Page 1

EDGE® Connect

Shape Cutting Control

Installation and Setup Manual

809340 | Revision 4 | English

Page 2

Register your new Hypertherm system

Benefits of registration

5 Safety: Registration allows us to contact you in the unlikely event a safety or quality notification

is required.

5 Education: Registration gives you free access to online product training content via the

Hypertherm Cutting Institute.

5 Confirmation of ownership: Registration can serve as proof of purchase in case of an

insurance loss.

Go to www.hypertherm.com/registration for easy and fast registration.

If you experience any problems with the product registration process, please contact

registration@hypertherm.com.

For your records

Serial number: __________________________________________________________________________

Purchase date: __________________________________________________________________________

Distributor: _____________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

Maintenance notes: ______________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

EDGE, Phoenix, HPR, HPRXD, HPR130XD, HPR260XD, HPR400XD, CutPro, Remote Help, XPR, Powermax, and Hypertherm

are trademarks of Hypertherm Inc. and may be registered in the United States and other countries. EtherCAT is a trademark of

Beckhoff Automation. All other trademarks are the property of their respective holders.

Environmental stewardship is one of Hypertherm’s core values, and it is critical to our success and our customers’ success. We

are striving to reduce the environmental impact of everything we do. For more information:www.hypertherm.com/environment

© 2020 Hypertherm, Inc.

.

Page 3

EDGE Connect

Installation and Setup Manual

809340

Revision 4

English

Original Instructions

October 2020

Hypertherm, Inc.

Hanover, NH 03755 USA

www.hypertherm.com

Page 4

Hypertherm Europe B.V.

Vaartveld 9, 4704 SE

Roosendaal, Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emea@hypertherm.com

(Technical Service Email)

Hypertherm (Shanghai) Trading Co., Ltd.

B301, 495 ShangZhong Road

Shanghai, 200231

PR China

86-21-80231122 Tel

86-21-80231120 Fax

86-21-80231128 Tel (Technical Service)

techsupport.china@hypertherm.com

(Technical Service Email)

South America & Central America: Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP – Brasil

CEP 07115-030

55 11 2409 2636 Tel

tecnico.sa@hypertherm.com (Technical Service Email)

Hypertherm Korea Branch

#3904. APEC-ro 17. Heaundae-gu. Busan.

Korea 48060

82 (0)51 747 0358 Tel

82 (0)51 701 0358 Fax

Marketing.korea@hypertherm.com (Marketing Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm Pty Limited

GPO Box 4836

Sydney NSW 2001, Australia

61 (0) 437 606 995 Tel

61 7 3219 9010 Fax

au.sales@Hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm (India) Thermal Cutting Pvt. Ltd

A-18 / B-1 Extension,

Mohan Co-Operative Industrial Estate,

Mathura Road, New Delhi 110044, India

91-11-40521201/ 2/ 3 Tel

91-11 40521204 Fax

HTIndia.info@hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com

(Technical Service Email)

Hypertherm, Inc.

Etna Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office Email)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service Email)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service Email)

866-643-7711 Tel (Return Materials Authorization)

877-371-2876 Fax (Return Materials Authorization)

return.materials@hypertherm.com (RMA email)

Hypertherm México, S.A. de C.V.

Avenida Toluca No. 444, Anexo 1,

Colonia Olivar de los Padres

Delegación Álvaro Obregón

México, D.F. C.P. 01780

52 55 5681 8109 Tel

52 55 5683 2127 Fax

Soporte.Tecnico@hypertherm.com (Technical Service Email)

Hypertherm Plasmatechnik GmbH

Sophie-Scholl-Platz 5

63452 Hanau

Germany

00 800 33 24 97 37 Tel

00 800 49 73 73 29 Fax

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emea@hypertherm.com (Technical Service Email)

Hypertherm (Singapore) Pte Ltd.

82 Genting Lane

Media Centre

Annexe Block #A01-01

Singapore 349567, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

Marketing.asia@hypertherm.com (Marketing Email)

TechSupportAPAC@hypertherm.com (Technical Service Email)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

HTJapan.info@hypertherm.com (Main Office Email)

TechSupportAPAC@hypertherm.com (Technical Service Email)

For training and education resources, go to the Hypertherm Cutting Institute (HCI) online at

www.hypertherm.com/hci.

Page 5

ENGLISH

WARNING! Before operating any Hypertherm equipment, read the safety

instructions in your product’s manual, the Safety and Compliance Manual

(80669C), Waterjet Safety and Compliance Manual (80943C), and

Radio Frequency Warning Manual (80945C). Failure to follow safety

instructions can result in personal injury or in damage to equipment.

Copies of the manuals may accompany the product in electronic and printed

formats. You can also obtain copies of the manuals, in all languages available

for each manual, from the “Documents library” at www.hypertherm.com.

BG (БЪЛГAPCКИ/BULGARIAN)

ПРЕДУПРЕЖДЕНИЕ! Преди да работите с което и да е оборудване

Hypertherm, прочетете инструкциите за безопасност в ръководството

на вашия продукт, „Инструкция за безопасност и съответствие“ (80669C),

„Инструкция за безопасност и съответствие на Waterjet“ (80943С)

и „Инструкция за предупреждение за радиочестота“ (80945С).

Копия на ръководствата може да придружават продукта в електронен

и в печатен формат. Можете да получите копия на ръководствата,

предлагани на всички езици, от „Documents library“ (Библиотека

за документи) на адрес www.hypertherm.com.

ET (EESTI/ESTONIAN)

HOIATUS! Enne Hyperthermi mis tahes seadme kasutamist lugege läbi toote

kasutusjuhendis olevad ohutusjuhised ning Ohutus- ja vastavusjuhend

(80669C), Veejoa ohutuse ja vastavuse juhend (80943C) ja Raadiosageduse

hoiatusjuhend (80945C). Ohutusjuhiste eiramine võib põhjustada vigastusi

ja kahjustada seadmeid.

Juhiste koopiad võivad olla tootega kaasas elektroonilises ja trükivormingus.

Juhiste koopiaid kõigis iga käsiraamatu jaoks saadaolevas keeles saate

hankida ka „Documents library (dokumentide raamatukogust)” lehel

www.hypertherm.com.

FI (SUOMI/FINNISH)

VAROITUS! Ennen minkään Hypertherm-laitteen käyttöä lue

tuotteen käyttöoppaassa olevat turvallisuusohjeet, turvallisuuden

ja vaatimustenmukaisuuden käsikirja (80669C), vesileikkauksen

turvallisuuden ja vaatimustenmukaisuuden käsikirja (80943C)

ja radiotaajuusvaroitusten käsikirja (80945C).

Käyttöoppaiden kopiot voivat olla tuotteen mukana elektronisessa

ja tulostetussa muodossa. Voit saada käyttöoppaiden kopiot kaikilla

kielillä ”latauskirjastosta”, joka on osoitteessa www.hypertherm.com.

