Page 1

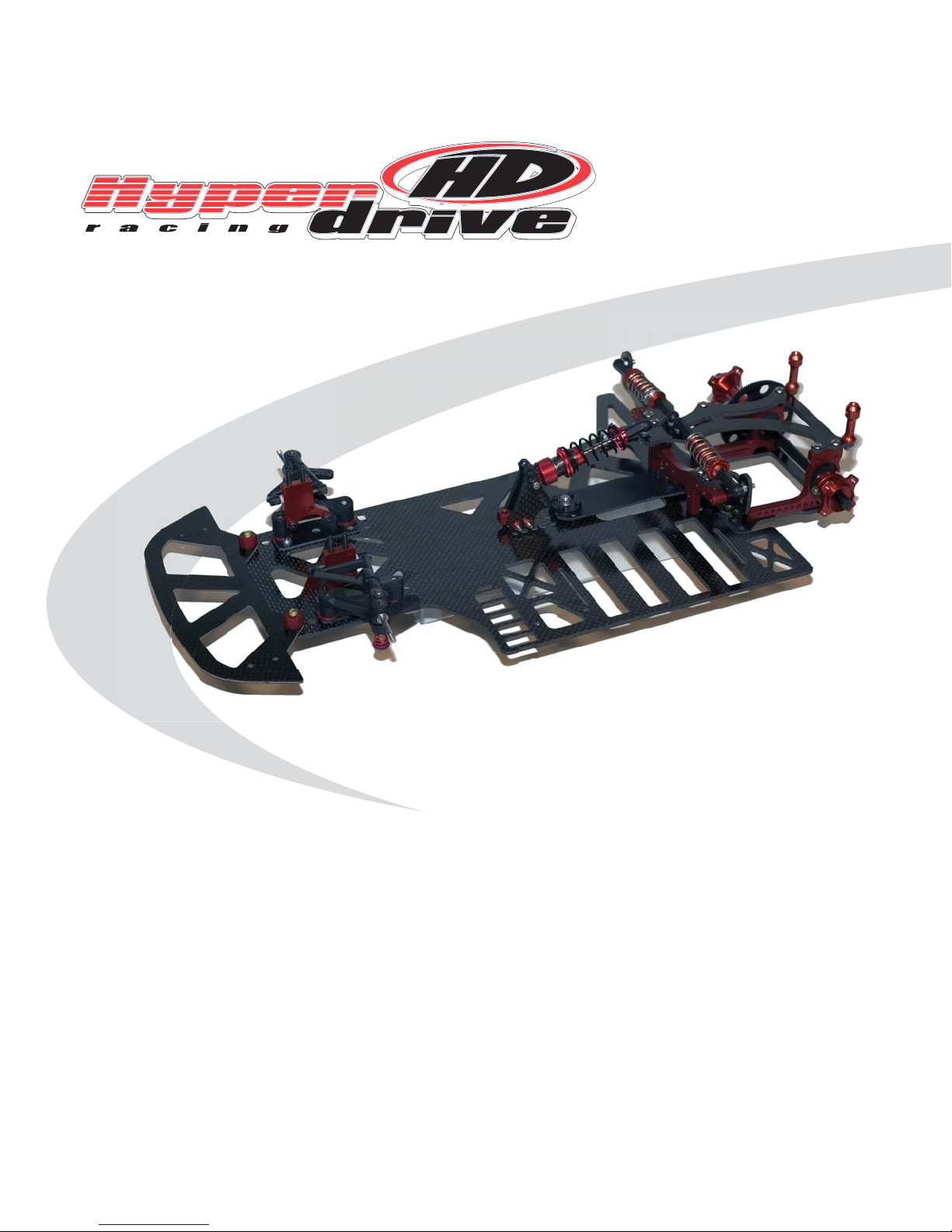

Hyperdrive Pro 3 Solid Chassis

© 2007 Hyperdrive Racing

Published September 2006

Page 2

Introduction

Congratulations! You now own a state of the art 1/10

scale oval race car. The Hyperdrive Pro 3 Solid Chassis

has gone through months of testing by our factory

drivers to insure that you get a car that has maximum

performance and adjustability built in. In purchasing this

kit you have not only helped the hobby and sport of Oval

pan car racing by supporting your local hobby shop but

you have also bought the quality of a Hyperdrive Racing

performance product.

How well your car performs is dependant upon the

assembly of your car kit. Take your time and assemble

your car as shown in this manual. This will give you a

good starting point from which you can make adjustments

dependant upon the track you are racing on.

