EoE (Ethernet over EtherCAT) Command

Messaging

Set up and use an EDGE® Connect CNC with Inkjet or

Dot Peen printing and marking systems

Application Note

810940 | Revision 0 | June 2023

Hypertherm, Inc.

21 Great Hollow Road, P.O. Box 5010

Hanover, NH 03755 USA

603-643-3441 Tel (Main Office)

603-643-5352 Fax (All Departments)

info@hypertherm.com (Main Office)

800-643-9878 Tel (Technical Service)

technical.service@hypertherm.com (Technical Service)

800-737-2978 Tel (Customer Service)

customer.service@hypertherm.com (Customer Service)

Hypertherm México, S.A. de C.V.

52 55 5681 8109 Tel

52 55 5681 7978 Tel

soporte.tecnico@hypertherm.com (Technical Service)

Hypertherm Plasmatechnik GmbH

Sophie-Scholl-Platz 5

63452 Hanau

Germany

00 800 33 24 97 37 Tel

00 800 49 73 73 29 Fax

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emeia@hypertherm.com (Technical Service)

Hypertherm (Singapore) Pte Ltd.

Solaris @ Kallang 164

164 Kallang Way #03-13

Singapore 349248, Republic of Singapore

65 6841 2489 Tel

65 6841 2490 Fax

marketing.asia@hypertherm.com (Marketing)

techsupportapac@hypertherm.com (Technical Service)

Hypertherm Japan Ltd.

Level 9, Edobori Center Building

2-1-1 Edobori, Nishi-ku

Osaka 550-0002 Japan

81 6 6225 1183 Tel

81 6 6225 1184 Fax

htjapan.info@hypertherm.com (Main Office)

techsupportapac@hypertherm.com (Technical Service)

Hypertherm Europe B.V.

Laan van Kopenhagen 100

3317 DM Dordrecht

Nederland

31 165 596907 Tel

31 165 596901 Fax

31 165 596908 Tel (Marketing)

31 (0) 165 596900 Tel (Technical Service)

00 800 4973 7843 Tel (Technical Service)

technicalservice.emeia@hypertherm.com (Technical Service)

Hypertherm (Shanghai) Trading Co., Ltd.

B301, 495 ShangZhong Road

Shanghai, 200231

PR China

86-21-80231122 Tel

86-21-80231120 Fax

86-21-80231128 Tel (Technical Service)

techsupport.china@hypertherm.com (Technical Service)

South America & Central America: Hypertherm Brasil Ltda.

Rua Bras Cubas, 231 – Jardim Maia

Guarulhos, SP – Brasil

CEP 07115-030

55 11 2409 2636 Tel

tecnico.sa@hypertherm.com (Technical Service)

Hypertherm Korea Branch

#3904. APEC-ro 17. Heaundae-gu. Busan.

Korea 48060

82 (0)51 747 0358 Tel

82 (0)51 701 0358 Fax

marketing.korea@hypertherm.com (Marketing)

techsupportapac@hypertherm.com (Technical Service)

Hypertherm Pty Limited

GPO Box 4836

Sydney NSW 2001, Australia

61 7 3103 1695 Tel

61 7 3219 9010 Fax

au.sales@hypertherm.com (Main Office)

techsupportapac@hypertherm.com (Technical Service)

Hypertherm (India) Thermal Cutting Pvt. Ltd

A-18 / B-1 Extension,

Mohan Co-Operative Industrial Estate,

Mathura Road, New Delhi 110044, India

91-11-40521201/ 2/ 3 Tel

91-11 40521204 Fax

htindia.info@hypertherm.com (Main Office)

technicalservice.emeia@hypertherm.com (Technical Service)

© 2023 Hypertherm, Inc. All rights reserved. 100% Associate-owned.

EDGE, Phoenix, and Hypertherm are trademarks of Hypertherm, Inc. and may be registered in the United States and/or other countries. EtherCAT is a

trademark of Beckhoff Automation. All other trademarks are the property of their respective holders.