CS (ČESKY/CZECH)

VAROVÁNÍ! Před uvedením jakéhokoli zařízení Hypertherm do provozu

si přečtěte bezpečnostní pokyny v příručce k produktu a v Manuálu pro

bezpečnost a dodržování předpisů (80669C), Manuálu pro bezpečnost

a dodržování předpisů při řezání vodním paprskem (80943C) a Manuálu

varování ohledně rádiových frekvencí (80945C).

Kopie příruček a manuálů mohou být součástí dodávky produktu,

a to v elektronické i tištěné formě. Kopie příruček a manuálů ve všech

jazykových verzích, v nichž byly dané příručky a manuály vytvořeny, naleznete

v „Knihovně dokumentů“ na webových stránkách www.hypertherm.com.

DA (DANSK/DANISH)

ADVARSEL! Inden Hypertherm udstyr tages i brug skal

sikkerhedsinstruktionerne i produktets manual og i Manual om sikkerhed

og overholdelse af krav (80669C), Manual om sikkerhed og overholdelse

af krav for vandstråleskæring (80943C), og Manual om radiofrekvensadvarsel

(80945C), gennemlæses.

Kopier af manualerne kan ledsage produktet i elektroniske og trykte formater.

Du kan også få kopier af manualer, på alle sprog der er til rådighed for hver

manuel, fra “Dokumentbiblioteket” på www.hypertherm.com.

DE (DEUTSCH/GERMAN)

WARNUNG! Bevor Sie ein Hypertherm-Gerät in Betrieb nehmen, lesen Sie

bitte die Sicherheitsanweisungen in Ihrer Bedienungsanleitung, das Handbuch

für Sicherheit und Übereinstimmung (80669C), das Handbuch für Sicherheit

und Compliance bei Wasserstrahl-Schneidanlagen (80943C) und das

Handbuch für Hochfrequenz-Warnung (80945C).

Bedienungsanleitungen und Handbücher können dem Gerät in elektronischer

Form oder als Druckversion beiliegen. Alle Handbücher und Anleitungen

können in den jeweils verfügbaren Sprachen auch in der

„Dokumente-Bibliothek“ unter www.hypertherm.com heruntergeladen werden.

ES (ESPAÑOL/SPANISH)

¡ADVERTENCIA! Antes de operar cualquier equipo Hypertherm, lea

las instrucciones de seguridad del manual de su producto, del Manual

de seguridad y cumplimiento (80669C), del Manual de seguridad

y cumplimiento en corte con chorro de agua (80943C) y del Manual

de advertencias de radiofrecuencia (80945C).

Pueden venir copias de los manuales en formato electrónico e impreso

junto con el producto. También se pueden obtener copias de los manuales,

en todos los idiomas disponibles para cada manual, de la “Biblioteca

de documentos” en www.hypertherm.com.

FR (FRANÇAIS/FRENCH)

AVERTISSEMENT! Avant d’utiliser tout équipement Hypertherm, lire les

consignes de sécurité dumanuel de votre produit, duManuel de sécurité

et de conformité (80669C), du Manuel de sécurité et de conformité du jet

d’eau (80943C) et du Manuel d'avertissement relatif aux radiofréqunces

(80945C).

Des copies de ces manuels peuvent accompagner le produit en format

électronique et papier. Vous pouvez également obtenir des copies de chaque

manuel dans toutes les langues disponibles à partir de la «Bibliothèque

de documents» sur www.hypertherm.com.

GR (ΕΛΛΗΝΙΚΆ/GREEK)

ΠΡΟΕΙΔΟΠΟΙΗΣΗ! Πριν θέσετε σε λειτουργία οποιονδήποτε εξοπλισμό της

Hypertherm, διαβάστε τις οδηγίες ασφαλείας στο εγχειρίδιο του προϊόντος

και στο εγχειρίδιο ασφάλειας και συμμόρφωσης (80669C), στο εγχειρίδιο

ασφάλειας και συμμόρφωσης του waterjet (80943C) και στο εγχειρίδιο

προειδοποιήσεων για τις ραδιοσυχνότητες (80945C).

Αντίγραφα των εγχειριδίων μπορεί να συνοδεύουν το προϊόν σε ηλεκτρονική

και έντυπη μορφή. Μπορείτε, επίσης, να λάβετε αντίγραφα των εγχειριδίων

σε όλες τις γλώσσες που διατίθενται για κάθε εγχειρίδιο από την ψηφιακή

βιβλιοθήκη εγγράφων (Documents library) στη διαδικτυακή τοποθεσία

www.hypertherm.com.

HU (MAGYAR/HUNGARIAN)

VIGYÁZAT! Mielőtt bármilyen Hypertherm berendezést üzemeltetne,

olvassa el a biztonsági információkat a termék kézikönyvében, a Biztonsági

és szabálykövetési kézikönyvben (80669C), a Vízsugaras biztonsági

és szabálykövetési kézikönyvben (80943C) és a Rádiófrekvenciás

figyelmeztetéseket tartalmazó kézikönyvben (80945C).

A termékhez a kézikönyv példányai elektronikus és nyomtatott formában

is mellékelve lehetnek. A kézikönyvek példányai (minden nyelven)

a www.hypertherm.com weboldalon a „Documents library”

(Dokumentum könyvtár) részben is beszerezhetők.

ID (BAHASA INDONESIA/INDONESIAN)

PERINGATAN! Sebelum mengoperasikan peralatan Hypertherm, bacalah

petunjuk keselamatan dalam manual produk Anda, Manual Keselamatan dan

Kepatuhan (80669C), Manual Keselamatan dan Kepatuhan Jet Air (80943C),

dan Manual Peringatan Frekuensi Radio (80945C). Kegagalan mengikuti

petunjuk keselamatan dapat menyebabkan cedera pribadi atau kerusakan

pada peralatan.

Produk mungkin disertai salinan manual dalam format elektronik maupun cetak.

Anda juga dapat memperoleh salinan manual, dalam semua bahasa yang

tersedia untuk setiap manual, dari "Perpustakaan dokumen"

di www.hypertherm.com.

Page 6

IT (ITALIANO/ITALIAN)

AVVERTENZA! Prima di usare un’attrezzatura Hypertherm, leggere le istruzioni

sulla sicurezza nel manuale del prodotto, nel Manuale sulla sicurezza e la

conformità (80669C), nel Manuale sulla sicurezza e la conformità Waterjet

(80943C) e nel Manuale di avvertenze sulla radiofrequenza(80945C).

Il prodotto può essere accompagnato da copie elettroniche e cartacee

del manuale. È anche possibile ottenere copie del manuale, in tutte le lingue

disponibili per ogni manuale, dall’“Archivio documenti” all’indirizzo

www.hypertherm.com.