The following items are required to complete your car:

• Two channel Surface Radio

• Electronic Speed Control

• Batteries (4 cell)

• 05 Electric Motor

• Shock Oil

• Tires

• Body

Tools needed in the construction of your car:

• Phillips Screwdriver

• Hobby Knife

• Allen Wrenches; 3/32, 1/16 & 0.050

• Pliers or appropriate sized Nut Drivers/Sockets

Page 3

Step 1 - Front Bumper Installation

Using part numbers FB-7045 (Woven Bumper), HD-7307

(Solid Chassis) locate two 8-32 fl at head screws and two

8-32 hex nuts (the 8-32 hardware is located in the bag

containing the Associated #8400 Front Suspension Kit).

Install the 8-32 fl at head screws through the bottom of the

chassis using the front bumper mounting holes. Place the

bumper on top of the chassis. Using the 8-32 hex nuts,

secure the bumper fi rmly to the chassis plate.

1

Page 4

Step 2 - Locator Plate Installation

Secure the Narrow Locator Plate (LP-7050) in the front

position of the mounting holes on the chassis using four

5/16” FH screws and four aluminum 4-40 lock nuts.

2

Page 5

Step 3 - Front Suspension Assembly

Assemble the front suspension (8400-003) as detailed

in the Associated 8400 Front Suspension Kit instruction

sheet, replacing the stock plastic castor blocks with

HY-8060R Red Aluminum caster blocks. Insert four 8-32

screws through the bottom of the chassis and narrow

locator plate. Place a red #10 washer over each screw.

Fasten the a-arms to the chassis.

3

Page 6

Step 4 - T-Plate Assembly

Locate the T-plate (HP-1516), 2 Tefl on Coated Aluminum

Pivot Balls (HY-8376), 8-button head mounting screws

(2-56 x 0.25” lg) and the plastic pivot housings

Place one of the pivot balls into one side of the socket.

Then place the other half of the socket onto the ball

and align the four screw mounting holes. Now mount

the socket assemblies onto the T-bar with the four 2-56

screws. Be careful not to over tighten the screws and also

note the orientation of the T-plate.

Note: when assembling the socket assemblies onto the

T-bar it is very important that the pivot balls move freely in

the socket housings. Not loose but smooth free movement.

4

Page 7

Step 5 - Rear Pod Assembly

Locate the Bottom Plate (HD-7365), Right Side Pod Plate

(HD-7340), Left Side Pod Plate (HD-7341), three .075

black t-plate spacers, four 1/4” FH screws, three 3/8” FH

screws and 3 4-40 Aluminum lock nuts.

Insert the three 3/8” FH screws threw the bottom of the

bottom plate using the right most set of holes. Next, place

the .075 t-plate spacers over each screw. Place the t-plate

over the screws and secure the t-plate with 3 4-40 locknuts

as shown in fi gure 5. Finally, using the 1/4” FH screws,

install both the right and left side pod plates to the bottom

plate as shown in fi gure 5.

5

Page 8

Step 6 - Nerf Wing Installation

Locate the Nerf Wing (HD-7303), two 5/16” FH screws,

and two 4-40 aluminum lock nuts. Insert two 5/16” FH

screws through the bottom of the chassis on the right hand

side to mount the Nerf Wing. Place the nerf wing over the

screws, and attach with two 4-40 locknuts.

6

Page 9

Step 7 - Pod Installation

Using the rear pod from step 5, insert one 1/2” FH screw

through the bottom of the chassis. Place the front t-plate

pivot ball over the screw, and secure with a 4-40 lock nut.

Refer to fi gure 7 for proper placement.

7

Slider Chassis Pictured

8

Page 10

Step 8 - Cross Brace and Center Shock Mount Installation

Assemble the Center Shock Mount with the supplied SHC

screws and 4-40 lock nuts as shown in fi gure 9. Secure

the fi nished shock mount to the chassis with two 1/4” FH

screws. Refer to fi gure 7 for proper placement, and fi gure

9 for the fi nished confi guration.

Secure the Cross Brace (HD-7326) using a 1/2” FH screw

through the chassis and rear pivot ball, one 5/16” FH

screw in the right, and a 5/16” FH screw in the left hand

side location. Refer to fi gure 7 for proper placement, and

fi gure 9 for the fi nished confi guration.

9

Page 11

Step 9 - Body & Side Shock Mount Installation

Locate the Shock & Body mounts (HD-7320), 2 Aluminum

Ball studs, 8 1/4” BH screws, 4 .020 shims, and 2 4-40

lock nuts.

