Page 1

IN-LINE POWER TUNING MODULE

2003-2004 Ford 6.0L Power Stroke

Super Duty F250/F350 & Excursion

Part #41042

STEP-BY-STEP INSTALLATION

INSTRUCTIONS

Revised 8.2.05

trademark of the Ford Motor Company

®

Part #593

© 2004-2005 Hypertech, Inc.

® Power Stroke is a registered

Page 2

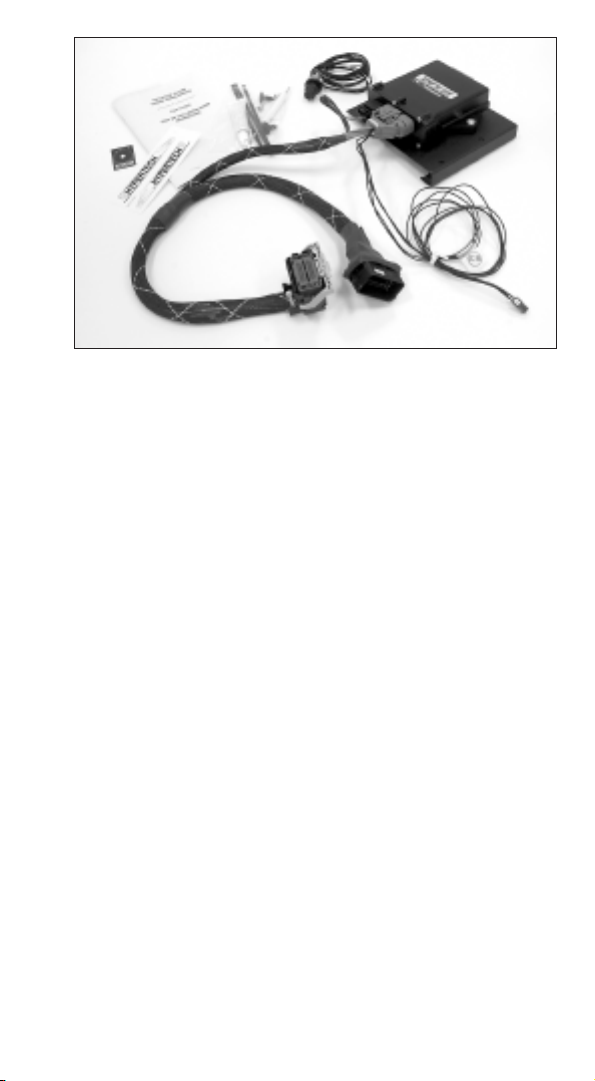

Kit Contains:

Hypertech Power Tuning Module

Wiring harness (connectors are marked for easy installation)

Hypertech rotary switch assembly

Hypertech mounting bracket (with module attached)

Hypertech switch plate (cable, switch with knob, connector/wire)

Small standard screwdriver

Installation and operation manual (instructions)

#10 Phillips-head screws (2 each)

Retaining plugs (2 each)

Tie-wraps (3 each)

One tube of Boss RTV sealer (0.5 oz.)

You will need the following:

Insulated adjustable wrench

(to tighten battery terminals and switch mounting nut)

Phillips-head screwdriver (for mounting bracket/module)

Standard (flat) screwdriver (for removing fuse panel)

10mm socket or nut-driver (for removing fuse block)

Drill and 1/8”, 3/8” and 1/2” drill bits

(for rotary switch installation)

Diagonal cutters (for removing tie-wrap excess)

2

Page 3

PLEASE READ BEFORE INSTALLING THE

HYPERTECH IN-LINE POWER TUNING

MODULE FOR THE 6.0L POWER STROKE

Special instructions for the 6.0L Power Stroke

2003-2004 Ford Super Duty F250/F350 & Excursion

SPECIAL NOTE: Power Stroke engines built before 9/29/03

must be updated to the newest calibration level (B27.9 or

later) by an authorized Ford, Lincoln, or Mercury dealer.

Ford Motor Company’s Technical Service Bulletin No. 03-20-12

states the following…

“Some vehicles may exhibit various driveability conditions

listed below:

• Rough/rolling idle when the engine is warm.

