HYOSUNG 2010 ST7 Service Manual

Servicemanual

ST7

GV700C

2010 -

Holtvej 8-10, Høruphav

6470 Sydals

Telefon: +45 73 15 11 00

Fax: +45 73 15 11 01

E-mail: info@scanmi.dk

www.scanmi.dk

CVR: 27 73 31 07

COPYRIGHT S&T Motors Co., Ltd.

ELECTRICAL SYSTEM

COOLING SYSTEM

GROUP INDEX

GENERAL INFORMATION

1

PERIODIC MAINTENANCE

2

ENGINE

3

EI SYSTEM DIAGNOSIS

4

FUEL SYSTEM AND THROTTLE BODY

5

6

7

CHASSIS

8

SERVICING INFORMATION

9

FOREWORD

This manual contains an introductory description on

HYOSUNG and procedures for its inspection/service and overhaul of its main components.

Other information considered as generally known is

not included.

Read GENERAL INFORMATION section to familiarize yourself with outline of the vehicle and MAINTENANCE and other sections to use as a guide for

proper inspection and service.

This manual will help you know the vehicle better so

that you can assure your customers of your optimum

and quick service.

This manual has been prepared on the basis of

the latest specification at the time of publica-

tion.

If modification has been made since then,

difference may exist between the content of

this manual and the actual vehicle.

Illustrations in this manual are used to show

the basic principles of operation and work pro-

cedures.

They may not represent the actual vehicle

exactly in detail.

WARNING

This manual is intended for those who have

enough knowledge and skills for servicing

HYOSUNG vehicles. Without such knowledge and

skills, you should not attempt servicing by relying

on this manual only.

Instead, please contact your nearby authorized

HYOSUNG motorcycle dealer.

HOW TO USE THIS MANUAL

TO LOCATE WHAT YOU ARE

LOOKING FOR :

1. The text of this manual is divided into sections.

2. As the title of these sections is listed on the previous

page as GROUP INDEX, select the section where you are

looking for.

3. Holding the manual as shown at the right will allow you to

find the first page of the section easily.

4. On the first page of each section, its contents are listed.

Find the item and page you need.

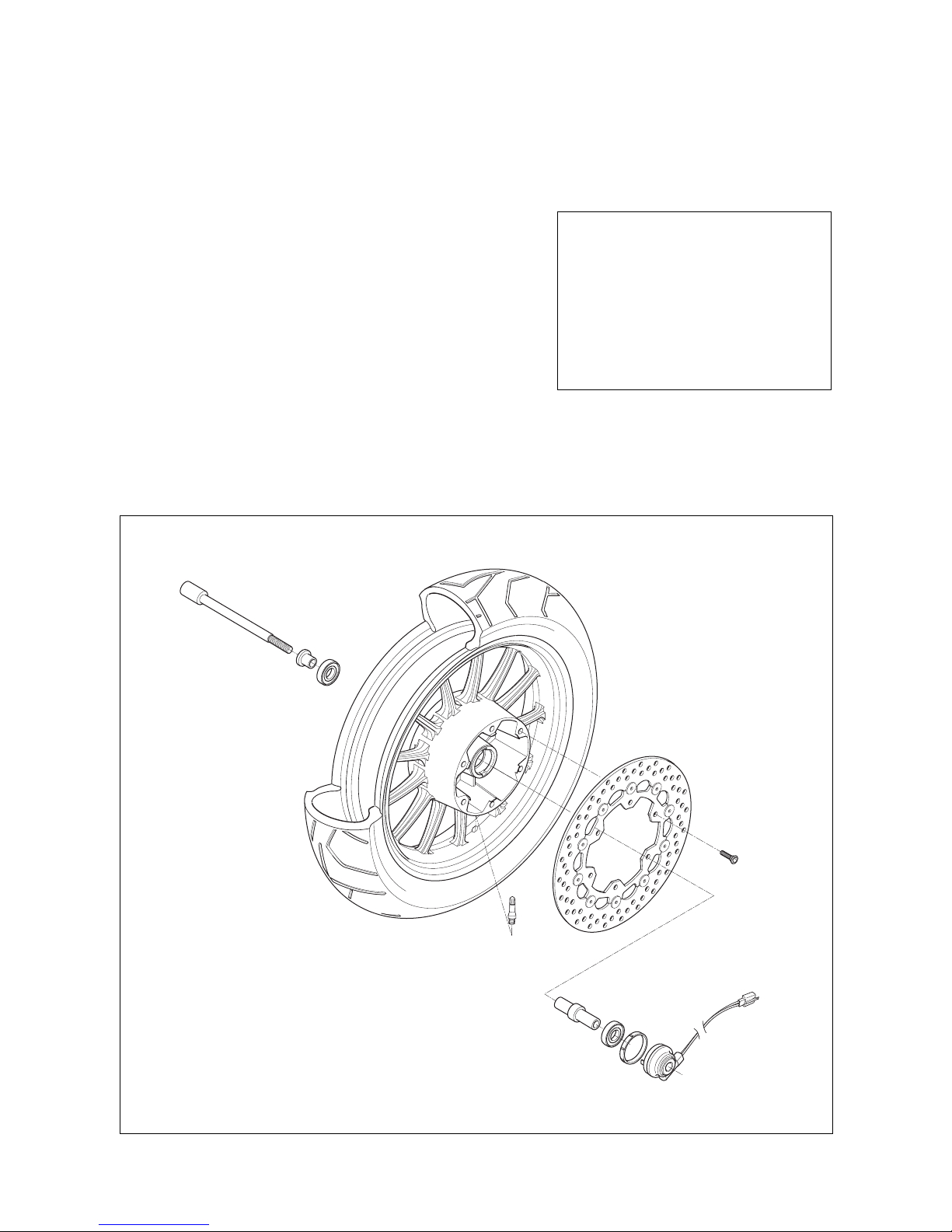

COMPONENT PARTS

Example : Front wheel

SYMBOL

Listed in the table below are the symbols indicating instructions and other information necessary for servicing.

The meaning of each symbol is also included in the table.

Apply THREAD LOCK 1324 .

Apply or use brake fluid.

Measure in voltage range.

Measure in resistance range.

Measure in current range.

Measure in diode test range.

Measure in continuity test range.

Use special tool.

Use engine coolant.

Torque control required.

Data beside it indicates specified torque.

Apply oil. Use engine oil unless otherwise

specified.

Apply SUPER GREASE

A .

Apply SILICONE GREASE.

Apply MOLY PASTE.

Apply BOND

1215 .

Use fork oil.

DEFINITIONSYMBOL DEFINITIONSYMBOL

Apply SUPER GREASE C .

NOTE

Difference between photographs and actual motorcycles depends on the markets.

A

ABDC : After Bottom Dead Center

AC : Alternating Current

API : American Petroleum Institute

ATDC : After Top Dead Center

B

BBDC : Before Bottom Dead Center

BDC : Bettom Dead Center

BTDC : Before Top Dead Center

D

DC : Direct Current

DOHC : Double Over Head Camshaft

E

ECU : Engine Control Unit,

EI Control Unit

EI : Electric fuel Injection,

Electric fuel Injector

F

FP : Fuel Pump

G

GP Switch : Gear Position Switch

I

IAP Sensor : Intake Air Pressure Sensor

(IAPS)

IAT Sensor : Intake Air Temperature Sensor

(IATS)

IG : Ignition

ISC Solenoid : Idle Speed Control Solenoid

L

LCD : Liquid Crystal Display

LED : Light Emitting Diode

LH : Left Hand

M

Max : Maximum

Min : Minimum

O

O2 Sensor : Oxygen Sensor (O2S)

P

PV : Purge control Valve

R

RH : Right Hand

RO Switch : Roll Over Switch

S

SAE :

Society of Automotive Engineers

SAV Solenoid : Secondary Air Valve Solenoid

T

TDC : Top Dead Center

TP Sensor : Throttle Position Sensor (TPS)

W

WT Sensor : Water Temperature Sensor

(WTS)

