Echion™

Operator Manual

810770 – REVISION 3

ENGLISH

HyPrecision, Echion, and Hypertherm are trademarks of Hypertherm, Inc. and may be registered in the United States and other

countries. All other trademarks are the property of their respective holders.

Environmental stewardship is one of Hypertherm’s core values, and it is critical to our success and our customers’ success. We

are striving to reduce the environmental impact of everything we do. For more information:www.hypertherm.com/environment.

© 2020 Hypertherm, Inc.

Echion

Operator Manual

810770

REVISION 3

ENGLISH

Original instructions

June 2020

Hypertherm, Inc.

Hanover, NH 03755 USA

www.hypertherm.com

Hypertherm Europe B.V.

Vaartveld 9, 4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emea@hypertherm.com

(Technical Service Email)

Hypertherm (Shanghai) Trading Co., Ltd.

B301, 495 ShangZhong Road

Shanghai, 200231

PR China

86-21-80231122 Tel

86-21-80231120 Fax

86-21-80231128 Tel (Technical Service)

techsupport.china@hypertherm.com

(Technical Service Email)

South America & Central America: Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP – Brasil

CEP 07115-030

55 11 2409 2636 Tel

tecnico.sa@hypertherm.com (Technical Service Email)

Hypertherm Korea Branch

#3904. APEC-ro 17. Heaundae-gu. Busan.

Korea 48060

82 (0)51 747 0358 Tel

82 (0)51 701 0358 Fax

Marketing.korea@hypertherm.com (Marketing Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm Pty Limited

GPO Box 4836

Sydney NSW 2001, Australia

61 (0) 437 606 995 Tel

61 7 3219 9010 Fax

au.sales@Hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm (India) Thermal Cutting Pvt. Ltd

A-18 / B-1 Extension,

Mohan Co-Operative Industrial Estate,

Mathura Road, New Delhi 110044, India

91-11-40521201/ 2/ 3 Tel

91-11 40521204 Fax

HTIndia.info@hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

877-371-2876 Fax (Return Materials Authorization)

return.materials@hypertherm.com (RMA email)

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Soporte.Tecnico@hypertherm.com (Technical Service Email)

Hypertherm Plasmatechnik GmbH

Sophie-Scholl-Platz 5

63452 Hanau

Germany

00 800 33 24 97 37 Tel

00 800 49 73 73 29 Fax

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emea@hypertherm.com (Technical Service Email)

Hypertherm (Singapore) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

Marketing.asia@hypertherm.com (Marketing Email)

TechSupportAPAC@hypertherm.com (Technical Service Email)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

HTJapan.info@hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com (Technical Service Email)

For training and education resources, go to the Hypertherm Cutting Institute (HCI) online at www.hypertherm.com/hci.

Hypertherm products are designed and manufactured with a commitment to continuous quality control and safety. Contact

a Hypertherm Technical Service Associate for information and support regarding the installation, operation, maintenance,

and repair of this equipment.

Contents

Warranty.............................................................................................................................. SC-11

Waterjet product warranty ........................................................................................................................ SC-12

Disclaimer ..................................................................................................................................................... SC-12

Product stewardship ......................................................................................................... SC-13

National and local safety regulations...................................................................................................... SC-14

Certification test marks.............................................................................................................................. SC-14

Differences in national standards............................................................................................................ SC-15

Higher-level systems .................................................................................................................................. SC-16

Environmental stewardship.............................................................................................. SC-17

Hypertherm products: waste and recycling.......................................................................................... SC-18

Chemical handling and usage.................................................................................................................. SC-19

Particle emission and waste water quality ............................................................................................ SC-20

Safety................................................................................................................................... SC-21

Manuals ......................................................................................................................................................... SC-22

User qualification and training.................................................................................................................. SC-23

Emergency medical information and treatment.................................................................................... SC-24

Safety information for operation, maintenance, repair, and installation .......................................... SC-25

Contents

Symbols and marks ........................................................................................................... SC-29

Information and symbols............................................................................................................................ SC-30

Symbols and marks found on the equipment....................................................................................... SC-31

1 Optional equipment ................................................................................................................. 35

2 Operation.................................................................................................................................... 37

Safety..................................................................................................................................................................... 38

About the controls .............................................................................................................................................. 38

Operation panel....................................................................................................................................... 38

Operator interface................................................................................................................................... 39

Turn on the pump: beginning of day ............................................................................................................... 41

Inspect the pump .................................................................................................................................... 41

Check the hydraulic fluid....................................................................................................................... 43

Turn on the utilities .................................................................................................................................. 44

Turn on the controls................................................................................................................................ 44

Start the pump......................................................................................................................................... 45

Do the preoperation maintenance checks......................................................................................... 46

Operate the pump............................................................................................................................................... 49

Select the pressure mode..................................................................................................................... 49

Set the target water pressure .............................................................................................................. 49

Stop the pump..................................................................................................................................................... 50

Stop the pump remotely ........................................................................................................................ 50

Stop the pump locally ............................................................................................................................ 50

Emergency stop....................................................................................................................................... 51

Turn off the pump: end of day .......................................................................................................................... 52

3 Preventive maintenance.......................................................................................................... 53

Safety..................................................................................................................................................................... 54

Benefits of preventive maintenance................................................................................................................ 55

Training .................................................................................................................................................................. 55

Operator interface: Maintenance screens..................................................................................................... 56

Move the plunger..................................................................................................................................... 56

Start the pump after maintenance....................................................................................................... 57

Prepare for storage................................................................................................................................. 57

Inputs and outputs .................................................................................................................................. 58

Alarm log ................................................................................................................................................... 58

Contents

Tools....................................................................................................................................................................... 59

Preventive maintenance schedule................................................................................................................... 60

Intensifier............................................................................................................................................................... 62

Repair the hydraulic center section .................................................................................................... 65

Repair the high-pressure cylinder, the check valve, and the low-pressure poppet ................ 66

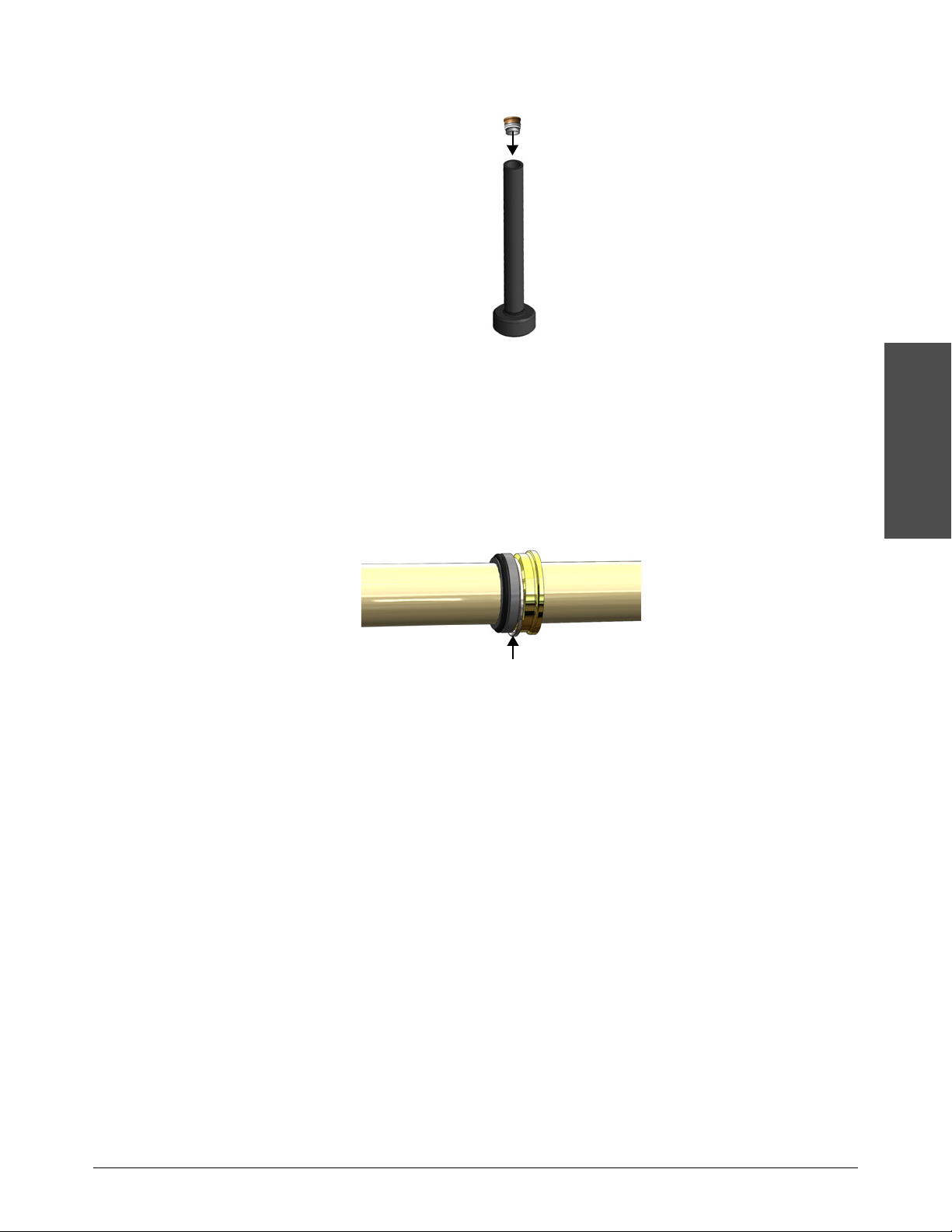

Install the high-pressure components................................................................................................ 69

