Page 1

Thick metal cutting techniques

For HPR400XD™ and HPR800XD plasma cutting systems

White paper

Introduction

Using plasma to successfully cut thick metal requires more

skill and technique than using plasma on thinner metal. The

thick metal cutting techniques described in this document

may be needed from the beginning of the cut with an edge

start all the way to finishing the cut with a completely

severed part.

Note: Unless otherwise specified, for the purposes of this document,

thick metal consists of stainless steel and aluminum from 5 inches to

6.25 inches (125 mm to 160 mm) thick. The techniques detailed in this

document were developed using 304L stainless steel. Materials used for the

development of this white paper were based on U.S. customary units

(inches). Metric conversions are provided for reference.

This document describes thick metal cutting techniques

developed for the HPR800XD that can help manage the

large plasma lag angles associated with thick metal cutting.

It also describes the timing and sequencing needed to be

successful in piercing up to 4 inches (100 mm) stainless

steel and 3 inches (75 mm) aluminum. This document is

broken into four sections:

• Thick metal cutting techniques overview on page 2 is an

overview of different lag angle management techniques for

thick metal cutting that covers a plasma cut from the

beginning to completion.

• Dogleg lead-out details for thick stainless steel on page 4

covers the details of a special lead-out technique (known as

the dogleg or acute angle lead-out) that can allow you to

completely sever a stainless steel part up to 6.25 inches

(160 mm) thick.

• Stationary piercing (up to 3-inch stainless steel and

aluminum) on page 8 describes the timing and sequence to

be followed to perform stationary piercing on 3 inch

(75 mm) stainless steel and aluminum.

• Moving pierce technique (up to 4-inch stainless steel) on

page 10 describes a moving pierce technique for thick

stainless steel that can be used with both the HPR800XD

and the HPR400XD. This technique, combined with

PowerPierce

the HPR800XD to 4 inches (100 mm) and for the

HPR400XD to 3inches (75mm).

®

technology, extends the pierce capacity for

Page 2

Thick metal cutting techniques overview

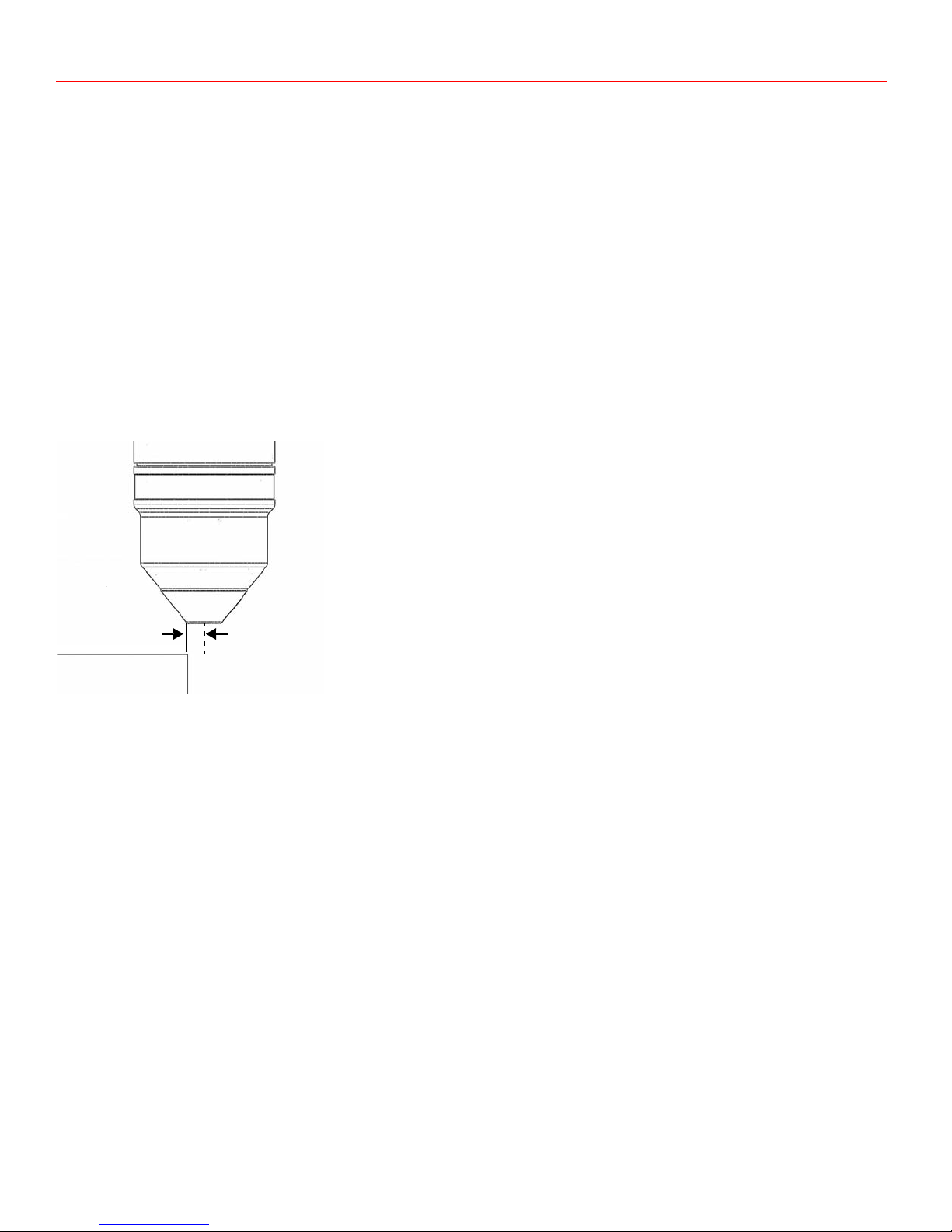

Approximately 0.25 inches (6 mm)

Edge start

Positioning

Proper positioning of the torch is important to allow the

molten metal (or melt) to carry down the majority of the

thickness (especially when starting on a rough edge). Set

the height of the torch to the cut height listed in the cut

chart, which you can find in the Operation section of the

HPR800XD Instruction Manual (806500 [Auto Gas] or

806490 [Manual Gas]). Place the torch center-line about

0.25 inches (6 mm) from the workpiece edge. The edge of

workpiece should be approximately lined up with the shield

face diameter, as shown in Figure 1.