ABBREVIATIONS USED IN THIS MANUAL

BL : Black with Blue tracer BBr : Black with Brown tracer

BG : Black with Green tracer BO : Black with Orange tracer

BR : Black with Red tracer BW : Black with White tracer

BY : Black with Yellow tracer LB : Blue with Black tracer

LG : Blue with Green tracer LR : Blue with Red tracer

LW : Blue with White tracer LY : Blue with Yellow tracer

BrB : Brown with Black tracer BrW : Brown with White tracer

GB : Green with Black tracer GR : Green with Red tracer

GY : Green with Yellow tracer GrB : Gray with Black tracer

GrR : Gray with Red tracer GrW : Gray with White tracer

OB : Orange with Black tracer OL : Orange with Blue tracer

OG : Orange with Green tracer OR : Orange with Red tracer

OW : Orange with White tracer OY : Orange with Yellow tracer

RB : Red with Black tracer RW : Red with White tracer

WB : White with Black tracer WL : White with Blue tracer

WR : White with Red tracer YB : Yellow with Black tracer

YL : Yellow with Blue tracer YG : Yellow with Green tracer

YR : Yellow with Red tracer

B : Black Gr : Gray Sb : Light blue

L : Blue Lg : Light green W : White

Br : Brown O : Orange Y : Yellow

G : Green R : Red

WIRE COLOR

GENERAL INFORMATION

INFORMATION LABELS 1

-

1

GENERAL PRECAUTIONS 1

-

1

SERIAL NUMBER LOCATION 1

-

3

FUEL, OIL AND ENGINE COOLANT RECOMMENDATIONS

1- 4

BREAK-IN PROCEDURES 1

-

6

CYLINDER CLASSIFICATION 1

-

6

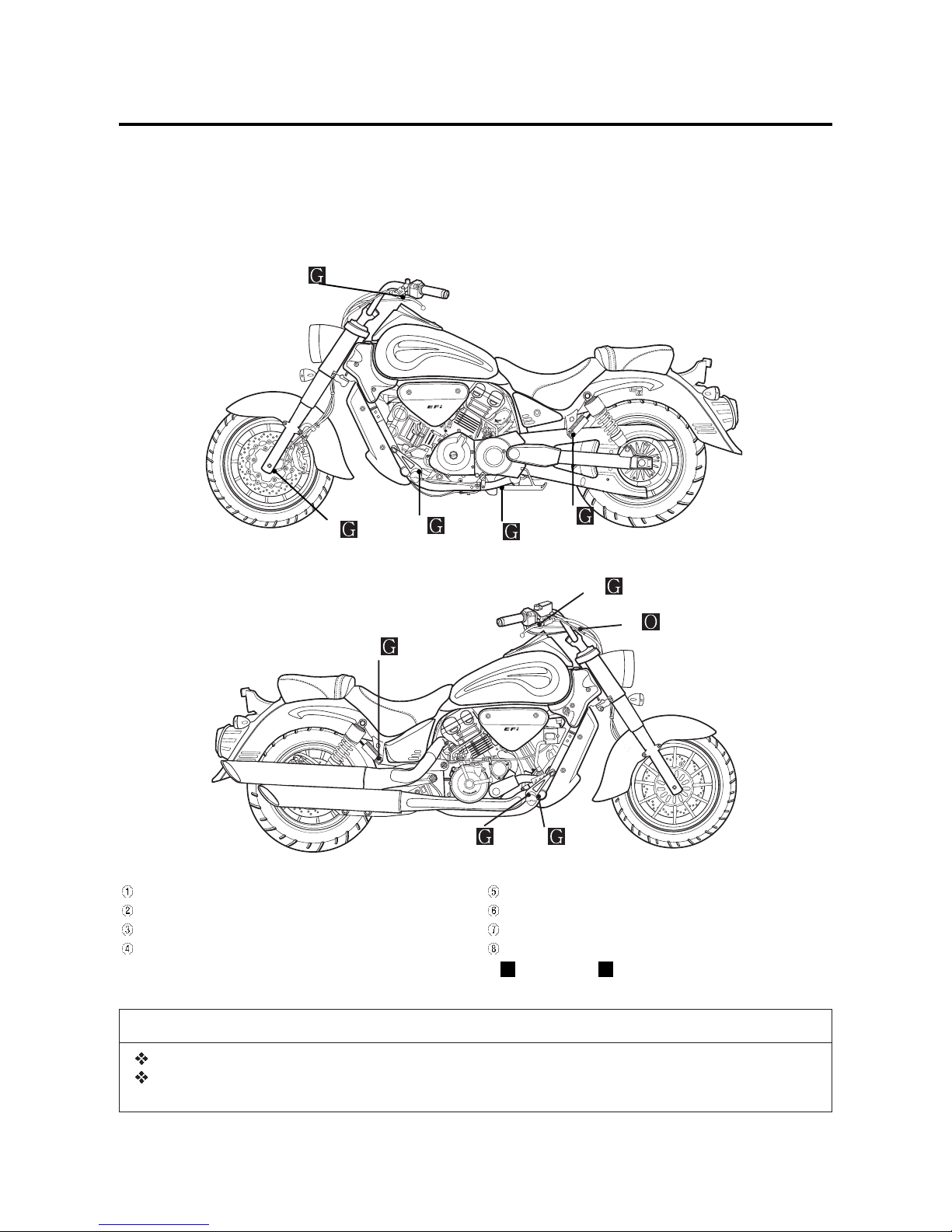

EXTERIOR ILLUSTRATION 1

-

7

SPECIFICATIONS 1

-

8

CONTENTS

1

1-1 GENERAL INFORMATION

Please note, however, that the warning and cautions contained in this manual cannot possibly cover all potential

hazards relating to the servicing, or lack of servicing, of the motorcycle. In addition to the WARNING and CAUTION

stated, you must use good judgement and basic mechanical safety principles. If you are unsure about how to perform a particular service operation, ask a more experienced mechanic for advice.

WARNING / CAUTION / NOTE

Please read this manual and follow its instructions carefully.

To emphasize special information, the symbol and the words WARNING, CAUTION and NOTE have special meanings. Pay special attention to the messages highlighted by these signal words.

CAUTION

Indicates a potential hazard that could result in vehicle damage.

WARNING

Indicates a potential hazard that could result in death or injury.

NOTE

Indicates special information to make maintenance easier or instructions cleaner.

GENERAL INFORMATION 1-2

GENERAL PRECAUTIONS

WARNING

Proper service and repair procedures are important for the safety of the service machanic and the safety

and reliability of the vehicle.

When 2 or more persons work together, pay attention to the safety of each other.

When it is necessary to run the engine indoors, make sure that exhaust gas is forced outdoors.

When working with toxic or flammable materials, make sure that the area you work in is well-ventilated and

that you follow all off the material manufacturer’s instructions.

Never use gasoline as a cleaning solvent.

To avoid getting burned, do not touch the engine, engine oil, exhaust system or radiator during or for a

while after engine operation.

After servicing fuel, oil, engine coolant, exhaust or brake systems, check all lines and fittings related to the

system for leaks.

WARNING

If parts replacement is necessary, replace the parts with HYOSUNG Genuine Parts or their equivalent.

When removing parts that are to be reused, keep them arranged in an orderly manner so that they may be

reinstalled in the proper order and orientation.

Be sure to use special tools when instructed.

Make sure that all parts used in reassembly are clean, and also lubricated when specified.

When use of a certain type of lubricant, bond, or sealant is specified, be sure to use the specified type.

When removing the battery, disconnect the battery lead wire first and then the battery lead wire.

When reconnecting the battery, connect the battery lead wire first and then the battery lead wire.

Finally, cover the battery terminal with the terminal cover.

When performing service to electrical parts, if the service procedures do not require use of battery power,

diconnect the battery lead wire at the battery.

Tighten cylinder head and case bolts and nuts, beginning with larger diameter and ending with smaller

diameter, from inside to outside diagonally, to the specified tightening torque.

Whenever you remove oil seals, gaskets, packing, O-rings, locking washers, cotter pins, circlips, and certain other parts as specified, be sure to replace them with new ones. Also, before installing these new

parts, be sure to remove any material left over from the mating surfaces.

Never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger than

required to slip the circlip over the shaft. After installing a circlip, always ensure that it is completely seated in its groove and securely fitted.

Do not use self-locking nuts a few times over.

Use a torque wrench to tighten fasteners to the torque values when specified. Wipe off grease or oil if a

thread is smeared with them.

After reassembly, check parts for tightness and operation.

WARNING

To protect environment, do not unlawfully dispose of used engine oil and other fluids: batteries, and tires.

To protect Earth’s natural resouces, properly dispose of used vehicles and parts.

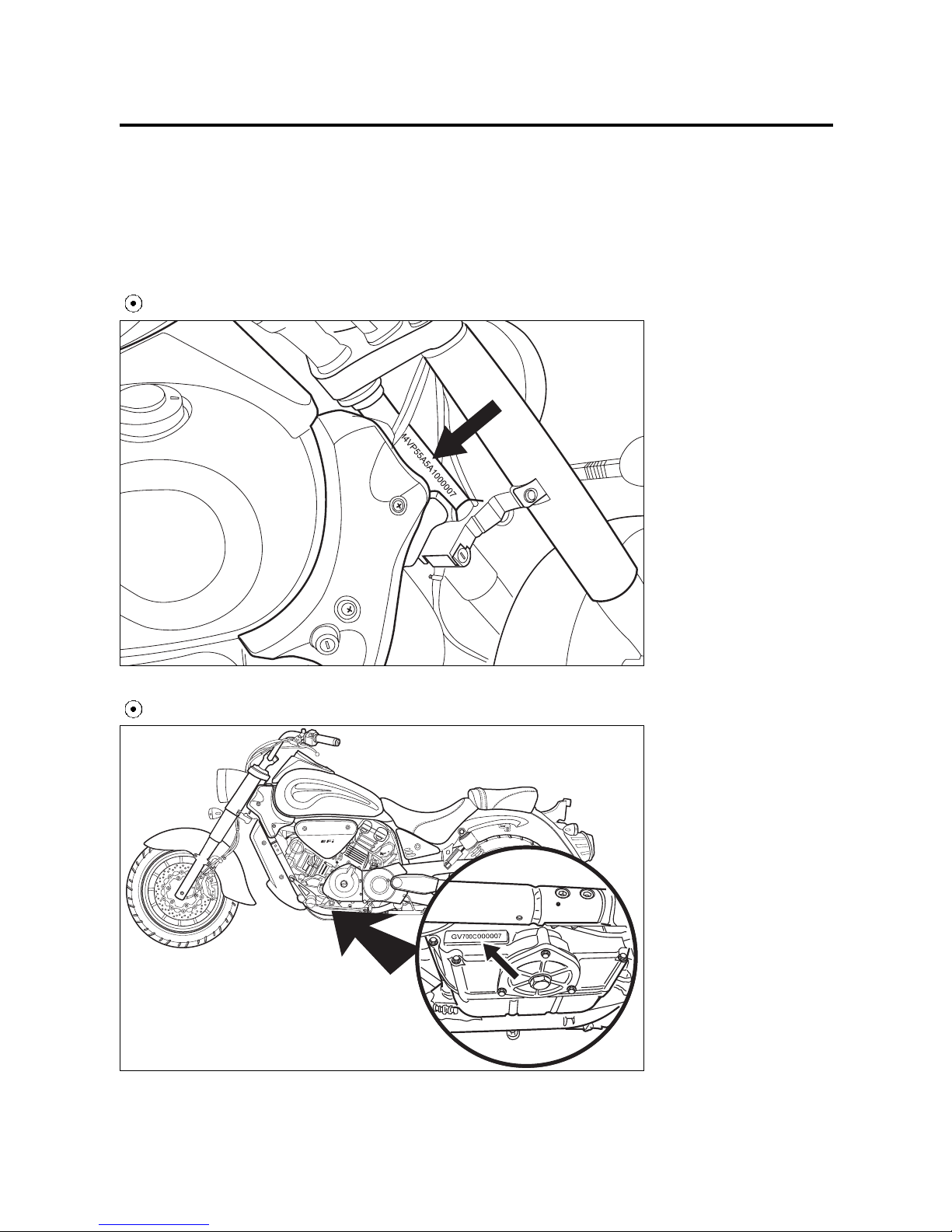

FRAME SERIAL NUMBER

ENGINE SERIAL NUMBER

1-3 GENERAL INFORMATION

SERIAL NUMBER LOCATION

The frame serial number or V.I.N. (Vehicle Identification Number) is stamped on the right side of the steering head tube.

The engine serial number is stamped on the left downside of the crankcase assembly.

These numbers are required especially for registering the machine and ordering spare parts.