Examine the output adapter and the high-pressure poppet assembly....................................... 73

Assemble the check valve and the low-pressure poppet.............................................................. 74

Repair the bleed-down valve............................................................................................................................ 75

Clean the air cooler ............................................................................................................................................ 78

Clean the air side of the cooler............................................................................................................ 78

Clean the hydraulic fluid side of the cooler....................................................................................... 79

Replace the water filter...................................................................................................................................... 80

Test the total dissolved solids (TDS) level .................................................................................................... 81

Test the water quality.............................................................................................................................. 83

Replace the hydraulic filter element................................................................................................................ 84

Add hydraulic fluid .................................................................................................................................. 85

Replace the hydraulic fluid................................................................................................................................ 86

Lubricate the primary motor bearings............................................................................................................. 88

Start the pump after maintenance................................................................................................................... 90

Postmaintenance start procedure ....................................................................................................... 91

Prepare for storage............................................................................................................................................. 93

Recycling and end of product life ................................................................................................................... 96

4 Parts lists................................................................................................................................... 97

Tools....................................................................................................................................................................... 98

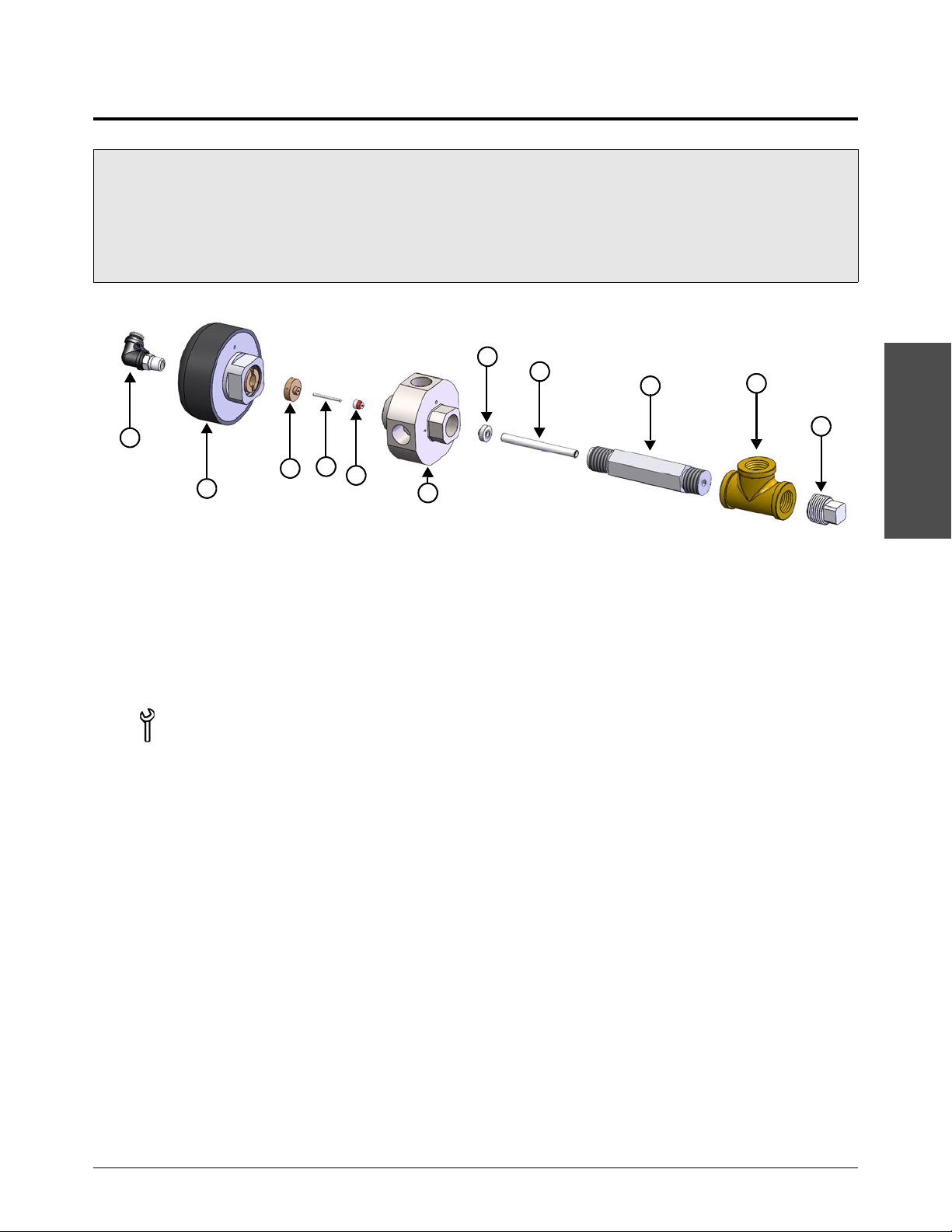

Intensifier repair tools............................................................................................................................. 99

Maintenance and repair kits............................................................................................................................ 100

Optional equipment kits................................................................................................................................... 103

Replacement parts........................................................................................................................................... 104

Lubricants .............................................................................................................................................. 104

Electrical system.................................................................................................................................... 105

High-pressure water system.............................................................................................................. 106

Low-pressure water system............................................................................................................... 108

Hydraulic system .................................................................................................................................. 109

Contents

5 Troubleshooting....................................................................................................................... 111

Safety.................................................................................................................................................................. 112

General............................................................................................................................................................... 112

Primary operation screen................................................................................................................................ 113

Alarms................................................................................................................................................................. 114

Types of alarms ..................................................................................................................................... 114

Primary motor.................................................................................................................................................... 117

Intensifier............................................................................................................................................................ 118

Leaks....................................................................................................................................................... 118

Overstroke ............................................................................................................................................. 121

Hydraulic fluid ................................................................................................................................................... 123

Temperature........................................................................................................................................... 124

Pressure ................................................................................................................................................. 125

Level ........................................................................................................................................................ 126

Appearance ........................................................................................................................................... 127

Water .................................................................................................................................................................. 128

Low-pressure water............................................................................................................................. 128

High-pressure water............................................................................................................................ 129

Leaks....................................................................................................................................................... 131

The pump makes noise during operation ................................................................................................... 133

Controller errors ............................................................................................................................................... 134

Input/output status............................................................................................................................... 134

6 Specifications.......................................................................................................................... 135

All Echion-model pumps ................................................................................................................................ 136

Environmental conditions ................................................................................................................... 136

Hydraulic fluid ....................................................................................................................................... 136

Utilities .................................................................................................................................................... 137

Echion 15........................................................................................................................................................... 138

Dimensions and weights .................................................................................................................... 138

Electrical................................................................................................................................................. 138

Water....................................................................................................................................................... 138

Echion 30........................................................................................................................................................... 139

Dimensions and weights .................................................................................................................... 139

Electrical................................................................................................................................................. 139

Water....................................................................................................................................................... 139

Echion 50........................................................................................................................................................... 140

Dimensions and weights .................................................................................................................... 140

Electrical................................................................................................................................................. 140

Water....................................................................................................................................................... 140

Contents

Orifices ............................................................................................................................................................... 141

Stroke rate ......................................................................................................................................................... 141

Torque values .................................................................................................................................................... 142

Fasteners................................................................................................................................................ 142