Environmental stewardship is one of Hypertherm’s core values.www.hypertherm.com/environment

Introduction

To operate Inkjet or Dot Peen marking systems and other external Internet Protocol (IP) devices, the

®

EDGE

This document explains how to set up your EDGE Connect CNC to send EoE command messages

to external devices with TCP (Transmission Control Protocol) and UDP (User Datagram Protocol).

Connect CNC sends command messages through EoE (Ethernet over EtherCAT).

Before you begin

EoE Command Messaging

The equipment that follows is necessary to operate an EDGE Connect CNC with Inkjet or Dot Peen

marking systems:

Ethernet enabled Inkjet/Dot Peen marking system, such as a REA JET (Inkjet), Telesis,

Markator (Dot Peen), RN Mark, or others

Beckhoff EL6601 or a Beckhoff EL6614 EoE module (with coupler)

If you only need 1 port, use the EL6601. If you need 2, 3, or 4 ports, use

the EL6614. Refer to Figure 2 on page 5. Only one of these modules is

supported per EtherCAT network.

EDGE Connect CNC with Phoenix

EDGE Connect Application Note 810940 3

®

10.22 or later

EoE Command Messaging

Set up EoE command messaging at the CNC

Here is a summary of how to set up an EDGE Connect CNC to send EoE command messages to a

printer, marker, or other external IP device:

1. Connect the hardware. Refer to page 5.

2. Scan the EtherCAT network. Refer to page 6.

3. Set the IP address in Hypertherm EtherCAT Studio. Refer to page 6.

4. Export the XML. Refer to page 8.

5. Set the IP address and port in Phoenix. Refer to page 8.

6. Create a test part program. Refer to page 10.

7. Test communication. Refer to page 11.

These steps are described in more detail in the sections that follow.

4 810940 Application Note EDGE Connect

Step 1: Connect the hardware

I/O module*

(Beckhoff

EL6601 or

EL6614)

External IP device

(connected with an

Ethernet cable)

Plasma

power

supply

(XPR300)

4 drives and 4 motors

* Install the I/O module in one of these two locations:

Between the EDGE Connect CNC and the drives (not shown)

OR

Between the last drive and the first plasma power supply on the EtherCAT network (as shown)

EtherCAT coupler

EDGE Connect TC

Ethernet port 1

Ethernet port 1

Ethernet port 2

Ethernet port 3

Ethernet port 4

Beckhoff EL6601 Beckhoff EL6614

It is necessary to connect the EDGE Connect CNC, Beckhoff module, and external IP device

(printer or marker). Refer to Figure 1.

Figure 1 – Example of the connections between an EDGE Connect CNC and an external IP device

EoE Command Messaging

To connect the hardware:

1. Use an Ethernet cable to connect your printer, marker, or other IP device to a Beckhoff EL6601

(1 port) or to a Beckhoff EL6614 (up to 4 ports) module.

Figure 2

EDGE Connect Application Note 810940 5

EoE Command Messaging

2. Use an EtherCAT cable to connect the EDGE Connect CNC to an EtherCAT coupler.

3. Attach the Beckhoff EL6601 or EL6614 to the EtherCAT coupler. Refer to Beckhoff’s

recommendations.

Step 2: Scan the EtherCAT network

Use Hypertherm EtherCAT Studio to create a new Network Configuration file (Phoenix.xml) that

includes the Beckhoff EL6601 or Beckhoff EL6614 module. Refer to the EDGE Connect

Installation and Setup Manual (809340 Revision 4). Technical documentation is available at

www.hypertherm.com/docs.

Step 3: Set the IP address in Hypertherm EtherCAT Studio

After the hardware is set up, use Hypertherm EtherCAT Studio to review the IP address that is

assigned to your printer.

By default, Hypertherm EtherCAT Studio and Phoenix assign these IP addresses to your printer:

192.168.50.101: 5002

192.168.50.102: 5003

192.168.50.103: 5004

192.168.50.104: 5005

To find out if it is necessary to edit the IP address and port destinations, refer to the documentation

from the printer manufacturer.