BRAKE FLUID

Specification and classification : DOT4

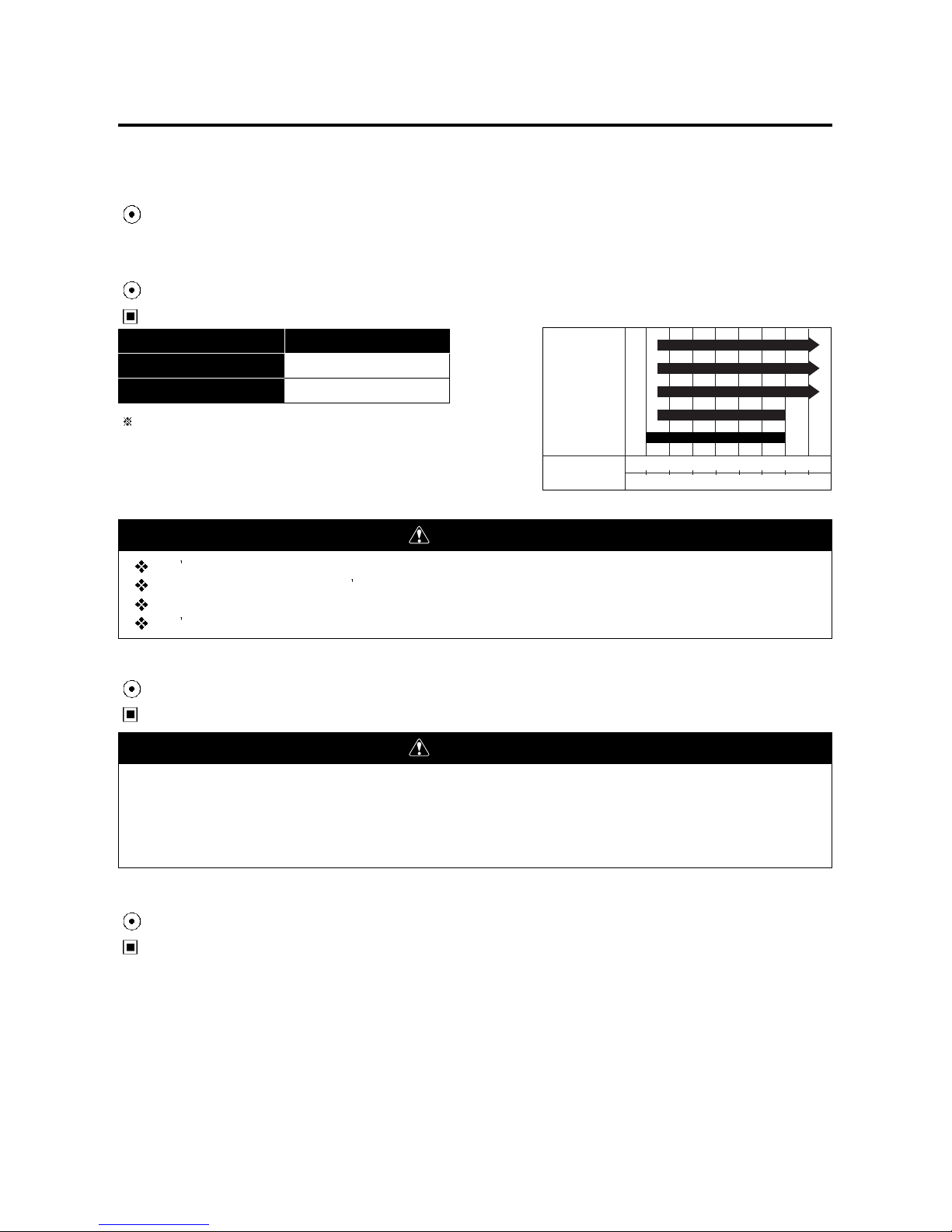

If an SAE 10W/40 motor oil is not available, select an

alternative according to the following chart.

Use a premium quality 4-stroke motor oil to ensure

longer service life of your motorcycle.

FUEL, OIL AND ENGINE COOLANT RECOMMENDATIONS

FUEL

Gasoline used should be graded 91 octane (Research Method) or higher. An unleaded gasoline type is

recommended.

ENGINE OIL

ENGINE OIL SPECIFICATION

GENERAL INFORMATION 1-4

Classification system

API

SAE

Grade

Over SL

10W/40

ENGINE OIL

Temperature

℃

℉

-30

-22

-20-4-101403210502068308640

104

20W50

15W40 15W50

10W40 10W50

10W30

5W30

FRONT FORK OIL

Use fork oil : TELLUS #32

WARNING

Don t mix the unrecommended oil. It could damage the engine.

When refilling the oil tank, don t allow the dust to get inside.

Wipe the spilled oil up immediately.

Don t put the patch on the cap. It could disturb the oil to be provided and damage the engine.

WARNING

Since the brake system of this motorcycle is filled with a glycol-based brake fluid by the manufacturer, do

not use or mix different types of fluid such as silicone-based and petroleum-based fluid for refilling the

system, otherwise serious damage will result.

Do not use any brake fluid taken from old or used or unsealed containers.

Never re-use brake fluid left over from a previous servicing, which has been stored for a long period.

1-5 GENERAL INFORMATION

ENGINE COOLANT

Use an anti-freeze/engine coolant compatible with an aluminum radiator, mixed with distilled water only.

WATER FOR MIXING

Use distilled water only. Water other than distilled water can corrode and clog the aluminum radiator.

ANTI-FREEZE/ENGINE COOLANT

The engine coolant perform as a corrosion and rust inhibitor as well as anti-freeze. Therefore, the engine coolant

should be used at all times even though the atmospheric temperature in your area does not go down to freezing point.

Hyosung recommends the use of HYOSUNG COOLANT anti-freeze/engine coolant. If this is not available, use an

equivalent which is compatible with an aluminum radiator.

LIQUID AMOUNT OF WATER/ENGINE COOLANT

For engine coolant mixture information, refer to cooling system section, page 6-1

CAUTION

Mixture of anti-freeze/engine coolant should be limited to 60%. Mixing beyond it would reduce its efficiency.

If the anti-freeze/engine coolant mixing ratio is below 50%, rust inhabiting performance is greatly reduced.

Be sure to mix it above 50% even though the atmospheric temperature does not go down to the freezing

point.

