimensions ........................................................................................................ 1‑2

Duramax MRT full‑length machine torch dimensions ................................................................................ 1‑3

Duramax MRT without positioning sleeve (mini torch) .............................................................................. 1‑3

Section 2

Torch Setup ..........................................................................................................................................2-1

Introduction ......................................................................................................................................................... 2‑2

Consumable life .................................................................................................................................................. 2‑2

Hand torch setup ............................................................................................................................................... 2‑3

Choose the hand torch consumables ................................................................................................ 2‑3

Hand torch consumables ...................................................................................................................... 2‑4

Install the hand torch consumables ..................................................................................................... 2‑5

Machine torch setup.......................................................................................................................................... 2‑6

Converting a Duramax retrofit machine torch into a mini torch .................................................... 2‑7

Mount the torch ........................................................................................................................................ 2‑9

Choose the machine torch consumables ........................................................................................2‑12

Machine torch consumables ...............................................................................................................2‑12

Install the machine torch consumables ............................................................................................2‑15

Aligning the torch ..................................................................................................................................2‑15

Torch installation ..............................................................................................................................................2‑16

Section 3

Operation ..............................................................................................................................................3-1

Using the cut charts .......................................................................................................................................... 3‑2

Estimated kerf‑width compensation .................................................................................................... 3‑2

100 amp mechanized shielded cutting for Powermax1650.......................................................... 3‑5

85 amp mechanized shielded cutting for Powermax1650 ............................................................ 3‑7

80 amp mechanized shielded cutting for Powermax1250/1650 ..............................................3‑11

Duramax Retrofit Torch Operator Manual i

Page 14

Table of ConTenTs

65 amp mechanized shielded cutting for Powermax1250/1650 ..............................................3‑13

60 amp mechanized shielded cutting for Powermax1000/1250/1650 ...................................3‑17

45 amp mechanized shielded cutting for Powermax1000/1250/1650 ...................................3‑19

100 amp mechanized unshielded cutting for Powermax1650 ...................................................3‑23

85 amp mechanized unshielded cutting for Powermax1650......................................................3‑25

65 amp mechanized unshielded cutting for Powermax1250/1650 ..........................................3‑29

45 amp mechanized unshielded cutting for Powermax1000/1250/1650 ..............................3‑33

FineCut® consumables for Powermax1000/1250/1650.............................................................3‑37

Using the hand torch .......................................................................................................................................3‑42

Operate the safety trigger ...................................................................................................................3‑42

Hand torch cutting hints ......................................................................................................................3‑43

Start a cut from the edge of the workpiece.....................................................................................3‑44

Pierce a workpiece ................................................................................................................................3‑45

Gouge a workpiece ..............................................................................................................................3‑46

Common hand‑cutting faults ..............................................................................................................3‑49

Using the machine torch ................................................................................................................................3‑50

Ensure the torch and table are set up correctly .............................................................................3‑50

Understand and optimize cut quality .................................................................................................3‑50

To pierce a workpiece using the machine torch ............................................................................3‑53

Common machine‑cutting faults ........................................................................................................3‑53

Section 4

Maintenance and parts .....................................................................................................................4-1

Perform routine maintenance .......................................................................................................................... 4‑2

Inspect the consumables ................................................................................................................................. 4‑3

Hand torch replacement parts ........................................................................................................................ 4‑4

Machine torch replacement parts .................................................................................................................. 4‑6

Accessory parts.................................................................................................................................................. 4‑7

ii Duramax Retrofit Torch Operator Manual

Page 15

Section 1

Specifications

In this section:

Component weights .......................................................................................................................................... 1‑2

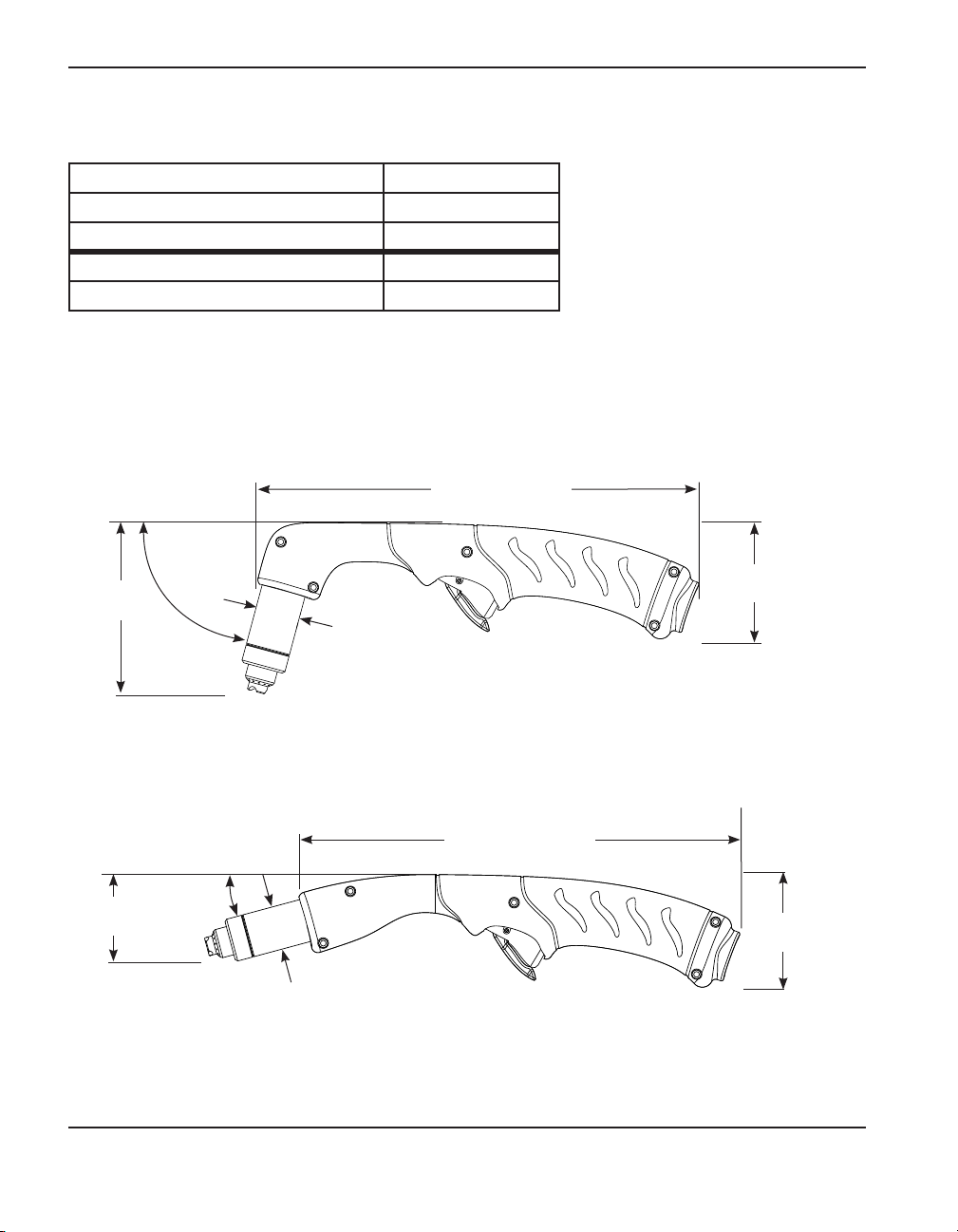

Duramax HRT hand torch dimensions .......................................................................................................... 1‑2

Duramax HRTs hand torch dimensions ........................................................................................................ 1‑2

Duramax MRT full‑length machine torch dimensions ................................................................................ 1‑3

Duramax MRT without positioning sleeve (mini torch) .............................................................................. 1‑3

Duramax Retrofit Torch Operator Manual 1-1

Page 16

SpecificationS

Component weights

Torch type Weight – lbs (kg)

Hand torch 25 ft (7.6 m) 7.1 (3.2)

Hand torch 50 ft (15 m) 12.5 (5.7)

Machine torch 25 ft (7.6 m) 7.6 (3.4)

Machine torch 50 ft (15 m) 13.2 (6.0)

Duramax HRT hand torch dimensions

9.9 in (25.2 cm)

75°

3.8 in

(9.8 cm)

angle

1.0 in

(2.5 cm)

Duramax HRTs hand torch dimensions

10.2 in (25.9 cm)

15°

1.9 in

(4.7 cm)

angle

1.0 in

(2.5 cm)

2.6 in

(6.6 cm)

2.6 in

(6.6 cm)

1-2 Duramax Retrofit Torch Operator Manual

Page 17

SpecificationS

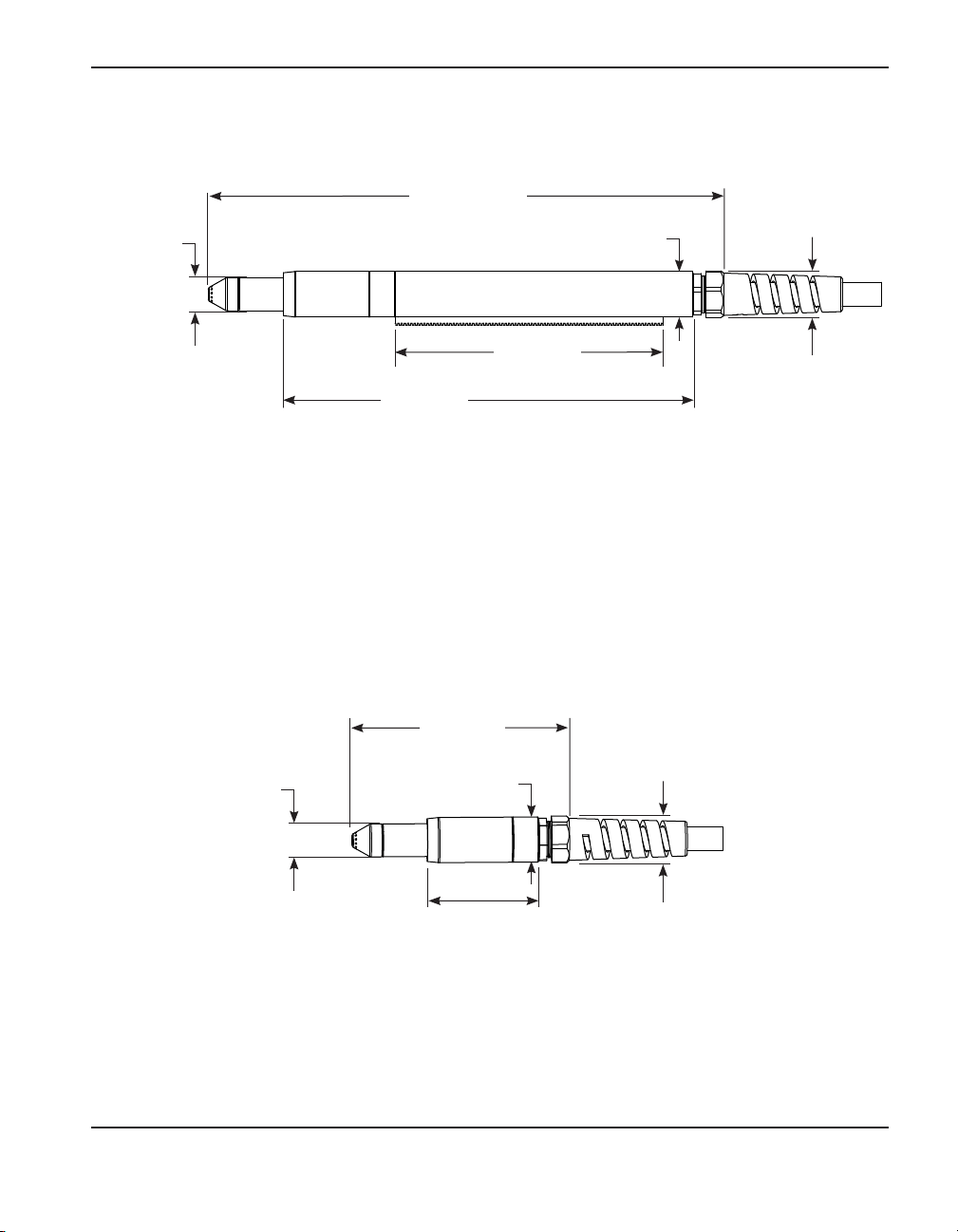

Duramax MRT full-length machine torch dimensions

15.6 in

(39.6 cm)

1.0 in

(2.5 cm)

8.1 in

(20.6 cm)

12.3 in

(31.3 cm)

1.4 in

(3.5 cm)

1.4 in (3.6 cm) outer

dimension, 1.3 in

(3.3cm) flat sides

Duramax MRT without positioning sleeve (mini torch)

6.6 in

(16.8 cm)

1.0 in

(2.5 cm)

Duramax Retrofit Torch Operator Manual 1-3

1.4 in

(3.5 cm)

3.3 in

(8.4 cm)

1.4 in (3.6 cm) outer

dimension, 1.3 in

(3.3cm) flat sides

Page 18

SpecificationS

1-4 Duramax Retrofit Torch Operator Manual

Page 19

Section 2

Torch Setup

In this section:

Introduction ......................................................................................................................................................... 2‑2

Consumable life .................................................................................................................................................. 2‑2

Hand torch setup ............................................................................................................................................... 2‑3

Choose the hand torch consumables ................................................................................................ 2‑3

Hand torch consumables ...................................................................................................................... 2‑4

Install the hand torch consumables ..................................................................................................... 2‑5

Machine torch setup.......................................................................................................................................... 2‑6

Converting a Duramax retrofit machine torch into a mini torch .................................................... 2‑7

Mount the torch ........................................................................................................................................ 2‑9

Choose the machine torch consumables ........................................................................................2‑12

Machine torch consumables ...............................................................................................................2‑12

Install the machine torch consumables ............................................................................................2‑15

Aligning the torch ..................................................................................................................................2‑15

Torch installation ..............................................................................................................................................2‑16

Duramax Retrofit Torch Operator Manual 2-1

Page 20

Torch seTup

Introduction

Duramax™ series handheld and machine retrofit torches are available for the Powermax1000,

Powermax1250, and Powermax1650 systems. The ETR (Easy Torch Removal)™ quick‑disconnect

system makes it easy to remove the torch for transport or to switch from one torch to the other if

your applications require the use of different torches. The torches are cooled by ambient air and do

not require special cooling procedures.

