Page 1

查询HY29F400供应商

KEY FEATURES

HY29F400

4 Megabit (512Kx8/256Kx16) 5 Volt-only Flash Memory

n 5 Volt Read, Program, and Erase

– Minimizes system-level power requirements

n High Performance

– Access times as fast as 45 ns

n Low Power Consumption

– 20 mA typical active read current in byte

mode, 28 mA typical in word mode

– 30 mA typical program/erase current

– 5 µA maximum CMOS standby current

n Compatible with JEDEC Standards

– Package, pinout and command-set

compatible with the single-supply Flash

device standard

– Provides superior inadvertent write

protection

n Sector Erase Architecture

– Boot sector architecture with top and

bottom boot block options available

– One 16 Kbyte, two 8 Kbyte, one 32 Kbyte

and seven 64 Kbyte sectors in byte mode

– One 8 Kword, two 4 Kword, one 16 Kword

and seven 32 Kword sectors in word mode

– A command can erase any combination of

sectors

– Supports full chip erase

n Erase Suspend/Resume

– Temporarily suspends a sector erase

operation to allow data to be read from, or

programmed into, any sector not being

erased

n Sector Protection

– Any combination of sectors may be

locked to prevent program or erase

operations within those sectors

n Temporary Sector Unprotect

– Allows changes in locked sectors

(requires high voltage on RESET# pin)

n Internal Erase Algorithm

– Automatically erases a sector, any

combination of sectors, or the entire chip

n Internal Programming Algorithm

– Automatically programs and verifies data

at a specified address

n Fast Program and Erase Times

– Byte programming time: 7 µs typical

– Sector erase time: 1.0 sec typical

– Chip erase time: 11 sec typical

n Data# Polling and Toggle Status Bits

– Provide software confirmation of

completion of program or erase

operations

n Ready/Busy# Output (RY/BY#)

– Provides hardware confirmation of

completion of program and erase

operations

n 100,000 Program/Erase Cycles Minimum

n Space Efficient Packaging

– Available in industry-standard 44-pin

PSOP and 48-pin TSOP and reverse

TSOP packages

GENERAL DESCRIPTION

The HY29F400 is a 4 Megabit, 5 volt only CMOS

Flash memory organized as 524,288 (512K) bytes

or 262,144 (256K) words. The device is offered in

industry-standard 44-pin PSOP and 48-pin TSOP

packages.

The HY29F400 can be programmed and erased

in-system with a single 5-volt V

supply. Inter-

CC

nally generated and regulated voltages are provided for program and erase operations, so that

the device does not require a high voltage power

supply to perform those functions. The device can

also be programmed in standard EPROM programmers. Access times as fast as 55 ns over

the full operating voltage range of 5.0 volts ± 10%

are offered for timing compatibility with the zero

wait state requirements of high speed micropro-

Revision 5.2, May 2001

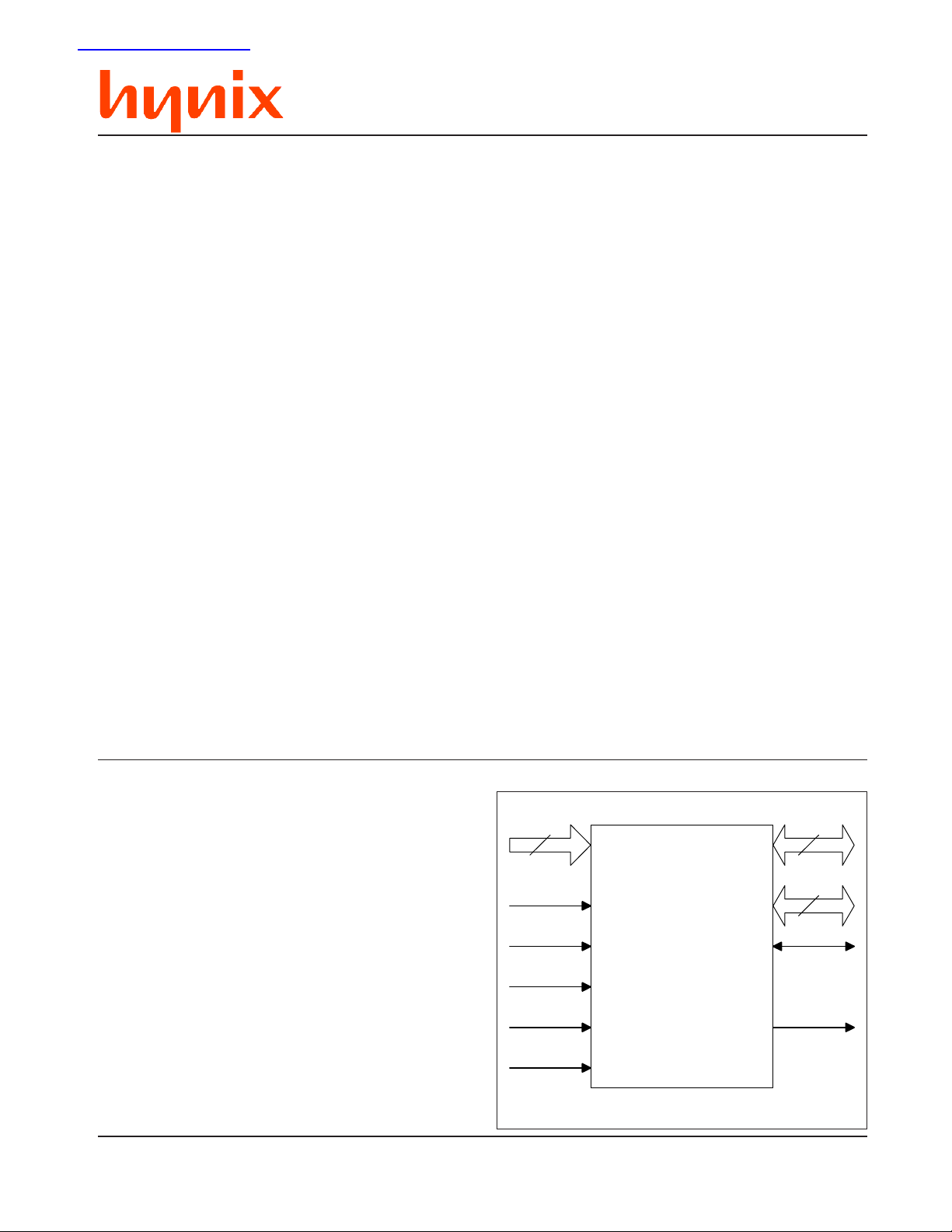

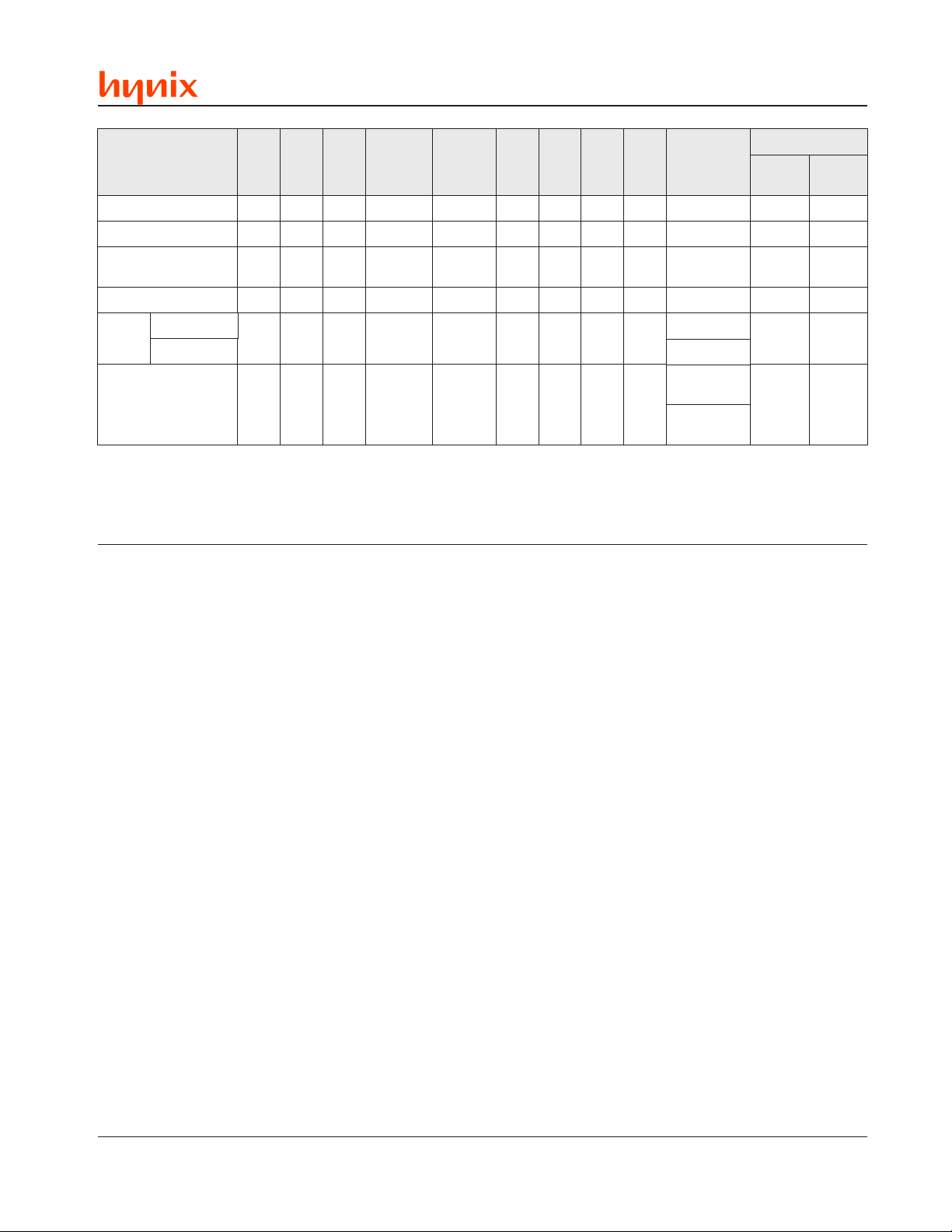

LOGIC DIAGRAM

18

A[17:0]

CE#

OE#

WE#

RESET#

BYTE#

8

DQ[7:0]

7

DQ[14:8]

DQ[15]/A-1

RY/BY#

Page 2

HY29F400

cessors. A 55 ns version operating over 5.0 volts

± 5% is also available. To eliminate bus contention, the HY29F400 has separate chip enable

(CE#), write enable (WE#) and output enable

(OE#) controls.

The device is compatible with the JEDEC single

power-supply Flash command set standard. Commands are written to the command register using

standard microprocessor write timings, from where

they are routed to an internal state-machine that

controls the erase and programming circuits.

Device programming is performed a byte or word

at a time by executing the four-cycle Program command. This initiates an internal algorithm that automatically times the program pulse widths and

verifies proper cell margin.

The HY29F400’s sector erase architecture allows

any number of array sectors to be erased and reprogrammed without affecting the data contents

of other sectors. Device erasure is initiated by

executing the Erase command. This initiates an

internal algorithm that automatically preprograms

the array (if it is not already programmed) before

executing the erase operation. During erase

cycles, the device automatically times the erase

pulse widths and verifies proper cell margin.