Fittings .................................................................................................................................................... 144

7 Installation............................................................................................................................... 147

Safety.................................................................................................................................................................. 148

Buyer responsibilities ...................................................................................................................................... 148

Requirements.................................................................................................................................................... 149

Location.................................................................................................................................................. 149

Cooling ................................................................................................................................................... 149

Hydraulic fluid ....................................................................................................................................... 149

Utilities .................................................................................................................................................... 150

Receive and unpack the equipment ............................................................................................................ 151

Install the pump ................................................................................................................................................ 152

Install the pump-mounted plumbing kit (optional) ........................................................................ 153

Connect the utilities to the pump................................................................................................................. 156

Connect the water and the air........................................................................................................... 157

Connect the electrical power ............................................................................................................ 158

Check the hydraulic fluid................................................................................................................................ 159

Do the first start................................................................................................................................................ 159

Do a preoperation inspection............................................................................................................ 160

Turn on the utilities............................................................................................................................... 160

Make sure that the primary motor turns in the correct direction ............................................... 161

Turn on the pump ................................................................................................................................. 162

Adjust the boost pump pressure ...................................................................................................... 162

Flush the pump and the high-pressure tubing .............................................................................. 163

Operator interface: Adjustment screens .................................................................................................... 164

Pump Adjustments............................................................................................................................... 164

Pressure ................................................................................................................................................. 169

Date / Time / Language...................................................................................................................... 169

Intensifier Control................................................................................................................................. 170

SD Card ................................................................................................................................................. 171

8 Declaration of Conformity ......................................................................................................173

Contents

9 Touchscreen maps.................................................................................................................. 175

Primary operation screen................................................................................................................................ 177

Adjustment screens......................................................................................................................................... 181

Maintenance screens ...................................................................................................................................... 185

10 Technical drawings................................................................................................................. 189

Warranty

Warranty

Echion Operator Manual 810770 SC-11

Warranty

Warranty

Waterjet product warranty

Product Warranty coverage up to

Echion™ pump

HyPrecision™ pump

PowerDredge™ abrasive removal system

EcoSift™ abrasive recycling system

Reverse osmosis system

Bulk abrasive pot

Abrasive regulator

On/off valve air actuator

Diamond orifice

27 months from the ship date,

or 24 months from the date of proven installation,

or 4,000 hours of operation, whichever occurs first

15 months from the ship date,

or 12 months from the date of proven installation,

whichever occurs first

600 hours of operation with the use of a thimble filter

and compliance with Hypertherm’s water quality

requirements

Hypertherm’s warranty does not extend to defects, failures, damages, deficiencies, or errors that

are:

not reported to Hypertherm within the warranty period; or

the result of modification, abuse, misuse, noncompliance with the installation or operation

instructions, unauthorized repair, inadequate maintenance, neglect, accident, or the use of

unapproved parts; or

the result of normal wear; or

the result of the system being operated contrary to Hypertherm’s instructions or stated limits

For information about the manufacturer’s warranty, refer to the conditions of sale provided when the

product was purchased.

Consumable parts are not included in this warranty. Consumable parts include high-pressure water

seals, check valves, cylinders, bleed-down valves, low-pressure seals, high-pressure tubing, and

filters.

All third-party motors, pumps, and plumbing accessories are warrantied by the respective

manufacturers and are not included in this warranty.

Disclaimer

All product information contained in this manual is believed to be reliable as of the date of

publication. The manual could contain technical inaccuracies or typographical errors and can be

changed or updated without notice.

of rated and normal use.

SC-12 810770 Operator Manual Echion

Product stewardship

Product stewardship

Hypertherm maintains a global regulatory management system to make sure that products comply

with regulatory and environmental requirements.

Echion Operator Manual 810770 SC-13

Product stewardship

Product stewardship

National and local safety regulations

National and local safety regulations shall take precedence over instructions supplied with the

product. The product shall be imported, installed, operated, and discarded in compliance with

national and local regulations applicable to the installation site.

Certification test marks

Certified products are identified by 1 or more certification test marks from accredited testing

laboratories.

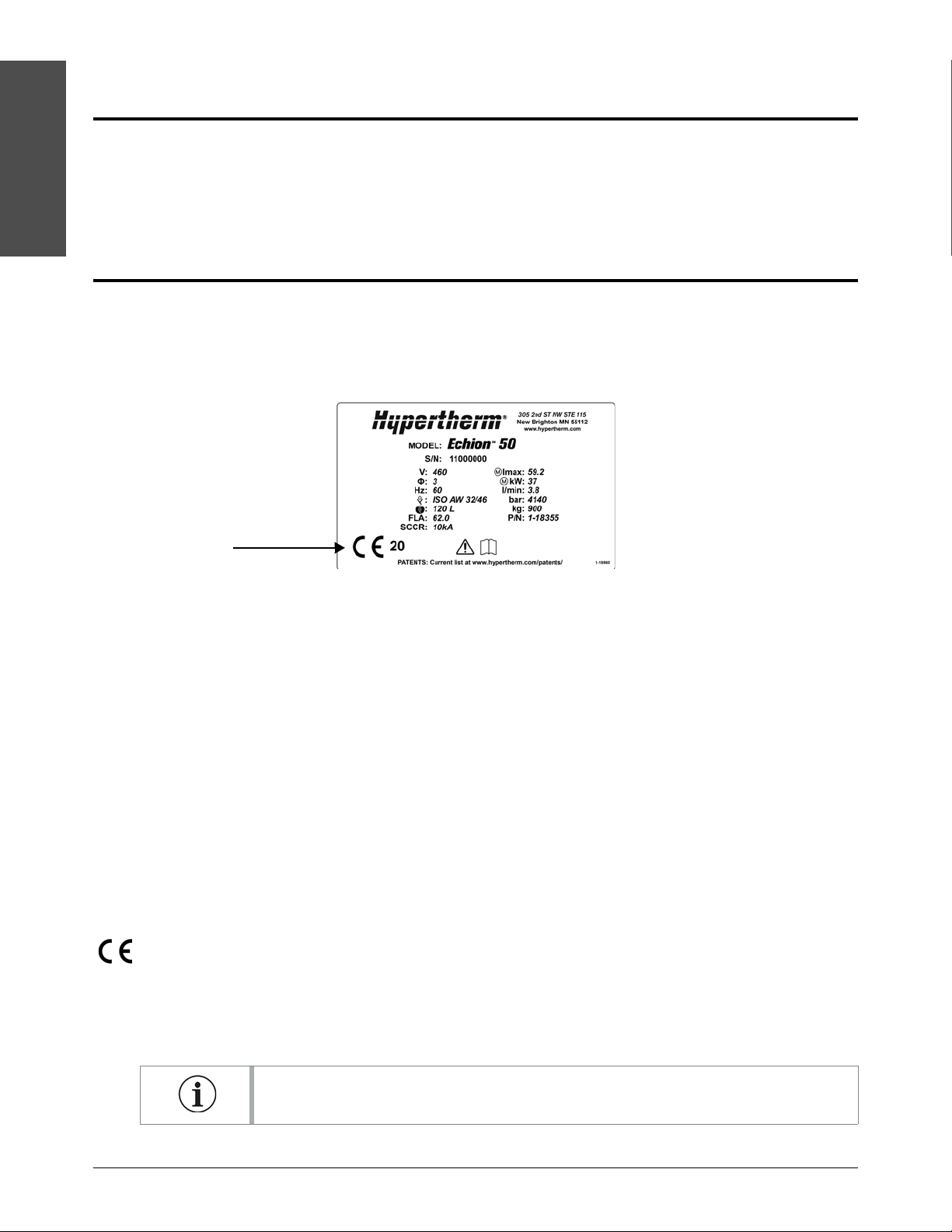

The certification test marks are on the pump’s data plate.

Each certification test mark means that the product and its safety-critical parts conform to the

national safety standards as reviewed and determined by that testing laboratory.

Hypertherm puts a certification test mark on its products only after that product is manufactured

with safety-critical parts that have been approved by the accredited testing laboratory.

Once the product has left the Hypertherm factory, the certification test marks are invalid if one or

more of these events occurs.

The product is modified in a manner that causes danger or does not conform with the

applicable standards.

Safety-critical parts are replaced with unapproved spare parts.

Assembly is unauthorized.

An accessory that uses or generates dangerous voltage is added.

A safety circuit or other feature that is designed into the product as part of the certification

has been tampered with.

