HYOSUNG GV250 EI, GT250R EI, GT250 EI Service Manual

SERVICE MANUAL

99000-95620

SERVICE MANUAL

NOTE

『』

model :

『』

model :

FOREWORD

This manual contains an introductory description on

HYOSUNG

『』

&

『』

and

procedures for its inspection / service and overhaul

of its main components.

It covers the differences from Carbure type and

please refer to the service manual of

『

(99000-95310)』,

『 &

(99000HR8310)』and

『&

(99000-94710)』for others which are not covered in

this manual.

Other information considered as generally known is

not included.

Read GENERAL INFORMATION section to

familiarize yourself with outline of the vehicle and

MAINTENANCE and other sections to use as a guide

for proper inspection and service.

This manual will help you know the vehicle better so

that you can assure your customers of your optimum

and quick service.

ELECTRICAL SYSTEM

GROUP INDEX

GENERAL INFORMATION

1

EI SYSTEM DIAGNOSIS

FUEL SYSTEM AND THROTTLE BODY

4-2

4-1

5

SERVICING INFORMATION

7

This manual has been prepared on the basis

of the latest specification at the time of

publication.

If modification has been made since then,

difference may exist between the content of

this manual and the actual vehicle.

Illustrations in this manual are used to show

the basic principles of operation and work

procedures.

They may not represent the actual vehicle

exactly in detail.

WARNING

This manual is intended for those who have

enough knowledge and skills for servicing

HYOSUNG vehicles. Without such knowledge and

skills, you should not attempt servicing by relying

on this manual only.

Instead, please contact your nearby authorized

HYOSUNG motorcycle dealer.

COPYRIGHT S&T Motors Co., Ltd.

2

HOW TO USE THIS MANUAL

TO LOCATE WHAT YOU ARE

LOOKING FOR :

1. The text of this manual is divided into sections.

2. As the title of these sections are listed on the previous

page as GROUP INDEX, select the section where you are

looking for.

3. Holding the manual as shown at the right will allow you to

find the first page of the section easily.

4. On the first page of each section, its contents are listed.

Find the item and page you need.

SYMBOL

Listed in the table below are the symbols indicating instructions and other information necessary for servicing.

The meaning of each symbol is also included in the table.

Apply THREAD LOCK “1324”.

Apply or use brake fluid.

Measure in voltage range.

Measure in resistance range.

Measure in current range.

Use special tool.

Measure in continuity test range.

Measure in diode test range.

Torque control required.

Data beside it indicates specified torque.

Apply oil.

Use engine oil unless otherwise specified.

Apply SUPER GREASE “A”.

Apply SILICONE GREASE.

Apply MOLY PASTE.

Apply BOND “1215”.

Use fork oil.

DEFINITION

SYMBOL

DEFINITIONSYMBOL

Apply SUPER GREASE “C”.

3

A

ABDC : After Bottom Dead Center

AC : Alternating Current

API : American Petroleum Institute

A TDC : After Top Dead Center

B

BBDC : Before Bottom Dead Center

BDC : Bettom Dead Center

BTDC : Before Top Dead Center

D

DC : Direct Current

DOHC : Double Over Head Camshaft

E

ECU : Engine Control Unit,

EI Control Unit

EI : Electric fuel Injection,

Electric fuel Injector

ET Sensor : Engine Temperature Sensor

(ETS)

F

FP : Fuel Pump

G

GP Switch : Gear Position Switch

I

IAP Sensor : Intake Air Pressure Sensor

(IAPS)

IA T Sensor : Intake Air Temperature Sensor

(IA TS)

IG : Ignition

ISC Solenoid : Idle Speed Control Solenoid

L

LCD : Liquid Crystal Display

LED : Light Emitting Diode

LH : Left Hand

M

Max : Maximum

Min : Minimum

O

O2 Sensor : Oxygen Sensor (O2S)

R

RH : Right Hand

RO Switch : Roll Over Switch

S

SAE :

Society of Automotive Engineers

SA V Solenoid : Secondary Air V alve Solenoid

T

TDC : Top Dead Center

TP Sensor : Throttle Position Sensor (TPS)

ABBREVIATIONS USED IN THIS MANUAL

4

BL : Black with Blue tracer BBr : Black with Brown tracer

BG : Black with Green tracer BO : Black with Orange tracer

BR : Black with Red tracer BW : Black with White tracer

BY : Black with Yellow tracer LB : Blue with Black tracer

LG : Blue with Green tracer LR : Blue with Red tracer

L W : Blue with White tracer L Y : Blue with Y ellow tracer

BrB : Brown with Black tracer BrW : Brown with White tracer

GB : Green with Black tracer GR : Green with Red tracer

GY : Green with Yellow tracer GrB : Gray with Black tracer

GrR : Gray with Red tracer GrW : Gray with White tracer

OB : Orange with Black tracer OL : Orange with Blue tracer

OG : Orange with Green tracer OR : Orange with Red tracer

OW : Orange with White tracer OY : Orange with Yellow tracer

RB : Red with Black tracer RW : Red with White tracer

WB : White with Black tracer WL : White with Blue tracer

WR : White with Red tracer YB : Yellow with Black tracer

YL : Yellow with Blue tracer YG : Yellow with Green tracer

YR : Yellow with Red tracer

B : Black Gr : Gray Sb : Light blue

L : Blue Lg : Light green W : White

Br : Brown O : Orange Y : Yellow

G : Green R : Red

WIRE COLOR

5

GENERAL INFORMATION

EXTERIOR PHOTOGRAPH ………………………………………………………… 6 (1-6-1)

EXTERIOR ILLUSTRATION

~~ ₩₩

……………………………… 8 (1-6-3)

EXTERIOR ILLUSTRATION

~~ ₩₩

…………………………… 9 (1-7-1)

EXTERIOR ILLUSTRATION

~~ ₩₩

………………………………… 10 (1-7-2)

FUNCTION OF EI SENSOR ………………………………………………………… 11 (1-8-1)

SPECIFICATIONS ……………………………………………………………………… 12 (1-8-2)

