Page 1

Duramax™ and Duramax Hyamp Robotic

Torches

45°, 90°, 180°

Service Manual

807460 | Revision 2 | English

Page 2

Register your new Hypertherm system

Register your product online at www.hypertherm.com/registration for easier technical

and warranty support. You can also receive updates on new Hypertherm products and a free

gift as a token of our appreciation.

For your records

Serial number:________________________________________________________________

Purchase date: _______________________________________________________________

Distributor: __________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

Maintenance notes:

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

____________________________________________________________________________

Duramax, Powermax, FastConnect, and Hypertherm are trademarks of Hypertherm Inc. and may be registered in the United States

and other countries. All other trademarks are the property of their respective holders.

© 2014 Hypertherm Inc.

Page 3

Duramax /Duramax Hyamp Robotic Torches

Service Manual

807460

Revision 2

English

March 2014

Hypertherm Inc.

Hanover, NH 03755 USA

Page 4

Hypertherm Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

877-371-2876 Fax (Return Materials Authorization)

return.materials@hypertherm.com (RMA email)

Hypertherm Plasmatechnik GmbH

Technologiepark Hanau

Rodenbacher Chaussee 6

D-63457 Hanau-Wolfgang, Deutschland

49 6181 58 2100 Tel

49 6181 58 2134 Fax

49 6181 58 2123 (Technical Service)

Hypertherm (S) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

65 6841 2489 (Technical Service)

Hypertherm (Shanghai) Trading Co., Ltd.

Unit 301, South Building

495 ShangZhong Road

Shanghai, 200231

PR China

86-21-60740003 Tel

86-21-60740393 Fax

Hypertherm Europe B.V.

Vaartveld 9

4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP - Brasil

CEP 07115-030

55 11 2409 2636 Tel

55 11 2408 0462 Fax

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Hypertherm Korea Branch

#3904 Centum Leaders Mark B/D,

1514 Woo-dong, Haeundae-gu, Busan

Korea, 612-889

82 51 747 0358 Tel

82 51 701 0358 Fax

Page 5

Safety information

Before operating any Hypertherm equipment, read the separate Safety and Compliance Manual (80669C) included

with your product for important safety information.

Page 6

Page 7

Contents

Electromagnetic Compatibility (EMC) ............................................................................ SC-11

Introduction ..............................................................................................................................................................................SC-11

Installation and use .................................................................................................................................................................SC-11

Assessment of area ................................................................................................................................................................SC-11

Methods of reducing emissions ..........................................................................................................................................SC-11

Mains supply ....................................................................................................................................................................SC-11

Maintenance of cutting equipment .....................................................................................................................................SC-12

Cutting cables .........................................................................................................................................................................SC-12

Equipotential bonding ....................................................................................................................................................SC-12

Earthing of the workpiece .............................................................................................................................................SC-12

Screening and shielding .......................................................................................................................................................SC-12

Warranty .................................................................................................................................. SC-13

Attention ....................................................................................................................................................................................SC-13

General .....................................................................................................................................................................................SC-13

Patent indemnity .....................................................................................................................................................................SC-14

Limitation of liability ................................................................................................................................................................SC-14

National and local codes .......................................................................................................................................................SC-14

Liability cap ..............................................................................................................................................................................SC-14

Insurance ..................................................................................................................................................................................SC-14

Transfer of rights .....................................................................................................................................................................SC-14

1 Specifications .............................................................................................................................. 15

Introduction .................................................................................................................................................................................... 15

Duramax component weights .................................................................................................................................................... 16

Duramax Hyamp component weights ...................................................................................................................................... 16

Torch dimensions ......................................................................................................................................................................... 17

Duramax 180° robotic torch dimensions ......................................................................................................................... 17

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 7

Page 8

Contents

Duramax 90° robotic torch dimensions ........................................................................................................................... 17

Duramax 45° robotic torch dimensions ........................................................................................................................... 18

Duramax Hyamp 180° robotic torch dimensions .......................................................................................................... 18

Duramax Hyamp 90° robotic torch dimensions ............................................................................................................. 19

Duramax Hyamp 45° robotic torch dimensions ............................................................................................................. 19

2 Torch Setup .................................................................................................................................. 21

Robotic torch components ......................................................................................................................................................... 21

Install the torch .............................................................................................................................................................................. 22

Disassemble the robotic torch .................................................................................................................................................. 23

Mount the torch ............................................................................................................................................................................. 30

Consumable life ............................................................................................................................................................................ 33

Choosing the consumables ....................................................................................................................................................... 34

Duramax robotic torches ..................................................................................................................................................... 34

Duramax consumables ........................................................................................................................................................ 34

Duramax mechanized shielded 105 A* .................................................................................................................... 34

Duramax mechanized shielded 45 A, 65 A, 85 A* ................................................................................................ 34

Duramax FineCut shielded 105 A* ........................................................................................................................... 34

Duramax FineCut shielded 65 A, 85 A* .................................................................................................................. 35

*Ohmic-sensing retaining cap ................................................................................................................................... 35

Duramax mechanized unshielded 105 A ................................................................................................................. 35

Duramax mechanized unshielded 45 A, 65 A, 85 A ............................................................................................. 35

Duramax FineCut unshielded 105 A ........................................................................................................................ 35

Duramax FineCut unshielded 65 A, 85 ................................................................................................................... 36

Duramax gouging 105 A ............................................................................................................................................. 36

Duramax gouging 65 A, 85 A .................................................................................................................................... 36

Duramax Hyamp robotic torches ....................................................................................................................................... 37

Duramax Hyamp consumables .......................................................................................................................................... 37

Duramax Hyamp mechanized shielded 105 A/125 A* ........................................................................................ 37

Duramax Hyamp mechanized shielded 45 A, 65 A* ............................................................................................. 37

Duramax Hyamp FineCut shielded* .......................................................................................................................... 37

*Ohmic-sensing retaining cap ................................................................................................................................... 37

Duramax Hyamp gouging ............................................................................................................................................ 37

Installing the consumables ................................................................................................................................................. 38

Connecting the torch lead .......................................................................................................................................................... 39

Connecting a remote-start pendant ......................................................................................................................................... 40

Connecting the machine interface cable ................................................................................................................................ 41

Machine interface pinout ..................................................................................................................................................... 43

Setting the five-position voltage divider .....................................................................................

Using the cut charts ..................................................................................................................................................................... 45

..................................... 44

8 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 9

Contents

3 Operation ...................................................................................................................................... 47

Using the robotic torch ................................................................................................................................................................ 47

Using the Duramax robotic teach tool .............................................................................................................................. 48

Understand and optimize cut quality ................................................................................................................................ 49

Cut or bevel angle ........................................................................................................................................................ 49

Dross ................................................................................................................................................................................ 49

Straightness of the cut surface .................................................................................................................................. 50

Piercing a workpiece using the robotic torch ................................................................................................................ 50

Common machine-cutting faults ....................................................................................................................................... 51

4 Component Replacement ........................................................................................................ 53

Duramax and Duramax Hyamp robotic torch overview ........................................................................................................ 53

Disconnect the power, gas supply, and torch ....................................................................................................................... 55

Replacing the positioning barrel ............................................................................................................................................... 56

Replacing the torch body ............................................................................................................................................................ 59

Replacing the cap-sensor switch ............................................................................................................................................. 61

Replacing the torch lead ............................................................................................................................................................. 62

5 Maintenance and Parts ............................................................................................................. 65

Perform routine maintenance ..................................................................................................................................................... 65

Routine maintenance tasks ................................................................................................................................................. 66

Inspect the consumables ............................................................................................................................................................ 67

Duramax robotic torch replacement parts ............................................................................................................................... 68

Duramax 180° robotic torch ............................................................................................................................................... 68

Duramax 90° robotic torch ................................................................................................................................................. 69

Duramax 45° robotic torch ................................................................................................................................................. 70

Duramax Hyamp robotic torch replacement parts ................................................................................................................ 71

Duramax Hyamp 180° robotic torch ................................................................................................................................. 71

Duramax Hyamp 90° robotic torch ................................................................................................................................... 72

Duramax Hyamp 45° robotic torch ................................................................................................................................... 73

Accessory parts ............................................................................................................................................................................ 74

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 9

Page 10

Contents

10 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 11

Electromagnetic Compatibility (EMC)

Introduction

Hypertherm’s CE-marked equipment is built in compliance

with standard EN60974-10. The equipment should be

installed and used in accordance with the information

below to achieve electromagnetic compatibility.

The limits required by EN60974-10 may not be adequate

to completely eliminate interference when the affected

equipment is in close proximity or has a high degree of

sensitivity. In such cases it may be necessary to use other

measures to further reduce interference.

This cutting equipment is designed for use only in an

industrial environment.

Installation and use

The user is responsible for installing and using the plasma

equipment according to the manufacturer’s instructions.

If electromagnetic disturbances are detected then it shall

be the responsibility of the user to resolve the situation

with the technical assistance of the manufacturer. In some

cases this remedial action may be as simple as earthing

the cutting circuit, see Earthing of the work piece. In other

cases, it could involve constructing an electromagnetic

screen enclosing the power source and the work

complete with associated input filters. In all cases,

electromagnetic disturbances must be reduced to the

point where they are no longer troublesome.