• Rough/rolling idle and white smoke after hot restart.

• Lacks power after initial start-up.

• Cold idle kicker performance at warm ambient temps.

• U0306 codes after reprogramming.

• P2263 code set during extended idle.

• False P0196 codes.”

According to this Technical Service Bulletin (Article No. 03-20-12),

a PTM/TCM/FICM module calibration level update is available

for vehicles equipped with the 6.0L Power Stroke engine built

before 9/29/03 that exhibit one (1) of the above conditions.

Since this problem can occur on completely stock engines,

modifying these particular vehicles to make even more power

could worsen the problem.

WARRANTY any damage claims to the vehicle or

NOT

product if their in-line Power Tuning Module is installed on

any vehicle equipped with the 6.0L Power Stroke engine that

has not been updated to the newest calibration level (B27.9 or

later) by an authorized Ford, Lincoln, or Mercury dealership.

In addition, Ford Motor Company’s Technical Service Bulletin

No. 04-09-03

states the following:

For this reason, Hypertech WILL

“ Some vehicles equipped with the 6.0L diesel engine may exhibit

engine oil diluted with fuel (OIL LEVEL MAY APPEAR OVER

FULL), runs rough, and/or a lower power condition.”

For this reason, Hypertech WILL NOT WARRANTY any

damage claims to the vehicle or product if their in-line Power

uning Module is installed on any vehicle equipped with the

T

Power Stroke engine that exhibits any of these conditions.

6.0L

3

Page 4

INSTALLATION INSTRUCTIONS

I. Disconnect the batteries

For specific instructions and precautionary steps regarding

recommendations for battery disconnection, refer to the

“Workshop Manual” for 2004 F250/350/450/550 vehicles,

published by Ford Motor Company. This manual also contains

battery-related precautionary steps regarding the Supplementary

Restraint System (SRS) or air bag system. Failure to read and

observe factory-recommended instructions may result in personal

injury or property damage.

disconnected and re-connected, some abnormal drive

symptoms may occur while the vehicle relearns its adaptive

strategy. The vehicle may need to be driven to re-learn its

adaptive strategy.

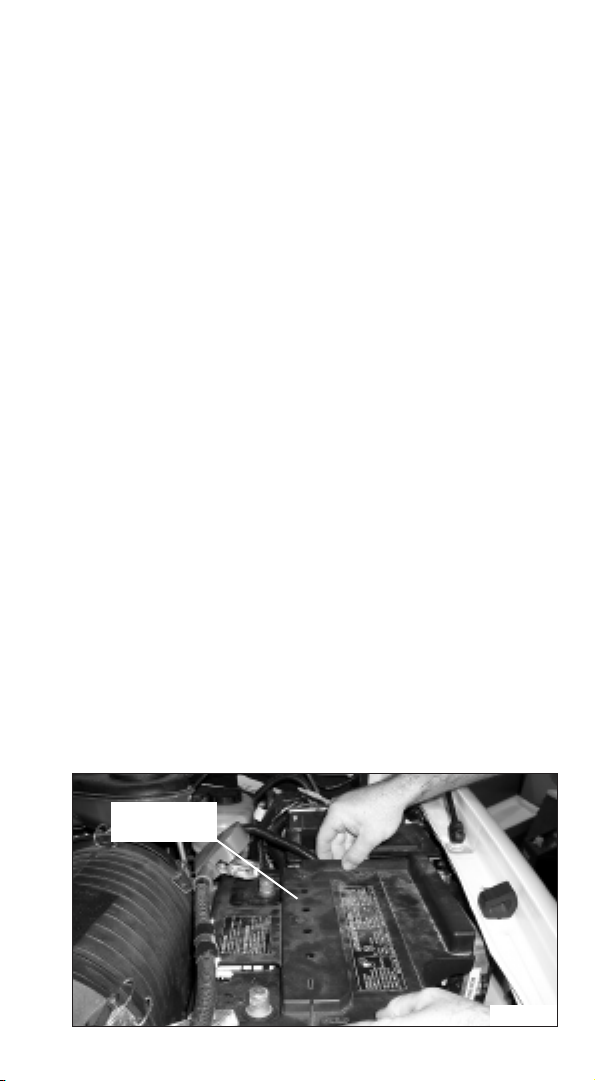

1. Disconnect the secondary battery ground cable (passenger side

of the engine compartment).