CONTENTS

1

6

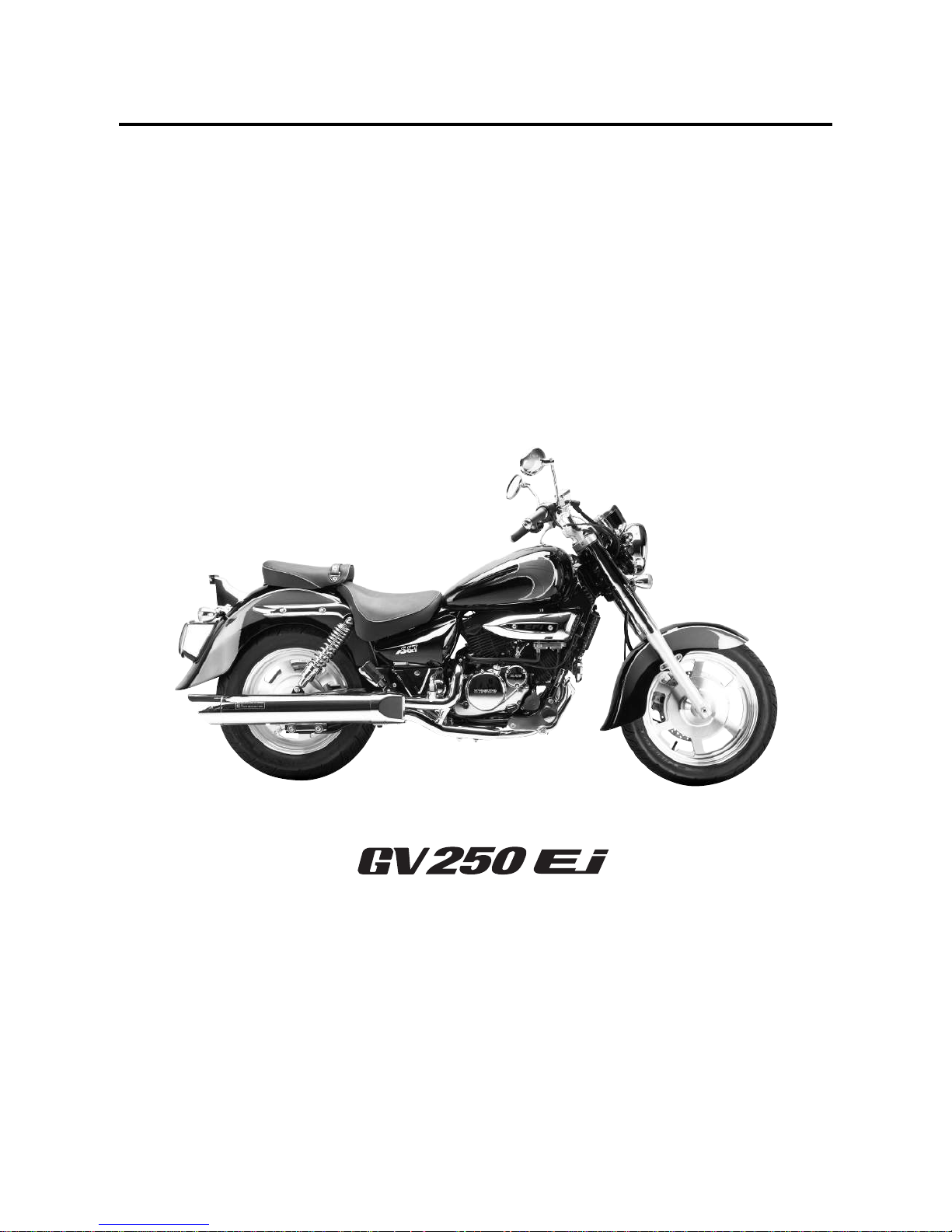

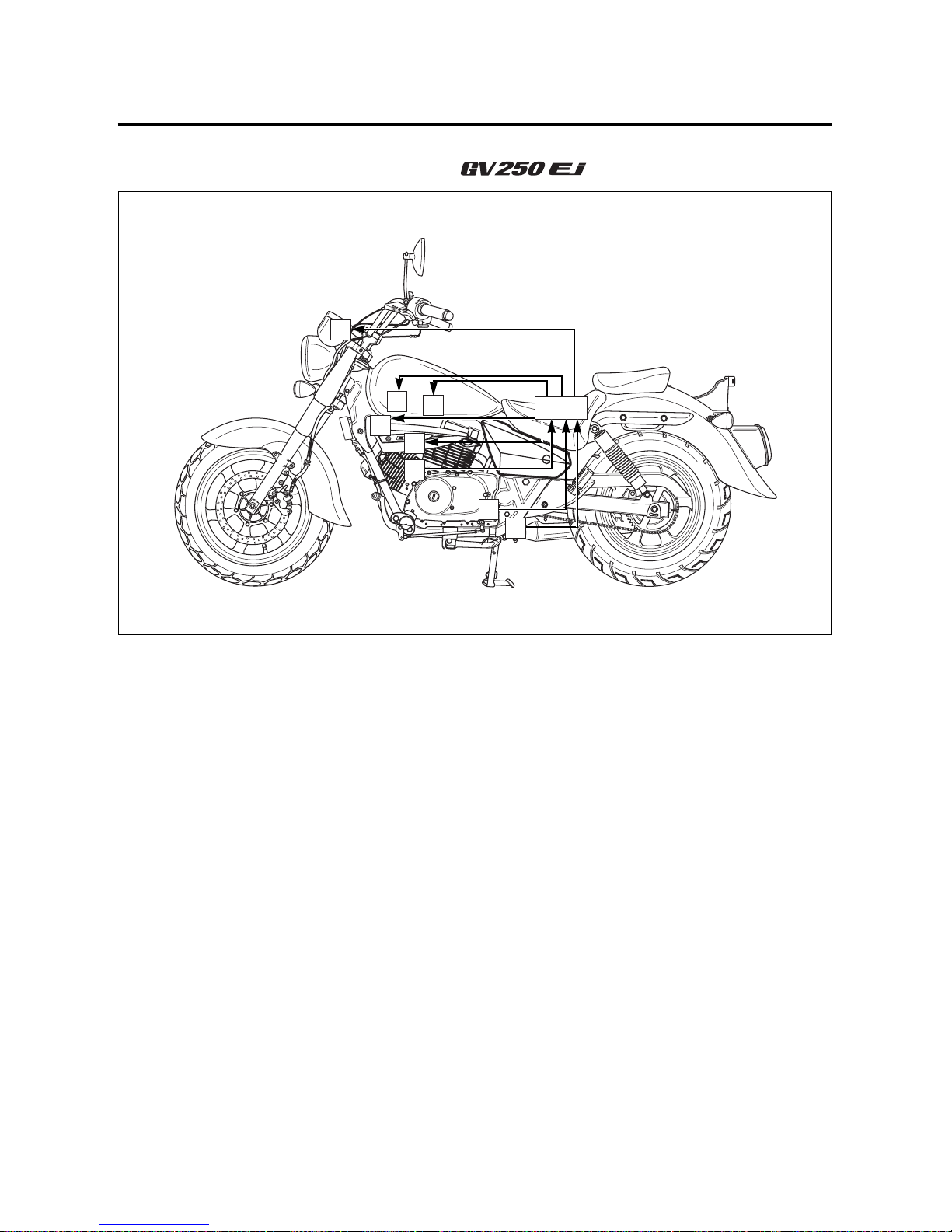

1-6-1 GENERAL INFORMATION

EXTERIOR PHOTOGRAPH

7

GENERAL INFORMATION 1-6-2

EXTERIOR PHOTOGRAPH

8

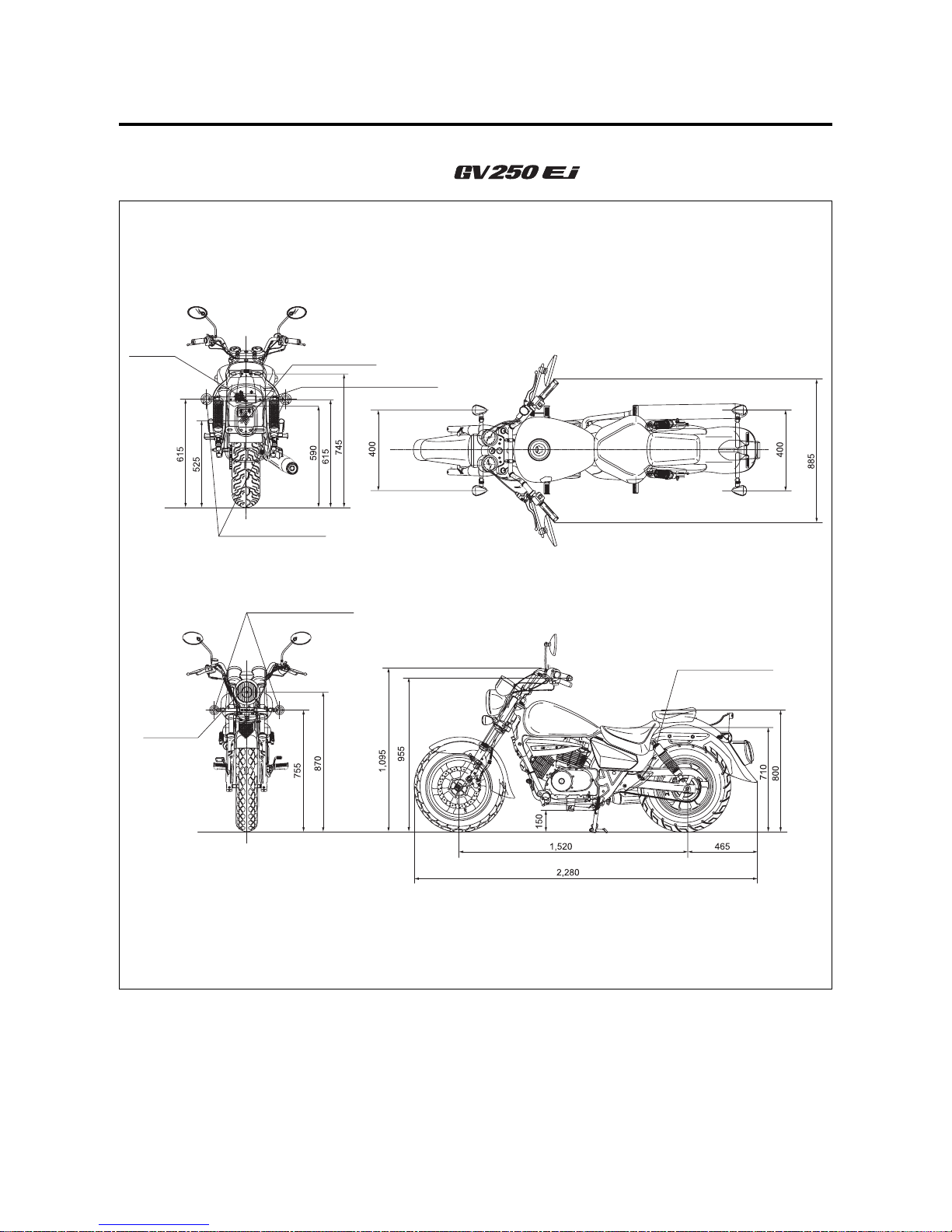

1-6-3 GENERAL INFORMATION

EXTERIOR ILLUSTRATION

~~ ₩₩

Rear

reflector

Brake / Tail lamp

Rear turn signal lamp

License plate lamp

Front turn signal lamp

Passenger footrests

Head lamp

(HEIGHT)

(WHEEL BASE)

(LENGTH)

(WIDTH)

