Page 1

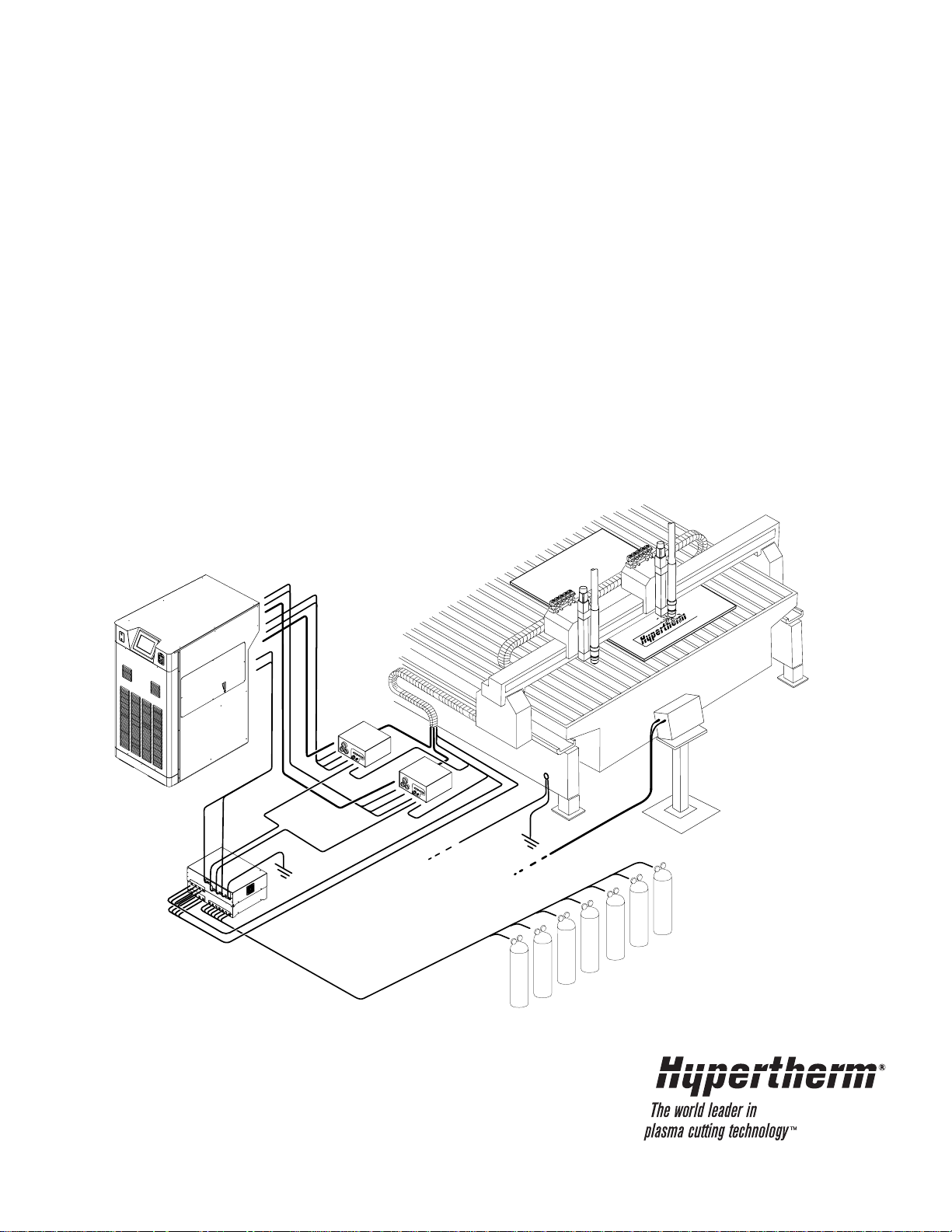

HyDefinition

®

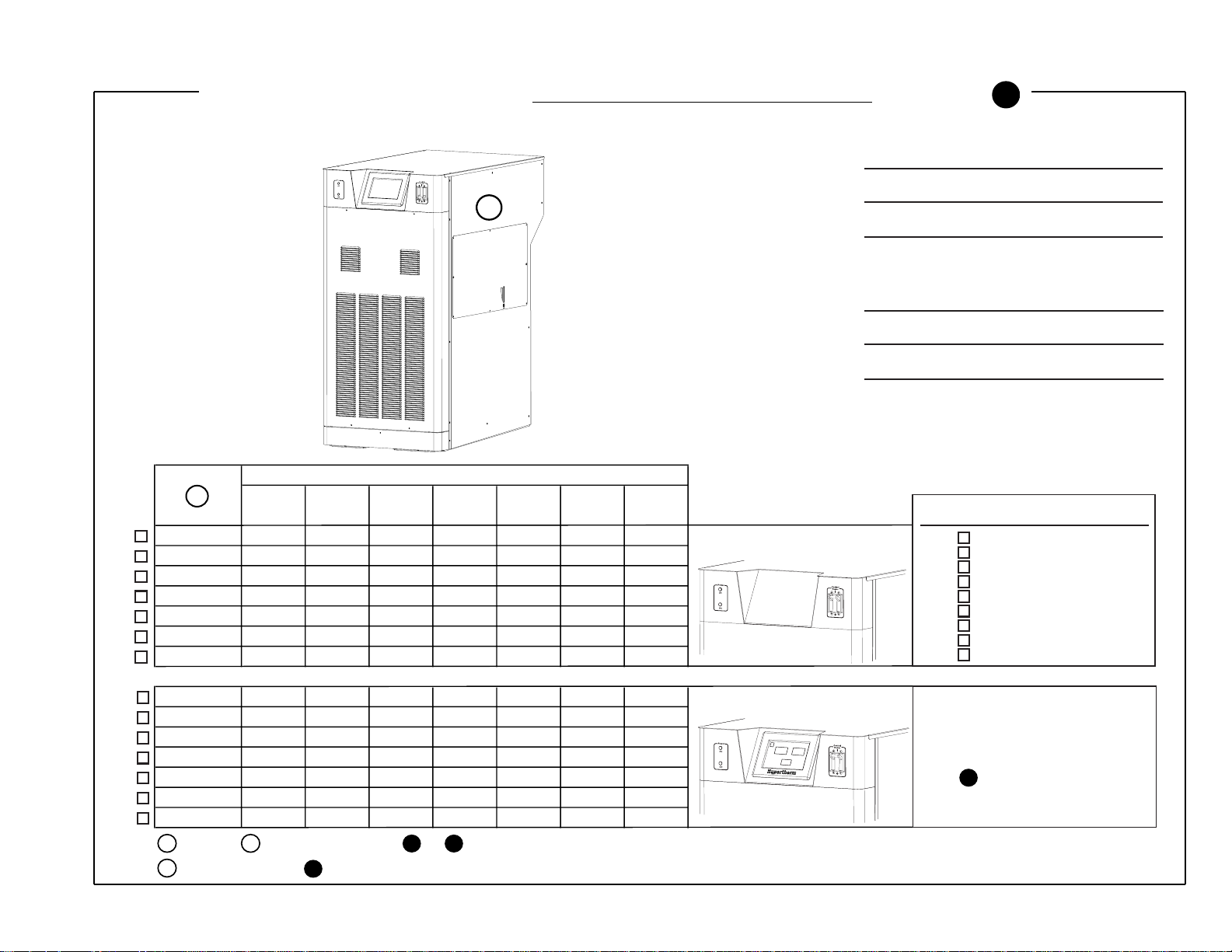

HD4070

Plasma Arc Cutting / Marking System

Product Configuration Manual

803770 – Revision 1

4070.97

Page 2

HD4070

Product Configuration Manual

(P/N 803770)

Revision 1 – December, 2002

© Copyright 2002 Hypertherm, Inc.

All Rights Reserved

Hypertherm, HyDefinition and HT are trademarks of Hypertherm, Inc.

and may be registered in the United States and/or other countries

Hypertherm, Inc.

Hanover, NH USA

www.hypertherm.com

Page 3

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

800-643-9878 Tel (Technical Service)

800-737-2978 Tel (Customer Service)

Hypertherm Automation, LLC

5 Technology Drive

West Lebanon, NH 03755 USA

603-298-7970 Tel

603-298-7977 Fax

Hypertherm Plasmatechnik, GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm (S) Pte Ltd

No. 19 Kaki Bukit Road 2

K.B. Warehouse Complex

Singapore 417847, Republic of Singapore

65 6 841 2489 Tel

65 6 841 2490 Fax

65 6 841 2489 (Technical Service)

Japan

1952-14 Yata-Natsumegi

Mishima City, Shizuoka Pref.

411-0801 Japan

81 0 559 75 7387 Tel

81 0 559 75 7376 Fax

Hypertherm UK, Ltd

9 Berkeley Court, Manor Park

Runcorn, Cheshire, England WA7 1TQ

44 1928 579 074 Tel

44 1928 579 604 Fax

France

15 Impasse des Rosiers

95610 Eragny, France

00 800 3324 9737 Tel

00 800 4973 7329 Fax

Hypertherm S.r.l.

Via Torino 2

20123 Milano, Italia

39 02 725 46 312 Tel

39 02 725 46 400 Fax

39 02 725 46 314 (Technical Service)

Hypertherm Europe B.V.

Vaartveld 9

4704 SE Roosendaal, Nederland

31 165 596908 Tel

31 165 596901 Fax

Technical Service:

00 800 49 73 7843 – toll-free in Europe

31 165 596900 Tel

Hypertherm Brasil Ltda.

Rua Visconde de Santa Isabel, 20 – Sala 611

Vila Isabel, RJ

Brasil CEP 20560-120

55 21 2278 6162 Tel

55 21 2578 0947 Fax

3/27/03

Page 4

0

HD4070 Product Configuration Manual 1-1

Section 1

SPECIFICATIONS

In this section:

Description................................................................................................................................................................1-2

General ............................................................................................................................................................1-2

Power Supply ..................................................................................................................................................1-2

Machine Torch..................................................................................................................................................1-2

Off-V alve Assembly..........................................................................................................................................1-2

Gas Console ....................................................................................................................................................1-2

Ignition Console ...............................................................................................................................................1-2

Options.............................................................................................................................................................1-3

Specifications............................................................................................................................................................1-7

System Requirements......................................................................................................................................1-7

Power Supply...................................................................................................................................................1-8

Gas Console Assembly – 078085..................................................................................................................1-10

Ignition Console Assembly – 078088.............................................................................................................1-11

Off-Valve Assembly – 129563........................................................................................................................1-12

Machine Torch Assembly with Leads.............................................................................................................1-13

Page 5

0

1-2 HD4070 Product Configuration Manual

SPECIFICATIONS

Description

General

The HD4070 is a fully automated 200 amp HyDefinition plasma cutting/marking system that requires minimal input

and adjustment by the operator. Using the HD4070 display touch screen (or CNC), the operator enters the material

and thickness to be cut. The HD4070 system automatically selects and adjusts the power and gas required to

optimize cutting, including amperage, gas type and gas flow rates.

Power Supply

The power supply houses two 100-amp, 15 kHz choppers to produce up to 200A of constant current DC output.

The HD4070 power supply provides the torch the energy to cut 1/2" (12.7 mm) mild steel at up to 90 ipm

(2286 mm/min.).

Machine Torch

The machine torch can cut 1/2 inch (12.7mm) mild steel at 90 ipm (2286 mm/min.). The maximum production

cutting capability of the torch is 1 inch (25 mm). To achieve consumable long life, all cuts must begin and end

on the plate surface.

Off-Valve Assembly

The off-valve assembly consists of 5 solenoid valves, a manifold block and a wiring harness with connector. The

assembly interfaces with the machine torch, the ignition console and the gas console.

Gas Console

The gas console manages all incoming gasses for selection and flow rates and is controlled by the HD4070 power

supply. The gas console includes motor valves, solenoid valves, check valves and pressure trans-ducers all

mounted on a single manifold assembly. The manifold significantly reduces gas leaks by eliminating the use of

flexible hose. The gas console also houses 2 relay PC boards and a control PC board.

Ignition Console

The ignition console generates a high voltage, high frequency signal and couples it to the cathode lead and pilot

arc lead. The ignition console is fully electronic eliminating the need for periodic maintenance.

Page 6

0

HD4070 Product Configuration Manual 1-3

SPECIFICATIONS

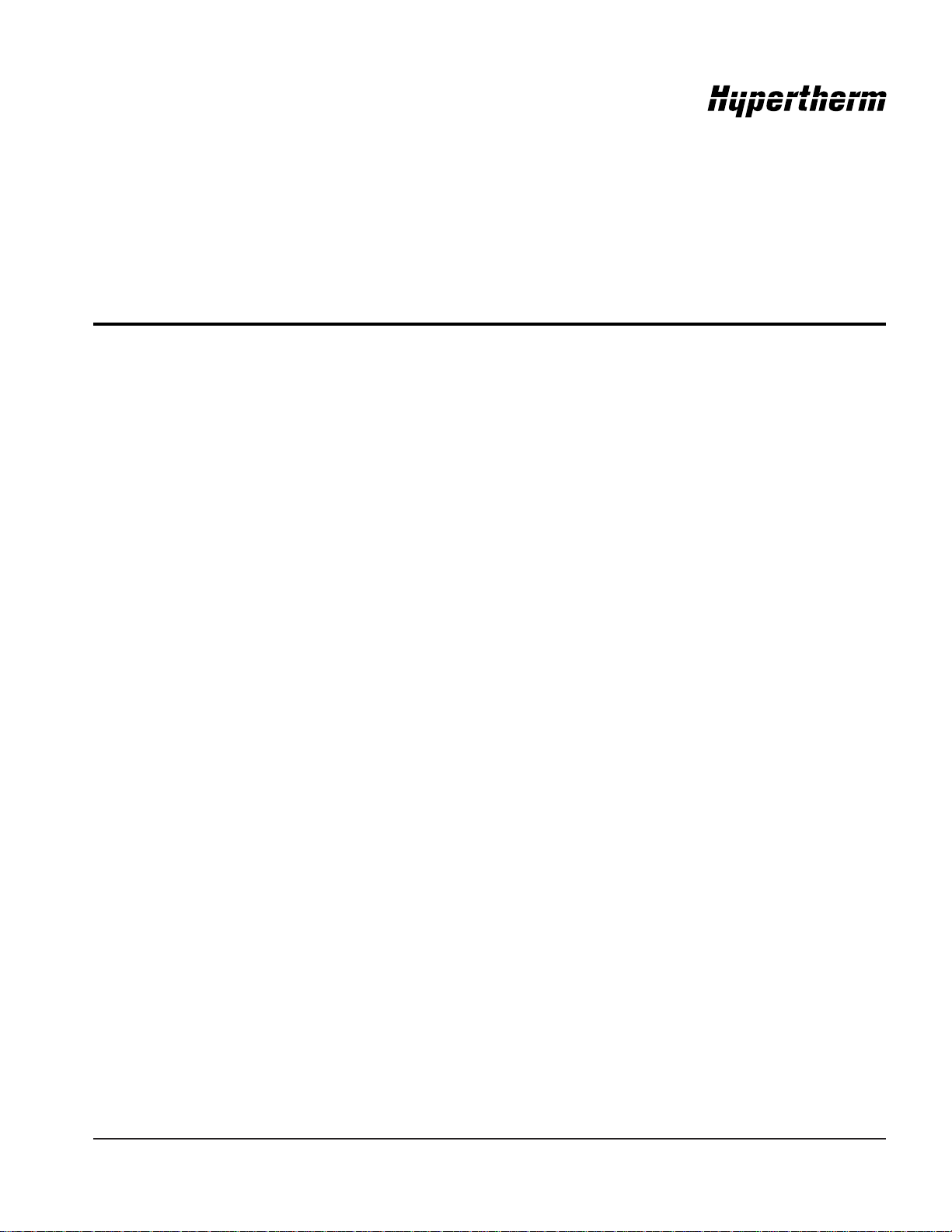

HD4070 System with 2-Torch Option

Options

• 2-Torch Option – The HD4070 plasma cutting/marking system has the ability to support 2 torches operated

from a single power supply and gas console. When one torch is selected for cutting the second torch is in

the off mode. This allows the operator to configure the system for two different processes (i.e. 100 amp

consumables installed in one torch and 200 amp consumables installed in the second torch). The operator

selects torch number-1 or torch number-2 from the HD4070 display (or CNC).