This section explains how to setup your torch and choose the appropriate consumables for the job.

Consumable life

How often you need to change the consumables on your retrofit torch will depend on a number of

factors:

• Thickness of the material – the thicker the material being cut, the more often consumables

need to be changed.

• Average length of cut – the longer the average cut, the more often consumables need to

be changed.

• Type of cutting – handheld cutting will require more consumable changes than machine

cutting.

• Air quality – the presence of oil, moisture, or other contaminants will reduce consumable

life.

• Piercing / edge starting – piercing the metal causes more consumable wear then starting

cuts from the edge of the metal.

• Proper torch‑to‑work distance – when gouging or cutting with unshielded consumables,

maintaining proper torch‑to‑work distance will result in better consumable life.

• Proper pierce height – maintaining proper pierce height will result in better consumable

life.

• Cutting in “continuous pilot arc” mode or normal cutting mode – cutting with a continuous

pilot arc causes more consumable wear than cutting in normal cutting mode.

You will find more information about proper cutting techniques in Section 3, Operation.

2-2 Duramax Retrofit Torch Operator Manual

Page 21

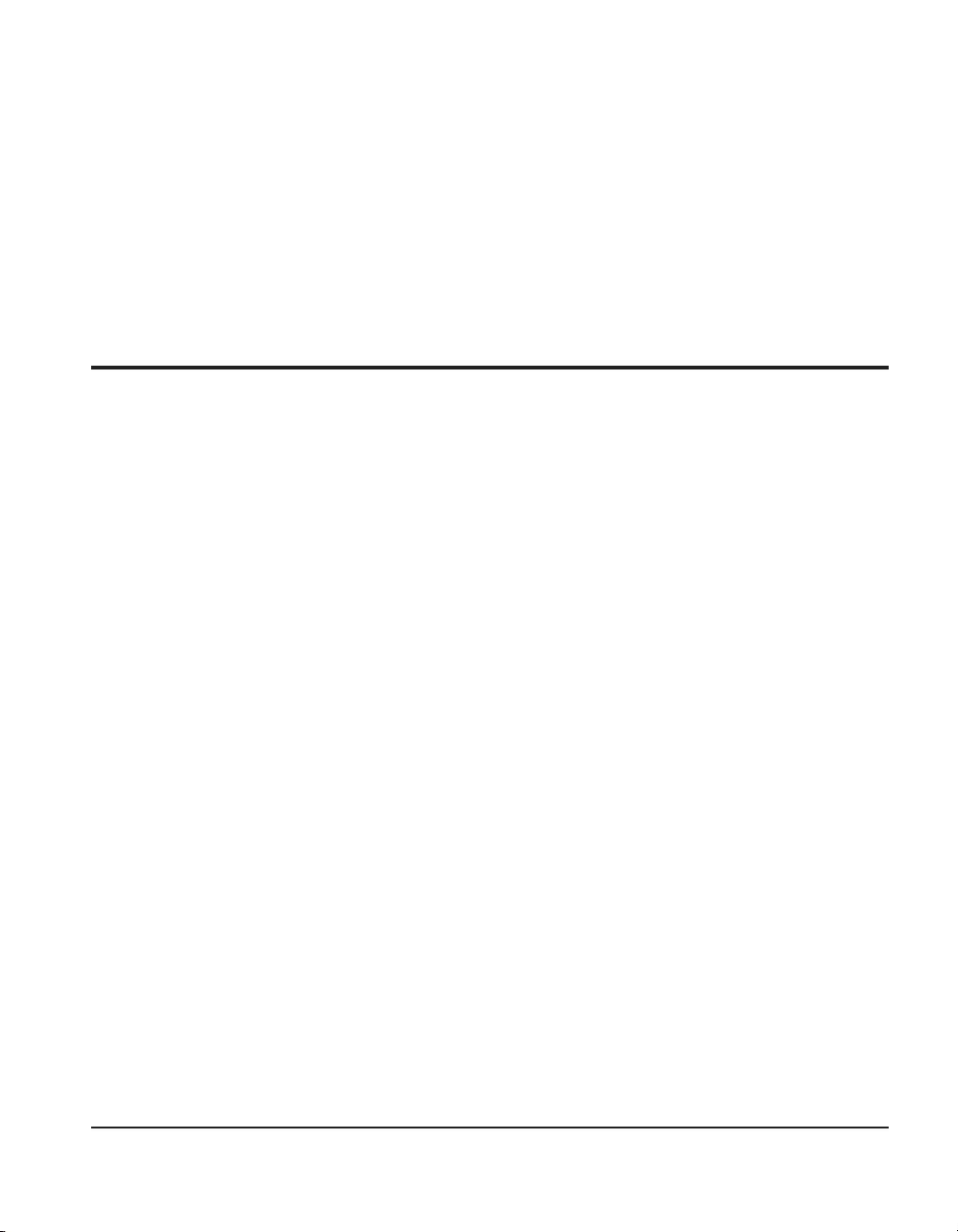

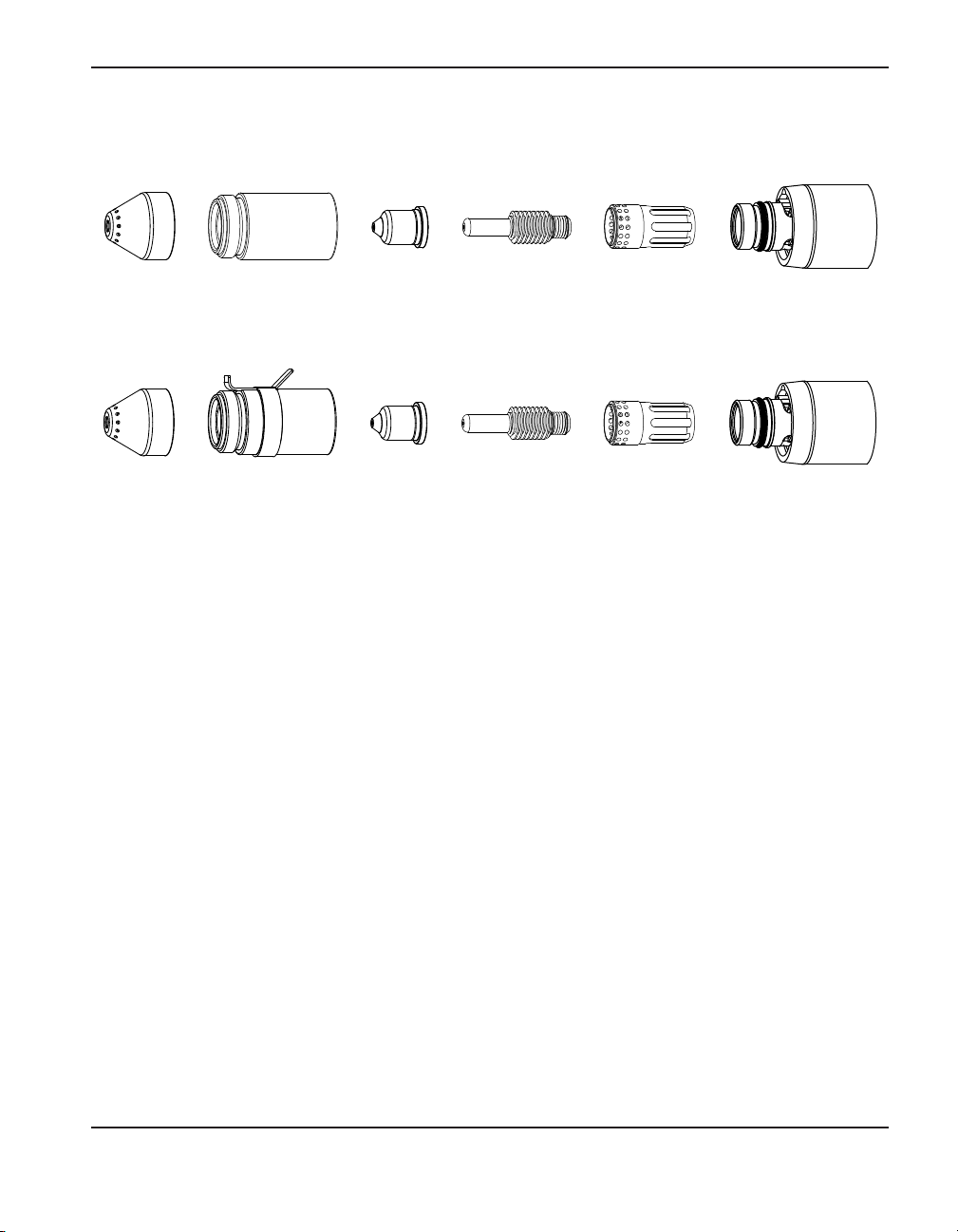

Hand torch setup

Duramax HRT

TORCH SETUP

Consumables

Duramax HRTs

Consumables

Safety trigger

Safety trigger

Choose the hand torch consumables

Duramax retrofit torches are shipped with a full set of cutting consumables pre‑installed.

Hypertherm also includes spare cutting electrodes, nozzles, and gouging consumables in the

consumables box, for handheld torches.

Consumables for handheld cutting are shown on the next page. Notice that the retaining cap and

electrode are the same for cutting, gouging, and FineCut® applications. Only the shield, nozzle,

and swirl ring are different.

For the best cut quality on thin materials, you may prefer to use FineCut consumables, or use a

45A nozzle and reduce the current setting to 45 amps.