To protect data in the device from accidental or

unauthorized attempts to program or erase the

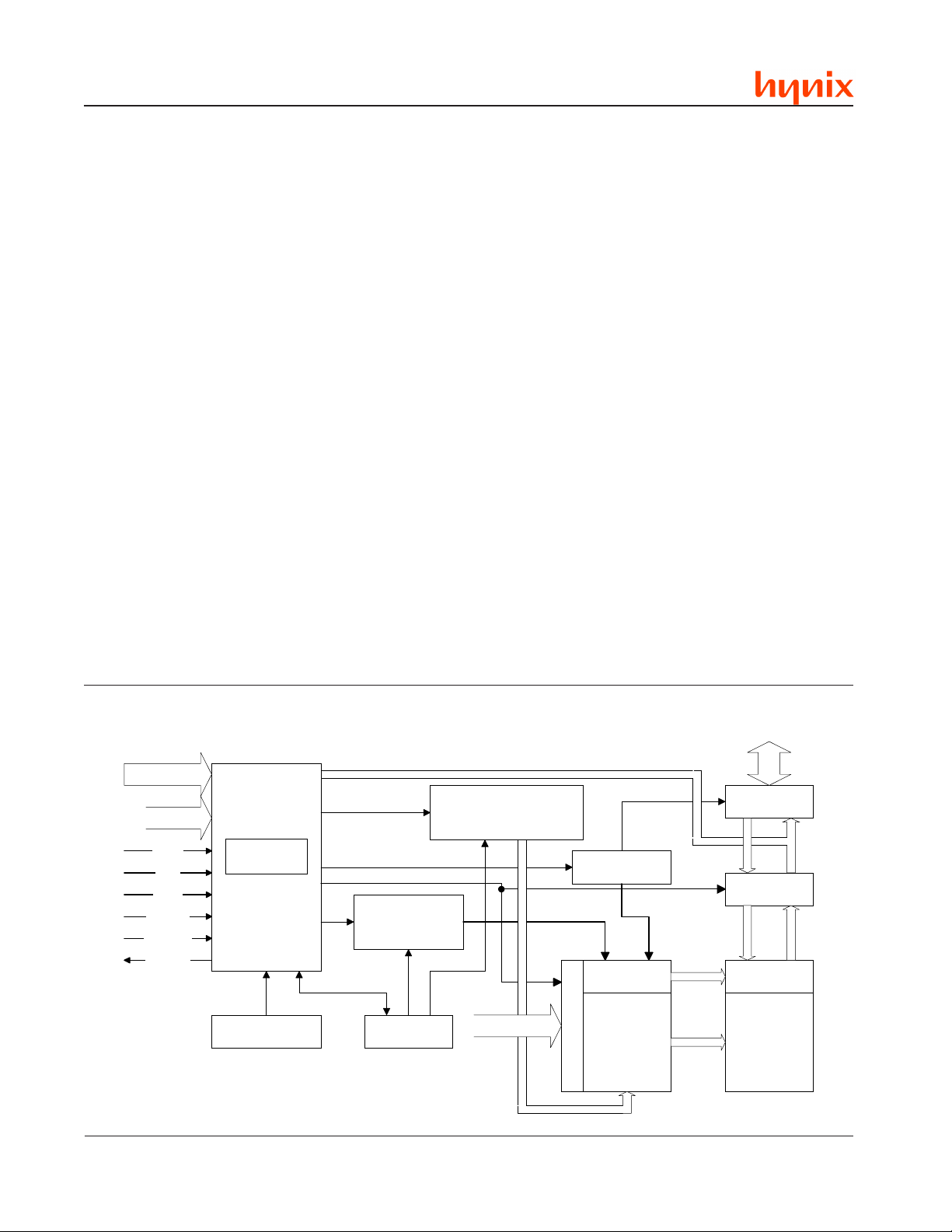

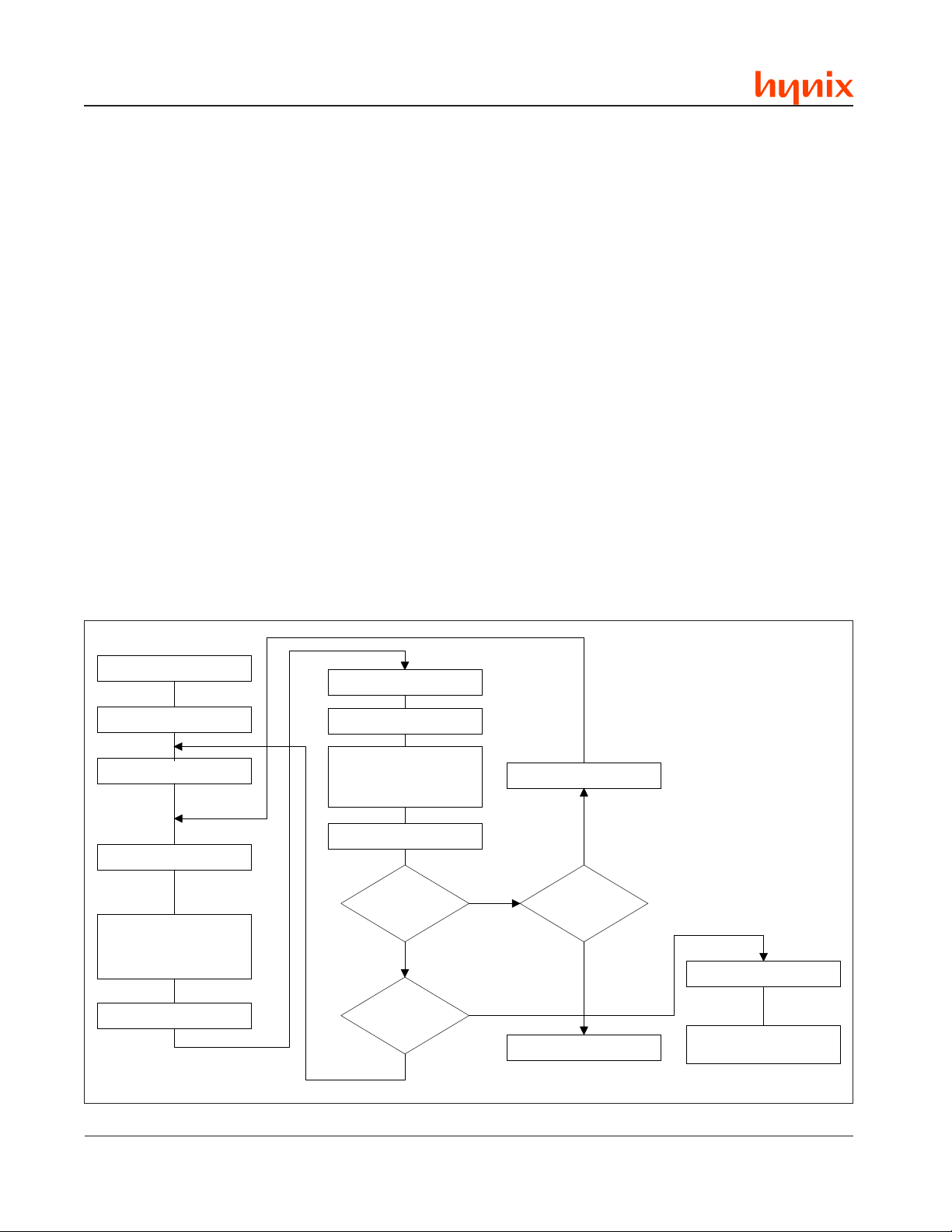

BLOCK DIAGRAM

device while it is in the system (e.g., by a virus),

the device has a Sector Protect function which

hardware write protects selected sectors. The

sector protect and unprotect features can be enabled in a PROM programmer. Temporary Sector Unprotect, which requires a high voltage, allows in-system erasure and code changes in previously protected sectors.

Erase Suspend enables the user to put erase on

hold for any period of time to read data from, or

program data to, any sector that is not selected

for erasure. True background erase can thus be

achieved. The device is fully erased when shipped

from the factory.

Addresses and data needed for the programming

and erase operations are internally latched during

write cycles, and the host system can detect

completion of a program or erase operation by

observing the RY/BY# pin, or by reading the DQ[7]

(Data# Polling) and DQ[6] (Toggle) status bits.

Reading data from the device is similar to reading

from SRAM or EPROM devices. Hardware data

protection measures include a low V

detector

CC

that automatically inhibits write operations during

power transitions.

The host can place the device into the standby

mode. Power consumption is greatly reduced in

this mode.

DQ[15:0]

A[17:0], A-1

DQ[15:0]