Note: Atorch receptacle plug must be used if a two torch system is running in single torch mode.

Single torch mode is when a table is loaded with plate material and one torch is doing all the

cutting or marking.

Dual torch mode is when one torch is performing one operation and the second torch is

performing another operation on the same plate material.

4070.97

Page 7

0

1-4 HD4070 Product Configuration Manual

SPECIFICATIONS

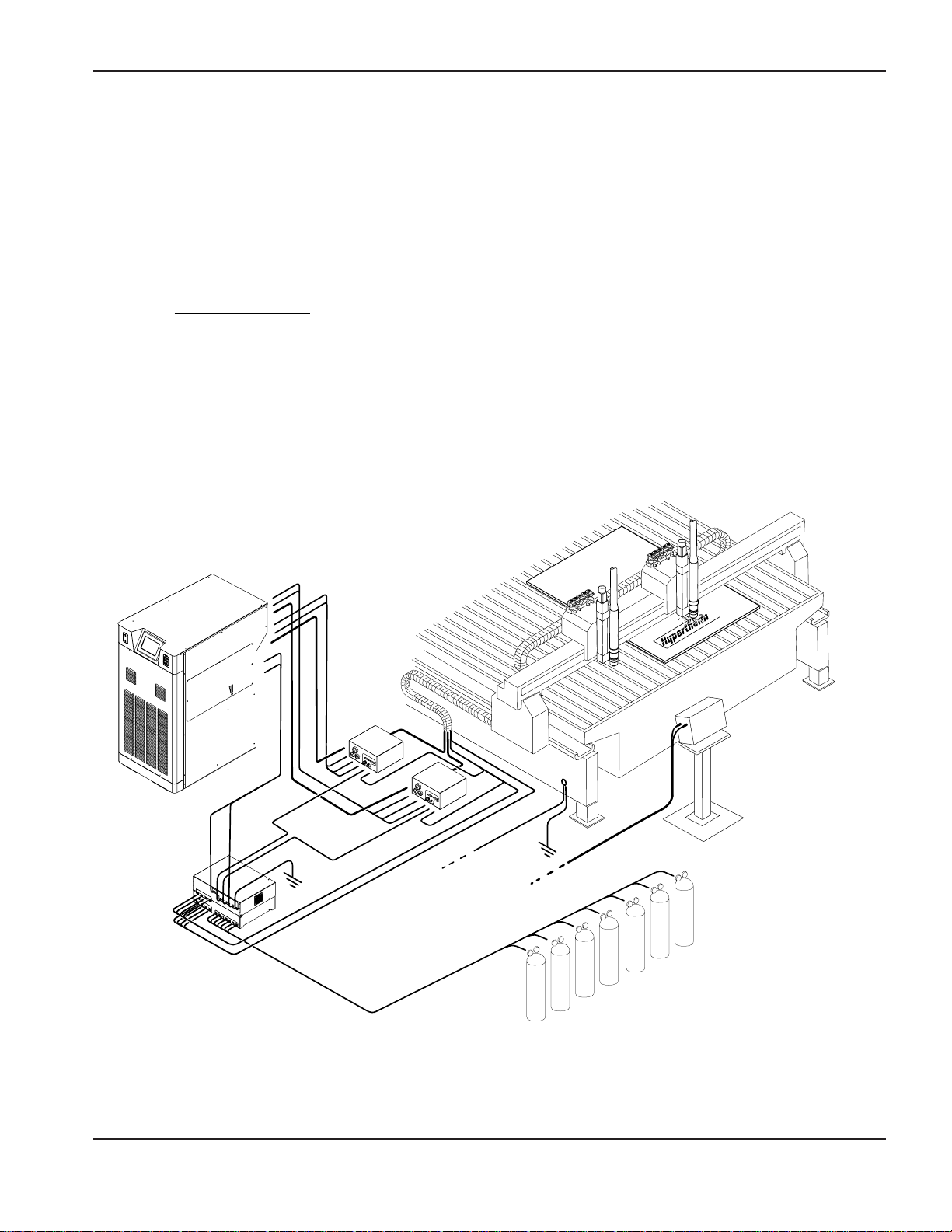

• Integrated Command THC Option – The Hypertherm Integrated Command THC takes full advantage of

the HD4070 automated capabilities. When the operator enters the material and thickness to be cut into the

HD4070 display touch screen (or CNC), the Integrated Command THC automatically adjusts the torch

settings required for the specific process, including arc volts, torch standoff, initial pierce height and pierce

time delay. The Integrated Command THC system uses the plasma arc voltage to control the physical

stand-off (distance) between the torch and workpiece during plasma arc cutting. Initial height sensing (IHS)

is accomplished by ohmic contact sensing or by limited force stall detection.

HD4070 power supplies that are equipped with the Integrated Command THC option include the THC motor

drive board, the THC control PC board and THC power supply required for torch lifter operation and control.

One or two Command THC options can be specified, depending on how many torches are installed with the

system.

Power Supply with Command THC Option for 2-Torch System

THC Motor

Drive Boards

THC Control

PC Boards

THC Power

Supplies

4070.48

Page 8

0

HD4070 Product Configuration Manual 1-5

SPECIFICATIONS

The Integrated Command THC option includes the X-Y lifter, torch mounting block and the related cables.

A torch breakaway (collision sensor) is also available to protect the torch, lifter and X-Y table. Adjustable air

pressure locks the torch to the THC lifter assembly. Upon side impact, the breakaway releases from the lock

position and allows the torch to float.

THC Cables

THC X-Y Lifter

THC Torch

Breakaway Option

4070.45A

Integrated Command THC Lifter, Cables and Breakaway

Page 9

0

1-6 HD4070 Product Configuration Manual

SPECIFICATIONS

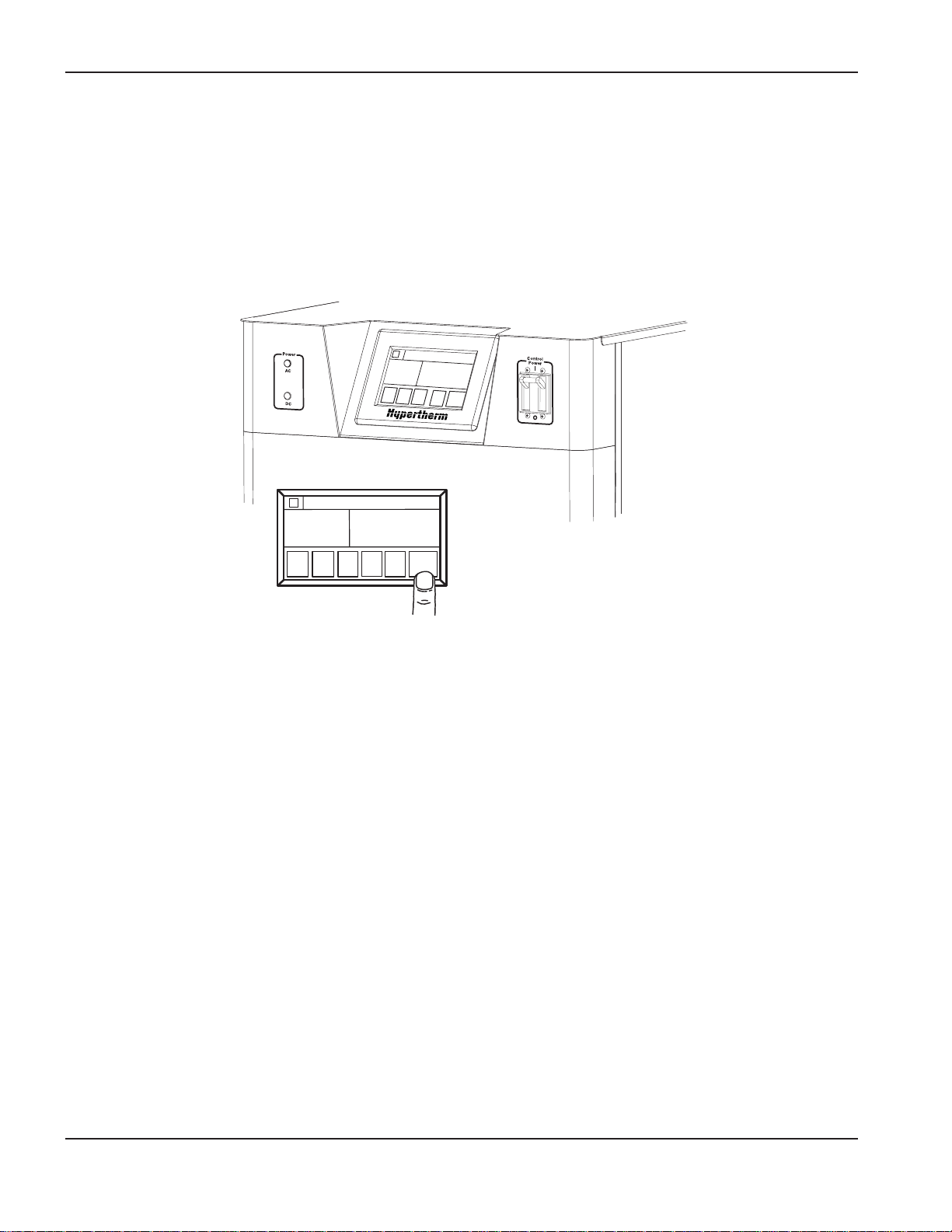

• Touch Screen Display Option – The HD4070 display is a touch screen interface, providing all system

control functions and plasma process information at a single location. The power supply may be ordered

with the display mounted in the front panel. Kits are also available for mounting the display remotely.

4070.23B

1

3

T

O

R

C

H

1

N

O

P

I

L

O

T

A

R

C

S

T

A

I

N

L

E

S

S

S

T

E

E

L

N

E

W

P

R

O

C

E

S

N

E

X

T

A

U

T

O

M

A

N

T

H

C

A

R

C

V

O

L

T

A

R

C

V

O

L

T

O

V

E

R

R

I

D

E

V

O

L

T

S

:

1

4

4

.

5

V

S

E

T

A

R

C

V

O

L

T

S

:

1

4

2

.

0

V

I

N

L

E

T

G

A

S

:

H

3

5

N

2

C

U

T

T

I

N

G

S

P

E

E

D

:

6

5

I

P

M

3

/

4

I

N

2

0

0

A

M

P

S

S

T

A

N

D

O

F

F

:

0

.

0

5

0

I

N

+

+

_

_

C

N

C

TORCH 1

READY

STAINLESS STEEL

NEW

PROCESS

NEXT

AUTO

MAN

THC

OVERRIDE VOLTS: 144.5 V

SET ARC VOLTS: 142.0 V

INLET GAS: H35 N2

CUTTING SPEED: 65 IPM

3/4 IN

200 AMPS

STANDOFF: 0.050 IN

ARC

VOLT

++

ARC

VOLT

_ _

13

HELP

Display Touch Screen Option

Warning: The HD4070 system can only support one touch screen display, either local or remote. The

installation of two displays on one system may cause malfunctions or damage.

Page 10

1

HD4070 Product Configuration Manual 1-7

SPECIFICATIONS

Specifications

System Requirements

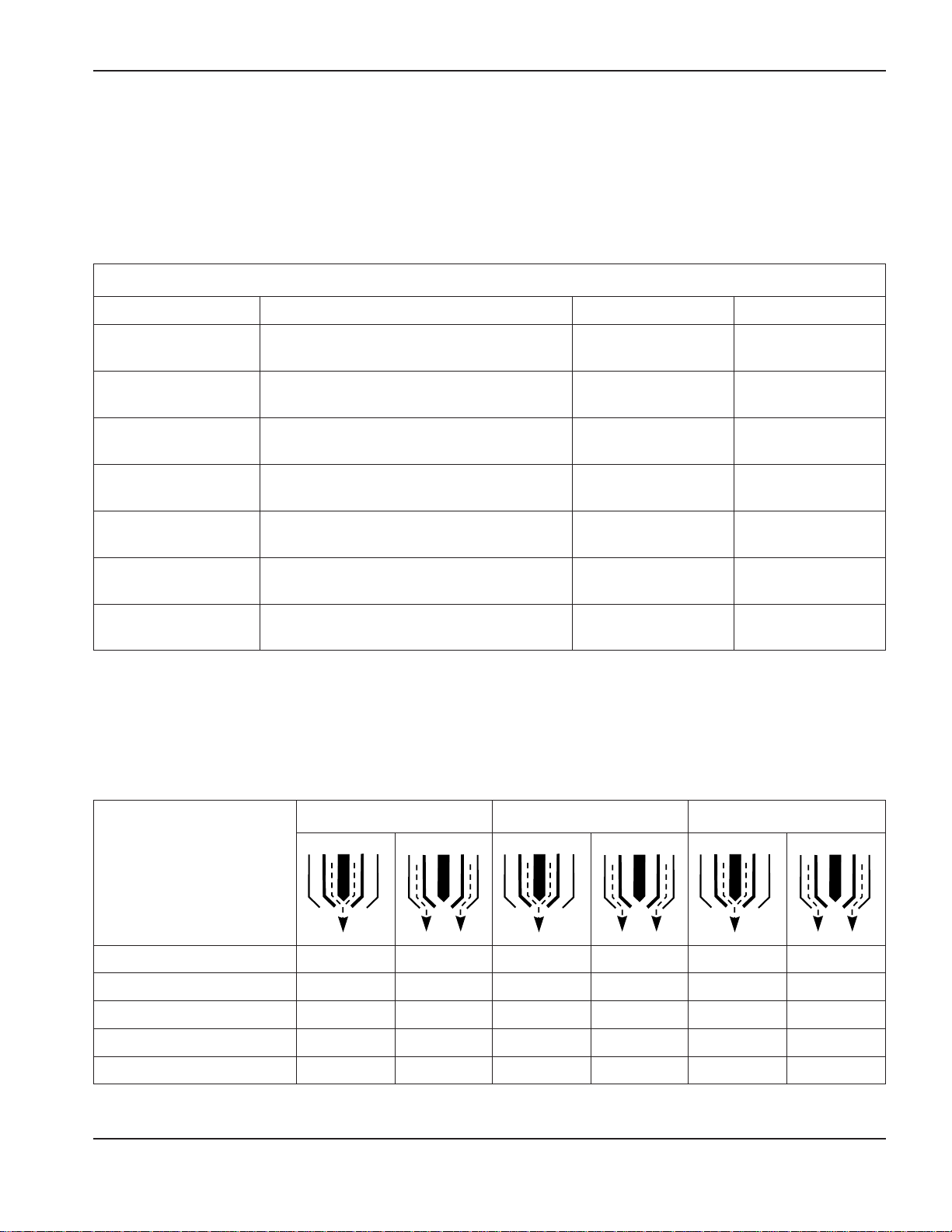

Gas Quality and Pressure Requirements

Quality Pressure + 5% Flow Rate

O2Oxygen 99.5% pure (liquid gas recommended) 120 psi 133 scfh (3780 l/h)