Duramax Retrofit Torch Operator Manual 2-3

Page 22

Torch seTup

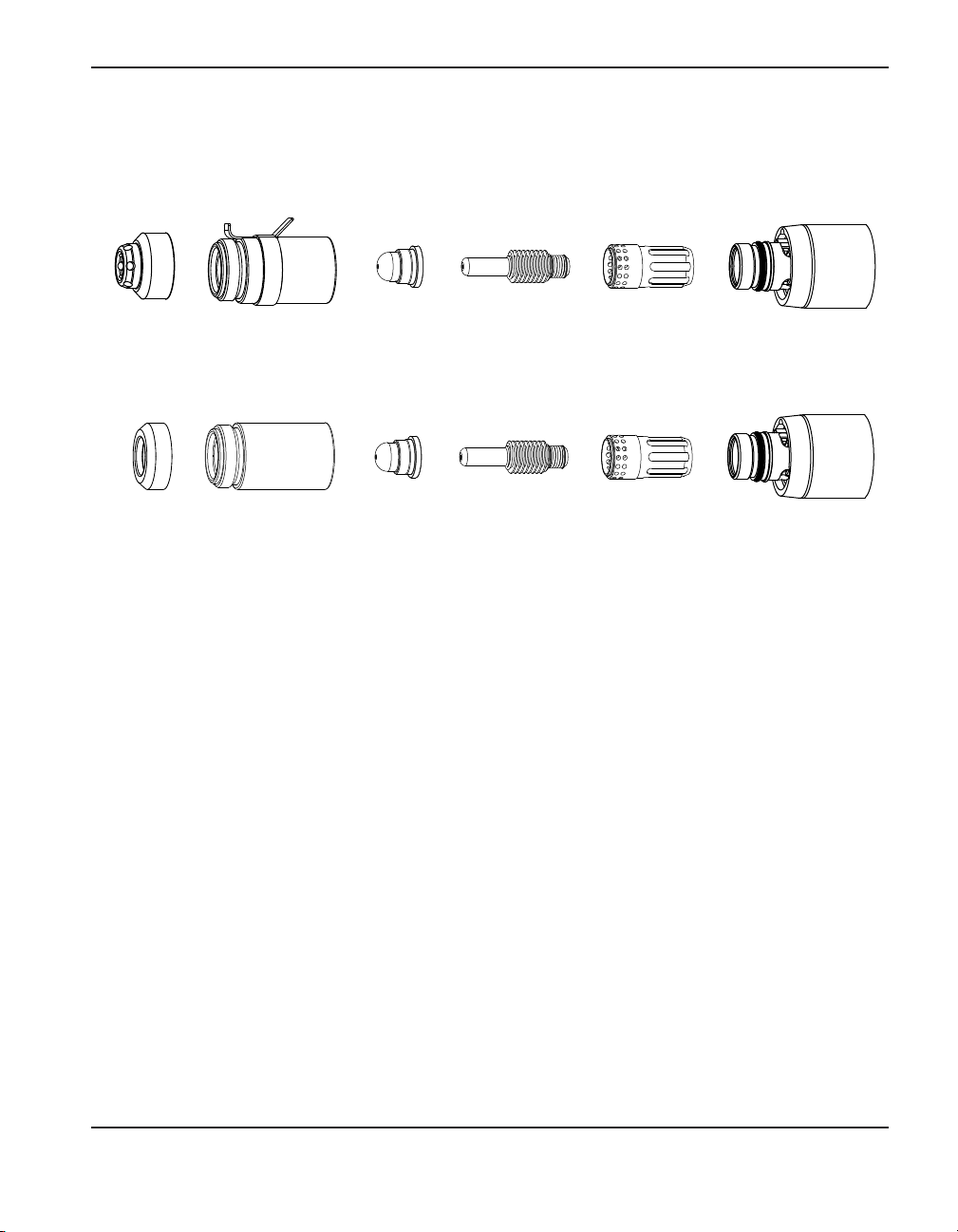

Hand torch consumables

Drag-cutting consumables: Powermax1000/1250/1650

4

5

A

220941

Nozzle

6

5

A

220818

Shield

220854

Retaining cap

220992

Shield

Gouging consumables: Powermax1000/1250/1650

220819

Nozzle

8

5

A

220816

Nozzle

1

0

0

A

220990

Nozzle

220842

Electrode

220857

Swirl ring

220994

Swirl ring

6

8

5

5

A

A

220798

Shield

FineCut

220931

Shield

220797

Nozzle

220854

Retaining cap

1

0

0

A

220991

220842

Electrode

Nozzle

®

consumables: Powermax1000/1250/1650

220854

Retaining cap

220930

Nozzle

220842

Electrode

220857

Swirl ring

220994

Swirl ring

220947

Swirl ring

Powermax1000 – Use 45‑65 A consumables

Powermax1250 – Use 45‑85 A consumables

Powermax1650 – Use 45‑100 A consumables

2-4 Duramax Retrofit Torch Operator Manual

Page 23

TORCH SETUP

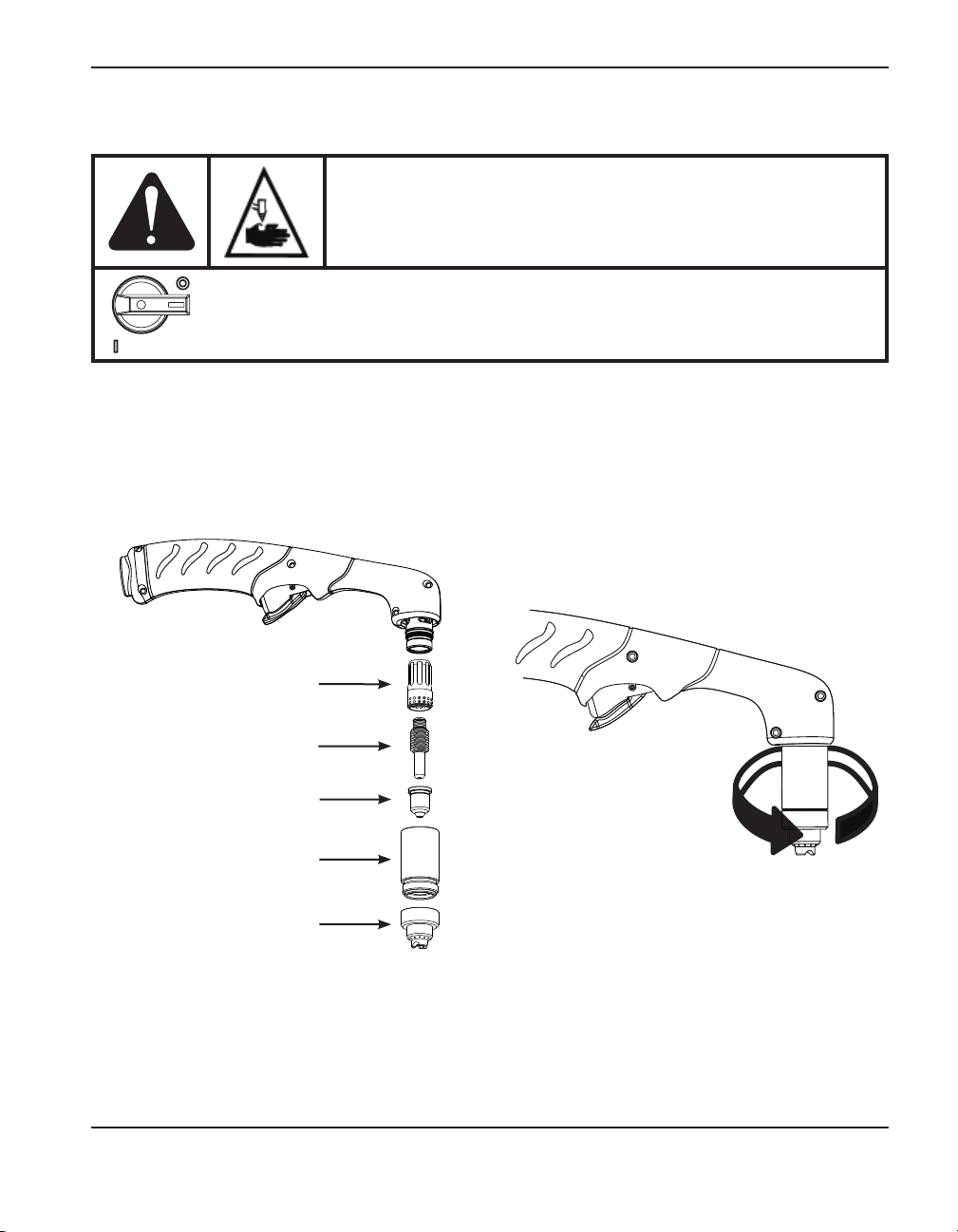

Install the hand torch consumables

WARNING

INSTANTON TORCHES

PLASMA ARC CAN CAUSE INJURY AND BURNS

The plasma arc comes on im me di ate ly when the torch trigger is

activated. Make sure the power is OFF before changing consumables.

To operate the hand torch, a complete set of consumable parts must be installed: shield, retaining

cap, nozzle, electrode, and swirl ring.

With the power switch in the OFF (O) position, install the torch consumables asshown below.

Swirl ring

Electrode

Nozzle

Retaining cap

Shield

Duramax Retrofit Torch Operator Manual 2-5

Page 24

Torch seTup

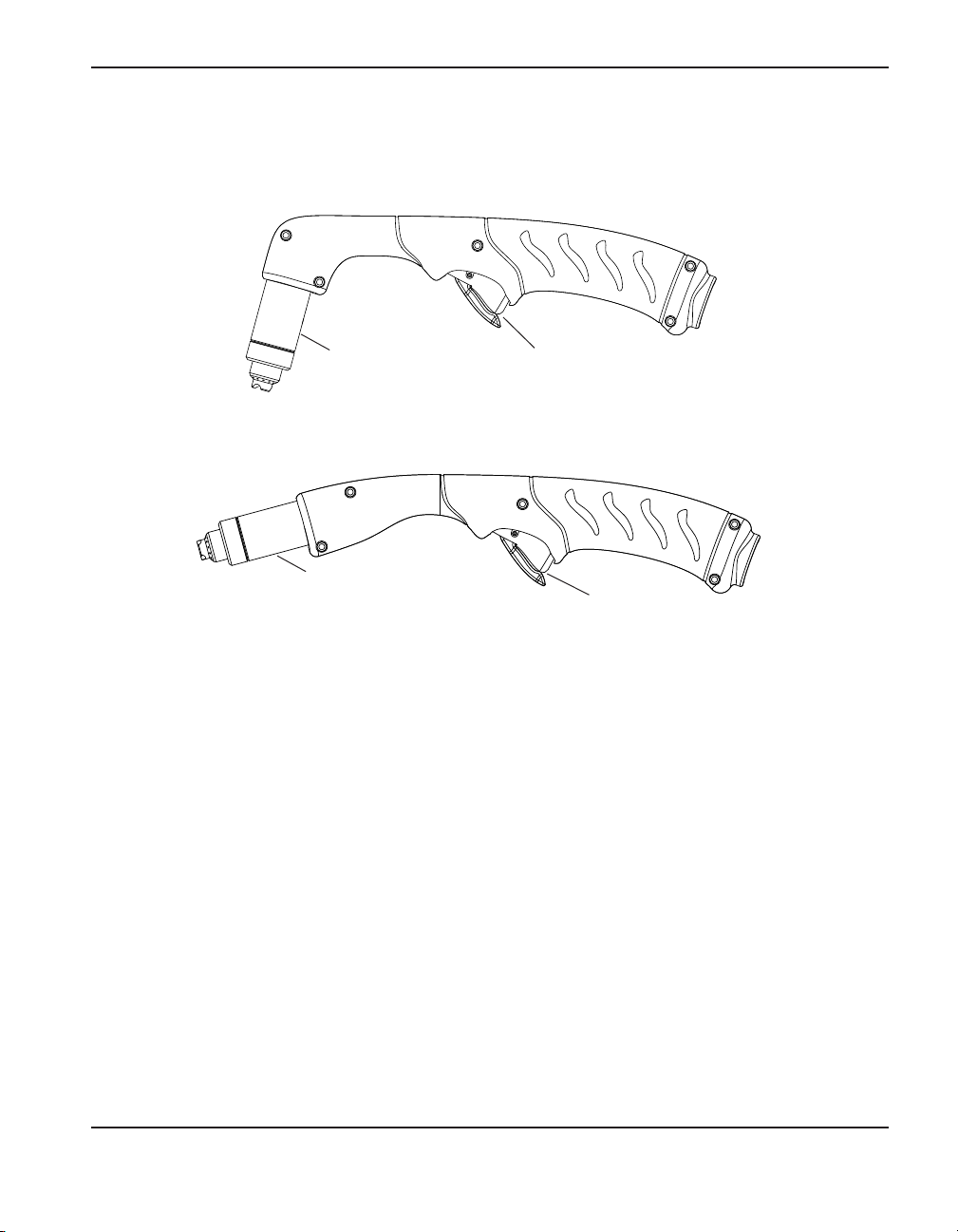

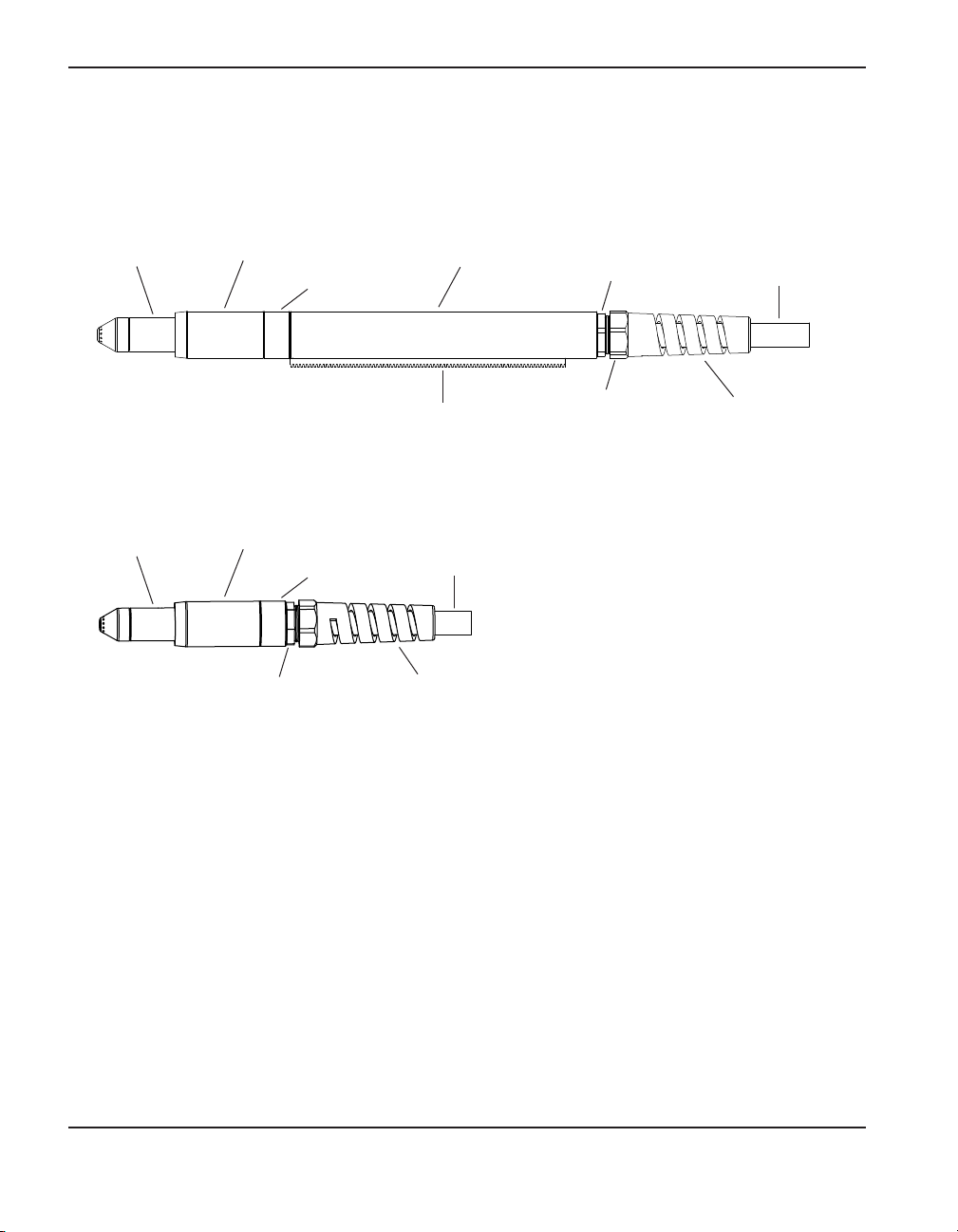

Machine torch setup

Duramax MRT

Mounting

Consumables

sleeve

Coupler

Positioning sleeve

Strain relief nut

Torch lead

Gear rack Strain relief body

Main strain

relief nut

Duramax MRT without positioning sleeve (mini torch)

Mounting

Consumables

sleeve

Coupler

Strain relief nut

Torch lead

Strain relief body

Before using either style of machine torch, you must:

• Mount the torch on your cutting table or other equipment.