Optional: Do these steps to edit the IP address destination for your printer in Hypertherm EtherCAT

Studio:

1. On the CNC, select the Windows Start icon and select Hypertherm > HT EtherCAT Studio.

2. In Hypertherm EtherCAT studio, select the Beckhoff module in the list, as shown in the example

below.

6 810940 Application Note EDGE Connect

EoE Command Messaging

Fourth octet

(Edit these characters only.)

3. On the Mailbox > EoE tab, select IP Port in the Port type section.

4. In the IP port settings section, use the guidelines below to edit the fourth octet (as shown in

the example below).

Example:

Here are the guidelines to know when you edit IP addresses:

Only digits 0 – 254 are supported. Do not use special characters or Chinese

characters.

Do not use these three IP addresses which are already in use:

192.168.50.50

192.168.50.100

192.168.50.255

For the EL6601 (1-port Beckhoff module), you can assign the IP address anywhere you

want within the above guidelines.

For the EL6614 (4-port Beckhoff module), the sequence of the IP addresses is

automatically assigned to be one after the other.

For example, if you edit the IP address to become 192.168.50.150 then ports 2, 3, and

4 will be automatically be assigned as:

192.168.50.151

192.168.50.152

192.168.50.153

If the IP address field cannot be edited, make sure that the EtherCAT

network is in the INIT state.

5. Record the IP addresses that you have selected. You will refer to these values in a later step.

EDGE Connect Application Note 810940 7

EoE Command Messaging

Step 4: Export the XML

To export the XML from Hypertherm EtherCAT studio, refer to the EDGE Connect Installation and

Setup Manual (809340 Revision 4). Technical documentation is available at

www.hypertherm.com/docs.

We recommend that you also save a copy of the EtherCAT Studio project

file with the updated IP addresses. Select File > Save Project As and

make sure that the Save as type field is set to *.ecsn.

Step 5: Set the IP address and ports in Phoenix

In Phoenix, review the destination and protocol values that are assigned to your printer, marker, or

other external IP device.

If you edited the IP address values in Hypertherm EtherCAT Studio (in Step 2: Scan the EtherCAT

network), you must select the same destination address values in Phoenix.

To view and edit the current settings for an IP device:

1. In Phoenix, select Setups > Password.

2. In the Password dialog, type CONFIGUREMESSAGING and then select OK.

3. In the Messaging Port Configuration dialog, review the settings for each external IP device.

Refer to Figure 3 on page 9.

8 810940 Application Note EDGE Connect

EoE Command Messaging

2

3

Fourth octet

Port

Figure 3 – Example of the Messaging Port Configuration dialog with the default settings

1

1

Source

2

Destination

(IP address: Port)

3

Protocol

This column shows the preset “IP address: Port” that is used by the

CNC. The IP address of the EDGE Connect CNC is preset to

192.168.50.100 on port 0.

This is the “IP address: Port” that is in use by your printer or other IP

device.

Edit the fourth octet and Port, if necessary, to make sure that Phoenix

sends EoE command messages to the correct device.

Example:

The IP addresses must be the same as the values in the external IP

device AND the Hypertherm EtherCAT Studio project file. Refer to

page 6.

The Port field supports 16-bit

unsigned integers (0 – 65535).

Select the protocol that your external IP device uses to receive

messages.

• TCP (Transmission Control Protocol)

• UDP (User Datagram Protocol)

4. Make sure that values in the Destination fields are the same as the values that you recorded

from Hypertherm EtherCAT Studio. Refer to page 6.

If necessary, you can restore the default destination IP address and

protocol for each device with the steps on page 18.

EDGE Connect Application Note 810940 9

EoE Command Messaging

Step 6: Create a test part program

To create a part program that you can use to test communication between the EDGE Connect

CNC and the external IP device:

1. Create a simple part program without EoE command messages.

For example:

M36 T4 // Enable Marker 2 process settings

M11 // Marker Offset 1 On

M09 // Start Marker Process

G01 X0.357 Y1 // Mark Geometry (optional)

G01 X0.357 Y-1

M10

M12 // Cancel Marker Offset 1

For information about part program codes, refer to the EDGE Connect

Programmer Reference (809550). Technical documentation is available at

www.hypertherm.com/docs.