Clean, dry, oil-free 8.3 bar / 827 kPa

N2Nitrogen 99.99% pure (liquid gas recommended) 120 psi 142 scfh 4020 l/h

Clean, dry, oil-free 8.3 bar / 827 kPa

Air Clean, dry, oil-free 120 psi 140 scfh 3960 l/h

8.3 bar / 827 kPa

CH4Methane 93% pure 120 psi 188 scfh 5340 l/h

8.3 bar / 827 kPa

H5 Argon-Hydrogen 99.995% pure (liquid gas recommended) 120 psi 122 scfh 3420 l/h

(H5=5% Hydrogen, 95% Argon) 8.3 bar / 827 kPa

H35 Argon-Hydrogen 99.995% pure (liquid gas recommended) 120 psi 146 scfh 4140 l/h

(H35=35% Hydrogen, 65% Argon) 8.3 bar / 827 kPa

*

CO2Carbon-Dioxide 99.5% pure 120 psi 113 scfh 3180 l/h

8.3 bar / 827 kPa

Mild Steel Stainless Steel Aluminum

Gas Types Plasma Shield Plasma Shield Plasma Shield

Marking N

2

N

2

H5 N

2

H5 N

2

Cutting 30 A O

2

O2& N

2

Air Air Air Air

Cutting 70 A O

2

O2& N

2

H35 & N

2

N

2

Air CH4& Air

Cutting 100 A to 200 A O

2

O2& N

2

H35 & N

2

N

2

H35 & N

2

N

2

*

CO2is not currently used on the HD4070 and there is no need to install the gas line.

Page 11

1

1-8 HD4070 Product Configuration Manual

SPECIFICATIONS

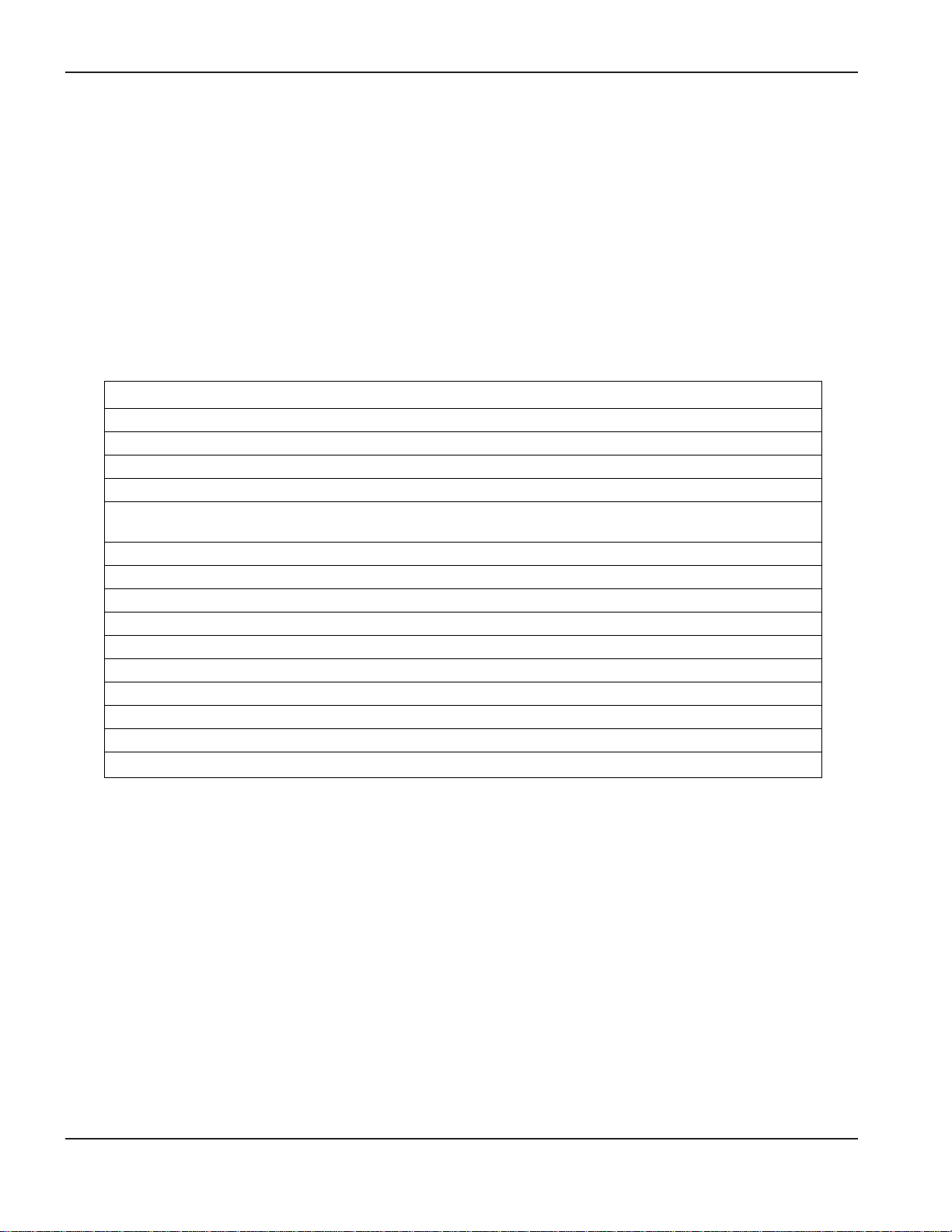

Power Supply

• Place the power supply in an area that is free of excessive moisture, has proper ventilation, and is relatively

clean. Allow room at the sides and rear of the power supply for servicing.

• Cooling air is drawn in through the front panel grating and is exhausted through the rear of the unit by a

cooling fan. Allow a minimum of 12 inches (305 mm) for air flow.

• Maximum distance to the ignition console = 150 feet (46 m).

• Maximum distance to the gas console = 150 feet (46 m).

General

Maximum OCV (U0) 311 VDC

Maximum Output Current (I2) 200 amps

Output Voltage (U2) 85 - 200 VDC

Duty Cycle Rating (X) 100% @ 40 kw, 104°F (40°C)

Ambient Temperature/Duty Cycle Power supplies will operate between +14° and 104°F

( -10°C and +40°C)

Power Factor(cosϕ) 0.98 @ 200A DC output

Cooling Forced Air (Class F)

Input Power (Input Voltage (U1) X Input Current (I1X 1.73)

200 VAC, 3ph, 50-60 Hz, 125A

220 VAC, 3ph, 50-60 Hz, 113A

240 VAC, 3ph, 60 Hz, 103A

400 VAC CE, 3ph, 50-60 Hz, 62A

440 VAC, 3ph, 50-60 Hz, 56A

480 VAC, 3ph, 60 Hz, 52A

600 VAC, 3ph, 60 Hz, 41A

Page 12

0

HD4070 Product Configuration Manual 1-9

SPECIFICATIONS

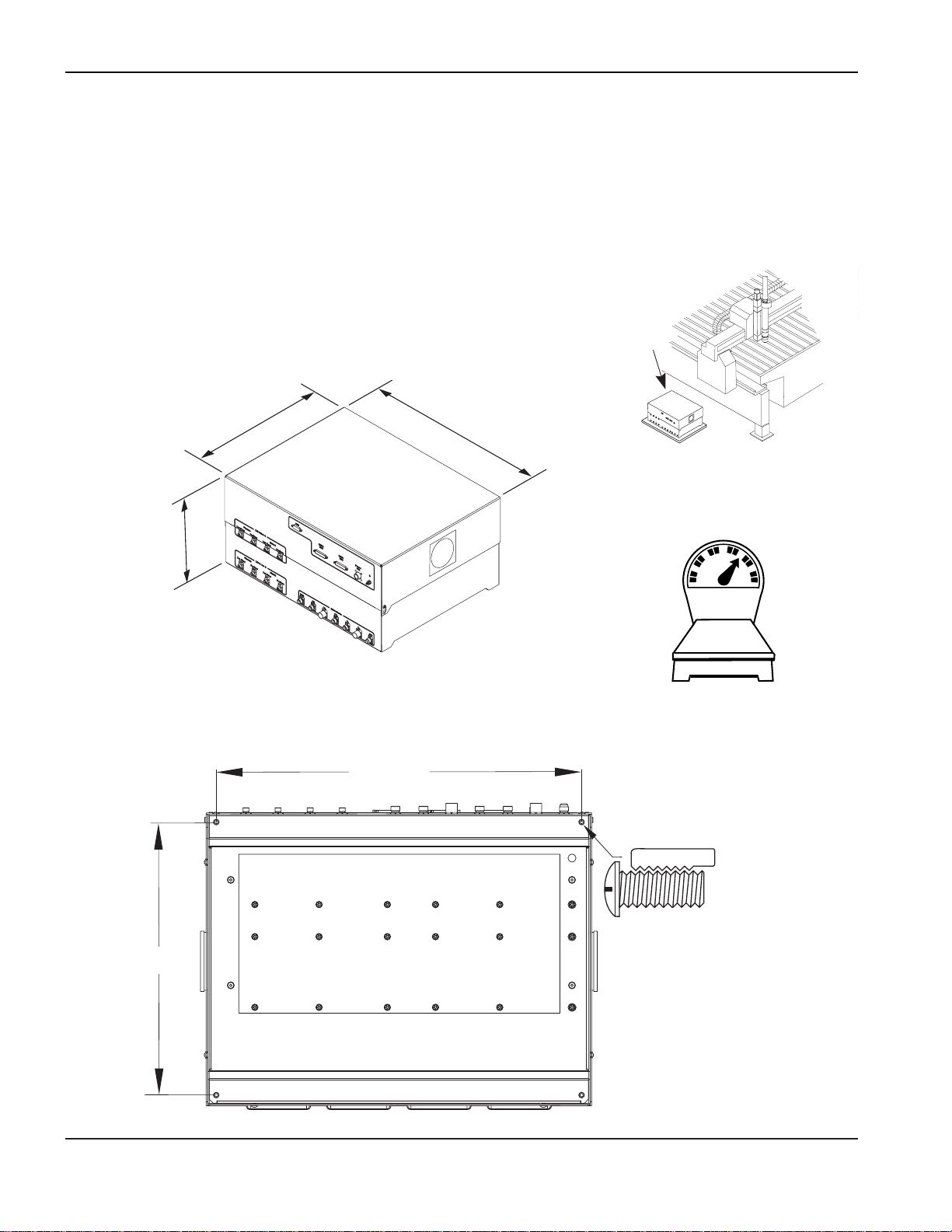

50.5"

1283 mm

39.4"

1001 mm

34.9"

886 mm

15.6"

396 mm

5"

127 mm

1068 lb

484.9 kg

24.25"

616 mm

34.4"

874 mm

4070.42

Page 13

0

1-10 HD4070 Product Configuration Manual

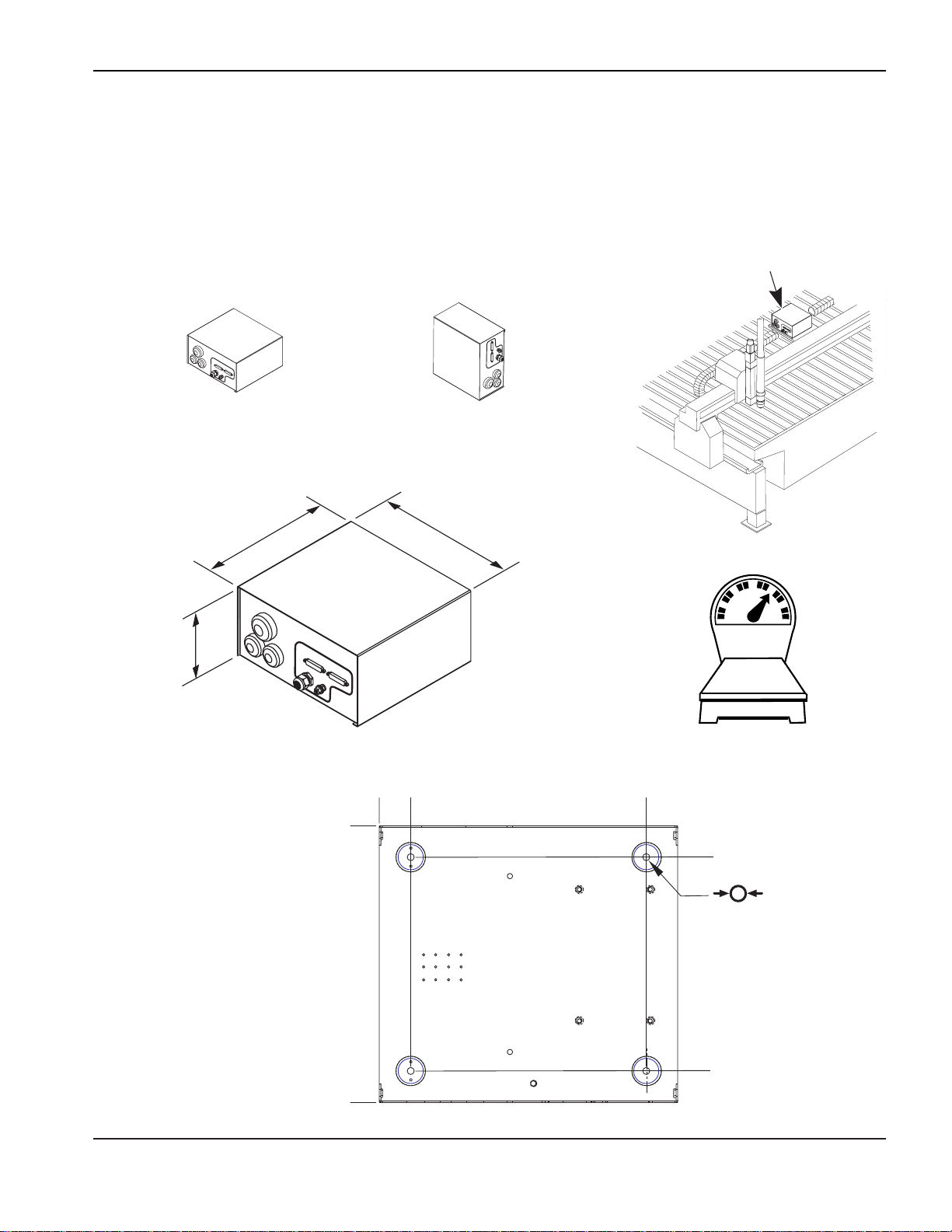

94 lb

42.7 kg

11.625"

295 mm

18.75"

476 mm

24.75"

629 mm

1/4-20

22.75" / 578 mm

17.0"

432 mm

4070.20A

SPECIFICATIONS

Gas Console Assembly – 078085

• Position the gas console near the cutting table. Allow room to open the hinged top for servicing.