• Choose and install the consumables.

• Align the torch.

• Attach the torch lead to the power supply.

• Set up the power supply for remote starting with either the remote‑start pendant or a

machine interface cable.

2-6 Duramax Retrofit Torch Operator Manual

Page 25

TORCH SETUP

Converting a Duramax retrofit machine torch into a mini torch

You can convert a full‑length machine torch to a mini‑machine torch by removing the positioning

sleeve.

Note: If you are converting a full‑length machine torch to a mini‑machine torch and

mounting the torch at the same time, skip this section and follow the instructions in

“Mount the torch” on page 2‑9.

Refer to the figures in the section “Machine torch setup” on page 2‑6 and follow these instructions.

Note: While disconnecting and reconnecting the torch parts, maintain the same orientation

between the torch head and torch lead. Twisting the torch head in relation to the

torch lead can cause damage.

1. Disconnect the torch lead from the power supply and remove the consumables from the torch.

2. Unscrew the strain relief body from the strain relief nut and slide the strain relief body back

along the torch lead.

3. Unscrew the strain relief nut from the positioning sleeve and slide the nut back along the torch

lead.

4. Unscrew the positioning sleeve from the coupler.

5. Unscrew the coupler from the mounting sleeve.

6. Remove the three screws from the consumables end of the mounting sleeve and slide the

mounting sleeve off the front of the torch body.

Duramax Retrofit Torch Operator Manual 2-7

Page 26

Torch seTup

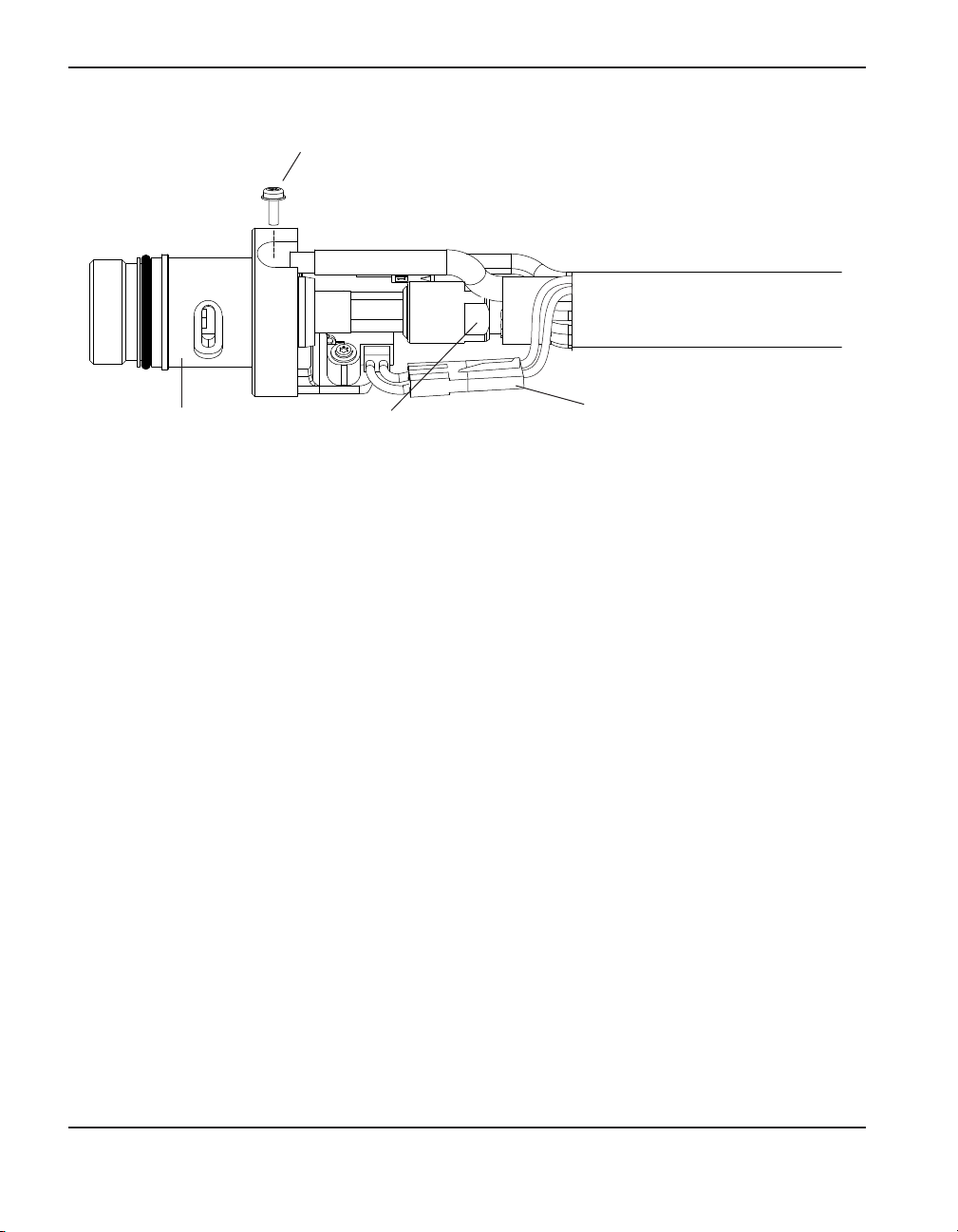

Pilot wire

terminal screw

Torch head

Gas supply line

connection

Wire connector for

cap‑sensor switch

7. Disconnect the wire connector for the cap‑sensor switch.

8. Use a #2 Phillips screwdriver to remove the screw that secures the torch’s pilot wire to the

torch body.

9. Use 1/4‑inch and 3/8‑inch wrenches, or adjustable wrenches, to loosen the nut that secures

the gas supply line to the torch lead. Set the torch body aside.

10. Slide the coupler and positioning sleeve off the front of the torch lead.

11. Slide the coupler over the torch lead.

12. Reconnect the gas line to the torch lead.

13. Reattach the torch’s pilot wire to the torch body using the screw.

14. Reconnect the cap‑sensor switch’s wire connector.

15. Slide the mounting sleeve over the front of the torch body. Align the slot on the front of the

mounting sleeve (next to one of the three screw holes) with the cap‑sensor plunger on the

torch body.

16. Attach the mounting sleeve to the torch body using the three screws.

17. Screw the coupler into the mounting sleeve.

18. Screw the strain relief nut into the coupler.

19. Screw the strain relief body into the strain relief nut.

2-8 Duramax Retrofit Torch Operator Manual

Page 27

TORCH SETUP

Mount the torch

Depending on the type of cutting table you have, you may or may not need to disassemble the

torch to route it through the track and mount it. If your cutting table’s track is large enough for you

to thread the torch through it without removing the torch body from the lead, do so and then attach

the torch to the lifter per the manufacturer’s instructions.

Note: The Duramax machine torches can be mounted on a wide variety of X‑Y tables, track

burners, pipe bevelers, and other equipment. Install the torch per the manufacturer’s

instructions and follow the instructions below for disassembly if necessary.

If you need to disassemble and reassemble the torch, refer to the figures in the section “Machine

torch setup” on page 2‑6 and follow these instructions.

Note: While disconnecting and reconnecting the torch parts, maintain the same orientation

between the torch head and torch lead. Twisting the torch head in relation to the

torch lead can cause damage.

1. Disconnect the torch lead from the power supply and remove the consumables from the torch.

2. Unscrew the strain relief body from the strain relief nut and slide the strain relief body back

along the torch lead.

3. Unscrew the strain relief nut from the positioning sleeve (full‑length machine torch) and slide

the nut back along the torch lead.

4. Unscrew the positioning sleeve from the coupler.

5. Unscrew the coupler from the mounting sleeve.

6. Remove the three screws from the consumables end of the mounting sleeve and slide the

mounting sleeve off the front of the torch body.

Duramax Retrofit Torch Operator Manual 2-9

Page 28

Torch seTup

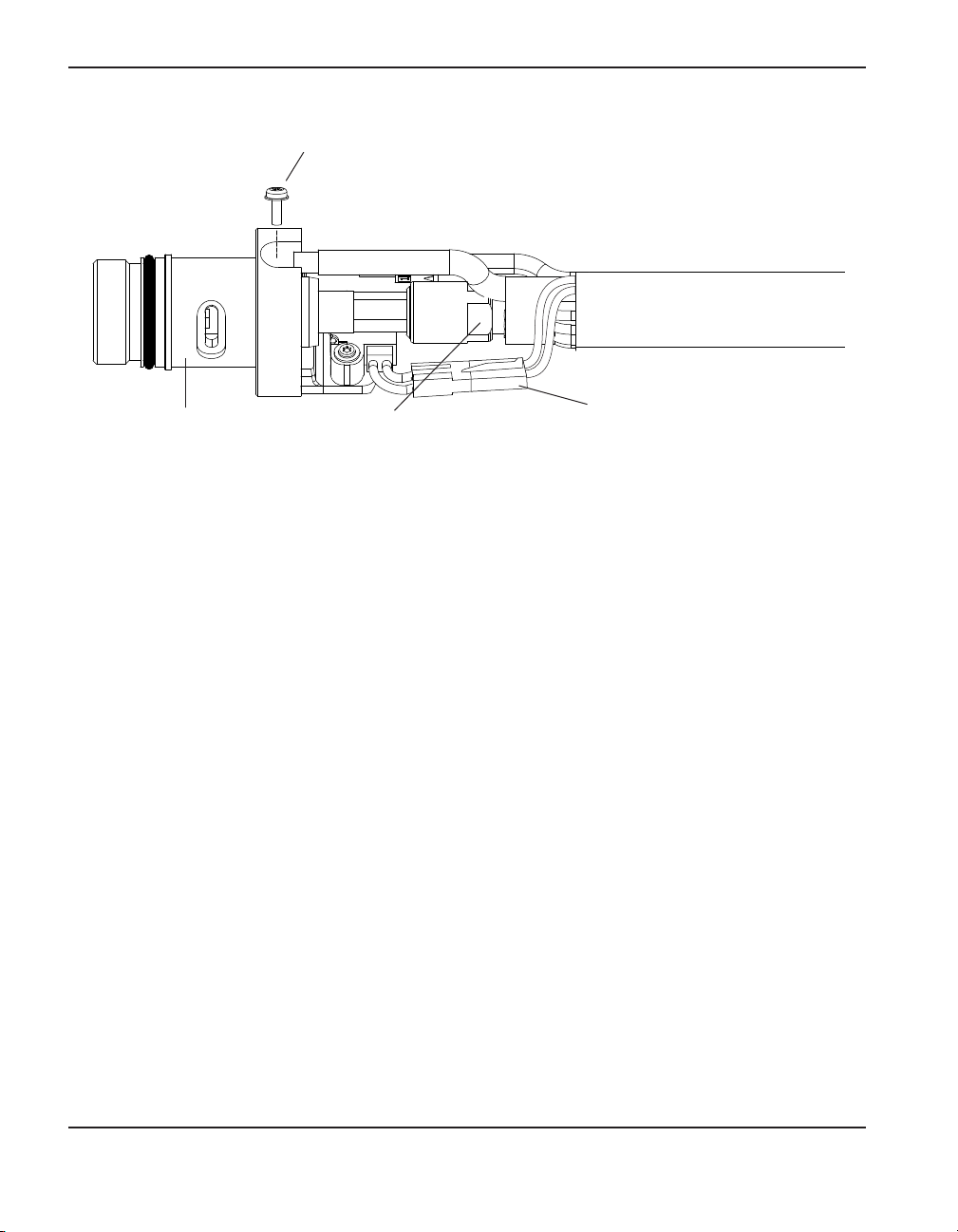

Pilot wire terminal screw

Wire connector for

Torch head

7. Disconnect the wire connector for the cap‑sensor switch.

8. Use a #2 Phillips screwdriver to remove the screw that secures the torch’s pilot wire to the

torch body.

9. Use 1/4‑inch and 3/8‑inch wrenches, or adjustable wrenches, to loosen the nut that secures

the gas supply line to the torch lead. Set the torch body aside.