RO (ROMÂNĂ/ROMANIAN)

AVERTIZARE! Înainte de utilizarea oricărui echipament Hypertherm, citiți

instrucțiunile de siguranță din manualul produsului, manualul de siguranță

și conformitate (80669C), manualul de siguranță și conformitate Waterjet

(80943C) și din manualul de avertizare privind radiofrecvența (80945C).

Produsul poate fi însoțit de copii ale manualului în format tipărit și electronic.

De asemenea, dumneavoastră puteţi obţine copii ale manualelor, în toate limbile

disponibile pentru fiecare manual, din cadrul secţiunii „Bibliotecă documente”

aflată pe site-ul www.hypertherm.com.

JA (日本語/JAPANESE)

警告 ! Hypertherm 機器を操作する前に、この製品説明書にある安全情報、

「安全とコンプライアンスマニュアル」 (80669C) 、「ウォータージェット

の安全とコンプライアンス」 (80943C)、「高周波警告」 (80945C) をお読み

ください。

説明書のコピーは、電子フォーマット、または印刷物として製品に同梱さ

れています。各説明書は、 www.hypertherm.com の「ドキュメントライブラ

リ」から各言語で入手できます。

KO (한국어/KOREAN)

경고! Hypertherm 장비를 사용하기 전에 제품 설명서와 안전 및 규정 준수

설명서(80669C), 워터젯 안전 및 규정 준수 설명서(80943C) 그리고 무선

주파수 경고 설명서(80945C)에 나와 있는 안전 지침을 읽으십시오.

전자 형식과 인쇄된 형식으로 설명서 사본이 제품과 함께 제공될

수 있습니다. www.hypertherm.com 의 'Documents library (문서라이브러리)'

에서도모든언어로이용할수있는설명서사본을얻을수있습니다.

NE (NEDERLANDS/DUTCH)

WAARSCHUWING! Lees voordat u Hypertherm-apparatuur gebruikt

de veiligheidsinstructies in de producthandleiding, in de Veiligheids-

en nalevingshandleiding (80669C) in de Veiligheids- en nalevingshandleiding

voor waterstralen (80943C) en in de Waarschuwingshandleiding

radiofrequentie (80945C).

De handleidingen kunnen in elektronische en gedrukte vorm met

het product worden meegeleverd. De handleidingen, elke handleiding

beschikbaar in alle talen, zijn ook verkrijgbaar via de “Documentenbibliotheek”

op www.hypertherm.com.

NO (NORSK/NORWEGIAN)

ADVARSEL! Før du bruker noe Hypertherm-utstyr, må du lese

sikkerhetsinstruksjonene i produktets håndbok, håndboken om sikkerhet

og samsvar (80669C), håndboken om vannjet sikkerhet og samsvar

(80943C), og håndboken om radiofrekvensadvarsler (80945C).

Eksemplarer av håndbøkene kan medfølge produktet i elektroniske og trykte

utgaver. Du kan også få eksemplarer av håndbøkene i alle tilgjengelige språk

for hver håndbok fra dokumentbiblioteket på www.hypertherm.com.

PL (POLSKI/POLISH)

OSTRZEŻENIE! Przed rozpoczęciem obsługi jakiegokolwiek systemu

firmy Hypertherm należy się zapoznać z instrukcjami bezpieczeństwa

zamieszczonymi w podręczniku produktu, w podręczniku bezpieczeństwa

i zgodności (80669C), podręczniku bezpieczeństwa i zgodności systemów

strumienia wody (80943C) oraz podręczniku z ostrzeżeniem o częstotliwości

radiowej (80945C).

Do produktu mogą być dołączone kopie podręczników w formacie

elektronicznym i drukowanym. Kopie podręczników, wkażdym udostępnionym

języku, można również znaleźć w„Bibliotece dokumentów” pod adresem

www.hypertherm.com.

PT (PORTUGUÊS/PORTUGUESE)

ADVERTÊNCIA! Antes de operar qualquer equipamento Hypertherm,

leia as instruções de segurança no manual do seu produto, no Manual

de Segurança e de Conformidade (80669C), no Manual de Segurança

e de Conformidade do Waterjet (80943C) e no Manual de Advertência

de radiofrequência (80945C).

Cópias dos manuais podem acompanhar os produtos nos formatos eletrônico

e impresso. Também é possível obter cópias dos manuais em todos os idiomas

disponíveis para cada manual na “Biblioteca de documentos” em

www.hypertherm.com.

RU (PУССКИЙ/RUSSIAN)

БЕРЕГИСЬ! Перед работой с любым оборудованием Hypertherm

ознакомьтесь с инструкциями по безопасности, представленными

в руководстве, которое поставляется вместе с продуктом,

в Руководстве по безопасности и соответствию (80669С),

в Руководстве по безопасности и соответствию для водоструйной

резки (80943C) и Руководстве по предупреждению о радиочастотном

излучении (80945С).

Копии руководств, которые поставляются вместе с продуктом, могут быть

представлены в электронном и бумажном виде. Копии руководств на всех

языках, на которые переведено то или иное руководство, можно также

загрузить в разделе «Библиотека документов» на веб-сайте

www.hypertherm.com.

SK (SLOVENČINA/SLOVAK)

VÝSTRAHA! Pred použitím akéhokoľvek zariadenia od spoločnosti Hypertherm

si prečítajte bezpečnostné pokyny v návode na obsluhu vášho zariadenia

avManuáli o bezpečnosti a súlade s normami (80669C), Manuáli

o bezpečnosti a súlade snormami pre systém rezania vodou (80943C)

avManuáli sinformáciami orádiofrekvencii (80945C).

Kópia návodu, ktorá je dodávaná s produktom, môže mať elektronickú

alebo tlačenú podobu. Kópie návodov, vo všetkých dostupných jazykoch,

sú k dispozícii aj v sekcii z „knižnice Dokumenty“ na www.hypertherm.com.

SL (SLOVE NŠČINA/SLOVENIAN)

OPOZORILO! Pred uporabo katerekoli Hyperthermove opreme preberite

varnostna navodila v priročniku vašega izdelka, v Priročniku za varnost in

skladnost (80669C), v Priročniku za varnost in skladnost sistemov rezanja

z vodnim curkom (80943C) in v Priročniku Opozorilo o radijskih frekvencah

(80945C).

Izdelku so lahko priloženi izvodi priročnikov v elektronski ali tiskani obliki.

Izvode priročnikov v vseh razpoložljivih jezikih si lahko prenesete tudi iz knjižnice

dokumentov “Documents library” na naslovu www.hypertherm.com.

SR (SRPSKI/SERBIAN)

UPOZORENJE! Pre rukovanja bilo kojom Hyperthermovom opremom

pročitajte uputstva o bezbednosti u svom priručniku za proizvod,

Priručniku o bezbednosti i usaglašenosti (80669C), Priručniku o bezbednosti

i usaglašenosti Waterjet tehnologije (80943C) i Priručniku sa upozorenjem

o radio-frekvenciji (80945C).