• Venting air is drawn in through fans on both sides and is exhausted through the front of the unit.

• Maximum distance from the power supply = 150 feet (46 m).

• Maximum distance to the off-valve assembly = 100 feet (31 m).

Page 14

0

HD4070 Product Configuration Manual 1-11

4070.19A

0

0

1.25" / 32 mm

11.0"

279 mm

9.75"

248 mm

0.28"

7 mm

1.25"

32 mm

10.63" / 270 mm

4070.21

6.25"

159 mm

11.25"

286 mm

12"

305 mm

20.5 lb

9.3 kg

Horizontal Mounting

Vertical Mounting

SPECIFICATIONS

Ignition Console Assembly – 078088

• Mount the ignition console near the torch. Allow room to remove the top for servicing.

• Mount the ignition console in the horizontal or the vertical position as shown below.

• Maximum distance to the torch = 15 feet (4.5 m).

Page 15

0

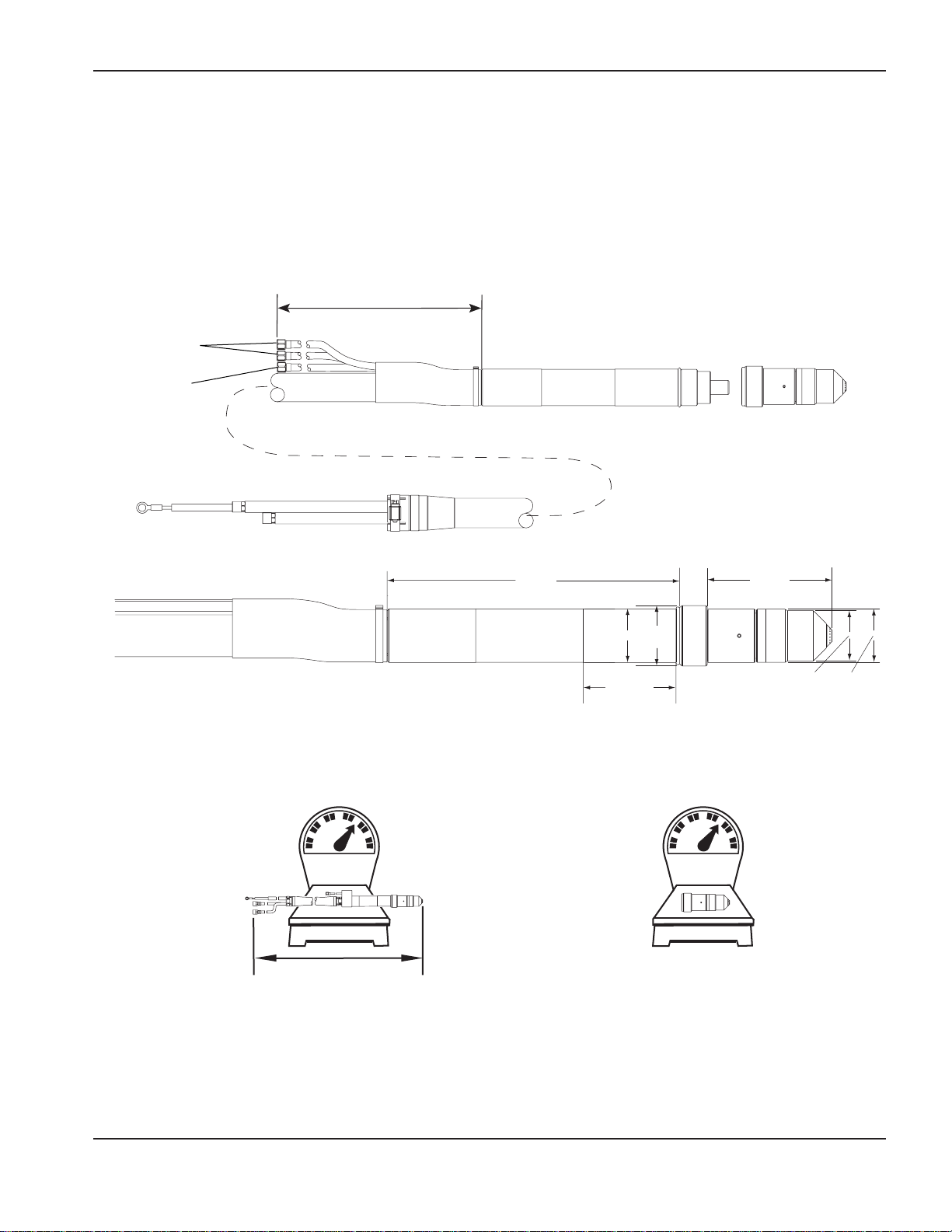

1-12 HD4070 Product Configuration Manual

4070.18A

A

A

A - A

6.18"

157 mm

1.18"

30 mm

0.187"

4.7 mm

0.75"

19 mm

6.5"

165 mm

3"

76 mm

2.75"

70 mm

2.5 lb

1.1 kg

SPECIFICATIONS

Off-Valve Assembly – 129563

• Mount the off-valve assembly near the torch.

• Maximum distance from the torch = 4 feet (1.2 m).

Page 16

0

HD4070 Product Configuration Manual 1-13

SPECIFICATIONS

Machine Torch Assembly with Leads

• Assembly includes leads, torch and consumables.

• 128500 6 ft / 2 m

128501 10 ft / 3 m

128502 15 ft / 4.5 m

Without Coolant

To off-valve

assembly

Plasma Gas

Vent

4 ft / 1.2 m

14.7 lb

6.7 kg

15 ft / 4.5 m

10.86"

(276 mm)

2"

(51 mm)

(89 mm)

3.5"

2.25"

(57 mm)

1.05"

(27

mm)

2 lb

0.9 kg

4.65"

(118 mm)

1.88"

(48 mm)

1.98"

(50 mm)

4070.44

Page 17

0

1-14 HD4070 Product Configuration Manual

SPECIFICATIONS

Page 18

0

HD4070 Product Configuration Manual 2-1

Section 2

ORDERING

In this section:

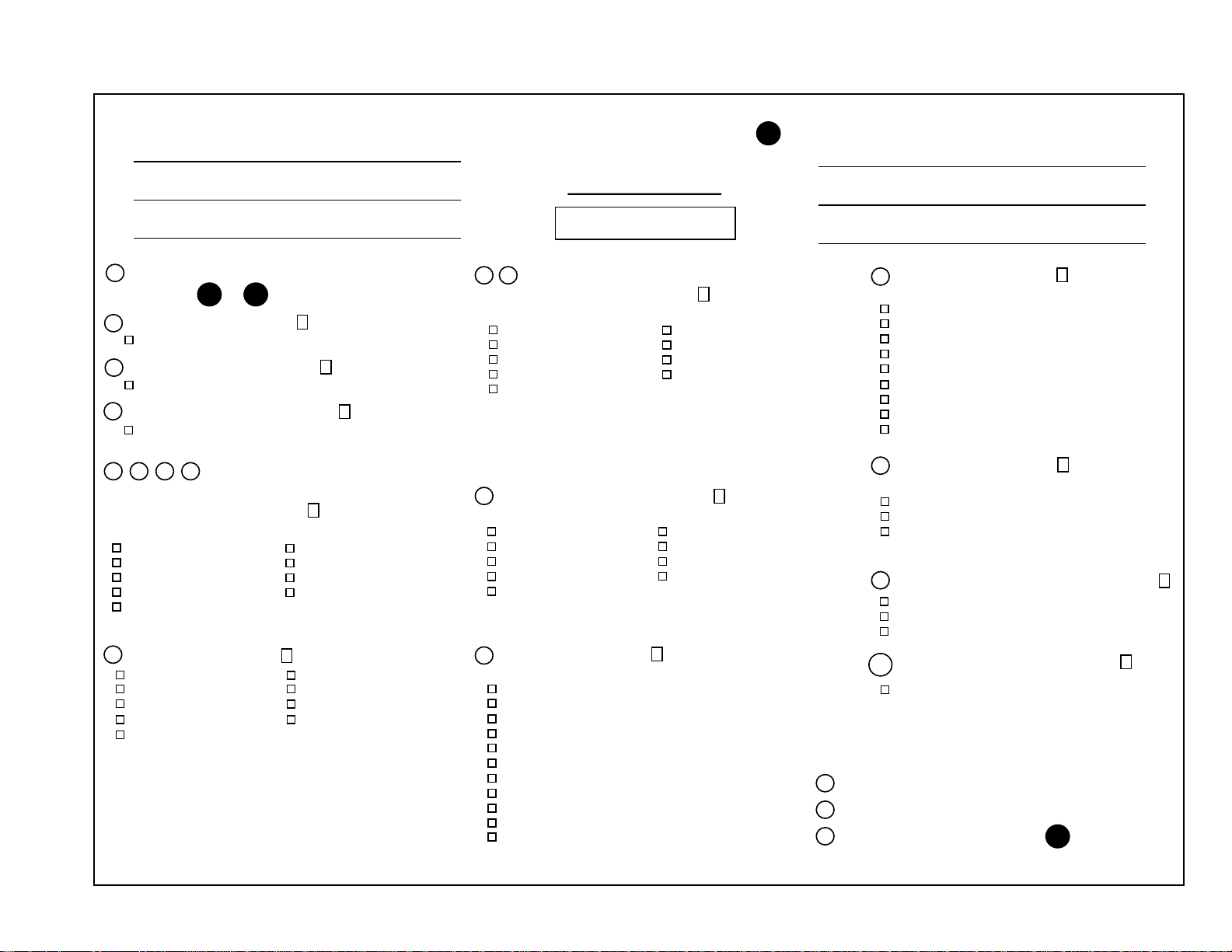

Ordering the HD4070 System...................................................................................................................................2-2

HD4070 Power Supply with NO Integrated Command THC Option Order Form A ..................................................2-3

HD4070 Power Supply with ONE Integrated Command THC Option Order Form B................................................2-5

HD4070 Power Supply with TWO Integrated Command THC Option Order Form C...............................................2-7

HD4070 Components, Cables and Hoses for 1-Torch Option Order Form D...........................................................2-9

HD4070 Components, Cables and Hoses for 2-Torch Option Order Form E .........................................................2-11

HD4070 Supply Gas Hoses, Regulators & Upgrade Kits Order form F..................................................................2-12

Page 19

0

2-2 HD4070 Product Configuration Manual

ORDERING

Ordering the HD4070 System

Ordering a system can be a complex procedure. The following components are required to operate the HD4070

system:

• Power supply

• Ignition console and connecting cables and hoses

• Gas console and connecting cables and hoses

• Off-Valve Assembly and connecting cables and hoses

• Torch and Lead Assembly

• Machine interface I/O cable to start and control the system from the CNC

Hypertherm offers three major options for the HD4070 system:

• Integrated command Torch Height Control (THC) Option

• 2-Torch option

• Touch screen display

Use the following order forms as required:

Order the HD4070 power supply using Order Form , or . Touch screen display and voltage choices are

found on each of these forms.

When using order Form use Form or to order Components, Cables & Hoses

When using order Form use Form to order Components, Cables & Hoses

When using order Form use Form to order Components, Cables & Hoses

Use order form to order Supply Gas Hoses, Regulators & Upgrade Kits. The upgrade kits are for use with

previously purchased power supplies.