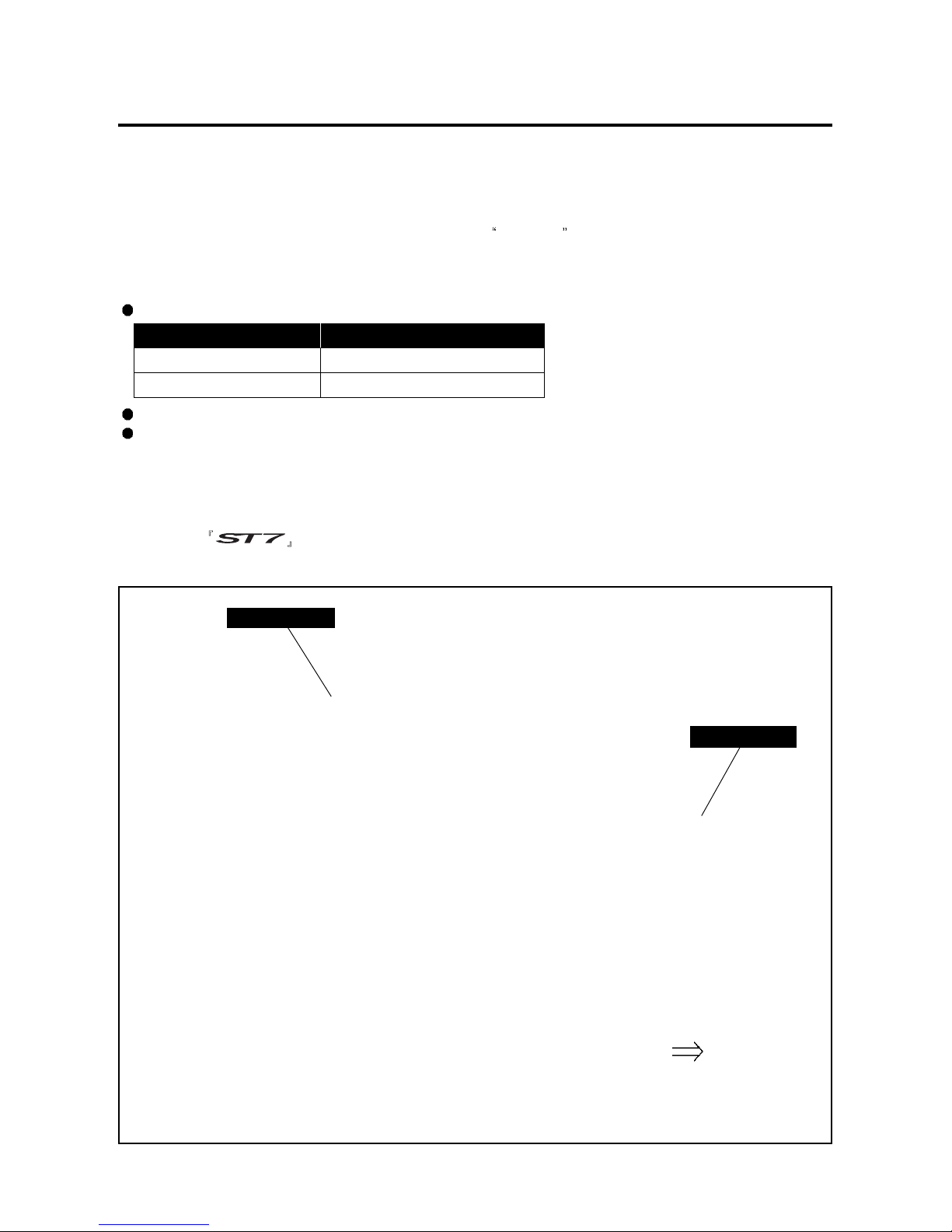

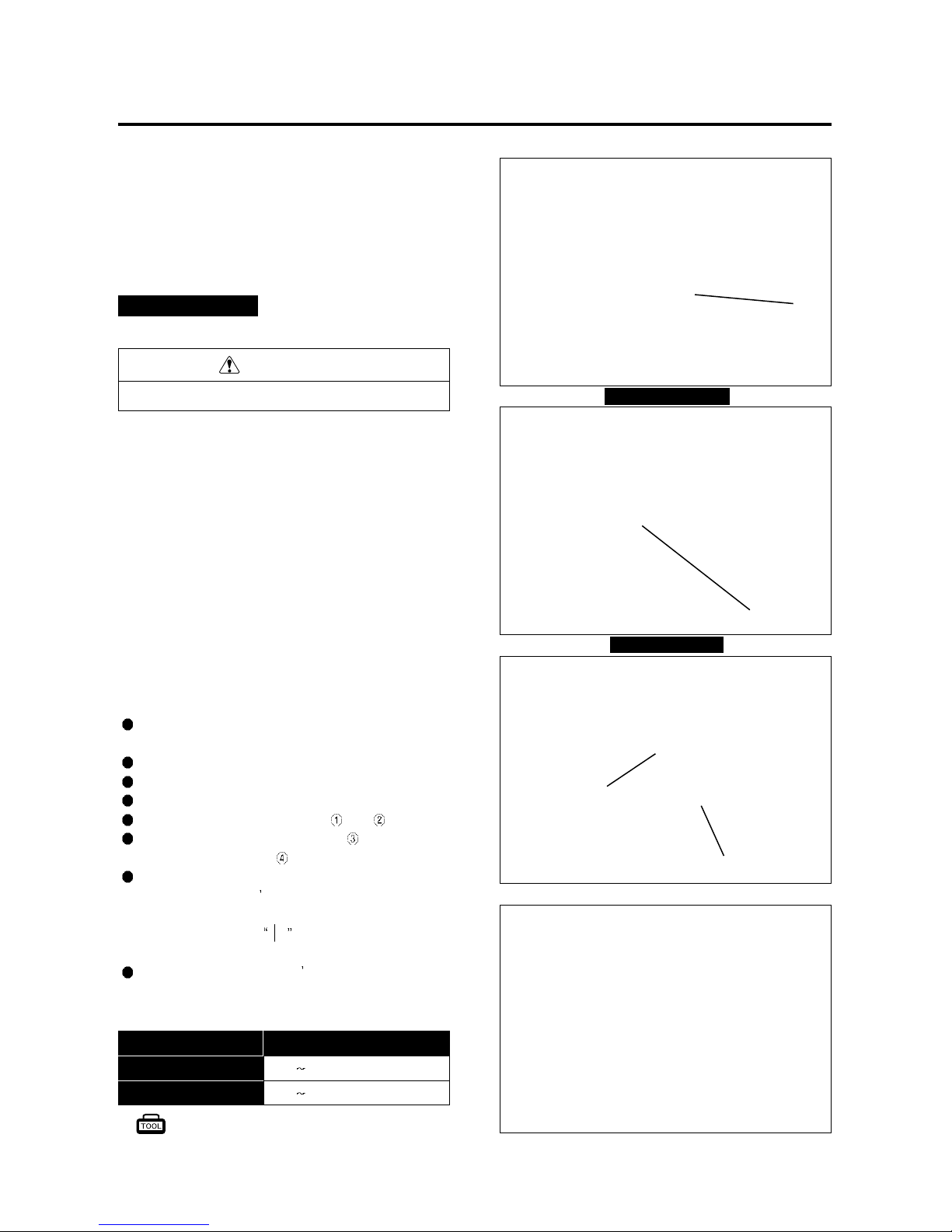

CYLINDER CLASSIFICATION

The engine of is composed of the two cylinder, is classified into the front cylinder and rear cylinder

as basis of the motorcycle ahead.

Upon reaching an odometer reading of 1,600 km (1,000 miles) you can subject the motorcycle to full throttle operation.

Do not maintain constant engine speed for an extended period during any portion of the break-in.

Try to vary the throttle position.

BREAK-IN PROCEDURES

During manufacture only the best possible materials are used and all machined parts are finished to a very high

standard but it is still necessary to allow the moving parts to BREAK-IN before subjecting the engine to maximum

stresses.

The future performance and reliability of the engine depends on the care and restraint exercised during its early life.

The general rules are as follows :

Keep to these break-in procedures :

FRONT

GENERAL INFORMATION 1-6

Interval Maximum throttle opening

Less than 1/2 throttle

Initial 800 km (500 miles)

Less than 3/4 throttle

Up to 1,600 km (1,000 miles)

Rear cylinder

Front cylinder

1-7 GENERAL INFORMATION

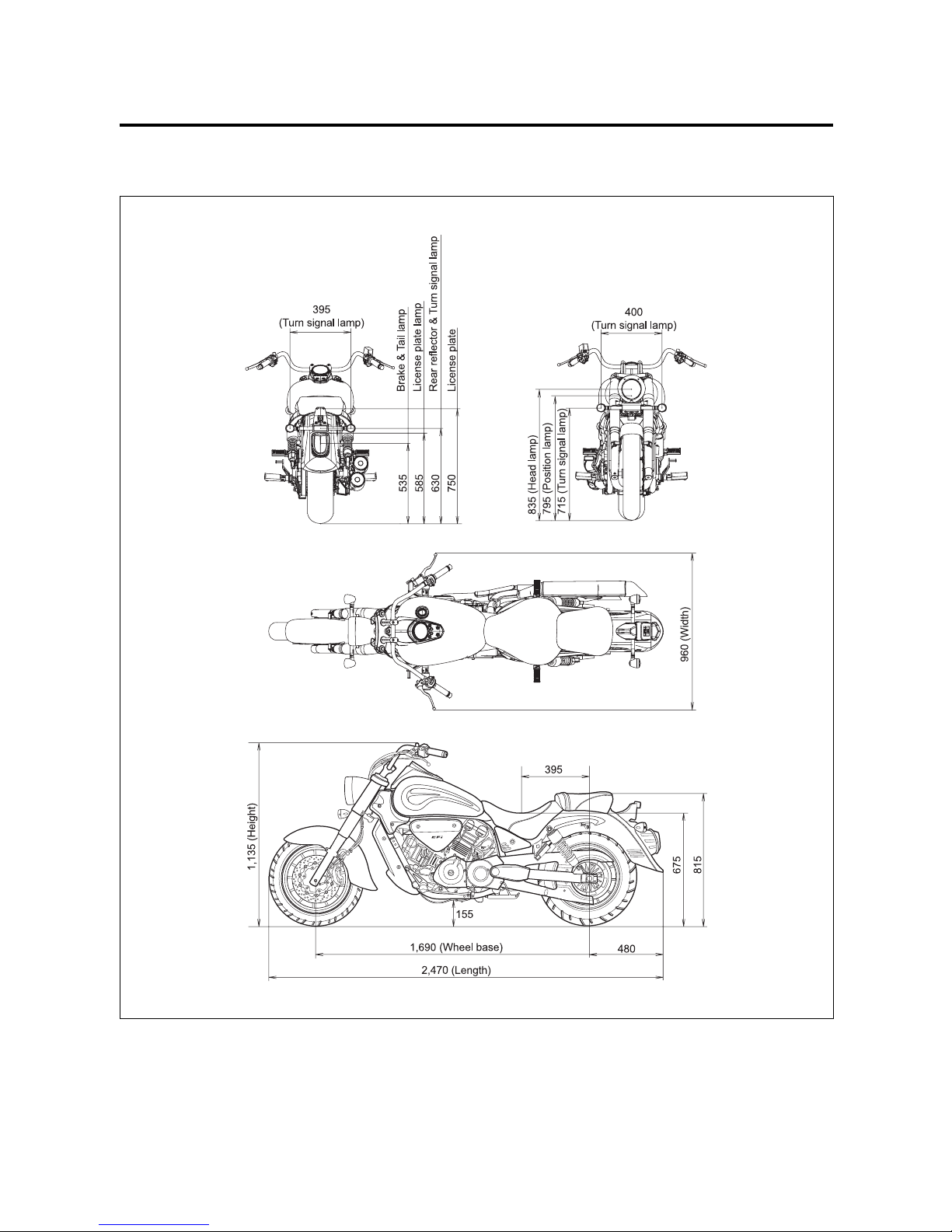

EXTERIOR ILLUSTRATION

Unit : mm

2,470 mm (97.2 in)

960 mm (37.8 in)

1,135 mm (44.7 in)

1,690 mm (66.5 in)

155 mm (6.1 in)

244 kg (538 lbs)

Overall length

Overall width

Overall height

Wheelbase

Ground clearance

Mass of vehicle in running order

ITEM

ITEM

ITEM

Four-stroke, DOHC, Liquid-cooled

V-2 cylinder

81.5 mm (3.21 in)

65.0 mm (2.56 in)

678.2 (41.4 in3)

Electric fuel injection

Electric starter

Wet sump

Type

Number of cylinder

Bore

Stroke

Piston displacement

Fuel system

Starter system

Lubrication system

Wet multi-plate type

5-speed constant mesh

1-down, 4-up

2.69

2.46

1.78

1.38

1.13

0.96

Poly chain belt

Gear ratio

Clutch

Transmission

Gearshift pattern

Final reduction

Drive belt

1st

2nd

3rd

4th

5th

GENERAL INFORMATION 1-8

SPECIFICATIONS

DIMENSIONS AND DRY MASS

ENGINE

TRANSMISSION

Telescopic type

Swingarm type

38 (right & left)

33

142 mm (5.6 in)

Disk brake

Disk brake

120/80 - 16 60H

170/80 - 15 77H

130 mm (5.12 in)

Front suspension

Rear suspension

Steering angle

Caster

Trail

Front brake

Rear brake

Front tire size

Rear tire size

Front fork stroke

ITEM

ITEM

ITEM

ECU

BTDC 5 / 1,600 rpm and BTDC 35 / 7,000 rpm

CR8E

12V 12Ah (MF)

Main : 30 A

ECU : 15 A

12 V - H4 : 60/55 W 1

12 V - W5 W 1

12 V - RY10 W 4

LED type

12 V - W5 W 1

Ignition type

Ignition timing

Spark plug

Battery

Head lamp

Position lamp

Turn signal lamp

Brake / Tail lamp

License plate lamp

LED : Light Emitting Diode

Fuel tank

Front fork oil capacity (One side)

Engine oil capacity

17.0

3,000

3,200

3,400

370 4 cc

1-9 GENERAL INFORMATION

CHASSIS

ELECTRICAL

CAPACITIES

Fuse

NOTE

The specifications are subject to change without notice.