Može se dogoditi da kopije priručnika prate proizvod u elektronskom

i štampanom formatu. Takođe možete da pronađete kopije priručnika, na svim

jezicima koji su dostupni za svaki od priručnika, u “Biblioteci dokumenata”

(“Documents library”) na www.hypertherm.com.

SV (SVENSKA/SWEDISH)

VARNING! Läs häftet säkerhetsinformationen i din produkts säkerhets- och

efterlevnadsmanual (80669C), säkerhets- och efterlevnadsmanualen för

Waterjet (80943C) och varningsmanualen för radiofrekvenser (80945C)

för viktig säkerhetsinformation innan du använder eller underhåller

Hypertherm-utrustning.

Kopior av manualen kan medfölja produkten i elektronisk och tryckform.

Du hittar även kopior av manualerna i alla tillgängliga språk

i dokumentbiblioteket (Documents library) på www.hypertherm.com.

Page 7

TH (ภาษาไทย/THAI)

คําเตือน! กอนการใชงานอุปกรณของ Hypertherm ทั้งหมด โปรดอานคําแนะนําดาน

ความปลอดภัยในคูมือการใชสินคา คูมือดานความปลอดภัยและการปฏิบัติ

ตาม (80669C), คูมือดานความปลอดภัยและการปฏิบัติตามสําหรับการใชหัวตัดระบบ

วอเตอรเจ็ต (80943C) และ คูมือคําเตือนเกี่ยวกับความถี่วิทยุ (80945C)

การไมปฏิบัติตามคําแนะนําดานความปลอดภัยอาจสงผลใหเกิดการบาดเจ็บหรือเกิด

ความเสียหายตออุปกรณ

สินคาอาจมีสําเนาคูมือในรูปแบบอิเล็กทรอนิกสและแบบสิ่งพิมพแนบมาดวย นอกจาก

นี้ คุณสามารถขอรับสําเนาคูมือแตละประเภทเปนภาษาตาง ๆ ที่มีใหใชงานไดที่ “คลัง

เอกสาร” ในเว็บไซต www.hypertherm.com

TR (TÜRKÇE/TURKISH)

UYARI! Bir Hypertherm ekipmanını çalıştırmadan önce, ürününüzün kullanım

kılavuzunda, Güvenlik ve Uyumluluk Kılavuzu’nda (80669C), Su Jeti Güvenlik

ve Uyumluluk Kılavuzu’nda (80943C) ve Radyo Frekansı Uyarısı Kılavuzu’nda

(80945C) yer alan güvenlik talimatlarını okuyun.

Kılavuzların kopyaları, elektronik ve basılı formatta ürünle birlikte verilebilir.

Her biri tüm dillerde yayınlanan kılavuzların kopyalarını www.hypertherm.com

adresindeki “Documents library” (Dosyalar kitaplığı) başlığından da elde

edebilirsiniz.

VI (TIẾNG VIỆ T/VIETNAMESE)

CẢNH BÁO! Trước khi vận hành bất kỳ thiết bị Hypertherm nào, hãy đọc

các hướng dẫn an toàn trong hướng dẫn sử dụng sản phẩm của bạn,

Sổ tay An toàn và Tuân thủ

(80943C), và

thủ các hướng dẫn an toàn có thể dẫn đến thương tích cá nhân hoặc hư

hỏng thiết bị.

Bản sao của các hướng dẫn sử dụng có thể đi kèm sản phẩm ở định dạng

điện tử và bản in. Bạn cũng có thể lấy bản sao của các hướng dẫn sử dụng,

thuộc tất cả các ngôn ngữ hiện có cho từng hướng dẫn sử dụng, từ “Thư

viện tài liệu” tại địa chỉ www.hypertherm.com.

Hướng dẫn Cảnh báo Tần số Vô tuyến

(80669C),

Sổ tay An toàn và Tuân thủ Tia nước

(80945C). Không tuân

ZH-CN (简 体中文/CHINESE SIMPLIFIED)

警告! 在操作任何海宝设备之前,请阅读产品手册、《安全和法规遵守手

册》 (80669C)、《水射流安全和法规遵守手册》 (80943C) 以及

《射频警告手册》 (80945C) 中的安全操作说明。

随产品提供的手册可能提供电子版和印刷版两种格式。您也可从

“Documents library” (文档资料库)中获取每本手册所有可用语言的副本,

网址为 www.hypertherm.com.

ZH-TW (繁 體中文/CHINESE TRADITIONAL)

警告!在操作任何Hypertherm設備前,請先閱讀您產品手冊內的安全指

示,包括 《安全和法規遵從手冊》(80669C)、《水刀安全和法規遵從手冊》

(80943C),以及 《無線電頻率警示訊號手冊》(80945C)。

手冊複本可能以電子和印刷格式隨附產品提供。您也可以在

www.hypertherm.com 的 「文檔資料庫」內獲取所有手冊的多語種複本。

Page 8

Page 9

Contents

Electromagnetic Compatibility (EMC) .................................................................................. 21

Introduction........................................................................................................................................................... 21

Installation and use ............................................................................................................................................. 21

Assessment of area ............................................................................................................................................ 21

Methods of reducing emissions....................................................................................................................... 21

Mains supply............................................................................................................................................. 21

Maintenance of cutting equipment.................................................................................................................. 21

Cutting cables...................................................................................................................................................... 21

Equipotential bonding ............................................................................................................................ 21

Earthing of the workpiece ..................................................................................................................... 22

Screening and shielding.................................................................................................................................... 22

Warranty..................................................................................................................................... 23

Attention................................................................................................................................................................ 23

General.................................................................................................................................................................. 23

Patent indemnity.................................................................................................................................................. 23

Limitation of liability............................................................................................................................................. 23

National and local codes................................................................................................................................... 23

Liability cap........................................................................................................................................................... 24

Insurance............................................................................................................................................................... 24

Transfer of rights ................................................................................................................................................. 24

Waterjet product warranty coverage.............................................................................................................. 24

Product...................................................................................................................................................... 24

Parts coverage......................................................................................................................................... 24

EDGE Connect Installation and Setup Manual 809340 9

Page 10

Contents

Shrink-wrap License Agreement ............................................................................................25

1 Specifications and Installation .............................................................................................. 27

Overview ............................................................................................................................................................... 27

Data plate.................................................................................................................................................. 28

Upon receipt............................................................................................................................................. 29

Claims............................................................................................................................................ 29

Installation requirements.................................................................................................................................... 29

Placement of system components.................................................................................................................. 30

Embedded-CNC specifications ...................................................................................................................... 30

Environmental requirements ............................................................................................................................. 30

EDGE Connect (model number 090184)..................................................................................................... 31

Before you begin..................................................................................................................................... 32

Enclosure ...................................................................................................................................... 32