WE#

CE#

OE#

BYTE#

RESET#

RY/BY#

2

STATE

CONTROL

COMMAND

REGISTER

PROGRAM

VOLTAGE

GENERATOR

VCC DETECTOR TIMER

ERASE VOLTAGE

GENERATOR AND

SECTOR SWITCHES

A[17:0], A-1

ADDRESS LATCH

I/O CONTROL

Y-DECODER

X-DECODER

I/O BUFFERS

DATA LATCH

Y-GATING

4 Mb FLASH

MEMORY

ARRAY

Rev. 5.2/May 01

Page 3

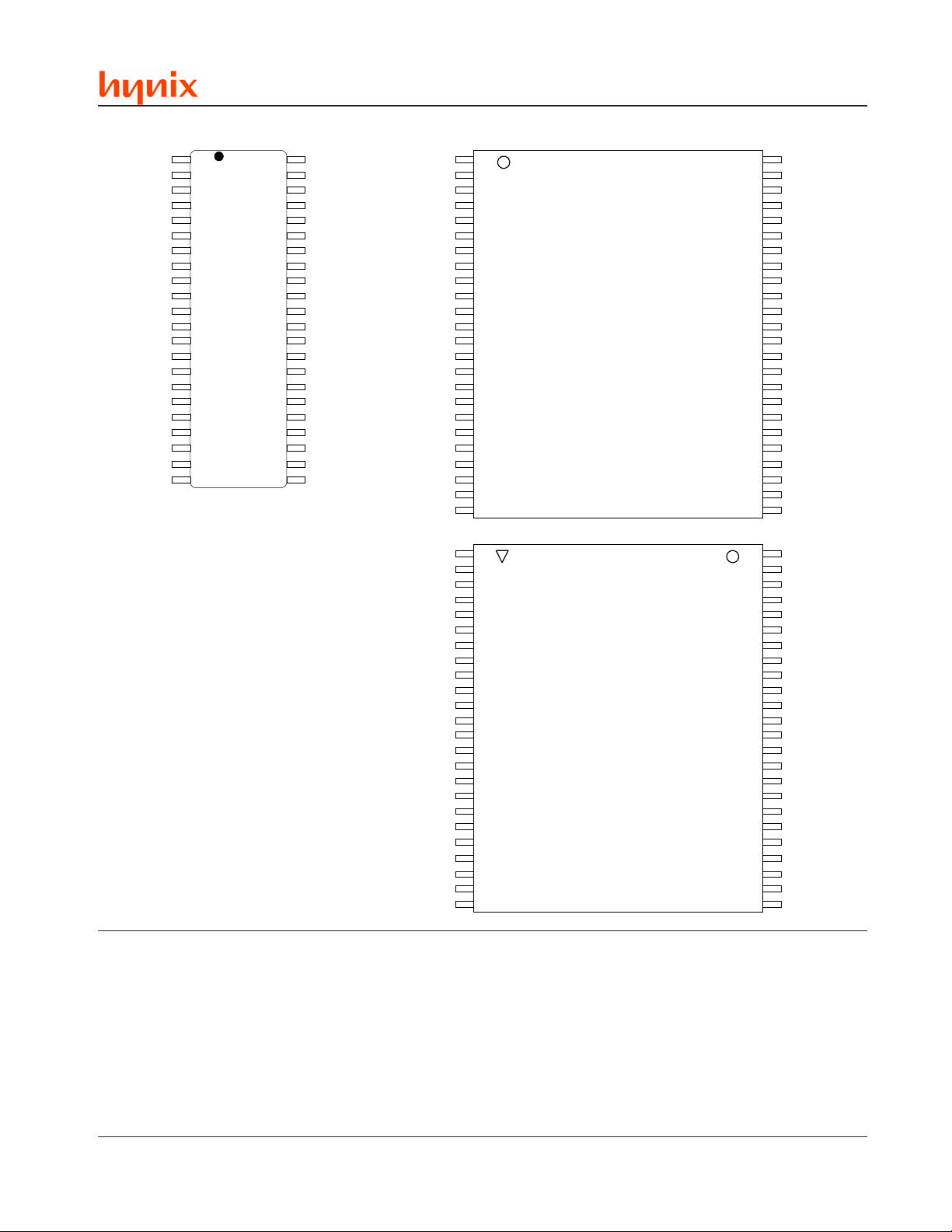

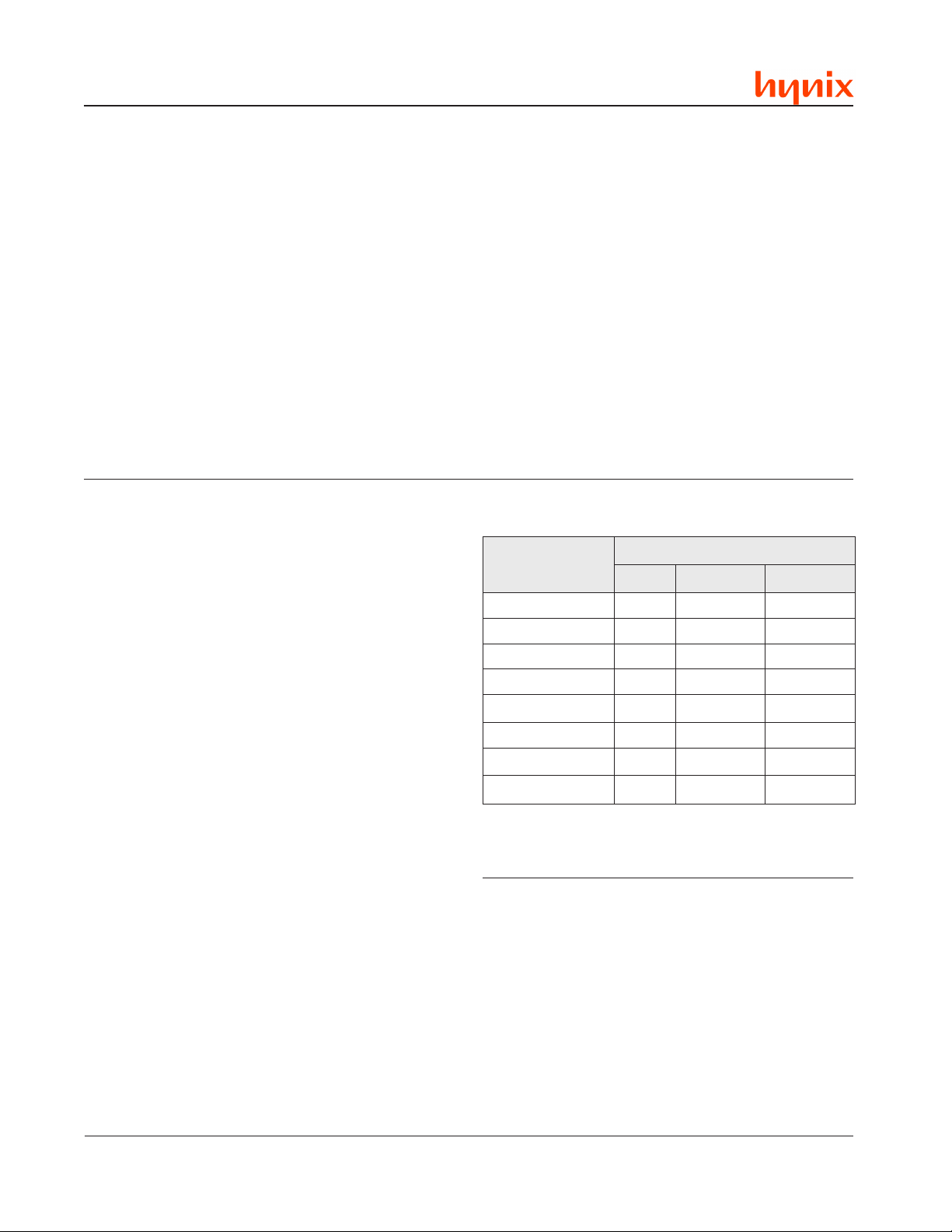

PIN CONFIGURATIONS

HY29F400

NC

RY/BY#12

A17

A7

A6

A5

A4

A3

A2

A1910

A0

CE#1112

V

SS

OE#1314

DQ0

DQ81516

DQ1

DQ91718

DQ2

DQ101920

DQ3

DQ112122

3

4

5

6

7

8

PSOP44

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

RESET#

WE#

A8

A9

A10

A11

A12

A13

A14

A15

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC910

WE#

RESET#1112

NC

NC1314

RY/BY#

NC1516

A17

A71718

A6

A51920

A4

A32122

A2

A12324

A16

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

A16

1

2

3

4

5

6

7

8

Standard

TSOP48

1

2

3

4

5

6

7

8

9

Reverse

TSOP48

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

BYTE#

V

SS

DQ15/A-1

DQ7

DQ14

DQ6

DQ13

DQ5

DQ12

DQ4

V

CC

DQ11

DQ3

DQ10

DQ2

DQ9

DQ1

DQ8

DQ0

OE#

V

SS

CE#

A0

A15

A14

A13

A12

A11

A10

A9

A8

NC

NC

WE#

RESET#

NC

NC

RY/BY#

NC

A17

A7

A6

A5

A4

A3

A2

A1

CONVENTIONS

Unless otherwise noted, a positive logic (active

High) convention is assumed throughout this document, whereby the presence at a pin of a higher,

more positive voltage (nominally 5VDC) causes

assertion of the signal. A ‘#’ symbol following the

signal name, e.g., RESET#, indicates that the signal is asserted in a Low state (nominally 0 volts).

Rev. 5.2/May 01

Whenever a signal is separated into numbered

bits, e.g., DQ[7], DQ[6], ..., DQ[0], the family of

bits may also be shown collectively, e.g., as

DQ[7:0].

The designation 0xNNNN (N = 0, 1, 2, . . . , 9, A, .

. . , E, F) indicates a number expressed in hexadecimal notation. The designation 0bXXXX indicates a

number expressed in binary notation (X = 0, 1).

3

Page 4

HY29F400

SIGNAL DESCRIPTIONS

emaN epyT noitpircseD

]0:71[AstupnI

,]1-[A/]51[QD

]0:41[QD

#ETYBtupnI

#ECtupnI

#EOtupnI

#EWtupnI

#TESERtupnI

#YB/YR

V

CC

V

SS

--

--

.hgiHevitca,sserddA 441,262foenotcelesstupni81eseht,edomdroWnI

eseht,edometyBnI.snoitarepoetirwrodaerrofyarraehtnihtiwsdrow)K652(

882,425foenotcelesot)BSL(tupni1-A/51QDehthtiwdenibmocerastupni

.snoitarepoetirwrodaerrofyarraehtnihtiwsetyb)K215(

hgiHevitca,suBataD htapatadtib-61aedivorpsnipeseht,edomdroWnI.

stuptuO/stupnI

etats-irT

htapatadtib-8naedivorp]0:7[QD,edometyBnI.snoitarepoetirwdnadaerrof

]8:41[QD.tupnisserddaetybtib-91ehtfoBSLehtsadesusi]1-[A/]51[QDdna

.edometyBnidetats-irtniamerdnadesunuera

.woLevitca,edoMetyB .ecivedehtfonoitarugifnocdroW/etyBehtslortnoC

.edomdroWstceleshgiH,edometyBstceleswoL

.woLevitca,elbanEpihC romorfataddaerotdetressaebtsumtupnisihT

ecivedehtdnadetats-irtsisubatadeht,hgiHnehW.004F92YHehtotatadetirw

.edomybdnatSehtnidecalpsi

woLevitca,elbanEtuptuO snoitarepodaerrofdetressaebtsumtupnisihT.

drowaroetybarehtehwsenimreted#ETYB.snoitarepoetirwrofdetagendna

eraecivedehtmorfstuptuoatad,hgiHnehW.noitarepodaerehtgniruddaersi

.etatsecnadepmihgihehtnidecalperasnipsubatadehtdnadelbasid

.woLevitca,elbanEetirW dnammocrosdnammocfognitirwslortnoC

A.yarrayromemehtfosrotcesesareroatadmargorpotredronisecneuqes

#EOdnawoLsi#ECelihwdetressasi#EWnehwecalpsekatnoitarepoetirw

etirwehtgnirudnettirwsidrowaroetybarehtehwsenimreted#ETYB.hgiHsi

.noitarepo

.woLevitca,teseRerawdraH ehtgnitteserfodohtemerawdrahasedivorP

yletaidemmiti,tesersiecivedehtnehW.etatsyarradaerehtot004F92YH

etirw/daerlladnadetats-irtsisubatadehT.ssergorpninoitarepoynasetanimret

,detressasi#TESERelihW.detressasitupniehtelihwderongierasdnammoc

.edomybdnatSehtnieblliwecivedeht

.sutatSysuB/ydaeR nisidnammocesareroetirwarehtehwsetacidnI

tuptuO

niarDnepO

ehtfoegdegnisirehtretfadilavsi#YB/YR.detelpmocneebsahrossergorp

siecivedehtelihwwoLsniamertI.ecneuqesdnammocafoeslup#EWlanif

daerotydaersitinehwhgiHseogdna,gnisareroatadgnimmargorpylevitca

.atadyarra

.ylppusrewoptlov-5

.dnuorglangisdnarewoP

4

Rev. 5.2/May 01

Page 5

MEMORY ARRAY ORGANIZATION

The 4 Mbit Flash memory array is organized into

11 blocks called sectors (S0, S1, . . . , S10). A

sector is the smallest unit that can be erased and

which can be protected to prevent accidental or

unauthorized erasure. See the ‘Bus Operations’

and ‘Command Definitions’ sections of this document for additional information on these functions.

In the HY29F400, four of the sectors, which comprise the boot block, vary in size from 8 to 32

Kbytes (4 to 16 Kwords), while the remaining

seven sectors are uniformly sized at 64 Kbytes

(32 Kwords). The boot block can be located at

the bottom of the address range (HY29F400B) or

at the top of the address range (HY29F400T).