Assessment of area

Before installing the equipment, the user shall make an

assessment of potential electromagnetic problems in the

surrounding area. The following shall be taken into

account:

a. Other supply cables, control cables, signaling

and telephone cables; above, below and adjacent

to the cutting equipment.

b. Radio and television transmitters and receivers.

c. Computer and other control equipment.

d. Safety critical equipment, for example guarding of

industrial equipment.

e. Health of the people around, for example the use

of pacemakers and hearing aids.

f. Equipment used for calibration or measurement.

g. Immunity of other equipment in the environment.

User shall ensure that other equipment being

used in the environment is compatible. This may

require additional protection measures.

h. Time of day that cutting or other activities are to

be carried out.

The size of the surrounding area to be considered will

depend on the structure of the building and other activities

that are taking place. The surrounding area may extend

beyond the boundaries of the premises.

Methods of reducing emissions

Mains supply

Cutting equipment must be connected to the mains

supply according to the manufacturer’s recommendations.

If interference occurs, it may be necessary to take

additional precautions such as filtering of the mains

supply.

Consideration should be given to shielding the supply

cable of permanently installed cutting equipment, in

metallic conduit or equivalent. Shielding should be

electrically continuous throughout its length. The shielding

should be connected to the cutting mains supply so that

good electrical contact is maintained between the conduit

and the cutting power source enclosure.

Safety and Compliance SC-11

Page 12

Electromagnetic Compatibility (EMC)

Maintenance of cutting equipment

The cutting equipment must be routinely maintained

according to the manufacturer’s recommendations. All

access and service doors and covers should be closed

and properly fastened when the cutting equipment is in

operation. The cutting equipment should not be modified

in any way, except as set forth in and in accordance with

the manufacturer’s written instructions. For example, the

spark gaps of arc striking and stabilizing devices should

be adjusted and maintained according to the

manufacturer’s recommendations.

Cutting cables

The cutting cables should be kept as short as possible

and should be positioned close together, running at or

close to the floor level.

Equipotential bonding

Bonding of all metallic components in the cutting

installation and adjacent to it should be considered.

Earthing of the workpiece

Where the workpiece is not bonded to earth for electrical

safety, nor connected to earth because of its size and

position, for example, ship’s hull or building steel work, a

connection bonding the workpiece to earth may reduce

emissions in some, but not all instances. Care should be

taken to prevent the earthing of the workpiece increasing

the risk of injury to users, or damage to other electrical

equipment. Where necessary, the connection of the

workpiece to earth should be made by a direct connection

to the workpiece, but in some countries where direct

connection is not permitted, the bonding should be

achieved by suitable capacitances selected according to

national regulations.

Note: The cutting circuit may or may not be earthed for

safety reasons. Changing the earthing arrangements

should only be authorized by a person who is competent

to assess whether the changes will in crease the risk of

injury, for example, by allowing parallel cutting current

return paths which may damage the earth circuits of other

equipment. Further guidance is provided in IEC 60974-9,

Arc Welding Equipment, Part 9: Installation and Use.

However, metallic components bonded to the workpiece

will increase the risk that the operator could receive a

shock by touching these metallic components and the

electrode (nozzle for laser heads) at the same time.

The operator should be insulated from all such bonded

metallic components.

Screening and shielding

Selective screening and shielding of other cables and

equipment in the surrounding area may alleviate problems

of interference. Screening of the entire plasma cutting

installation may be considered for special applications.

SC-12 Safety and Compliance

Page 13

Warranty

Attention

Genuine Hypertherm parts are the factory-recommended

replacement parts for your Hypertherm system. Any

damage or injury caused by the use of other than genuine

Hypertherm parts may not be covered by the Hypertherm

warranty, and will constitute misuse of the Hypertherm

Product.

You are solely responsible for the safe use of the Product.

Hypertherm does not and cannot make any guarantee or

warranty regarding the safe use of the product in your

environment.

General

Hypertherm, Inc. warrants that its Products shall be free

from defects in materials and workmanship for the specific

periods of time set forth herein and as follows: if

Hypertherm is notified of a defect (i) with respect to the

plasma power supply within a period of two (2) years from

the date of its delivery to you, with the exception of

Powermax brand power supplies, which shall be within a

period of three (3) years from the date of delivery to you,

and (ii) with respect to the torch and leads within a period

of one (1) year from its date of delivery to you, and with

respect to torch lifter assemblies within a period of one (1)

year from its date of delivery to you, and with respect to

Automation products one (1) year from its date of delivery

to you, with the exception of the EDGE Pro CNC,

EDGE Pro Ti CNC, MicroEDGE Pro CNC, and

ArcGlide THC, which shall be within a period of two (2)

years from the date of delivery to you, and (iii) with respect

to HyIntensity fiber laser components within a period of

two (2) years from the date of its delivery to you, with the

exception of laser heads and beam delivery cables, which

shall be within a period of one (1) year from its date of

delivery to you.

Hypertherm provides repair, replacement or adjustment of

the Product as the sole and exclusive remedy, if and only if

the warranty set forth herein properly is invoked and

applies. Hypertherm, at its sole option, shall repair,

replace, or adjust, free of charge, any defective Products

covered by this warranty which shall be returned with

Hypertherm’s prior authorization (which shall not be

unreasonably withheld), properly packed, to Hypertherm’s

place of business in Hanover, New Hampshire, or to an

authorized Hypertherm repair facility, all costs, insurance

and freight pre paid by the customer. Hypertherm shall not

be liable for any repairs, replacement, or adjustments of

Products covered by this warranty, except those made

pursuant to this paragraph and with Hypertherm’s prior

written consent.

The warranty set forth above is exclusive and is in lieu of all

other warranties, express, implied, statutory, or otherwise

with respect to the Products or as to the results which

may be obtained therefrom, and all implied warranties or

conditions of quality or of merchantability or fitness for a

particular purpose or against infringement. The foregoing

shall constitute the sole and exclusive remedy for any

breach by Hypertherm of its warranty.

Distributors/OEMs may offer different or additional

warranties, but Distributors/OEMs are not authorized to

give any additional warranty protection to you or make any

representation to you purporting to be binding upon

Hypertherm.

This warranty shall not apply to any Powermax brand

power supplies that have been used with phase

converters. In addition, Hypertherm does not warranty

systems that have been damaged as a result of poor

power quality, whether from phase converters or incoming

line power. This warranty shall not apply to any product

which has been incorrectly installed, modified, or

otherwise damaged.

Safety and Compliance SC-13

Page 14

Warranty

Patent indemnity

Except only in cases of products not manufactured by

Hypertherm or manufactured by a person other than

Hypertherm not in strict conformity with Hypertherm’s

specifications and in cases of designs, processes,

formulae, or combinations not developed or purported to

be developed by Hypertherm, Hypertherm will have the

right to defend or settle, at its own expense, any suit or

proceeding brought against you alleging that the use of

the Hypertherm product, alone and not in combination

with any other product not supplied by Hypertherm,

infringes any patent of any third party. You shall notify

Hypertherm promptly upon learning of any action or

threatened action in connection with any such alleged

infringement (and in any event no longer than fourteen

(14) days after learning of any action or threat of action),

and Hypertherm’s obligation to defend shall be

conditioned upon Hypertherm’s sole control of, and the

indemnified party’s cooperation and assistance in, the

defense of the claim.

Limitation of liability

In no event shall Hypertherm be liable to any

person or entity for any incidental, consequential

direct, indirect, punitive or exemplary damages

(including but not limited to lost profits) regardless

of whether such liability is based on breach of

contract, tort, strict liability, breach of warranty,

failure of essential purpose, or otherwise, and even

if advised of the possibility of such damages.

National and local codes

Liability cap

In no event shall Hypertherm’s liability, if any,

whether such liability is based on breach of

contract, tort, strict liability, breach of warranties,

failure of essential purpose or otherwise, for any

claim, action, suit or proceeding (whether in court,

arbitration, regulatory proceeding or otherwise)

arising out of or relating to the use of the Products

exceed in the aggregate the amount paid for the

Products that gave rise to such claim.

Insurance

At all times you will have and maintain insurance in such

quantities and types, and with coverage sufficient and

appropriate to defend and to hold Hypertherm harmless in

the event of any cause of action arising from the use of the

products.

Transfer of rights

You may transfer any remaining rights you may have

hereunder only in connection with the sale of all or

substantially all of your assets or capital stock to a

successor in interest who agrees to be bound by all of the

terms and conditions of this Warranty. Within thirty (30)

days before any such transfer occurs, you agree to notify

in writing Hypertherm, which reserves the right of

approval. Should you fail timely to notify Hypertherm and

seek its approval as set forth herein, the Warranty set forth

herein shall be null and void and you will have no further

recourse against Hypertherm under the Warranty or

otherwise.

National and local codes governing plumbing and

electrical installation shall take precedence over any

instructions contained in this manual. In no event shall

Hypertherm be liable for injury to persons or property

damage by reason of any code violation or poor work

practices.

SC-14 Safety and Compliance

Page 15

Section 1

Specifications

Introduction

The Duramax robotic torch line consists of 3 torches: 180°, 90°, and 45°, designed for use with the Powermax65®,

Powermax85, and Powermax105 systems. The Duramax robotic torches are not compatible with the Powermax125

system. These torches use only Duramax consumables.

The Duramax Hyamp robotic torch line also consists of 3 torches: 180°, 90°, and 45°, designed for use with the

Powermax65, Powermax85, Powermax105, and Powermax125 systems. These torches use only Duramax Hyamp

consumables.

Both lines of torches are designed for use in robotic applications. They can also be used in other mechanized

applications where careful positioning of the torch and the ability to approach the workpiece at an angle are important

considerations.