The Conformité Européene (CE) mark affixed to a product signifies the manufacturer’s declaration

of conformity to applicable European directives and standards.

Only those versions of Hypertherm products with a CE mark on or near the data plate have been

tested for compliance with the applicable European directives, such as the Low Voltage Directive,

the Electromagnetic Compatibility Directive, and the Machinery Directive.

If this product has a Declaration of Conformity, a copy (in English) is included. Refer to

Declaration of Conformity on page 173.

SC-14 810770 Operator Manual Echion

Product stewardship

Differences in national standards

Nations can apply different performance, safety, or other standards. National differences in

standards include, but are not limited to:

voltage.

plug and cord ratings.

language requirements.

electromagnetic compatibility requirements.

Differences in national or other standards can make it impractical or impossible for all certification

test marks to be put on the same version of a product. For example, the Canadian Standards

Association (CSA) versions of Hypertherm’s products do not comply with European

electromagnetic compatibility requirements; therefore, they do not have a CE mark on the data

plate.

Countries where the CE mark in necessary or that have compulsory electromagnetic compatibility

regulations must use CE versions of Hypertherm products with the CE mark on the data plate.

Product stewardship

These could include:

countries in the European Union.

Australia.

New Zealand.

Russia.

It is important that the product and its certification test mark be suitable for the end-use installation

site. When Hypertherm products are shipped to one country for export to a different country, the

product must be correctly configured and certified for the end-use installation site.

Echion Operator Manual 810770 SC-15

Product stewardship

Product stewardship

Higher-level systems

When an original equipment manufacturer (OEM) or a system integrator adds equipment such as

cutting tables, motor drives, motion controllers, or robots to a Hypertherm waterjet cutting system,

the system is considered a higher-level system. A higher-level system with dangerous moving parts

can constitute industrial machinery or robotic equipment, in which case the OEM, system integrator,

or end-use customer can be subject to more regulations and standards than those applicable to the

waterjet cutting system manufactured by Hypertherm.

It is the responsibility of the end-use customer and the OEM or system integrator to do a risk

assessment for the higher-level system and to provide protection against dangerous moving parts.

Unless the higher-level system is certified when the OEM or system integrator incorporates

Hypertherm products into it, the installation can be subject to approval by local authorities. Get

advice from legal counsel and local regulatory experts if you are not sure about compliance.

External cables connecting parts of the higher-level system must be made for exposure to

contamination and movement as necessary for the end-use installation site. When the external

interconnecting cables are subject to exposure to oil, dust, water, or other contamination, hard

usage ratings could be necessary.

When external interconnecting cables are subject to continuous movement, constant flexing ratings

can be necessary. It is the responsibility of the OEM, system integrator, or end-use customer to

make sure that external connecting cables are correct for the application and obey all national, state,

and local regulations.

SC-16 810770 Operator Manual Echion

Environmental stewardship

Environmental stewardship

Echion Operator Manual 810770 SC-17

Environmental stewardship

Environmental stewardship

Hypertherm products: waste and recycling

Hypertherm waterjet cutting systems, like all products with electronics, can contain materials or

parts, such as printed circuit boards, that cannot be discarded with ordinary waste. It is your

responsibility to discard Hypertherm products or parts in an environmentally suitable manner and in

compliance with national and local codes.

In the United States, read all national, state, and local laws. In the European Union (EU), read the EU

directives, national, and local laws. In other countries, refer to national and local laws. Consult with

legal or other compliance experts, when applicable. For information, go to

www.hypertherm.com/customer-support/product-service/recycling.

SC-18 810770 Operator Manual Echion

Environmental stewardship

Chemical handling and usage

Material safety data sheets (MSDS) and safety data sheets (SDS) are part of a hazard

communication plan that supplies detailed information about dangerous chemicals. The information

includes the chemical’s toxicity and reactivity, first aid for exposure, approved storage and disposal,

recommended protective equipment, and spill-handling procedures.

The Occupational Safety and Health Administration (OSHA) has presented new dangerous

chemical labeling requirements as a part of its recent revision of the Hazard Communication

Standard (29 CFR 1910.1200), to align with the United Nations’ Globally Harmonized System of

Classification and Labelling of Chemicals (GHS). The GHS is an international system for

standardizing chemical classification and labeling.

Chemical regulations in the USA, Europe, and other locations require that MSDS and SDS be

made available for chemicals that are supplied with the product and chemicals used in or on the

product. The list of chemicals is supplied by Hypertherm.

To see M S D S a nd S D S:

1. Go to www.hypertherm.com/docs.

Environmental stewardship

2. Look for “To view all regulatory and compliance documents, click here” below the Select your

product box.

3. Look for Safety Data Sheets. Click +.

These navigation instructions can change without notice.

Echion Operator Manual 810770 SC-19

Environmental stewardship

Environmental stewardship

Particle emission and waste water quality

Hypertherm does not manufacture or supply the materials that are cut and has no knowledge about

the particles released from materials that are cut and if they can pose a physical danger or health

risk. Get advice from your supplier or other technical advisor for guidance concerning the properties

of the material you cut with a Hypertherm product.

If you are not familiar with the current applicable government regulations and legal standards for the

installation site, get advice from a local expert before you purchase, install, and operate this

equipment.

SC-20 810770 Operator Manual Echion

Safety

The end user is responsible for the safe operation of this equipment.

Safety

WAR NING

Before operating Hypertherm equipment, read the safety instructions in your product's

manual.

Echion Operator Manual 810770 SC-21

Safety

Safety

Manuals

Copies of Hypertherm manuals can accompany the product in electronic and printed formats.

Copies of the manuals are online, in all languages available for each manual.

1. Go to www.hypertherm.com/docs.

2. Under Select your product, choose Waterjet Family in the dropdown list.

3. Go to the Operator and instruction manuals section and click +.

4. Click on the manual for your product. You may have to click on SHOW ALL at the bottom of the

section.

A PDF of the manual downloads to your device.

These navigation instructions can change without notice.

The safety precautions in this manual are general and cannot anticipate every situation. Hypertherm,

Inc. acknowledges that unforeseen situations such as equipment failure, site variability, insufficient

maintenance, failure of control equipment, and other events can cause equipment damage, injuries,

or death. It is the user’s responsibility to identify dangers and to take the steps necessary to

minimize risks.

Keep these instructions near the equipment. This manual is intended to familiarize the user with the

equipment and its parts, safe operation, and maintenance.

All personnel who operate or have access to this equipment must know this information:

applicable safety standards.

the use, limitations, and maintenance of personal protective equipment.

the location of the written hazard communication program and safety data sheets.

how to recognize dangerous energy sources.

the correct methods for isolating and controlling energy, to include lock out–tag out

procedures.

SC-22 810770 Operator Manual Echion

Safety

User qualification and training

All users must read and understand these instructions before installing, operating, or doing

maintenance on this equipment.

Do not let an untrained person operate this equipment. Operators must be approved to operate and

maintain this equipment.

Training should include:

how to start and stop the equipment during operation and in an emergency situation.

conditions and procedures that can lead to injuries to personnel and damage to the

equipment.

how to operate all controls.

how to identify and respond to a problem with the equipment.

how to do maintenance procedures.

a copy of the operator manual.

Safety

This list is not all-inclusive.

Echion Operator Manual 810770 SC-23

Safety

Safety

Emergency medical information and treatment

WAR NING

A waterjet is a cutting tool.

Keep away from high-pressure streams and leaks. Pressurized fluid can cause injuries.

Delayed treatment can cause injuries or death.

WAR NING

Do not put ice or heat on a waterjet injury.

If possible, use a support to keep injured body parts above heart level.

High-pressure equipment puts the operator and other personnel at risk of contact with

high-pressure water. Possible injuries include eye damage, lacerations, infections, and amputations.

Waterjet operators should have a waterproof emergency medical tag or card that describes the

recommended treatment for high-pressure water injuries. Show the tag or card to emergency

responders and medical professionals.

This wallet-size card can be copied, laminated, and folded.

injuries.

high-pressure waterjet

immediately for all

Get medical treatment

emergency.

injury is a surgical

A high-pressure injection

INFORMATION

MEDICAL

The person with this card has been exposed to a waterjet

of up to4,140bar(60,000psi) and a velocity

of609m/s(2,000feet/second). Abrasive waterjets can

eject water and abrasive materials that can be injected into

body tissues, leading to a dangerous infection.

Skin can appear to be not damaged or show a small

pinhole-sized puncture wound.