9

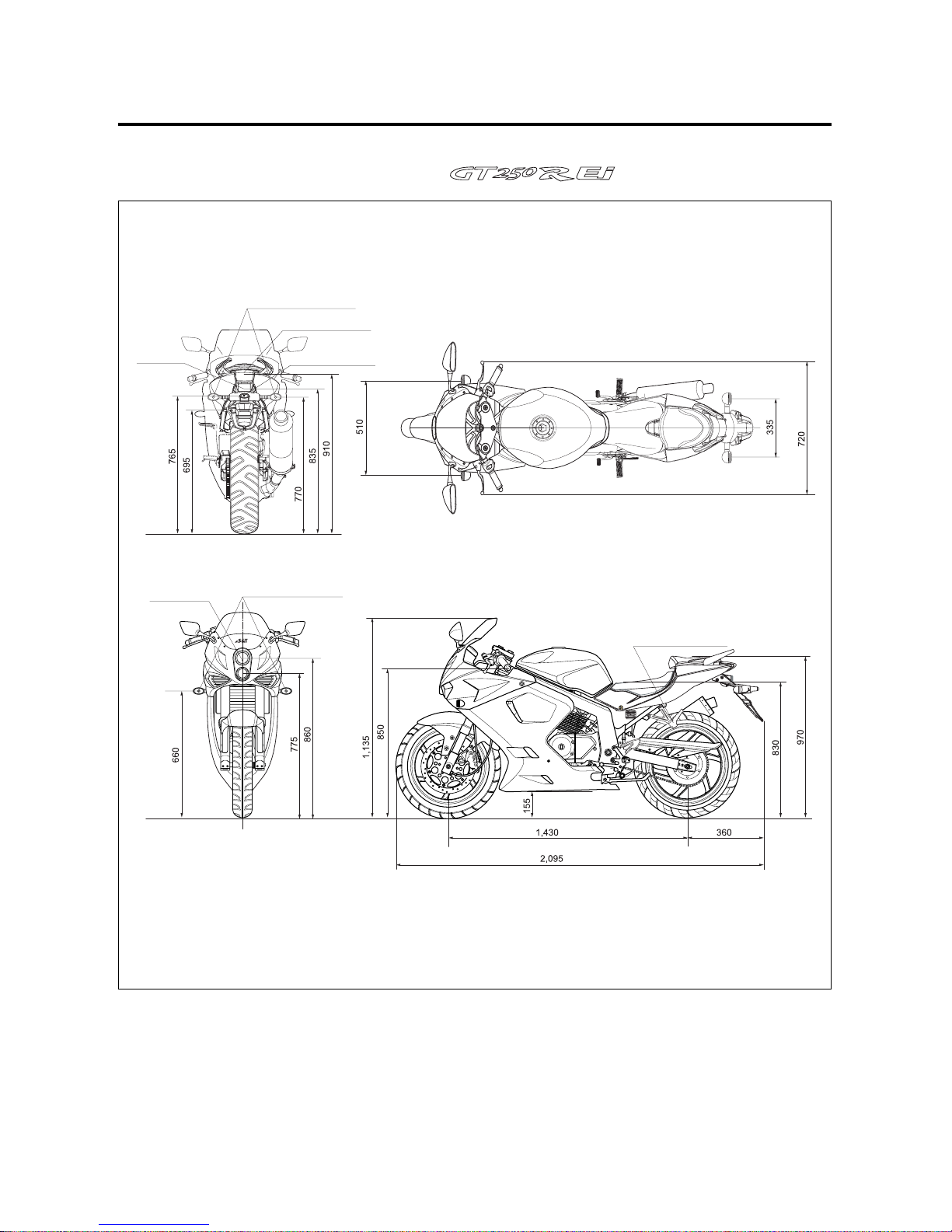

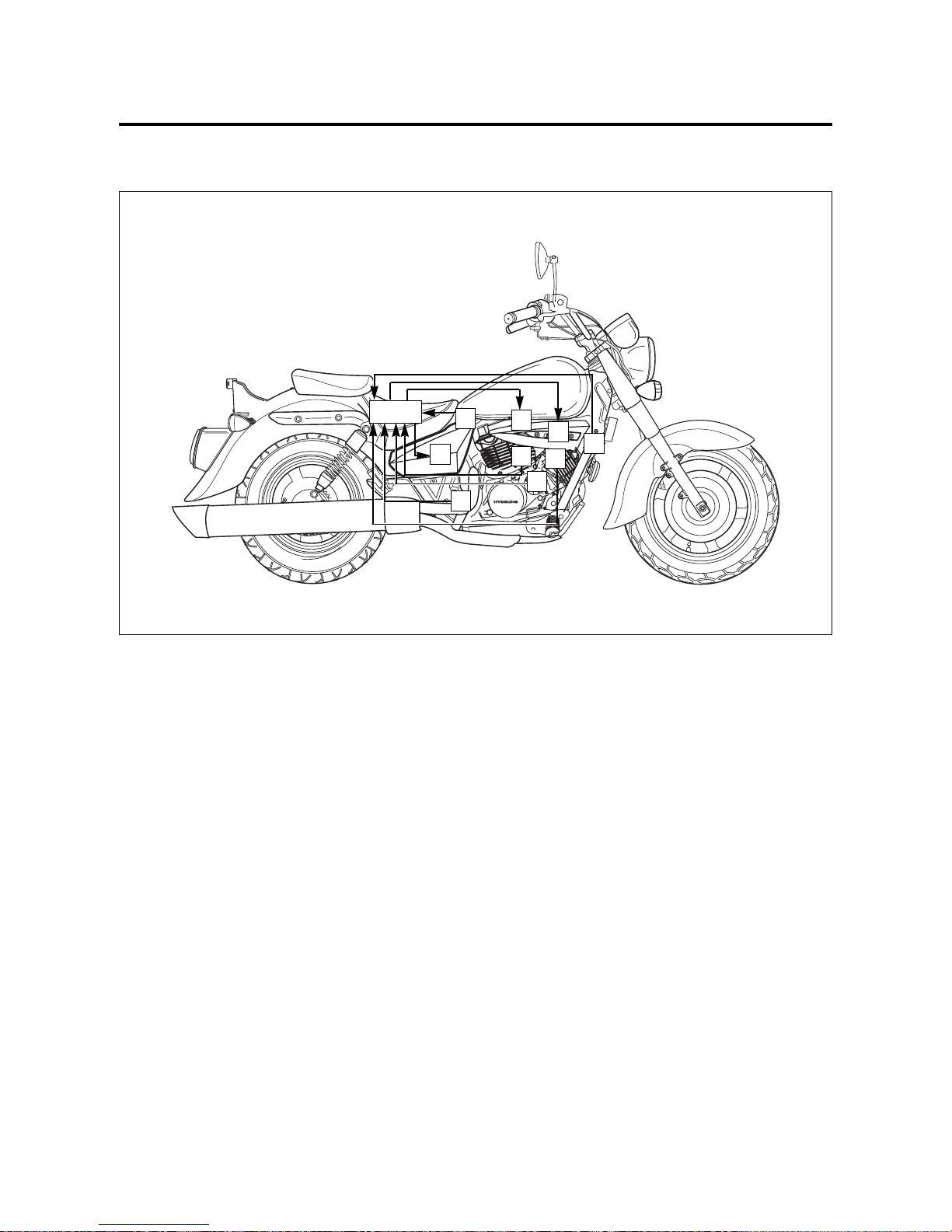

GENERAL INFORMATION 1-7-1

EXTERIOR ILLUSTRATION

~~ ₩₩

Rear

reflector

Brake / Tail lamp

License plate lamp

Rear turn signal lamp

Front turn signal lamp

Passenger footrests

Head lamp

(HEIGHT)

(WHEEL BASE)

(LENGTH)

(WIDTH)