The FastConnect™ quick-disconnect system makes it easy to remove the torch for transport or to switch from one torch

to the other if your applications require the use of different torches. The torches are cooled by ambient air and do not

require special cooling procedures.

Duramax and Duramax Hyamp robotic torches comply with IEC 60974-7 and are not suitable for use in the rain or snow.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 15

Page 16

1 – Specifications

76 mm

(3.0 inches)

76 mm

(3.0 inches)

152 mm

(6.0 inches)

Diameter = 2 x Radius = 152 mm (6.0 inches)

10 2 m m

(4.0 inches)

10 2 m m

(4.0 inches)

204 mm

(8.0 inches)

Diameter = 2 x Radius = 204 mm (8.0 inches)

Duramax component weights

180° Duramax robotic torch with 7.6 m (25 foot) lead 3.3 kg (7.2 pounds)

90° Duramax robotic torch 7.6 m (25 foot) lead 3.3 kg (7.2 pounds)

45° Duramax robotic torch 7.6 m (25 foot) lead 3.3 kg (7.2 pounds)

Each Duramax robotic torch weighs 0.43 kg/m (0.29 pounds/foot).

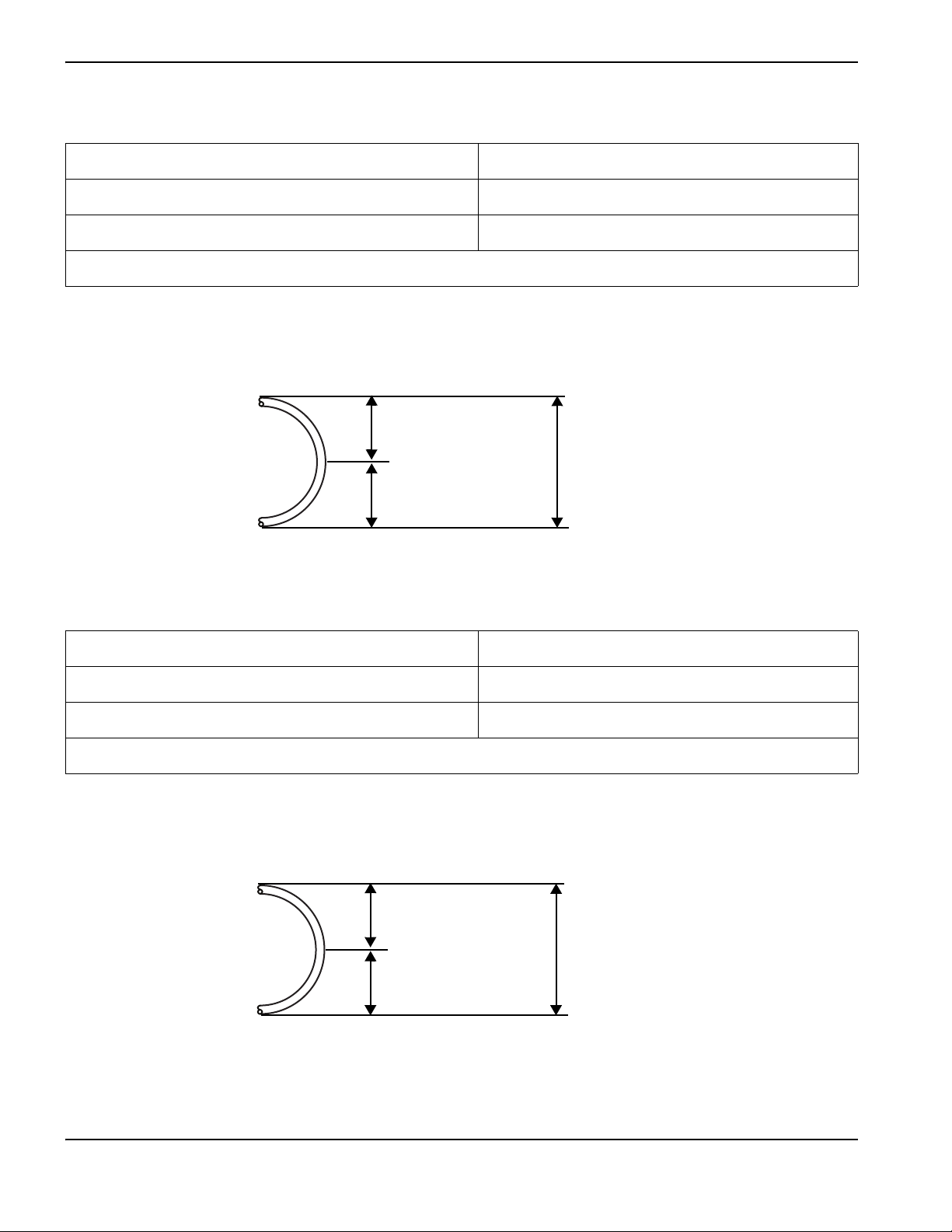

The recommended minimum bend radius for the Duramax torch lead is 76 mm (3.0 inches). See Figure 1.

Figure 1 – Duramax bend radius

Duramax Hyamp component weights

180° Duramax Hyamp robotic torch with 7.6 m (25 foot) lead 3.5 kg (7.8 pounds)

90° Duramax Hyamp robotic torch 7.6 m (25 foot) lead 3.5 kg (7.8 pounds)

45° Duramax Hyamp robotic torch 7.6 m (25 foot) lead 3.5 kg (7.8 pounds)

Each Duramax Hyamp robotic torch weighs 0.46 kg/m (0.31 pounds/foot).

The recommended minimum bend radius for the Duramax Hyamp torch lead is 102 mm (4.0 inches). See Figure 2.

Figure2–Duramax Hyamp bend radius

16 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 17

Torch dimensions

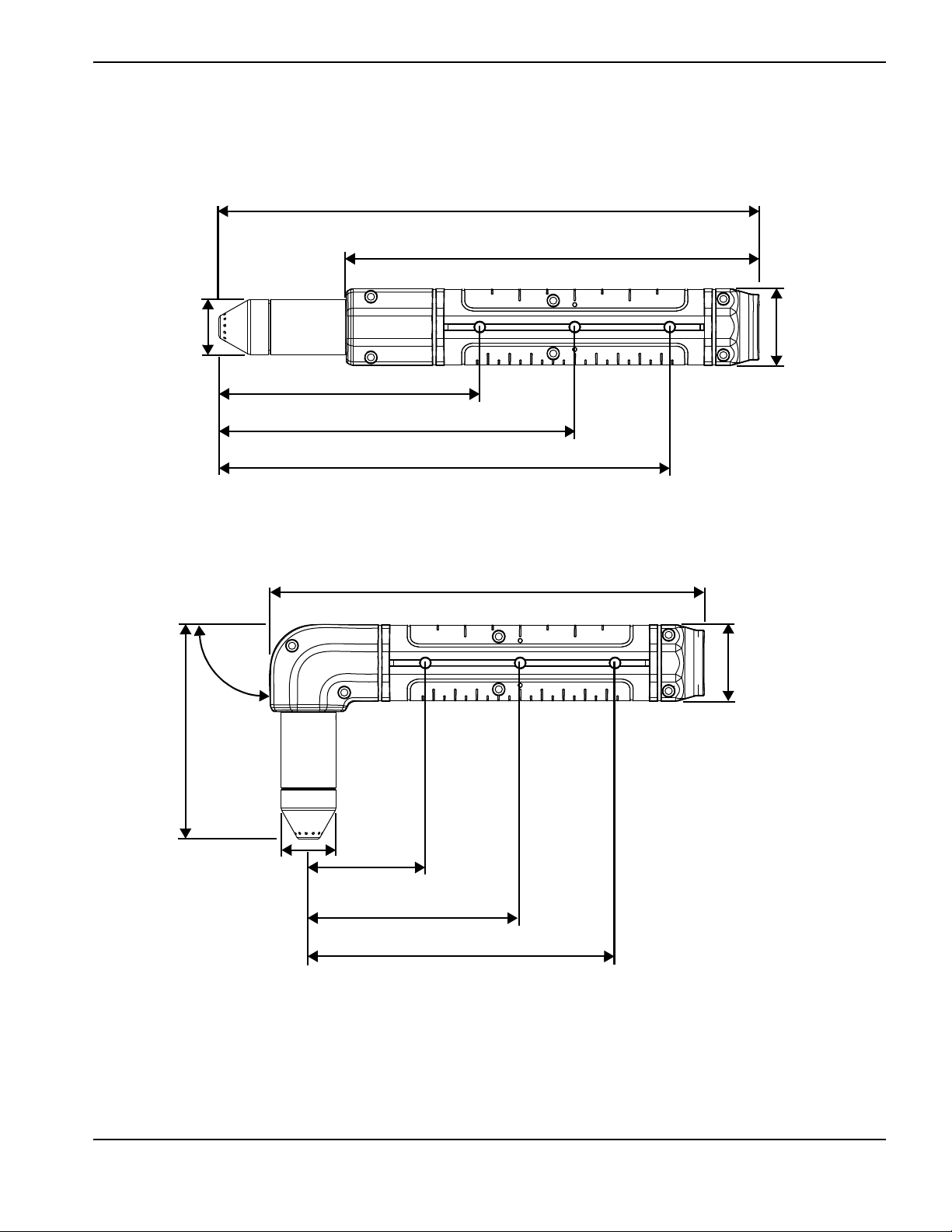

25.1 cm (9.89 inches)*

3.5 cm

(1.38 inches)

2.5 cm

(1.0 inch)

19.1 cm (7.50 inches)