Oil change

Oil and filter change

Engine overhaul

PERIODIC MAINTENANCE SCHEDULE 2

-

1

PERIODIC MAINTENANCE CHART 2-1

LUBRICATION POINTS 2-2

MAINTENANCE PROCEDURES 2

-

3

VALVE CLEARANCE 2-3

SPARK PLUG 2-5

EXHAUST PIPE BOLTS AND MUFFLER MOUNTING BOLTS 2-7

AIR CLEANER 2-7

ENGINE IDLE SPEED 2-9

THROTTLE CABLE PLAY 2-9

FUEL HOSE 2-10

CLUTCH 2-10

ENGINE OIL 2-12

ENGINE OIL FILTER 2-14

DRIVE BELT 2-15

BRAKE SYSTEM 2-17

STEERING 2-22

FRONT FORK

2-22

REAR SUSPENSION

2-22

TIRE 2-23

CHASSIS BOLTS AND NUTS

2-23

ENGINE COOLANT

2-24

RADIATOR HOSE

2-26

COMPRESSION PRESSURE 2-27

OIL PRESSURE

2-28

CONTENTS

2

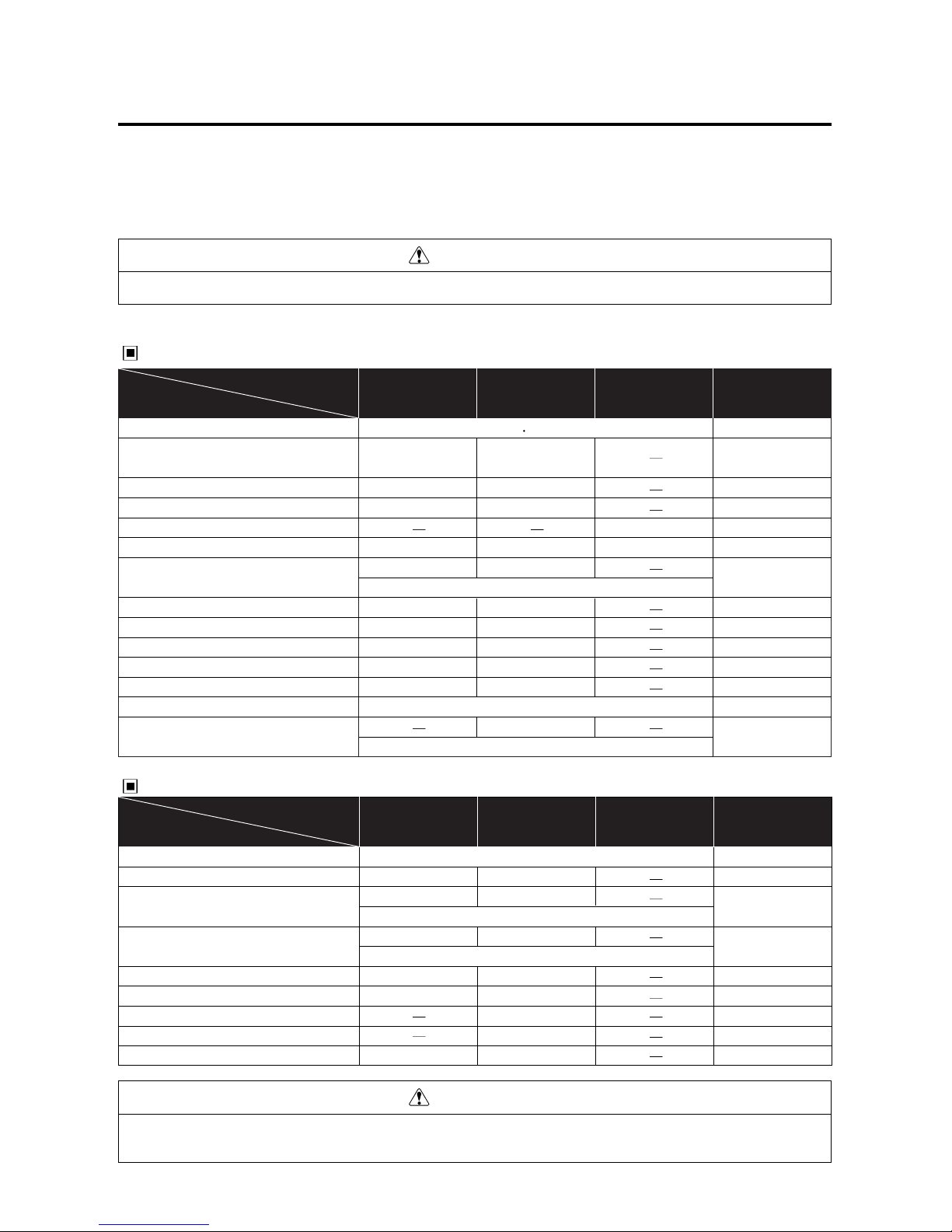

PERIODIC MAINTENANCE

2-1 PERIODIC MAINTENANCE

Item

Initial 1,000 km Every 6,000 km

Every 12,000 km

page

Interval

Air cleaner element

Exhaust pipe bolts and

muffler mounting bolts

Valve clearance adjust

Cylinder head bolt

Cylinder head & Cylinder

Spark plug

Fuel hose

Engine oil filter

Engine oil

Throttle cable

Idle speed

Clutch

Engine coolant

Radiator hoses

Tighten

Inspect

Tighten

Clean

Inspect

Replace

Replace

Inspect

Inspect

Inspect

Remove carbon

Replace

Replace every 4 years

Replace every 2 years

Replace every 4 years

Item

Initial 1,000 km Every 6,000 km

Every 12,000 km

page

Interval

Drive belt

Brake

Brake hoses

Brake fluid

Tires

Steering

Front forks

Rear suspension

Chassis bolts and nuts

Inspect

Inspect

Inspect

Inspect

Inspect

Tighten

Inspect

Inspect

Inspect

Inspect

Inspect

Inspect

Inspect

Tighten

Inspect every 1,000km

Replace every 4 years

Replace every 2 years

CHASSIS

2-15

2-17

2-17

2-17

2-23

2-22

2-22

2-22

2-23

PERIODIC MAINTENANCE SCHEDULE

The chart below lists the recommended intervals for all the required periodic service work necessary to keep the

motorcycle operating at peak performance and economy.

Tighten

Inspect

Tighten

Clean

Inspect

Replace

Replace

Inspect

Inspect

Inspect

Inspect

Clean every 3,000 km Replace every 12,000 km

PERIODIC MAINTENANCE CHART

ENGINE

2-7

2-7

2-3

3-52

3-23

2-5

2-10

2-14

2-12

2-9

2-9

2-10

2-24

2-26

CAUTION

More frequent servicing should be performed on motorcycles that are used under severe conditions.

CAUTION

Using poor quality replacement parts can cause your motorcycle to wear more quickly and shorten its useful life.

Use only genuine Hyoung replacement parts or their equivalent.

PERIODIC MAINTENANCE 2-2

LUBRICATION POINTS

Proper lubrication is important for smooth operation and long life of each working part of the motorcycle.

Major lubrication points are indicated below.

Clutch lever holder and clutch cable

Passenger footrests pivot

Side stand pivot and spring hook

Footrests pivot

Speedo sensor

Front brake lever holder

Throttle cable

Rear brake pedal pivot

O - Motor oil, G - Grease

❶

❺

❷

❸

❹

❷

❻

❼

❽

❹

NOTE

Before lubricating each part, clean off any rusty spots and wipe off any grease, oil, dirt or grime.

Lubricate exposed parts which are subject to rust, with either engine oil or grease whenever the

motorcycle has been operated under wet or rainy condition.

2-3 PERIODIC MAINTENANCE

MAINTENANCE PROCEDURES

This section describes the service procedures for

each item mentioned in the Periodic Maintenance chart.

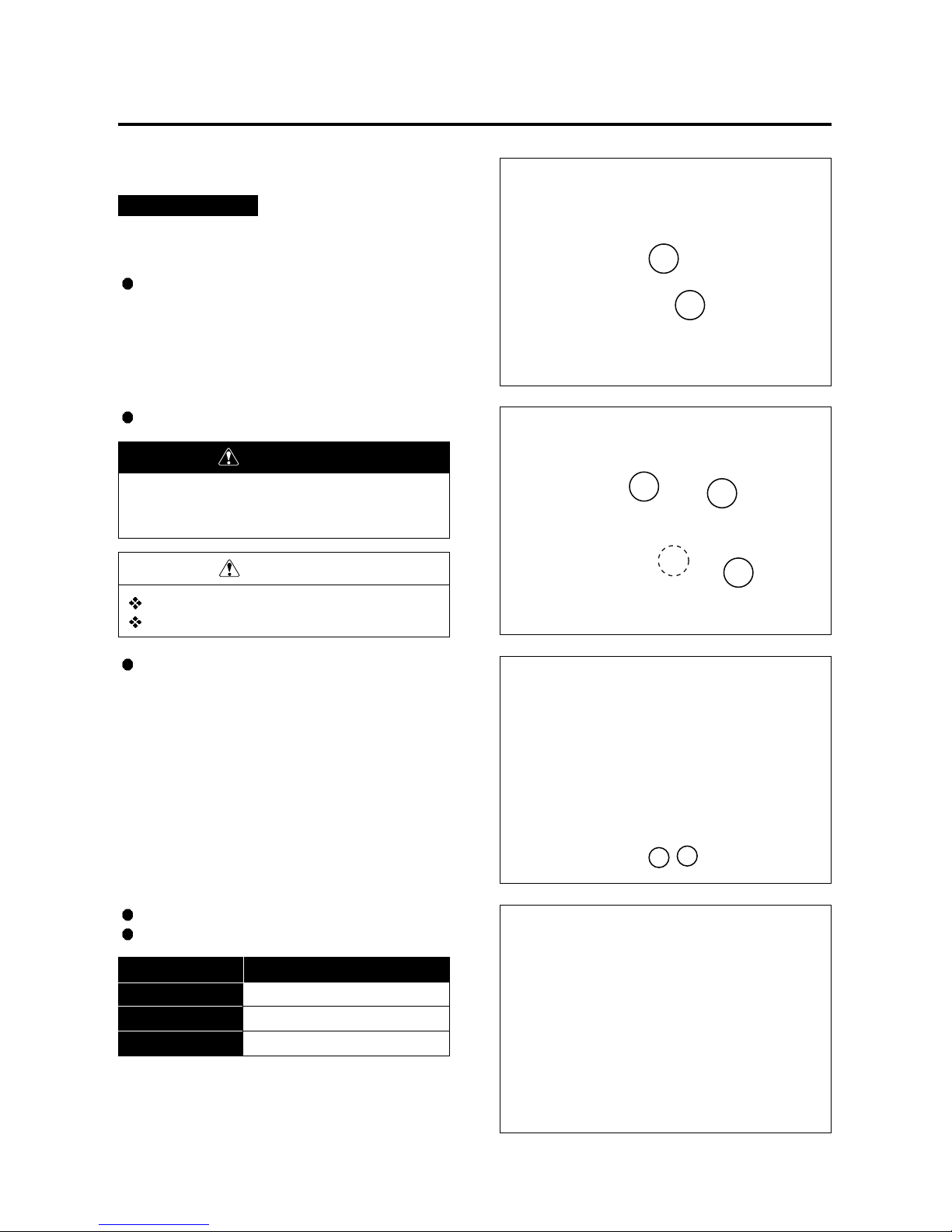

VALVE CLEARANCE

Excessive valve clearance results in valve noise and

insufficient valve clearance results in valve damage and

reduce power.

Check the intake and exhaust valve clearances at the

distances indicated above and adjust the valve clearances to specification, if necessary.

The valve clearance specification is different for

intake and exhaust valves.

Valve clearance adjustment must be checked and

adjusted :

1) at the time of periodic inspection,

2) when the valve mechanism is serviced, and

3) when the camshafts are removed.

Remove the radiator cover and radiator.

(Refer to page 2-5)

Remove the right air cleaner box.

Remove the seat and fuel tank. (Refer to page 5-2)

Remove the spark plugs. (Refer to page 2-5)

Remove the cylinder head cover and .

Remove the magneto cover plug and the valve

timing inspection plug

.

Rotate the magneto rotor counter-clockwise to set

the front cylinder

s piston at TDC (Top Dead

Center) of the compression stroke.

(Rotate the rotor until

F line on the rotor is aligned

with the center of hole on the crankcase.)

To inspect the front cylinder s valve clearance, insert

the thickness gauge to the clearance between the

camshaft and the tappet.

0.1 0.2 mm (0.004 ~ 0.008 in)

0.28

0.32 mm (0.011 ~ 0.013 in)

IN.

EX.

Standard (When cold)

Valve clearance

Inspect Interval

Inspect Initial 1,000 km and Every 6,000 km thereafter.

CAUTION

The clearance specification is for COLD state.

FRONT CYLINDER

REAR CYLINDER

Thickness gauge : 09900-20806

①

②

③

④

PERIODIC MAINTENANCE 2-4

If the clearance is out of specification, first remove the

cam chain tensioner, camshaft housing, camshaft.

To install the tappet shim at original position, record

the shim NO. and clearance to present by A , B ,

C , D mark on the cylinder head.