// End Marker Process

2. Create EoE command messages to add to your part program. You can copy and edit the

example commands below to support your configuration. Refer to page 12.

For example:

(>22,0,2,0,0<MessagePort1)

(>22,0,2,1,0<MessagePort2)

(>22,0,2,2,0<MessagePort3)

(>22,0,2,3,0<MessagePort4)

3. Put a command message (from the previous step) inside the cut cycle or inside the marker

cycle in your part program.

For example:

M36 T4 // Enable Marker 2 process settings

M11 // Marker Offset 1 On

M09 // Start Marker Process

(>22,0,2,0,0<StartPrintPort1) // Send EoE command to port 1

G01 X0.357 Y1 // Mark Geometry (optional)

G01 X0.357 Y-1

M10

M12 // Cancel Marker Offset 1

// End Marker Process

10 810940 Application Note EDGE Connect

Step 7: Test communication

To test communication, use Phoenix Version 10.22 or later to load and execute the part program that

you created in the previous step.

These status messages show up below the Part Preview on the Main screen in Phoenix during part

program execution:

“Message Transmit” can sometimes be shown when a message is being sent.

“Message Delay” is shown for Message Type 20 during a delay at the end of a message.

“Message Verify” is shown for Message Type 22 when Phoenix is waiting for the ACK

command to be returned by the external serial device.

“Message Error” is shown for Message Type if the Delay Time expires before an ACK

command is returned to Phoenix.

For information about Message Type and Delay Time, refer to page 12.

EoE Command Messaging

EDGE Connect Application Note 810940 11

EoE command reference

The ASCII message strings in EoE command messages must have this format:

(>[Message type], [Special Format], [Delay or Time Out], [Port Number], [Jog on Path]<[Message Content])

Example

(>22,0,2,0,0<MessagePort1)

All parameters are necessary. All characters except for the brackets “[]”

are also necessary.

Message type = Delay the part program until an Acknowledge message is received.

Special format = Use 0 if no format is required. Refer to page 13.

Time out = An error will be displayed if this message is not acknowledged (ACK Hexadecimal 06) within 2 seconds.

Jog on path = Disable this message during Jog on Path.

Port = First port on a Beckhoff module.

Refer to the table on the right for more details.