Figure 1 – Edge start positioning

Initial cut speed (lead-in speed)

A reduced cut speed should be used for at least the first

1 inch (25 mm) of the cut before traveling at the full cut

speed. The recommended initial cut speed should be 75%

of the full cut speed.

Cornering

Special cornering considerations may be necessary when

working with thick metal due to the extreme lag of the tail

(bottom portion) of the arc. If no technique is used, the cut

edge may lose its form, especially near the bottom of the

cut. Use one of the following methods:

• Rounding corners

•Corner delay

• Corner slow-down

Rounding corners

One method to maintain edge form is to round off corners of

90 degrees or less. In general, the radius should be equal to

or greater than the kerf value (larger is better).

Motion (or pierce) delay

An adequate motion delay must be used to allow enough

time for the arc to melt the majority of the edge prior to

motion being initiated. Suggested motion delays for 800 A

thick metal cutting are listed in the cut charts in the

HPR800XD Instruction Manual. These times may need to

be adjusted based on your application.

Corner delay

Allow the motion to dwell in the corner for approximately one

second to allow the arc tail to “catch up.”

Corner slow-down

Approximately 1 inch (25 mm) before entering the corner,

slow down the cut speed to 75% of the full cut speed.

Maintain 75% of the cut speed for approximately 1 inch

(25 mm) after the corner before resuming the full cut speed.

2

Page 3

Completing the cut

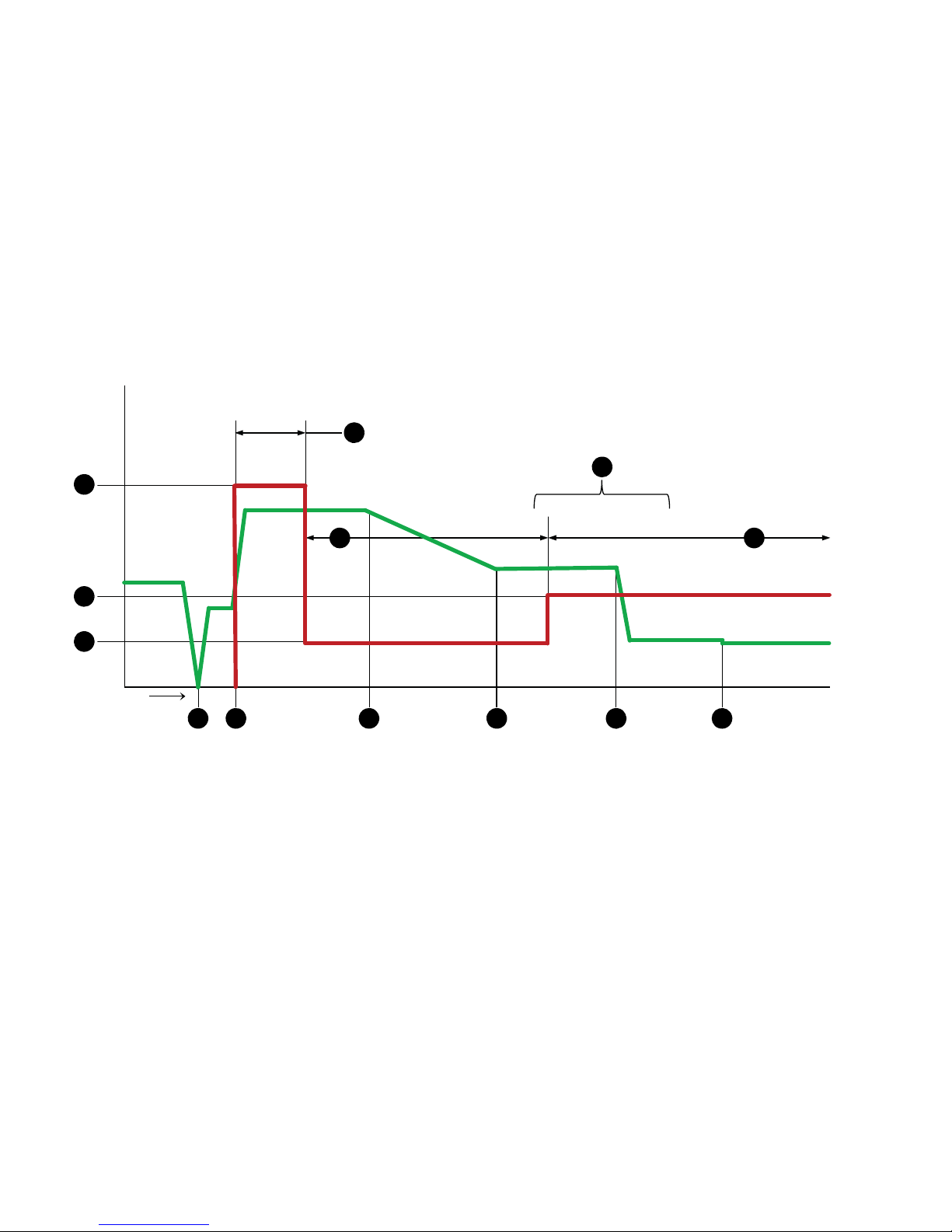

Dogleg lead-out region

Lead-in

Part

One of the following techniques may be necessary on metal

5 inches (125 mm) thick or greater to fully complete the cut.

Otherwise, the arc may jump the very bottom portion of the

cut as it exits the edge of the metal or enters the kerf,

resulting in an incomplete sever of the cut piece.

Exiting the edge of material (lead-out speed)

For cuts that involve the arc exiting the edge of the material

(as shown in Figure 2), a reduced cut speed should be used

for the last 1 inch (25 mm) of the cut. The recommended

final cut speed should be 75% of the full cut speed. The

cutting table must continue motion beyond the edge of

the plate.