10

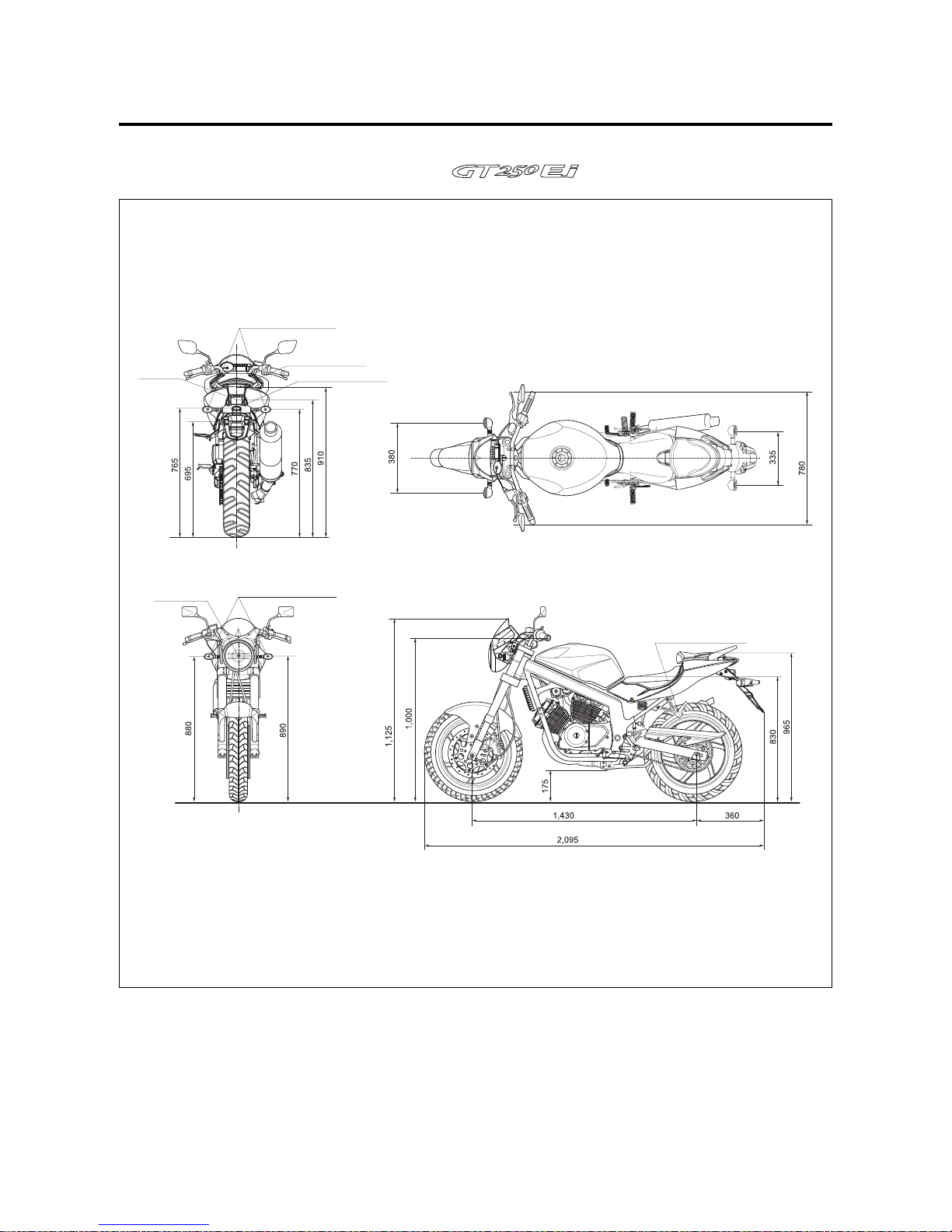

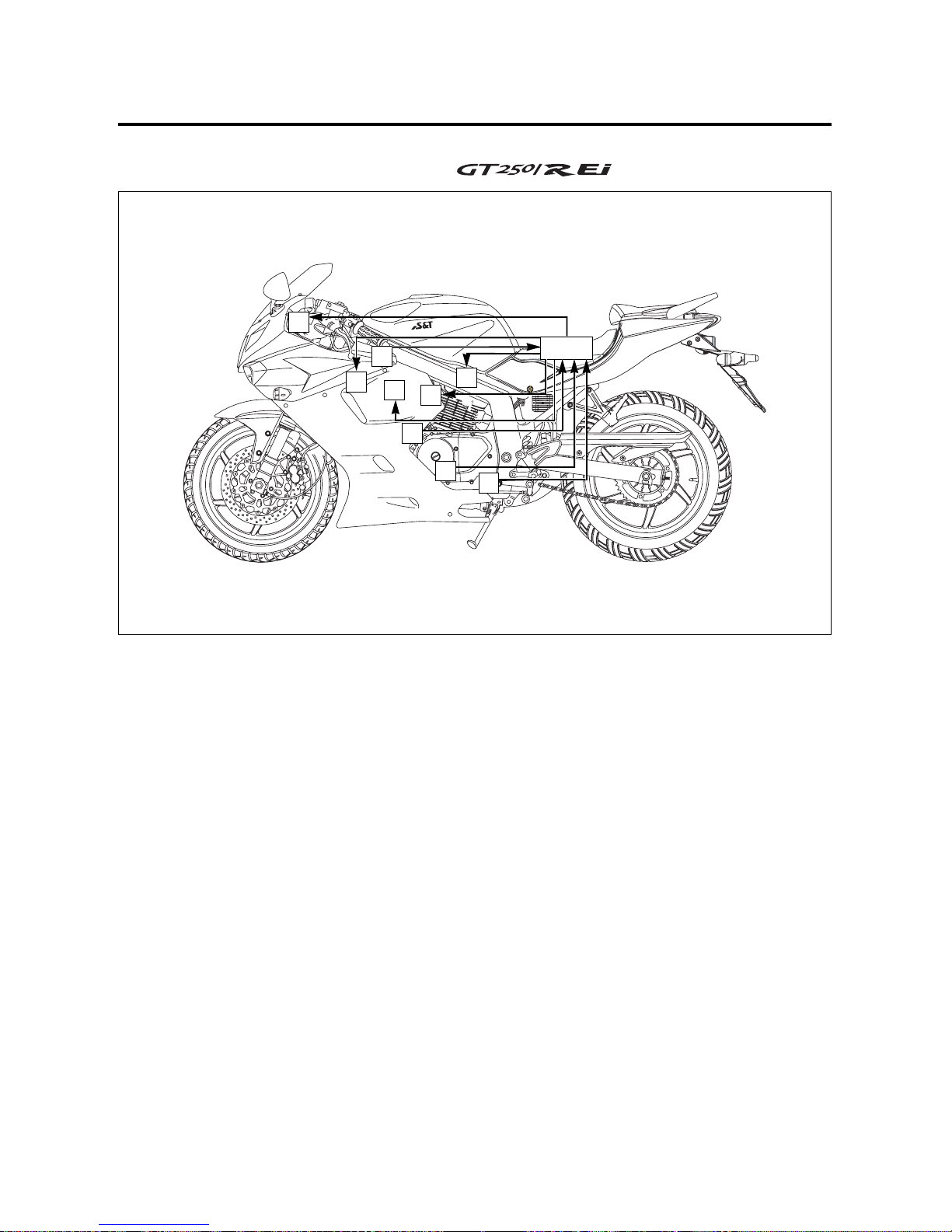

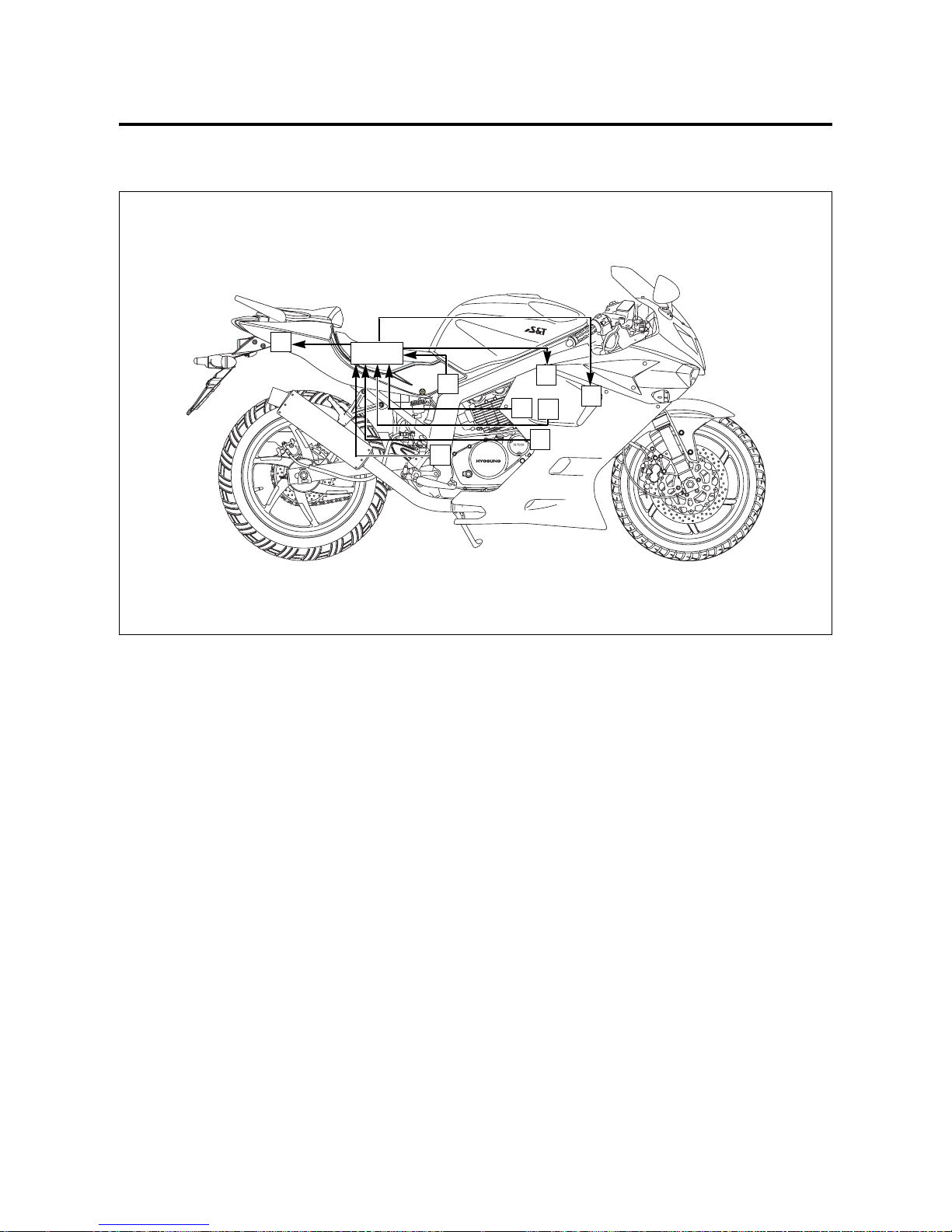

1-7-2 GENERAL INFORMATION

EXTERIOR ILLUSTRATION

~~ ₩₩

Rear

reflector

Brake / Tail lamp

License plate lamp

Rear turn signal lamp

Front turn signal lamp

Passenger footrests

Head lamp

(HEIGHT)

(WHEEL BASE)

(LENGTH)

(WIDTH)

11

GENERAL INFORMATION 1-8-1

FUNCTION OF EI SENSOR

★★

ECU (Engine Control Unit, EI Control Unit)

: ECU decide the fuel injection volume and ignition time to adjust the fuel injector opening and closing rate

which is considered the engine speed, intake air pressure, intake air volume, engine temperature, oxygen

volume and throttle opening angle, etc.

★★

EI (Electric fuel Injector)

: EI spray the fuel to intake pipe by ECU’s injection signal.

Fuel which is needed combustion in the combustion chamber is supplied from the fuel tank.

★★

ET sensor (Engine Temperature Sensor : ETS)

: ET sensor communicate the perceived engine temperature to ECU.

ET sensor is located the outside of the cylinder to measure the engine temperature.

★★

GP switch (Gear Position Switch)

: GP switch is used when start / stop and control ECU as the converted electrical signal of the gear position is

supplied ECU.

★★

IAP sensor (Intake Air Temperature : IAPS)

: IAP sensor measure the pressure which is generated from the intake pipe and compare with the provided

absolute pressure, then analogize the air volume indirectly and help to work the fuel injector properly.

★★

IAT sensor (Intake Air Temperature Sensor : IATS)

: IAT sensor perceive the atmospheric temperature and is located the air cleaner case.

★★

ISC solenoid (Idle Speed Control Solenoid)

: ISC solenoid is interlocked with the throttle body, so ECU control the engine idle speed.

★★

O2 sensor (Oxygen Sensor : O2S)

:O2 sensor measure the oxygen volume from the exhaust gas and convert the oxygen volume into voltage

value, then communicate the output voltage to ECU.

★★

Pick-up Coil

: Pick-up coil perceive the front and rear cylinder’s engine speed and realtime of piston position.

★★

RO switch (Roll Over Switch)

: RO switch is the fuel cut-off system when the motorcycle is leaned over 60°for upset accident.

★★

SAV solenoid (Secondary Air Valve Solenoid)

: SAV solenoid supply the fresh air to the exhaust pipe for decrease of the exhaust gas.

★★

TP sensor (Throttle Position Sensor : TPS)

: TP sensor detect the throttle opening angle and is located the throttle body.

It decide the fuel injection volume and compensate the ignition time as inform idle·acceleration·

deceleration condition and throttle full opening etc. to ECU.

12

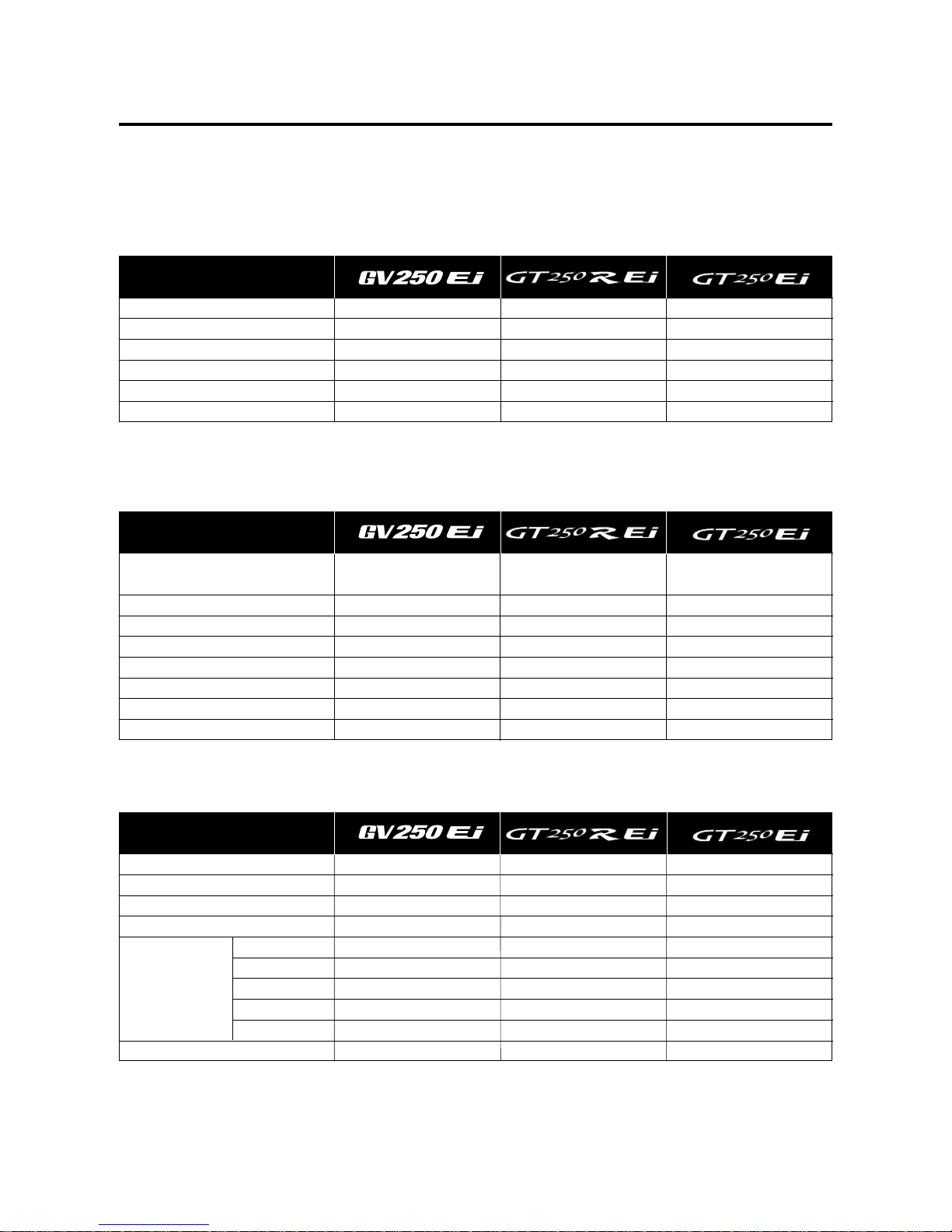

1-8-2 GENERAL INFORMATION

2,280 mm (89.8 in)

885 mm (34.8 in)

1,095 mm (43.1 in)

1,520 mm (59.8 in)

150 mm (5.9 in)

175 kg (386 lbs)

2,095 mm (82.5 in)

720 mm (28.4 in)

1,135 mm (44.7 in)

1,430 mm (56.3 in)

155 mm (6.1 in)

185 kg (408 lbs)

Overall length

Overall width

Overall height

Wheelbase

Ground clearance

Mass

ITEM

SPECIFICATIONS

⊙⊙

DIMENSIONS AND MASS

Four-stroke, DOHC,

air-cooled and oil-cooled

V-2 cylinder

57.0 mm (2.24 in)

48.8 mm (1.92 in)

249 ㎤(15.2 in3)

Electric fuel Injection

Electric starter

Wet sump

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

Type

Number of cylinder

Bore

Stroke

Piston displacement

Fuel system

Starter system

Lubrication system

ITEM

⊙⊙

ENGINE

Wet multi-plate type

5-speed constant mesh

1-down, 4-up

3.290

2.460

1.560

1.190

0.960

0.840

520HO, 116 links

←

←

←

←

←

←

←

←

←

520HO, 112 links

←

←

←

←

←

←

←

←

←

←

Clutch

Transmission

Gearshift pattern

Reduction ratio

1st

2nd

3rd

4th

5th

Drive chain

ITEM

⊙⊙

TRANSMISSION

←

780 mm (30.7 in)

1,125 mm (44.3 in)

←

175 mm (6.9 in)

175 kg (386 lbs)

Gear ratio

13

GENERAL INFORMATION 1-9

NOTE

The specifications are subject to change without notice.