2. Disconnect the primary battery ground cable on the driver’s

side of the engine compartment.

remove the retaining clip holding this cable to the battery cover.

3. Disconnect the primary battery positive cable (driver’s side of

the engine compartment).

4. Disconnect the secondary battery positive cable (passenger side

of the engine compartment).

NOTE: When the battery is

Note: You will also need to

5. Remove the battery cover from the primary battery (driver’s

side of the engine compartment) and set it aside. See Figure A.

When removing this cover, take care to ensure that the cables

around the cover are not damaged.

Battery On

Driver’s Side

Figure A

4

Page 5

II. Locate the Powertrain Control Module (PCM)

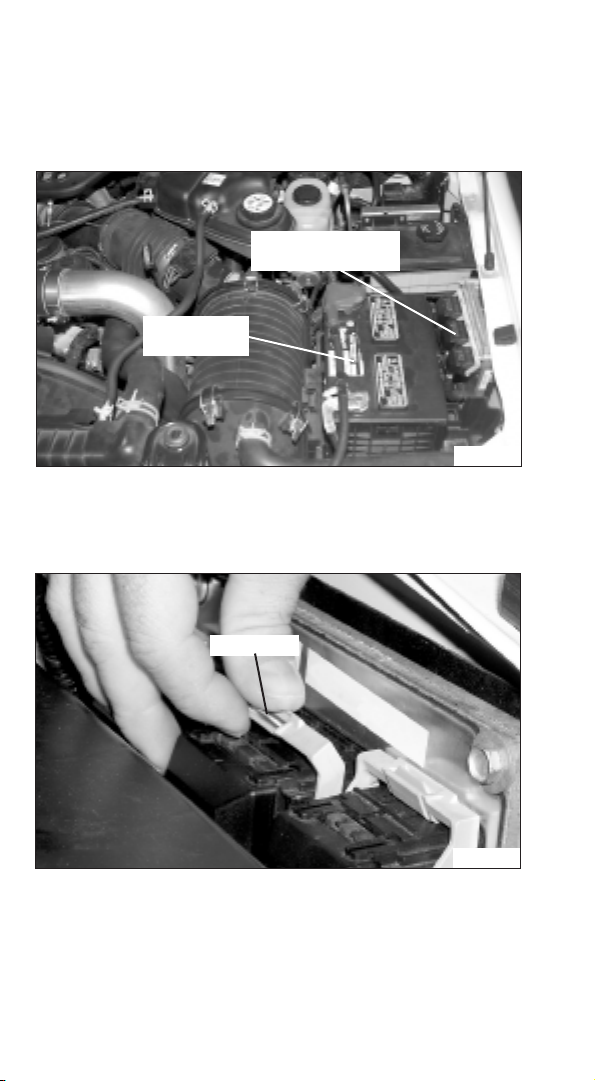

6. See Figure B. Locate the powertrain control module (PCM).

It is located on the right side of the engine compartment beside

the primary battery. The PCM has three (3) connectors visible

at the front, facing the battery.

PCM with three (3)

connectors

Battery On

Driver’s Side

Figure B

7. See Figure C. Remove the center connector by pinching

the lever lock (small tab or tongue in the middle of the

connector, as shown) and pushing the lever away from the

PCM. The connector will slide out as you push the lever.