12.2cm (4.82inches)*

16.6 cm (6.54 inches)*

21.0cm (8.27inches)*

14.2cm (5.58inches)*

20.1 cm (7.90 inches)

3.5 cm

(1.38 inches)

10 .1 c m

(3.97 inches)*

2.5 cm

(1.0 inch)

90°

5.41 cm

(2.13 inches)*

9.78 cm (3.85 inches)*

Duramax 180° robotic torch dimensions

1 – Specifications

Duramax 90° robotic torch dimensions

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 17

Page 18

1 – Specifications

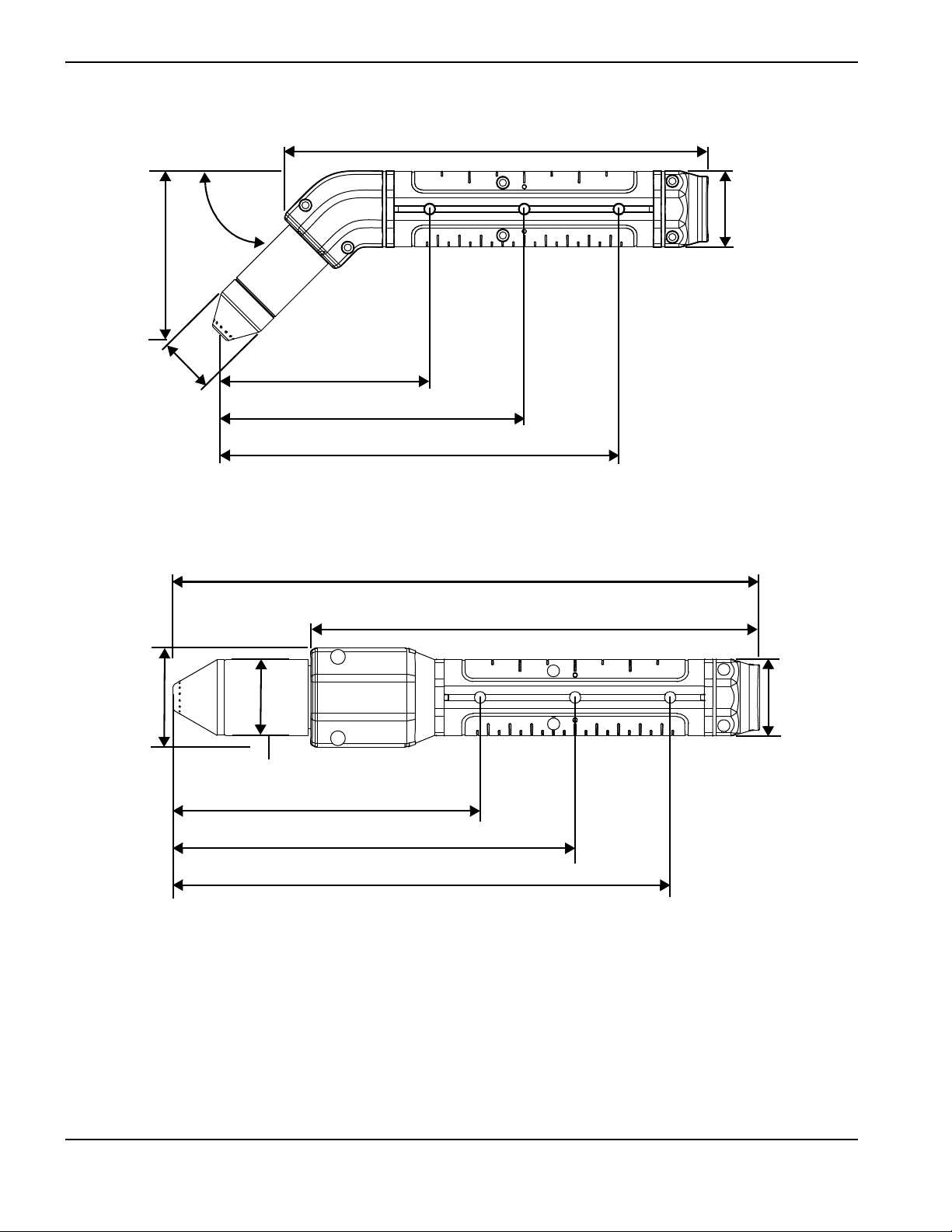

19.6 cm (7.72 inches)

3.51 cm

(1.38 inches)

8.0 cm

(3.15 inches)*

2.5 cm

(1.0 inch)

45°

9.88 cm (3.89 inches)*

14.3 cm (5.61 inches)*

18.6 cm (7.34 inches)*

27.1 cm (10.7 inches)*

3.5 cm

(1.38 inches)

3.5 cm

(1.38 inches)

20.8 cm (8.15 inches)

14.1 cm (5.57 inches)*

18.5 cm (7.30 inches)*

22.9cm (9.02inches)*

4.5 cm

(1.8 inches)

Duramax 45° robotic torch dimensions

Duramax Hyamp 180° robotic torch dimensions

18 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 19

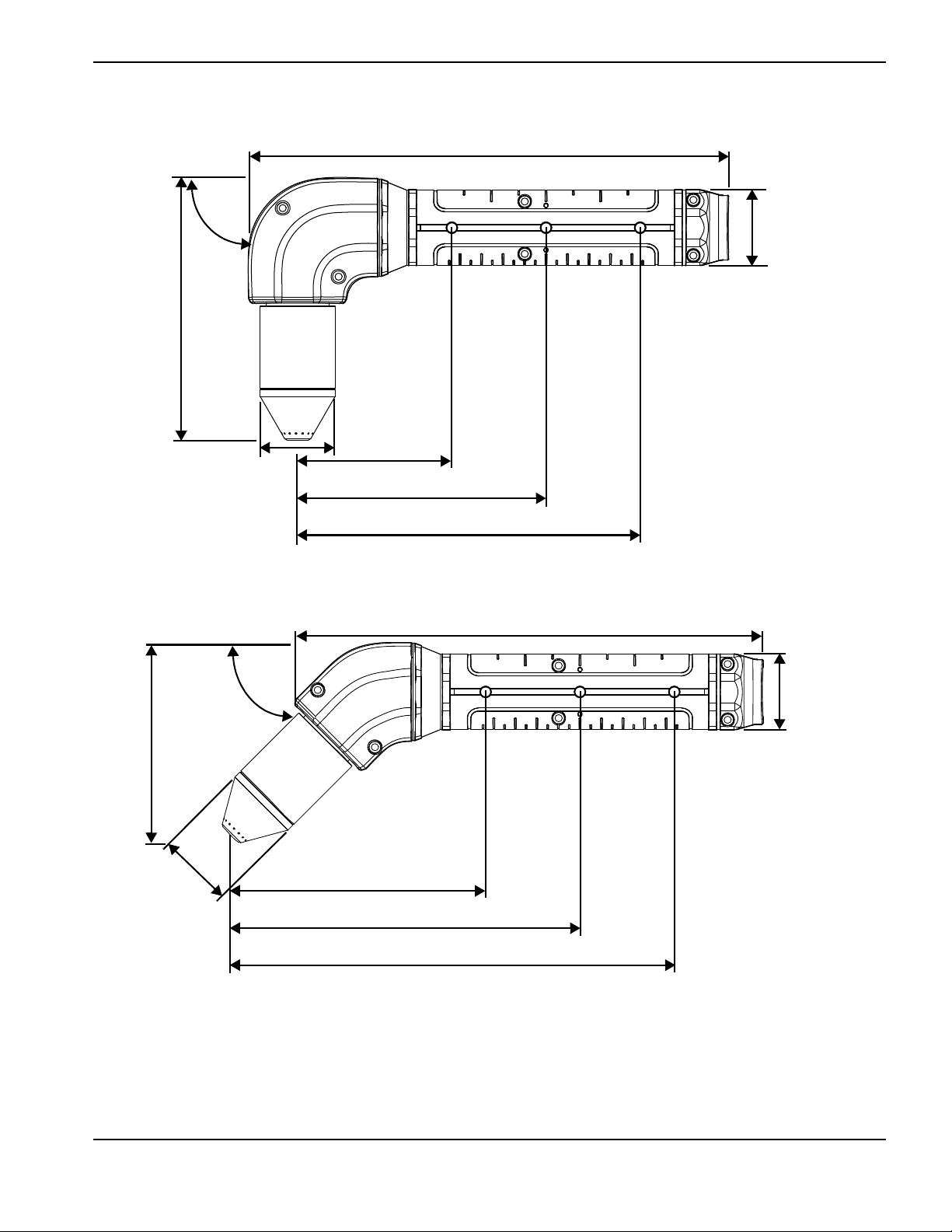

Duramax Hyamp 90° robotic torch dimensions

22.4 cm (8.80 inches)

3.5 cm

(1.38 inches)

12.2 cm

(4.79 inches)*

3.5 cm

(1.38 inches)

7.2cm (2.83inches)*

11.6 cm (4.55 inches)*

16.0cm (6.28inches)*

90°

21.8 cm (8.57 inches)

3.5 cm

(1.38 inches)

9.3 cm

(3.66 inches)*

3.5 cm

(1.38 inches)