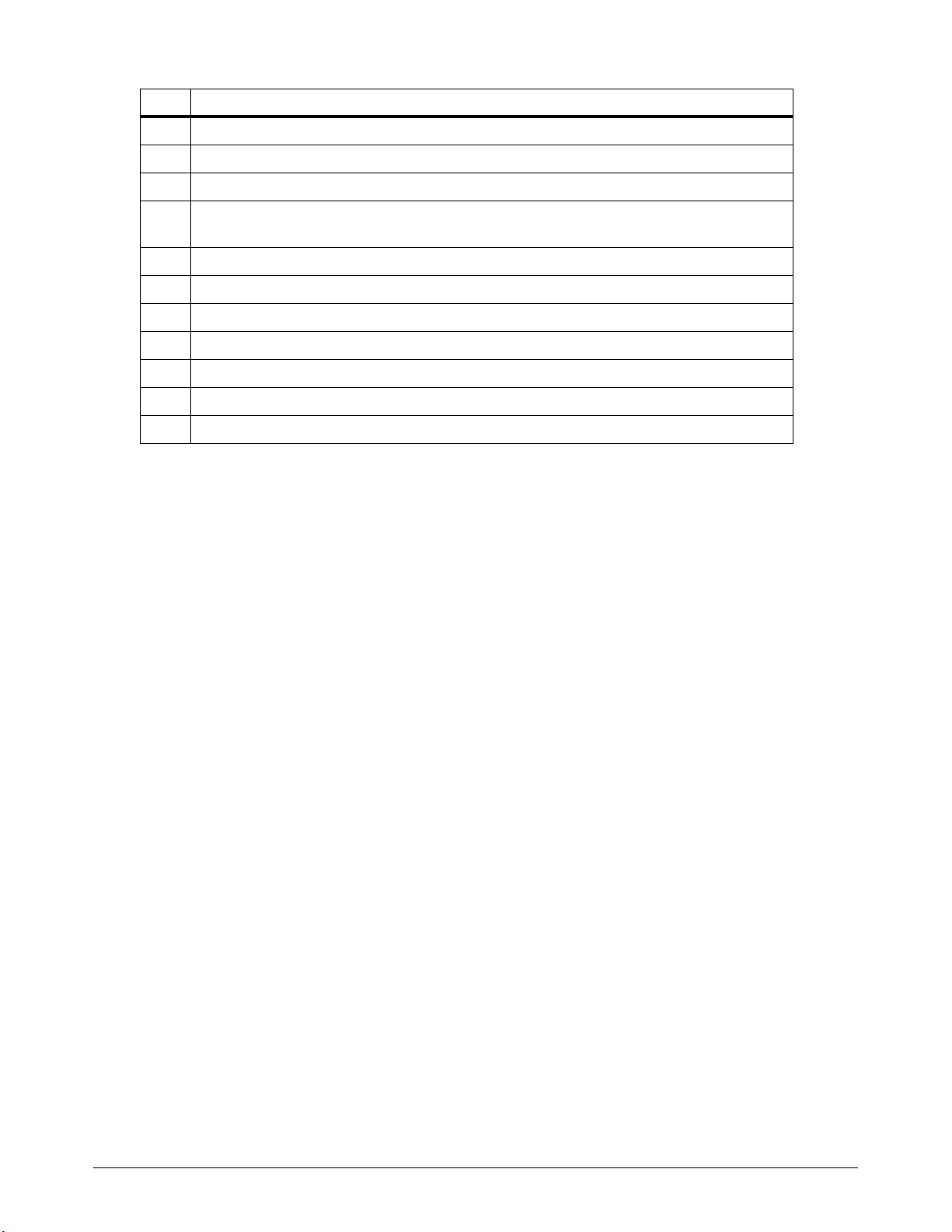

Parameter Sequence Description

• 20 = Delay the part program until all bytes have been transmitted and the Delay Time expires.

• 21 = Send the message without a time delay or acknowledgment during the part program execution.

Message Type First

Special

Format

Delay Time or

Time Out

Second

Third

• 22 = Delay the part program until all bytes have been transmitted and Phoenix receives an acknowledgment from the external

device (ACK = Hexadecimal 06). Report the “Message Verify” status message below the Part Preview until the Delay Time

expires. Once the Delay Time expires, the “Message Error” status message shows below the Part Preview.

Special format, such as a carriage return. Use 0 if no format is required. Refer to page 13.

•For Message Type 20, this is the maximum Delay Time (0.00 – 999.99 seconds) at the end of a message.

•For Message Type 21, the value must be 0.

•For Message Type 22, this is a Time Out value (0.00 – 999.99 seconds). An error will be displayed if the message is not

acknowledged (ACK Hexadecimal 06) within the specified time.

Table 1 – EoE command parameter reference

(>22,0,2,0,0<MessagePort1)

Port Number Fourth

Jog On Path Fifth

Message

Content

12 810940 Application Note EDGE Connect

Sixth

The TCP or UDP Port Number of the destination printer, or other IP device. A value of 0 represents a remote printer host setup on

192.168.50.101.

• 0 = Port 1 (First port on a Beckhoff EL6601 or a Beckhoff EL6614 module)

•1 = Port 2

•2 = Port 3

•3 = Port 4

Selects if command messages are enabled or disabled while the torch jogs on the path.

• 0 = Disables command messaging during Jog On Path.

• 1 = Lets the CNC send command messages while the torch is jogging forward on the path only.