Figure 2 – Lead-out exiting the edge of the material

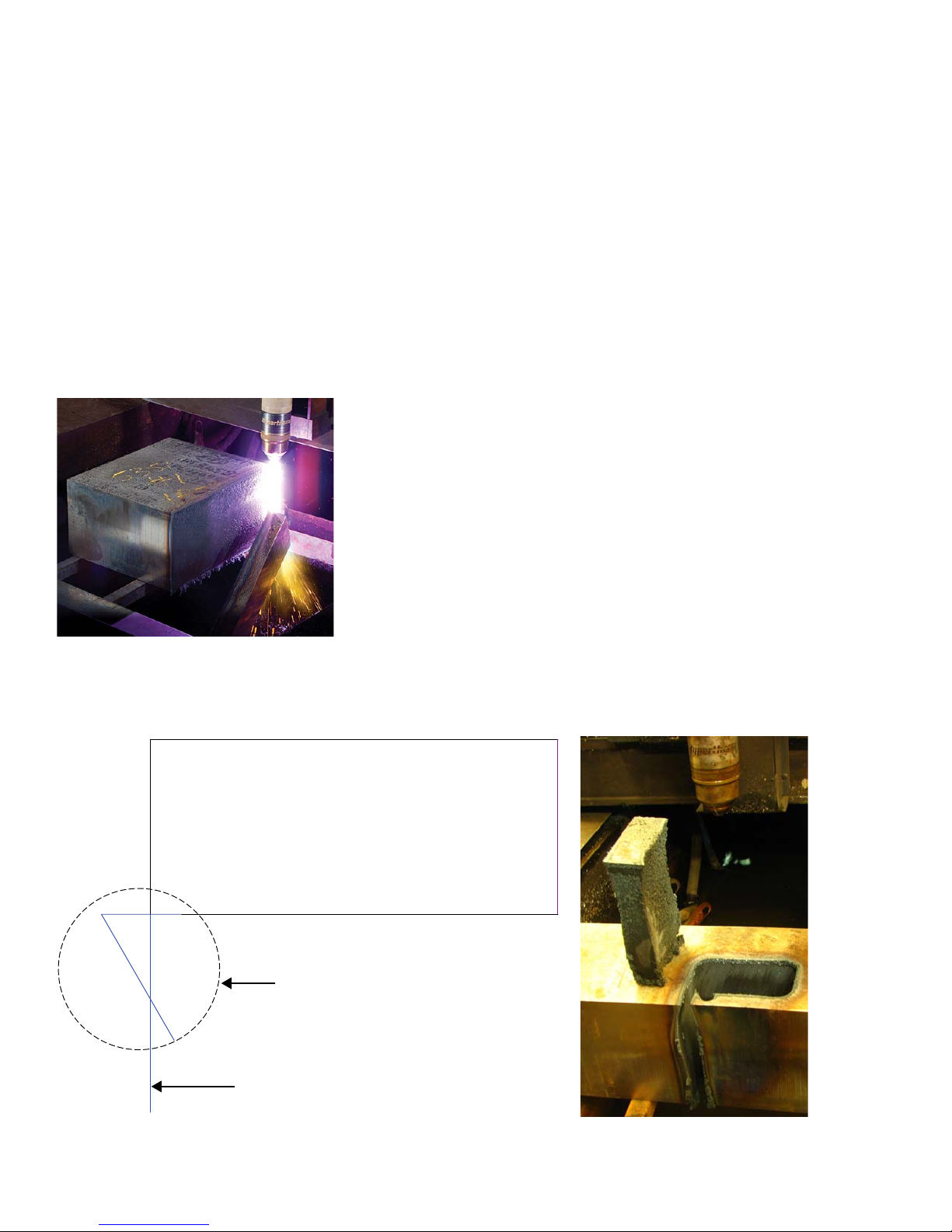

External contour part cut (dogleg or acute angle lead-out)

The dogleg (or acute angle) lead-out technique can be used

to redirect the tail of the arc and the molten metal flow into

the remaining portion of the cut (or “tab”), thereby allowing

for a complete cut (see Figure 3 and Figure 4).

1 Follow the edge start, lead-in, and cornering

recommendations previously listed.

2 Cut the external contour of the part and approach lead-out.

3 Just as the arc breaks through to kerf, change the cut

direction by approximately 120 degrees into the skeleton at

115% of the cut speed.

4 Continue the lead-out segment for approximately

1.25 inches (32 mm) – the molten metal flow from cutting

into the skeleton melts the tab, which completes the cut and

allows the part to “drop.”

Dogleg lead-out details are included in the Dogleg lead-out

details for thick stainless steel section in this document.

Figure 3 – Example of dogleg lead-out programmed cut path Figure 4 – 6 inch (150 mm) “dropped” external

contour cut

3

Page 4

Dogleg lead-out details for thick stainless steel

Location of tab

Proper lead-out for thick material is critical to completely

sever a part; otherwise, a small tab may keep the part

attached to the skeleton at the point where the lead-out

enters the lead-in (as shown in Figure 5).

Figure 5 – Example of a “tab” in a thick stainless steel contour cut

This tab is due to the extreme lagging tail of the arc, the lack

of molten material flowing through the kerf, and the

insufficient voltage to maintain the arc attachment at this

distance from the torch. Crossing the kerf for the thickest

materials may not be possible for the same voltage limitation

reason, and even if the arc does transfer to the opposite

side of the kerf, the arc tail is likely to jump over the tab.

The dogleg method for stainless steel takes advantage of

this lagging arc by focusing it onto the tab section of the

cut. At the point where the leading kerf edge breaks into the

lead-in edge (and before the voltage reaches the critical

value of the transformer), the cut path changes direction into

an acute angle (60 degrees works well) toward the skeleton

(see Figure 6). This allows the arc to transfer to the skeleton

material, which reduces the voltage while driving the molten

material down towards the tab and subsequently melting it

off.