Lever lock

Figure C

5

Page 6

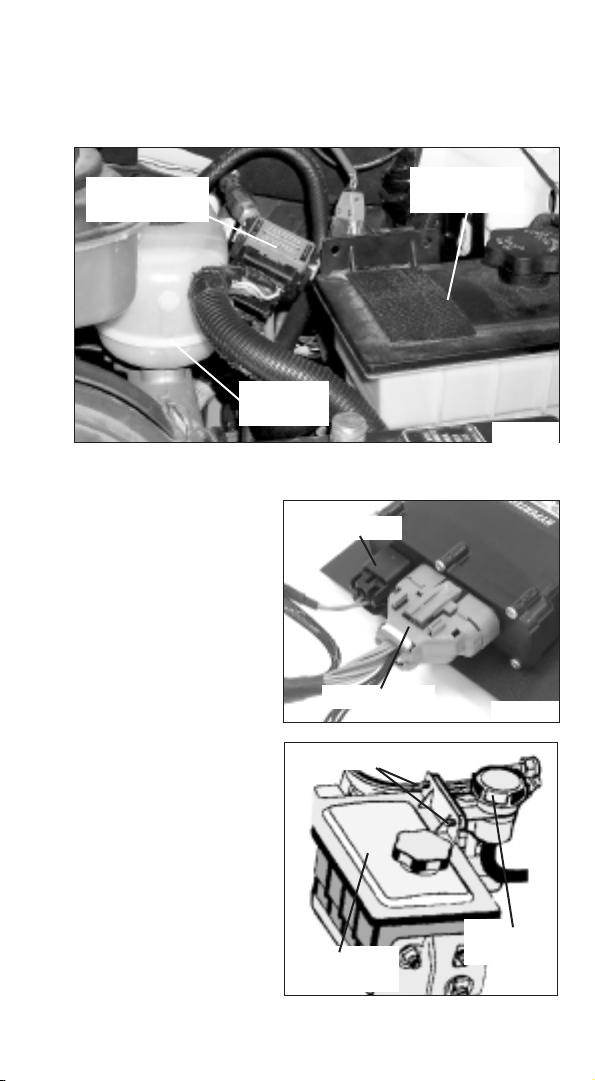

8.See Figure D. The cable for the center connector lies in the

space between the battery and the power steering fluid

reservoir. Pull the connector and cable out from this space and

re-route it so that the connector is between the power steering

reservoir and the brake fluid reservoir.

Center connector

from PCM

Brake fluid

reservoir

III. Inspecting the Hypertech cable

9.The Hypertech

mounting bracket is

C3 connector

provided with the

in-line Power Tuning

Module and two (2)

mounting clips already

installed.

NOTE:

If these cables are

NOT already

connected as shown in

Figure E, identify

them and connect

them now.

Retaining plugs

C2 connector

Power steering

reservoir

Figure D

Figure E

10.

Manual Transmission

applications ONLY.

See Figure F.

Remove the retaining

plugs holding the clutch

fluid reservoir to the

bracket on the power

steering fluid reservoir

and lay the reservoir

out of the way

, prior

to beginning this step.

Power steering

reservoir

Clutch fluid

reservoir

Figure F

6

Page 7

IV. Position the Hypertech mounting bracket & PTM

11. See Figure G. Keeping

the Hypertech cable out

of the way, position the

Mounting

bracket

mounting bracket on the

rear side of the power

steering fluid reservoir.

There is a bracket with

two (2) holes on this

side of the power

steering fluid reservoir.

Align the mounting

clips with these holes

and secure the

Hypertech bracket

using the phillips-head

screws provided.

12. See Figure H. If you

previously removed the

clutch fluid reservoir

Retaining

plugs

PTM and

mounting

bracket

(Manual transmission

applications), re-mount

the reservoir to the

holes located above

the Hypertech in-line

Power Tuning Module

on the Hypertech

mounting bracket.

Two (2) retaining

plugs have been

provided, in case

the originals were damaged when you removed them.

Push the retaining plugs in all the way to secure the

clutch fluid reservoir to the Hypertech mounting bracket.

Figure G

Clutch

fluid

reservoir

Figure H

13. See Figure I. The

large connector on the

Hypertech cable,

marked C5, will plug

into the PCM where

the factory cable was

removed in Step 7 on

page 5 (Figure C).

There must be

enough room beside

the cable to r

the primary battery cover.

7

e-install

Vehicle

PCM

C5 connector

Figure I

Page 8

14.