• 2 = Lets the CNC send command messages while the torch is jogging forward and backward on the path.

Message content with Printable ASCII codes and non-printing ASCII codes. Refer to ASCII Codes on page 15.

• Each command message supports up to 300 characters. The Command characters (information between and including the “>”

and “<” signs) are included in this character limit.

• Non-printing characters are supported with a two-character command. Non-printing characters can send a binary code in the

range from 0-255.

• Double-byte characters that are used to support combinations affect the maximum length count with each pair and decrease the

maximum data characters by 1.

Special format characters

01= nn of the Data field, printer-specific

&C = End of Text (ETX)

&A= Start of Header (SOH)

1= Type value, printer-specific

&B= Start of Text (STX)

(>22,17,3,0<&A1&B01PRINTME&C)

PRINTME= Text to print on material

Replaces the BCC and CR. Refer to the next section.

EoE command messages support the special format characters that follow.

Hex Name Description

01 SOH Start of Header

02 STX Start of Text

03 ETX End of Text

04 EOT End of Transmission

0D CR Carriage Return

0A LF Line Feed

BCC “Exclusive Or” Check Byte

EoE Command Messaging

Checksum is always an “Exclusive OR” of the Data because it does not

include any of the “Format” characters, including the CR/LF option. Refer

to the “ASCII Codes” section in the EDGE Connect Programmer

Reference (809550) for more details.

For example, this command below uses SOH, STX, and ETX:

Optional format character assignments

EoE command messages support the optional format characters that follow.

Value Description

0 No special assignment. If no format options are necessary, use a value of 0 in the format

location of the EoE command.

1 Append a Carriage Return (<CR> = Hex value OD) and a Line Feed (<LF> = Hex

Value 0A).

16 Append an “Exclusive OR” (<BCC>) to the end of the message.

17 Appends a combination of 16 and 1.

32 Encloses the message with Start of Text (<STX> = Hex Value 02) and End of Text

EDGE Connect Application Note 810940 13

(<ETX> = Hex Value 03).

The <ETX> follows the message and the optional <CR><LF>> append codes but

precedes the Check Byte <BCC>.

EoE Command Messaging

Value Description

33 Appends a combination of 1 and 32.

48 Appends a combination of 16 and 32.

49 Appends a combination of 1, 16, and 32.

64 Append a Start of Header (<SOH> = Hex value 01) and an End of Transmission

(<EOT> = Hex Value 04) to the message.

65 Appends a combination of 1and 64.

80 Appends a combination of 16 and 64.

81 Appends a combination of 1, 16, and 64.

96 Appends a combination of 32 and 64.

97 Appends a combination of 1, 32, and 64.

112 Appends a combination of 16, 32, and 64.

113 Appends a combination of 1, 16, 32, and 64.

14 810940 Application Note EDGE Connect

ASCII Codes

This section gives the 128 ASCII codes (American Standard Code for Information Interchange) as

defined by ANSI (American National Standards Institute) Standard X3.4-1977.

ASCII Control Codes

Hex Dec Character* name Description

00 0 ^ @ NUL Null

01 1 ^A SOH Start of Header

02 2 ^B STX Start of Text

03 3 ^C ETX End of Text

04 4 ^D EOT End of Transmission

05 5 ^E ENQ Enquiry

06 6 ^F ACK Acknowledge

EoE Command Messaging

07 7 ^G BEL Bell

08 8 ^H BS Backspace

09 9 ^I HT Horizontal Tab

0A 10 ^J LF Line Feed

0B 11 ^K VT Vertical Tab

0C 12 ^L FF Form Feed

0D 13 ^M CR Carriage Return

0E 14 ^N SO Shift Out

0F 15 ^O SI Shift In

10 16 ^P DLE Data Link Escape

11 17 ^Q DCI Device Control 1

12 18 ^R DC2 Device Control 2

13 19 ^S DC3 Device Control 3

14 20 ^T DC4 Device Control 4

15 21 ^U NAK Negative Acknowledge

16 22 ^V SYN Synchronous Idle

17 23 ^W ETB End Transmission Block

18 24 ^X CAN Cancel

19 25 ^Y EM End of Medium

* The "^" in the Character column sometimes can be replaced with "&" in the Message Port part of the serial string.