Select the tappet that agree with tappet clearance

(vertical line) and shim NO.(horizontal line) as refer to the

tappet shim selection chart. (Refer to page 9-39 40)

Adjust valve timing, install the camshaft housing and

the tension adjuster.

After the crankshaft rotate about 10 times, measure

the valve clearance.

If the clearance be not correct, adjust the standard

clearance as the same manner above.

In case of valve adjustment which is not the tappet

shim selection chart, please follow instructions of

example in the below.

For example, the intake clearance is 0.4 and the shim

is 170 (1.70 mm), select 195 (1.95 mm) of the shim

which 170 (1.70 mm) of the shim add up the excess

clearance 0.25 mm when adjust with the standard

0.15 as the intake standard clearance 0.1 0.2 mm.

Rotate the magneto rotor to set the rear cylinder s

piston at TDC(Top Dead Center) of the compression

stroke.

(Rotate the rotor 285 counter-clockwise from the

F line, and until the R line on the rotor is

aligned with the center of hole on the crankcase.)

Inspect the rear cylinder s valve clearance with the

same manner of the front cylinder.

CAUTION

Valve clearance should be checked when the

engine is cold.

If you don t rotate the crankshaft about 10

times before measuring the valve clearance,

there is no meaning of valve clearance.

A B

C D

2-5 PERIODIC MAINTENANCE

TYPE SPARK PLUG SPECIFICATION

CR7E

CR8E

CR9E

Hot type

Standard type

Cold type

Remove the four radiator mounting bolts.

Remove the four radiator cover mounting bolts.

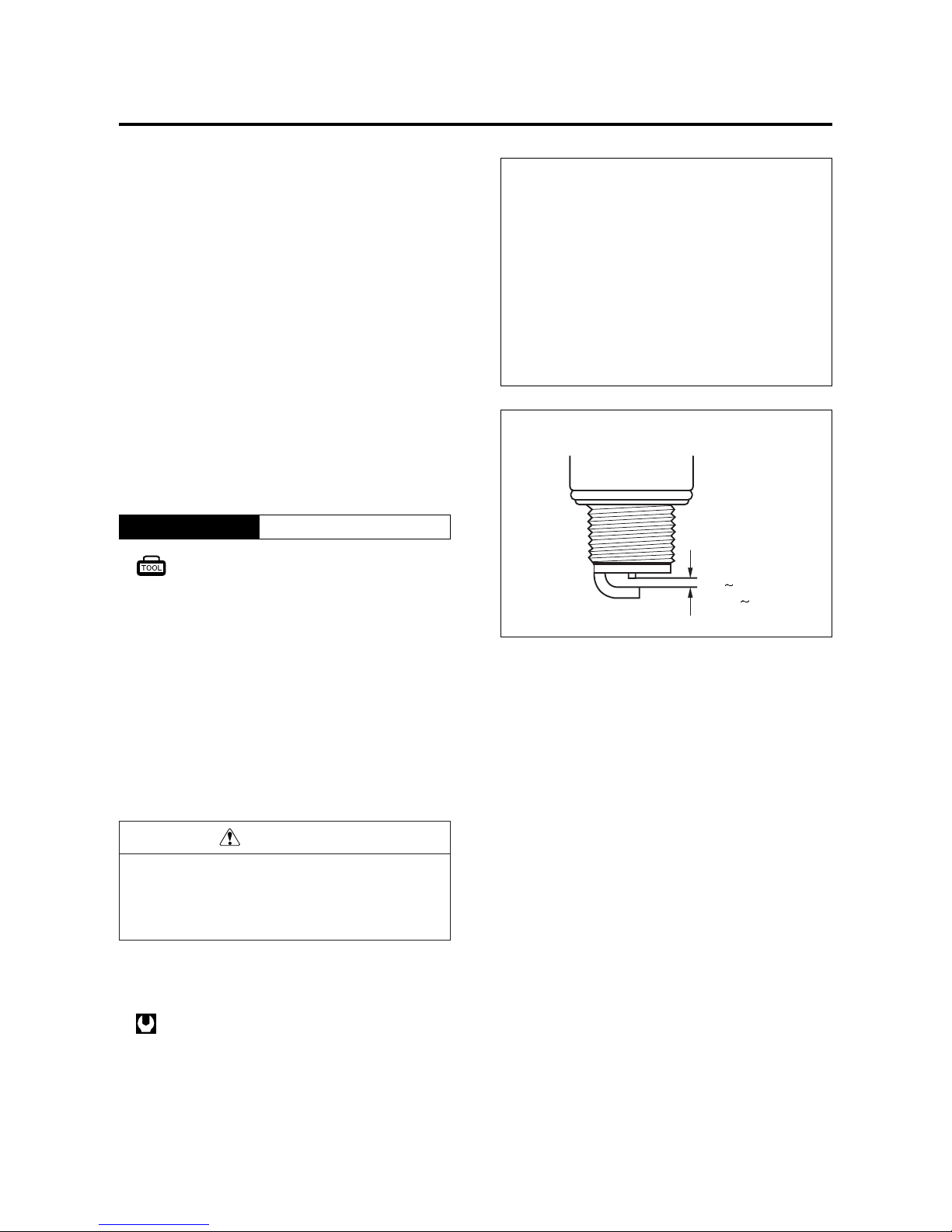

SPARK PLUG

Inspect Interval

Clean Initial 1,000 km and Every 6,000 km thereafter.

Replace Every 12,000 km.

Disconnect the spark plug caps.

Remove the spark plugs.

Remove the front seat and fuel tank.

(Refer to page 5-2)

CAUTION

Be careful not to damage the radiator fins.

Do not extract the radiator hose.

WARNING

The hot radiator and the hot engine can burn you.

Wait until the radiator and the engine are cool

enough to touch.

PERIODIC MAINTENANCE 2-6

0.7 0.8 mm

(0.028 0.032 in)

0.7 ∼ 0.8 mm (0.028 ~ 0.032 in)

Spark plug gap

▣▣

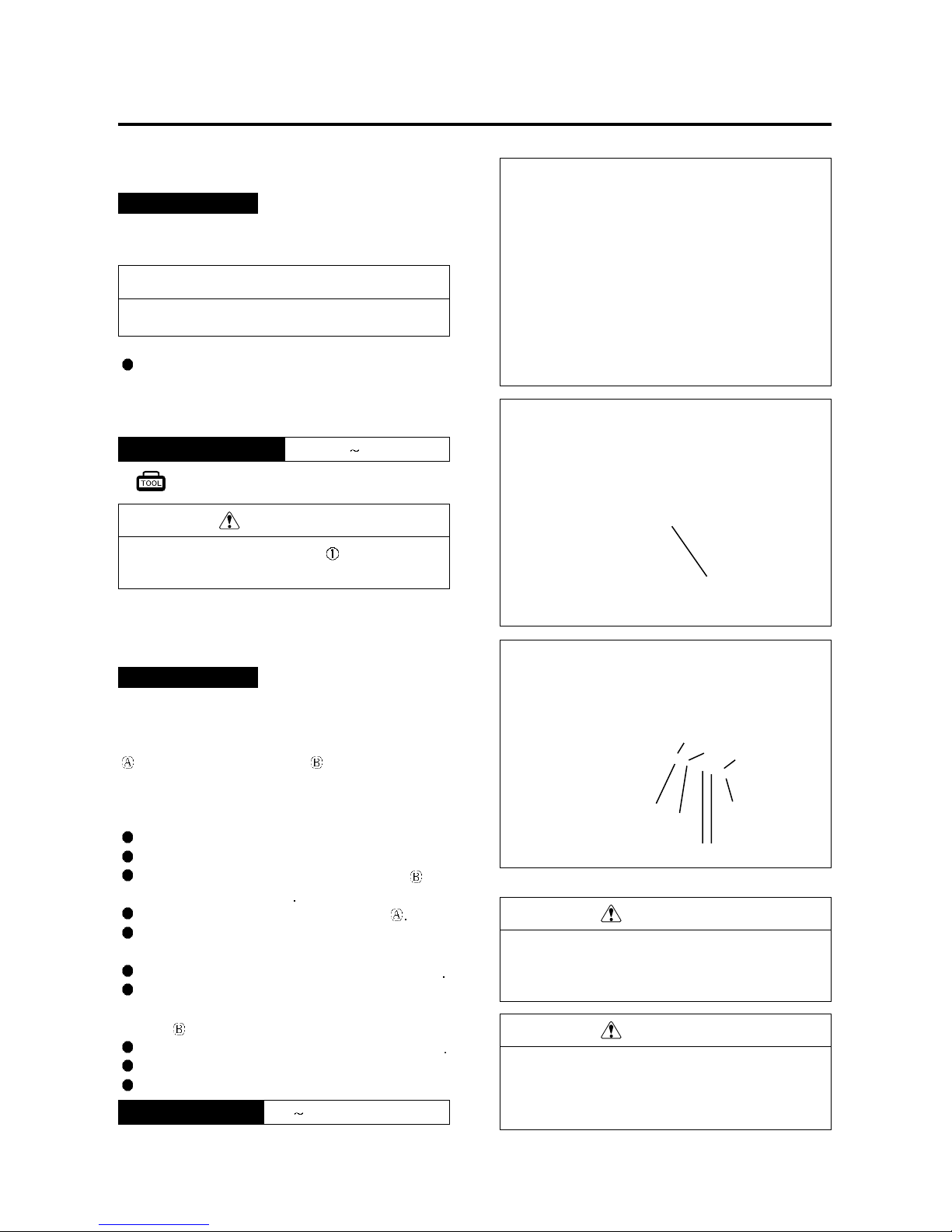

CARBON DEPOSITS

Check to see if there are carbon deposits on the

spark plug.

If carbon is deposited, remove it using a wire or pin

with a pointed end.

▣▣

SPARK PLUG GAP

Measure the spark plug gap using a thickness

gauge.

If the spark plug gap is out of specification, adjust the

gap.

▣▣

ELECTRODE

Check to see the worn or burnt condition of the electrodes.

If it is extremly worn or burnt, replace the spark plug

with a new one.

And also replace the spark plug if it has a broken

insulator, damaged thread, etc.

● Insert the spark plug and finger tighten it to the

cylinder head and then tighten it to the specified

torque.

Spark plug : 11 N··m (1.1 kgf··m)

Thickness gauge : 09900-20806

CAUTION

To avoid damaging the cylinder head threads ;

first, finger tighten the spark plug, and then tighten it to the specified torque using the spark plug

wrench.

2-7 PERIODIC MAINTENANCE

EXHAUST PIPE BOLTS AND

MUFFLER MOUNTING BOLTS

Tighten the exhaust pipe bolts ①, and muffler

mounting bolts ②to the specified torque.

Inspect Interval

Tighten Initial 1,000 km and Every 6,000 km thereafter.