45°

11.8 cm (4.66 inches)*

16.2cm (6.39inches)*

20.6 cm (8.11 inches)*

1 – Specifications

Duramax Hyamp 45° robotic torch dimensions

* Torch dimensions will vary depending on the type of consumables installed. The preceding figures show the mechanized shielded

consumables installed.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 19

Page 20

1 – Specifications

20 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 21

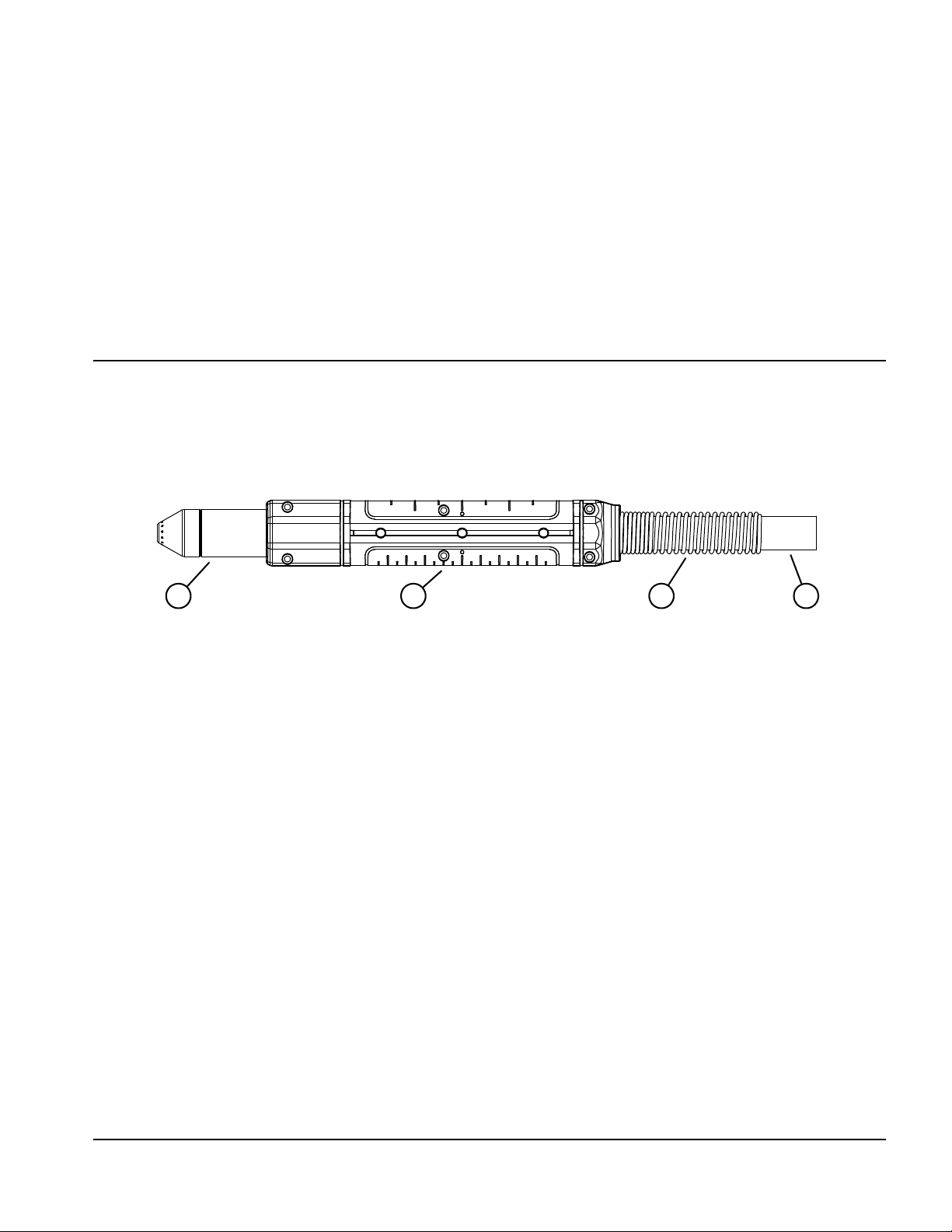

Robotic torch components

1 2 3 4

1 Consumables

2 Positioning barrel

3 Strain relief

4 Tor ch l ead

Duramax 180° is shown.

Section 2

Torch Setu p

Before using any robotic torch, you must:

Install and mount the torch.

Choose and install the consumables.

Attach the torch lead to the power supply.

Set up the power supply for remote starting with either the remote-start pendant or a machine interface cable.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 21

Page 22

2 – Torch Setup

1

2

3

4

5

6

4.20 cm

(1.65 inches)

3.68 cm

(1.45 inches)

1 Disconnect button

2 Ta b

3 Top shell

4 Strain relief

5 Bottom shell

6 Mounting screws (4)

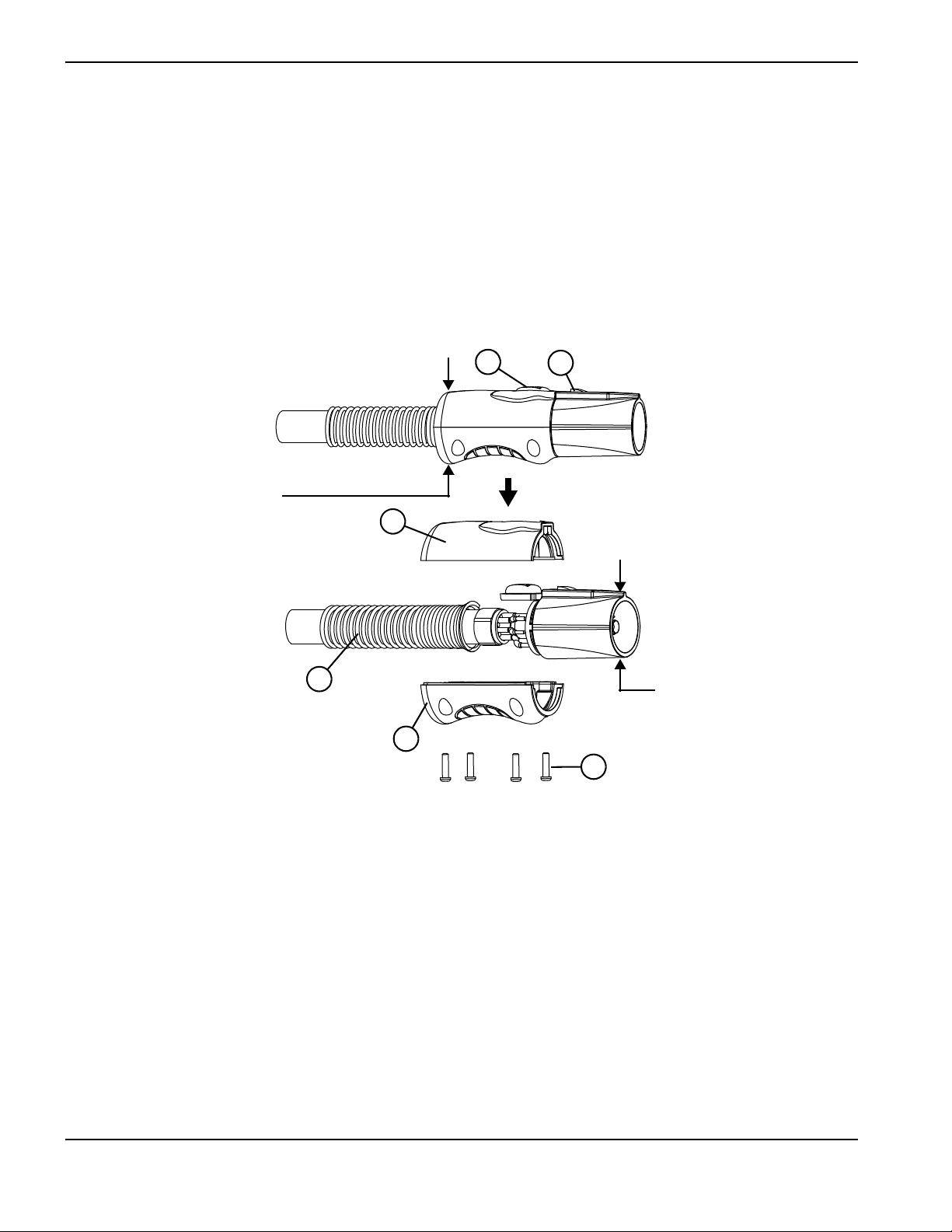

Install the torch

Depending on the type of torch, robot, and installation method, you may need to disassemble the FastConnect plug or

torch to install the torch. For the outside mounting method, it is not necessary to disassemble the torch. The torch can be

mounted per the instructions in Mount the torch on page 30.

For the through-arm mounting method, see Figure 3 to determine if the robot’s through-arm cavity is large enough to

accept the torch lead’s FastConnect plug as assembled or with the 2 shells removed. If the through-arm cavity is large

enough for the FastConnect plug as assembled, route the torch lead through the through-arm cavity. Then, mount the

torch to the robot arm per the instructions in Mount the torch on page 30.

Figure 3

22 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 23

2 – Torch Setup

If the through-arm cavity is large enough for the disassembled FastConnect plug (see Figure 3 for dimensions), complete

the following instructions.

1. Remove the mounting screws from the bottom shell and pull the 2 shells apart.

The red disconnect button and tab on top of the FastConnect plug are spring loaded and

self-adjust below the surface of the plug while being routed through the through-arm

cavity.

2. Cover the end of the FastConnect plug with tape to keep dirt and other contaminants from getting into the gas line.

3. Route the torch lead through the through-arm cavity.

4. Install the 2 shells by aligning them over the torch lead, making sure the strain relief is held in place by the slot in the

FastConnect shells.