F

E

C

D

B

E

D

A

C

B

A

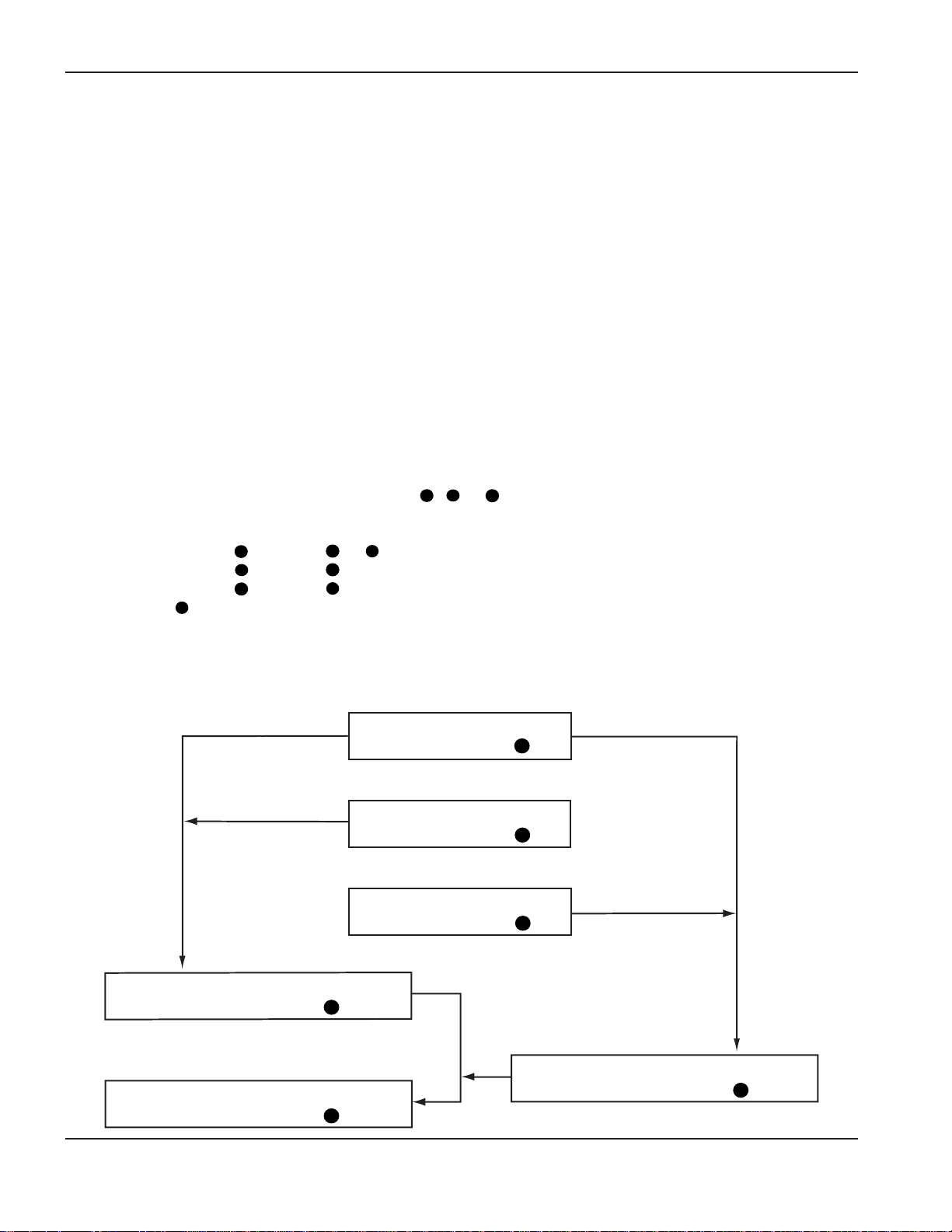

HD4070 System Configuration

Order Forms

C

Power Supply with 2-THC Option

Use Order Form

B

Power Supply with 1-THC Option

Use Order Form

A

Power Supply with No THC Option

Use Order Form

D

Components, Cables & Hoses for 1-Torch Option

Use Order Form

Components, Cables & Hoses for 2-Torch Option

Use Order Form

E

- OR -

- OR -

Supply Gas Hoses, Regulators & Upgrade Kits

Use Order Form

F

Page 20

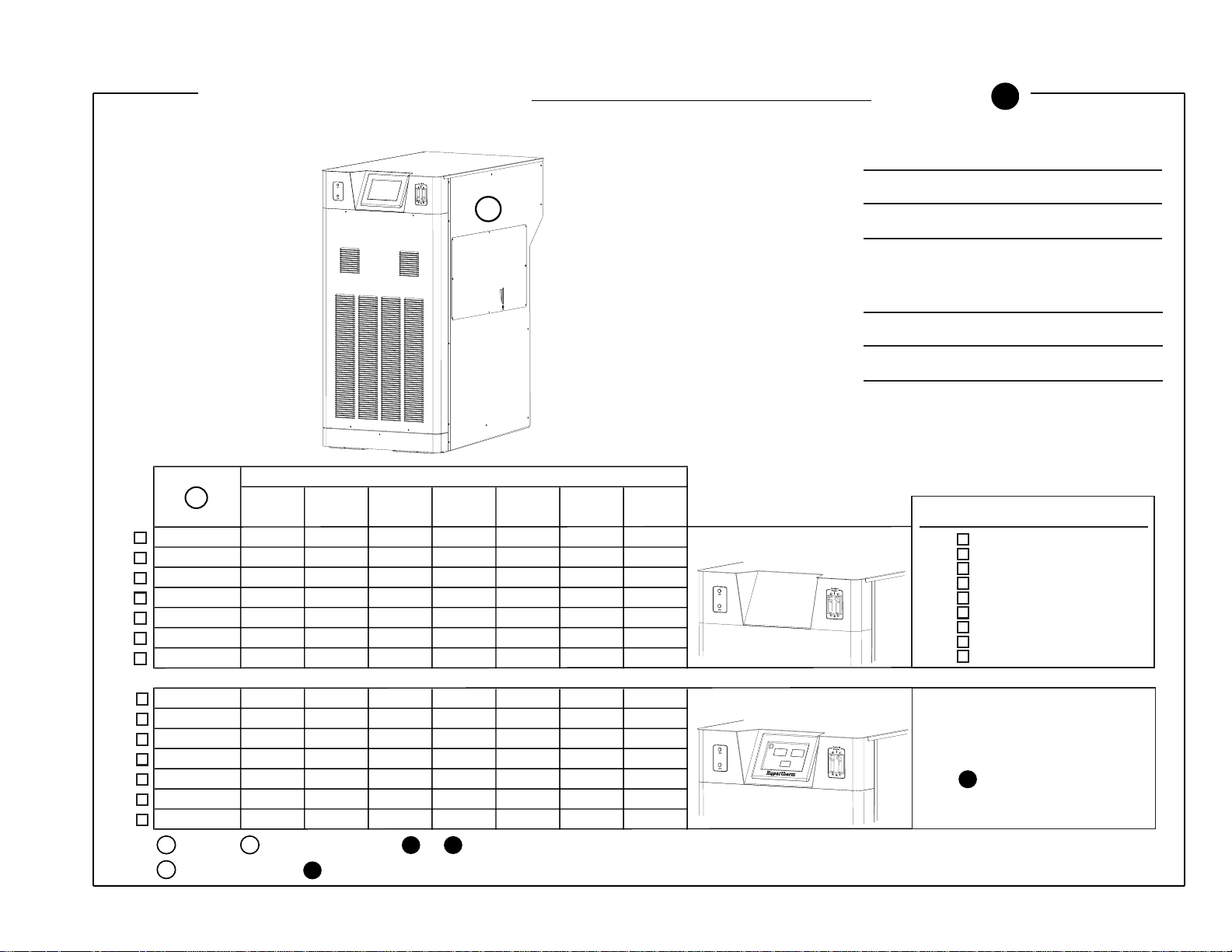

Distributor Information:

Customer Information:

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

078087 X –––––– No Display Installed

078134 – X –––––

078089 ––X ––––

078135 –––X –––

078095 ––––X ––

078141 –––––X –

078106 ––––––X

078103 X ––––––

With Display Installed

078149 – X –––––

078092 ––X ––––

078138 –––X –––

078098 ––––X ––

078144 –––––X –

078109 ––––––X

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

- Use Order Form or

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

ED

F

HYPERTHERM – HD4070 Power Supply with NO Integrated Command THC Option – Order Form

A

1

0

Voltage

1

3

REPEA

NEW

T

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 21

Page 22

0

Distributor Information:

Customer Information:

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

078087 X –––––– No Display Installed

078134 – X –––––

078089 ––X ––––

078135 –––X –––

078095 ––––X ––

078141 –––––X –

078106 ––––––X

078103 X ––––––

With Display Installed

078149 – X –––––

078092 ––X ––––

078138 –––X –––

078098 ––––X ––

078144 –––––X –

078109 ––––––X

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

- Use Order Form or

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

ED

F

HYPERTHERM – HD4070 Power Supply with NO Integrated Command THC Option – Order Form

A

1

Voltage

1

3

REPEA

NEW

T

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 23

Page 24

Distributor Information:

Customer Information:

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

078087 X –––––– No Display Installed

078134 – X –––––

078089 ––X ––––

078135 –––X –––

078095 ––––X ––

078141 –––––X –

078106 ––––––X

078103 X ––––––

With Display Installed

078149 – X –––––

078092 ––X ––––

078138 –––X –––

078098 ––––X ––

078144 –––––X –

078109 ––––––X

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

- Use Order Form or

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

ED

F

HYPERTHERM – HD4070 Power Supply with NO Integrated Command THC Option – Order Form

A

1

0

Voltage

1

3

REPEA

NEW

T

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 25

Page 26

Distributor Information:

Customer Information:

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

078087 X –––––– No Display Installed

078134 – X –––––

078089 ––X ––––

078135 –––X –––

078095 ––––X ––

078141 –––––X –

078106 ––––––X

078103 X ––––––

With Display Installed

078149 – X –––––

078092 ––X ––––

078138 –––X –––

078098 ––––X ––

078144 –––––X –

078109 ––––––X

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

- Use Order Form or

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

ED

F

HYPERTHERM – HD4070 Power Supply with NO Integrated Command THC Option – Order Form

A

1

0

Voltage

1

3

REPEA

NEW

T

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 27

Page 28

Distributor Information:

Customer Information:

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

078087 X –––––– No Display Installed

078134 – X –––––

078089 ––X ––––

078135 –––X –––

078095 ––––X ––

078141 –––––X –

078106 ––––––X

078103 X ––––––

With Display Installed

078149 – X –––––

078092 ––X ––––

078138 –––X –––

078098 ––––X ––

078144 –––––X –

078109 ––––––X

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

- Use Order Form or

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

ED

F

HYPERTHERM – HD4070 Power Supply with NO Integrated Command THC Option – Order Form

A

1

0

Voltage

1

3

REPEA

NEW

T

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 29

Page 30

Page 31

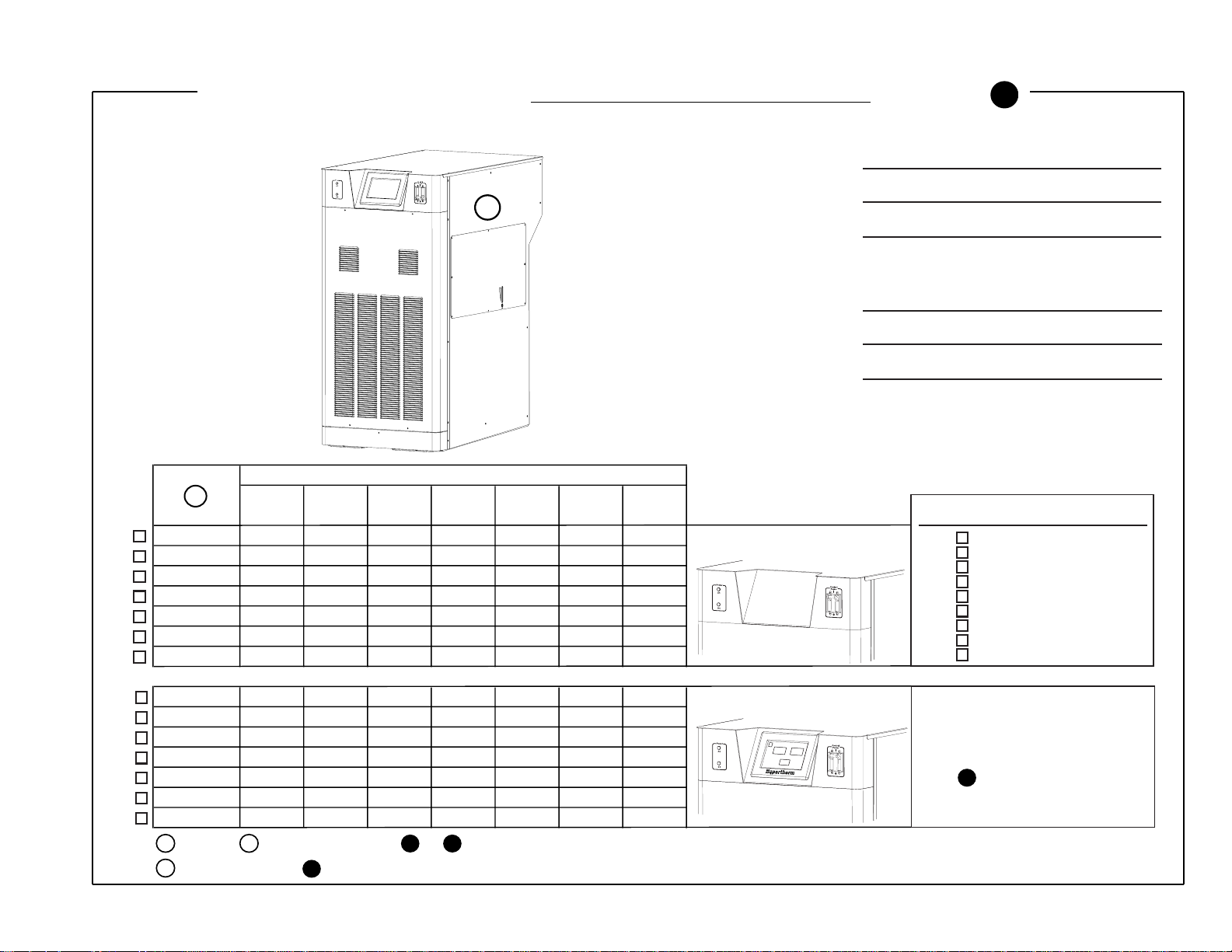

HD4070 Power Supply with ONE Integrated Command THC Option

Use with Order Form

B

20

THC Power

Supply

THC Control

PC Board

Note: These components

are factory installed

1

THC Motor

Drive Board

22

23

Torch and Lead

Assembly

24

4070.46A

21

25

Page 32

HYPERTHERM – HD4070 Power Supply with ONE Integrated Command THC Option – Order Form

B

20

X-Y Lifter - Quantity 1

128606

21

Torch Mounting Block Kit - Quantity 1

128279

25

Torch Breakaway Kit Option - Quantity 1

128281

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 1

- Use Order Form

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

D

F

1

Voltage

1

078101 X –––––– No Display Installed

078147 – X –––––

078090 ––X ––––

078136 –––X –––

078096 ––––X ––

078142 –––––X –

078107 ––––––X

078104 X ––––––

078150 – X –––––

078093 ––X ––––

078139 –––X –––

078099 ––––X ––

078145 –––––X –

078110 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

4070.33B

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

4070.33

Page 33

Page 34

HYPERTHERM – HD4070 Power Supply with ONE Integrated Command THC Option – Order Form

B

20

X-Y Lifter - Quantity 1

128606

21

Torch Mounting Block Kit - Quantity 1

128279

25

Torch Breakaway Kit Option - Quantity 1

128281

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 1

- Use Order Form

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

D

F

1

Voltage

1

078101 X –––––– No Display Installed

078147 – X –––––

078090 ––X ––––

078136 –––X –––

078096 ––––X ––

078142 –––––X –

078107 ––––––X

078104 X ––––––

078150 – X –––––

078093 ––X ––––

078139 –––X –––

078099 ––––X ––

078145 –––––X –

078110 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

4070.33B

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

4070.33

Page 35

Page 36

HYPERTHERM – HD4070 Power Supply with ONE Integrated Command THC Option – Order Form

B

20

X-Y Lifter - Quantity 1

128606

21

Torch Mounting Block Kit - Quantity 1

128279

25

Torch Breakaway Kit Option - Quantity 1

128281

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 1

- Use Order Form

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

D

F

1

Voltage

1

078101 X –––––– No Display Installed

078147 – X –––––

078090 ––X ––––

078136 –––X –––

078096 ––––X ––

078142 –––––X –

078107 ––––––X

078104 X ––––––

078150 – X –––––

078093 ––X ––––

078139 –––X –––

078099 ––––X ––

078145 –––––X –

078110 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

4070.33B

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

4070.33

Page 37

Page 38

HYPERTHERM – HD4070 Power Supply with ONE Integrated Command THC Option – Order Form