The injured area can become swollen, painful, and pale

over the next4to6hours.

Tissue becomes ischemic and necrotic within12hours.

Do not use digital or local nerve blocks.

Give analgesics by mouth or injection.

SC-24 810770 Operator Manual Echion

Consult a surgical specialist immediately for

decompression, removal of foreign materials, and

debridement.

Give broad-spectrum, intravenous antibiotics for

Gram-negative and Gram-positive organisms.

X-ray is the preferred imaging method.

Acute compartment syndrome is possible.

Leave the wound open.

Do not use solvents other than isotonic sodium chloride

solution for irrigating the wound.

Safety

Safety information for operation, maintenance, repair, and installation

Before opening the electrical enclosure or doing maintenance or repairs on this equipment, turn

DANG ER

OFF the electrical power and release water pressure and hydraulic pressure from the system.

Use standard lock out-tag out procedures.

Isolate all sources of electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other

energy with a lockable energy-isolating device that satisfies national and local requirements.

Safety

WAR NING

WAR NING

WAR NING

WAR NING

WAR NING

WAR NING

Make sure that all connections, fasteners, locking devices, hoses, and fittings are tight before

operation.

Make sure that the shaft access cover and all other safety devices are correctly installed before

operating this machine.

Do not stand in line with high-pressure fittings when operating this equipment.

If a high-pressure fitting fails, it can cause a stream of water or hydraulic fluid to eject from the

system with force.

Do not leave waterjet cutting equipment unattended while it is operating.

During operation, keep a restricted-access area clear that is larger than the maximum movement

range of the cutting equipment’s moving parts.

Let only approved personnel operate this machinery.

WAR NING

WAR NING

WAR NING

Echion Operator Manual 810770 SC-25

Release all high-pressure water before doing work on this equipment.

Do not touch a hot surface.

Water leaking from a high-pressure fitting or the bleed-down valve can be hot.

Obey all safety requirements and applicable safety laws and regulations.

Obey national and local codes regarding installation, repairs, and maintenance of the electrical

and plumbing systems.

All work that requires opening the electrical enclosure or removing covers or panels from this

equipment must be done only by an approved technician.

It is your responsibility to investigate and obey all local codes.

Safety

Safety

WAR NING

WAR NING

WAR NING

WAR NING

A person who works on deenergized machinery can be injured or killed if the machinery is

energized without permission.

All personnel in an area where energy-control procedures are used must receive training for

energy-control procedures.

DANGEROUS VOLTAGE/RISK OF SHOCK

Doing work on this equipment while it is energized is dangerous.

Personnel who maintain and repair this equipment can be injured or killed if dangerous energy is

not controlled.

Injuries can include burns, cuts, fractures, or electrocution.

Before removing a lock-out device:

obey the employer’s energy-control procedure.

examine machines and parts to make sure that they are operational.

make sure that all personnel are safely away from machines.

After removing energy-isolation devices, make sure that all personnel in the area know that the

devices are removed and that the machine is being energized.

To reduce the risk of injuries or death, wear approved protection and obey safety

recommendations when doing work with electricity.

WAR NING

WAR NING

WAR NING

WAR NING

WAR NING

When work must be done in a small space or an area with limited access, the access must not

be blocked by ventilation ducts, hoses, pipes, or other equipment.

Do not block or remove warnings, cautions, or instructions.

Personal protective equipment is recommended.

If you do not use personal protective equipment, there is a risk of injury or death.

High-pressure water can cause eye injuries.

Wear approved eye protection when operating or doing work near this equipment.

This waterjet equipment could make more noise than is permitted by national or local codes.

When this intensifier is operating, the noise level is75dB(A) to85dB(A).

Water flow rate, pipe layout, and the acoustical characteristics of the building have an effect on

noise level.

Long periods of exposure to noise can cause permanent hearing loss.

Wear approved ear protection and control exposure time when operating or doing work near this

equipment.

SC-26 810770 Operator Manual Echion

Safety

Safety

WAR NING

WAR NING

CAUTION

High-pressure water can cause cuts, abrasions, and punctures.

Precision parts can have sharp corners or edges.

Wear approved hand protection when operating or doing work near this equipment and when

touching parts.

Some materials can cause airborne contamination or particles when cut.

Wear approved respiratory protection when operating or doing work near this equipment.

Examine and clean the equipment regularly.

Refer to the Preventive maintenance schedule on page 60.

Do repairs immediately.

Echion Operator Manual 810770 SC-27

Safety

Safety

SC-28 810770 Operator Manual Echion

Symbols and marks

Symbols and marks

Echion Operator Manual 810770 SC-29

Symbols and marks

Symbols and marks

Information and symbols

Some symbols in this table could apply to other products.

DANGER

WAR NING

CAUTION

NOTICE

DANGER identifies an imminently dangerous condition or a situation that WILL cause

serious injuries or death if ignored.

WARNING identifies a dangerous condition or a situation that COULD cause injuries or

death if ignored.

CAUTION, when used with the yellow warning sign, identifies a dangerous condition or a

situation that COULD cause minor or moderate injuries or WILL cause damage to the

equipment if ignored.

NOTICE identifies a condition or a situation that COULD cause damage to the

equipment if ignored.

This symbol identifies a mandatory action.

This symbol identifies a prohibited action.

This symbol identifies tools or materials that are necessary or recommended for a

procedure.

This symbol identifies information that could cause the user to fail at the task if ignored.

This symbol identifies a tip or helpful information.

SC-30 810770 Operator Manual Echion

Symbols and marks

Symbols and marks found on the equipment

Some symbols or marks in this table could apply to other Hypertherm products.

Symbols and marks

DANGER

DANGER ARC FLASH AND SHOCK HAZARD

WAR NING

WAR NING

WAR NING

DANGER identifies an imminently dangerous condition or a situation that WILL cause

serious injuries or death if ignored.

Follow all requirements inNFPA70E for safe work practices and for Personal Protective

Equipment.

WARNING identifies a dangerous condition or a situation that COULD cause injuries or

death if ignored.

HAZARDOUS VOLTAGE

Disconnect power before servicing.

WAR NING

This product can expose you to chemicals including lead and lead compounds, which are

known to the State of California to cause cancer and birth defects or other reproductive

harm.

For more information go to www.p65warnings.ca.gov.

WAR NING

CAUTION

CAUTION

S/N

V

Hydraulic, water, and electrical connections can come loose during shipping and normal

operation.

It is recommended that all connections are checked at installation and annually.

CAUTION, when used with the yellow warning sign, identifies a dangerous condition or a

situation that COULD cause minor or moderate injuries or WILL cause damage to the

equipment if ignored.

Do not touch a hot surface.

Read and fully understand operator’s manual before using this machine.

Failure to follow operating instructions could result in death or serious injury.

Correct direction of motor rotation (motor rotation arrow)

Serial number

Volts

Echion Operator Manual 810770 SC-31

Symbols and marks

Symbols and marks

Φ

HZ

FLA

SCCR

IMAX

KW

L/MIN

BAR

KG

Number of phases in a power system

Frequency (hertz)

Type of hydraulic fluid recommended

Hydraulic fluid tank volume (liters)

Full-load current (amperage)

Short-circuit current rating

Primary motor maximum current draw (amperes)

Primary motor power output (kilowatts)

Maximum outlet flow rate (liters/minute)

Maximum outlet water pressure (bar)

Weight (kilograms)

P/N

Electrical enclosure part number

The Conformité Européene (CE) mark affixed to a product signifies the manufacturer’s

declaration of conformity to applicable European directives and standards.

Only those versions of Hypertherm products with a CE mark on or near the data plate

have been tested for compliance with the applicable European directives, such as the

Low Voltage Directive, the Electromagnetic Compatibility Directive, and the Machinery

Directive.

Use caution when operating this equipment.

Refer to the instruction manual. Read and understand all of the safety guidelines in this

manual.

Identifies the terminal of a protective earth (ground) electrode or a terminal intended to

connect to an external conductor for protection against electric shock during a fault

condition

Controls

Remote key switch off

The key switch is in the Local position.

SC-32 810770 Operator Manual Echion

Remote key switch on

The key switch is in the Remote position.

Symbols and marks

Symbols and marks

COMPRESSED AIR

The bleed-down valve uses compressed air to operate.

CUTTING WATER IN

This line carries low-pressure water from a water softener, a reverse osmosis system, a

well, or a public utility to the pump.