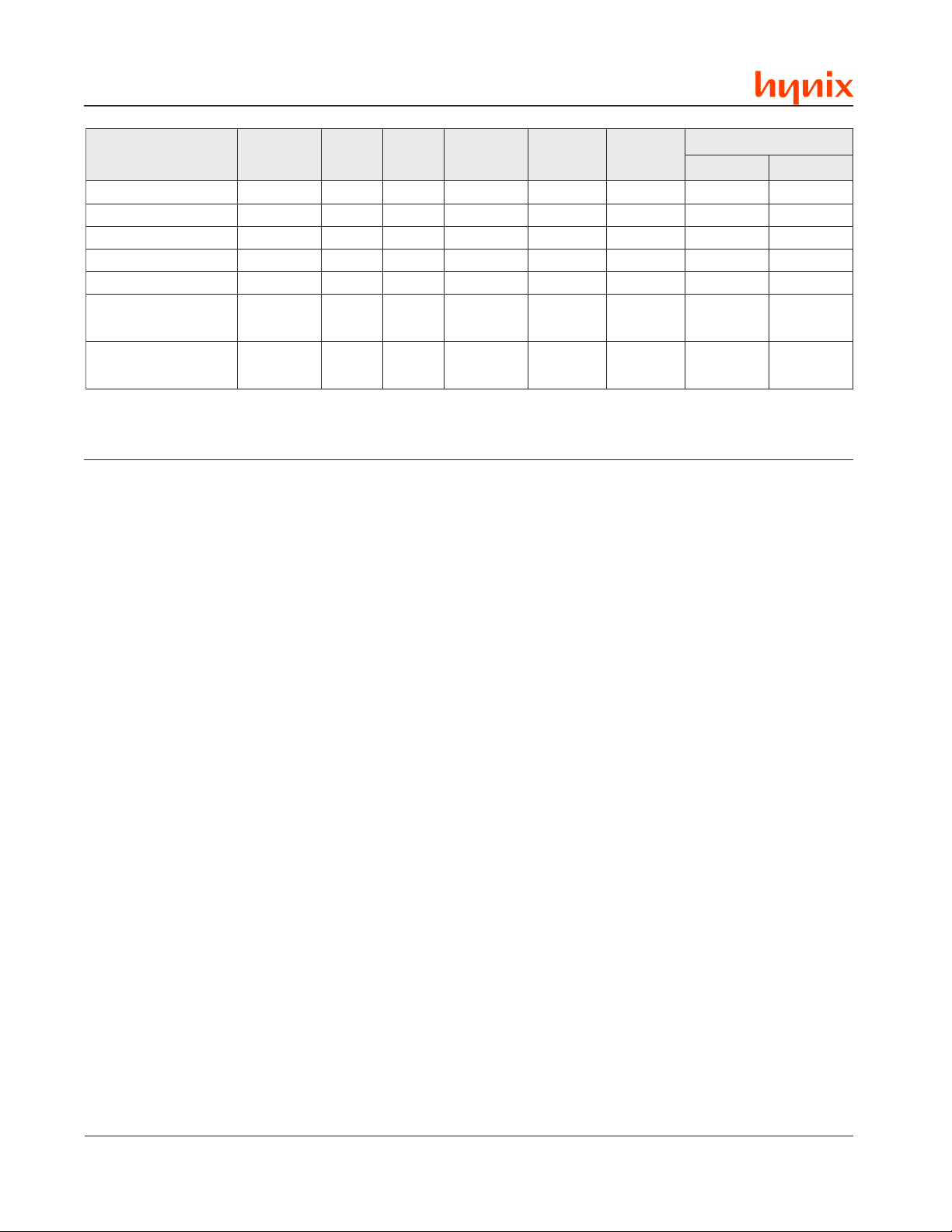

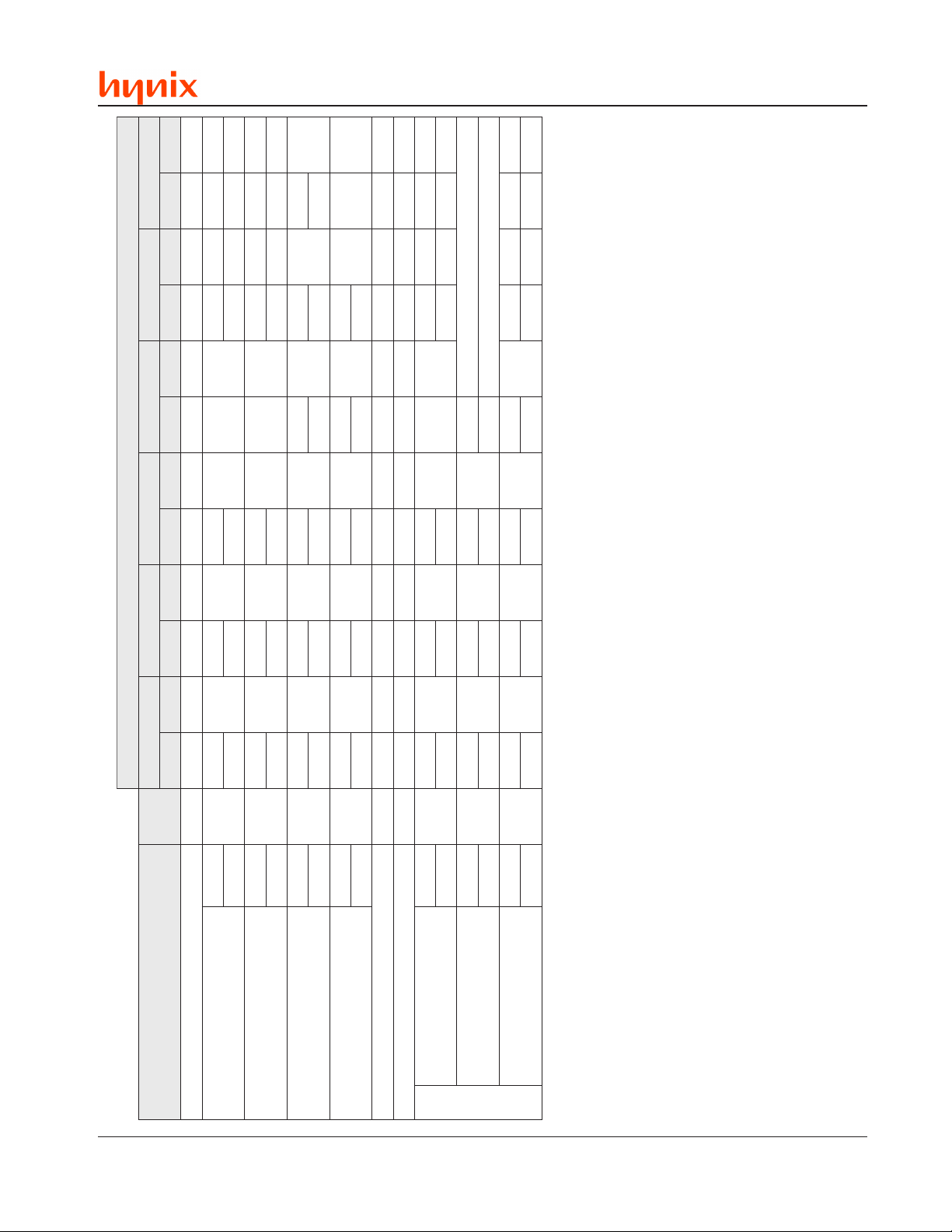

Table 1. HY29F400 Memory Array Organization

HY29F400

Table 1 defines the sector addresses and corresponding address ranges for the top and bottom

boot block versions of the HY29F400.

BUS OPERATIONS

Device bus operations are initiated through the

internal command register, which consists of sets

of latches that store the commands, along with

the address and data information, if any, needed

to execute the specific command. The command

register itself does not occupy any addressable

memory location. The contents of the command

register serve as inputs to an internal state machine whose outputs control the operation of the

device. Table 2 lists the normal bus operations,

eciveD rotceS

0S23/46 000XXX FFFF0x0-00000x0FFF70x0-00000x0

1S23/46 00 1XXX FFFF1x0-00001x0FFFF0x0-00080x0

2S23/46 010XXX FFFF2x0-00002x0FFF71x0-00001x0

3S23/46 011XXX FFFF3x0-00003x0FFFF1x0-00081x0

4S23/46 100XXX FFFF4x0-00004x0FFF72x0-00002x0

5S23/46 10 1XXX FFFF5x0-00005x0FFFF2x0-00082x0

6S23/46 110XXX FFFF6x0-00006x0FFF73x0-00003x0

7S61/23 1110XX FFF77x0-00007x0FFFB3x0-00083x0

8S4/8 111100 FFF97x0-00087x0FFFC3x0-000C3x0

HY29F400T - Top Boot BlockHY29F400B - Bottom Boot Block

Notes:

1. X indicates Don’t Care.

2. Address in Byte Mode is A[17:-1].

3. Address in Word Mode is A[17:0].

9S4/8 111101 FFFB7x0-000A7x0FFFD3x0-000D3x0

01S8/61 11111X FFFF7x0-000C7x0FFFF3x0-000E3x0

0S8/61 00000X FFF30x0-00000x0FFF10x0-00000x0

1S4/8 000010 FFF50x0-00040x0FFF20x0-00020x0

2S4/8 000011 FFF70x0-00060x0FFF30x0-00030x0

3S61/23 0001XX FFFF0x0-00080x0FFF70x0-00040x0

4S23/46 00 1XXX FFFF1x0-00001x0FFFF0x0-00080x0

5S23/46 010XXX FFFF2x0-00002x0FFF71x0-00001x0

6S23/46 011XXX FFFF3x0-00003x0FFFF1x0-00081x0

7S23/46 100XXX FFFF4x0-00004x0FFF72x0-00002x0

8S23/46 10 1XXX FFFF5x0-00005x0FFFF2x0-00082x0

9S23/46 110XXX FFFF6x0-00006x0FFF73x0-00003x0

01S23/46 111XXX FFFF7x0-00007x0FFFF3x0-00083x0

eziS

)WK/BK(

]71[A ]61[A ]51[A ]41[A ]31[A ]21[A

sserddArotceS

edoMetyB

2

egnaRsserddA

edoMdroW

3

egnaRsserddA

Rev. 5.2/May 01

5

Page 6

HY29F400

Table 2. HY29F400 Normal Bus Operations

noitarepO #EC #EO #EW #TESER sserddA

daeRLLHHA

etirWLHLHA

elbasiDtuptuOLHHHXZ-hgiHZ-hgiHZ-hgiH

ybdnatSLTT#ECHXXHXZ-hgiHZ-hgiHZ-hgiH

ybdnatSSOMC#ECV

teseRerawdraH

)ybdnatSLTT(

V5.0±XXVCCV5.0±X Z-hgiHZ-hgiHZ-hgiH

CC

XXXL X Z-hgiHZ-hgiHZ-hgiH

1

2

NI

NI

]0:7[QD

D

TUO

D

NI

3

]8:51[QD

H=#ETYB L=#ETYB

D

TUO

D

NI

Z-hgiH

Z-hgiH

teseRerawdraH

)ybdnatSSOMC(

Notes:

1. L = V

2. Address is A[17:-1] in Byte Mode and A[17:0] in Word Mode.

3. DQ[15] is the A[-1] input in Byte Mode (BYTE# = L).

, H = VIH, X = Don’t Care, D

IL

XXXV

= Data Out, DIN = Data In. See DC Characteristics for voltage levels.

OUT

SS

the inputs and control levels they require, and the

resulting outputs. Certain bus operations require

a high voltage on one or more device pins. Those

are described in Table 3.

Read Operation

Data is read from the HY29F400 by using standard microprocessor read cycles while placing the

address of the byte or word to be read on the

device’s address inputs, A[17:0] in Word mode

(BYTE# = H) or A[17:-1] in Byte mode (BYTE# =

L) . As shown in Table 2, the host system must

drive the CE# and OE# inputs Low and drive WE#

High for a valid read operation to take place. The

device outputs the specified array data on DQ[7:0]

in Byte mode and on DQ[15:0] in Word mode.

Note that DQ[15] serves as address input A[-1]

when the device is operating in Byte mode.

The HY29F400 is automatically set for reading

array data after device power-up and after a hardware reset to ensure that no spurious alteration of

the memory content occurs during the power transition. No command is necessary in this mode to

obtain array data, and the device remains enabled

for read accesses until the command register contents are altered.

This device features an Erase Suspend mode.

While in this mode, the host may read the array

data from any sector of memory that is not marked

for erasure. If the host attempts to read from an

address within an erase-suspended sector, or

while the device is performing an erase or byte/

V5.0±X Z-hgiHZ-hgiHZ-hgiH

word program operation, the device outputs status data instead of array data. After completing a

programming operation in the Erase Suspend

mode, the system may once again read array data

with the same exceptions noted above. After completing an internal program or internal erase algorithm, the HY29F400 automatically returns to the

Read Array Data mode.

The host must issue a hardware reset or the software reset command (see Command Definitions)

to return a sector to the read array data mode if

DQ[5] goes high during a program or erase cycle,

or to return the device to the Read Array Data

mode while it is in the Electronic ID mode.

Write Operation

Certain operations, including programming data

and erasing sectors of memory, require the host

to write a command or command sequence to the

HY29F400. Writes to the device are performed

by placing the byte or word address on the device’s

address inputs while the data to be written is input

on DQ[7:0] in Byte mode (BYTE# = L) and on

DQ[15:0] in Word mode (BYTE# = H). The host

system must drive the CE# and WE# pins Low

and drive OE# High for a valid write operation to

take place. All addresses are latched on the falling edge of WE# or CE#, whichever happens later.

All data is latched on the rising edge of WE# or

CE#, whichever happens first.

6

Rev. 5.2/May 01

Page 7

Table 3. HY29F400 Bus Operations Requiring High Voltage

3

noitarepO

tcetorProtceSLV

tcetorpnUrotceSV

rotceSyraropmeT

tcetorpnU

eciveD

edoC

#EC #EO #EW #TESER ]21:71[A ]9[A ]6[A ]1[A ]0[A ]0:7[QD

XH AS

DI

V

DI

XXX V

XH XVDIXXX X X Z-hgiH

DI

DI

edoCrerutcafunaMLLHHXV

4

V

XXX X X Z-hgiH

DI

X XXXX DNID

LLL DAx0XZ-hgiH

DI

B004F92YH

LLH H X V

T004F92YH 32x0

LLH

DI

puorGrotceS

4

noitcetorP

LLH H AS

V

LHL

DI

noitacifireV

Notes:

1. L = V

2. Address bits not specified are Don’t Care.

3. See text for additional information.

4. SA = sector address. See Table 1.

5. DQ[15] is the A[-1] input in Byte Mode (BYTE# = L).

The ‘Device Commands’ section of this document

provides details on the specific device commands

implemented in the HY29F400.

, H = VIH, X = Don’t Care. See DC Characteristics for voltage levels.

IL

the HY29F400 will be in the RESET# TTL Standby

mode, but the standby current will be greater. See

Hardware Reset Operation section for additional

information on the reset operation.

Output Disable Operation

When the OE# input is at V

, output data from the

IH

device is disabled and the data bus pins are placed

in the high impedance state.

The device requires standard access time (t

read access when the device is in either of the

standby modes, before it is ready to read data. If

the device is deselected during erasure or programming, it continues to draw active current until

Standby Operation

the operation is completed.

1, 2

HY29F400

]8:51[QD

#ETYB

H=

NI

BAx0

22x0Z-hgiH

=00x0

detcetorpnU

=10x0

XZ-hgiH

detcetorP

CE

5

L=

Z-hgiH

) for

#ETYB

When the system is not reading from or writing to

the HY29F400, it can place the device in the

Standby mode. In this mode, current consumption is greatly reduced, and the data bus outputs

are placed in the high impedance state, independent of the OE# input. The Standby mode can be

invoked using two methods.

The device enters the CE# CMOS Standby mode

if the CE# and RESET# pins are both held at V

CC

± 0.5V. Note that this is a more restricted voltage

range than V

High, but not within V

. If both CE# and RESET# are held

IH

± 0.5V, the device will be

CC

in the CE# TTL Standby mode, but the standby

current will be greater.

The device enters the RESET# CMOS Standby

mode when the RESET# pin is held at V

If RESET# is held Low but not within V

Rev. 5.2/May 01

± 0.5V.

SS

± 0.5V,

SS

Hardware Reset Operation

The RESET# pin provides a hardware method of

resetting the device to reading array data. When

the RESET# pin is driven Low for the minimum

specified period, the device immediately terminates any operation in progress, tri-states the data

bus pins, and ignores all read/write commands for

the duration of the RESET# pulse. The device also

resets the internal state machine to reading array

data. If an operation was interrupted by the assertion of RESET#, it should be reinitiated once

the device is ready to accept another command

sequence to ensure data integrity.

Current is reduced for the duration of the RESET#

pulse as described in the Standby Operation section above.

7

Page 8

HY29F400

If RESET# is asserted during a program or erase

operation, the RY/BY# pin remains Low (busy) until

the internal reset operation is complete, which requires a time of t

(during Automatic Algo-

READY

rithms). The system can thus monitor RY/BY# to

determine when the reset operation completes,

and can perform a read or write operation t

RB

after

RY/BY# goes High. If RESET# is asserted when

a program or erase operation is not executing (RY/

BY# pin is High), the reset operation is completed

within a time of t

form a read or write operation t

. In this case, the host can per-

RP

after the RE-

RH

SET# pin returns High .