EDGE Connect Application Note 810940 15

EoE Command Messaging

Hex Dec Character* name Description

1A 26 ^Z Sub Substitute

1B 27 ^[ ESC Escape

1C 28 ^\ FS File Separator

1D 29 ^] GS Group Separator

1E 30 ^^ RS Record Separator

1F 31 ^_ US Unit Separator

20 32 SP Space

* The "^" in the Character column sometimes can be replaced with "&" in the Message Port part of the serial string.

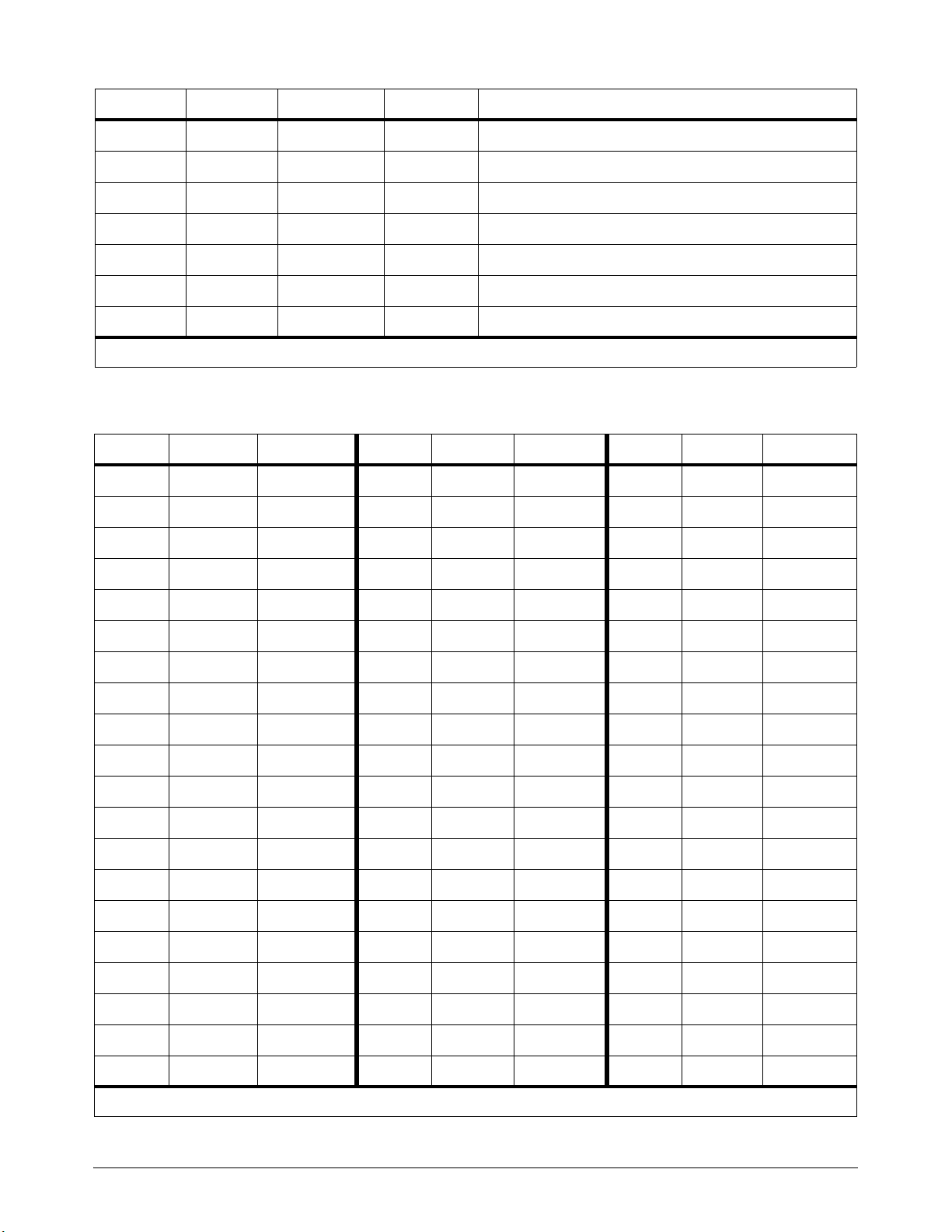

All ASCII codes

Hex Dec Character* Hex Dec Character* Hex Dec Character*

00 0 ^ @ 2B 43 + 56 86 V

01 1 ^A 2C 44 , 57 87 W

02 2 ^B 2D 45 - 58 88 X

03 3 ^C 2E 46 . 59 89 Y

04 4 ^D 2F 47 / 5A 90 Z

05 5 ^E 30 48 0 5B 91 [

06 6 ^F 31 49 1 5C 92 \

07 7 ^G 32 50 2 5D 93 ]

08 8 ^H 33 51 3 5E 94 ^

09 9 ^I 34 52 4 5F 95 _

0A 10 ^J 35 53 5 60 96 `

0B 11 ^K 36 54 6 61 97 a

0C 12 ^L 37 55 7 62 98 b

0D 13 ^M 38 56 8 63 99 c

0E 14 ^N 39 57 9 64 100 d

0F 15 ^O 3A 58 : 65 101 e

10 16 ^P 3B 59 ; 66 102 f

11 17 ^Q 3C 60 < 67 103 g

12 18 ^R 3D 61 = 68 104 h

13 19 ^S 3E 62 > 69 105 i

* The "^" in the Character column sometimes can be replaced with "&" in the Message Port part of the serial string.

16 810940 Application Note EDGE Connect

EoE Command Messaging

Hex Dec Character* Hex Dec Character* Hex Dec Character*

14 20 ^T 3F 63 ? 6A 106 j

15 21 ^U 40 64 @ 6B 107 k

16 22 ^V 41 65 A 6C 108 l

17 23 ^W 42 66 B 6D 109 m

18 24 ^X 43 67 C 6E 110 n

19 25 ^Y 44 68 D 6D 111 o