CUTTING WATER OUT

This tubing carries high-pressure water from the intensifier to the cutting table.

WASTE WATER OUT

This hose carries water from the bleed-down valve to a drain.

COOLING IN

This line carries low-pressure water from the local utility or a chiller to the pump’s cooling

loop.

COOLING OUT

This line carries low-pressure water from the heat exchanger to the chiller or to the drain.

Start the pump symbol

Stop the pump symbol

Echion Operator Manual 810770 SC-33

Symbols and marks

Symbols and marks

SC-34 810770 Operator Manual Echion

Optional equipment

Optional equipment

Boost pump

The pump will not operate satisfactorily if the supply water pressure is too low for the pump to get to

stable pressure. A boost pump increases the water pressure to a value higher than the minimum

requirement.

Modbus TCP/IP communication

All Hypertherm waterjet pumps can use Ethernet to communicate with a CNC.

Utility connection panel kit

The utility connections for the Echion pump are inside the pump, at the point of use. With this kit,

utility connections are made on the outside of the pump.

Metric conversion kit

This kit includes adapter fittings for use in countries where metric connections are standard.

Pump-mounted high-pressure plumbing kit

This kit includes a bracket and a high-pressure tube to connect a high-pressure line directly to the

pump.

For part numbers, refer to Optional equipment kits on page 103.

Echion Operator Manual 810770 35

Optional equipment

1

Optional equipment

36 810770 Operator Manual Echion

Operation

Operation

This section assumes that the user is familiar with the Safety, Preventive maintenance,

Troubleshooting, and Specifications sections of this manual.

Images in this manual are for reference purposes. It is possible that your product configuration is

not shown accurately.

It is possible that not all of the information in this section applies to all pump models.

Echion Operator Manual 810770 37

2

Operation

Safety

1

2

3

4

1 Controls button

Push this button to turn

ON the control circuit in

the pump. The button lights when the control

circuit is on.

2 Local/Remote key switch

When the key switch is in the Local

position, use the operator interface to

operate the pump.

When the key switch is in the Remote

position, use the remote source, such as a

computer numerical control (CNC)

operator console, to controls the pump.

Most functions on the operator interface are not

available when the key switch is in the Remote

position.

3 EMERGENCY STOP button

Push this button to turn off the control circuit.

Refer to Emergency stop on page 51.

4 Remote indicator light

When the key switch is in the Remote position, this

indicator light is on.

Operation

WARNING

Read and understand all of the safety guidelines in this manual.

Refer to Safety on page 21 before operating, doing maintenance on, repairing, and installing

your pump.

About the controls

Operation panel

38 810770 Operator Manual Echion

2

Operation

Operator interface

1

2

5

3 4

1 Hour meter

This shows the total hours the pump motor has

been in operation.

2 Primary operation screen tab

• Turn the pump on or off.

• Select the pressure mode (cut or pierce).

• Set or change the water pressure.

• Monitor the status of the intensifier.

3 Operator interface: Adjustment screens tab

• See information about your system.

• Change some display options, such as

pressure units (bar or psi) or language.

• Change timer durations.

• Turn features such as Modbus mode on or

off.

Refer to Operator interface: Adjustment screens

on page 164.

4 Operator interface: Maintenance screens tab

• Move the plunger to one end of the

intensifier.

• Prepare the pump for storage.

• See the alarm log.

• See the inputs-outputs from the controller.

Refer to Operator interface: Maintenance

screens on page 56.

5 Date and time

Refer to Date / Time / Language on page 169.

Refer to Touchscreen maps on page 175 to see all of the screens available on the controller.

Primary operation screen

These elements are on most screens.

Operation

Echion Operator Manual 810770 39

Operation

2

Operation

6

7

8

12

11

9 10

6Stop

Touch this symbol to stop the pump.

7Start

Touch this symbol to start the pump.

8 LED light on/off

Touch this symbol to turn the red LED lights

ON

or

OFF.

9 Pierce-pressure mode (off)

Touch this symbol to put the pump in

pierce-pressure mode.

10 Cut-pressure mode (on)

Touch this symbol to put the pump in

cut-pressure mode.

Cut-pressure mode is active in this

image.

Refer to Select the pressure mode on page 49

for information about pressure modes.

11 Target water pressure

12 Output water pressure

This shows the actual water pressure when the

pump is operating.

This is the target water pressure set by the user.

Refer to Set the target water pressure on

page 49.

3

2

1

1 Intensifier status indicator

Enabled (green)

Not enabled (red)

2 Intensifier stroke rate to the left

3 Intensifier stroke rate to the right

The stroke rate is within the permitted

range (green).

The stroke rate is at the limit of the

permitted range (yellow).

The intensifier is overstroking (red).

Intensifier status indicator and stroke-rate bars

The stroke-rate bars show the speed of the piston moving to each side of the intensifier.

40 810770 Operator Manual Echion

Refer to Primary operation screen on page 113 for more information.

2

Operation

Turn on the pump: beginning of day

2

1

1

2

2

1

2

1

1

2

Follow this procedure when starting the pump for the first time each day or at the beginning of each

work shift. Daily preventive maintenance tasks are included in these instructions.

Inspect the pump

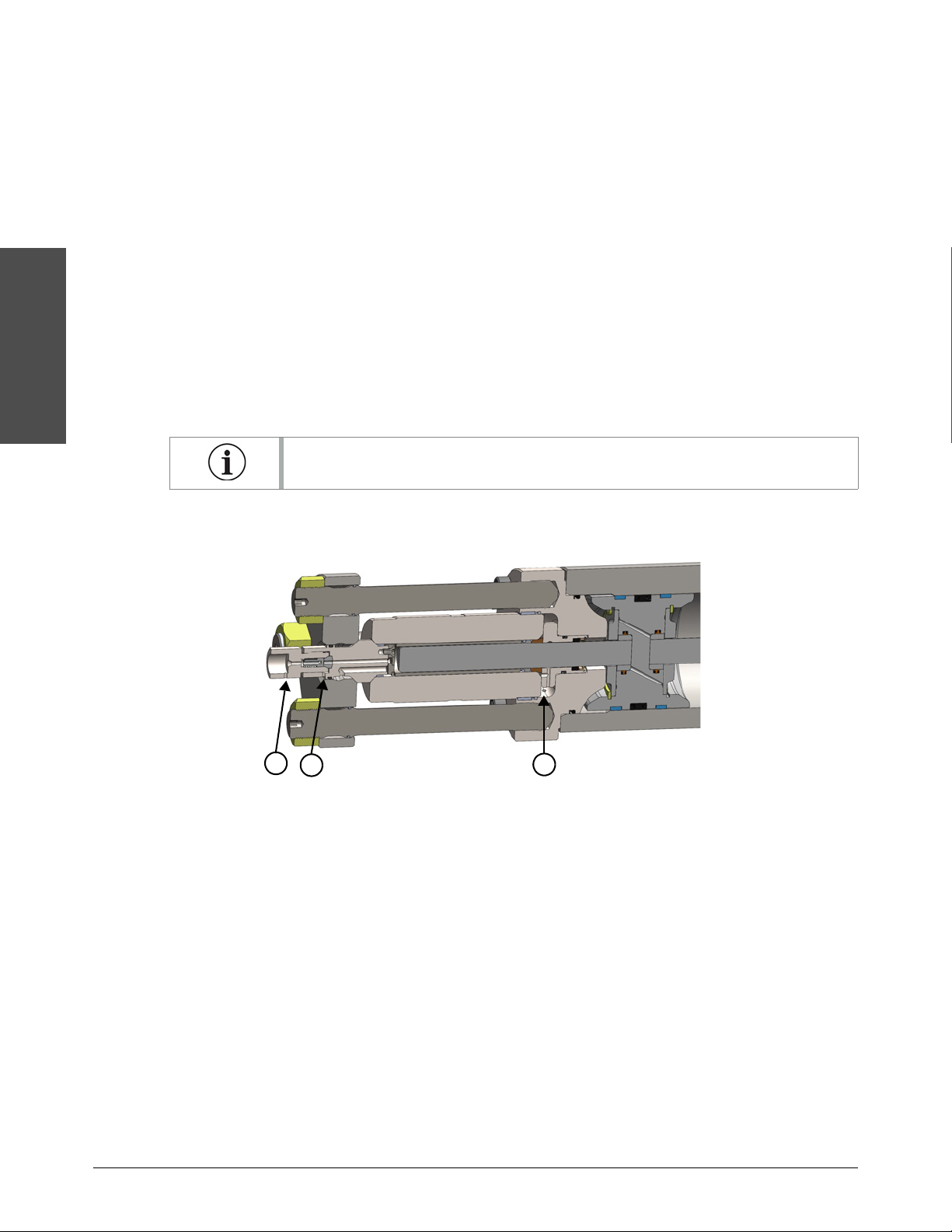

Unless otherwise recommended, install the top cover and the front panel before operating the

pump.