B

20

X-Y Lifter - Quantity 1

128606

21

Torch Mounting Block Kit - Quantity 1

128279

25

Torch Breakaway Kit Option - Quantity 1

128281

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 1

- Use Order Form

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

D

F

1

Voltage

1

078101 X –––––– No Display Installed

078147 – X –––––

078090 ––X ––––

078136 –––X –––

078096 ––––X ––

078142 –––––X –

078107 ––––––X

078104 X ––––––

078150 – X –––––

078093 ––X ––––

078139 –––X –––

078099 ––––X ––

078145 –––––X –

078110 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

4070.33B

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

4070.33

Page 39

Page 40

HYPERTHERM – HD4070 Power Supply with ONE Integrated Command THC Option – Order Form

B

20

X-Y Lifter - Quantity 1

128606

21

Torch Mounting Block Kit - Quantity 1

128279

25

Torch Breakaway Kit Option - Quantity 1

128281

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 1

- Use Order Form

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

D

F

1

Voltage

1

078101 X –––––– No Display Installed

078147 – X –––––

078090 ––X ––––

078136 –––X –––

078096 ––––X ––

078142 –––––X –

078107 ––––––X

078104 X ––––––

078150 – X –––––

078093 ––X ––––

078139 –––X –––

078099 ––––X ––

078145 –––––X –

078110 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

4070.33B

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

4070.33

Page 41

Page 42

Page 43

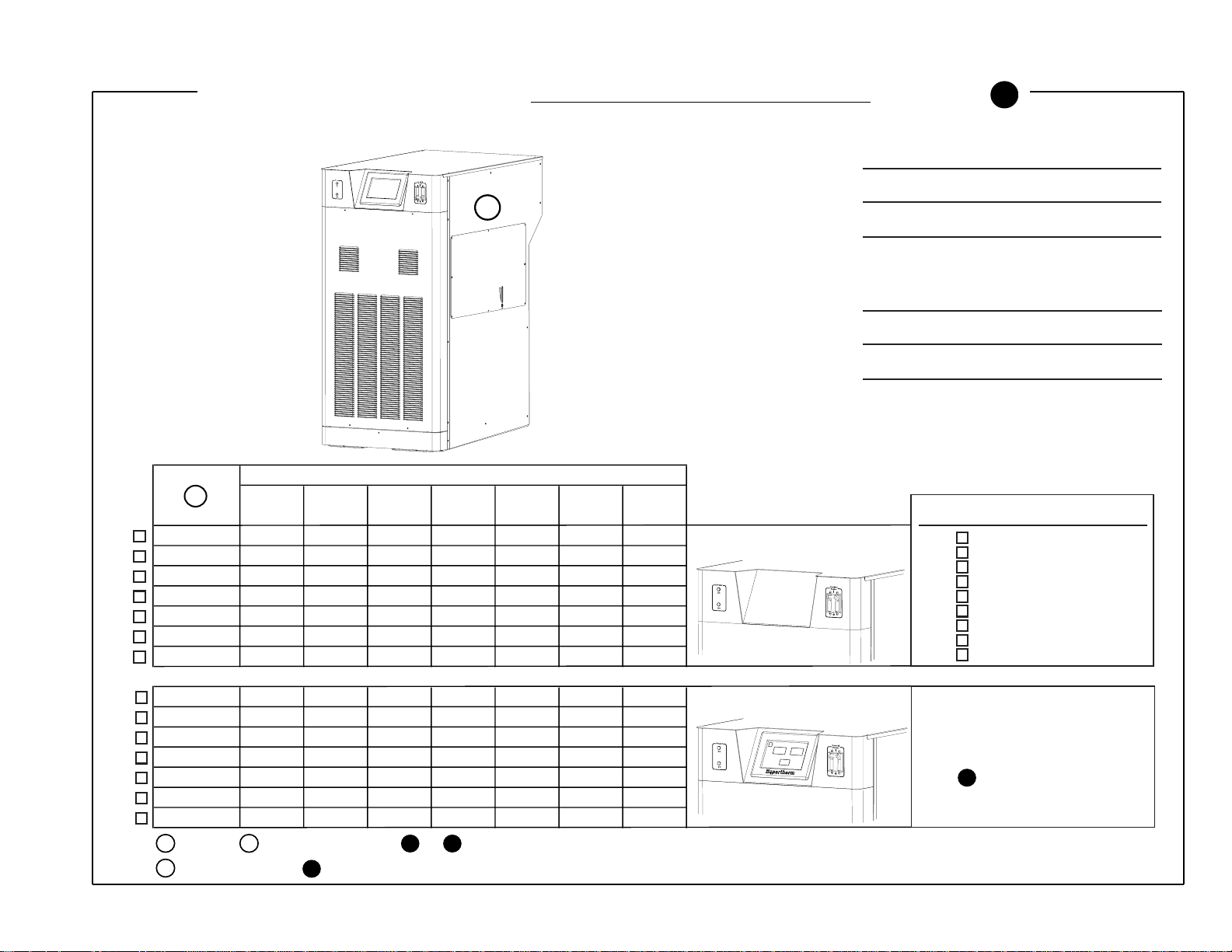

4070.48A

THC Control

PC Boards

THC Power

Supplies

THC Motor

Drive Boards

Note: These components

are factory installed

22

21

25

23

20

Torch and Lead

Assembly

24

Note: A torch receptacle plug must be used

if a two torch system is being used in

single torch mode. See form

16 a

E

HD4070 Power Supply with TWO Integrated Command THC Option

Use with Order Form

C

Page 44

HYPERTHERM – HD4070 Power Supply with TWO Integrated Command THC Option – Order Form

C

20

X-Y Lifter - Quantity 2

128606

21

Torch Mounting Block Kit - Quantity 2

128279

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 2

25

Torch Breakaway Kit Option - Quantity

128281

2

- Use Order Form

E

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

Note: A torch receptacle plug

16 a

must be used if a two torch system is being used in

single torch mode.

F

1

Voltage

1

078102 X –––––– No Display Installed

078148 – X –––––

078091 ––X ––––

078137 –––X –––

078097 ––––X ––

078143 –––––X –

078108 ––––––X

078105 X ––––––

078151 – X –––––

078094 ––X ––––

078140 –––X –––

078100 ––––X ––

078146 –––––X –

078111 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 45

Page 46

HYPERTHERM – HD4070 Power Supply with TWO Integrated Command THC Option – Order Form

C

20

X-Y Lifter - Quantity 2

128606

21

Torch Mounting Block Kit - Quantity 2

128279

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 2

25

Torch Breakaway Kit Option - Quantity

128281

2

- Use Order Form

E

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

Note: A torch receptacle plug

16 a

must be used if a two torch system is being used in

single torch mode.

F

1

Voltage

1

078102 X –––––– No Display Installed

078148 – X –––––

078091 ––X ––––

078137 –––X –––

078097 ––––X ––

078143 –––––X –

078108 ––––––X

078105 X ––––––

078151 – X –––––

078094 ––X ––––

078140 –––X –––

078100 ––––X ––

078146 –––––X –

078111 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 47

Page 48

HYPERTHERM – HD4070 Power Supply with TWO Integrated Command THC Option – Order Form

C

20

X-Y Lifter - Quantity 2

128606

21

Torch Mounting Block Kit - Quantity 2

128279

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 2

25

Torch Breakaway Kit Option - Quantity

128281

2

- Use Order Form

E

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

Note: A torch receptacle plug

16 a

must be used if a two torch system is being used in

single torch mode.

F

1

Voltage

1

078102 X –––––– No Display Installed

078148 – X –––––

078091 ––X ––––

078137 –––X –––

078097 ––––X ––

078143 –––––X –

078108 ––––––X

078105 X ––––––

078151 – X –––––

078094 ––X ––––

078140 –––X –––

078100 ––––X ––

078146 –––––X –

078111 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 49

Page 50

HYPERTHERM – HD4070 Power Supply with TWO Integrated Command THC Option – Order Form

C

20

X-Y Lifter - Quantity 2

128606

21

Torch Mounting Block Kit - Quantity 2

128279

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 2

25

Torch Breakaway Kit Option - Quantity

128281

2

- Use Order Form

E

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

Note: A torch receptacle plug

16 a

must be used if a two torch system is being used in

single torch mode.

F

1

Voltage

1

078102 X –––––– No Display Installed

078148 – X –––––

078091 ––X ––––

078137 –––X –––

078097 ––––X ––

078143 –––––X –

078108 ––––––X

078105 X ––––––

078151 – X –––––

078094 ––X ––––

078140 –––X –––

078100 ––––X ––

078146 –––––X –

078111 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 51

Page 52

HYPERTHERM – HD4070 Power Supply with TWO Integrated Command THC Option – Order Form

C

20

X-Y Lifter - Quantity 2

128606

21

Torch Mounting Block Kit - Quantity 2

128279

128526 10 ft.(3 m)

128527 20 ft.(6.1 m)

128528 25 ft.(7.6 m)

128529 30 ft.(9.1 m)

128530 40 ft.(12.2 m)

128531 50 ft.(15.2 m)

128532 75 ft.(22.9 m)

128533 100 ft.(30.5 m)

128534 150 ft.(45.7 m)

Remote Display Option Kit

Installed Display can be removed

and mounted at a remote location

with a remote cable kit. See Order

form or instruction manual

parts list for kit numbers.

Distributor Information:

Customer Information:

22

Lifter I/O Cable, Motor Drive Cable, Ohmic Contact Wire

23 24

128452 10 ft.(3 m)

128453 20 ft.(6.1 m)

128454 25 ft.(7.6 m)

128455 30 ft.(9.1 m)

128456 40 ft.(12.2 m)

128457 50 ft.(15.2 m)

128458 75 ft.(22.9 m)

128459 100 ft.(30.5 m)

128460 150 ft.(45.7 m)

THC to Power Supply Cable Package - Quantity 2

25

Torch Breakaway Kit Option - Quantity

128281

2

- Use Order Form

E

2

18

through

Warning: Each power supply can only support one display.

Installation of two displays with one power supply may result in

malfunction or damage.

19

Use Order Form

F

Note: A torch receptacle plug

16 a

must be used if a two torch system is being used in

single torch mode.

F

1

Voltage

1

078102 X –––––– No Display Installed

078148 – X –––––

078091 ––X ––––

078137 –––X –––

078097 ––––X ––

078143 –––––X –

078108 ––––––X

078105 X ––––––

078151 – X –––––

078094 ––X ––––

078140 –––X –––

078100 ––––X ––

078146 –––––X –

078111 ––––––X

480V 240V 400V 200V 440V 220V 600V

60 HZ 60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 50-60 HZ 60 HZ

With Display Installed

3

REPEAT

NEW

PROCESS

PREVIOUS

PROCESS

S

E

T

U

P

Page 53

Page 54

Page 55

5

6

8

9

12

2

16

3

15

17

18

10

14

4

19

11

7

13

1

4070.99A

17

17

17

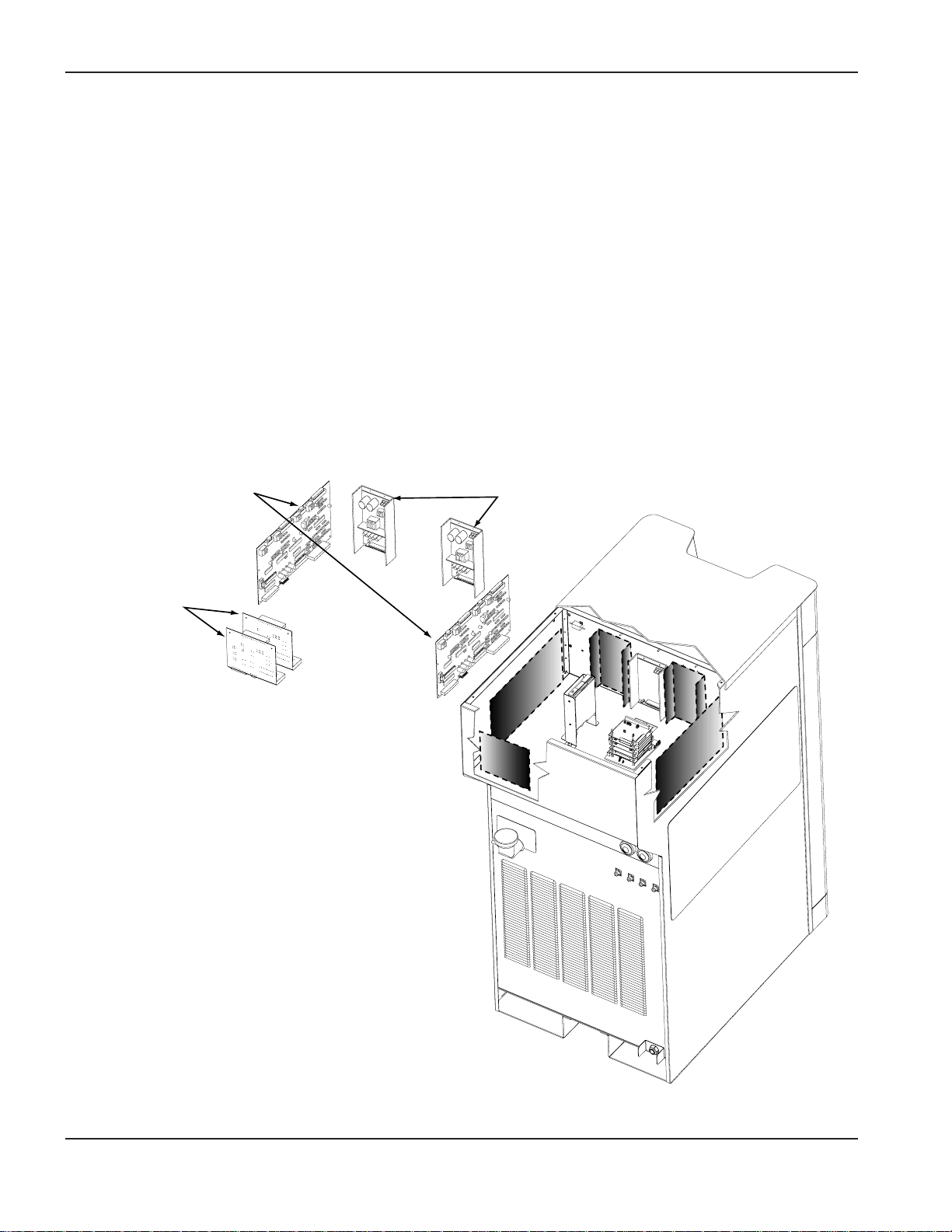

HD4070 Components, Cables and Hoses For 1-Torch Option Use with Order Form

D

Page 56

Distributor Information:

Customer Information:

Work Lead

9

123418 10 ft (3 m)

023136 20 ft (6.1 m)

023078 25 ft (7.6 m)

023101 30 ft (9.1 m)

023135 40 ft (12.2 m)

023079 50 ft (15.2 m)

023124 75 ft (23 m)

023080 100 ft (30.5 m)

023081 150 ft (45.7 m)

CNC Interface Cable Power Supply to CNC

12

123437 10 ft (3 m)

123438 20 ft (6.1 m)

123439 25 ft (7.6 m)

123440 30 ft (9.1 m)

123441 40 ft (12.2 m)

123442 50 ft (15.2 m)

123443 75 ft (23 m)

123444 100 ft (30.5 m)

123445 150 ft (45.7 m)

Power Cable Ignition Console to Off Valve

15

123451 6 ft (1.8 m)

123452 10 ft (3 m)

123453 15 ft (4.6 m)

Torch Assembly with Leads

16

128500 6 ft (1.8 m)

128501 10 ft (3 m)

128502 15 ft (4.6 m)

Quantity 1 Each

Gas Console

078085

Ignition Console

078088

Off Valve Assembly

129563

2

3

4

Coolant Hoses, Pilot Arc & Negative Leads

5

6

7 8

128412 10 ft (3 m)

128413 20 ft.(6.1 m)

128414 25 ft.(7.6 m)

128415 30 ft.(9.1 m)

128416 40 ft.(12.2 m)

128417 50 ft.(15.2 m)

128418 75 ft.(23 m)

128419 100 ft.(30.5 m)

128420 150 ft.(45.7 m)

Power Supply to Ignition Console Hose/Lead Package

Signal Cable & Power Cable

10

11

Power Supply to Gas Console Cable Package

128421 10 ft.(3 m)

128422 20 ft.(6.1 m)

128423 25 ft.(7.6 m)

128424 30 ft.(9.1 m)

128425 40 ft.(12.2 m)

128426 50 ft.(15.2 m)

128427 75 ft.(23 m)

128428 100 ft.(30.5 m)

128429 150 ft.(45.7 m)

Grounding Wires - Customer Supplied

Power Supply Cable - Customer Supplied

Gas Supply Hoses - Use form

17

18

19

Power Cable Gas Console to Ignition Console

14

123446 10 ft (3 m)

123447 20 ft (6.1 m)

123448 25 ft (7.6 m)

123449 30 ft (9.1 m)

123450 40 ft (12.2 m)

123512 50 ft (15.2 m)

123559 60 ft (18.3 m)

123513 75 ft (23 m)

123514 100 ft (30.5 m)

Gas Hoses Gas Console to Off-Valve

13

128445 15 ft (4.6 m)

128446 20 ft (6.1 m)

128447 25 ft (7.6 m)

128448 30 ft (9.1 m)

128449 35 ft (10.7 m)

128450 40 ft (12.2 m)

128451 45 ft (13.7 m)

128558 50 ft (15.2 m)

128559 60 ft (18.3 m)

128550 75 ft (23 m)

128551 100 ft (30.5 m)

HYPERTHERM - Order Form

HD4070 Components, Cables and Hoses

For 1-Torch Option

D

1

Power Supply

Use form or

BA

F

0

Page 57

Page 58

Distributor Information:

Customer Information:

Work Lead

9

123418 10 ft (3 m)

023136 20 ft (6.1 m)

023078 25 ft (7.6 m)

023101 30 ft (9.1 m)

023135 40 ft (12.2 m)

023079 50 ft (15.2 m)

023124 75 ft (23 m)

023080 100 ft (30.5 m)

023081 150 ft (45.7 m)

CNC Interface Cable Power Supply to CNC

12

123437 10 ft (3 m)

123438 20 ft (6.1 m)

123439 25 ft (7.6 m)

123440 30 ft (9.1 m)

123441 40 ft (12.2 m)

123442 50 ft (15.2 m)

123443 75 ft (23 m)

123444 100 ft (30.5 m)

123445 150 ft (45.7 m)

Power Cable Ignition Console to Off Valve

15

123451 6 ft (1.8 m)

123452 10 ft (3 m)

123453 15 ft (4.6 m)

Torch Assembly with Leads

16

128500 6 ft (1.8 m)

128501 10 ft (3 m)

128502 15 ft (4.6 m)

Quantity 1 Each

Gas Console

078085

Ignition Console

078088

Off Valve Assembly

129563

2

3

4

Coolant Hoses, Pilot Arc & Negative Leads

5

6

7 8

128412 10 ft (3 m)

128413 20 ft.(6.1 m)

128414 25 ft.(7.6 m)

128415 30 ft.(9.1 m)

128416 40 ft.(12.2 m)

128417 50 ft.(15.2 m)

128418 75 ft.(23 m)

128419 100 ft.(30.5 m)

128420 150 ft.(45.7 m)

Power Supply to Ignition Console Hose/Lead Package

Signal Cable & Power Cable

10

11

Power Supply to Gas Console Cable Package

128421 10 ft.(3 m)

128422 20 ft.(6.1 m)

128423 25 ft.(7.6 m)

128424 30 ft.(9.1 m)

128425 40 ft.(12.2 m)

128426 50 ft.(15.2 m)

128427 75 ft.(23 m)

128428 100 ft.(30.5 m)

128429 150 ft.(45.7 m)

Grounding Wires - Customer Supplied

Power Supply Cable - Customer Supplied

Gas Supply Hoses - Use form

17

18

19

Power Cable Gas Console to Ignition Console

14

123446 10 ft (3 m)

123447 20 ft (6.1 m)

123448 25 ft (7.6 m)

123449 30 ft (9.1 m)

123450 40 ft (12.2 m)

123512 50 ft (15.2 m)

123559 60 ft (18.3 m)

123513 75 ft (23 m)

123514 100 ft (30.5 m)

Gas Hoses Gas Console to Off-Valve

13

128445 15 ft (4.6 m)

128446 20 ft (6.1 m)

128447 25 ft (7.6 m)

128448 30 ft (9.1 m)

128449 35 ft (10.7 m)

128450 40 ft (12.2 m)

128451 45 ft (13.7 m)

128558 50 ft (15.2 m)

128559 60 ft (18.3 m)

128550 75 ft (23 m)

128551 100 ft (30.5 m)

HYPERTHERM - Order Form

HD4070 Components, Cables and Hoses

For 1-Torch Option

D

1

Power Supply

Use form or

BA

F

0

Page 59

Page 60

Distributor Information:

Customer Information:

Work Lead

9

123418 10 ft (3 m)

023136 20 ft (6.1 m)

023078 25 ft (7.6 m)

023101 30 ft (9.1 m)

023135 40 ft (12.2 m)

023079 50 ft (15.2 m)

023124 75 ft (23 m)

023080 100 ft (30.5 m)

023081 150 ft (45.7 m)

CNC Interface Cable Power Supply to CNC

12

123437 10 ft (3 m)

123438 20 ft (6.1 m)

123439 25 ft (7.6 m)

123440 30 ft (9.1 m)

123441 40 ft (12.2 m)

123442 50 ft (15.2 m)

123443 75 ft (23 m)

123444 100 ft (30.5 m)

123445 150 ft (45.7 m)

Power Cable Ignition Console to Off Valve

15

123451 6 ft (1.8 m)

123452 10 ft (3 m)

123453 15 ft (4.6 m)

Torch Assembly with Leads

16

128500 6 ft (1.8 m)

128501 10 ft (3 m)

128502 15 ft (4.6 m)

Quantity 1 Each

Gas Console

078085

Ignition Console

078088

Off Valve Assembly

129563

2

3

4

Coolant Hoses, Pilot Arc & Negative Leads

5

6

7 8

128412 10 ft (3 m)

128413 20 ft.(6.1 m)

128414 25 ft.(7.6 m)

128415 30 ft.(9.1 m)

128416 40 ft.(12.2 m)

128417 50 ft.(15.2 m)

128418 75 ft.(23 m)

128419 100 ft.(30.5 m)

128420 150 ft.(45.7 m)

Power Supply to Ignition Console Hose/Lead Package

Signal Cable & Power Cable

10

11

Power Supply to Gas Console Cable Package

128421 10 ft.(3 m)

128422 20 ft.(6.1 m)

128423 25 ft.(7.6 m)

128424 30 ft.(9.1 m)

128425 40 ft.(12.2 m)

128426 50 ft.(15.2 m)

128427 75 ft.(23 m)

128428 100 ft.(30.5 m)

128429 150 ft.(45.7 m)

Grounding Wires - Customer Supplied

Power Supply Cable - Customer Supplied

Gas Supply Hoses - Use form

17

18

19

Power Cable Gas Console to Ignition Console

14

123446 10 ft (3 m)

123447 20 ft (6.1 m)

123448 25 ft (7.6 m)

123449 30 ft (9.1 m)

123450 40 ft (12.2 m)

123512 50 ft (15.2 m)

123559 60 ft (18.3 m)

123513 75 ft (23 m)

123514 100 ft (30.5 m)

Gas Hoses Gas Console to Off-Valve

13

128445 15 ft (4.6 m)

128446 20 ft (6.1 m)

128447 25 ft (7.6 m)

128448 30 ft (9.1 m)

128449 35 ft (10.7 m)

128450 40 ft (12.2 m)

128451 45 ft (13.7 m)

128558 50 ft (15.2 m)

128559 60 ft (18.3 m)

128550 75 ft (23 m)

128551 100 ft (30.5 m)

HYPERTHERM - Order Form

HD4070 Components, Cables and Hoses

For 1-Torch Option

D

1

Power Supply

Use form or

BA

F

0

Page 61

Page 62

Distributor Information:

Customer Information:

Work Lead

9

123418 10 ft (3 m)

023136 20 ft (6.1 m)

023078 25 ft (7.6 m)

023101 30 ft (9.1 m)

023135 40 ft (12.2 m)

023079 50 ft (15.2 m)

023124 75 ft (23 m)

023080 100 ft (30.5 m)

023081 150 ft (45.7 m)

CNC Interface Cable Power Supply to CNC

12

123437 10 ft (3 m)

123438 20 ft (6.1 m)

123439 25 ft (7.6 m)

123440 30 ft (9.1 m)

123441 40 ft (12.2 m)

123442 50 ft (15.2 m)

123443 75 ft (23 m)

123444 100 ft (30.5 m)

123445 150 ft (45.7 m)

Power Cable Ignition Console to Off Valve

15

123451 6 ft (1.8 m)

123452 10 ft (3 m)

123453 15 ft (4.6 m)

Torch Assembly with Leads

16

128500 6 ft (1.8 m)

128501 10 ft (3 m)

128502 15 ft (4.6 m)

Quantity 1 Each

Gas Console

078085

Ignition Console

078088

Off Valve Assembly

129563

2

3

4

Coolant Hoses, Pilot Arc & Negative Leads

5

6

7 8

128412 10 ft (3 m)

128413 20 ft.(6.1 m)

128414 25 ft.(7.6 m)

128415 30 ft.(9.1 m)

128416 40 ft.(12.2 m)

128417 50 ft.(15.2 m)

128418 75 ft.(23 m)

128419 100 ft.(30.5 m)

128420 150 ft.(45.7 m)

Power Supply to Ignition Console Hose/Lead Package

Signal Cable & Power Cable

10

11

Power Supply to Gas Console Cable Package

128421 10 ft.(3 m)

128422 20 ft.(6.1 m)

128423 25 ft.(7.6 m)

128424 30 ft.(9.1 m)

128425 40 ft.(12.2 m)

128426 50 ft.(15.2 m)

128427 75 ft.(23 m)

128428 100 ft.(30.5 m)

128429 150 ft.(45.7 m)

Grounding Wires - Customer Supplied

Power Supply Cable - Customer Supplied

Gas Supply Hoses - Use form

17

18

19

Power Cable Gas Console to Ignition Console

14

123446 10 ft (3 m)

123447 20 ft (6.1 m)

123448 25 ft (7.6 m)

123449 30 ft (9.1 m)

123450 40 ft (12.2 m)

123512 50 ft (15.2 m)

123559 60 ft (18.3 m)

123513 75 ft (23 m)

123514 100 ft (30.5 m)

Gas Hoses Gas Console to Off-Valve

13

128445 15 ft (4.6 m)

128446 20 ft (6.1 m)

128447 25 ft (7.6 m)

128448 30 ft (9.1 m)

128449 35 ft (10.7 m)

128450 40 ft (12.2 m)

128451 45 ft (13.7 m)

128558 50 ft (15.2 m)

128559 60 ft (18.3 m)

128550 75 ft (23 m)

128551 100 ft (30.5 m)

HYPERTHERM - Order Form

HD4070 Components, Cables and Hoses

For 1-Torch Option

D

1

Power Supply

Use form or

BA

F

0

Page 63

Page 64

Distributor Information:

Customer Information:

Work Lead

9

123418 10 ft (3 m)

023136 20 ft (6.1 m)

023078 25 ft (7.6 m)

023101 30 ft (9.1 m)

023135 40 ft (12.2 m)

023079 50 ft (15.2 m)

023124 75 ft (23 m)

023080 100 ft (30.5 m)

023081 150 ft (45.7 m)

CNC Interface Cable Power Supply to CNC

12

123437 10 ft (3 m)

123438 20 ft (6.1 m)

123439 25 ft (7.6 m)

123440 30 ft (9.1 m)

123441 40 ft (12.2 m)

123442 50 ft (15.2 m)

123443 75 ft (23 m)

123444 100 ft (30.5 m)

123445 150 ft (45.7 m)

Power Cable Ignition Console to Off Valve

15

123451 6 ft (1.8 m)

123452 10 ft (3 m)

123453 15 ft (4.6 m)

Torch Assembly with Leads

16

128500 6 ft (1.8 m)

128501 10 ft (3 m)

128502 15 ft (4.6 m)

Quantity 1 Each

Gas Console

078085

Ignition Console

078088

Off Valve Assembly

129563

2

3

4

Coolant Hoses, Pilot Arc & Negative Leads

5

6

7 8

128412 10 ft (3 m)

128413 20 ft.(6.1 m)

128414 25 ft.(7.6 m)

128415 30 ft.(9.1 m)

128416 40 ft.(12.2 m)

128417 50 ft.(15.2 m)

128418 75 ft.(23 m)

128419 100 ft.(30.5 m)

128420 150 ft.(45.7 m)

Power Supply to Ignition Console Hose/Lead Package

Signal Cable & Power Cable

10

11

Power Supply to Gas Console Cable Package

128421 10 ft.(3 m)

128422 20 ft.(6.1 m)

128423 25 ft.(7.6 m)

128424 30 ft.(9.1 m)

128425 40 ft.(12.2 m)

128426 50 ft.(15.2 m)

128427 75 ft.(23 m)