The RESET# pin may be tied to the system reset

signal. Thus, a system reset would also reset the

device, enabling the system to read the boot-up

firmware from the Flash memory.

Sector Protect/Unprotect Operations

Hardware sector protection can be invoked to disable program and erase operations in any single

sector or combination of sectors. This function is

typically used to protect data in the device from

unauthorized or accidental attempts to program

or erase the device while it is in the system (e.g.,

by a virus) and is implemented using programming equipment. Sector unprotection re-enables

the program and erase operations in previously

protected sectors.

Table 1 identifies the eleven sectors and the address range that each covers for both versions of

the device. The device is shipped with all sectors

unprotected.

The sector protect/unprotect operations require a

high voltage (V

) on address pin A[9] and the CE#

ID

and/or OE# control pins, as detailed in Table 3.

When implementing these operations, note that

must be applied to the device before applying

V

CC

, and that VID should be removed before remov-

V

ID

ing V

from the device.

CC

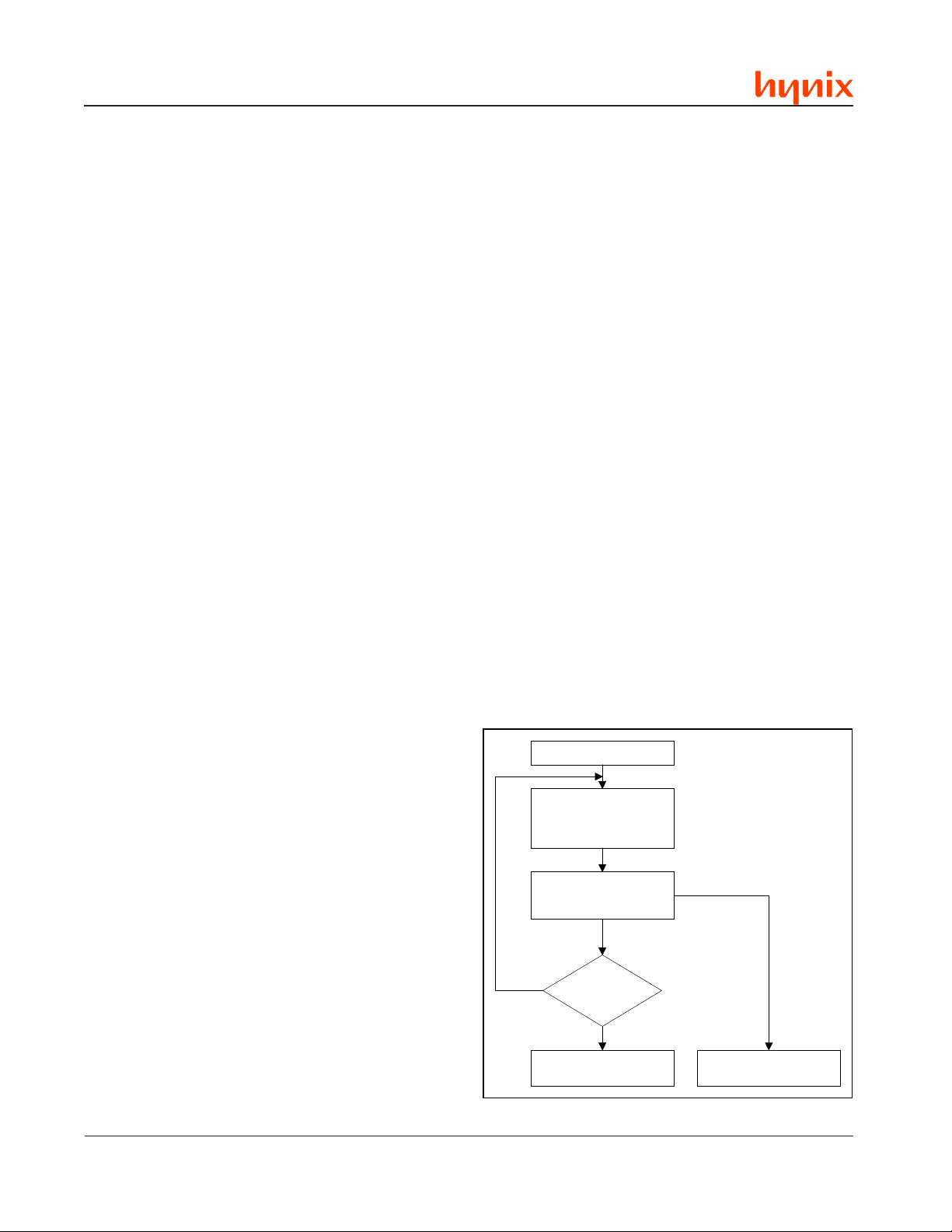

The flow chart in Figure 1 illustrates the procedure for protecting sectors, and timing specifications and waveforms are shown in the specifications section of this document. Verification of protection is accomplished as described in the Electronic ID Mode section and shown in the flow chart.

START

APPLY V

Set TRYCNT = 1

Set A[9] = OE# = V

Set Address:

A[17:12] = Sector to Protect

RESET# = V

CC

CE# = V

IL

WE# = V

ID

IH

IL

Wait t

WPP1

WE# = V

IH

A[9] = V

A[17:12] = Sector to Protect

OE# = CE# = V

A[6] = A[0] = VIL, A[1] = V

Data = 0x01?

Protect Another

ID

Read Data

YES

Sector?

YES

IL

IH

NO

NO

Increment TRYCNT

NO

TRYCNT = 25?

YES

DEVICE FAILURE

Figure 1. Sector Protect Procedure

Remove VID from A[9]

SECTOR PROTECT

COMPLETE

8

Rev. 5.2/May 01

Page 9

The procedure for sector unprotection is illustrated

in the flow chart in Figure 2, and timing specifications and waveforms are given at the end of this

document. Note that to unprotect any sector, all

unprotected sectors must first be protected prior

to the first unprotect write cycle.

Sectors can also be temporarily unprotected as

described in the next section.

Temporary Sector Unprotect Operation

START

RESET# = V

(All protected sector groups

become unprotected)

Perform Program or Erase

Operations

ID

HY29F400

This feature allows temporary unprotection of previously protected sectors to allow changing the

data in-system. Temporary Sector Unprotect

mode is activated by setting the RESET# pin to

V

. While in this mode, formerly protected sec-

ID

tors can be programmed or erased by invoking

the appropriate commands (see Device Commands section). Once V

is removed from RE-

ID

SET#, all the previously protected sectors are protected again. Figure 3 illustrates the algorithm.

START

NOTE: All sectors must be

previously protected.

APPLY V

Set: TRYCNT = 1

Set: NSEC = 0

Set: A[9] = CE# = OE# = V

CC

ID

Set Sector Address:

A[17:12] = Sector NSEC

A[0] = A[6] = V

A[1] = V

Read Data

Data = 0x00?

IL

IH

NO

RESET# = V

(All previously protected

sector groups return to

protected state)

TEMPORARY SECTOR

UNPROTECT COMPLETE

IH

Figure 3. T emporary Sector Unprotect

Increment TRYCNT

NO

TRYCNT = 1000?

YES

Set: RESET# = V

WE# = V

Wait t

WE# = V

A[9] = V

OE# = CE# = V

Rev. 5.2/May 01

Set:

WPP2

IH

IL

NSEC = NSEC + 1

IH

ID

IL

YES

NSEC = 10?

NO

YES

Remove VID from A[9]

SECTOR UNPROTECT

COMPLETE

DEVICE FAILURE

Figure 2. Sector Unprotect Procedure

9

Page 10

HY29F400

Electronic ID Mode Operation

The Electronic ID mode provides manufacturer and

device identification and sector protection verification through identifier codes output on DQ[7:0]

or DQ[15:0]. This mode is intended primarily for

programming equipment to automatically match

a device to be programmed with its corresponding programming algorithm. The Electronic ID information can also be obtained by the host through

a command sequence, as described in the Device Commands section.

Operation in the Electronic ID mode requires V

on address pin A[9], with additional requirements

for obtaining specific data items as listed in Table

2:

n A read cycle at address 0xXXX00 retrieves the

manufacturer code (Hynix = 0xAD).

DEVICE COMMANDS

Device operations are initiated by writing designated address and data command sequences into

the device. A command sequence is composed

of one, two or three of the following sub-segments:

an unlock cycle, a command cycle and a data

cycle. Table 4 summarizes the composition of the

valid command sequences implemented in the

HY29F400, and these sequences are fully described in Table 5 and in the sections that follow.

Writing incorrect address and data values or writing them in the improper sequence resets the

HY29F400 to the Read mode.

Read/Reset 1, 2 Commands

The HY29F400 automatically enters the Read

mode after device power-up, after the RESET#

input is asserted and upon the completion of certain commands. Read/Reset commands are not

required to retrieve data in these cases.

A Read/Reset command must be issued in order

to read array data in the following cases:

n If the device is in the Electronic ID mode, a

Read/Reset command must be written to return to the Read mode. If the device was in the

Erase Suspend mode when the device entered

the Electronic ID mode, writing the Read/Reset command returns the device to the Erase

Suspend mode.

n A read cycle at address 0xXXX01 returns the

device code:

- HY29F400T = 0x23 in Byte mode, 0x2223 in

Word mode.

- HY29F400B = 0xAB in Byte mode, 0x22AB

in Word mode.

n A read cycle containing a sector address (Table

1) in A[17:12] and the address 0x02 in A[7:0]

returns 0x01 if that sector is protected, or 0x00

if it is unprotected.

ID

Table 4. Composition of Command Sequences

dnammoC

ecneuqeS

1teseR/daeR011etoN

2teseR/daeR211etoN

margorPetyB211

esarEpihC411

esarErotceS41)2etoN(1

dnepsuSesarE010

emuseResarE010

DIcinortcelE213etoN

Notes:

1. Any number of Flash array read cycles are permitted.

2. Additional data cycles may follow. See text.

3. Any number of Electronic ID read cycles are permitted.

Note: When in the Electronic ID bus operation mode,

the device returns to the Read mode when V

moved from the A[9] pin. The Read/Reset command is

not required in this case.

kcolnU dnammoC ataD

n If DQ[5] (Exceeded Time Limit) goes High dur-

ing a program or erase operation, writing the

Read/Reset command returns the sectors to

the Read mode (or to the Erase Suspend mode

if the device was in Erase Suspend).

The Read/Reset command may also be used to

abort certain command sequences:

selcyCsuBforebmuN

is re-

ID

10

Rev. 5.2/May 01

Page 11

HY29F400

01

555

55

55AS03

AA2

AA2

SUTATS

AA

AA

3,2,1

555

555

20X)AS(

10X)tooBmottoB(BA22,)tooBpoT(3222

40X)AS(

selcyCsuB

0FARDR

0AAPDP

08

08

555

555

555

555

55

55

55

55

AA2

AA2

AA2

AA2

AA

AA

AA

AA

0900XDA

09

09

555

555

555

55

55

55

AA2

AA2

AA2

AA

AA

AA

tsriF dnoceS drihT htruoF htfiF htxiS

ddA ataD ddA ataD ddA ataD ddA ataD ddA ataD ddA ataD

555

etirW

555

555

555

selcyC

1XXX0FARDR

3

6

4

6

555

555

555

1XXX0B

1XXX03

3

3

3

droW

droW

droW

etyBAAA555AAA

etyBAAA555AAA

droW

etyBAAA555AAAAAA555AAA

etyBAAA555AAAAAA555

ecneuqeSdnammoC

8,7

8,6

2teseR/teseR

1teseR/daeR

4

5

dnepsuSesarE

esarErotceS

emuseResarE

esarEpihC

margorP

Table 5. HY29F400 Command Sequences

Rev. 5.2/May 01

droW

droW

droW

etyBAAA555AAA

etyBAAA555AAA

etyBAAA555AAA20X)tooBmottoB(BA,)tooBpoT(32

yfireVtcetorProtceS

edoCrerutcafunaM

edoCeciveD

7

Electronic ID

Legend:

X = Don’t Care PA = Address of the data to be programmed

RA = Memory address of data to be read PD = Data to be programmed at address PA

RD = Data read from location RA during the read operation SA = Sector address of sector to be erased or verified (see Note 3 and Table 1).

STATUS = Sector protect status: 0x00 = unprotected, 0x01 = protected.

Notes:

1. All values are in hexadecimal. DQ[15:8] are don’t care for unlock and command cycles.

• For RA and PA, A[17:11] are the upper address bits of the byte to be read or programmed.

• For the sixth cycle of Sector Erase, SA = A[17:12] are the sector address of the sector to be erased.