1. Remove the top cover.

Operation

a. Use a standard screwdriver to turn the bolt on each end counterclockwise1/4 turn.

b. Lift the cover off of the alignment pins .

2. Remove the front panel.

Push down on the horizontal surface on top of the panel to release the retainers tabs from the

frame .

Echion Operator Manual 810770 41

Operation

2

Operation

1

2

4

1

2

4

3

3

3. Clean all debris, water, and hydraulic fluid off of the hydraulic fluid tank , the intensifier

bridge , and the bottom deck .

4. Empty the dirty water container , if necessary.

Refer to local regulations regarding waste water. Environmental rules can apply to

disposal.

5. Clean the operator interface, if necessary.

To prevent damage to the operator interface:

do not use cleaners that contain alcohol, ammonia, acetone, phosphates, or

ethylene glycol.

do not push hard on the touchscreen.

do not use paper towels, abrasive cloth, or dirty rags.

do not put liquid directly onto the touchscreen.

Gently wipe the touchscreen and keys with a clean microfiber cloth.

Use a cleaner made for touchscreens or use a1:1 solution of distilled water and white

vinegar.

6. Examine electrical cords and cables for kinks or damage to the insulation. Examine electrical

plugs and other electrical connections for corrosion or damage.

7. Look for leaks, deterioration, damage, or other conditions that can interfere with operation.

8. Make sure that all connections, fasteners, locking devices, hoses, and fittings are tight.

9. Make sure that all warning decals are visible and legible.

Contact Hypertherm for replacement decals.

42 810770 Operator Manual Echion

2

Operation

Check the hydraulic fluid

Replace the hydraulic fluid:

• every 3,000 hours.

• if it is dark or milky in color.

• if it has a strong odor.

• if a test laboratory finds the quality is unsatisfactory.

Refer to Replace the hydraulic fluid on page 86.

Operation

CAUTION

Heat and other conditions cause hydraulic fluid to degrade. Degraded hydraulic fluid can

cause damage to hydraulic components.

Collect a sample of hydraulic fluid from the hydraulic fluid tank and send it to a test

laboratory for analysis.

Refer to Hydraulic fluid on page 136 for recommended limits.

Contact a hydraulic fluid supplier for a precise report about your hydraulic fluid quality.

Do this task when the pump is not operating.

1. Look through the sight gauge to see the color of the hydraulic fluid. Good hydraulic fluid is

almost transparent.

2. Remove the filler cap.

3. Smell the hydraulic fluid. Good hydraulic fluid has almost no odor.

4. Install the filler cap.

Echion Operator Manual 810770 43

Operation

2

Operation

12324

Turn on the utilities

1. Tu rn ON the water to the pump.

2. Tu rn

3. Tu rn

ON the compressed air source.

ON the electrical main (line disconnect switch).

4. Turn the primary breaker disconnect lever on the electrical enclosure door to

Turn on the controls

Turn on the controls remotely

Refer to the OEM’s instructions for starting the pump and for operating the pump from a

remote source.

ON.

1. Make sure that the EMERGENCY STOP is not engaged. If the button is pushed in, turn the

button clockwise until it releases.

2. Make sure that the key switch is set to Local .

3. Push the Controls button .

4. Turn the key switch to Remote . The remote indicator light is on .

44 810770 Operator Manual Echion

2

Operation

Turn on the controls locally

3

2

1

123

1

1

1. Make sure that the EMERGENCY STOP is not engaged. If the button is pushed in, turn the

button clockwise until it releases.

2. Make sure that the key switch is set to Local .

3. Push the Controls button .

Start the pump

Operation

Use the Postmaintenance start procedure on page 91 if maintenance or repairs have been done

CAUTION

on:

• the high-pressure water system.

• intensifier components.

• the primary motor.

1. On the operator interface, touch the symbol.

The controller starts the pump.

A progress bar shows below the intensifier on the screen.

The normal start sequence is fully automated. Refer to Primary operation screen on page 177 for

a description of the sequence.

Monitor for leaks.

2. When the start sequence is complete, complete the Daily preventive maintenance tasks. Refer

to the Preventive maintenance schedule on page 60.

Echion Operator Manual 810770 45

Operation

2

Operation

1

2

3

1

Output adapter leak

2

High-pressure seat leak

3

Dynamic seal leak

Do the preoperation maintenance checks

Examine the pump for leaks or damage

Do this task when the pump is operating and the system is pressurized.

1. Look for hydraulic fluid leaks. Monitor these areas.

Hydraulic connections

Valves

Intensifier bridge and bottom deck

2. Examine the low-pressure tubes and the hoses for leaks.

3. Examine the bleed-down valve for leaks or damage.

A hot bleed-down valve can suggest that there is a leak.

4. Examine the weep holes in the high-pressure ends for leaks. Water leaking from a weep hole is

a sign of a faulty part or a loose connection.

5. Examine the high-pressure tubing for leaks.

6. Look for deterioration, damage, or other problems.

46 810770 Operator Manual Echion

2

Operation

Check the hydraulic fluid level

Do this task when the pump is operating.

Make sure that the hydraulic fluid level is at the top mark on the sight gauge.

Add hydraulic fluid, if necessary. Refer to Add hydraulic fluid on page 85 for instructions.

Check the hydraulic filter gauge

Operation

Replace the hydraulic filter element:

• every 1,500 hours.

• when the needle on the gauge stays in the red zone while the pump is operating.

Refer to Replace the hydraulic filter element on page 84.

Do this task when the pump is operating at a stable temperature.

Make sure that the needle on the hydraulic gauge is not in the red zone.