Rear Cylinder

Front Cylinder

①

①

AIR CLEANER

If the air cleaner is clogged with dust, intake resistance will be increased, with a resultant decrease in

power output and an increase in fuel consumption.

Check and clean the air cleaner element in the following manner :

● Remove the air cleaner cover ④ by loosening the

two air cleaner cover screws ③.

● Loosen the four air cleaner element screws ⑤.

● Remove the air cleaner element .

Inspect Interval

Clean Every 3,000 km,

Replace Every 12,000 km.

Exhaust pipe bolt

: 18 ~ 28 N

m (1.8 ~ 2.8 kgf m)

Muffler mounting bolt

: 20 ~ 25 N

m (2.0 ~ 2.5 kgf m)

②

③

④

❺

❺

PERIODIC MAINTENANCE 2-8

Clean the air cleaner element for the following :

When the air cleaner element clean with the air gun,

necessarily blow at the inside by compressed air.

Carefully examine the air cleaner element for tears during

cleaning. Replace it with a new one if it is torn.

Assemble the element completely or damage severely

the engine.

Be careful not to allow water to go inside the air clea-

ner element.

▣▣

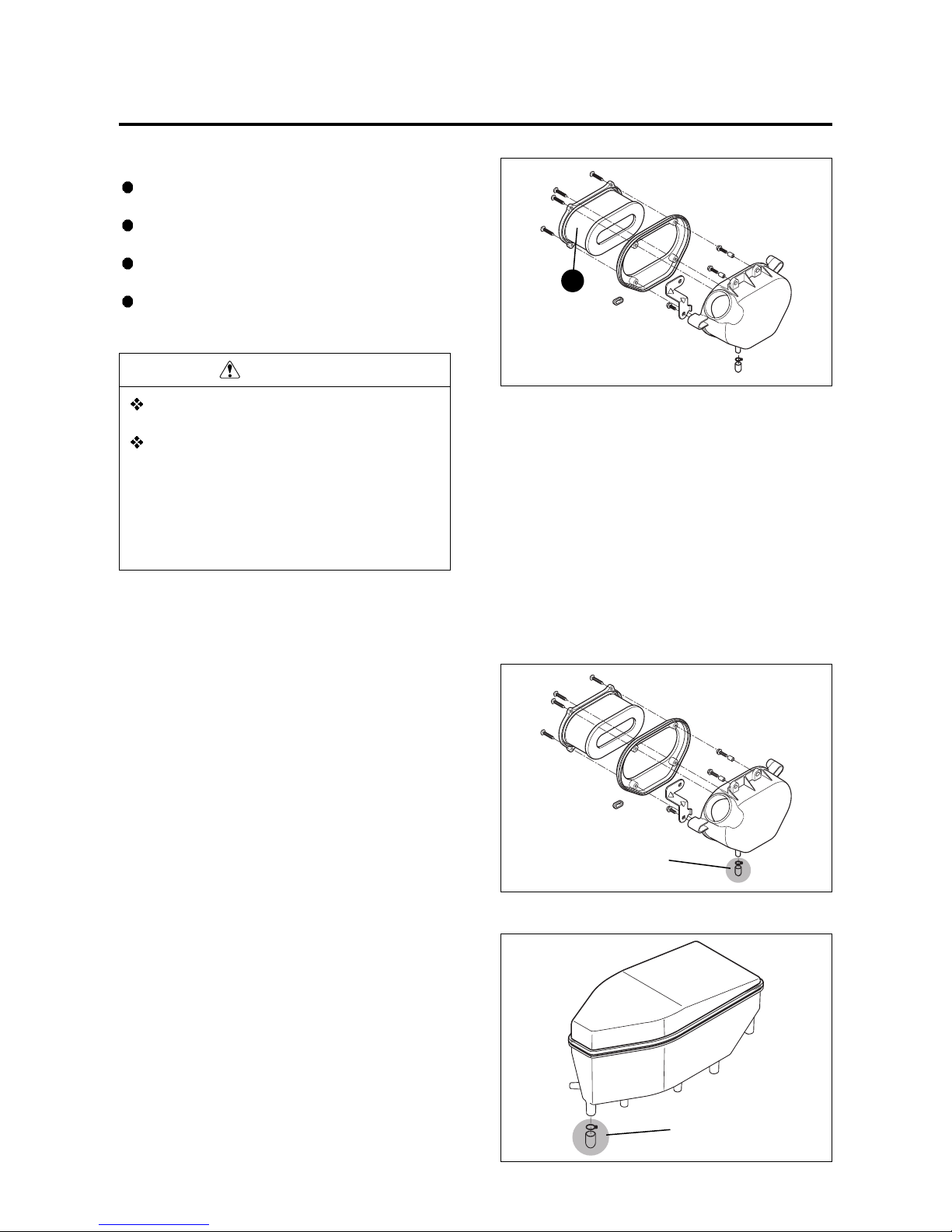

AIR CLEANER OIL DRAIN PLUG

Inspect the plug ① and drain water and oil at the

periodic maintenance interval.

The air cleaner oil drain plug ① is located beneath

the air cleaner case.

CAUTION

Inspect the air cleaner element for tears.

A torn element must be replaced.

If driving under dusty conditions, clean the air

cleaner element more frequently. The surest

way to accelerate engine wear is to operate the

engine without the element or with torn element. Make sure that the air cleaner element is

in good condition at all times. Life of the

engine depends largely on this component!

①

▣▣

AIR CLEANER CHAMBER OIL

DRAIN PLUG

Inspect the plug ② and drain water and oil at the

periodic maintenance interval.

The air cleaner chamber oil drain plug ② is located

beneath the air cleaner chamber.

②

2-9 PERIODIC MAINTENANCE

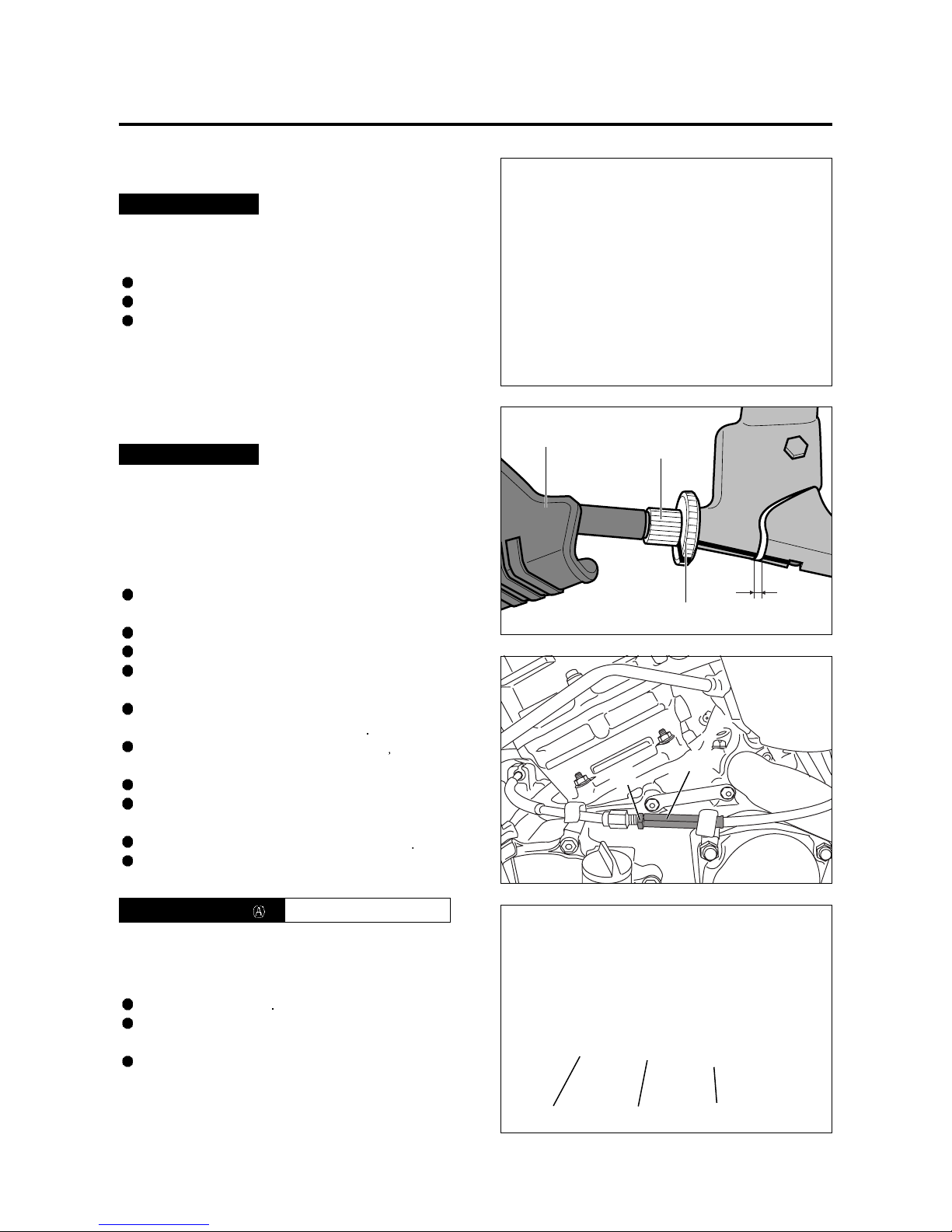

THROTTLE CABLE PLAY

This motorcycle has a twin throttle cable system. Cable

is for throttle cable and cable is for returning cable.

There should be 0.5 ~ 1.0 mm (0.02 ~ 0.04 in) play on

the throttle cable.

To adjust the throttle cable play :

Hold the motorcycle vertically.

Uncover the protection.

Loosen the lock nut ②of the returning cable and

fully turn in the adjuster

③

Loosen the lock nut ④of the throttle cable

Turn the adjuster ⑤in or out until the throttle cable

play is between 0.5 ~ 1.0 mm (0.02 ~ 0.04 in).

Tighten the lock nut ④while holding the adjuster

⑤

While holding the throttle grip at the fully closed posi-

tion, slowly turn out the adjuster ③of the returning

cable until resistance is felt.

Tighten the lock nut ②while holding the adjuster

③

Check free play again.

Cover the protection.

Connect an engine tachometer to the high ten-

sion cord.

Start the engine and inspect the engine idle

speed between specified range.

1,400 1,600 rpmEngine idle speed

0.5 1.0 mm (0.02 ~ 0.04 in)Throttle cable play

ENGINE IDLE SPEED

Inspect Interval

Inspect Initial 1,000 km and Every 6,000 km thereafter.

Inspect Interval

Inspect Initial 1,000 km and Every 6,000 km thereafter.

NOTE

④

⑤

③

①

②

0.5 ~ 1.0 mm

(0.02 ~ 0.04 in)

Make this inspection when the engine is hot.

CAUTION

Never operate the idle screw to avoid variations of the carburetion setting.

Engine tachometer : 09900-26006

CAUTION

After the adjustment is completed, check that

throttle grip movement does not raise the engine

idle speed and that the throttle grip returns

smoothly and automatically.