Monitor........................................................................................................................................... 32

Video cable................................................................................................................................... 35

USB cable..................................................................................................................................... 35

Ethernet cable.............................................................................................................................. 35

EtherCAT cable ........................................................................................................................... 36

External power supply and power cord.................................................................................. 36

Power button and cable ............................................................................................................ 37

EtherCAT drives .......................................................................................................................... 37

EDGE Connect installation overview.................................................................................................. 38

EDGE Connect dimensions and weight............................................................................................ 39

Mount the EDGE Connect.................................................................................................................... 39

EDGE Connect wall mount....................................................................................................... 39

EDGE Connect DIN rail mount................................................................................................ 40

Ground the EDGE Connect ................................................................................................................. 40

EDGE Connect connector locations.................................................................................................. 41

EDGE Connect TC (model number 090198).............................................................................................. 42

Before you begin..................................................................................................................................... 43

Ethernet cable.............................................................................................................................. 43

EtherCAT cable ........................................................................................................................... 43

External power supply and power cord.................................................................................. 44

EtherCAT drives .......................................................................................................................... 44

EDGE Connect TC installation overview........................................................................................... 45

EDGE Connect TC touchscreen specifications.............................................................................. 46

EDGE Connect TC dimensions and weight..................................................................................... 46

Mount the EDGE Connect TC............................................................................................................. 48

EDGE Connect TC bottom mount.......................................................................................... 48

EDGE Connect TC VESA mount............................................................................................ 49

10 809340 Installation and Setup Manual EDGE Connect

Page 11

Contents

EDGE Connect TC flush-mount.............................................................................................. 50

Ground the EDGE Connect TC .......................................................................................................... 53

EDGE Connect TC rear I/O panel connector locations ................................................................ 54

Recommended grounding and shielding....................................................................................................... 55

Introduction............................................................................................................................................... 55

Types of grounding................................................................................................................................. 55

Grounding practices............................................................................................................................... 56

Example grounding diagram with an HPR or MAXPRO200 cutting system............................. 60

Example grounding diagram with an XPR cutting system............................................................. 61

Symbols and marks ............................................................................................................................................ 62

2 Operate ....................................................................................................................................... 63

Operate Phoenix.................................................................................................................................................. 64

Operate the standard Hypertherm Soft Op Con......................................................................................... 65

Station control tab .................................................................................................................................. 66

Program control....................................................................................................................................... 66

Manual motion tab................................................................................................................................... 67

Screen capture and live video tab....................................................................................................... 68

Information tab ......................................................................................................................................... 69

Automatically open a custom software operator console.......................................................................... 70

Before you begin..................................................................................................................................... 70

Modify the EDGE Connect Launcher................................................................................................. 70

Phoenix Help and technical documentation ................................................................................................. 73

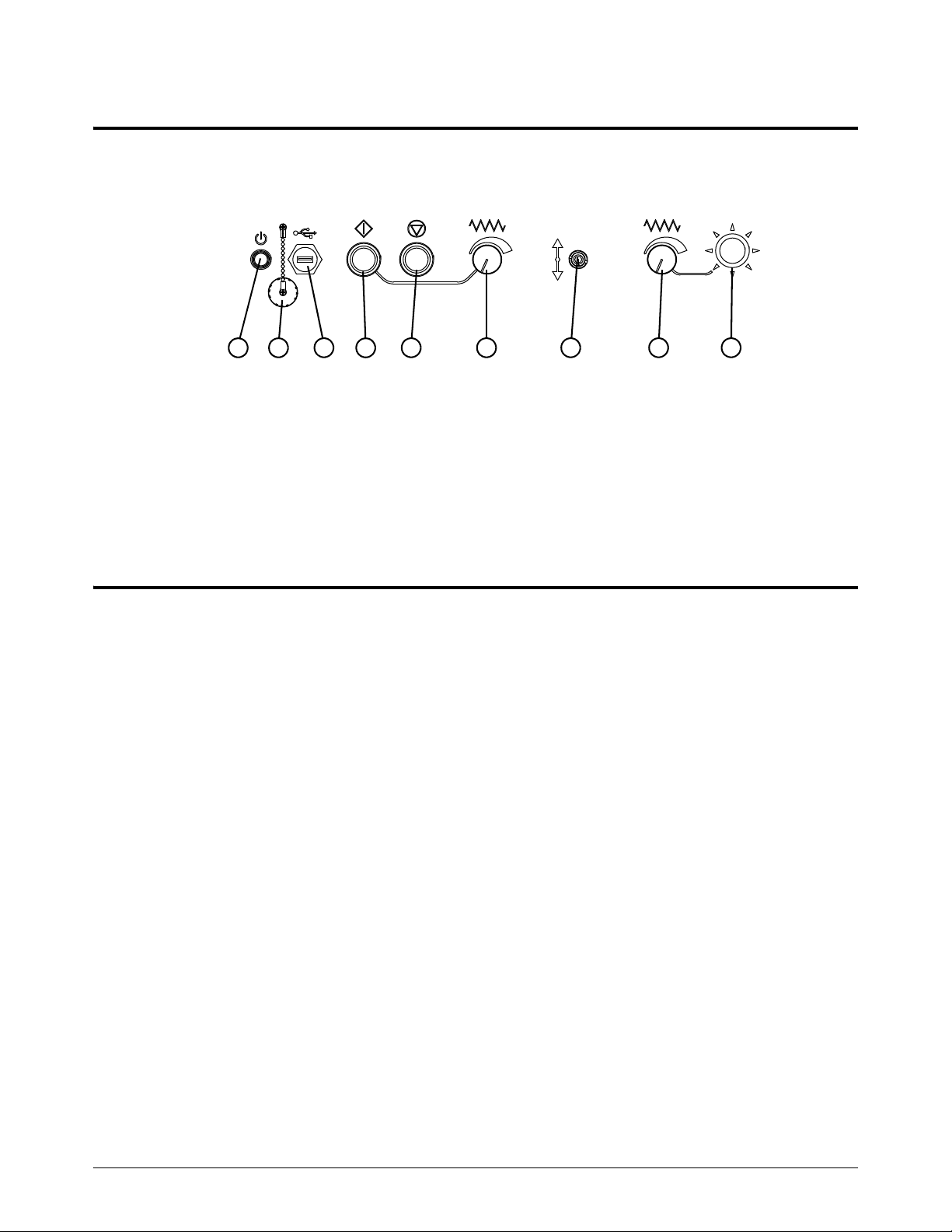

Operate the EDGE Connect TC hardware operator console.................................................................. 77

Operate the touchscreen .................................................................................................................................. 77

Touchscreens, drops of water, and unintended motion................................................................. 77

Optional keyboard and mouse......................................................................................................................... 78

3 Machine Stop Strategies and Table Hardware ....................................................................79

Machine stop strategies .....................................................................................................................................79