Gas supply line

connection

cap‑sensor switch

Note: Cover the end of the gas line on the torch lead with tape to keep dirt and other

contaminants from getting in the gas line when you route the lead through the track.

10. Slide the coupler, positioning sleeve (full‑length machine torch), strain relief nut, and strain

relief body off the front of the torch lead.

11. If you do not need the gear rack on a full‑length machine torch, slide the gear rack from the

positioning sleeve toward the consumables end of the sleeve.

12. Route the torch lead through the cutting table’s track.

2-10 Duramax Retrofit Torch Operator Manual

Page 29

TORCH SETUP

13. Slide the strain relief body and strain relief nut over the torch lead.

14. If you are mounting a full‑length machine torch, slide the positioning sleeve over the torch

head.

15. Slide the coupler over the torch lead.

16. Reconnect the gas line to the torch lead.

17. Reattach the torch’s pilot wire to the torch body using the screw.

18. Reconnect the cap‑sensor switch’s wire connector.

19. Slide the mounting sleeve over the front of the torch body. Align the slot on the front of the

mounting sleeve (next to one of the three screw holes) with the cap‑sensor plunger on the

torch body.

20. Attach the mounting sleeve to the torch body using the three screws.

21. Screw the coupler into the mounting sleeve.

22. If you are mounting a full‑length machine torch, screw the positioning sleeve into the coupler.

23. Reconnect the strain relief nut and strain relief body.

24. Attach the torch to the lifter per the manufacturer’s instructions.

Duramax Retrofit Torch Operator Manual 2-11

Page 30

Torch seTup

Choose the machine torch consumables

Powermax systems with the Duramax MRT retrofit torch are shipped with a complete set

of consumables. Hypertherm also includes spare electrodes and nozzles. In addition, an

ohmic‑sensing retaining cap is available for use with shielded consumables. With shielded

consumables, the torch tip may touch the metal when cutting. With unshielded consumables, you

must keep the torch a small distance, about .08 inch (2 mm), away from the metal. Unshielded

consumables generally have a shorter life than shielded consumables.

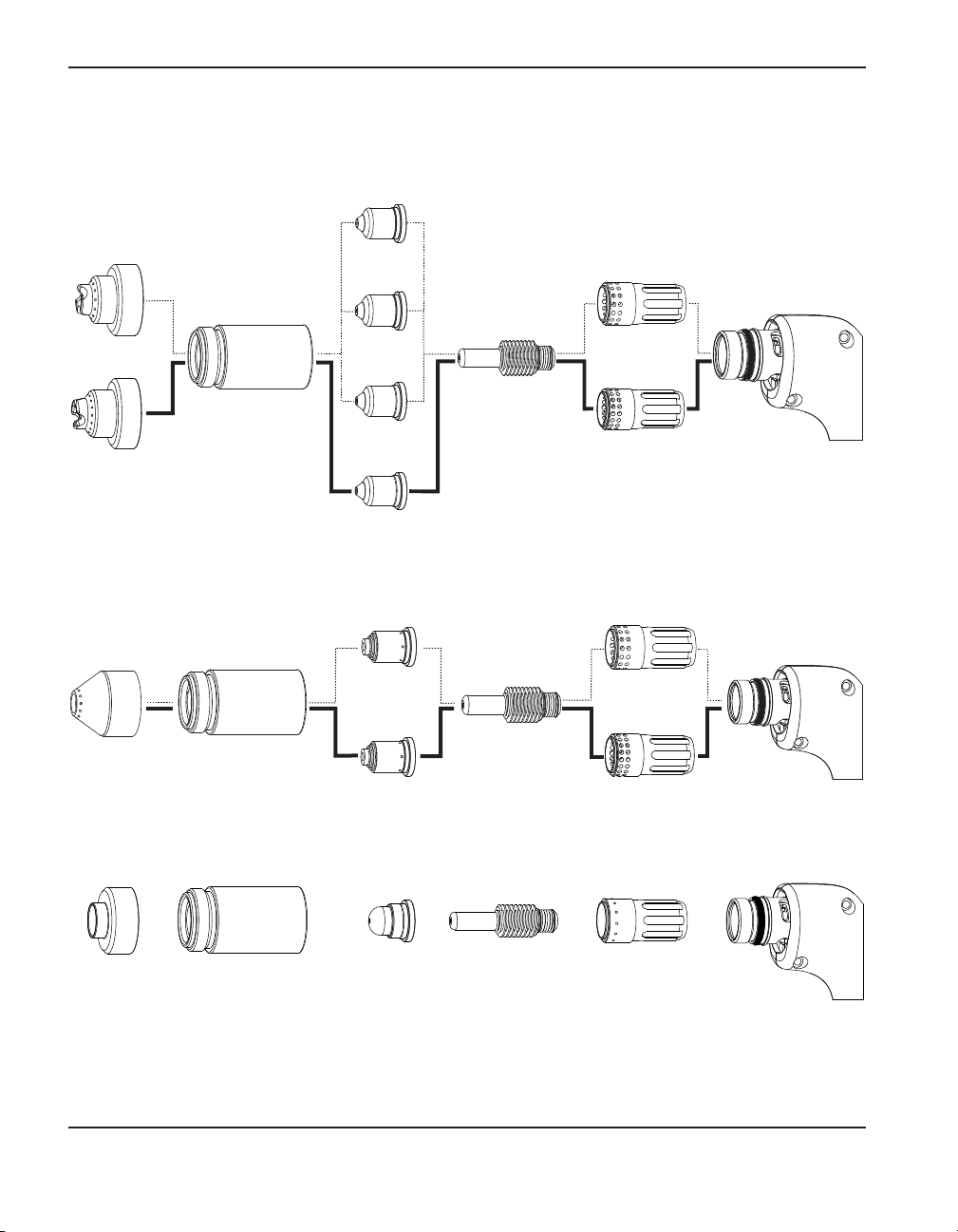

Machine torch consumables

Mechanized shielded consumables: Powermax1000/1250/1650

4

5

A

220941

Nozzle

6

5

A

220817

Shield

220993

Shield

220854

Retaining cap

220819

Nozzle

8

5

A

220816

Nozzle

1

0

0

A

220842

Electrode

220857

Swirl ring

220994

Swirl ring

220990

Nozzle

Powermax1000 – Use 45‑65 A consumables

Powermax1250 – Use 45‑85 A consumables

Powermax1650 – Use 45‑100 A consumables

2-12 Duramax Retrofit Torch Operator Manual

Page 31

TORCH SETUP

Mechanized shielded with ohmic consumables: Powermax1000/1250/1650

4

5

A

220941

Nozzle

6

5

A

220817

Shield

220993

Shield

220953

Ohmic‑sensing

retaining cap

220819

Nozzle

8

5

A

220816

Nozzle

1

0

0

A

220842

Electrode

220857

Swirl ring

220994

Swirl ring

220990

Nozzle

Mechanized unshielded consumables: Powermax1000/1250/1650

4

5

A

220941

Nozzle

6

5

A

220857

Swirl ring

220994

Swirl ring

220955

Deflector

220854

Retaining cap

220819

Nozzle

8

5

A

220816

Nozzle

1

0

0

A

220990

Nozzle

220842

Electrode

Powermax1000 – Use 45‑65 A consumables

Powermax1250 – Use 45‑85 A consumables

Powermax1650 – Use 45‑100 A consumables

Duramax Retrofit Torch Operator Manual 2-13

Page 32

Torch seTup

Gouging consumables: Powermax1000/1250/1650

6

8

5

5

A

A

220798

Shield

FineCut

220948

Shield

220797

220854

Retaining cap

®

shielded consumables: Powermax1000/1250/1650

220953

Retaining cap

220991

220930

Nozzle

Nozzle

1

0

0

A

Nozzle

220842

Electrode

220842

Electrode

220857

Swirl ring

220994

Swirl ring

220857

Swirl ring

FineCut® unshielded consumables: Powermax1000/1250/1650

220955

Deflector

220854

Retaining cap

220930

Nozzle

220842

Electrode

220857

Swirl ring

Powermax1000 – Use 45‑65 A consumables

Powermax1250 – Use 45‑85 A consumables

Powermax1650 – Use 45‑100 A consumables

2-14 Duramax Retrofit Torch Operator Manual

Page 33

TORCH SETUP

Install the machine torch consumables

WARNING

INSTANT-ON TORCHES

PLASMA ARC CAN CAUSE INJURY AND BURNS

The plasma arc comes on im me di ate ly when the torch is

activated. Make sure the power is OFF before changing the

consumables.

To operate the machine torch, a complete set of consumable parts must be installed: shield,

retaining cap, nozzle, electrode, and swirl ring.

With the power switch in the OFF (O) position, install the machine torch consumables in a manner

similar to the hand torch consumables. Refer to “Install the hand torch consumables” on page 2‑5.

Aligning the torch

Mount the machine torch perpendicular to the workpiece in order to get a vertical cut. Use a

square to align the torch at 0° and 90°.

Torch

0°

90°

Duramax Retrofit Torch Operator Manual 2-15

Page 34

Torch seTup

Torch installation

1. Turn OFF the power.

OFF

ON

2. Remove the power cord from the power receptacle.

3. Open the Easy Torch Removal (ETR) door and route the lead through the end cap.

AMPS

60

40

30

80

100

AC

V

50

60

PSI

70 80

4.0

5.0

6.0

BAR

_

+

ETR door

End cap

2-16 Duramax Retrofit Torch Operator Manual

Page 35

4. Align the marks on the strain relief.

5. Pull back the quick‑release collar and insert

the lead’s gas fitting.

TORCH SETUP

Quick‑release collar

6. Slide the quick‑release collar forward to lock

the gas fitting in place. Make sure that the gas

fitting is secure.

7. Make sure that the red dot on the connector is

on top, then plug in the electrical connector.

Close the ETR door.

Duramax Retrofit Torch Operator Manual 2-17

Page 36

Torch seTup

2-18 Duramax Retrofit Torch Operator Manual

Page 37

Section 3

Operation

In this section:

Using the cut charts .......................................................................................................................................... 3‑2

Estimated kerf‑width compensation .................................................................................................... 3‑2

100 amp mechanized shielded cutting for Powermax1650.......................................................... 3‑5

85 amp mechanized shielded cutting for Powermax1650 ............................................................ 3‑7

80 amp mechanized shielded cutting for Powermax1250/1650 ..............................................3‑11

65 amp mechanized shielded cutting for Powermax1250/1650 ..............................................3‑13

60 amp mechanized shielded cutting for Powermax1000/1250/1650 ...................................3‑17

45 amp mechanized shielded cutting for Powermax1000/1250/1650 ...................................3‑19

100 amp mechanized unshielded cutting for Powermax1650 ...................................................3‑23

85 amp mechanized unshielded cutting for Powermax1650......................................................3‑25

65 amp mechanized unshielded cutting for Powermax1250/1650 ..........................................3‑29

45 amp mechanized unshielded cutting for Powermax1000/1250/1650 ..............................3‑33

FineCut® consumables for Powermax1000/1250/1650 ............................................................3‑37

Using the hand torch .......................................................................................................................................3‑42

Operate the safety trigger ...................................................................................................................3‑42

Hand torch cutting hints ......................................................................................................................3‑43

Start a cut from the edge of the workpiece.....................................................................................3‑44

Pierce a workpiece ................................................................................................................................3‑45

Gouge a workpiece ..............................................................................................................................3‑46

Common hand‑cutting faults ..............................................................................................................3‑49

Using the machine torch ................................................................................................................................3‑50

Ensure the torch and table are set up correctly .............................................................................3‑50

Understand and optimize cut quality .................................................................................................3‑50

To pierce a workpiece using the machine torch ............................................................................3‑53

Common machine‑cutting faults ........................................................................................................3‑53

Duramax Retrofit Torch Operator Manual 3-1

Page 38

OPERATION

Using the cut charts

The following sections provide cut charts for each set of mechanized consumables. A consumable

diagram with part numbers precedes each section.

The arc voltage increases as the consumables wear and the voltage setting should be increased to

maintain the correct Torch‑to‑Work Distance.

Note: Hypertherm collected the data under laboratory test conditions using new

consumables.