1A 26 ^Z 45 69 E 70 12 p

1B 27 ^[ 46 70 F 71 113 q

1C 28 ^\ 47 71 G 72 114 r

1D 29 ^] 48 72 H 73 115 s

1E 30 ^^ 49 73 I 74 116 t

1F 31 ^_ 4A 74 J 75 117 u

20 32 4B 75 K 76 118 v

21 33 ! 4C 76 L 77 119 w

22 34 “ 4D 77 M 78 120 x

23 35 # 4E 78 N 79 121 y

24 36 $ 4F 79 O 7A 122 z

25 37 % 50 80 P 7B 123 {

26 38 & 51 81 Q 7C 124 |

27 39 ‘ 52 82 R 7D 125 }

28 40 ( 53 83 S 7E 126 ~

29 41 ) 54 84 T 7F 127 ¬

2A 42 ‘ 55 85 U

* The "^" in the Character column sometimes can be replaced with "&" in the Message Port part of the serial string.

EDGE Connect Application Note 810940 17

EoE Command Messaging

Review or restore the default settings

You can review and restore the factory default settings for the IP address, port, or protocol for an IP

device in Phoenix.

To review the factory default IP address and port settings:

1. In Phoenix, select Setups > Password.

2. In the Password dialog, type CONFIGUREMESSAGING/DEFAULTS and then select OK.

3. In the Messaging Port Configuration dialog, review the information for each IP device. Refer to

Figure 3 on page 9.

To apply the default settings to your current settings, select OK.

If you do not want to apply the default settings, you can:

Select Cancel to close the dialog without making changes.

-or-

Edit the Destination and Protocol settings on this dialog and then select OK to

apply your changes.

18 810940 Application Note EDGE Connect

Loading...

Loading...