How the CNC stops motion..............................................................................................................................80

Program pause/stop (non-urgent stop)..............................................................................................80

Fast stop/fast deceleration (urgent stop)...........................................................................................80

Fault ramp ..................................................................................................................................................80

Emergency stop (E-stop) and Fast Stop compared........................................................................82

Fast Stop........................................................................................................................................82

Emergency stop............................................................................................................................82

Enable the cutting machine after a power cycle or stop.............................................................................83

Safety circuit example .........................................................................................................................................84

Drive enable signals.............................................................................................................................................85

EDGE Connect Installation and Setup Manual 809340 11

Page 12

Contents

Drive Enable output .................................................................................................................................85

Drive Disabled input ................................................................................................................................85

Hardware overtravel limits..................................................................................................................................85

Software travel limits ...........................................................................................................................................86

Home switches.....................................................................................................................................................87

General recommendations.................................................................................................................................88

4 Configure the EtherCAT Network........................................................................................... 89

Before you begin................................................................................................................................................. 89

Scan your slave devices.................................................................................................................................... 90

Enable and set up distributed clocks............................................................................................................. 94

Export your network configuration to the CNC............................................................................................ 98

5 Machine Axes.......................................................................................................................... 101

Overview ............................................................................................................................................................ 101

Axis orientation and positive motion ............................................................................................................ 102

Axis assignments.............................................................................................................................................. 103

4-axis, I-cutting, no Dual Gantry....................................................................................................... 103

5-axis, I-cutting, with Dual Gantry.................................................................................................... 104

6-axis, 2-station, I-cutting, with Dual Gantry ................................................................................. 104

Machine setups screen................................................................................................................................... 104

Transverse or Rail axis ........................................................................................................................ 105

Using software travel limits ................................................................................................................ 108

Dual Gantry axis.................................................................................................................................... 110

6 Speeds ...................................................................................................................................... 111

Set speeds ........................................................................................................................................................ 111

Set speed ranges (speed breaks).................................................................................................... 111

Acceleration rates ................................................................................................................................ 112

Maximum machine speed................................................................................................................... 113

Set the speed for manual moves...................................................................................................... 113

Home speeds........................................................................................................................................ 114

Corner speed........................................................................................................................................ 114

Limited speeds...................................................................................................................................... 114

Trapezoidal motion compared to S-curve motion .................................................................................... 115

S-curve setup........................................................................................................................................ 117

Change the cutting speed ............................................................................................................................. 118

Cutting speed and acceleration affects cut quality...................................................................... 118

12 809340 Installation and Setup Manual EDGE Connect

Page 13

Contents

7 I/O – Inputs and Outputs....................................................................................................... 119

Introduction........................................................................................................................................................ 119

Types of I/O....................................................................................................................................................... 119

Fixed function I/O (virtual).................................................................................................................. 119

How to view fixed function I/O.......................................................................................................... 120

Fixed function I/O for HPRXD plasma power supplies................................................... 120

Fixed function I/O for the EDGE Connect TC hardware operator console................ 121

General purpose I/O ........................................................................................................................... 121

Numbered I/O....................................................................................................................................... 121

Assign I/O.......................................................................................................................................................... 122

How Phoenix assigns I/O................................................................................................................... 122

Assign the digital I/O........................................................................................................................... 123

Logic............................................................................................................................................ 124

Torch Collision uses................................................................................................................ 124

Drive Enables ............................................................................................................................ 124

Initial Feedback Delay ............................................................................................................. 124

Joystick Installed....................................................................................................................... 125

Analog I/O.............................................................................................................................................. 125

Arc voltage................................................................................................................................. 125

Enable speed pots................................................................................................................... 125

Speed overrides ....................................................................................................................... 126

Assign analog inputs ............................................................................................................... 126

Analog Input Offset 1 – 32.................................................................................................... 127

Analog outputs...................................................................................................................................... 127

Digital I/O definitions........................................................................................................................... 127

Digital inputs.............................................................................................................................. 127

Digital outputs........................................................................................................................... 131

8 Torch Height Control (THC)................................................................................................... 135

Sensor THC ...................................................................................................................................................... 135

About plasma torch height control................................................................................................... 135

Sensor THC setup............................................................................................................................... 136

Assign the Sensor THC to an axis............................................................................................................... 137

Set speeds and acceleration......................................................................................................................... 137

Set up Torch Height Disable......................................................................................................................... 138

Define the THC axis......................................................................................................................................... 140

Voltage Gain.......................................................................................................................................... 140

Servo Error Tolerance ......................................................................................................................... 140

Stall Force Tolerance .......................................................................................................................... 140

Encoder Counts per mm (inch) ........................................................................................................ 141

Retry on Transfer Fail .......................................................................................................................... 141

EDGE Connect Installation and Setup Manual 809340 13

Page 14

Contents

Slide Length .......................................................................................................................................... 141

Home setting for current-type drives............................................................................................... 142

Tracking Mode ...................................................................................................................................... 142

Home the axis ................................................................................................................................................... 143

Manual .................................................................................................................................................... 143

Automatic............................................................................................................................................... 143

Set the Sensor THC operating modes ....................................................................................................... 143

Automatic modes ................................................................................................................................. 143

Manual mode......................................................................................................................................... 143

Sample Arc Voltage mode ................................................................................................................. 144

Set Arc Voltage mode......................................................................................................................... 146

Methods for changing the Set Arc Voltage........................................................................ 146

THC voltage offsets................................................................................................................. 146

Change offsets automatically for Sensor THC.................................................................. 147

Increase or decrease arc voltage in Automatic mode ..................................................... 148

Raise and lower cut height in Manual mode.................................................................................. 148

Change arc voltage in the Process screen or cut chart ............................................................. 148

Initial height sense ........................................................................................................................................... 149

IHS sequence ....................................................................................................................................... 149

IHS in Manual mode ............................................................................................................................ 149

Perform a first IHS ............................................................................................................................... 149

Offset IHS.................................................................................................................................. 150

When to disable height control......................................................................................................... 151

THC sequence of operations........................................................................................................................ 151

Set up a Watch Window................................................................................................................................ 153

9 Station Setup........................................................................................................................... 155

Overview ............................................................................................................................................................ 155

Generic and numbered I/O............................................................................................................................ 156

Generic I/O............................................................................................................................................ 156

Numbered I/O....................................................................................................................................... 156

Enable station I/O ............................................................................................................................................ 157

Auto Select and Manual Select inputs and Station Enable LED output................................. 157

Use Manual mode as an override..................................................................................................... 159

Summary ................................................................................................................................................ 159

THC and cut chart setup on the Station Configuration screen ............................................................ 161

Guidelines for using the Station Configuration screen ............................................................... 162

Conflicting process ......................................................................................................................................... 162

Example of a conflicting process...................................................................................................... 163

How a tool is associated with a station .............................................................................. 163