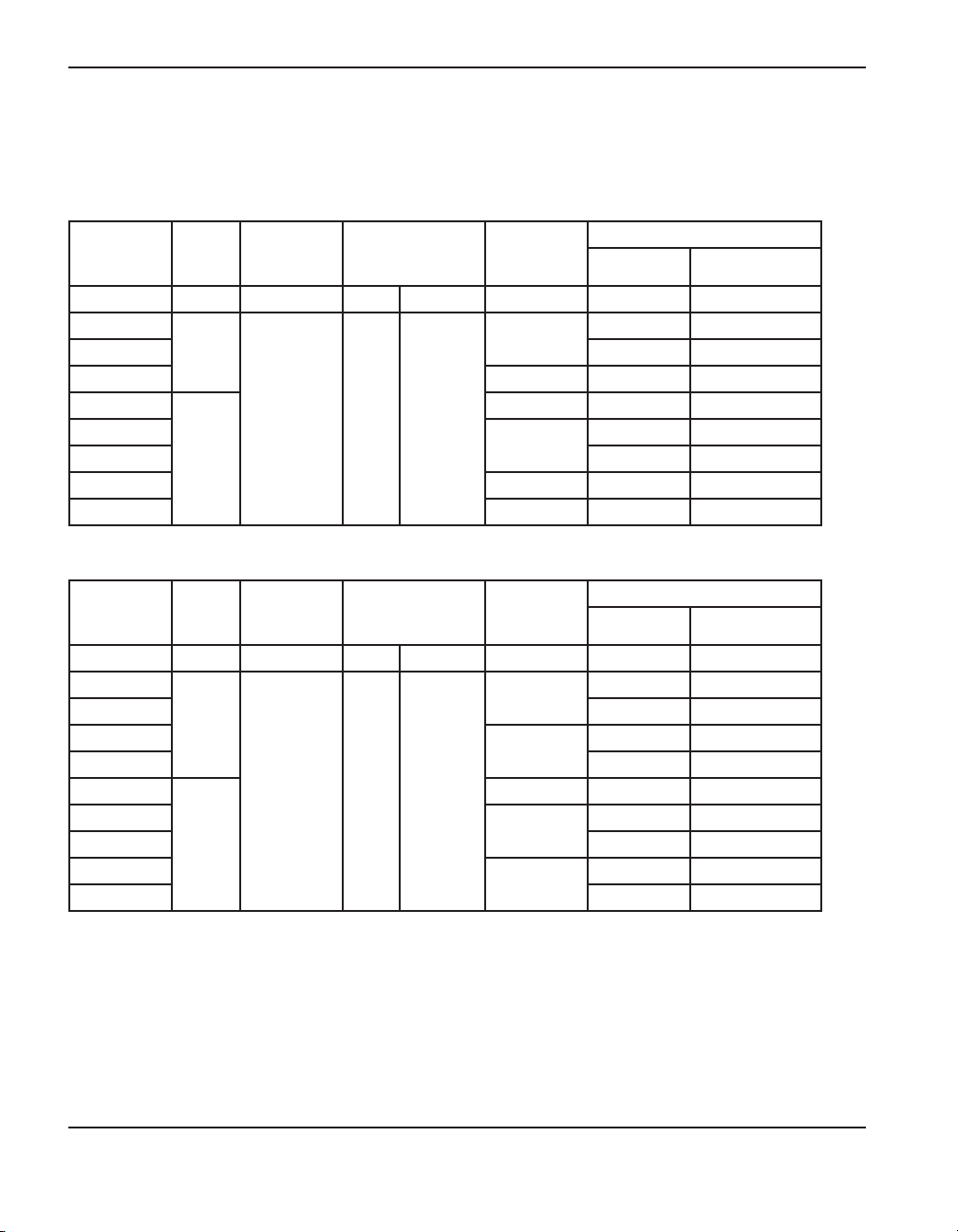

Estimated kerf-width compensation

The widths in the tables on the following two pages are for reference. The data is obtained with

the “Best Quality” settings. Differences between installations and material composition may cause

actual results to vary from those shown in the tables.

3-2 Duramax Retrofit Torch Operator Manual

Page 39

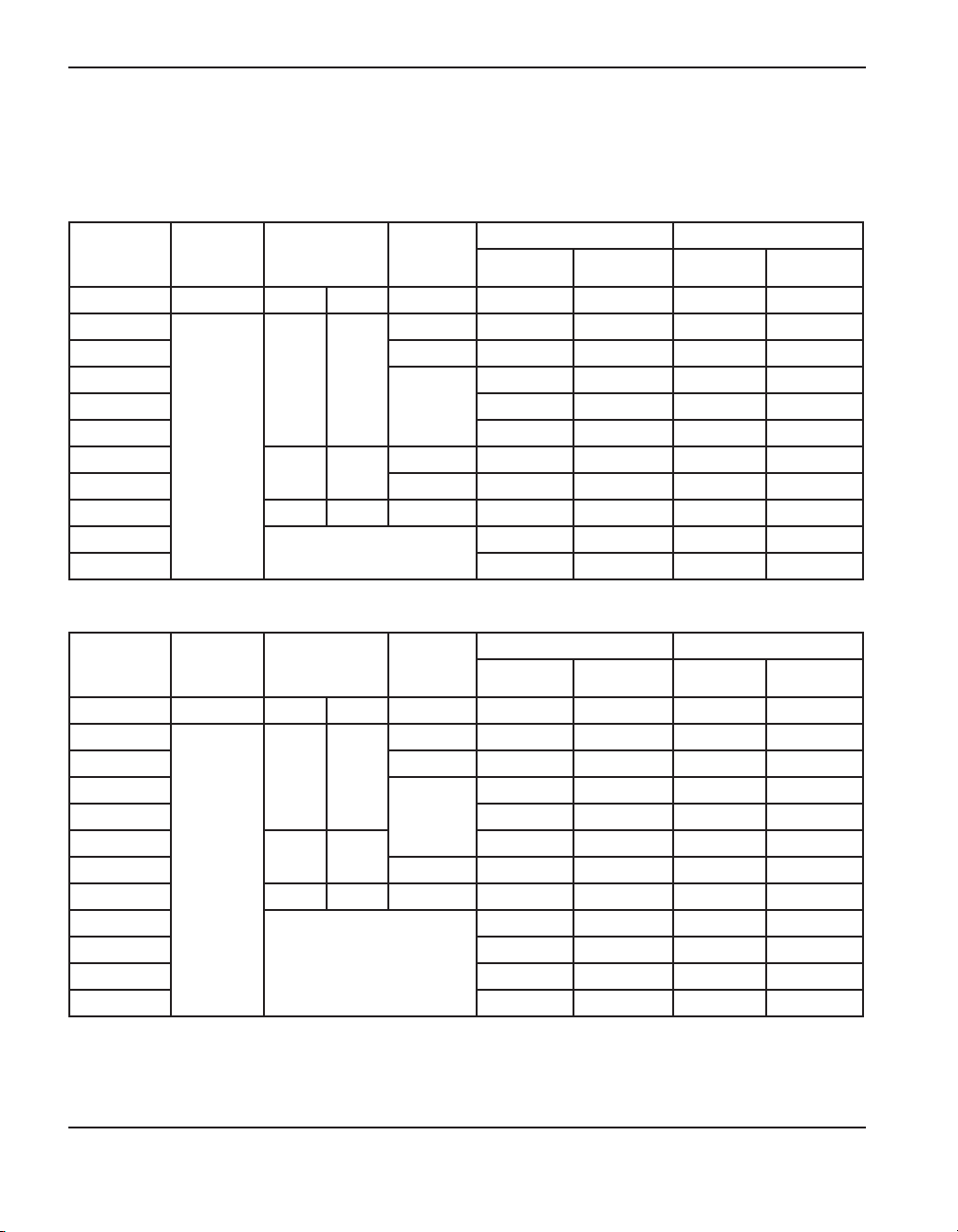

Estimated kerf-width compensation – Metric (mm)

Thickness (mm)

Process

100 A Shielded

85 A Shielded

80 A Shielded

65 A Shielded

60 A Shielded

45 A Shielded

FineCut

85 A Unshielded

65 A Unshielded

45 A Unshielded

100 A Shielded

85 A Shielded

80 A Shielded

65 A Shielded

60 A Shielded

45 A Shielded

FineCut

85 A Unshielded

65 A Unshielded

45 A Unshielded

100 A Shielded

85 A Shielded

80 A Shielded

65 A Shielded

60 A Shielded

45 A Shielded

85 A Unshielded

65 A Unshielded

45 A Unshielded

0.5 1 2 3 6 8 10 12 16 20

1.7 1.8 1.9 2.0 2.2 2.4 2.6

1.7 1.7 1.8 1.8 1.8 2.0 2.3

1.6 1.6 1.8 1.9 2.0 2.2 2.3

1.4 1.4 1.6 1.6 1.7 1.8 1.9

1.1 1.1 1.4 1.5 1.7

0.7 0.7 1.3 1.3

1.7 1.8 1.9 2.0 2.1 2.1 2.3

1.6 1.6 1.7 1.8 1.9 2.0

0.5 0.9 1.3 1.3

Stainless Steel

1.6 1.8 1.9 2.1 2.3 2.4 2.5

1.7 1.7 1.8 1.8 1.9 2.1 2.2

1.4 1.5 1.8 1.9 2.0 2.2 2.4

1.5 1.5 1.6 1.7 1.8 1.8 2.0

0.9 1.1 1.5 1.6 1.8

0.6 0.6 1.4 1.5

1.7 1.7 1.8 1.9 2.1 2.2 2.4

1.6 1.6 1.8 1.8 1.9 2.0

0.5 1.0 1.3 1.5 1.5

Aluminum

2.0 1.9 2.0 2.1 2.2 2.4 2.6

1.7 1.7 1.7 1.8 1.8 1.8

1.9 1.9 1.9 2.0 2.1 2.3 2.5

1.5 1.5 1.5 1.5 1.6 1.6 1.6

1.5 1.5 1.6 1.5

1.9 1.9 1.9 2.0 2.0 2.1 2.2

1.8 1.8 1.8 1.8 1.9 2.0

1.6 1.5 1.4 1.5

OPERATION

Mild Steel

2.0 2.1 2.2 2.2 2.3 2.7

1.9 1.9 2.0 2.1 2.2 2.3

2.1 2.1 2.1 2.1 2.1 2.3

Duramax Retrofit Torch Operator Manual 3-3

Page 40

OPERATION

Estimated kerf-width compensation – English (inches)

Thickness (inches)

Process

100 A Shielded

85 A Shielded

80 A Shielded

65 A Shielded

60 A Shielded

45 A Shielded

FineCut

85 A Unshielded

65 A Unshielded

45 A Unshielded

100 A Shielded

85 A Shielded

80 A Shielded

65 A Shielded

60 A Shielded

45 A Shielded

FineCut

85 A Unshielded

65 A Unshielded

45 A Unshielded

100 A Shielded

85 A Shielded

80 A Shielded

65 A Shielded

60 A Shielded

45 A Shielded

85 A Unshielded

65 A Unshielded

45 A Unshielded

22 GA 18 GA 14 GA 10 GA 3/16 1/4 3/8 1/2 5/8 3/4

Mild Steel

0.068 0.071 0.073 0.078 0.090 0.095 0.100

0.068 0.068 0.071 0.073 0.078 0.088

0.062 0.065 0.068 0.070 0.076 0.088 0.090 0.091

0.055 0.057 0.060 0.063 0.067 0.071 0.076 0.084

0.035 0.054 0.055 0.061 0.065 0.066

0.024 0.043 0.049 0.051

0.070 0.073 0.075 0.080 0.085 0.090

0.062 0.064 0.066 0.068 0.075 0.081

0.020 0.050 0.051 0.054 0.057 0.059

Stainless Steel

0.068 0.071 0.073 0.078 0.090 0.095 0.100

0.062 0.065 0.068 0.070 0.076 0.088 0.090 0.091

0.035 0.054 0.055 0.061 0.065 0.066

0.024 0.043 0.049 0.051

0.070 0.073 0.075 0.080 0.085 0.090

0.062 0.064 0.066 0.068 0.075 0.081

0.020 0.050 0.051 0.054 0.057 0.059

Aluminum

1/32 1/16 1/8 3/16 1/4 3/8 1/2 5/8 3/4

0.080 0.078 0.075 0.080 0.090 0.095 0.100

0.069 0.065 0.072 0.069 0.075

0.073 0.074 0.075 0.076 0.083 0.091 0.100

0.064 0.061 0.057 0.061 0.063 0.065

0.059 0.061 0.065 0.060

0.075 0.075 0.075 0.080 0.082 0.088

0.070 0.070 0.070 0.070 0.072 0.079

0.062 0.058 0.057 0.061

0.079 0.085 0.085 0.089 0.107

0.074 0.079 0.083 0.087 0.090

0.066 0.072 0.077 0.082 0.088

0.065 0.069 0.073 0.080 0.088

0.083 0.085 0.080 0.084 0.089

3-4 Duramax Retrofit Torch Operator Manual

Page 41

100 amp mechanized shielded cutting for Powermax1650

1

0

0

A

OPERATION

220993

Shield

220993

Shield

220854

Retaining cap

220953

Ohmic‑sensing

220990

Nozzle

1

0

0

A

220990

Nozzle

220842

Electrode

220842

Electrode

220994

Swirl ring

220994

Swirl ring

retaining cap

• Recommended cut speeds are a good starting point for finding the best quality cut (best

angle, least dross, and best cut‑surface finish). Adjust the speed for your application and

table to obtain the desired cut quality.

• Maximum cut speeds are the fastest speeds possible to cut material without regard to cut

quality.

Duramax Retrofit Torch Operator Manual 3-5

Page 42

OPERATION

Note: Torch‑to‑work dis tance for the following cut chart is 1/8 in (3.2 mm) for all cuts.