2. All bus cycles are write operations unless otherwise noted.

3. Address is A[10:0] in Word mode and A[10:-1] in Byte mode. A[17:11] are don’t care except as follows:

Electronic ID mode, while in the Erase Suspend mode.

• For the fourth cycle of Sector Protect Verify, SA = A[17:12] are the sector address of the sector to be verified.

4. The Erase Suspend command is valid only during a sector erase operation. The system may read and program in non-erasing sectors, or enter the

5. The Erase Resume command is valid only during the Erase Suspend mode.

6. The second bus cycle is a read cycle.

DQ[5] goes High during a program or erase operation. It is not required for normal read operations.

7. The fourth bus cycle is a read cycle.

8. Either command sequence is valid. The command is required only to return to the Read mode when the device is in the Electronic ID command mode or if

11

Page 12

HY29F400

n In a Sector Erase or Chip Erase command se-

quence, the Read/Reset command may be

written at any time before erasing actually begins, including, for the Sector Erase command,

between the cycles that specify the sectors to

be erased (see Sector Erase command description). This aborts the command and resets the device to the Read mode. Once erasure begins, however, the device ignores Read/

Reset commands until the operation is complete.

n In a Program command sequence, the Read/

Reset command may be written between the

sequence cycles before programming actually

begins. This aborts the command and resets

the device to the Read mode, or to the Erase

Suspend mode if the Program command sequence is written while the device is in the

Erase Suspend mode. Once programming

begins, however, the device ignores Read/

Reset commands until the operation is complete.

n The Read/Reset command may be written be-

tween the cycles in an Electronic ID command

sequence to abort that command. As described

above, once in the Electronic ID mode, the

Read/Reset command must be written to return to the Read mode.

Byte/Word Program Command

sure data integrity, the aborted program command

sequence should be reinitiated once the reset

operation is complete.

Programming is allowed in any sequence. Only

erase operations can convert a stored “0” to a “1”.

Thus, a bit cannot be programmed from a “0” back

to a “1”. Attempting to do so will set DQ[5] to “1”,

and the Data# Polling algorithm will indicate that

the operation was not successful. A Read/Reset

command or a hardware reset is required to exit

this state, and a succeeding read will show that

the data is still “0”.

Figure 4 illustrates the procedure for the Byte/Word

Program operation.

Chip Erase Command

The Chip Erase command sequence consists of

two unlock cycles, followed by the erase command, two additional unlock cycles and then the

chip erase data cycle. During chip erase, all sectors of the device are erased except protected

sectors. The command sequence starts the Automatic Erase algorithm, which preprograms

and verifies the entire memory, except for protected sectors, for an all zero data pattern prior to

electrical erase. The device then provides the

required number of internally generated erase

pulses and verifies cell erasure within the proper

cell margins. The host system is not required to

The host processor programs the device a byte or

word at a time by issuing the Program command

sequence shown in Table 5. The sequence begins by writing two unlock cycles, followed by the

Program setup command and, lastly, a data cycle

specifying the program address and data. This

initiates the Automatic Programming algorithm,

which provides internally generated program

pulses and verifies the programmed cell margin.

The host is not required to provide further controls or timings during this operation. When the

Automatic Programming algorithm is complete, the

device returns to the Read mode. Several methods are provided to allow the host to determine

the status of the programming operation, as described in the Write Operation Status section.

Commands written to the device during execution

of the Automatic Programming algorithm are ignored. Note that a hardware reset immediately

terminates the programming operation. To en-

12

START

Issue PROGRAM

Command Sequence:

Last cycle contains

program Address/Data

Check Programming Status

(See Write Operation Status

Section)

Normal Exit

NO

Last Word/Byte

Done?

YES

PROGRAMMING

COMPLETE

DQ[5] Error Exit

GO TO

ERROR RECOVERY

Figure 4. Programming Procedure

Rev. 5.2/May 01

Page 13

HY29F400

provide any controls or timings during these operations.

Commands written to the device during execution

of the Automatic Erase algorithm are ignored. Note

that a hardware reset immediately terminates the

erase operation. To ensure data integrity, the

aborted Chip Erase command sequence should

be reissued once the reset operation is complete.

When the Automatic Erase algorithm is finished,

the device returns to the Read mode. Several

methods are provided to allow the host to determine the status of the erase operation, as described in the Write Operation Status section.

Figure 5 illustrates the Chip Erase procedure.

Sector Erase Command

The Sector Erase command sequence consists

of two unlock cycles, followed by the erase command, two additional unlock cycles and then the

sector erase data cycle, which specifies which

sector is to be erased. As described later in this

section, multiple sectors can be specified for erasure with a single command sequence. During

sector erase, all specified sectors are erased sequentially. The data in sectors not specified for

erasure, as well as the data in any protected sectors, even if specified for erasure, is not affected by the sector erase operation.

The Sector Erase command sequence starts the

Automatic Erase algorithm, which preprograms

and verifies the specified unprotected sectors for

an all zero data pattern prior to electrical erase.

The device then provides the required number of

START

Issue CHIP ERASE

Command Sequence

Check Erase Status

(See Write Operation Status

Section)

Normal Exit

CHIP ERASE COMPLETE

DQ[5] Error Exit

GO TO

ERROR RECOVERY

Figure 5. Chip Erase Procedure

internally generated erase pulses and verifies cell

erasure within the proper cell margins. The host

system is not required to provide any controls or

timings during these operations.

After the sector erase data cycle (the sixth bus

cycle) of the command sequence is issued, a sector erase time-out of 50 µs, measured from the

rising edge of the final WE# pulse in that bus cycle,

begins. During this time, an additional sector erase

data cycle, specifying the sector address of another sector to be erased, may be written into an

internal sector erase buffer. This buffer may be

loaded in any sequence, and the number of sectors specified may be from one sector to all sectors. The only restriction is that the time between

these additional data cycles must be less than 50

µs, otherwise erasure may begin before the last

data cycle is accepted. To ensure that all data

cycles are accepted, it is recommended that host

processor interrupts be disabled during the time

that the additional cycles are being issued and then

be re-enabled afterwards.

Note: The device is capable of accepting three ways

of invoking Erase Commands for additional sectors

during the time-out window. The preferred method,

described above, is the sector erase data cycle after

the initial six bus cycle command sequence. However,

the device also accepts the following methods of

specifying additional sectors during the sector erase

time-out:

n Repeat the entire six-cycle command sequence,

specifying the additional sector in the sixth cycle.

n Repeat the last three cycles of the six-cycle command

sequence, specifying the additional sector in the third

cycle.

If all sectors scheduled for erasing are protected,

the device returns to reading array data after approximately 100 µs. If at least one scheduled sector is not protected, the erase operation erases

the unprotected sectors, and ignores the command

for the scheduled sectors that are protected.

The system can monitor DQ[3] to determine if the

50 µs sector erase time-out has expired, as described in the Write Operation Status section. If

the time between additional sector erase data

cycles can be insured to be less than the timeout, the system need not monitor DQ[3].

Any command other than Sector Erase or Erase

Suspend during the time-out period resets the

device to reading array data. The system must

then rewrite the command sequence, including any

Rev. 5.2/May 01

13

Page 14

HY29F400

additional sector erase data cycles. Once the sector erase operation itself has begun, only the Erase

Suspend command is valid. All other commands

are ignored.

As for the Chip Erase command, note that a hardware reset immediately terminates the erase operation. To ensure data integrity, the aborted Sector Erase command sequence should be reissued

once the reset operation is complete.

When the Automatic Erase algorithm terminates,

the device returns to the Read mode. Several

methods are provided to allow the host to determine the status of the erase operation, as described in the Write Operation Status section.

Figure 6 illustrates the Sector Erase procedure.

Erase Suspend/Erase Resume Commands

The Erase Suspend command allows the system

to interrupt a sector erase operation to read data

from, or program data to, any sector not being

erased. The command causes the erase operation to be suspended in all sectors selected for

erasure. This command is valid only during the

sector erase operation, including during the 50 µs

time-out period at the end of the initial command

sequence and any subsequent sector erase data

cycles, and is ignored if it is issued during chip

erase or programming operations.

The HY29F400 requires a maximum of 20 µs to

suspend the erase operation if the Erase Suspend

command is issued during active sector erasure.

However, if the command is written during the timeout, the time-out is terminated and the erase operation is suspended immediately. Any subsequent attempts to specify additional sectors for

erasure by writing the sector erase data cycle (SA/

0x30) will be interpreted as the Erase Resume

command (XXX/0x30), which will cause the Automatic Erase algorithm to begin its operation. Note

that any other command during the time-out will

reset the device to the Read mode.

Once the erase operation has been suspended,

the system can read array data from or program

data to any sector not selected for erasure. Normal read and write timings and command definitions apply. Reading at any address within erasesuspended sectors produces status data on

DQ[7:0]. The host can use DQ[7], or DQ[6] and

DQ[2] together, to determine if a sector is actively

erasing or is erase-suspended. See “Write Operation Status” for information on these status bits.

START

Write First Five Cycles of

SECTOR ERASE

Command Sequence

Setup First (or Next) Sector

Address for Erase Operation

Write Last Cycle (SA/0x30)

of SECTOR ERASE

Command Sequence

Erase An

Additional Sector?

NO

14

YES

NO

Sector Erase

Time-out (DQ[3])

Expired?

YES

Figure 6. Sector Erase Procedure

Check Erase Status

(See Write Operation Status

Section)

Normal Exit

ERASE COMPLETE

Sectors which require erasure

but which were not specified in

this erase cycle must be erased

later using a new command

sequence

DQ[5] Error Exit

GO TO

ERROR RECOVERY

Rev. 5.2/May 01

Page 15

HY29F400

After an erase-suspended program operation is

complete, the host can initiate another programming operation (or read operation) within non-suspended sectors. The host can determine the status of a program operation during the erase-suspended state just as in the standard programming

operation.

The system must write the Erase Resume command to exit the Erase Suspend mode and continue the sector erase operation. Further writes of

the Resume command are ignored. Another Erase

Suspend command can be written after the device has resumed erasing.

The host may also write the Electronic ID command sequence when the device is in the Erase

Suspend mode. The device allows reading Electronic ID codes even if the addresses used for the

ID read cycles are within erasing sectors, since

the codes are not stored in the memory array.

When the device exits the Electronic ID mode, the

device reverts to the Erase Suspend mode, and

is ready for another valid operation. See Electronic

ID section for more information.

Electronic ID Command

The Electronic ID operation intended for use in

programming equipment has been described previously. The host processor can also be obtain

the same data by using the Electronic ID command sequence shown in Table 5. This method

does not require V

on any pin. The Electronic ID

ID

command sequence may be invoked while the

device is in the Read mode or the Erase Suspend

WRITE OPERATION STATUS

mode, but is invalid while the device is actively

programming or erasing.

The Electronic ID command sequence is initiated

by writing two unlock cycles, followed by the Electronic ID command. The device then enters the

Electronic ID mode, and:

n A read cycle at address 0xXXX00 retrieves the

manufacturer code (Hynix = 0xAD).

n In Word mode, a read cycle at address

0xXXX01 returns the device code (HY29F400T

= 0x2223, HY29F400B = 0x22AB). In Byte

mode, the same information is retrieved from

address 0xXXX02 (HY29F400T = 0x23,

HY29F400B = 0xAB).

n In Word mode, a read cycle containing a sec-

tor address in A[17:12] and the address 0x02

in A[7:0] returns 0xXX01 if that sector is protected, or 0xXX00 if it is unprotected. In Byte

mode, the status information is retrieved using

0x04 in A[6:-1] (0x01 if the sector is protected,

0x00 if the sector is unprotected).

The host system may read at any address any

number of times, without initiating another command sequence. Thus, for example, the host may

determine the protection status for all sectors by

doing successive reads at the address specified

above while changing the sector address for each

cycle.

The system must write the Reset command to exit

the Electronic ID mode and return to the Read

mode, or to the Erase Suspend mode if the device was in that mode when the command sequence was issued.

The HY29F400 provides a number of facilities to

determine the status of a program or erase operation. These are the RY/BY# (Ready/Busy#)

pin and certain bits of a status word which can be

read from the device during the programming and

erase operations. Table 6 summarizes the status

indications and further detail is provided in the

subsections which follow.

RY/BY# - Ready/Busy#

RY/BY# is an open-drain output pin that indicates

whether a programming or erase Automatic Algorithm is in progress or has completed. A pull-up

resistor to V

Rev. 5.2/May 01

is required for proper operation. RY/

CC

BY# is valid after the rising edge of the final WE#

pulse in the corresponding command sequence.

If the output is Low (busy), the device is actively

erasing or programming, including programming

while in the Erase Suspend mode. If the output is

High (ready), the device has completed the operation and is ready to read array data in the normal or Erase Suspend modes, or it is in the standby

mode.