4

Page 5

Overshoot

Lead-in

Leading kerf edge

Overshoot distance

Kerf width (K)

Lead-in edge

α

Programmed path

1

2

α

2

---

tan

------------------------ -

1

2

---

– Correction+

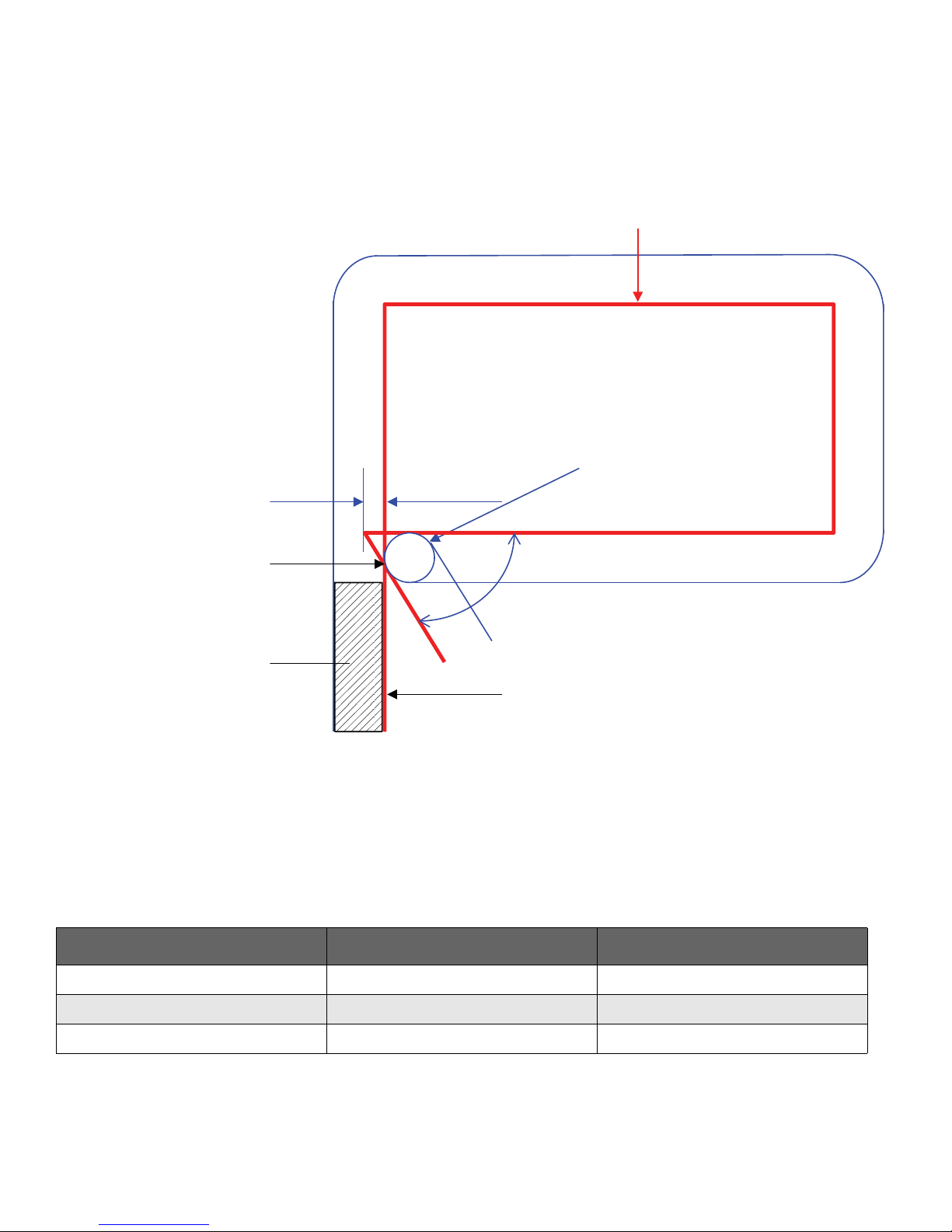

In order for the leading kerf edge to enter the lead-in edge

(with kerf compensation active), the programmed path must

overshoot by some distance (see Figure 6).

Figure 6 – Overshoot definition

This overshoot distance can be calculated using the

following equation:

Overshoot = K

Tabl e 1 – Correction factors.

Thickness Kerf Correction Factor

5 inches (125 mm) 0.530 inches (13.43 mm) 0.30

6 inches (150 mm) 0.680 inches (17.27 mm) 0.25

6.25 inches (160 mm) 0.700 inches (17.78 mm) 0.25

As an example, if α = 60° for a thickness of 6 inches, the

overshoot value is:

where K is kerf, α is angle, and Correction is an additional

factor necessary to ensure adequate penetration of the arc

into the lead-in section. The Correction factor values for

5–6.25 inches (125–160 mm) are shown in Ta bl e 1 .

K(0.866-0.5+0.25) = 0.68(0.616) = 0.419 inches

5

Page 6

First segment and geometry limitation

K

2

α

2

---

tan

------------------------ -

A geometric limitation was found during the development of

the dogleg method that resulted in a “Kerf Too Large” CNC

error message. This limitation had to do with the length of

the first segment approaching the 60-degree corner of the

dogleg (refer to the first segment, highlighted in green, in

Figure 7 on page 7).Essentially the first segment length has

to be long enough that, at a minimum, the kerf right-hand

side enters this segment.For the 6 inch (150 mm) thickness

the minimum length is 0.589 inches (14.96 mm) or

First Segment =

where K is kerf and α is angle.

Assuming 60 degrees, the minimum length of the first

segment would have to be:

• 0.459 inches (11.66 mm) for 5 inches (125 mm) stainless

steel, based on 0.530 inches (13.46 mm) kerf

• 0.607 inches (15.42 mm) for 6.25 inches (160 mm)

stainless steel, based on 0.700 inches (17.78 mm) kerf

It is recommended that a value larger than the minimum

length be used to allow minor adjustments to the kerf value

(for part dimension adjustment) without causing a geometric

“Kerf Too Large” error.