5. Tighten the mounting screws.

6. Mount the torch to the robot arm per the instructions in Mount the torch on page 30.

Disassemble the robotic torch

If the through-arm cavity is not large enough to accept the FastConnect plug at all (see Figure 3 for dimensions),

complete the following instructions to disassemble, install, and reassemble the torch.

WARNING!

ELECTRIC SHOCK CAN KILL

Disconnect electrical power before performing any maintenance.

The maintenance procedures in this section must be performed by a qualified

technician.

See the Safety and Compliance Manual (80669C) for more safety

precautions.

The instructions to disassemble and reassemble all 3 models of robotic torches are the same. The 45° robotic torch

is shown in the figures that follow.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 23

Page 24

2 – Torch Setup

1

2

3

4

5

6

7

8

9

10

11

1 Right half of the positioning barrel

2 Cap-sensor switch connector

3 Cap-sensor switch

4 Pilot terminal screw

5 Torch body (torch head and gas tube)

6 Gas supply tube fitting

7 Gas fitting flange

8 Positioning barrel screws (6)

9 Left half of the positioning barrel

10 Tor ch le ad

11 Strain relief

1

2

3

4

5

6

7

8

9

10

11

1 Right half of the positioning barrel

2 Cap-sensor switch connector

3 Cap-sensor switch

4 Pilot terminal screw

5 Torch body (torch head and gas tube)

6 Gas supply tube fitting

7 Gas fitting flange

8 Positioning barrel screws (6)

9 Left half of the positioning barrel

10 Tor ch le ad

11 Strain relief

Figure4–Duramax 45°

24 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Figure 5 – Duramax Hyamp 45°

Page 25

2 – Torch Setup

2 3 41

1 Cap-sensor switch mounting post

2 Cap-sensor switch post hole

3 Gas fitting flange slot

4 Strain relief slot

1. Disconnect the torch lead from the power supply.

While disconnecting and reconnecting the torch parts, maintain the same orientation

between the torch body and torch lead. Twisting the torch body in relation to the torch

lead can cause damage.

2. Remove the consumables.

3. Place the torch on a flat surface with the left half of the positioning barrel facing up.

The left half of the positioning barrel is the side with the screws.

It may be helpful to clamp the lead in place to keep it from moving.

4. Remove the screws from the left half of the positioning barrel.

5. Lift the left half of the positioning barrel away from the torch.

6. The torch body fits snugly into the right half of the positioning barrel. While holding the torch body, gently press the

right half of the positioning barrel away from the torch body to remove it.

7. Slide the cap-sensor switch off its mounting post.

Figure6–Duramax 45° (top) and Duramax Hyamp 45° (bottom)

8. Remove the pilot terminal screw.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 25

Page 26

2 – Torch Setup

9. Use 2 wrenches to loosen the gas fitting that secures the torch body to the torch lead.

Heating the gas fitting can help loosen the threadlocker and make removing the torch

body easier. Slowly heat only the fitting with a heat gun until you can easily loosen the

fitting.

CAUTION!

Do not apply heat to the wires. Heating the wires could cause damage to the connections in the torch

lead.

CAUTION!

Always use 2 wrenches to properly loosen and tighten the hex nuts and bolts mentioned in these

procedures. A strong threadlocker is used to assemble the torch, and loosening the nuts incorrectly

can damage the threads.

10. Cover the end of the gas line on the torch lead with tape to keep dirt and other contaminants from getting in the gas

line.

11 . Route the torch lead through the robot’s through-arm cavity.

12. Being careful not to get any threadlocker on the conical surface of the gas tube fitting, apply a drop of threadlocker,

included in the kit, to the threads of the gas tube fitting on the torch body.

The drop should not be wider than 2 threads in diameter.

CAUTION!

Do not get any threadlocker on the conical surface of the gas tube fitting to avoid causing damage

to the torch. If any threadlocker does get on this surface, clean it off immediately.

26 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 27

13. Thread the torch body into the torch lead until snug.

Conical surface of the gas tube

fitting

The white wires of the lead should be facing up.

2 – Torch Setup

Figure 7

14. Use 2 wrenches to tighten the gas fitting that secures the torch body to the torch lead to 69.1 kg∙cm

(60 inch∙pounds).

15. Route the pilot arc wire under the gas tube and above the slot for the gas hose fitting’s flange. See Figure 8 and

Figure 9.

16. Tighten the pilot terminal screw to 17.3 kg∙cm (15 inch∙pounds).

The wire should go slightly down into the positioning barrel.

17. Press the cap-sensor switch into its post hole and onto its mounting post. (See Figure 6.)

18. Route the cap-sensor wires below the slot for the gas hose fitting’s flange.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 27

Page 28

2 – Torch Setup

2

3

4

1

5

1 Pilot arc wire terminal

2 Cap-sensor switch

3 Cap-sensor switch connector

4 Gas fitting flange

5 Strain relief

2

3

4

1

5

1 Pilot arc wire terminal

2 Cap-sensor switch

3 Cap-sensor switch connector

4 Gas fitting flange

5 Strain relief

Figure8–Duramax wire routing

Figure9–Duramax Hyamp wire routing

19. Press the torch body into the right half of the positioning barrel with the gas fitting flange aligned with the slot in the

positioning barrel.

20. Align the strain relief with the strain relief slot in the positioning barrel.

21. Being careful that the positioning barrel and gas fitting flange do not pinch the wires, align the left half of the

positioning barrel with the right half.

22. Install the screws in the left half of the positioning barrel. Tighten to 15.0 kg∙cm (13.0 inch∙pounds).

28 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 29

2 – Torch Setup

23. If the O-ring on the torch body is dry, lubricate it and the threads with a thin layer of silicone lubricant.

Silicone lubricant is included in several of the replacement kits.

24. Install the consumables.

25. Reconnect the torch and gas supply, and turn ON (I) the power.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 29

Page 30

2 – Torch Setup

1

2

3

1 Increment markings

2 Anti-rotational slot

3 Positioning holes (3)

Mount the torch

Each style of robotic torch has 2 different mounting methods to maintain consistent positioning:

1. Increment markings – These are located on each side of the positioning barrel. One set is in inches and the other set

is in centimeters.

2. Positioning holes – These are equally spaced along the anti-rotational slots on each side of the barrel.

Figure 10

The robotic torch must be correctly mounted to the robot’s arm to make sure that there is proper torch-to-work distance

throughout each cut. A robotic torch clamp with mating positioning dowels and anti-rotational tabs is available from

Hypertherm. If you choose to use an alternate torch clamp, follow the manufacturer’s instructions on how to mount the

torch in the clamp. It is the customer’s responsibility to interface between the torch clamp and the robot’s arm.

30 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 31

For the recommended minimum bend radius of the torch lead, see Figure 1 or Figure 2 on page 16.

0.76 cm

(0.30 inch)

1.91 cm

(0.75 inch)

2

1

1

2 11

1 0.45 cm (0.18 inch) through hole 2 M4 x 0.7 threaded hole

1

2

3

4

5

1 Positioning dowel

2 Rear half of the clamp

3 Front half of the clamp

4 Screws (4)

5 Anti-rotational tabs

If you are using Hypertherm’s robotic torch clamp (228806), complete the following instructions:

1. Mount the robotic torch clamp using one set of mounting holes (through hole or threaded).

Figure 11

2 – Torch Setup

2. Separate the torch clamp by removing the 4 screws from the front half of the torch clamp.

A second positioning dowel is provided in the kit to be used for additional mounting

support, if necessary, or as a replacement part.

Figure 12

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 31

Page 32

2 – Torch Setup

1

4

1

2

3

4

3. Align the torch with the clamp using either the increment markings or the positioning holes.

If you are using the increment markings, you must remove the positioning dowel from the

rear half of the torch clamp. Remove the dowel by pressing the end located in the center

hole of the torch clamp until it comes out.

4. Verify that the anti-rotational tabs on each half of the torch clamp are aligned with the slots in the torch.

5. Loosely hand tighten the 4 screws.

6. Starting with the upper left screw, step torque the 4 screws to 17.3 kg∙cm (15 inch∙pounds) in the pattern shown

below – .

Figure 13

32 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 33

2 – Torch Setup

Consumable life

How often you need to change the consumables on your torch will depend on a number of factors:

The thickness of the metal being cut.

The average length of cut.

The air quality (presence of oil, moisture, or other contaminants).

Whether you are piercing the metal or starting cuts from the edge.

Proper torch-to-work distance when gouging or cutting with unshielded consumables.

Proper pierce height.

Whether you are cutting in “continuous pilot arc” mode or normal mode. Cutting with a continuous pilot arc causes

more consumable wear.

You will find more information about proper cutting techniques in Operation on page 47.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 33

Page 34

2 – Torch Setup

220993

Shield

220854

Retaining cap

220990

Nozzle

220842

Electrode

220994

Swirl ring

220857

Swirl ring

220817

Shield

220854

Retaining cap

220816

Nozzle (85 A)

220842

Electrode

220819

Nozzle (65 A)

220941

Nozzle (45 A)

220948

Shield

220930

Nozzle

220842

Electrode

220994

Swirl ring

220854

Retaining cap

Choosing the consumables

Duramax robotic torches

Duramax robotic torches are shipped with a consumable kit that includes enough consumables to create a complete

consumable set for 65, 85, or 105 amperage shielded cutting. An ohmic-sensing retaining cap is available for use with

shielded consumables, a deflector is available for unshielded cutting and FineCut

fine-featured cutting on thin materials. All 3 styles of Duramax robotic torches use the same consumables.