Telescopic type

Swingarm type

40˚(right & left)

34˚

142 mm (5.59 in)

Disk brake

Drum brake

110/90 - 16 59S

150/80 - 15M/C 70S

120 mm (4.72 in)

←

←

27˚(right & left)

25.5˚

90 mm (3.54 in)

Double disk brake

Disk brake

110/70 - 17 54H

150/70 - 17 69H

←

←

←

←

←

←

Disk brake

←

←

←

←

Front suspension

Rear suspension

Steering angle

Caster

Trail

Front brake

Rear brake

Front tire size

Rear tire size

Front fork stroke

ITEM

⊙⊙

CHASSIS

ITEM

⊙⊙

ELECTRICAL

14.0 ℓ

1,450 ㎖

1,500 ㎖

1,800 ㎖

260 cc

17.0 ℓ

←

←

←

400 ±2.5 cc

←

←

←

←

←

Fuel tank

Engine oil

Front fork oil capacity (One side)

Oil change

Oil and filter change

Engine overhaul

ITEM

⊙⊙

CAPACITIES

Ignition type

Ignition timing

Spark plug

Battery

Fuse

Head lamp

Turn signal lamp

Brake / Tail lamp

License plate lamp

Illumination lamp

High beam indicator lamp

Turn signal indicator lamp(right & left)

Neutral indicator lamp

Fuel meter lamp

“FI”(Fuel Injection) check lamp

ECU

13˚B.T.D.C. at 2,000 rpm and

30˚B.T.D.C. at 6,000 rpm

CR8E

12 V 10 Ah (MF)

30 A & 15 A

12 V - H4 : 60 W ×1

12 V - H4 : 55 W ×1

12 V - RY10 W × 4

12 V - P21/5 W × 1

12 V - W5 W × 1

12 V - 1.7 W × 2

12 V - 1.7 W × 1

12 V - 1.7 W × 2

12 V - 1.7 W × 1

12 V - 1.7 W × 1

LED type

←

←

←

←

←

12 V - H1 : 55 W ×1

12 V - H3 : 55 W ×1

←

LED type

←

LED type

LED type

LED type

LED type

LED type (Level type)

←

←

←

←

←

←

12 V - H4 : 60 W ×1

12 V - H4 : 55 W ×1

←

←

←

←

←

←

←

←

←

HI

LO

※ LED : Light Emitting Diode

14

15

PRECAUTIONS IN SERVICING

………………………………………

16 (4-1-1)

EI SYSTEM TECHNICAL FEATURES

………………………………

20 (4-1-5)

SELF-DIAGNOSIS FUNCTION

~~ ₩₩

………………

27 (4-1-12)

SELF-DIAGNOSIS FUNCTION

~~ ₩₩

…………………

29 (4-1-14)

EI SYSTEM TROUBLESHOOTING

…………………………………

33 (4-1-18)

CUSTOMER COMPLAINT ANALYSIS

…………………………………

33 (4-1-18)

SELF-DIAGNOSTIC PROCEDURES

…………………………………

35 (4-1-20)

SELF-DIAGNOSIS RESET PROCEDURE

……………………………

36 (4-1-21)

MALFUNCTION CODE AND DEFECTIVE CONDITION

……………

37 (4-1-22)

““

C12””PICK-UP COIL CIRCUIT MALFUNCTION

……………………

39 (4-1-24)

““

C14””TP SENSOR CIRCUIT MALFUNCTION

………………………

40 (4-1-25)

““

C15””ET SENSOR CIRCUIT MALFUNCTION

………………………

43 (4-1-28)

““

C17

””oorr““

C18””IAP SENSOR CIRCUIT MALFUNCTION

……………

45 (4-1-30)

““

C21””IAT SENSOR CIRCUIT MALFUNCTION

………………………

47 (4-1-32)

““

C22””OXYGEN SENSOR CIRCUIT MALFUNCTION

………………

49 (4-1-34)

““

C23””RO SWITCH CIRCUIT MALFUNCTION

………………………

50 (4-1-35)

““

C24

””oorr““

C25””IGNITION COIL MALFUNCTION

……………………

51 (4-1-36)

““

C27””ISC SOLENOID RANGE ABNORMAL

………………………

52 (4-1-37)

““

C31””GP SWITCH CIRCUIT MALFUNCTION

………………………

53 (4-1-38)

““

C32

””oorr““

C33””FUEL INJECTOR CIRCUIT MALFUNCTION

………

54 (4-1-39)

““

C37””SAV SOLENOID MALFUNCTION

……………………………

56 (4-1-41)

““

C41””FUEL PUMP RELAY CIRCUIT MALFUNCTION

………………

57 (4-1-42)

““

C43””OXYGEN SENSOR HEATER CIRCUIT MALFUNCTION

……

58 (4-1-43)

SENSORS

…………………………………………………………………

59 (4-1-44)

4 -1

EI SYSTEM DIAGNOSIS

CONTENTS

16

PRECAUTIONS IN SERVICING

When handling the component parts or servicing the

EI system, observe the following points for the safety

of the system.

⊙⊙

ELECTRICAL PARTS

▣▣

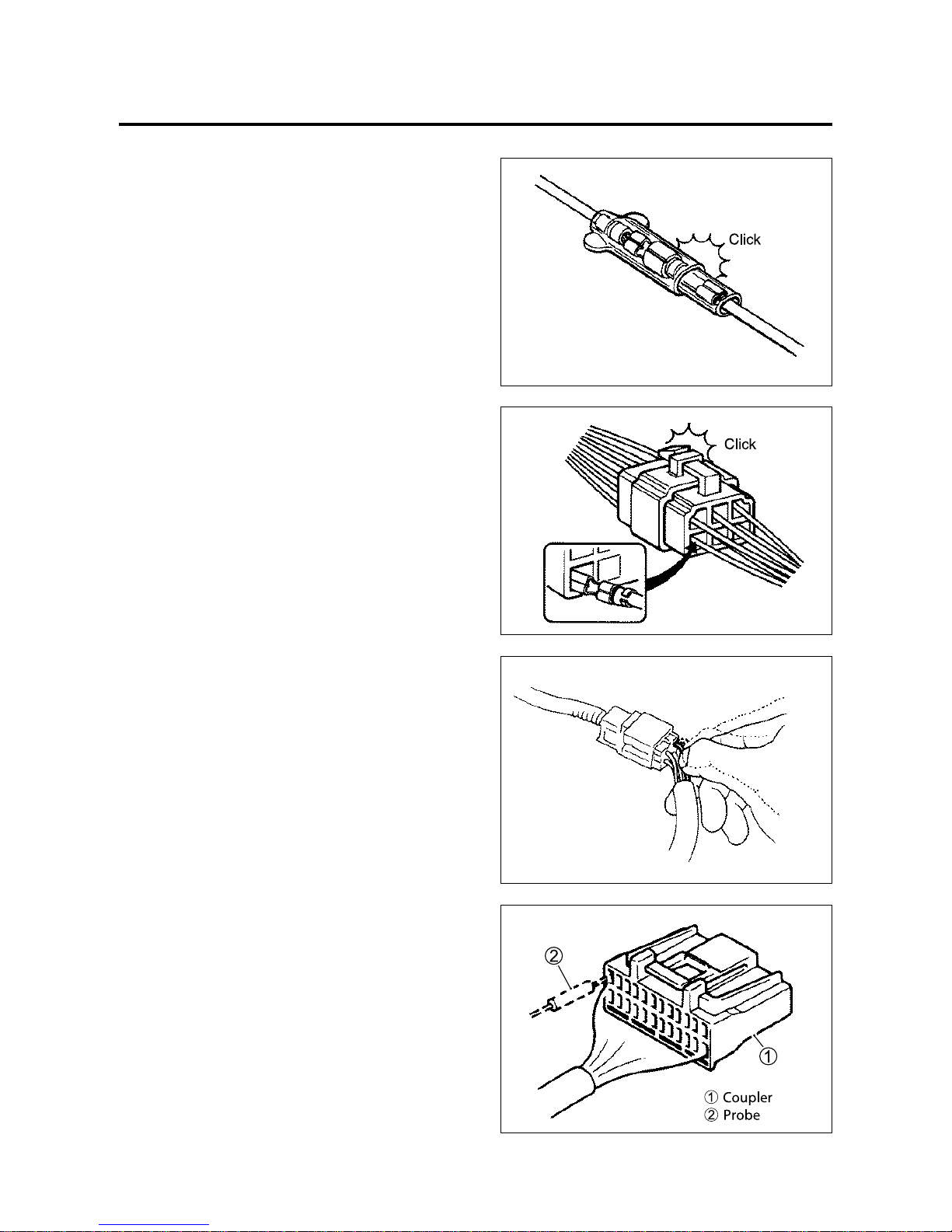

CONNECTOR / COUPLER

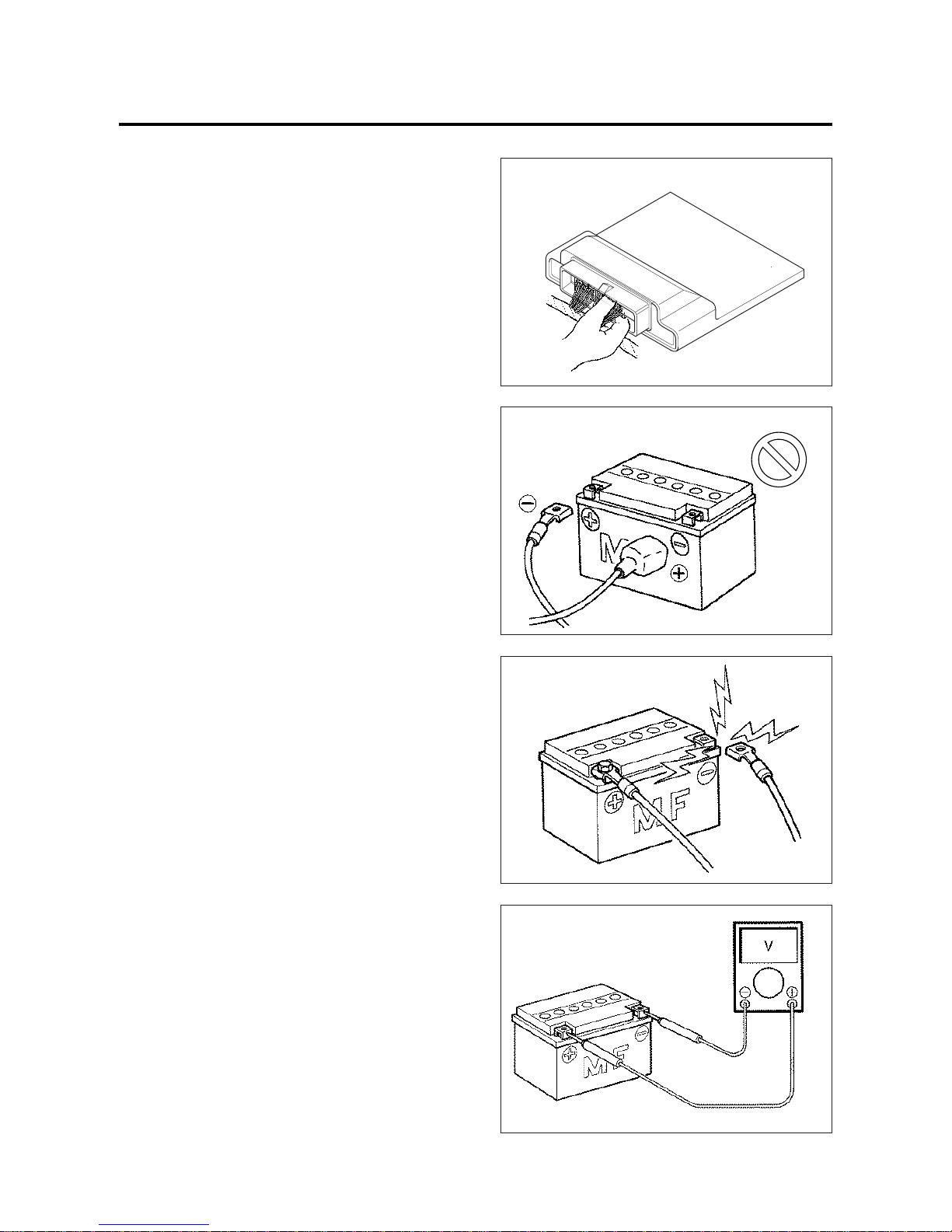

● When connecting a connector, be sure to push it

in until a click is felt.