DQ[7] - Data# Polling

The Data# (“Data Bar”) Polling bit, DQ[7], indicates

to the host system whether an Automatic Algo-

15

Page 16

HY29F400

Table 6. Write and Erase Operation Status Summary

edoM noitarepO ]7[QD

ssergorpnignimmargorP#]7[QDelggoT1/0

lamroN

detelpmocesarE1ataD

rotces

esarE

dnepsuS

Notes:

1. A valid address is required when reading status information. See text for additional information.

2. DQ[5] status switches to a ‘1’ when a program or erase operation exceeds the maximum timing limit.

3. A ‘1’ during sector erase indicates that the 50 µs time-out has expired and active erasure is in progress. DQ[3] is not

applicable to the chip erase operation.

4. Equivalent to ‘No Toggle’ because data is obtained in this state.

5. Programming can be done only in a non-suspended sector (a sector not marked for erasure).

detelpmocgnimmargorPataDataD

ssergorpniesarE0elggoT1/0

dednepsusesarenihtiwdaeR

esare-nonnihtiwdaeR

rotcesdednepsus

5

ssergorpnignimmargorP

5

detelpmocgnimmargorP

1

1elggotoN0A/NelggoT1

ataDataDataDataDataD1

#]7[QDelggoT1/0

ataDataD

]6[QD ]5[QD ]3[QD ]2[QD

2

4

4

4

ataDataDataD1

2

ataDataDataD

2

ataDataDataD1

A/NA/N0

3

1

A/NA/N0

1

elggoT0

4

#YB/YR

1

rithm is in progress or completed, or whether the

device is in Erase Suspend mode. Data# Polling

is valid after the rising edge of the final WE# pulse

in the Program or Erase command sequence.

The system must do a read at the program address to obtain valid programming status information on this bit. While a programming operation is

in progress, the device outputs the complement

of the value programmed to DQ[7]. When the programming operation is complete, the device outputs the value programmed to DQ[7]. If a program operation is attempted within a protected

sector, Data# Polling on DQ[7] is active for approximately 2 µs, then the device returns to reading array data.

The host must read at an address within any nonprotected sector scheduled for erasure to obtain

valid erase status information on DQ[7]. During

an erase operation, Data# Polling produces a “0”

on DQ[7]. When the erase operation is complete,

or if the device enters the Erase Suspend mode,

Data# Polling produces a “1” on DQ[7]. If all sectors selected for erasing are protected, Data#

Polling on DQ[7] is active for approximately 100

µs, then the device returns to reading array data.

If at least one selected sector is not protected, the

erase operation erases the unprotected sectors,

and ignores the command for the selected sectors that are protected.

When the system detects that DQ[7] has changed

from the complement to true data (or “0” to “1” for

erase), it should do an additional read cycle to read

valid data from DQ[7:0]. This is because DQ[7]

may change asynchronously with respect to the

other data bits while Output Enable (OE#) is asserted low.

Figure 7 illustrates the Data# Polling test algorithm.

DQ[6] - Toggle Bit I

Toggle Bit I on DQ[6] indicates whether an Automatic Program or Erase algorithm is in progress

or complete, or whether the device has entered

the Erase Suspend mode. Toggle Bit I may be

read at any address, and is valid after the rising

edge of the final WE# pulse in the program or erase

command sequence, including during the sector

erase time-out. The system may use either OE#

or CE# to control the read cycles.

Successive read cycles at any address during an

Automatic Program algorithm operation (including

programming while in Erase Suspend mode)

cause DQ[6] to toggle. DQ[6] stops toggling when

the operation is complete. If a program address

falls within a protected sector, DQ[6] toggles for

approximately 2 µs after the program command

sequence is written, then returns to reading array

data.

16

Rev. 5.2/May 01

Page 17

While the Automatic Erase algorithm is operating,

successive read cycles at any address cause

DQ[6] to toggle. DQ[6] stops toggling when the

erase operation is complete or when the device is

placed in the Erase Suspend mode. The host may

use DQ[2] to determine which sectors are erasing

or erase-suspended (see below). After an Erase

command sequence is written, if all sectors selected for erasing are protected, DQ[6] toggles for

approximately 100 µs, then returns to reading array data. If at least one selected sector is not

protected, the Automatic Erase algorithm erases

the unprotected sectors, and ignores the selected

sectors that are protected.

START

Read DQ[7:0]

at Valid Address (Note 1)

DQ[7] = Data?

NO

NO

DQ[5] = 1?

HY29F400

Test for DQ[7] = 1?

for Erase Operation

YES

Note: In the current version of the device, unreliable

testing of DQ[6] for erase completion may occur if the

test is done before the Sector Erase Timer (DQ[3]) has

expired. It is recommended that for erase operations

the DQ[6] test be delayed for a minimum of 100 µs or

until after DQ[3] switches from a ‘0’ to a ‘1’. This anomaly

will be corrected in a future revision of the device.

DQ[2] - Toggle Bit II

Toggle Bit II, DQ[2], when used with DQ[6], indicates whether a particular sector is actively erasing or whether that sector is erase-suspended.

Toggle Bit II is valid after the rising edge of the

final WE# pulse in the command sequence. The

device toggles DQ[2] with each OE# or CE# read

cycle.

DQ[2] toggles when the host reads at addresses

within sectors that have been selected for erasure,

but cannot distinguish whether the sector is actively erasing or is erase-suspended. DQ[6], by

comparison, indicates whether the device is actively erasing or is in Erase Suspend, but cannot

distinguish which sectors are selected for erasure.

Thus, both status bits are required for sector and

mode information.

Figure 8 illustrates the operation of Toggle Bits I

and II.

YES

Read DQ[7:0]

at Valid Address (Note 1)

Test for DQ[7] = 1?

for Erase Operation

DQ[7] = Data?

(Note 2)

NO

PROGRAM/ERASE

EXCEEDED TIME ERROR

Notes:

1. During programming, the program address.

During sector erase, an address within any non-protected sector

scheduled for erasure.

During chip erase, an address within any non-protected sector.

2. Recheck DQ[7] since it may change asynchronously at the same time

as DQ[5].

YES

PROGRAM/ERASE

COMPLETE

Figure 7. Data# Polling Test Algorithm

The DQ[5] failure condition will also be signaled if

the host tries to program a ‘1’ to a location that is

previously programmed to ‘0’, since only an erase

operation can change a ‘0’ to a ‘1’.

For both of these conditions, the host must issue

a Read/Reset command to return the device to

the Read mode.

DQ[5] - Exceeded Timing Limits

DQ[5] is set to a ‘1’ when the program or erase

time has exceeded a specified internal pulse count

limit. This is a failure condition that indicates that

the program or erase cycle was not successfully

completed. DQ[5] status is valid only while DQ[7]

or DQ[6] indicate that the Automatic Algorithm is

in progress.

Rev. 5.2/May 01

DQ[3] - Sector Erase Timer

After writing a Sector Erase command sequence,

the host may read DQ[3] to determine whether or

not an erase operation has begun. When the

sector erase time-out expires and the sector erase

operation commences, DQ[3] switches from a ‘0’

to a ‘1’. Refer to the “Sector Erase Command”

section for additional information. Note that the

17

Page 18

HY29F400

START

Read DQ[7:0]

at Valid Address (Note 1)

Read DQ[7:0]

at Valid Address (Note 1)

DQ[6] Toggled?

NO

(Note 4)

NO

(Note 3)

PROGRAM/ERASE

COMPLETE

:

Notes

1. During programming, the program address.

During sector erase, an address within any sector scheduled for erasure.

2. Recheck DQ[6] since toggling may stop at the same time as DQ[5] changes from 0 to 1.

3. Use this path if testing for Program/Erase status.

4. Use this path to test whether sector is in Erase Suspend mode.

YES

NO

NO

DQ[5] = 1?

YES

Read DQ[7:0]

at Valid Address (Note 1)

DQ[6] Toggled?

(Note 2)

YES

PROGRAM/ERASE

EXCEEDED TIME ERROR

Read DQ[7:0]

Read DQ[7:0]

DQ[2] Toggled?

SECTOR BEING READ

IS IN ERASE SUSPEND

Figure 8. Toggle Bit I and II Test Algorithm

sector erase timer does not apply to the Chip Erase

command.

After the initial Sector Erase command sequence

is issued, the system should read the status on

DQ[7] (Data# Polling) or DQ[6] (Toggle Bit I) to

ensure that the device has accepted the command

sequence, and then read DQ[3]. If DQ[3] is a ‘1’,

the internally controlled erase cycle has begun and

all further sector erase data cycles or commands

(other than Erase Suspend) are ignored until the

erase operation is complete. If DQ[3] is a ‘0’, the

device will accept a sector erase data cycle to mark

an additional sector for erasure. To ensure that

the data cycles have been accepted, the system

software should check the status of DQ[3] prior to

and following each subsequent sector erase data

cycle. If DQ[3] is high on the second status check,

the last data cycle might not have been accepted.

NO

YES

SECTOR BEING READ

IS NOT IN ERASE SUSPEND

HARDWARE DATA PROTECTION

The HY29F400 provides several methods of protection to prevent accidental erasure or programming which might otherwise be caused by spurious system level signals during V

power-up and

CC

power-down transitions, or from system noise.

These methods are described in the sections that

follow.

Command Sequences

Commands that may alter array data require a

sequence of cycles as described in Table 5. This

provides data protection against inadvertent writes.

18

Low V

To protect data during V

Write Inhibit

CC

power-up and power-

CC

down, the device does not accept write cycles

when VCC is less than V

(typically 3.7 volts). The

LKO

command register and all internal program/erase

circuits are disabled, and the device resets to the

Read mode. Writes are ignored until V

than V

. The system must provide the proper

LKO

is greater

CC

signals to the control pins to prevent unintentional

writes when VCC is greater than V

.

LKO

Rev. 5.2/May 01

Page 19

HY29F400

Write Pulse “Glitch” Protection

Noise pulses of less than 5 ns (typical) on OE#,

CE# or WE# do not initiate a write cycle.

Logical Inhibit

Write cycles are inhibited by asserting any one of

the following conditions: OE# = V

WE# = V

. To initiate a write cycle, CE# and WE#

IH

, CE# = VIH, or

IL

must be a logical zero while OE# is a logical one.

Power-Up Write Inhibit

If WE# = CE# = V

and OE# = VIH during power

IL

up, the device does not accept commands on the

rising edge of WE#. The internal state machine is

automatically reset to the Read mode on powerup.

Sector Protection

Additional data protection is provided by the

HY29F400’s sector protect feature, described previously, which can be used to protect sensitive

areas of the Flash array from accidental or unauthorized attempts to alter the data.

Rev. 5.2/May 01

19

Page 20

HY29F400

ABSOLUTE MAXIMUM RATINGS

4

lobmyS retemaraP eulaV tinU

T

GTS

T

SAIB

1

V

V

2NI

I

SO

CC

Notes:

1. Minimum DC voltage on input or I/O pins is –0.5 V. During voltage transitions, input or I/O pins may undershoot V

-2.0V for periods of up to 20 ns. See Figure 9. Maximum DC voltage on input or I/O pins is V

transitions, input or I/O pins may overshoot to V

2. Minimum DC input voltage on pins A[9], OE#, and RESET# is -0.5 V. During voltage transitions, A[9], OE#, and RESET#

may undershoot V

V which may overshoot to 13.5 V for periods up to 20 ns.

to –2.0 V for periods of up to 20 ns. See Figure 9. Maximum DC input voltage on these pins is +12.5

SS

3. No more than one output at a time may be shorted to V

4. Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a

stress rating only; functional operation of the device at these or any other conditions above those indicated in the

operational sections of this data sheet is not implied. Exposure of the device to absolute maximum rating conditions for

extended periods may affect device reliability.

RECOMMENDED OPERATING CONDITIONS

erutarepmeTegarotS 521+ot56-Cº

deilppArewoPhtiwerutarepmeTtneibmA 521+ot55-Cº

VottcepseRhtiwniPnoegatloV

:

SS

0.7+ot0.2-

2

#TESER,#EO,]9[A

1

sniPrehtOllA

3

tnerruCtiucriCtrohStuptuO

+2.0 V for periods up to 20 ns. See Figure 10.

CC

. Duration of the short circuit should be less than one second.