A conflicting process example that prevents a program from loading..................................... 164

14 809340 Installation and Setup Manual EDGE Connect

Page 15

Contents

Troubleshooting a conflicting process error.................................................................................. 165

The settings look correct on the screen below................................................................. 165

The cause of the error............................................................................................................. 166

Troubleshooting steps .................................................................................................................................... 166

Remove a station from the Soft Op Con........................................................................................ 167

10 Plasma Setup........................................................................................................................... 169

Overview ............................................................................................................................................................ 169

Plasma 1 and Plasma 2.................................................................................................................................. 170

Sample settings for a single-torch cutting system....................................................................... 170

Sample settings for a multiple-torch cutting system.................................................................... 171

Sample settings for a two-torch cutting system........................................................................... 173

Plasma cut sequence...................................................................................................................................... 174

Setting up inputs and outputs for plasma .................................................................................................. 177

Fixed function I/O for HPRXD........................................................................................................... 177

Station I/O for the Soft Op Con....................................................................................................... 177

Summary: setting up the plasma routine .................................................................................................... 178

I/O, plasma power supply status, and diagnostics information............................................................. 179

Plasma power supply status.............................................................................................................. 179

Remote tools (HPR diagnostics)...................................................................................................... 180

Plasma power supply and gas console I/O ................................................................................... 181

Plasma power supply inputs.................................................................................................. 181

Gas console inputs.................................................................................................................. 182

Plasma power supply outputs............................................................................................... 183

Gas console outputs ............................................................................................................... 184

11 Phoenix Setup Files................................................................................................................ 185

About setup files .............................................................................................................................................. 185

Setup files from previous versions of Phoenix............................................................................... 186

Save and load the setup file .......................................................................................................................... 186

Save a setup file with a different name ........................................................................................... 187

Load a setup file................................................................................................................................... 187

Save system files for troubleshooting ......................................................................................................... 188

Save and load default settings...................................................................................................................... 188

Save Default.ini..................................................................................................................................... 188

Load Default.ini..................................................................................................................................... 189

Reload factory settings................................................................................................................................... 190

EDGE Connect Installation and Setup Manual 809340 15

Page 16

Contents

12 Local Area Networking........................................................................................................... 191

Connect to a local area network with wireless or Ethernet.................................................................... 191

Notes....................................................................................................................................................... 193

Map a drive........................................................................................................................................................ 194

13 Back Up and Restore the System........................................................................................ 197

Introduction........................................................................................................................................................ 197

Backup................................................................................................................................................................ 198

Restore ............................................................................................................................................................... 200

14 Troubleshooting and Diagnostics ........................................................................................ 203

Save system files for troubleshooting ......................................................................................................... 204

™

Remote Help

CNC troubleshooting...................................................................................................................................... 205

CNC messages.................................................................................................................................... 205

CNC information screen..................................................................................................................... 205

General CNC troubleshooting.......................................................................................................... 207

Test the PC board and connectors ................................................................................................. 211

Log data with the oscilloscope ......................................................................................................... 213

HPRXD plasma power supply troubleshooting ........................................................................................ 217

HPR error help...................................................................................................................................... 217

HPR information screens ................................................................................................................... 217

Bypass an HPRXD on the EtherCAT network .............................................................................. 218

from a technician .................................................................................................................. 205

When you push the power button, the CNC does not power ON............................... 207

The power button is illuminated, but the touchscreen or monitor is black ................. 208

The warning message The display settings for this system are not at the optimal values

appears....................................................................................................................................... 209

The monitor displays a burn-in, ghost, or dim outline of a previously displayed image....

209

Previously mapped local network drives do not show when you try to load a part .. 209

You cannot download part programs over the local network (LAN or wireless)....... 210

The CNC does not recognize a USB device..................................................................... 210

LEDs and test points for EDGE Connect TC.................................................................... 211

Test the USB, EtherCAT, and LAN connectors and hardware operator console..... 213

Hardware operator console for EDGE Connect TC only ............................................... 213

Save an oscilloscope file........................................................................................................ 215

Load an oscilloscope file........................................................................................................ 215

View an oscilloscope file ........................................................................................................ 216

Bypass the HPRXD in a single-HPRXD cutting system................................................. 219

Put the HPRXD back on the network in a single-HPRXD cutting system.................. 220

16 809340 Installation and Setup Manual EDGE Connect

Page 17

Contents

Bypass an HPRXD in a multiple-HPRXD cutting system............................................... 220

Put an HPRXD back on the network in a multiple-HPRXD cutting system................ 222

Status messages.............................................................................................................................................. 224

Plasma cut sequence status messages.......................................................................................... 224

Tool status messages ......................................................................................................................... 225

Dialog box messages: pauses, faults, and errors..................................................................................... 226

Tool dialog box messages.................................................................................................................. 226

Tool error dialog box example ............................................................................................... 226

Troubleshooting tool errors.................................................................................................... 227

CNC pauses, faults, and errors ........................................................................................................ 227

Troubleshooting CNC pauses, faults, and errors ............................................................. 228

CNC dialog box message examples .................................................................................. 229

CNC fault message reference .......................................................................................................... 231

Fast Stop Active ....................................................................................................................... 231

HPR Fault................................................................................................................................... 231

Cut Gas Lost............................................................................................................................. 232

Cut Sense Lost......................................................................................................................... 232

Invalid Process Requested in Part Program ...................................................................... 233

Remote Pause Active.............................................................................................................. 234

Safety Mat Active ..................................................................................................................... 234

Software Limit Active............................................................................................................... 235

Torch Collision.......................................................................................................................... 235

Field Bus Drives Not Ready................................................................................................... 236

Take HPR# Out for Service? ................................................................................................ 236

CNC error message reference ......................................................................................................... 238

Error 1) Transverse position error......................................................................................... 238

Error 2) Rail Position Error ..................................................................................................... 238

Error 3) Dual Gantry Position Error...................................................................................... 238

Error 4) Rotate Position Error................................................................................................ 239

Error 5) Tilt Position Error....................................................................................................... 239

Error 6) CBH Position Error................................................................................................... 239

Error 7) THC Position Error ................................................................................................... 239

Error 8) Transverse Positive Hardware Overtravel........................................................... 240

Error 9) Rail Positive Hardware Overtravel ........................................................................ 241

Error 13) Transverse Negative Hardware Overtravel....................................................... 242

Error 14) Rail Negative Hardware Overtravel.................................................................... 243

Error 18) Transverse Positive Software Overtravel.......................................................... 243

Error 19) Rail Positive Software Overtravel ....................................................................... 244

Error 23) Transverse Negative Software Overtravel........................................................ 244

Error 24) Rail Negative Software Overtravel ..................................................................... 244

Error 28) Tilt Positive Hardware Overtravel ....................................................................... 245