● With a lock type coupler, be sure to release the

lock when disconnecting, and push it in fully till the

works when connecting it.

● When disconnecting the coupler, be sure to hold

the coupler body and do not pull the lead wires.

● Inspect each terminal on the connector / coupler

for looseness or bending.

● Inspect each terminal for corrosion and

contamination.

The terminals must be clean and free of any

foreign material which could impede proper

terminal contact.

● Inspect each lead wire circuit for poor connection

by shaking it by hand lightly. If any abnormal

condition is found, repair or replace.

● When taking measurements at electrical

connectors using a tester probe, be sure to insert

the probe from the wire harness side (backside) of

the connector / coupler.

4-1-1 EI SYSTEM DIAGNOSIS

17

EI SYSTEM DIAGNOSIS 4-1-2

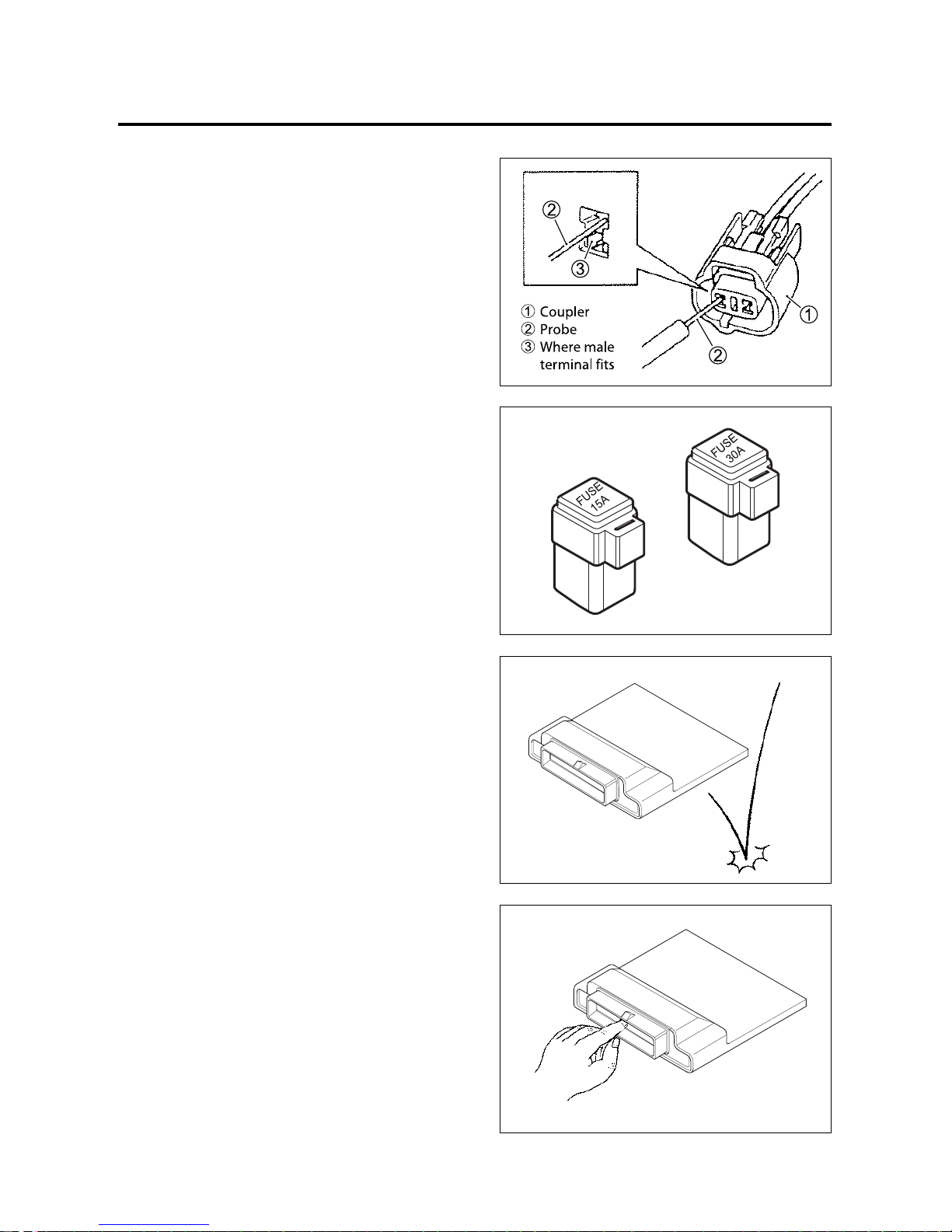

● When connecting meter probe from the terminal

side of the coupler (connection from harness side

not being possible), use extra care not to force

and cause the male terminal to bend or the female

terminal to open.

Connect the probe as shown to avoid opening of

female terminal.

Never push in the probe where male terminal is

supposed to fit.

● Check the male connector for bend and female

connector for excessive opening. Also check the

coupler for locking (looseness), corrosion, dust,

etc.

⊙⊙

FUSE

● When a fuse blows, always investigate the cause

to correct it and then replace the fuse.

● Do not use a fuse of a different capacity.

● Do not use wire or any other substitute for the

fuse.

⊙⊙

ECU / VARIOUS SENSORS

● Since each component is a high-precision part,

great care should be taken not to apply any sharp

impacts during removal and installation.

● Be careful not to touch the electrical terminals of

the ECU.

The static electricity from your body may damage

this part.

18

4-1-3 EI SYSTEM DIAGNOSIS

INCORRECT

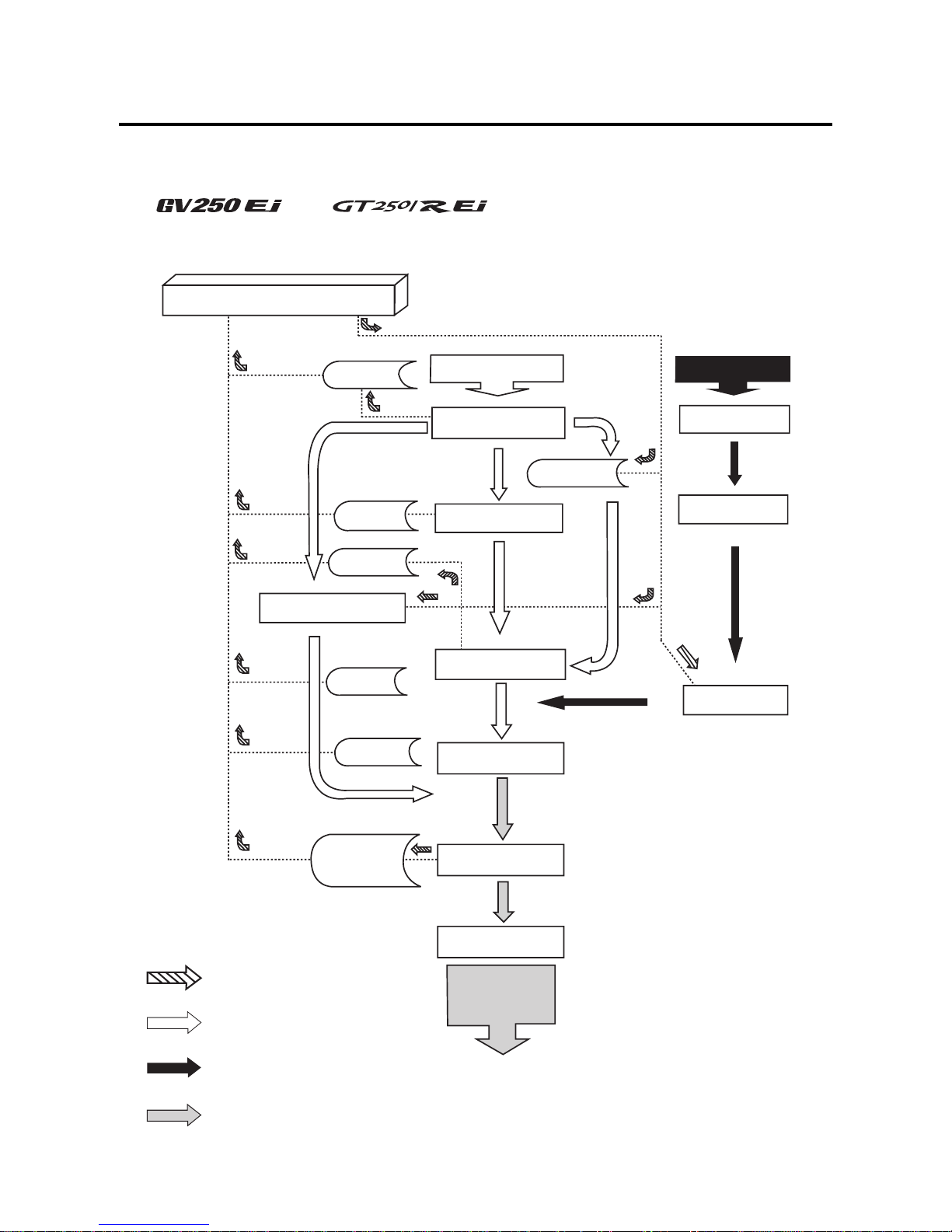

● When disconnecting and connecting the ECU,

make sure to turn “OFF” the ignition switch, or

electronic parts may get damaged.

● Battery connection in reverse polarity is strictly

prohibited.

Such a wrong connection will damage the

components of the EI system instantly when

reverse power is applied.

● Removing any battery terminal of a running

engine is strictly prohibited.

The moment such removal is made, damaging

counter electromotive force will be applied to the

ECU which may result in serious damage.

● Before measuring voltage at each terminal, check

to make sure that battery voltage is 11 V or

higher.

Terminal voltage check at low battery voltage will

lead to erroneous diagnosis.

19

EI SYSTEM DIAGNOSIS 4-1-4

● Never connect an ohmmeter to the ECU with its

coupler connected. If attempted, damage to ECU

or sensors may result.

● Be sure to use a specified voltmeter / ohmmeter.

Otherwise, accurate measurements may not be

obtained and personal injury may result.

⊙⊙

USING TESTERS

● Use well-charged batteries in the tester.

● Be sure to set the tester to the correct testing

range.

▣▣

USING THE TESTER

● Incorrectly connecting the and probes may

cause the inside of the tester to burnout.

● If the voltage and current are not known, make

measurements using the highest range.

● After using the tester, turn the power off.