Second and third segments

It was found that an increased speed during the second

segment was useful to minimize the time it takes for the arc

to reattach to the opposite side of the kerf, which minimizes

any voltage spikes. Therefore, for the second segment the

feed rate should be increased to 400% of the cut speed,

after which, during the third segment, it should be slowed

down to 115% of the cut speed. This last section of the

move (or third segment) is where the tab will finally be

melted. Ta bl e 2, together with Figure 7, summarizes the

parameters for stainless steel thicknesses of 5 inches

(125 mm), 6 inches (150 mm), and 6.25 inches (160 mm).

6

Page 7

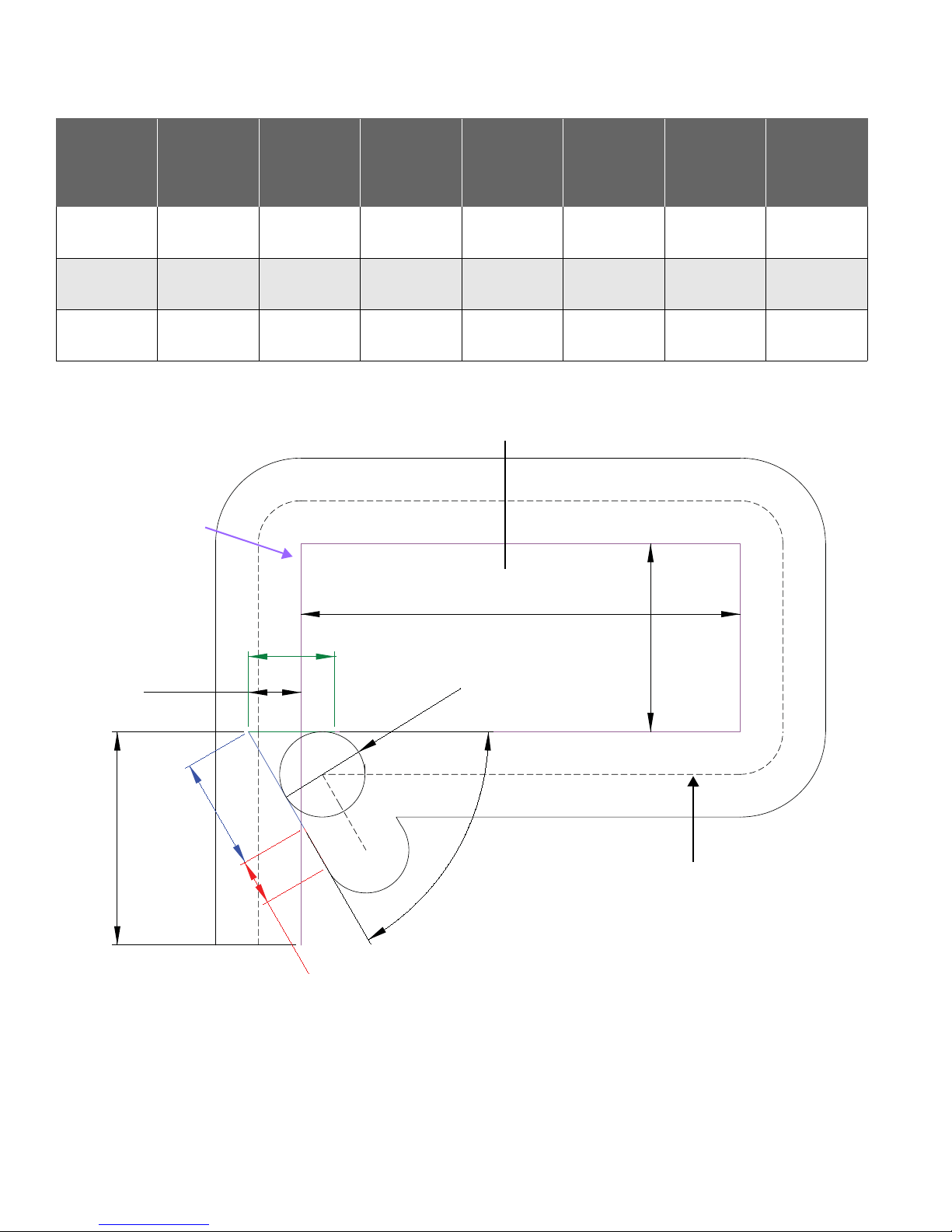

Tabl e 2 – Dogleg parameters for 5 inch (125 mm), 6 inch (150 mm), and 6.25 inch (160 mm) stainless steel

Part

3.50 inches (88.9 mm)

Programmed cut path

First segment

60º

Second segment

Lead-in

Kerf compensated cut path

Overshoot

Third segment

Kerf

1.50 inches

(38.1 mm)

Thickness Lead-in length Kerf Angle

5in

(125 mm)

6in

(150 mm)

6.25 in

(160 mm)

1.5 in

(38 mm)

1.75 in

(45 mm)

1.75 in

(45 mm)

0.530 in

(13.46 mm)

0.680 in

(17.27 mm)

0.700 in

(17.78 mm)

Figure 7 – Dogleg (acute angle) lead-out geometry

60° ≥0.459 in

60° ≥0.589 in

60° ≥0.607 in

Calculated first

segment

minimum length

at cut speed

(≥11.66 mm)

(≥14.96 mm)

(≥15.42 mm)

Overshoot length

0.353 in

(8.97 mm)

0.419 in

(10.64 mm)

0.431 in

(10.95 mm)

Second segment

length at 400%

cut speed

0.720 in

(18.29 mm)

0.888 in

(22.56 mm)

0.911 in

(23.14 mm)

Third segment

length at 115%

cut speed

0.307 in

(7.80 mm)

0.362 in

(9.19 mm)

0.334 in

(8.48 mm)

7

Page 8

Stationary piercing (up to 3-inch stainless steel and aluminum)

Piercing thicknesses over 2 inches (50 mm) has been

challenging in the past. As a result of the PowerPierce

technology incorporated into the HPR800XD, piercing up

to 3 inches (75 mm) is easily achievable with stainless steel

and aluminum. The torch lifter must have the capability of

using transfer height, pierce height, and cut height

settings.