EDGE Connect Installation and Setup Manual 809340 17

Page 18

Contents

Error 29) Tilt Negative Hardware Overtravel ..................................................................... 246

Error 30) Tilt Positive Software Overtravel......................................................................... 246

Error 31) Tilt Negative Software Overtravel....................................................................... 247

Error 34) Rotate Positive Software Overtravel.................................................................. 247

Error 35) Rotate Negative Software Overtravel................................................................ 247

Error 36) Dual Gantry Skew Error........................................................................................ 248

Error 37) Collision Fault.......................................................................................................... 248

Error 38) Excessive Mechanical Skew................................................................................ 249

Error 41) Dual Head Collision Fault..................................................................................... 250

Error 42) Torch Collision........................................................................................................ 251

Error 44) Hardware Fault or Failure ..................................................................................... 252

Error 45) Dual Transverse Positive Hardware Overtravel............................................... 253

Error 46) Dual Transverse Negative Software Overtravel .............................................. 253

Error 47) Dual Transverse Positive Software Overtravel ................................................ 253

Error 48) Dual Transverse Negative Software Overtravel .............................................. 254

Error 60) Field Bus Configuration Fault.............................................................................. 254

Error 61) Field Bus Device Fault .......................................................................................... 255

Network diagnostic screen................................................................................................................ 255

Error 62) Field Bus Network Fault........................................................................................ 256

Error 64) Field Bus Slave Fault............................................................................................. 257

Error 66) RTOS Watchdog Fault......................................................................................... 258

Error 67) PLC application ...................................................................................................... 258

Error 68) PLC............................................................................................................................ 258

HASP warning and error message reference................................................................................ 259

The warning message Use of this control has expired appears................................... 259

Error 18) HASP key ID not found......................................................................................... 260

Error 19) HASP invalid update data.................................................................................... 260

Error 54) HASP Update Too Old......................................................................................... 260

Error 55) HASP Update Too New ....................................................................................... 261

Plasma cutting tips .......................................................................................................................................... 262

Cut quality problems ........................................................................................................................... 262

Angularity.................................................................................................................................... 262

Dross........................................................................................................................................... 263

Surface finish............................................................................................................................. 263

Color............................................................................................................................................ 264

Basic steps to improve cut quality ................................................................................................... 264

Step 1: Is the plasma arc cutting in the appropriate direction?.................................... 264

Step 2: Was the correct process selected for the material and thickness?.............. 265

Step 3: Are the consumables worn?................................................................................... 266

Step 4: Is the torch square to the workpiece?.................................................................. 266

Step 5: Is the cut height set at the proper height?.......................................................... 266

18 809340 Installation and Setup Manual EDGE Connect

Page 19

Contents

Step 6: Is the cutting speed set too fast or too slow?.................................................... 267

Step 7: Are there problems with the gas delivery system?............................................ 267

Step 8: Is there torch vibration? ........................................................................................... 267

Step 9: Does the table need to be tuned? ........................................................................ 267

Bevel cutting tips.............................................................................................................................................. 268

Types of bevel cuts.............................................................................................................................. 268

I cut.............................................................................................................................................. 268

V cut ............................................................................................................................................ 268

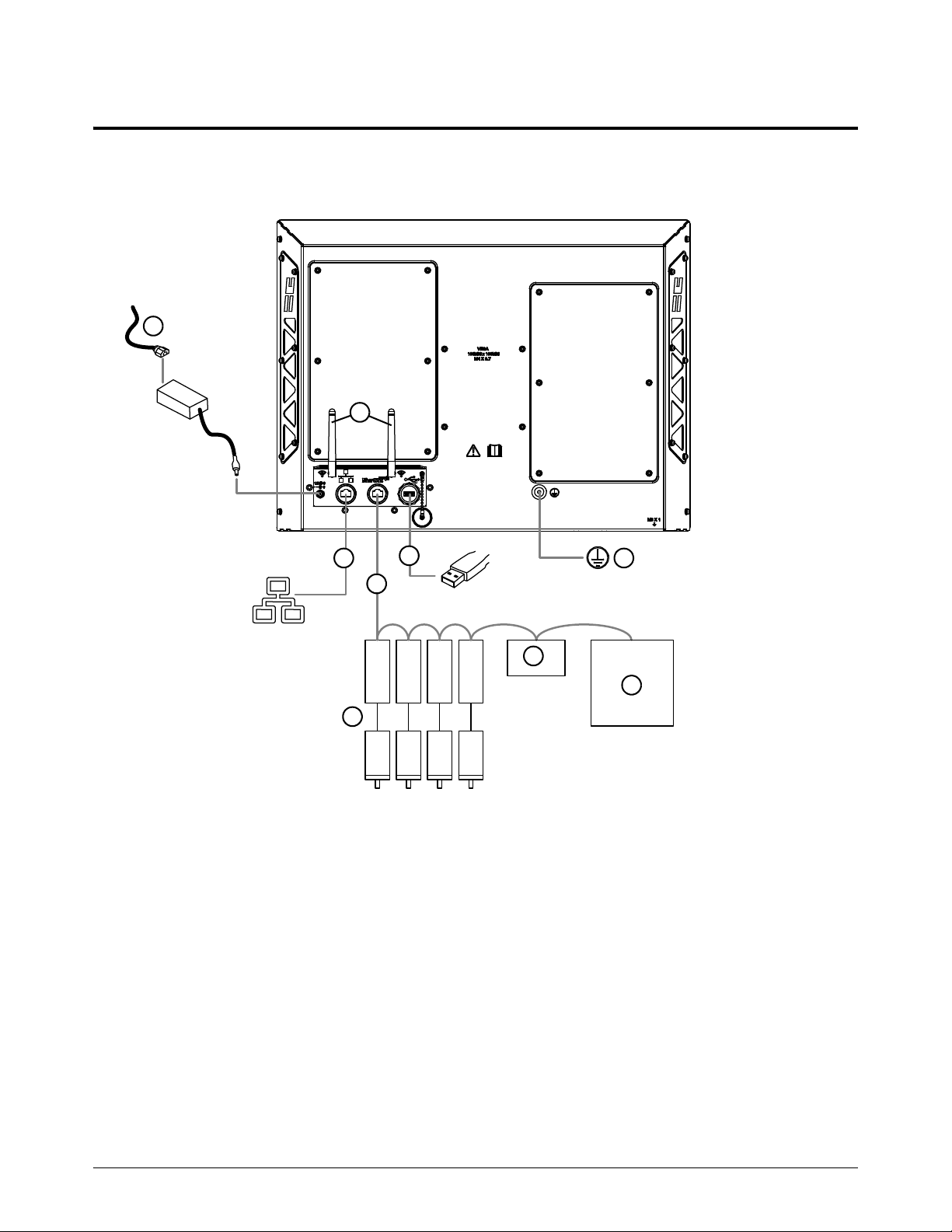

A cut............................................................................................................................................ 268