20

4-1-5 EI SYSTEM DIAGNOSIS

EI SYSTEM TECHNICAL FEATURES

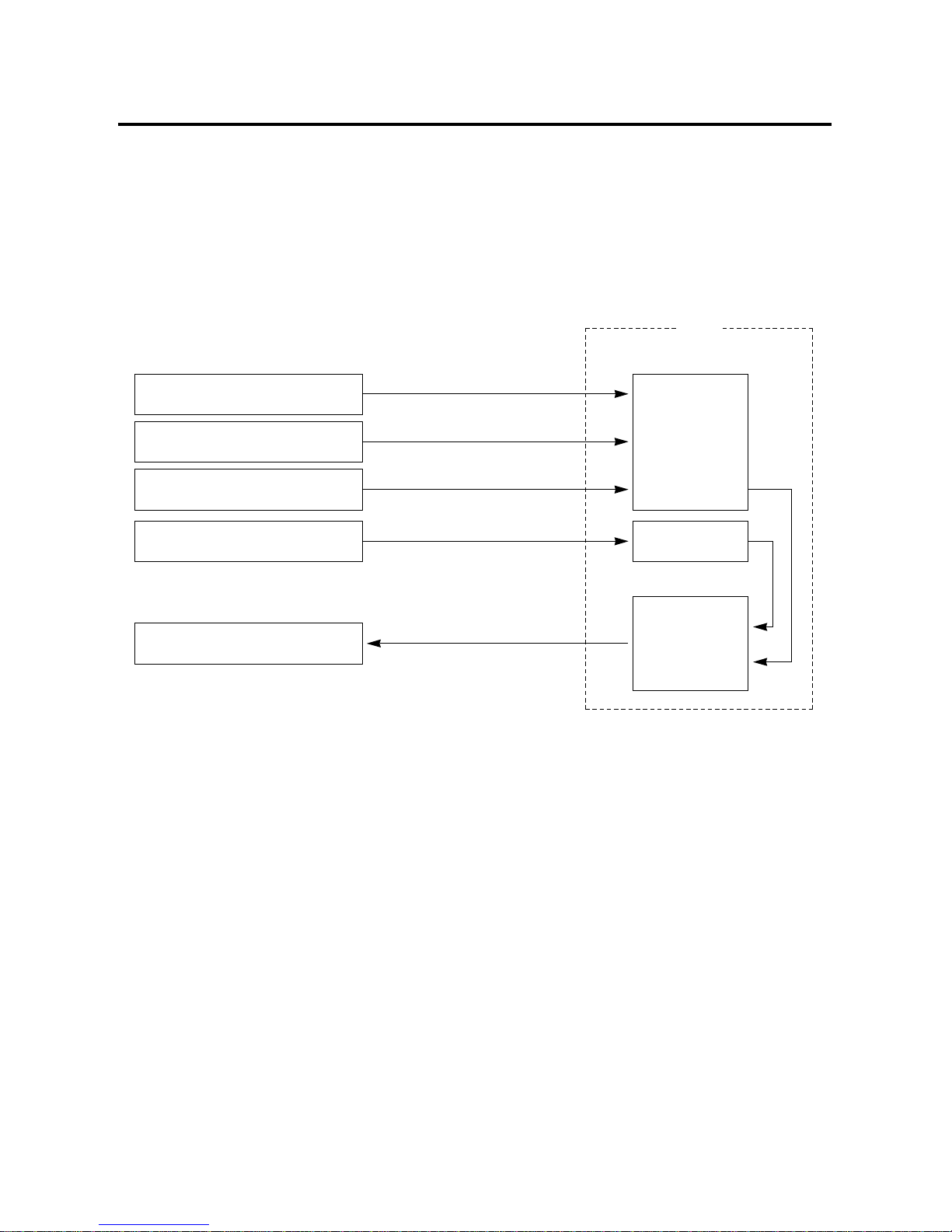

⊙⊙『『 』』& 『『 』』

EI SYSTEM’S CONTROL

DIAGRAM

ECU

IAT Sensor

TP Sensor

IAP Sensor

ISC Solenoid

AIR

AIR CLEANER

THROTTLE BODY

FUEL TANK

FUEL

FUEL PUMP

FUEL INJECTOR

INTAKE PIPE

CYLINDER

EXHAUST PIPE

O2 Sensor

: Electrical signal flow

: Air flow

: Fuel flow

: Exhaust gas flow

Pick-up Coil

ET Sensor

SAV Solenoid

MUFFLER

EXHAUST GAS

21

EI SYSTEM DIAGNOSIS 4-1-6

⊙⊙

INJECTION TIME (INJECTION VOLUME)

The factors to determine the injection time include the basic fuel injection time, which is calculated on the basis of

intake air pressure, engine speed and throttle opening angle, and various compensations.

These compensations are determined according to the signals from various sensors that detect the engine and

driving conditions.

Intake Air Pressure Sensor

(IAP Sensor)

Intake air pressure signal

Basic

fuel

injection

time

Compensation

Ultimate

fuel

injection

time

Pick-up coil

Throttle Position Sensor

(TP Sensor)

Various Sensors

Injectors

Engine speed signal

Throttle opening signal

Various signals

Injection signal

ECU

22

4-1-7 EI SYSTEM DIAGNOSIS

⊙⊙

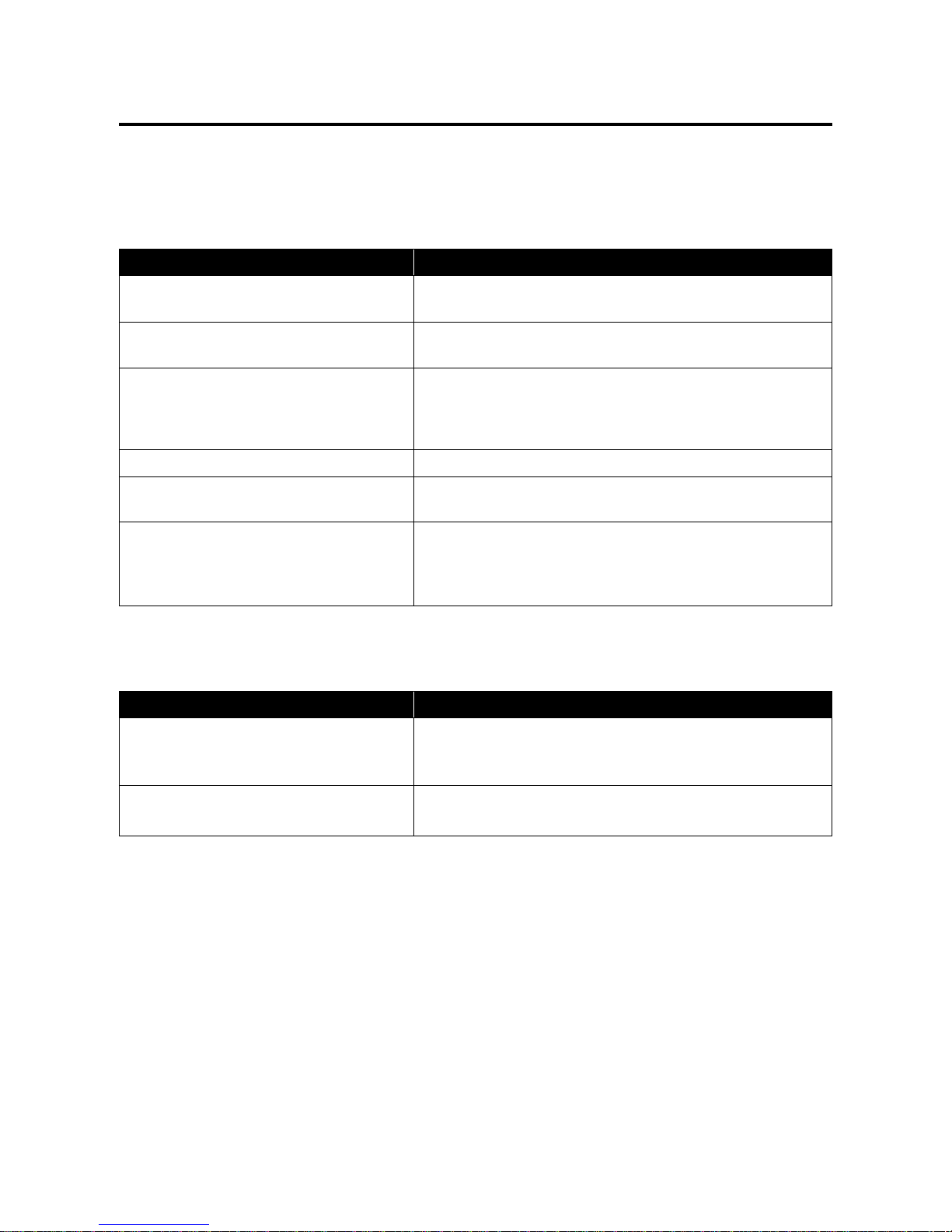

COMPENSATION OF INJECTION TIME (VOLUME)

The following different signals are output from the respective sensors for compensation of the fuel injection time

(volume).

⊙⊙

INJECTION STOP CONTROL

SIGNAL DESCRIPTION

ENGINE TEMPERATURE

SENSOR SIGNAL

INTAKE AIR TEMPERATURE SENSOR

SIGNAL

BATTERY VOLTAGE SIGNAL

ENGINE RPM SIGNAL

STARTING SIGNAL

ACCELERATION SIGNAL /

DECELERATION SIGNAL

When engine temperature is low, injection time (volume) is

increased.

When intake air temperature is low, injection time (volume) is

increased.

ECU operates on the battery voltage and at the same time, it

monitors the voltage signal for compensation of the fuel injection

time (volume). A longer injection time is needed to adjust

injection volume in the case of low voltage.

At high speed, the injection time (volume) is increased.

When starting engine, additional fuel is injected during cranking

engine.

During acceleration, the fuel injection time (volume) is increased

in accordance with the throttle opening speed and engine rpm.

During deceleration, the fuel injection time (volume) is

decreased.

SIGNAL DESCRIPTION

ROLL OVER SWITCH SIGNAL

(FUEL CUT-OFF)

OVER-REV. LIMITER SIGNAL

When the motorcycle rolls over, the roll over switch sends a

signal to the ECU. Then, this signal cuts OFF current supplied to

the fuel pump, fuel injector and ignition coil.

The fuel injectors stop operation when engine rpm reaches rev.

limit rpm.