See Figure J. Route the remaining large connector (marked C4)

on the Hypertech cable between the power steering fluid

reservoir and the brake fluid reservoir. Position the two (2)

large connectors (one is the connector removed from the

middle of the PCM) to mate to each other. Mate the connectors

and lock the lever.

Figure J

V. Reconnect the batteries

NOTE: When the battery is disconnected and re-connected,

some abnormal conditions may occur while the vehicle

re-learns it adaptive strategy. This typically requires the

vehicle be driven about 10 miles (or fifteen minutes) in

the “stock tuning” (setting) mode of operation. This should

be done after installation is complete.

15. See Figure K. There is one (1) section of the Hypertech cable

remaining. It has a small, 4-pin connector (C6). Set this out of

the way of the primary battery and proceed with re-attaching

the battery cover and cables.

C6 connector

Figure K

8

Page 9

16. Re-install the battery cover onto the primary battery (driver’s

side of the engine compartment). Make sure the cables

around the cover are positioned such that the cover can

be properly seated when installed. Connect the secondary

battery positive cable (passenger side of the engine

compartment). Connect the primary battery positive cable

(driver’s side of the engine compartment). Connect the

primary battery ground cable (driver’s side of the engine

compartment). Connect the secondary battery ground cable

(passenger side of the engine compartment).

INSTALLING ROTARY POWER SELECTOR

Below are two (2) possible ways to install the Hypertech Rotary

Power Selector for the Power Tuning Module. The first method

requires no drilling. The second requires some drilling and mounts

Rotary Power Selector in the dash below the headlight controls.

the

The Rotary Power Selector can be mounted in any location in

the vehicle, as these are only suggestions of possible mounting

locations.

Option 1 (No drilling required)

1. See Figures L & M. Route the Rotary Power Selector switch

cable from the Hypertech Power Tuning Module along the

driver’s side inner fender

panel, past the hood hinge, and

toward the windshield molding

(as shown in Figure L). Then

route the cable beneath the

driver’s side door molding and

into the cab at the left edge of

the dashboard (as shown in

Figure M). Once this cable

routing is completed, attach

the Rotary Power Selector

switch to the cable. The switch

can now be mounted in a

convenient location or the

cable and switch coiled for

storage behind the driver’s

side dashboard for easy access

when a tuning level change is

desired.

is provided for installations

where it is undesirable to

drill a mounting hole in the

dashboard. For a more permanent installation of the

Rotar

(NOTE: This method

y Power

Selector

switch, option 2 is pr

ovided.)

9

Figure L

Figure M

Page 10

Option 2 (Drilling required)

1. See Figure N. Locate the fuse

block panel. The panel is

marked “Fuse Panel” in the

upper left corner. Using a

flathead screwdriver, loosen

the four (4) retaining clips by

turning them a half turn. Then

remove the panel and set aside.

2. See Figure O. There are four

Fuse block

panel

(4) bolts that hold the fuse

block in place. Use a 10mm

socket or nut-driver to remove

these bolts and pull out the

fuse block. Swing the block

out and to the left to access

the lower edge of the dash.

3. The suggested location area

for the switch installation is

shown in Figure P.

4. Using the template provided

on page 14 of these

instructions, locate and drill

a 3/8” hole in the desired

location for the switch and a

1/8” hole below and to the

right of the main hole.

This 1/8” hole is used to lock

the switch in place.

Note: Make sure that there

Option 2

mounting location

are no obstructions behind the

chosen location, prior to drilling. In addition, use the

Hypertech switch assembly to check that the location

of the hole will allow enough room for the switch.

Fuse block

Figure N

Fuse block

Figure O

Figure P

10

Page 11

5. See Figure Q. On the Hypertech Rotary Power Selector switch,

remove the mounting nut and washer from the switch shaft.