Install a ball stud from the front of the shock mount using

the second hole down from the top. Place two .020” shims

over the threaded shank of both ball studs. Secure them

using a 4-40 lock nut. Repeat for the opposite side. Using

two 1/4” BH screws each, attach the completed shock

mount to the cross brace. Refer to fi gure 10 for proper

placement.

Using the remaining four 1/4” BH screws, attach the body

mounts to the cross brace.

10

11

Page 12

Step 10 - Top Plate Installation

Locate the Center/Offset top plate (HD-7315), four 1/4”

BH screws, three aluminum ball studs, and three 4-40 lock

nuts. From the top of the top plate, insert one ball stud in

the right most forward hole and secure it with a 4-40 lock

nut from the bottom of the plate. Insert two more ball studs

in the right most hole locations securing each with a 4-40

lock nut. Install the fi nished top plate onto the rear pod

using the remaining four 1/4” BH screws. Refer to fi gure 12

as needed.

12

Page 13

Step 11 - Shock Assembly and Installation

Assemble the Center shock (TAM-1000R) and the side

shocks (SK-1000R) as per the instructions included

with each shock. Hyperdrive suggests using high quality

silicon shock oils in your shocks. A good starting point on

the shock setup is 40 wt. in the center shock and 30 wt.

in both side shocks. Also start with the softer of the

provided springs. At this time also attach the side shocks

onto the ball ends. Make sure to use the included

Associated Heavy Duty Ball Cups on both ends of the side

shocks to attain proper shock length. The center shock will

require a SHC screw and 4-40 lock nut supplied with the

center shock mount for installation.

13

Page 14

Step 12 - Bearing Carrier Installation

Locate the Ride Height Set (PP-2312) and choose the

two adjusters with the holes in the center. Depending on

the Final ride height of your car these may have to be

changed. Note: Always install the same adjuster on each

side of the pod in the same orientation. Failure to do this

will cause the rear axle to bind and possibly destroy your

bearings.

Insert the two adjusters into the Pod sides. Press them in

until they are fl ush with the inside of the Pod sides. Install

a Rear Axle / Right Hub Bearing (1/4” x 3/8” fl anged) into

each of the Ride Height Adjusters (see fi gure 14).

14

Page 15

Step 13 - Rear Axle / Differential Assembly

Locate the following for the Diff and Rear Axle assembly:

Rear Axle (RA-0401), Offset Diff Hub (RA-2405R), Left

Side Wheel Hub (RA-2410R), Micro-Washers (RA-0403),

Spur Gear Bearing (RA-0408-NF), Rear Axle and Right

Hub Bearings (RA-0408), Diff Centering Set (RA-0411R),

Diff balls (DB-0901), Diff Rings (DR-1002) and Spur Gear

(SG-0116).

Install the Spur Gear Bearing (1/4” x 3x8” fl angeless) into

the center of the Spur Gear. At this time also install the Diff

Balls into the outer ring of holes in the Spur Gear. Install

two of the Rear Axle / Right Hub Bearings (1/4” x 3/8”

fl anged) into the Diff Hub. Place one of the Diff rings onto

the shoulder of the axle.

Place a small amount of diff lube on each of the diff

balls installed in the spur gear and place the spur gear

assembly onto the axle. Now place the second diff ring

onto the spur gear and slide the Diff Hub down over the

axle making sure the diff ring aligns onto the shoulder of

the hub.

15

Install the Diff Centering cone over the end of the axle and

secure it with the supplied nylon nut. Tighten just enough

to hold the assembly fi rmly together.

Page 16

Step 14 - Axle Installation

Place three micro washers over the free end of the axle.

Insert through the right bearing carrier. Place one more

micro washer, and two wide axle spacers, and the left

side clamping hub on the free end of the axle and tighten

assembly.

16

Page 17

Final Assembly

Finally install your electronics, Motor, Battery, Tires and

Body. The location of your Steering Servo, Electronic

Speed Control and Receiver are entirely up to you. Take

great care when mounting these to the Chassis as their

location effects the balance of the car. Also care should

be taken when drilling, fi ling or sanding on any of the

graphite components of your car as graphite dust is

hazardous to your health. Tires are not included with

this kit because every track and driver will have different

preferences. If you are unsure of which tires to put on your

car, consult your local hobby shop staff and they should be

able to help you get the right combination for the track you

are racing on.

Loading...

Loading...