With unshielded consumables, you must keep the torch a small distance, about 2.0 mm (0.08 inch), away

from the workpiece. Unshielded consumables generally have a shorter life than shielded consumables.

Duramax consumables

Duramax mechanized shielded 105 A*

®

consumables are available for

Duramax mechanized shielded 45 A, 65 A, 85 A*

Duramax FineCut shielded 105 A*

34 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 35

Duramax FineCut shielded 65 A, 85 A*

220948

Shield

220930

Nozzle

220842

Electrode

220857

Swirl ring

220854

Retaining cap

220955

Deflector

220854

Retaining cap

220990

Nozzle

220842

Electrode

220994

Swirl ring

220955

Deflector

220854

Retaining cap

220816

Nozzle (85 A)

220842

Electrode

220857

Swirl ring

220819

Nozzle (65 A)

220941

Nozzle (45 A)

220955

Deflector

220854

Retaining cap

220930

Nozzle

220842

Electrode

220994

Swirl ring

*Ohmic-sensing retaining cap

You can use the ohmic-sensing retaining cap (220953) with the above consumable sets instead

of the standard retaining cap (220854).

Duramax mechanized unshielded 105 A

2 – Torch Setup

Duramax mechanized unshielded 45 A, 65 A, 85 A

Duramax FineCut unshielded 105 A

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 35

Page 36

2 – Torch Setup

220955

Deflector

220854

Retaining cap

220930

Nozzle

220842

Electrode

220857

Swirl ring

220798

Shield

220854

Retaining cap

220991

Nozzle

220842

Electrode

220994

Swirl ring

220798

Shield

220854

Retaining cap

220797

Nozzle

220842

Electrode

220857

Swirl ring

Duramax FineCut unshielded 65 A, 85

Duramax gouging 105 A

Duramax gouging 65 A, 85 A

36 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 37

2 – Torch Setup

220976

Shield

220975

Nozzle

220971

Electrode

220997

Swirl ring

220977

Retaining cap

420168

Shield

220977

Retaining cap

420158 (45 A)

420169 (65 A)

Nozzle

220971

Electrode

220997

Swirl ring

420152

Shield

420151

Nozzle

220971

Electrode

220997

Swirl ring

220977

Retaining cap

420112

Shield

220977

Retaining cap

420001

Nozzle

220971

Electrode

220997

Swirl ring

Duramax Hyamp robotic torches

Duramax Hyamp robotic torches ship with a consumable kit that includes enough consumables to create a complete

consumable set for 45, 65, 105, or 125 amperage shielded cutting. Also notice that specific consumables are not

available for cutting at 85 A. Use the standard (drag-cutting) 105/125 A consumables to cut at 85 A. An ohmic-sensing

retaining cap is available for use with shielded consumables, and FineCut

®

consumables are available for fine-featured

cutting on thin materials. All 3 styles of Duramax Hyamp robotic torches use the same consumables.

Duramax Hyamp consumables

Duramax Hyamp mechanized shielded 105 A/125 A*

Duramax Hyamp mechanized shielded 45 A, 65 A*

Duramax Hyamp FineCut shielded*

*Ohmic-sensing retaining cap

You can use the ohmic-sensing retaining cap (420156) with the above consumable sets instead

of the standard retaining cap (220977).

Duramax Hyamp gouging

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 37

Page 38

2 – Torch Setup

1

2

3

4

5

1

2

3

4

5

Duramax Duramax Hyamp

1 Swirl ring

2 Electrode

3 Nozzle

4 Retaining cap

5 Shield

Installing the consumables

WARNING!

INSTANT-ON TORCHES

PLASMA ARC CAN CAUSE INJURY AND BURNS

The plasma arc comes on immediately when the torch trigger is activated. Make sure the

power is OFF before changing the consumables.

To operate the robotic torch, a complete set of consumable parts must be installed: shield, retaining cap, nozzle,

electrode, and swirl ring.

If the O-ring on the torch body is dry, lubricate it and the threads with a thin layer of silicone lubricant. Silicone lubricant is

included in several of the replacement kits. Then, to operate the torch, install the consumables as shown in Figure 14.

Make sure to use the appropriate parts to the corresponding system amperage. To replace the consumables, turn the

power switch to the OFF (O) position, remove the consumables, and install the new consumables by referring to

Figure 14.

Figure 14

38 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 39

2 – Torch Setup

Red button

Connecting the torch lead

The Powermax65, Powermax85, Powermax105, and Powermax125 have FastConnect, a quick-disconnect system for

connecting and disconnecting hand, machine, and robotic torch leads. When connecting or disconnecting a torch, first

turn OFF the system. To connect the torch, push the connector into the receptacle on the front of the power supply.

Figure 15

To remove the torch, press the red button on the connector and pull the connector out of the receptacle.

Figure 16

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 39

Page 40

2 – Torch Setup

Receptacle for the remote-start

pendant or a machine interface cable.

Remote-start pendant

Connecting a remote-start pendant

An optional remote-start pendant is available for use with Powermax systems.

Part number 128650: 7.6 m (25 feet)

Part number 128651: 15 m (50 feet)

Part number 128652: 23 m (75 feet)

If your power supply has the machine interface receptacle on the rear of the power supply, remove the receptacle cover

and plug the Hypertherm remote-start pendant into the receptacle. If the system does not have a receptacle installed, a

CPC port upgrade kit (228697 for Powermax65/85) (228884 for Powermax105/125) is available from Hypertherm.

The remote-start pendant is for use only with a robotic or machine torch. It will not operate

if a hand torch is installed.

Figure 17

40 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 41

2 – Torch Setup

Connecting the machine interface cable

The power supply may be equipped with a five-position voltage divider board. The built-in voltage divider provides a

scaled down arc voltage of 20:1, 21.1:1, 30:1, 40:1, or 50:1 (maximum output of 16 V). A receptacle on the rear of the

power supply (see Figure 17) provides access to the scaled down arc voltage and signals for arc transfer and plasma

start.

The factory presets the voltage divider to 50:1. To change the voltage divider to a different

setting, see Setting the five-position voltage divider on page 44.

CAUTION!

The factory-installed internal voltage divider provides a maximum of 16 V under open circuit

conditions. This is an impedance-protected functional extra low voltage (ELV) output to prevent

shock, energy, and fire under normal conditions at the machine interface receptacle and under single

fault conditions with the machine interface wiring. The voltage divider is not fault tolerant, and ELV

outputs do not comply with safety extra low voltage (SELV) requirements for direct connection to

computer products.

Hypertherm offers several choices of machine interface cables:

To use the built-in voltage divider that provides a scaled down arc voltage in addition to signals for arc transfer and

plasma start:

Use part number 228350 (7.6 m, 25 feet) or 228351 (15 m, 50 feet) for wires terminated with spade

connectors.

Use one of the following part numbers for a cable terminated with a D-sub connector. (Compatible with

Hypertherm products, such as EDGE

223354 (3.0 m, 10 feet)

223355 (6.1 m, 20 feet)

223048 (7.6 m, 25 feet)

223356 (10.7 m, 35 feet)

123896 (15 m, 50 feet)

To use signals for arc transfer and plasma start only, use either part number 023206 (7.6 m, 25 feet) or part

®

Pro Ti and Sensor™ PHC.)

number 023279 (15 m, 50 feet). These cables have spade connectors as follows:

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 41

Page 42

2 – Torch Setup

Refer to Machine interface pinout on page 43 for receptacle pinout information.

The cover on the machine interface receptacle prevents dust and moisture from damaging

the receptacle when not in use. This cover (127204) should be replaced if damaged or

lost.

Refer to Maintenance and Parts on page 65 for more information.

Installation of the machine interface cable must be performed by a qualified service technician. To install a machine

interface cable:

1. Turn OFF the power and disconnect the power cord.

2. Remove the machine interface receptacle’s cover from the rear of the power supply.

3. Connect the Hypertherm machine interface cable to the power supply.

4. If you are using a cable with a D-sub connector on the other end, plug it into the appropriate pin connector on the

torch height controller or CNC. Secure it with the screws on the D-sub connector.

If you are using a cable with wires and spade connectors on the other end, terminate the machine interface cable

inside the electrical enclosure of the torch height controller or CNC controller to prevent unauthorized access to the

connections after installation. Verify that the connections are correct and that all live parts are enclosed and

protected before operating the equipment.

The integration of Hypertherm equipment and customer-supplied equipment including

interconnecting cords and cables, if not listed and certified as a system, is subject to

inspection by local authorities at the final installation site.

The connector sockets for each type of signal available through the machine interface cable are shown in Figure 18.

Ta bl e 1 on page 43 provides details about each signal type.

42 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 43

2 – Torch Setup

3

4

5

6

12

13

14

Machine interface pinout

Figure 18 – Connector sockets

Refer to Ta bl e 1 when connecting the power supply to a torch height controller or CNC controller with a machine

interface cable.

Table 1 – Machine interface cable signals

Signal Type Notes

Start (start plasma) Input Normally open.

18 VDC open circuit voltage at

START terminals. Requires dry

contact closure to activate.

Transfer (start machine

motion)

Ground Ground 13

Voltage divider Output Divided arc signal of 20:1, 21.1:1,

Output Normally open. Dry contact closure

when the arc transfers.

120 VAC/1 A maximum at the

machine interface relay.

30:1, 40:1, 50:1 (provides a

maximum of 16 V).