Mild steel

Recommended cut

speed

Recommended cut

speed

Maximum cut speed

Maximum cut speed

Arc current Arc voltage

153 0.5 1/4 6.4 135 3429 208 5283

155 0.5 3/8 9.5 77 1955 119 3022

159 1.0 1/2 12.7 57 1447 88 2235

100

160 1.0 5/8 15.9 40 1016 61 1549

161 1.5 3/4 19.0 26 660 47 1193

163

167 1 1/4 31.8 12 305 19 482

Stainless steel

Arc current Arc voltage

154 0.5 1/4 6.4 150 3810 231 5867

156 0.5 3/8 9.5 79 2006 122 3099

161 1.0 1/2 12.7 52 1320 79 2006

100

162 1.0 5/8 15.9 34 863 52 1320

164 1.5 3/4 19.0 25 635 39 990

166

169 1 1/4 31.8 9 228 14 355

Pierce

delay

NA

Pierce

delay

NA

Material thickness

in mm ipm mm/min ipm mm/min

1 25.4 18 457 28 711

Material thickness

in mm ipm mm/min ipm mm/min

1 25.4 15 381 23 584

Aluminum

Recommended cut

speed

Maximum cut speed

Arc current Arc voltage

154 0.5 1/4 6.4 164 4165 253 6426

157 0.5 3/8 9.5 92 2336 142 3606

160 1.0 1/2 12.7 70 1778 108 2743

100

161 1.0 5/8 15.9 50 1270 77 1955

162 1,5 3/4 19.0 33 838 57 1447

165 NA 1 25.4 21 533 33 838

Pierce

delay

Material thickness

in mm ipm mm/min ipm mm/min

3-6 Duramax Retrofit Torch Operator Manual

Page 43

85 amp mechanized shielded cutting for Powermax1650

8

5

A

OPERATION

220817

Shield

220817

Shield

220854

Retaining cap

220953

Ohmic‑sensing

retaining cap

220816

Nozzle

8

5

A

220816

Nozzle

220842

Electrode

220842

Electrode

220857

Swirl ring

220857

Swirl ring

• Best Quality Settings (cut speed and voltage) — Settings that provide the starting point

for finding the best cut quality (best angle, least dross, best cut‑surface finish). Adjust the

speed for your application and table to obtain the desired result.

• Production Settings (cut speed and voltage) — 80% of the maximum speed ratings. These

speeds result in the greatest number of cut parts, but not necessarily the best possible cut

quality.

Duramax Retrofit Torch Operator Manual 3-7

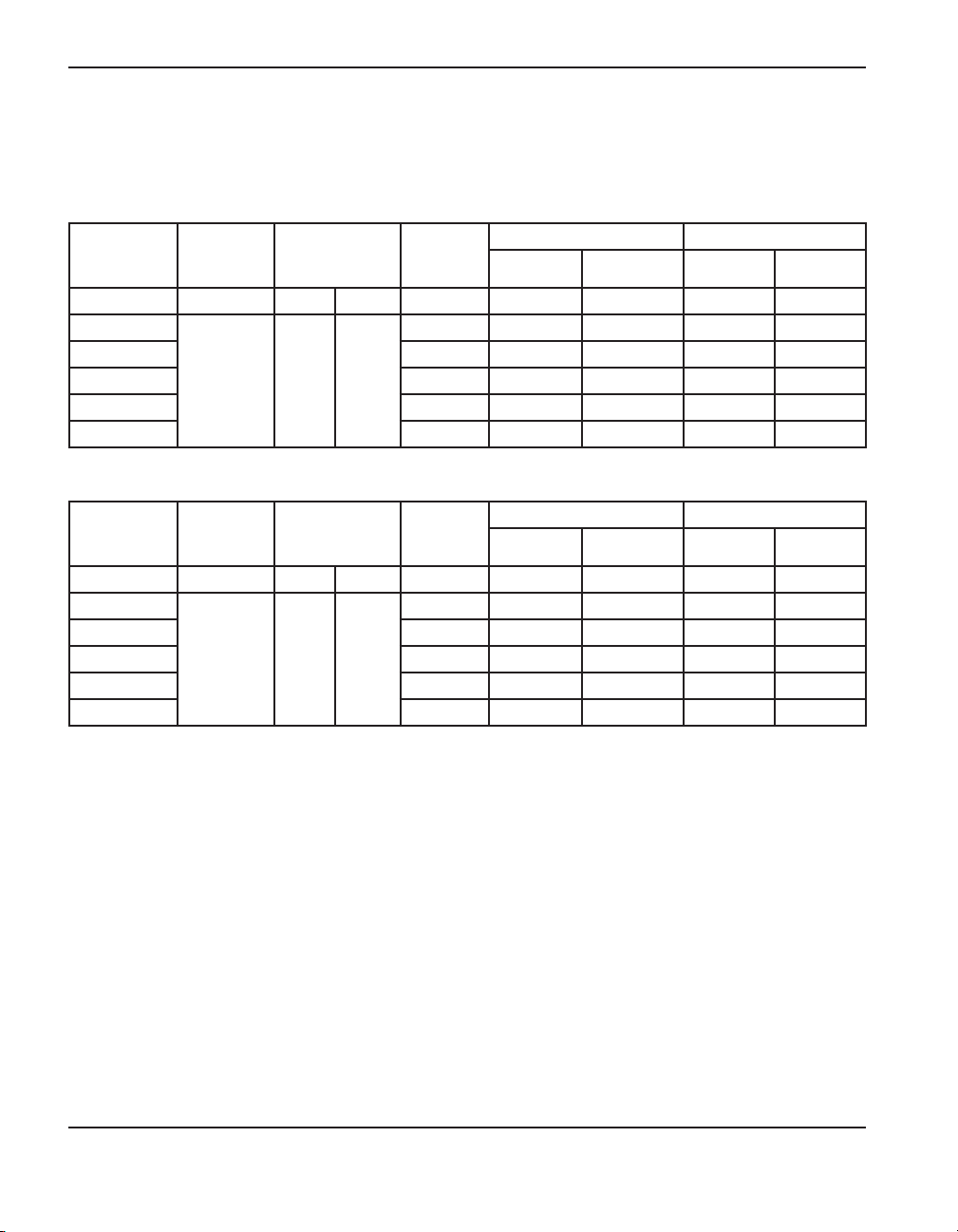

Page 44

OPERATION

85 A Shielded

Mild Steel

Metric

Material

Thickness

mm mm mm % seconds mm/min Volts mm/min Volts

3

4 0.2 5650 122 7300 122

6

8 2500 125 3100 127

10 1680 127 2070 128

12

16 1.0 870 134 930 133

20 6.0 400 1.5 570 137 680 136

25

30 200 146 300 144

Torch-

to-Work

Distance

1.5

Initial Pierce

Height

3.8 250

4.5 300

Edge Start

Pierce

Delay Time

0.1 6800 122 9200 120

0.5

0.7 1280 130 1600 130

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

3600 123 4400 125

350 142 450 141

English

Material

Thickness

in in in % seconds ipm Volts ipm Volts

10 GA

3/16 0.2 185 123 220 123

1/4

3/8 70 126 86 127

1/2

5/8 1.0 35 134 37 133

3/4 0.24 400 1.5 24 136 29 135

7/8

1 13 142 17 141

1‑1/8 9 145 13 143

1‑1/4 7 148 10 146

Torch-

to-Work

Distance

0.06

Initial Pierce

Height

0.15 250

0.18 300

Edge Start

Pierce

Delay Time

0.0 250 122 336 121

0.5

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

130 123 160 126

45 131 56 131

19 139 22 138

3-8 Duramax Retrofit Torch Operator Manual

Page 45

OPERATION

85 A Shielded

Stainless Steel

Metric

Material

Thickness

mm mm mm % seconds mm/min Volts mm/min Volts

3

4 0.2 6100 122 7500 120

6

8 2450 124 3050 124

10

12 0.7 1100 131 1400 130

16 1.0 700 135 760 134

20

25 300 143 370 141

English

Material

Thickness

in in in % seconds ipm Volts ipm Volts

10 GA

3/16 200 122 240 121

1/4

3/8 65 126 80 125

1/2

5/8 1.0 28 135 30 134

3/4

7/8 16 140 19 139

1 11 143 14 141

Torch-

to-Work

Distance

1.5

Torch-

to-Work

Distance

0.06

Initial Pierce

Height

3.8 250

4.5 300

Edge Start

Initial Pierce

Height

0.15 250

0.18 300

Edge Start

Pierce

Delay Time

0.1 7500 122 9200 120

0.5

Pierce

Delay Time

0.2

0.5

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

3700 122 4600 122

1550 127 1900 126

480 138 570 137

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

275 122 336 120

130 122 164 122

36 132 48 131

20 137 24 136

Duramax Retrofit Torch Operator Manual 3-9

Page 46

OPERATION

85 A Shielded

Aluminum

Metric

Material

Thickness

mm mm mm % seconds mm/min Volts mm/min Volts

3

4 0.2 6500 123 8000 123

6

8 2650 130 3470 129

10

12 0.7 1450 134 1930 133

16 1.0 950 139 1200 137

20

25 380 146 540 144

English

Material

Thickness

in in in % seconds ipm Volts ipm Volts

1/8

1/4

3/8 80 132 104 131

1/2

5/8 1.0 38 139 48 137

3/4

7/8 20 144 29 142

1 14 146 20 144

Torch-

to-Work

Distance

1.5

Torch-

to-Work

Distance

0.06

Initial Pierce

Height

3.8 250

4.5 300

Edge Start

Initial Pierce

Height

0.15 250

0.18 300

Edge Start

Pierce

Delay Time

0.1 8000 122 9400 121

0.5

Pierce

Delay Time

0.2 300 122 360 121

0.5

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

3800 126 4900 126

1920 132 2500 131

600 143 880 141

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

130 127 172 127

50 135 68 133

25 142 37 140

3-10 Duramax Retrofit Torch Operator Manual

Page 47

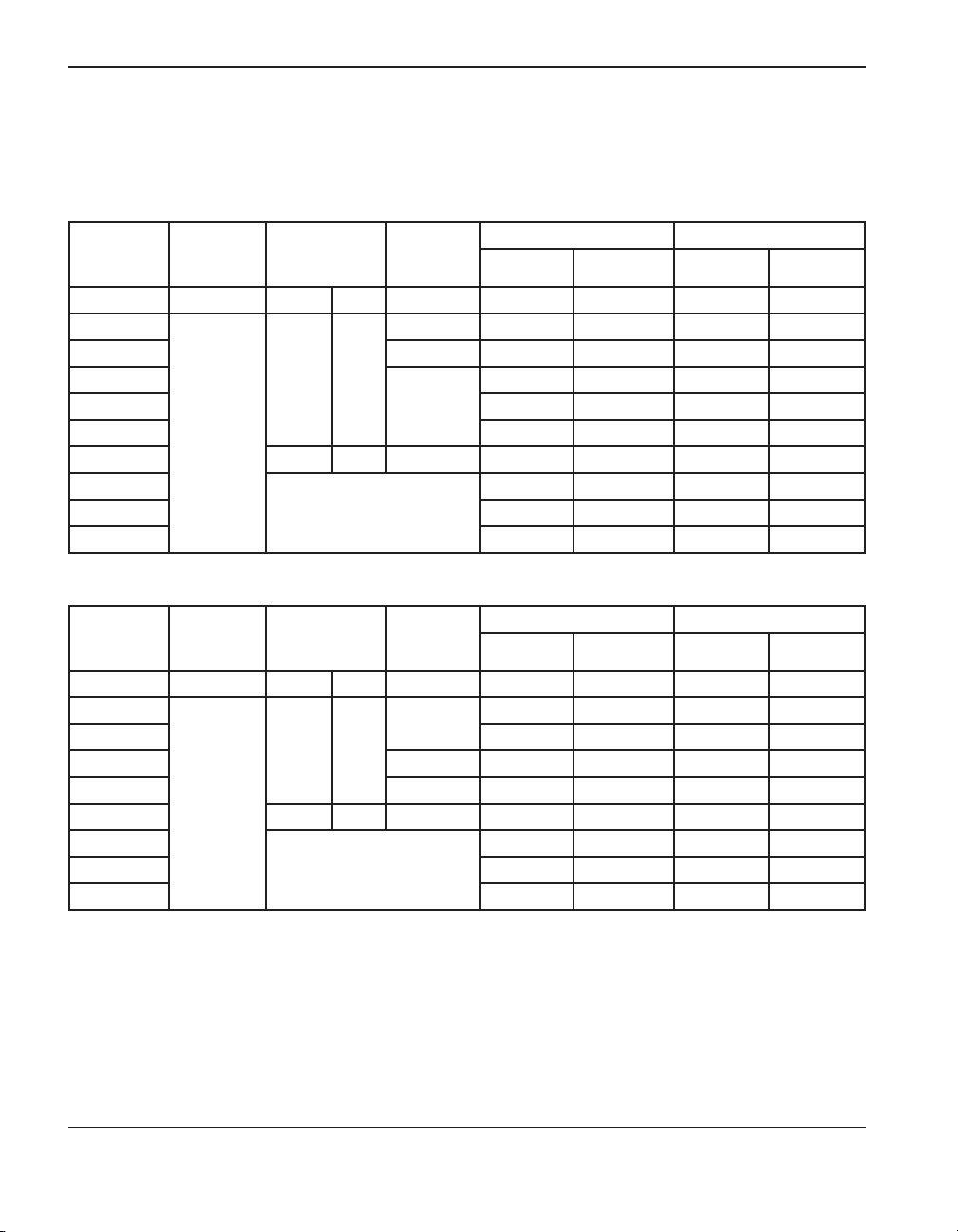

80 amp mechanized shielded cutting for Powermax1250/1650

8

5

A

OPERATION

220817

Shield

220817

Shield

220854

Retaining cap

220953

Ohmic‑sensing

retaining cap

220816

Nozzle

8

5

A

220816

Nozzle

220842

Electrode

220842

Electrode

220857

Swirl ring

220857

Swirl ring

• Recommended cut speeds are a good starting point for finding the best quality cut (best

angle, least dross, and best cut‑surface finish). Adjust the speed for your application and

table to obtain the desired cut quality.