CAUTION

Inadequate throttle cable play can cause engine

speed to rise suddenly when you turn the throttle

grip. This can lead to loss of rider control.

PERIODIC MAINTENANCE 2-10

FUEL HOSE

Remove the seat. (Refer to page 8-1)

Remove the fuel tank. (Refer to page 5-2)

Remove the frame cover. (Refer to page 8-2)

Inspect the fuel hoses for damage and fuel leakage.

If any defects are found, the fuel hoses must be

replaced.

Inspect Interval

Inspect Initial 1,000 km and Every 6,000 km thereafter.

Replace every 4 years.

①

⑤

②

CLUTCH

Clutch play should be 2 mm (0.08 in) as measured at the

clutch lever holder before the clutch begins to disengage.

If the play in the clutch is incorrect, adjust it in the following

way :

A basis adjustment be allowed by the clutch lever

adjuster ②.

Uncover the rubber boot ⑤.

Loosen the lock nut ①counter-clockwise.

Turn the clutch lever adjuster ②in or out to acquire

the specified play.

After end of adjustment, tighten the lock nut ①clock-

wise fully and cover the rubber boot

⑤

If not adjust by the clutch lever adjuster ②adjust by

the clutch cable adjuster ④.

Loosen the clutch cable adjuster lock nut ③.

Turn the clutch cable adjuster ④in or out to acquire

the specified play.

After end of adjustment, tighten the lock nut

③

The clutch cable should be lubricated with a light

weight oil whenever it is adjusted.

▣▣

GEARSHIFT LEVER HEIGHT

ADJUSTMENT

Loosen the lock nut

⑥

With the link rod ⑦turned, adjust the gearshift lever

height.

Tighten the lock nut ⑥.

2 mm (0.08 in)Clutch cable play

Inspect Interval

Inspect Initial 1,000 km and Every 6,000 km thereafter.

⑥

⑥

⑦

④

③

2-11 PERIODIC MAINTENANCE

FOOTREST POSITION ADJUST-

MENT

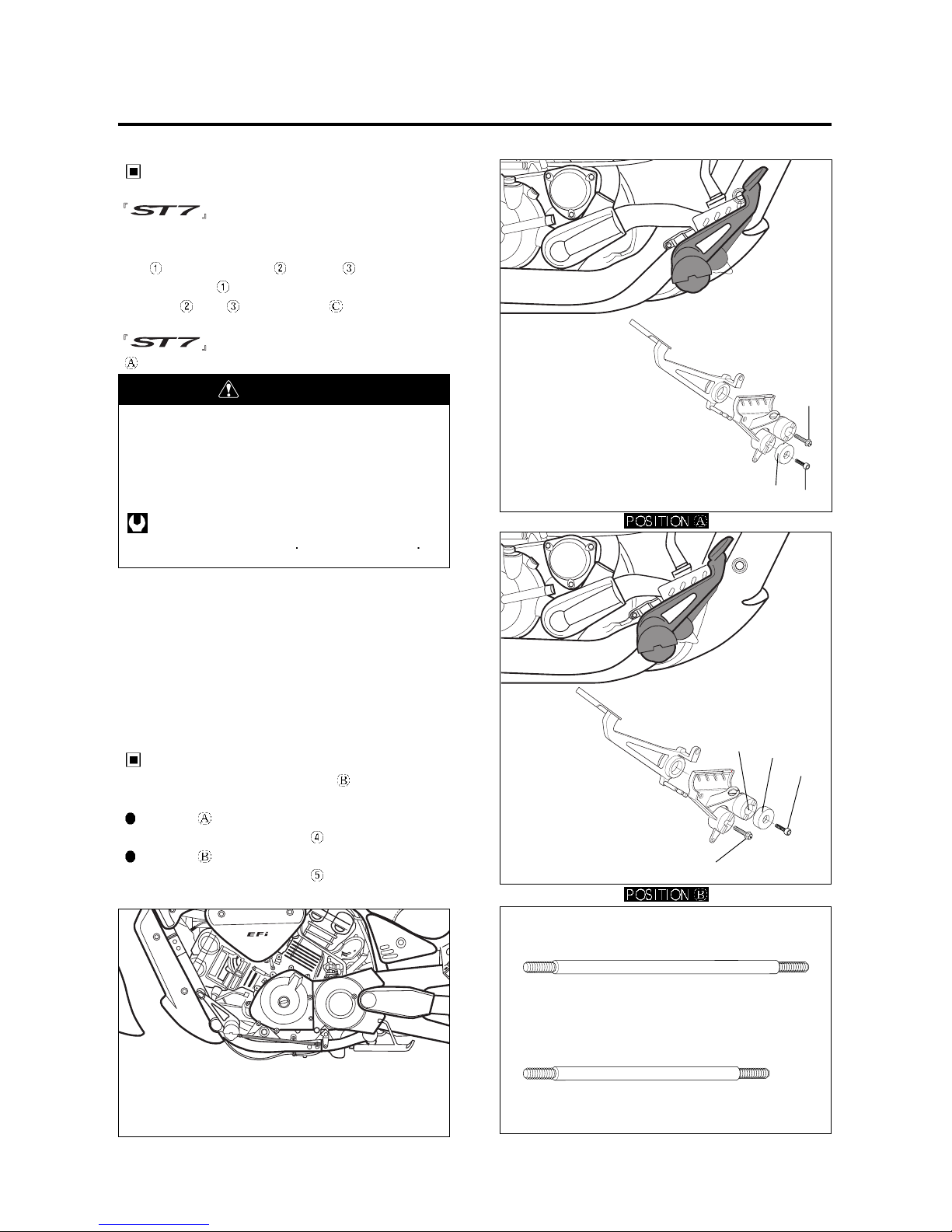

has 2 type of the footrest position, right

and left.

To change the position, remove the footrest mounting

bolt , footrest boss cap and bolt .

Install the bolt to the desired position and footrest

boss cap , bolt to the position .

is delivered from the factory on position

.

GEARSHIFT LINK ROD

When the footrests in position , exchange the

gearshift link rod for appropriate riding position.

Position

: Install the gearshift link rod

Position

: Install the gearshift link rod

②

③

③

①

④

⑤

Footrest mounting bolt

: 40 ~ 60 N m (4.0 ~ 6.0 kgf m)

①

②

WARNING

When adjusting the footrest position, the footrest

mounting bolt be torque to the proper specification.

If they are not, the footrest can come off unexpectedly.

PERIODIC MAINTENANCE 2-12

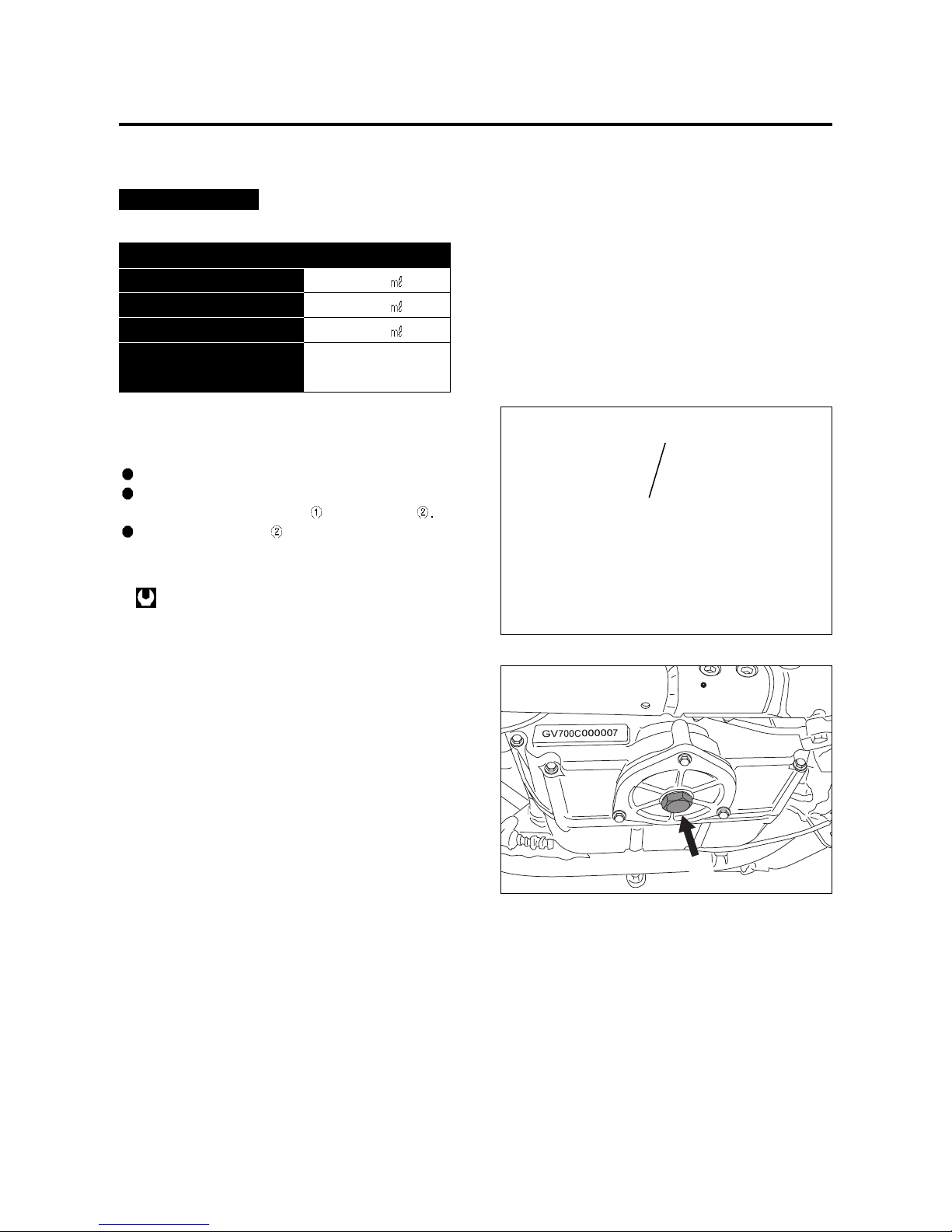

Necessary amount of engine oil

Oil change

Oil and filter change

Engine overhaul

Engine oil type

SAE 10W/40

API Over SL

3,000

3,200

3,400

ENGINE OIL

Inspect Interval

Replace Initial 1,000 km and Every 6,000 km thereafter.

The oil should be changed while the engine is warm.

Oil filter replacement at the above intervals,

should be together with the engine oil change.

Keep the motorcycle upright.

Place an oil pan below the engine, and drain the

oil by removing the filler cap and drain plug

Tighten the drain plug to the specified torque, and

pour fresh oil through the oil filler. Use an API classification of Over SL oil with SAE 10W/40 viscosity.

Oil drain plug : 21 N··m (2.1 kgf··m)

②

①

Loading...

Loading...