Connector

sockets

3, 4 Green, black

12, 14 Red, black

5(-), 6(+) Black (-), white (+)

External cable wires

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 43

Page 44

2 – Torch Setup

20:1 21.1:1 30:1 40:1 50:1

Setting the five-position voltage divider

To change the factory preset voltage divider from 50:1 to a different setting:

1. Turn OFF the power supply and disconnect the power cord.

2. Remove the power supply cover.

3. Locate the voltage divider DIP switches on the left side of the power supply.

Figure 19 shows the default setting (50:1) with the number 4 switch up.

Figure 19 – Voltage divider at default setting (50:1)

4. Set the DIP switches to one of the following settings, and replace the power supply cover.

If the Hypertherm five-position voltage divider does not supply the required voltage for your application, contact your

system integrator for assistance.

44 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 45

2 – Torch Setup

Using the cut charts

The cut charts for each set of mechanized consumables can be found in the Tor ch Set up section of the Operator Manual

that shipped with the system. The manuals also can be downloaded from Hypertherm’s website (www.hypertherm.com

using the “Downloads library” link. A consumable diagram with part numbers precedes each set of charts. For each

consumable type, there are Metric and English charts for mild steel, stainless steel, and aluminum.

Each chart contains the following information:

Material Thickness – Thickness of the workpiece (metal plate being cut).

Torch-to-Work Distance – For shielded consumables, the distance between the shield and the workpiece during

cutting. For unshielded consumables, the distance between the nozzle and the workpiece during cutting.

Initial Pierce Height – Distance between the shield (shielded) or the nozzle (unshielded) and the workpiece when

the torch is triggered, prior to descending to the cut height.

Pierce Delay Time – Length of time the triggered torch remains stationary at the pierce height before the torch

starts the cutting motion.

Best Quality Settings (cut speed and voltage) – Settings that provide the starting point for finding the best cut

quality (best angle, least dross, best cut-surface finish). Adjust the speed for your application and table to obtain the

desired result.

)

Production Settings (cut speed and voltage) – 70% to 80% of the maximum speed ratings. These speeds result in

the greatest number of cut parts, but not necessarily the best possible cut quality.

The arc voltage increases as the consumables wear, so the voltage setting may need to

be increased to maintain the correct torch-to-work distance. Some CNCs monitor the arc

voltage and adjust the torch lifter automatically.

Each cut chart lists hot and cold air flow rates.

Hot air flow rate – Plasma is on, the system is operating at running current, and the system is in a steady state at

the default system pressure (automatic mode).

Cold air flow rate – Plasma is off and the system is in a steady state with air flowing through the torch at the default

system pressure.

Hypertherm collected the cut chart data under laboratory test conditions using new

consumables.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 45

Page 46

2 – Torch Setup

46 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 47

Section 3

Operation

Using the robotic torch

Since the robotic torch, combined with a Powermax system, can be used in a wide variety of applications, you will need to

refer to the robot manufacturer’s instructions for specifics on operating the robotic torch in your configuration. However,

the information in the following section will help you optimize cut quality and maximize consumable life.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 47

Page 48

3 – Operation

Using the Duramax robotic teach tool

A robotic torch teach tool (229456) for only the Duramax robotic torches is available from Hypertherm to assist with

programming the robot before cutting. The torch teach tool enables the system operator to program the robot’s cutting

path, while visually verifying the torch will not touch the workpiece while cutting. Contact with the workpiece while cutting

can damage the shield and nozzle and affect the cut surface. The torch teach tool is equipped with a spring-loaded tip to

allow for variations in consumable lengths and stand-off distances.

To install the torch teach tool:

1. Tur n O FF (O) the power.

2. Remove the consumables from the torch.

3. Thread the torch teach tool onto the end of the torch

in place of the consumables.

As a safety feature, the torch teach tool does not engage

the cap-sensor switch. This will cause a cap-sensor fault

code to be generated when the system is turned ON,

thereby disabling the torch from firing while in teach

mode.

After programming the robot:

1. Tur n O FF (O) the power.

2. Remove the torch teach tool.

3. Install the consumables.

48 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 49

3–Operation

Negative cut angle

Square cut

Positive cut angle

Problem Cause

The torch is too low.

The torch is too high.

Solution

Raise the torch; or if you are using a torch height

control, increase the arc voltage.

Lower the torch; or if you are using a torch height

control, decrease the arc voltage.

Understand and optimize cut quality

Several factors affect cut quality:

Cut angle – The degree of angularity of the cut edge.

Dross – The molten material that solidifies on the top or bottom of the workpiece.

Straightness of the cut surface – The cut surface can be concave or convex.

The following topics explain how these factors can affect cut quality.

Cut or bevel angle

A positive cut angle results when more material is removed from the top of the cut than from the bottom.

A negative cut angle results when more material is removed from the bottom of the cut.

Figure 20 – Cut angles

The squarest cut angle will be on the right side with respect to the forward motion of the

torch. The left side will always have some degree of cut angle.

To determine whether a cut-angle problem is being caused by the plasma system or the drive system, make a test cut and

measure the angle of each side. Next, turn the torch 90° in its holder and repeat the process. If the angles are the same in

both tests, the problem is in the drive system.

If a cut-angle problem persists after mechanical causes have been eliminated, check the torch-to-work distance,

especially if the cut angles are all positive or all negative. Also consider the material being cut: if the metal is magnetized

or hardened, you are more likely to experience cut angle problems.

Dross

Some amount of dross will always be present when cutting with air plasma. However, you can minimize the amount and

type of dross by adjusting your system correctly for your application.

Excess dross appears on the top edge of both pieces of the plate when the torch is too low (or voltage is too low when

using a torch height control). Adjust the torch or adjust the voltage in small increments (5 volts or less) until the dross is

reduced.

Duramax/Duramax Hyamp Robotic Torches Service Manual 807460 49

Page 50

3 – Operation

Low-speed dross forms when the torch’s cutting speed is too slow and the arc angles ahead. It forms as a heavy, bubbly

deposit at the bottom of the cut and can be removed easily. Increase the speed to reduce this type of dross.

High-speed dross forms when the cutting speed is too fast and the arc angles behind. It forms as a thin, linear bead of

solid metal attached very close to the cut. It is more firmly attached to the bottom of the cut than at low speed and is

difficult to remove. To reduce high-speed dross:

Decrease the cutting speed.

Decrease the torch-to-work distance.

Straightness of the cut surface

A typical plasma cut surface is slightly concave.

The cut surface may become more concave, or convex. Correct torch height is required to keep the cut

surface acceptably close to straight. Worn consumables also affect the straightness of the cut.

A strongly concave cut surface occurs when the torch-to-work distance is too low. Increase the

torch-to-work distance to straighten the cut surface.

A convex cut surface occurs when the torch-to-work distance is too great or the cutting current is too

high. First, try lowering the torch, then reduce the cutting current.

Piercing a workpiece using the robotic torch

As with the hand torch and machine torch, you can start a cut with the robotic torch at the edge of the workpiece or by

piercing the workpiece. Piercing may result in a shorter consumable life than with edge starts.

The cut charts, provided in the system’s Operator Manual, include a column for the recommended torch height when

starting a pierce. For the Powermax65, Powermax85, and Powermax105, the pierce height is generally 2.5 times the

cutting height. For the Powermax125, the pierce height is generally between 1.5 and 4 times the cut height. Refer to the

cut charts for specific values.

The pierce delay must be long enough that the arc can pierce the material before the torch moves, but not so long that

the arc “wanders” while trying to find the edge of a large hole. As consumables wear, this delay time may need to be

increased. Pierce delay times given in the cut charts are based on average delay times throughout the life of the

consumables.

When piercing materials close to the maximum thickness for a specific process, consider the following important factors:

Allow a lead-in distance approximately equal to the thickness of the material being pierced. For example, 20 mm

(0.75 inch) material requires a 20 mm lead-in.

To avoid damage to the shield from the buildup of molten material created by the pierce, do not allow the torch to

descend to cut height until it has cleared the puddle of molten material.

Different material chemistries can have an adverse effect on the pierce capability of the system. In particular,

high-strength steel with a high manganese or silicon content can reduce the maximum pierce capability. Hypertherm

calculates mild steel parameters with certified A-36 plate.

Using a “flying pierce” (that is, starting torch motion immediately after transfer and during the pierce process) can

extend the piercing capability of the system in some cases. Because this can be a complex process that can damage

the torch or other components, a stationary or edge start is recommended.

50 Duramax/Duramax Hyamp Robotic Torches Service Manual 807460

Page 51

3–Operation

Common machine-cutting faults

The torch’s pilot arc will initiate, but will not transfer.

The work lead is not making good contact with the cutting table, or the cutting table is not making good contact with

the workpiece.

The torch-to-work distance/cut height is too large.

The workpiece is not totally pierced, and there is excessive sparking on the top of the workpiece.

The metal surface is not clean of rust or paint.

The consumables are worn and need to be replaced. For optimized performance in a mechanized application, replace

the nozzle and the electrode together.

The work lead is not making good contact with the cutting table, or the cutting table is not making good contact with

the workpiece.

The current (amperage) is set too low. See the Torch S etu p section in the system’s Operator Manual for more

information.

The cut speed is too high. See the cut charts in the Torch Setup section of the system’s Operator Manual for more

information.

The metal being cut exceeds the maximum capacity for the selected amperage. See the Specifications section in the

system’s Operator Manual for more information.

Excessive dross forms on the bottom of the cut.

The gas setting is too high or too low.

The consumables are worn and need to be replaced. For optimized performance in a mechanized application, replace

the nozzle and the electrode together.