There is one (1) additional ring on the switch shaft. The tab on

this ring needs to remain in position number 4 when the switch

is installed. From behind the panel, insert the switch into the

panel hole. Line up the positioning tab into the small drilled

hole. On the outside of the dash, place the provided Hypertech

switch plate over the shaft. Make sure that the plate is lined up

so that the numbers 1 and 2 are spaced equally on either side

of the 12 o’clock position. Secure the switch in place with the

washer and mounting nut. Using the small screwdriver

provided, install the knob onto the switch shaft. The screw

should set against the flat portion of the knob shaft. Rotate the

knob left (counter-clockwise) until you reach the stop. The

white indicator on the knob should now point to the number 0

on the switch plate.

6. Temporarily re-install the fuse block (Step 2) so that it is out of

the way during the next step.

Headlight

controls

Hypertech

rotary switch

Figure Q

Rectangular

grommet

Figure R

7. See Figure R. From inside the vehicle, look below the dash at

the firewall, behind the parking brake, and locate the large

rectangular grommet. Using a 1/2” drill bit, carefully drill

a hole through the grommet into the engine compartment.

Note: Prior to drilling, make sure that no obstructions

(

exist on the engine side of the grommet.)

8. Remove the fuse block and pull to the side, as performed in

Step 2 of the power selector installation.

9. Beneath the dash, route the switch cable along existing cable

paths toward the 1/2” hole. Feed the connector through the

1/2” hole.

11

Page 12

10. See Figure S. From the engine side, pull the connector and

cable through the firewall. Attach the connector to the main

Hypertech cable by mating the two (2) 4-pin connectors.

NOTE: The latch on the switch cable connector should

snap over the tab on the mating connector.

Figure S

11. Use the tie-wraps provided to secure the cable to existing

cables, both inside beneath the dash and inside the engine

compartment.

the switch

brake assembly

engine compartment, make sure that the switch cable

is routed away from sources of heat.

12. Beneath the dash, use the provided small tube of silicone

to seal the grommet hole around the cable if desired.

The silicone will be dry to the touch in about 1 hour,

and fully cured in about 24 hours.

Note: Beneath the dash, make sure that

cable is out of the way and clear of the parking

and driver’s leg and foot area. In the

13. Re-install the fuse block and fuse block panel.

14. Check entire installation to make sure that all cables are

secure. Use additional tie-wraps to secure as necessary.

12

Page 13

USER INSTRUCTIONS

NOTE: Due to the adaptive learning strategy, the vehicle

will need to be driven about 10 miles (or 15 minutes) on

the 0 position (stock tuning) if the Power Tuning Module

is ever removed and re-installed.

Once you have completed all installation instructions, complete

the following steps setting or changing power levels.

1. Set the rotary power selector switch to 0 (stock tuning).

2. Start the engine. Keep the transmission in PARK.

3. Bring the engine up to a normal operating temperature level.

NOTE: The engine MUST be at operating temperature

for tuning to be accepted (Typically five (5) minutes of

normal engine operation is sufficient to initiate tuning).

4. Select the tuning level by turning the rotary power selector

switch from position 0 to position 1, 2, or 3.

a. Setting 0 is the stock engine tuning.

b. Setting 1 is Stage 1 engine tuning (

c. Setting 2 is Stage 2 engine tuning (

d. Setting 3 is Stage 3 engine tuning (

Changing Power Levels

1. You can change power levels while driving by performing the

following steps:

a. Back off the throttle (to reduce strain on the powertrain).

b. Select tuning level 1, 2, 3, or 0 (back-to-stock).

c. Resume normal driving operations.

+56 HP).

+82 HP).

+125 HP).

13

Page 14

What To Do Before Taking Your Vehicle In For Service

If you take your vehicle to a dealer or mechanic for service,

you must first restore the vehicle’s stock tuning. Hypertech

recommends you temporarily remove the Power Tuning Module,

even if the vehicle is restored to stock tuning. This assures the

Hypertech Power Tuning Module will not interfere with any

diagnostic procedures that may be performed during vehicle

servicing. The Hypertech Power Tuning Module for the 2003-

6.0L Ford Power Stroke can be restored to stock tuning by

2004

either

of two methods: (1) placing the Tuning Level Selector

switch in the “0” position or (2) removing the Power Tuning

Module. Once this service has been completed, you may reinstall the system by repeating the initial installation steps. If

you have any questions related to service issues, please call

Hypertech technical services at 901-385-1888.