128428 100 ft.(30.5 m)

128429 150 ft.(45.7 m)

Grounding Wires - Customer Supplied

Power Supply Cable - Customer Supplied

Gas Supply Hoses - Use form

17

18

19

Power Cable Gas Console to Ignition Console

14

123446 10 ft (3 m)

123447 20 ft (6.1 m)

123448 25 ft (7.6 m)

123449 30 ft (9.1 m)

123450 40 ft (12.2 m)

123512 50 ft (15.2 m)

123559 60 ft (18.3 m)

123513 75 ft (23 m)

123514 100 ft (30.5 m)

Gas Hoses Gas Console to Off-Valve

13

128445 15 ft (4.6 m)

128446 20 ft (6.1 m)

128447 25 ft (7.6 m)

128448 30 ft (9.1 m)

128449 35 ft (10.7 m)

128450 40 ft (12.2 m)

128451 45 ft (13.7 m)

128558 50 ft (15.2 m)

128559 60 ft (18.3 m)

128550 75 ft (23 m)

128551 100 ft (30.5 m)

HYPERTHERM - Order Form

HD4070 Components, Cables and Hoses

For 1-Torch Option

D

1

Power Supply

Use form or

BA

F

0

Page 65

Page 66

Page 67

18

Bold lines show second torch cables, hoses and components

7

8

5

6

1

15

16

17

14

13

17

2

3

4

4070.98A

4

3

17

17

17

10

11

9

12

19

16

16 a

HD4070 Components, Cables and Hoses For 2-Torch Option Use with Order Form

E

Page 68

Distributor Information:

Customer Information:

Quantity: As Marked

Gas Console - Quantity 1

078085

Ignition Console - Quantity 2

078088

Off Valve Assembly - Quantity 2

129563

2

3

4

CNC Interface Cable - Quantity 1

Power Supply to CNC

12

123437 10 ft (3 m)

123438 20 ft (6.1 m)

123439 25 ft (7.6 m)

123440 30 ft (9.1 m)

123441 40 ft (12.2 m)

123442 50 ft (15.2 m)

123443 75 ft (23 m)

123444 100 ft (30.5 m)

123445 150 ft (45.7 m)

Work Lead - Quantity 1

9

123418 10 ft (3 m)

023136 20 ft (6.1 m)

023078 25 ft (7.6 m)

023101 30 ft (9.1 m)

023135 40 ft (12.2 m)

023079 50 ft (15.2 m)

023124 75 ft (23 m)

023080 100 ft (30.5 m)

023081 150 ft (45.7 m)

Torch Assembly with Leads - Quantity 2

16

128500 6 ft (1.8 m)

128501 10 ft (3 m)

128502 15 ft (4.6 m)

Power Cable - Quantity 2

Ignition Console to Off Valve

15

123451 6 ft (1.8 m)

123452 10 ft (3 m)

123453 15 ft (4.6 m)

Coolant Hoses, Pilot Arc & Negative Leads

5

6

7 8

128412 10 ft (3 m)

128413 20 ft.(6.1 m)

128414 25 ft.(7.6 m)

128415 30 ft.(9.1 m)

128416 40 ft.(12.2 m)

128417 50 ft.(15.2 m)

128418 75 ft.(23 m)

128419 100 ft.(30.5 m)

128420 150 ft.(45.7 m)

Power Supply to Ignition Console

Hose/Lead Package - Quantity 2

Signal Cable & Power Cable

10

11

Power Supply to Gas Console

Cable Package - Quantity 1

128421 10 ft.(3 m)

128422 20 ft.(6.1 m)

128423 25 ft.(7.6 m)

128424 30 ft.(9.1 m)

128425 40 ft.(12.2 m)

128426 50 ft.(15.2 m)

128427 75 ft.(23 m)

128428 100 ft.(30.5 m)

128429 150 ft.(45.7 m)

1

Power Supply

Use form or

Power Cable - Quantity 2

Gas Console to Ignition Console

14

123446 10 ft (3 m)

123447 20 ft (6.1 m)

123448 25 ft (7.6 m)

123449 30 ft (9.1 m)

123450 40 ft (12.2 m)

123512 50 ft (15.2 m)

123559 60 ft (18.3 m)

123513 75 ft (23 m)

123514 100 ft (30.5 m)

16 a

Torch Receptacle Plug - Quantity

1

129671

Gas Hoses - Quantity 2

Gas Console to Off-Valve

13

128445 15 ft (4.6 m)

128446 20 ft (6.1 m)

128447 25 ft (7.6 m)

128448 30 ft (9.1 m)

128449 35 ft (10.7 m)

128450 40 ft (12.2 m)

128451 45 ft (13.7 m)

128558 50 ft (15.2 m)

128559 60 ft (18.3 m)

128550 75 ft (23 m)

128551 100 ft (30.5 m)

Grounding Wires - Customer Supplied

Power Supply Cable - Customer Supplied

Gas Supply Hoses - Use form

17

18

19

F

A C

HYPERTHERM - Order Form

HD4070 Components, Cables and Hoses

For 2-Torch Option

E

Note: A torch receptacle plug must be used if a

two torch system is being used in single torch

mode. See form E

0

Page 69

Page 70

Distributor Information:

Customer Information:

Quantity: As Marked

Gas Console - Quantity 1

078085

Ignition Console - Quantity 2

078088

Off Valve Assembly - Quantity 2

129563

2

3

4

CNC Interface Cable - Quantity 1

Power Supply to CNC

12

123437 10 ft (3 m)

123438 20 ft (6.1 m)

123439 25 ft (7.6 m)

123440 30 ft (9.1 m)

123441 40 ft (12.2 m)

123442 50 ft (15.2 m)

123443 75 ft (23 m)

123444 100 ft (30.5 m)

123445 150 ft (45.7 m)

Work Lead - Quantity 1

9

123418 10 ft (3 m)

023136 20 ft (6.1 m)

023078 25 ft (7.6 m)

023101 30 ft (9.1 m)

023135 40 ft (12.2 m)

023079 50 ft (15.2 m)

023124 75 ft (23 m)

023080 100 ft (30.5 m)

023081 150 ft (45.7 m)

Torch Assembly with Leads - Quantity 2

16

128500 6 ft (1.8 m)

128501 10 ft (3 m)

128502 15 ft (4.6 m)

Power Cable - Quantity 2

Ignition Console to Off Valve

15

123451 6 ft (1.8 m)

123452 10 ft (3 m)

123453 15 ft (4.6 m)

Coolant Hoses, Pilot Arc & Negative Leads

5

6

7 8

128412 10 ft (3 m)

128413 20 ft.(6.1 m)

128414 25 ft.(7.6 m)

128415 30 ft.(9.1 m)

128416 40 ft.(12.2 m)

128417 50 ft.(15.2 m)

128418 75 ft.(23 m)

128419 100 ft.(30.5 m)

128420 150 ft.(45.7 m)

Power Supply to Ignition Console

Hose/Lead Package - Quantity 2

Signal Cable & Power Cable

10

11

Power Supply to Gas Console

Cable Package - Quantity 1

128421 10 ft.(3 m)

128422 20 ft.(6.1 m)

128423 25 ft.(7.6 m)

128424 30 ft.(9.1 m)

128425 40 ft.(12.2 m)

128426 50 ft.(15.2 m)

128427 75 ft.(23 m)

128428 100 ft.(30.5 m)

128429 150 ft.(45.7 m)

1

Power Supply

Use form or

Power Cable - Quantity 2

Gas Console to Ignition Console

14

123446 10 ft (3 m)

123447 20 ft (6.1 m)

123448 25 ft (7.6 m)

123449 30 ft (9.1 m)

123450 40 ft (12.2 m)

123512 50 ft (15.2 m)

123559 60 ft (18.3 m)

123513 75 ft (23 m)

123514 100 ft (30.5 m)

16 a

Torch Receptacle Plug - Quantity

1

129671

Gas Hoses - Quantity 2

Gas Console to Off-Valve

13

128445 15 ft (4.6 m)

128446 20 ft (6.1 m)

128447 25 ft (7.6 m)

128448 30 ft (9.1 m)

128449 35 ft (10.7 m)

128450 40 ft (12.2 m)

128451 45 ft (13.7 m)

128558 50 ft (15.2 m)

128559 60 ft (18.3 m)

128550 75 ft (23 m)

128551 100 ft (30.5 m)

Grounding Wires - Customer Supplied

Power Supply Cable - Customer Supplied

Gas Supply Hoses - Use form

17

18

19

F

A C

HYPERTHERM - Order Form

HD4070 Components, Cables and Hoses

For 2-Torch Option

E

Note: A torch receptacle plug must be used if a

two torch system is being used in single torch

mode. See form E

0

Page 71

Page 72

Distributor Information:

Customer Information:

Quantity: As Marked

Gas Console - Quantity 1

078085

Ignition Console - Quantity 2

078088

Off Valve Assembly - Quantity 2

129563

2

3

4

CNC Interface Cable - Quantity 1

Power Supply to CNC

12

123437 10 ft (3 m)

123438 20 ft (6.1 m)

123439 25 ft (7.6 m)

123440 30 ft (9.1 m)

123441 40 ft (12.2 m)

123442 50 ft (15.2 m)

123443 75 ft (23 m)

123444 100 ft (30.5 m)

123445 150 ft (45.7 m)

Work Lead - Quantity 1

9

123418 10 ft (3 m)

023136 20 ft (6.1 m)

023078 25 ft (7.6 m)

023101 30 ft (9.1 m)

023135 40 ft (12.2 m)

023079 50 ft (15.2 m)

023124 75 ft (23 m)

023080 100 ft (30.5 m)

023081 150 ft (45.7 m)

Torch Assembly with Leads - Quantity 2

16

128500 6 ft (1.8 m)

128501 10 ft (3 m)

128502 15 ft (4.6 m)

Power Cable - Quantity 2

Ignition Console to Off Valve

15

123451 6 ft (1.8 m)

123452 10 ft (3 m)

123453 15 ft (4.6 m)

Coolant Hoses, Pilot Arc & Negative Leads

5

6

7 8

128412 10 ft (3 m)

128413 20 ft.(6.1 m)

128414 25 ft.(7.6 m)

128415 30 ft.(9.1 m)

128416 40 ft.(12.2 m)

128417 50 ft.(15.2 m)

128418 75 ft.(23 m)

128419 100 ft.(30.5 m)

128420 150 ft.(45.7 m)

Power Supply to Ignition Console

Hose/Lead Package - Quantity 2

Signal Cable & Power Cable

10

11

Power Supply to Gas Console

Cable Package - Quantity 1

128421 10 ft.(3 m)

128422 20 ft.(6.1 m)

128423 25 ft.(7.6 m)

128424 30 ft.(9.1 m)

128425 40 ft.(12.2 m)

128426 50 ft.(15.2 m)

128427 75 ft.(23 m)

128428 100 ft.(30.5 m)

128429 150 ft.(45.7 m)

1

Power Supply

Use form or

Power Cable - Quantity 2

Gas Console to Ignition Console

14

123446 10 ft (3 m)

123447 20 ft (6.1 m)

123448 25 ft (7.6 m)

123449 30 ft (9.1 m)

123450 40 ft (12.2 m)

123512 50 ft (15.2 m)

123559 60 ft (18.3 m)

123513 75 ft (23 m)

123514 100 ft (30.5 m)

16 a

Torch Receptacle Plug - Quantity

1

129671

Gas Hoses - Quantity 2

Gas Console to Off-Valve

13

128445 15 ft (4.6 m)

128446 20 ft (6.1 m)

128447 25 ft (7.6 m)

128448 30 ft (9.1 m)

128449 35 ft (10.7 m)

128450 40 ft (12.2 m)

128451 45 ft (13.7 m)

128558 50 ft (15.2 m)

128559 60 ft (18.3 m)

128550 75 ft (23 m)

128551 100 ft (30.5 m)

Grounding Wires - Customer Supplied

Power Supply Cable - Customer Supplied

Gas Supply Hoses - Use form

17

18

19

F

A C

HYPERTHERM - Order Form

HD4070 Components, Cables and Hoses

For 2-Torch Option

E

Note: A torch receptacle plug must be used if a

two torch system is being used in single torch

mode. See form E

0

Page 73

Page 74

Distributor Information:

Customer Information:

Quantity: As Marked

Gas Console - Quantity 1

078085

Ignition Console - Quantity 2

078088

Off Valve Assembly - Quantity 2

129563

2

3

4

CNC Interface Cable - Quantity 1

Power Supply to CNC

12

123437 10 ft (3 m)

123438 20 ft (6.1 m)

123439 25 ft (7.6 m)

123440 30 ft (9.1 m)

123441 40 ft (12.2 m)

123442 50 ft (15.2 m)

123443 75 ft (23 m)

123444 100 ft (30.5 m)

123445 150 ft (45.7 m)

Work Lead - Quantity 1

9

123418 10 ft (3 m)

023136 20 ft (6.1 m)

023078 25 ft (7.6 m)

023101 30 ft (9.1 m)

023135 40 ft (12.2 m)

023079 50 ft (15.2 m)

023124 75 ft (23 m)

023080 100 ft (30.5 m)

023081 150 ft (45.7 m)

Torch Assembly with Leads - Quantity 2

16

128500 6 ft (1.8 m)

128501 10 ft (3 m)

128502 15 ft (4.6 m)

Power Cable - Quantity 2

Ignition Console to Off Valve

15

123451 6 ft (1.8 m)

123452 10 ft (3 m)

123453 15 ft (4.6 m)

Coolant Hoses, Pilot Arc & Negative Leads

5

6

7 8

128412 10 ft (3 m)

128413 20 ft.(6.1 m)

128414 25 ft.(7.6 m)

128415 30 ft.(9.1 m)

128416 40 ft.(12.2 m)

128417 50 ft.(15.2 m)

128418 75 ft.(23 m)

128419 100 ft.(30.5 m)

128420 150 ft.(45.7 m)

Power Supply to Ignition Console

Hose/Lead Package - Quantity 2

Signal Cable & Power Cable

10

11

Power Supply to Gas Console

Cable Package - Quantity 1

128421 10 ft.(3 m)

128422 20 ft.(6.1 m)

128423 25 ft.(7.6 m)

128424 30 ft.(9.1 m)

128425 40 ft.(12.2 m)

128426 50 ft.(15.2 m)

128427 75 ft.(23 m)

128428 100 ft.(30.5 m)

128429 150 ft.(45.7 m)

1

Power Supply

Use form or

Power Cable - Quantity 2

Gas Console to Ignition Console

14

123446 10 ft (3 m)

123447 20 ft (6.1 m)

123448 25 ft (7.6 m)

123449 30 ft (9.1 m)

123450 40 ft (12.2 m)

123512 50 ft (15.2 m)

123559 60 ft (18.3 m)

123513 75 ft (23 m)

123514 100 ft (30.5 m)