Pierce control (or pierce complete) signal

High amounts of shield flow during the piercing operation

can be helpful in:

• Clearing the molten pool of metal away from the pierce hole

• Deflecting slag away from the torch

• Cooling the shield

Normal gas operation for HPRXD power supplies switches

both the plasma and the shield gases from preflow to

cutflow as soon as arc transfer is sensed. HPRXD power

supplies incorporate a “pierce control” signal that, when

turned on, delays the switching of the shield flow from

preflow to cutflow until after the pierce delay has expired.

For any HPRXD process with the shield preflow setting

higher than the shield cutflow setting, the pierce control

signal must be turned ON. Conversely, for any HPRXD

process with the shield preflow setting lower than the shield

cutflow setting, the pierce control signal must be turned

OFF. For the 600 A and 800 A processes, the pierce

control signal must be turned OFF. For HPRXD

processes where the shield preflow setting is equal to the

shield cutflow setting, it does not matter whether the pierce

control signal is turned on or off.

Move to transfer height

Position the torch to the transfer height as listed in the cut

chart (by process and metal thickness).

Note: You can find the cut charts in the Operation section of the

HPR800XD Instruction Manual.

Initiate arc transfer

Initiate the arc firing sequence. The arc will extend from the

torch and transfer to the surface of the plate.

Pull torch back from plate to pierce height

Immediately after arc transfer, move the torch to the pierce

height as listed in cut chart.

Allow arc to penetrate material

Remain stationary for the duration of the pierce delay as

listed in the cut chart. The arc should be fully through the

plate prior to initiating motion. Some adjustment may be

necessary to the pierce delay based on the material type

and the condition of the consumables in the torch.

Initiate motion into part lead-in

Maintain the torch at the pierce height and begin motion into

the part lead-in. Drop the torch to the cut height before the

end of the lead-in section. Lead-in lengths may vary, but as a

general rule lead-in length should be equal to the material

thickness to ensure the pierce puddle has been cleared

prior to initiating the cut.

Cut the part

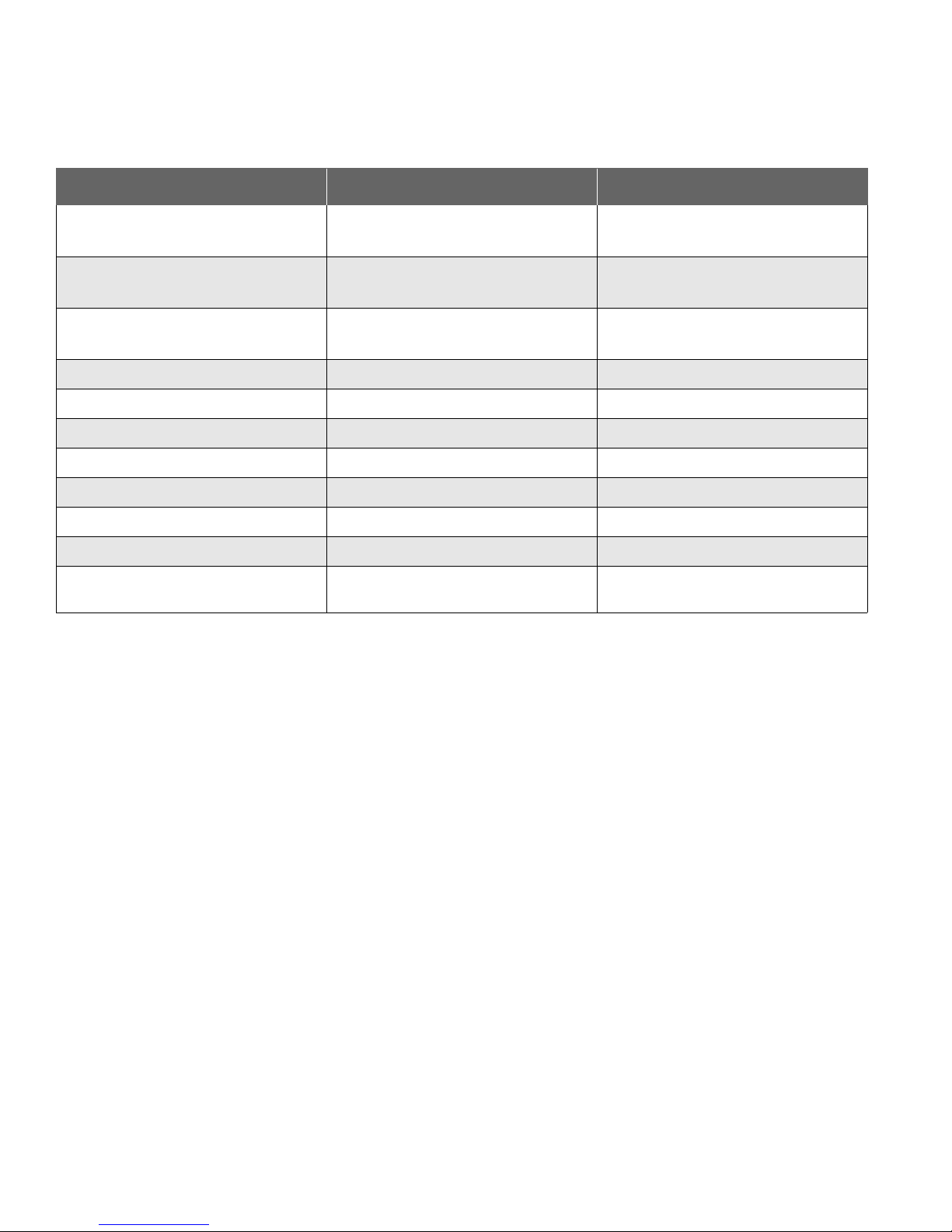

Initial height sense

Position the torch over the pierce location and command the

torch lifter to perform the initial height routine. Refer to the

timing diagram (Figure 8 on page 9).

8

Finally, complete the contour cut of the part.