SS

1

5.21+ot0.2-

0.7+ot0.2-

002Am

+ 0.5 V. During voltage

CC

V

V

V

to

SS

lobmyS retemaraP eulaV tinU

T

A

erutarepmeTgnitarepOtneibmA07+ot0Cº

:egatloVylppuSgnitarepO

V

CC

snoisreV54-

snoisreVrehtOllA

52.5+ot57.4+

05.5+ot05.4+

V

V

Notes:

1. Recommended Operating Conditions define those limits between which the functionality of the device is guaranteed.

20 ns

0.8 V

20 ns 20 ns

VCC + 2.0 V

- 0.5 V

V

+ 0.5 V

CC

- 2.0 V

20 ns

2.0 V

20 ns 20 ns

Figure 9. Maximum Undershoot Waveform Figure 10. Maximum Overshoot Waveform

20

Rev. 5.2/May 01

Page 21

DC CHARACTERISTICS

TTL/NMOS Compatible

retemaraP noitpircseD puteStseT niM pyT xaM tinU

V=

Vot

V

NI

I

IL

I

TIL

I

OL

tnerruCdaoLtupnI

tnerruCdaoLtupnI

V

VCCV=

#TESER,#EO,]9[A

tnerruCegakaeLtuptuO

V

V

SS

V=

CC

V=

TUO

V=

CC

V=#EC

I

I

I

I

V

V

V

V

V

V

V

1CC

2CC

3CC

4CC

LI

HI

DI

LO

HO

OKL

CC

V

CC

V

CC

V

CC

dellortnoC#EC

egatloVwoLtupnI5.0-8.0V

egatloVhgiHtupnI0.2V

egatloVwoLtuptuO

egatloVhgiHtuptuO

VwoL

CC

Notes:

1. The I

2. Maximum ICC specifications are tested with VCC = VCC Max.

3. I

4. Not 100% tested.

current is listed is typically less than 2 mA/MHz with OE# at VIH.

CC

active while the Automatic Erase or Automatic Program algorithm is in progress.

CC

2,1

tnerruCdaeRevitcA

4,3,2

tnerruCetirWevitcA

2

tnerruCybdnatSLTT

V=#EC

V=#EC

V=

HI

dellortnoC#TESER

2

tnerruCybdnatSLTT

dnaDIcinortcelErofegatloV

V

CC

tcetorpnUrotceSyraropmeT

V=

V

CC

I

LO

V=

V

CC

I

4

egatloVtuokcoL

HO

,

CC

xaM

CC

CC

Vot

SS

xaM

CC

LI

=]9[A;xaM

,

CC

V=#EO,

,

HI

edoMetyB,zHM5=f

V=#EO,

LI

,

HI

edoMdroW,zHM5=f

LI

V=#EO,

HI

#TESER=#EC=#EO

V=#TESER

LI

V0.5=5.115.21V

,niM

CC

Am8.5=

,niM

CC

Am5.2-=

HY29F400

0.1±Aµ

V5.21=#TESER=#EO

9104Am

9105Am

6306Am

4.00.1Am

4.00.1Am

4.2V

2.32.4V

05Aµ

0.1±Aµ

5.0+V

CC

54.0V

Rev. 5.2/May 01

21

Page 22

HY29F400

DC CHARACTERISTICS

CMOS Compatible

retemaraP noitpircseD puteStseT niM pyT xaM tinU

V

V=

Vot

NI

I

IL

I

TIL

I

OL

tnerruCdaoLtupnI

tnerruCdaoLtupnI

V

VCCV=

#TESER,#EO,]9[A

tnerruCegakaeLtuptuO

V

V

SS

V=

CC

V=

TUO

V=

CC

V=#EC

I

I

I

I

V

V

HI

V

DI

V

V

V

V

1CC

2CC

3CC

4CC

LI

CC

V

CC

V

CC

V

CC

dellortnoC#EC

egatloVwoLtupnI5.0-8.0V

egatloVhgiHtupnIVx7.0

LO

HO

OKL

VwoL

CC

egatloVwoLtuptuO

egatloVhgiHtuptuO

Notes:

1. The I

2. Maximum ICC specifications are tested with VCC = VCC Max.

3. I

4. Not 100% tested.

5. I

current is listed is typically less than 2 mA/MHz with OE# at VIH.

CC

active while the Automatic Erase or Automatic Program algorithm is in progress.

CC

= 20 µA maximum for industrial and extended temperature versions.

CC3

2,1

tnerruCdaeRevitcA

4,3,2

tnerruCetirWevitcA

V=#EC

V=#EC

VCCV=

5,2

tnerruCybdnatSSOMC

dellortnoC#TESER

tnerruCybdnatSSOMC

egatloVtuokcoL

VCCV=

5,2

dnaDIcinortcelErofegatloV

V

CC

tcetorpnUrotceSyraropmeT

V

V=

CC

I

LO

V

V=

CC

I

HO

V=

V

CC

I

HO

3

001-=Aµ

,

CC

xaM

CC

CC

Vot

SS

xaM

CC

LI

=]9[A,xaM

,

CC

V=#EO,

,

HI

edoMetyB,zHM5=f

V=#EO,

LI

,

HI

edoMdroW,zHM5=f

LI

CC

=#TESERV

CC

=#TESERV

V=#EO,

HI

=#EC,xaM

± V5.0

CC

,xaM

± V5.0

SS

V0.5=5.115.21V

,niM

CC

Am8.5=

,niM

CC

Am5.2-=

,niM

CC

0.1±Aµ

V5.21=#TESER=#EO

05Aµ

0.1±Aµ

0204Am

8205Am

0305Am

3.05Aµ

3.05Aµ

CC

V

3.0+V

CC

54.0V

Vx58.0

CC

V

4.0-V

CC

V

2.32.4V

22

Rev. 5.2/May 01

Page 23

KEY TO SWITCHING WAVEFORMS

MROFEVAW STUPNI STUPTUO

HY29F400

ydaetS

LotHmorfgnignahC

HotLmorfgnignahC

dettimrePegnahCynA,eraCt'noDnwonknUetatS,gnignahC

TEST CONDITIONS

DEVICE

UNDER

TEST

C

L

Figure 11. Test Setup

3.0 V

6.2

KOhm

+ 5V

2.7

KOhm

All diodes

are

1N3064

or

equivalent

ylppAtoNseoD

Table 7. Test Specifications

tseT

noitidnoC

daoLtuptuOetaGLTT1

ecnaticapaCdaoLtuptuO

C(

)

L

semiTllaFdnaesiRtupnI5502sn

leveLwoLlangiStupnI0.054.054.0V

leveLhgiHlangiStupnI0.34.24.2V

tnemerusaeMgnimiTwoL

leveLlangiS

tnemerusaeMgnimiThgiH

leveLlangiS

etatSecnadepmIhgiHsienilretneC

)ZhgiH(

54- 55-

07-

tinU

09-

0303001Fp

5.18.08.0V

5.10.20.2V

0.0 V

2.4 V

0.45 V

Rev. 5.2/May 01

I

nput

1.5 V

Measurement Level

HY29F400-45 Version

2.0 V

Measurement

Levels

0.8 V

2.0 V

0.8 V

HY29F400-55, -70, -90 Versions

Figure 12. Input Waveforms and Measurement Levels

1.5 V

Output

OutputInput

23

Page 24

HY29F400

AC CHARACTERISTICS

Read Operations

retemaraP

CEDEJ dtS 54- 55- 07- 09-

t

t

t

t

t

t

t

t

VAVA

VQVA

VQLE

ZQHE

VQLG

ZQHG

XQXA

CR

t

CCA

t

EC

t

FD

t

EO

t

FD

t

HEO

t

HO

1

emiTdloH

Notes:

1. Not 100% tested.

2. See Figure 11 and Table 7 for test conditions.

1

emiTelcyCdaeR

yaleDtuptuOotsserddA

elbanEtuptuO

noitpircseD puteStseT

noitpOdeepS

niM54550709sn

V=#EC

LI

xaM54550709sn

LI

xaM54550709sn

LI

xaM51510202sn

xaM52520353sn

LI

xaM51510202sn

yaleDtuptuOotelbanEpihCV=#EO

1

ZhgiHtuptuOotelbanEpihC

yaleDtuptuOotelbanEtuptuOV=#EC

1

ZhgiHtuptuOotelbanEtuptuO

V=#EO

daeRniM0sn

dnaelggoT

gnilloP#ataD

#EC,sesserddAmorfemiTdloHtuptuO

1

tsriFsruccOrevehcihW,#EOro

niM01sn

niM0sn

tinU

Addresses

CE#

OE#

WE#

Outputs

RESET#

t

OEH

t

RC

Addresses Stable

t

ACC

t

OE

t

CE

t

OH

Output Valid

t

DF

24

RY/BY#

0 V

Figure 13. Read Operation Timings

Rev. 5.2/May 01

Page 25

AC CHARACTERISTICS

Hardware Reset (RESET#)

retemaraP

CEDEJ dtS 54- 55- 07- 09-

t

YDAER

t

YDAER

t

PR

t

HR

t

BR

Notes:

1. Not 100% tested.

2. See Figure 11 and Table 7 for test conditions.

htdiWesluP#TESERniM005sn

emiTyrevoceR#YB/YRniM0sn

noitpircseD puteStseT

citamotuAgniruD(woLniP#TESER

1

etirWrodaeRot)smhtiroglA

citamotuAgniruDTON(woLniP#TESER

1

etirWrodaeRot)smhtiroglA

1

daeRerofeBemiThgiH#TESER

HY29F400

noitpOdeepS

xaM02sµ

xaM005sn

niM05sn

tinU

RY/BY#

CE#, OE#

RESET#

RY/BY#

CE#, OE#

RESET#

0 V

t

RH

t

RP

t

Ready

Reset Timings NOT During Automatic Algorithms

t

Ready

t

t

RP

RB

Rev. 5.2/May 01

Reset Timings During Automatic Algorithms

Figure 14. RESET# Timings

25

Page 26

HY29F400

AC CHARACTERISTICS

Word/Byte Configuration (BYTE#)

retemaraP

CEDEJ dtS 54- 55- 07- 09-

t

LFLE

t

HFLE

t

ZQLF

t

VQHF

CE#

OE#

BYTE#

BYTE#

switching

from word to

byte mode

DQ[15]/A-1

DQ[14:0]

t

ELFL

noitpircseD

noitpOdeepS

woLgnihctiwS#ETYBot#ECxaM5sn

hgiHgnihctiwS#ETYBot#ECxaM5sn

Z-hgiHtuptuOotwoLgnihctiwS#ETYBxaM51510202sn

evitcAtuptuOothgiHgnihctiwS#ETYBniM54550709sn

Data Output DQ[14:0] Data Output DQ[7:0]

Output DQ[15] Address Input A-1

tinU

BYTE#

switching

from byte to

word mode

BYTE#

BYTE#

DQ[14:0]

DQ[15]/A-1

CE#

WE#

t

FLQZ

Data Output DQ[7:0] Data Output DQ[14:0]

Address Input A-1 Data Output DQ[15]

t

ELFH

t

FHQV

Figure 15. BYTE# Timings for Read Operations

Falling edge of the last WE# signal

t

SET (tAS

)

t

(tAH)

HOLD

Note: Refer to the Program/Erase Operations table for tAS and tAH specifications.

Figure 16. BYTE# Timings for Write Operations

26

Rev. 5.2/May 01

Page 27

HY29F400

AC CHARACTERISTICS

Program and Erase Operations

retemaraP

CEDEJ dtS 54- 55- 07- 09-

t

t

t

t

t

t

t

t

t

t

t

t

t

t

VAVA

LWVA

XALW

HWVD

XDHW

LWHG

LWLE

HEHW

HWLW

LWHW

1HWHW

2HWHW

3HWHW

CW

t

SA

t

HA

t

SD

t

HD

t

LWHG

t

SC

t

HC

t

PW

t

HPW

t

1HWHW

t

2HWHW

t

3HWHW

V

t

SCV

CC

t

BR

t

YSUB

1

emiTelcyCetirW

emiTputeSsserddAniM0 sn

emiTdloHsserddAniM54545454sn

emiTputeSataDniM52520354sn

emiTdloHataDniM0 sn

emiTputeS#ECniM0 sn

emiTdloH#ECniM0 sn

htdiWesluPetirWniM03035354sn

hgiHhtdiWesluPetirWniM02sn

noitarepOgnimmargorP

noitarepOesarErotceS

noitarepOesarEpihC

emiTputeSniM05sµ

yaleD#YB/YRot#EWniM03030353sn

noitpircseD

niM54550709sn

etirWerofeBemiTyrevoceRdaeRniM0 sn

pyT7sµ

edoMetyB

3,2,1

droW

edoM

5,3,2,1

noitarepOgnimmargorPpihC

droW

edoM

4,2,1

xaM003sµ

pyT21sµ

xaM005sµ

pyT6.3ces

edoMetyB

xaM8.01ces

pyT1.3ces

xaM3.9ces

pyT1ces

xaM8 ces

4,2,1

pyT11ces

xaM88ces

ecnarudnEelcyCmargorPdnaesarE

pyT000,000,1selcyc

niM000,001selcyc

#YB/YRmorfemiTyrevoceRniM0 sn

Notes:

1. Not 100% tested.

2. Typical program and erase times assume the following conditions: 25 °C, V

programming typicals assume a checkerboard pattern. Maximum program and erase times are under worst case conditions of 90 °C, V