23

EI SYSTEM DIAGNOSIS 4-1-8

⊙⊙

EI SYSTEM PARTS LOCATION

~~ ₩₩

① Speedometer

② Ignition coil, NO.1

③ Ignition coil, NO.2

④ Pick-up coil

⑤ GP switch

⑥ Fuel injector, NO.1

⑦ Fuel injector, NO.2

⑧ TP sensor

ECU

3

4

2

6

5

7

8

1

24

4-1-9 EI SYSTEM DIAGNOSIS

⑨ ISC solenoid

⑩ IAT sensor

⑪ RO switch

⑫ Fuel pump relay

⑬ IAP sensor, NO.2

⑭ IAP sensor, NO.1

⑮ ET sensor

⒃ Oxygen sensor

⒔ SAV solenoid

ECU

15

12

17

16

13

11

14

10

9

25

⊙⊙

EI SYSTEM PARTS LOCATION

~~ ₩₩

① Speedometer

② Fuel injector, NO.1

③ Fuel injector, NO.2

④ IAT sensor

⑤ GP switch

⑥ Pick-up coil

⑦ Ignition coil, NO.1

⑧ Ignition coil, NO.2

⑨ TP sensor

EI SYSTEM DIAGNOSIS 4-1-10

ECU

3

4

2

6

5

7

8

9

1

26

4-1-11 EI SYSTEM DIAGNOSIS

26

⑩ ISC solenoid

⑪ Fuel pump relay

⑫ RO switch

⑬ IAP sensor, NO.2

⑭ IAP sensor, NO.1

⑮ ET sensor

⒃ Oxygen sensor

⒔ SAV solenoid

10

17

11

12

16

13

14

15

ECU

27

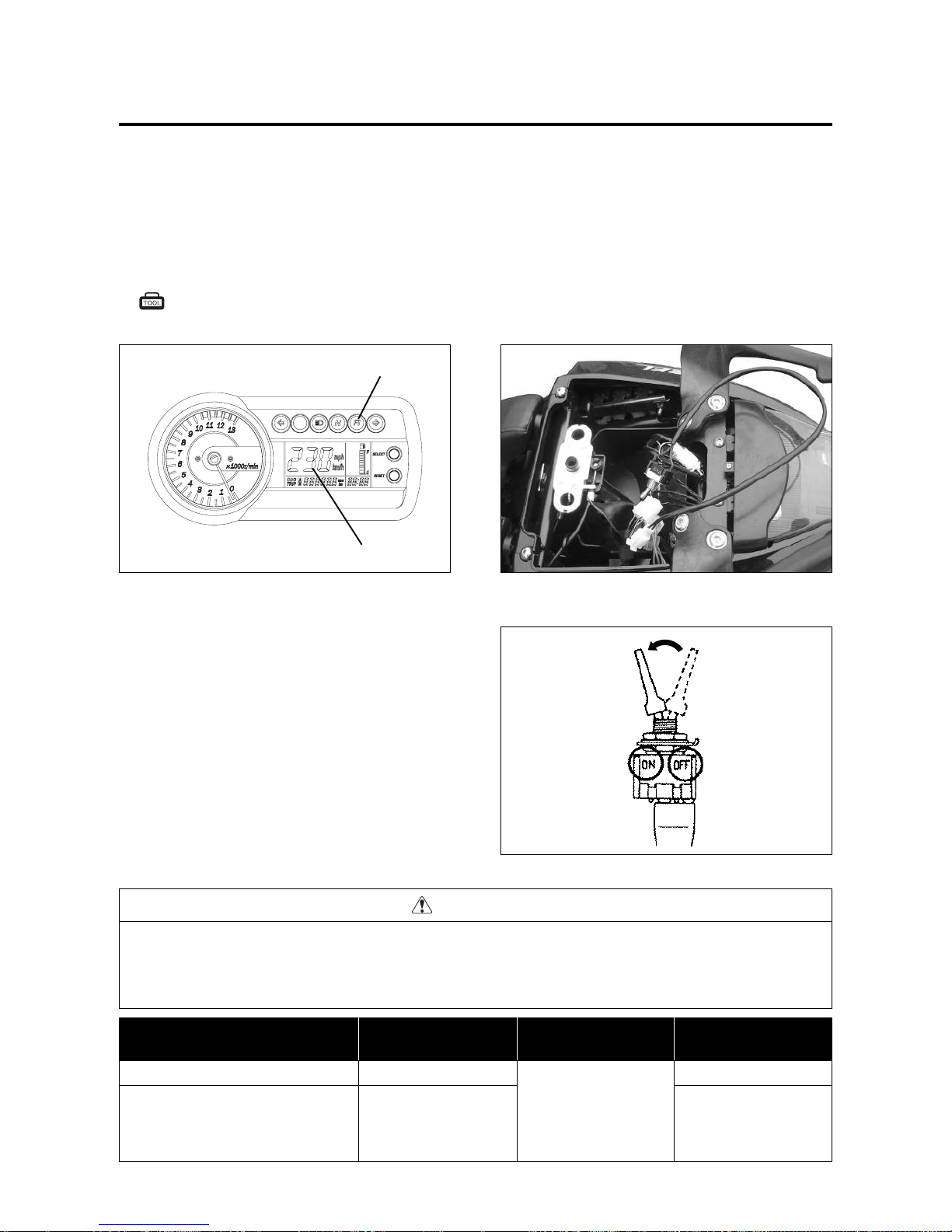

EI SYSTEM DIAGNOSIS 4-1-12

SELF-DIAGNOSIS FUNCTION

~~ ₩₩

The self-diagnosis function is incorporated in the ECU.

The function has two modes, “USER MODE” and “DEALER MODE”.

The user can only be notified by the LCD(DISPLAY) panel ① and the “FI” check lamp “ ” ②.

To check the function of the individual EI system devices, the dealer mode is prepared.

In this check, the special tool is necessary to read the code of the malfunction items.

A

When one of the signals is not received by ECU, the fail-safe circuit works and injection is not stopped.

In this case, “FI” letters and speedometer are indicated in the LCD panel ① and motorcycle can run.

B

The injection signal is stopped, when the pick-up coil signal, roll over switch signal, NO.1 & NO.2 ignition signals,

NO.1 & NO.2 injector signals, fuel pump relay signal or ignition switch signal is not sent to ECU.

In this case, “FI” letters is indicated in the LCD panel ①. Motorcycle does not run.

“CHE” : The LCD panel ① indicates “CHE” letters when no communication signal from the ECU is received for 3

seconds.

For example, The ignition switch is turned “ON” position, and the engine stop switch is turned “ ” position.

In this case, the speedometer does not receive any signal from ECU, and the LCD panel ① indicates “CHE”

letters.

If “CHE” letters is indicated, the LCD panel ① does not indicate the trouble code.

The possible cause of this indication is as follows, Engine stop switch is in “ ” position. Ignition fuse is burnt.

It is necessary to check the wiring harness between ECU and speedometer couplers.

⊙⊙

USER MODE

MALFUNCTION

“NO”

“YES”

“FI” check lamp

comes on.

Each 2 sec.

Speedometer or “FI”

letters is indicated.

Speedometer

--

Speedometer

and

“FI” letters

A

“FI” letters

B

Engine can start

Engine can not

start

“FI” check lamp comes

on and blinks.

“FI” letters is indicated

continuously.

LCD (DISPLAY)

INDICATION

①①

INDICATION

MODE

“FI”

CHECK LAMP

INDICATION

②②

①

②

The “FI” check lamp “ ” ② comes on for about three seconds whenever the ignition switch is set to “ON”

position with the engine stopped as a test of the injection system operation.

The check lamp must go off after three seconds.

28

4-1-13 EI SYSTEM DIAGNOSIS

CAUTION

Do not disconnect the ECU lead wire couplers, before checking the malfunction code, or the malfunction

code memory is erased and the malfunction code can not be checked.

Confirm the malfunction code after turn the ignition switch “ON” position or cranking the engine for few

seconds.

Mode select switch : 09900-27000

⊙⊙

DEALER MODE

The defective function is memorized in the ECU.

Use the special tool’s coupler to connect to the dealer mode coupler. (Refer to page 4-1-20)

The memorized malfunction code is displayed on LCD (DISPLAY) panel .

Malfunction means that the ECU does not receive signal from the devices.

These affected devices are indicated in the code form.

MALFUNCTION

“NO”

“YES”

“FI” check lamp

goes off.

For each 2 sec.,

code is indicated.

C

-

C**code is indicated

from small numeral to

large one.

LCD (DISPLAY)

INDICATION

INDICATION

MODE

“FI”

CHECK LAMP

INDICATION

29

EI SYSTEM DIAGNOSIS 4-1-14

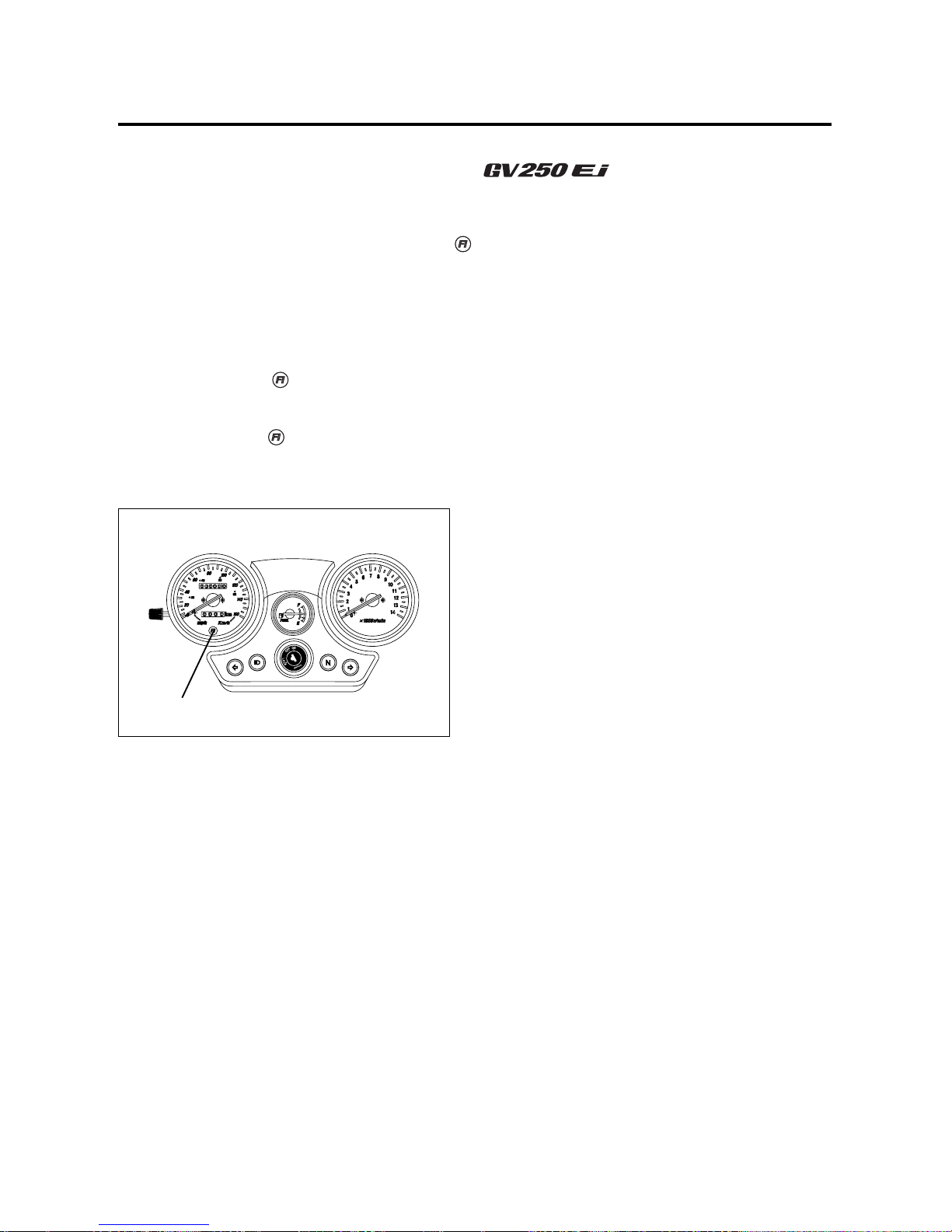

SELF-DIAGNOSIS FUNCTION

~~ ₩₩

The self-diagnosis function is incorporated in the ECU.

The function has two modes, “USER MODE” and “DEALER MODE”.

The user can only be notified by the “FI” check lamp “ ” ①.

To check the function of the individual EI system devices, the dealer mode is prepared.

In this check, the special tool is necessary to read the code of the malfunction items.

⊙⊙

USER MODE

The “FI” check lamp “ ” ① comes on for about three seconds whenever the ignition switch is set to “ON”

position with the engine stopped as a test of the injection system operation.

The check lamp must go off after three seconds.

If the “FI” check lamp “ ” ① comes on during normal engine operation, it means that the electric fuel injection

system is not operating correctly.

When this is the case, inspect the electric fuel injection system to refer to “Dealer mode”.

①

Loading...

Loading...