Page 9

9

Figure 8 – Stationary pierce timing diagram

7

8

9

1

0

1

2

3

4

5

6

1

2

1

1

1

3

Time

Torch height

1 Pierce height

2 Transfer height

3 Cut height

4 Initial height sense

5 Arc transfer, shield flow switches from preflow to cutflow

6 Arc penetrates plate

7 Motion begins

8 Torch drops to cut height prior to beginning contour cut

9 Move to transfer height

10 Pierce delay

11 Move to pierce height

12 Lead-in

13 Move to cut height

Page 10

Moving pierce technique (up to 4-inch stainless steel)

Pierce capacity can be extended by utilizing a technique

known as “moving pierce.” This technique combined with

PowerPierce

®

technology has extended the stainless steel

pierce capacity for the HPR800XD to 4 inches (100 mm)

and for the HPR400XD to 3 inches (75 mm).

The torch lifter must have the capability to use transfer

height, pierce height, and cut height settings along with cut

height and automatic voltage control (AVC) delays. The

cutting table and controller must be able to allow motion

upon transfer. Hypertherm’s EDGE

Phoenix™ 9.72 or later), Sensor™ THC or ArcGlide

and ProNest

®

nesting software all support this technique

®

Pro controller (running

®

lifter,

with the provided parameters.

Basic description

Moving pierce (also known as a running pierce or flying

pierce) is a technique that has been used by plasma

operators for years in order to have their plasma systems

penetrate thick plates without having to resort to other

operations such as drilling.

The method of moving pierce described here utilizes a

synchronization of torch lifter positioning, table motion, and

plasma current ramping to achieve a relatively short pierce

lead-in that directs the molten material to the side and away

from the torch. At the same time, it keeps the torch as far

away from the molten material as possible while also

maintaining an arc voltage that the HPRXD power supply

can sustain.

plasma cutting operations). Moving pierce direction should

be planned such that the molten material is not directed at

the lifter, gantry, adjacent torches, controller, or other

sensitive equipment.

Note: The moving pierce parameters in this document were developed

using linear motion only.

Molten material accumulated on the plate can impact

subsequent cutting paths, so you may be required to either

carefully plan cutting paths that avoid the slag pile or to stop

the cutting process (after the arc has penetrated the plate)

to scrape the slag pile from the plate.

Lifter and table motion sequencing

During the moving pierce, both the torch height and the

table motion are simultaneously controlled to optimize the

thick plate piercing capability. The details for a typical pierce

are listed in the following Lifter sequence and Table moti o n

sequence sections.

Lifter sequence

Refer to Figure 9 for an illustration of the following

sequence.

1 An initial height sense (IHS) is performed, and the torch is

positioned at the transfer height.

2 The torch is started and transfers to the workpiece; current

ramp-up begins.

The basic process consists of combining motion during

piercing to create a trough in the plate that can then be

used as an evacuation channel for the molten material to be

directed out of the deepening pierce “slot.” The molten

material is directed to the side of the torch in the opposite

direction of the table motion, with the majority being

deposited onto the top of the plate surface. Once the arc

penetrates the plate the standard settings for cutting can be

used.

Limitations and equipment and safety hazards

Using this technique results in a “rooster tail” of molten

material and hot gases that can cause personal injury,

damage to equipment, and fires if proper precautions are

not taken. Guards may be required to protect operators and

to prevent the molten material from reaching any flammable

materials (flammable materials should be kept away from

3 After transfer, the torch quickly moves to the pierce height,

and the table motion begins at the first speed programmed

using an embedded “F” code. (See Table motion sequence

on page 12.)

4 The torch is maintained at the pierce height until the

moving delay has expired (percentage of the total pierce

delay).

5 When the moving delay has expired, the torch will move to

the pierce end height. This move is timed to arrive at the

end height when the pierce delay has expired.

6 The torch will remain at the pierce end height for the

duration of the cut height delay. When the cut height

delay expires, the torch will move to the cut height and will

remain at this height until the moving pierce (MP) AVC

delay expires.

7 When the MP AVC delay expires, the arc voltage control will

begin.

8 The contour cut of the part is completed.

10

Page 11

Figure 9 – Moving pierce torch height timing diagram

Torch height

7

8

9

1

0

1

2

3

4

5

6

1

1

1

2

1

3

141

4

1

5

1

7

1

6

1

8

Time

1 Pierce height

2 Pierce end height

3 Transfer height

4 Cut height

5 Initial height sense

6 Arc transfer, motion begins, shield flow switches from preflow to cutflow

(if preflow is lower than cutflow)

7 Torch begins to lower toward pierce end height

8 Torch reaches pierce end height as pierce delay expires

9 Torch lowers to cut height as cut height delay expires

10 AVC begins as MP AVC delay expires prior to starting cut

11 Move to transfer height

12 Pierce delay

13 Moving delay

14 Move to pierce height

15 Cut height delay

16 Arc penetrates plate in this region

17 MP AVC delay

18 Move to cut height

11

Page 12

Table motion sequence

Feed rate

7

8

9

1

0

1

2

3

45

6

Time

1

2

1

1

1

3

1 Gouge speed

2 Cut speed

3 Creep or intermediate speed

4 Initial height sense

5 Arc transfer, motion begins, shield flow switches from preflow to cutflow

(if preflow is lower than cutflow)

6 Torch begins to lower toward pierce end height

7 Torch reaches pierce end height as pierce delay expires

8 Torch lowers to cut height as cut height delay expires

9 AVC begins as MP AVC delay expires prior to starting cut

10 Establishes evacuation trough

11 Penetration of plate advances while molten material is evacuated via trough

12 Arc penetrates plate in this region

13 Transition to cut speed as arc penetrates plate

Refer to Figure 10 for an illustration of the following sequence.

1 After transfer, the table motion begins for the first segment at a fast gouge

speed (the first “F” code) for the required segment length necessary to

establish the evacuation channel (or trough).

2 The second segment table motion begins at an intermediate speed (second

“F” code) for the required segment length necessary to penetrate the plate.