Echion Operator Manual 810770 47

Operation

2

Operation

1

2

1

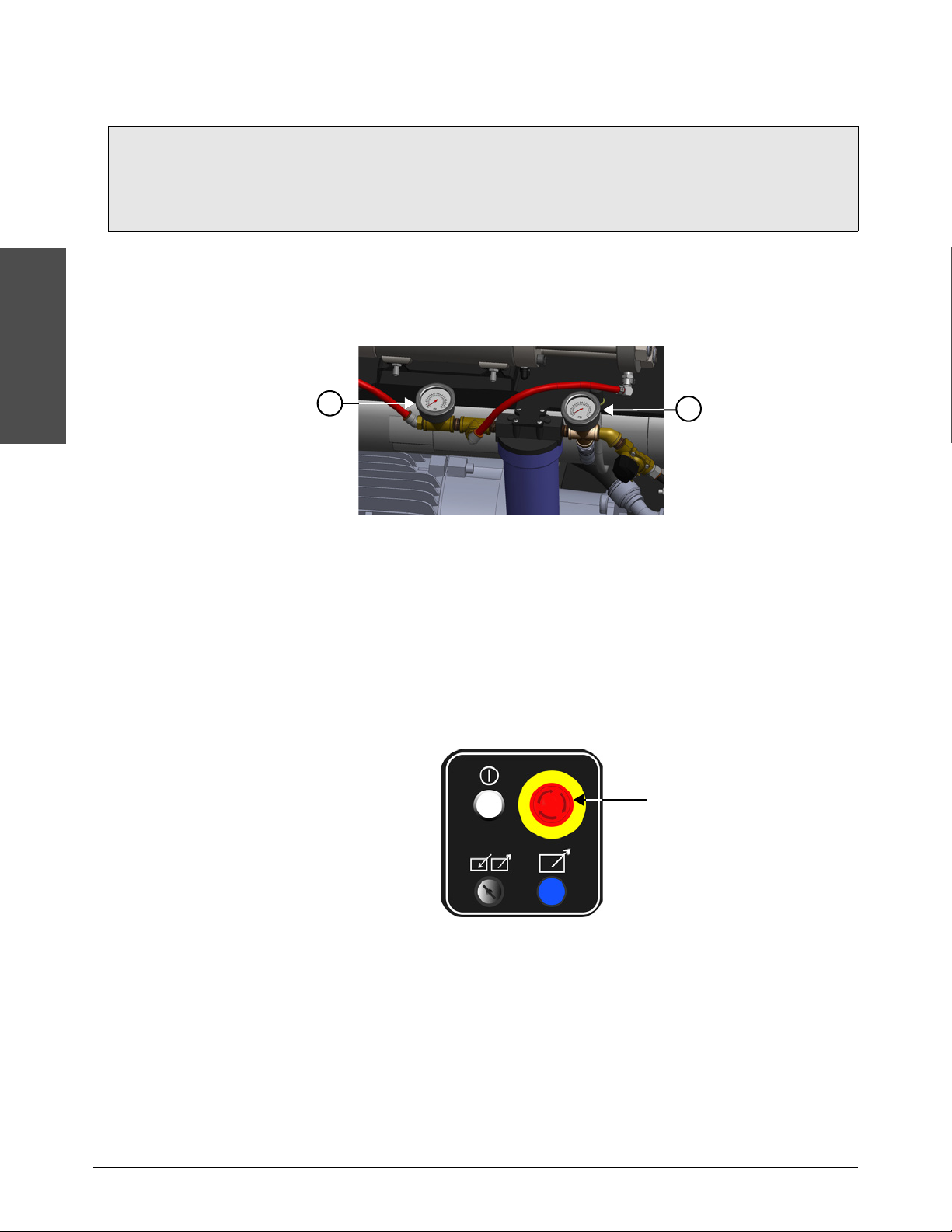

Postfilter water-pressure gauge

2

Prefilter water-pressure gauge

Check the low-pressure water pressure gauges

Replace the water filter:

• every 1,000 hours.

• if the difference between the values is more than0.7bar(70kPa/10psi).

Refer to Replace the water filter on page 80.

The prefilter water-pressure gauge shows the water pressure before the water goes through the

filter. The postfilter water-pressure gauge shows the water pressure after the water goes through

the filter.

The usual range is2.8bar to7.6bar (280kPa to760kPa/40psi to110psi).

Do this task when the pump is operating.

Subtract the value shown on the postfilter water pressure from the value shown on the prefilter

water pressure.

If the difference between the values is more than0.7bar(70kPa/10psi), replace the water filter.

Make sure that the emergency stop operates correctly

Do this task when the pump is operating.

On the operation panel, push the EMERGENCY STOP button. Refer to Emergency stop on

page 51.

48 810770 Operator Manual Echion

2

Operation

Operate the pump

4

1

2 3

1 Target water pressure

Touch this to set the target water pressure.

2 Pierce-pressure mode (off)

Touch this symbol to put the pump in

pierce-pressure mode.

3 Cut-pressure mode (on)

Touch this symbol to put the pump in cut-pressure

mode.

4 Output water pressure

This shows the actual water pressure when the

pump is operating.

3

2

1

Operation

Select the pressure mode

Cut-pressure mode is used for most cutting jobs.

Pierce-pressure mode (low-pressure mode) is applicable for:

making a hole in the material to be cut.

decreasing the risk of cracking when cutting brittle materials, such as glass or ceramic.

preventing composite materials like carbon fiber from delaminating.

Pierce pressure is typically less than or equal to1,380 bar(138,000kPa/20,000psi).

Set the target water pressure

There are2 ways to change the target water pressure on the operator interface.

Touch the symbol or the symbol to change the target water pressure in preset

increments.

To change the increments, refer to Pressure Adjustments on page 167.

Touch the target water pressure button to open a numeric keypad. Type the number and

then touch Enter.

Echion Operator Manual 810770 49

Operation

2

Operation

Stop the pump

Stop the pump remotely

You can stop the pump from the operator interface while using remote controls. On the

operator interface, touch the symbol to stop the pump.

Refer to Stop the pump on page 50.

Refer to Emergency stop on page 51 for information about the EMERGENCY STOP button.

Refer to the OEM’s instructions for turning the pump off.

Stop the pump locally

Use this procedure during normal operation.

On the operator interface, touch the symbol.

The pump, the primary motor, and the intensifier turn off.

The bleed-down valve opens to release high-pressure water from the system.

The supply-water valve closes to stop low-pressure water from entering the system.

No output water pressure shows.

The control circuit stays on.

50 810770 Operator Manual Echion

2

Operation

Emergency stop

Operation

WAR NING

The EMERGENCY STOP button does not disconnect main electrical power from the

machine.

Use the emergency stop to stop the controls immediately to prevent injury or to reduce the risk of

injury to personnel, machinery, or work in progress. This is not the preferred method of turning

off the pump.

On the operation panel, push the EMERGENCY STOP button.

The control circuit turns off, which turns off the pump, the primary motor, and the intensifier.

Remote controls that are wired to the pump controller turn off.

The bleed-down valve opens to release high-pressure water from the system.

The supply-water valve closes to stop low-pressure water from entering the system.

The EMERGENCY STOP button must be reset before the equipment can be turned on.

Turn the button clockwise until it releases.

Echion Operator Manual 810770 51

Operation

2

Operation

124

1

2

4

3

3

Turn off the pump: end of day

Do this procedure at the end of the day.

1. On the operator interface, touch the symbol to stop the pump.

2. Turn the primary breaker disconnect lever on the electrical enclosure door to

3. Tu rn

OFF the utility water to the pump. Make sure that the water pressure gauges

OFF.

show0.0bar(0kPa/0psi).

4. Tu rn

5. Tu rn

OFF the compressed air source.

OFF the electrical main (line disconnect switch). Use standard lock out–tag out procedures.

6. Remove the top cover and the front panel.

7. Clean all debris, water, and hydraulic fluid off of the hydraulic fluid tank , the intensifier

bridge , and the bottom deck .

8. Empty the dirty water container , if necessary.

Refer to local regulations regarding waste water. Environmental rules can apply to

disposal.

52 810770 Operator Manual Echion

Preventive maintenance

Preventive maintenance

This section assumes that the user is familiar with the Safety, Operation, Troubleshooting, and

Specifications sections of this manual.

Images in this manual are for reference purposes. It is possible that your product configuration is

not shown accurately.

It is possible that not all of the information in this section applies to all pump models.

Echion Operator Manual 810770 53

3

Preventive maintenance

Safety

Preventive maintenance

WAR NING

CAUTION

CAUTION

CAUTION

CAUTION

Read and understand all of the safety guidelines in this manual.

Refer to Safety on page 21 before operating, doing maintenance on, repairing, and installing

your pump.

Do not tighten a fitting too much. The fitting can fail.

Hydraulic, water, and electrical connections can become loose during shipping and normal

operation. Examine all connections at installation and during regular maintenance.

When replacing wiring, use only the same size, type, and color as the original wiring.

Before assembling high-pressure or hydraulic parts, clean the parts to remove grease and other

contamination.

Clean and examine parts that will be replaced to identify wear patterns or damage that can show

other problems.

Clean each part with a towel and isopropyl alcohol. Examine all parts for deterioration, corrosion,

or damage.

Do not use soap, detergent, or solvents.

Keep the work area clean and dry. Clean fluid spills immediately.

Use a pan or a tray below areas where water or hydraulic fluid can spill during maintenance or

repair procedures.

Obey local protocols for recycling or disposal of parts, materials, and fluids.

National and local environmental rules can apply to disposal.

Refer to Recycling and end of product life on page 96.

Keep accurate maintenance records. Records can help with predicting and preventing

maintenance problems.

Keep spare parts and repair kits available.

54 810770 Operator Manual Echion

3

Preventive maintenance

Benefits of preventive maintenance

Hypertherm recommends preventive and scheduled maintenance for Echion pumps. High-quality

equipment that is maintained on a schedule lasts longer than equipment that is not maintained

regularly. This maintenance includes adjustments, cleaning, lubrication, repairs, and replacement of

parts.

Improves reliability

Finds possible problems before they cause unplanned downtime and become expensive

repairs

Extends the life of equipment and decreases the frequency of replacement

Contributes positively to reputation and profits

Gives traceability through records

Training

Preventive maintenance

The employer must provide training for maintenance procedures. Retrain personnel when:

there is a change in job assignment, machinery, or procedures that can present a new

danger.

energy-control procedures change.

there is reason to believe there is a deficiency in a person’s knowledge of the energy-control

procedure.

Echion Operator Manual 810770 55

Preventive maintenance

3

Preventive maintenance

2

41

5

3

1

Move the plunger

2

Start the pump after maintenance

3

Prepare for storage

4

Inputs and outputs

5

Alarm log