• Maximum cut speeds are the fastest speeds possible to cut material without regard to cut

quality.

Duramax Retrofit Torch Operator Manual 3-11

Page 48

OPERATION

Note: Torch‑to‑work dis tance for the following cut chart is 1/16 in (1.5 mm) for all cuts.

Mild steel

Recommended

cutspeed

Recommended

cutspeed

Maximum cut speed

Maximum cut speed

ipm mm/min ipm mm/min

Arc current Arc voltage

132 0.25 3/16 4.8 140 3556 216 5486

134

137 3/8 9.5 61 1549 94 2388

80

140 1/2 12.7 39 991 60 1524

145 1.0 5/8 15.9 26 660 40 1016

148

150 7/8 22.2 15 381 23 584

156 1 25.4 10 254 16 406

Stainless steel

Arc current Arc voltage

134 0.25 3/16 4.8 140 3556 216 5486

136 0.50 1/4 6.4 103 2616 158 4013

139

80

142 1/2 12.7 33 838 50 1270

145 1.0 5/8 15.9 22 559 34 864

150

153 1 25.4 9 229 14 356

Pierce

delay

0.50

N/A

Pierce

delay

0.75

N/A

Material thickness

in mm ipm mm/min ipm mm/min

1/4 6.4 105 2667 161 4089

3/4 19.0 20 508 31 787

Material thickness

in mm

3/8 9.5 54 1372 83 2108

3/4 19.0 16 406 24 610

Aluminum

Recommended

cutspeed

Maximum cut speed

Arc current Arc voltage

134

139 1/4 6.4 114 2896 176 4470

80

143

146 1/2 12.7 37 940 75 1905

154 N/A 3/4 19.0 19 483 37 940

Pierce

delay

0.25

0.75

Material thickness

in mm ipm mm/min ipm mm/min

1/8 3.2 295 7493 454 11532

3/8 9.5 60 1524 121 3073

3-12 Duramax Retrofit Torch Operator Manual

Page 49

65 amp mechanized shielded cutting for Powermax1250/1650

6

5

A

OPERATION

220817

Shield

220817

Shield

220854

Retaining cap

220953

Ohmic‑sensing

retaining cap

220819

Nozzle

6

5

A

220819

Nozzle

220842

Electrode

220842

Electrode

220857

Swirl ring

220857

Swirl ring

• Best Quality Settings (cut speed and voltage) — Settings that provide the starting point

for finding the best cut quality (best angle, least dross, best cut‑surface finish). Adjust the

speed for your application and table to obtain the desired result.

• Production Settings (cut speed and voltage) — 80% of the maximum speed ratings. These

speeds result in the greatest number of cut parts, but not necessarily the best possible cut

quality.

Duramax Retrofit Torch Operator Manual 3-13

Page 50

OPERATION

65 A Shielded

Mild Steel

Metric

Material

Thickness

mm mm mm % seconds mm/min Volts mm/min Volts

2

3 0.2 5200 125 6100 123

4

6 2550 127 3240 127

8 1700 129 2230 128

10

12 1.2 850 134 1140 131

16 6.0 400 2.0 560 138 650 136

20

25 210 145 270 145

Torch-

to-Work

Distance

1.5

Initial Pierce

Height

3.8 250

4.5 300

Edge Start

Pierce

Delay

Time

0.1 6050 124 7000 121

0.5

0.7 1100 131 1500 129

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

4250 125 5100 124

350 142 450 142

English

Material

Thickness

in in in % seconds ipm Volts ipm Volts

16 GA

10 GA 190 125 224 123

3/16 0.2 140 126 168 125

1/4 0.5 90 127 116 127

3/8 0.7 45 130 62 129

1/2 0.18 300 1.2 30 135 40 132

5/8 0.24 400 2.0 23 138 26 136

3/4

7/8 12 143 14 143

1 8 145 10 145

Torch-

to-Work

Distance

0.06

Initial Pierce

Height

0.15 250

Edge Start

Pierce

Delay

Time

0.1

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

260 123 294 121

15 141 19 141

3-14 Duramax Retrofit Torch Operator Manual

Page 51

OPERATION

65 A Shielded

Stainless Steel

Metric

Material

Thickness

mm mm mm % seconds mm/min Volts mm/min Volts

2

3 0.2 6700 125 8260 123

4

6 2450 126 2850 126

8

10

12 1.2 750 135 920 134

16

20 300 143 370 143

English

Material

Thickness

in in in % seconds ipm Volts ipm Volts

16 GA

10 GA 240 125 296 123

3/16 0.2 155 126 168 125

1/4 0.5 80 126 96 126

3/8 0.7 40 131 52 131

1/2 0.18 300 1.2 26 136 32 135

5/8

3/4 14 142 15 142

Torch-

to-Work

Distance

1.5

Torch-

to-Work

Distance

0.06

Initial Pierce

Height

3.8 250

4.5 300

Edge Start

Initial Pierce

Height

0.15 250

Edge Start

Pierce

Delay Time

0.1 8100 125 10000 121

0.5

0.7

Pierce

Delay Time

0.1

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

5200 125 6150 124

1500 129 1860 129

960 132 1250 132

500 139 500 139

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

345 124 426 121

20 139 20 139

Duramax Retrofit Torch Operator Manual 3-15

Page 52

OPERATION

65 A Shielded

Aluminum

Metric

Material

Thickness

mm mm mm % seconds mm/min Volts mm/min Volts

2

3 0.2 7400 124 8800 124

4

6 3200 130 4400 128

8

10

12 1.2 1000 138 1330 136

16

20 380 147 560 145

English

Material

Thickness

in in in % seconds ipm Volts ipm Volts

1/16

1/8 280 124 336 124

1/4 0.5 105 131 152 128

3/8 0.7 50 135 68 131

1/2 0.18 300 1.2 35 139 48 138

5/8

3/4 16 146 24 144

Torch-

to-Work

Distance

1.5

Torch-

to-Work

Distance

0.06

Initial Pierce

Height

3.8 250

4.5 300

Edge Start

Initial Pierce

Height

0.15 250

Edge Start

Pierce

Delay

Time

0.1 8800 121 10300 122

0.5

0.7

Pierce

Delay

Time

0.1

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

6000 126 7350 125

1950 133 2750 130

1200 136 1650 132

650 143 800 141

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

365 121 428 121

26 143 32 141

3-16 Duramax Retrofit Torch Operator Manual

Page 53

OPERATION

60 amp mechanized shielded cutting for Powermax1000/1250/1650

6

5

A

220817

Shield

220817

Shield

220854

Retaining cap

220953

Ohmic‑sensing

retaining cap

220819

Nozzle

6

5

A

220819

Nozzle

220842

Electrode

220842

Electrode

220857

Swirl ring

220857

Swirl ring

• Recommended cut speeds are a good starting point for finding the best quality cut (best

angle, least dross, and best cut‑surface finish). Adjust the speed for your application and

table to obtain the desired cut quality.

• Maximum cut speeds are the fastest speeds possible to cut material without regard to cut

quality.

Duramax Retrofit Torch Operator Manual 3-17

Page 54

OPERATION

Note: Torch‑to‑work dis tance for the following cut chart is 1/16 in (1.5 mm) for all cuts.

Mild steel

Recommended

cutspeed

Recommended

cutspeed

Maximum cut speed

Maximum cut speed

ipm mm/min ipm mm/min

Arc current Arc voltage

134

134 10 Ga 3.4 211 5359 264 6706

138 0.25 1/4 6.4 86 2184 132 3353

60

141 0.75 3/8 9.5 41 1041 63 1600

141

147 5/8 15.9 20 512 31 787

153 3/4 19.0 14 363 22 559

Stainless steel

Arc current Arc voltage

134 0 16 Ga 1.5 406 10312 625 15875

136 0.25 10 Ga 3.4 159 4039 244 6198

139 0.50 1/4 6.4 72 1829 110 2794

60

145 0.75 3/8 9.5 34 864 53 1346

146

149 5/8 15.9 17 429 26 660

154 3/4 19.0 12 297 18 457

Pierce

delay

0

1.50

Pierce

delay

2.00

Material thickness

in mm ipm mm/min ipm mm/min

16 Ga 1.5 502 12751 627 15926

1/2 12.7 27 686 42 1067

Material thickness

in mm

1/2 12.7 23 584 35 889

Aluminum

Recommended

cutspeed

Maximum cut speed

Arc current Arc voltage

135 0 1/16 1.6 433 10995 666 16916

138

141 1/4 6.4 94 2388 145 3683

60

146 0.75 3/8 9.5 48 1219 74 1880

149

153 5/8 15.9 21 545 33 838

Pierce

delay

0.25

1.50

Material thickness

in mm ipm mm/min ipm mm/min

1/8 3.2 260 6604 400 10160

1/2 12.7 30 762 51 1295

3-18 Duramax Retrofit Torch Operator Manual

Page 55

OPERATION

45 amp mechanized shielded cutting for Powermax1000/1250/1650

4

5

A

220817

Shield

220817

Shield

220854

Retaining cap

220953

Ohmic‑sensing

retaining cap

220941

Nozzle

4

5

A

220941

Nozzle

220842

Electrode

220842

Electrode

220857

Swirl ring

220857

Swirl ring

• Best Quality Settings (cut speed and voltage) — Settings that provide the starting point

for finding the best cut quality (best angle, least dross, best cut‑surface finish). Adjust the

speed for your application and table to obtain the desired result.

• Production Settings (cut speed and voltage) — 80% of the maximum speed ratings. These

speeds result in the greatest number of cut parts, but not necessarily the best possible cut

quality.

Duramax Retrofit Torch Operator Manual 3-19

Page 56

OPERATION

45 A Shielded

Mild Steel

Metric

Material

Thickness

mm mm mm % seconds mm/min Volts mm/min Volts

0.5

1 9000 128 10800 128

1.5 0.1 9000 130 10200 129

2 0.3 6600 130 7800 129

3

4 2200 134 3560 131

6 0.5 1350 137 2050 132

English

Material

Thickness

in in in % seconds ipm Volts ipm Volts

26 GA

22 GA 350 128 450 128

18 GA

16 GA 350 130 400 129

14 GA

12 GA

10 GA 100 134 164 131

3/16 0.5 70 135 108 132

1/4 0.6 48 137 73 132

Torch-

to-Work

Distance

1.5 3.8 250

Torch-

to-Work

Distance

0.02 0.08 400

0.06 0.15 250

Initial Pierce

Height

Initial Pierce

Height

Pierce

Delay Time

0.0

0.4

Pierce

Delay Time

0.0

0.1

0.2 270 130 320 129

0.4

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

9000 128 12500 126

3850 133 4900 131

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

350 128 500 128

350 129 400 128

190 133 216 131

3-20 Duramax Retrofit Torch Operator Manual

Page 57

OPERATION

45 A Shielded

Stainless Steel

Metric

Material

Thickness

mm mm mm % seconds mm/min Volts mm/min Volts

0.5

1 9000 130 10800 130

1.5 0.1 9000 130 10200 130

2 0.3 6000 132 8660 131

3

4 2000 134 2600 134

6 0.5 900 140 1020 139

English

Material

Thickness

in in in % seconds ipm Volts ipm Volts

26 GA

22 GA 350 130 450 129

18 GA

16 GA 350 130 400 130

14 GA

12 GA

10 GA 100 133 134 134

3/16 0.5 52 135 58 135

1/4 0.6 30 141 35 140

Torch-

to-Work

Distance

1.5 3.8 250

Torch-

to-Work

Distance

0.02 0.08 400

0.06 0.15 250

Initial Pierce

Height

Initial Pierce

Height

Pierce

Delay Time

0.0

0.4

Pierce

Delay Time

0.0

0.1

0.2 250 132 360 131

0.4

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

9000 130 12500 129

3100 132 4400 132

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

350 130 500 129

350 130 400 130

140 132 206 131

Duramax Retrofit Torch Operator Manual 3-21

Page 58

OPERATION

45 A Shielded

Aluminum

Metric

Material

Thickness

mm mm mm % seconds mm/min Volts mm/min Volts

1

2 0.1 6600 136 9200 135

3 0.2 3100 139 6250 134

4 0.4 2200 141 4850 135

6 0.5 1500 142 2800 137

English

Material

Thickness

in in in % seconds ipm Volts ipm Volts

1/32

1/16 0.1 325 136 400 136

3/32 0.2 200 136 328 134

1/8 0.4 100 140 224 134

1/4 0.5 54 142 96 137

Torch-

to-Work

Distance

1.5 3.8 250

Torch-

to-Work

Distance

0.06 0.15 250

Initial Pierce

Height

Initial Pierce

Height

Pierce

Delay Time

0.0 8250 136 11000 136

Pierce

Delay Time

0.0 325 136 450 136

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

3-22 Duramax Retrofit Torch Operator Manual

Page 59

100 amp mechanized unshielded cutting for Powermax1650

1

0

0

A

OPERATION

220955

Deflector

220854

Retaining cap