3 The third segment of table motion begins at the programmed cut speed. The

remainder of the cut is completed at this speed (third “F” code).

4 Finally, the contour cut of the part is completed.

Figure 10 – Moving pierce table motion timing diagram

12

Page 13

Embedded part program parameters

If you are using the EDGE Pro controller, use the following list of parameters to

control the moving pierce (MP) sequence.

Tabl e 3 – Moving pierce (MP) embedded part program parameters

Parameter name Embedded program code Description

MP feed #1 - fast gouge F45

G01 X0 Y1

MP feed #2 - intermediate F20

G01 X0 Y0.5

MP feed #3 - cut speed F10

G01 X0 Y2.5

Transfer height factor G59 V604 F300 Transfer height = 300% of cut height

Pierce delay G59 V601 F8.0 Total pierce delay = 8.0 seconds

Moving delay (lifter) G59 V610 F50 Percent moving delay = 50% of pierce delay

Pierce height factor G59 V602 F500 Pierce height = 500% of cut height

Pierce end height factor G59 V611 F250 Pierce end height = 250% of cut height

Cut height delay G59 V605 F3.0 Cut height delay = 3.0 seconds

Cut height G59 V603 F0.25 Cut height = 0.25 inches (6 mm)

MP AVC delay M51T15 MP AVC delay = 4 seconds (the M51T value is the sum of

Speed=45ipm (1143mm/m)

Move 1 inch (25 mm) Yaxis

Speed = 20 ipm (508 mm/m)

Move 0.5 inch (13 mm) Yaxis

Speed = 10 ipm (254 mm/m)

Move 2.5 inch (65 mm) Y axis

MP AVC delay, cut height delay, and pierce delay)

13

Page 14

14

Thick stainless steel moving pierce parameters

The following tables contain the moving pierce parameters (both English and metric) that have been developed for

piercing up to 4 inches (100 mm) of stainless steel.

Tab le 4 – Thick stainless steel moving pierce (MP) parameters – English

Process

Thickness

(inch)

Speed 1

(ipm)

Speed 2

(ipm)

Speed 3

(ipm)

Segment 1

(inch)

Segment 2

(inch)

Segment 3

(inch)

Transfer Height Factor

(% Cut Height)

Pierce Delay

(Seconds)

Percent Moving Delay

(% Pierce Delay)

Pierce Height Factor

(% Cut Height)

Pierce End Height Factor

(% Cut Height)

Cut Height Delay

(Seconds)

Cut Height

(inch)

MP AVC Delay

(Seconds)

800 A

H35/ N

4406112 11.515065047527580.52

400 A

H35-N/ N

3 45 20 10 0.998 0.417 2.5 300 8 50 500 250 3 0.25 4

400 A

H35-N/ N

2 45 15 20 0.75 0.417 1.5 300 4.8 50 500 25 0 0.5 0.25 5.7

Tab le 5 – Thick stainless steel moving pierce (MP) parameters – metric

Process

Thickness

(mm)

Speed 1

(mm/m)

Speed 2

(mm/m)

Speed 3

(mm/m)

Segment 1

(mm)

Segment 2

(mm)

Segment 3

(mm)

Transfer Height Factor

(% Cut Height)

Pierce Delay

(Seconds)

Percent Moving Delay

(% Pierce Delay)

Pierce Height Factor

(% Cut Height)

Pierce End Height Factor

(% Cut Height)

Cut Height Delay

(Seconds)

Cut Height

(mm)

MP AVC Delay

(Seconds)

800 A

H35/ N

100 1016 152 279 50.8 25.4 38.1 150 6 50 475 275 8 12.7 2

400 A

H35-N/ N

75 114 3 508 254 25.3 10. 6 63.5 300 8 50 500 250 3 6.4 4

400 A

H35-N/ N

50 1143 381 508 19.1 10.6 38.1 300 4.8 50 500 250 0.5 6.4 5.7

Page 15

Sample EDGE Pro code for 400 A – 3-inch (75-mm) stainless steel

The following sample code from a Hypertherm EDGE Pro CNC assumes the

use of U.S. customary units (inches) and is intended to provide an example of

the codes that may be used to perform a moving pierce on a 3-inch (75-mm)

stainless steel plate at 400 A.

G99 X1 Y180 I0 J0

G20 (select English units [inches])

G91 (incremental programming mode)

G43X0.265 (kerf value = 0.265 inches)

G41 (enable left kerf compensation)

G59 V502 F35 (plasma torch/consumable type)

G59 V503 F2 (material type)

G59 V504 F400 (current setting)

G59 V505 F23 (plasma/shield gas type)

G59 V507 F58 (material thickness)

G59 V600 F202 (arc voltage)

G59 V601 F8 (pierce delay)

G59 V602 F500 (pierce height factor)

G59 V603 F0.25 (cut height)

G59 V604 F300 (transfer height factor)

G59 V605 F3 (cut height delay)

G59 V610 F50 (moving delay = 50%)

G59 V611 F250 (pierce end height = 250%)

M07 (plasma start)

M51T15 (MP AVC delay = 4)

(Add pierce delay, cut height

delay, and AVC delay)

F45 (gouge speed)

G01 X0 Y.9975 (linear motion)

F20 (creep speed)

G01 X0 Y.4166 (linear motion)

F10 (cut speed)

G01 X0 Y2.5 (linear motion)

M08 (plasma stop)

G40 (disable kerf compensation)

M02 (end of program)

15

Page 16

www.hypertherm.com

™

HPRXD, PowerPierce, EDGE Pro, Phoenix, Sensor THC, ArcGlide THC, ProNest, and

Hypertherm are trademarks of Hypertherm Inc. and may be registered in the United States and/or

other countries. All other trademarks are the property of their respective holders.

One of Hypertherm’s long-standing core values is a focus on minimizing our impact on the

environment. Doing so is critical to our, and our customers’ success. We are always striving to

become better environmental stewards; it is a process we care deeply about.

© 6/2014 Hypertherm Inc. Revision 2

807850

Loading...

Loading...