PRODUCT WARRANTY

Warranty only applies to the original purchaser of a Hypertech

product. (Note: Warranty for the Hypertech Power Tuning

Module for 6.0L Ford Power Stroke will not apply, if used on

engines built prior to 9/29/03 and not updated to the B27.9

calibration.)

Template for switch installation

as described on Page 14

3/8” hole (main)

1/8” hole

14

Page 15

SPECIALTY AUTO PARTS

CONSUMER’S BILL OF RIGHTS

Your Rights To Personalize Your Vehicle

Article 1: You have the Right to buy high-quality, reliable aftermarket

Article 2: You have the Right to use high-quality aftermarket parts

Article 3: You have the Right to install and use emissions-legal

Article 4: You have the Right to actively oppose any proposed

Article 5: You have the

performance and specialty parts, accessories, and styling options.

and know that your new vehicle warranty claims will be

honored. In fact, your vehicle dealer may not reject a

warranty claim simply because an aftermarket product is

present. A warranty denial under such circumstances may be

proper only if an aftermarket part caused the failure being claimed.

aftermarket performance parts without incurring hassles

and onerous procedures during state vehicle emissions inspections.

(or existing) laws or regulations that will reduce your

freedom to use aftermarket automotive parts and service

or will curtail your ability to take part in the automotive

hobbies of your choice.

Right to patronize independent retail

stores and shops for vehicle parts and service. The U.S.

aftermarket offers the world’s finest selection of

performance and specialty parts, accessories, and styling

options. These aftermarket products satisfy the most

discriminating customers seeking personalized vehicles

for today’s lifestyle.

The Consumer’s Bill Of Rights courtesy of

Specialty Equipment Market Association (SEMA)

15

Page 16

Typical Performance Gains

NOTE: All dynamometer tests are performed under controlled

conditions. Results may vary, depending on the specific vehicle,

altitude, temperature, fuel used, and various other conditions that

affect vehicle performance. Power gains shown are specific to the

vehicle tested and representative of the average gains verified.

For a color, printable power graph of your particular

application, check out our website at www.hypertech.com.

16

Page 17

Hypertech Merchandise

T-Shirts

Available in long- or short-sleeve,

these T-shirts are high-quality,

printed in full-color and display

the Hypertech Power Tuning logo.

Available in sizes ranging from

Small to XXX-large.

Polo Shirts

These short-sleeve polo shirts

available in blue, red, white, or black

are high-quality 100% cotton and

have a full-color Hypertech logo

embroidered on the left chest.

Available in sizes ranging from

medium to XX-large.

T-Shirts Part #

Short Sleeve - Small 600

Short Sleeve - Medium 601

Short Sleeve - Large 602

Short Sleeve - X-Large 603

Short Sleeve - XX-Large 604

Short Sleeve - XXX-Large 605

Long Sleeve - Medium 606

Long Sleeve - Large 607

Long Sleeve - X-Large 608

Long Sleeve - XX-Large 609

Long Sleeve - XXX-Large 610

T-Shirts (cont’d) Part #

Long Sleeve - Medium 606

Long Sleeve - Large 607

Long Sleeve - X-Large 608

Long Sleeve - XX-Large 609

Long Sleeve - XXX-Large 610

Polo Shirts (Order part# & color)

Medium 638

Large 639

X-Large 640

XX-Large 641

Baseball Caps

Hypertech baseball caps are available

in three styles and come with a full-color

Hypertech logo embroidered on the front.

All baseball caps are one-size-fits-all.

Solid Navy Blue 633

Denim w/Khaki Bill 634

Khaki w/Navy Blue Bill 635

Part #

Coffee Mugs

Enjoy your morning coffee with the

Hypertech coffee mug, displaying the

Hypertech logo and engine icon in full

color on both sides - Part #626.

To Place An Order, Call Hypertech at 901-385-1888.

Page 18

Notes

Page 19

Loading...

Loading...