Hyline Offroad TJ-YJ REAR SWINGOUT TIRE CARRIER ASSEMBLY User Manual

USA

Qty:

1 Swingout Tire Carrier

1 Slide Adjustable Tire Mount

1 Black Tailgate Bracket Plate

1 Machined Pivot Pin

1 Short White Plastic Alignment Block

1 Long White Plastic Alignment Block

2 Brass Washers for Pivot Pin

5 ½”-13 x 1-1/2 Gr. 8 Hex Head Bolts

5 ½” Lock Washers Gr. 8

5 ½” Flat Washers Gr. 8

2 5/16”-18 x 1-3/4” Gr. 5 Hex Head Bolts

4 5/16” Flat Washers Gr. 5

2 5/16”-18 Nylok Hex Nut Gr. 5

2 3/8” Flat Washers Gr. 5

2 3/8”-24 Nylok Hex Nut Gr. 5

1 3/8”-24 RH Thread Thin Hex Nut Gr. 5

1 3/8”-24 LH Thread Thin Hex Nut Gr. 5

1 Right Hand Thread Ball Joint Rod End

1 Left Hand Thread Ball Joint Rod End

1 1/8” PTF Stainless Steel Grease Fitting

1 Round Plastic Tube Plug

1 Aluminum Connector Rod

3 Wheel Studs

1 Black Rubber Stem Bumper

Proudly Made In

Installation Instructions:

TJ/YJ Gen II Swingout Tire

Carrier

Part Number: 250.200.120

13mm Socket

¾” Socket

½” Socket

9/16” Socket

Torx Bit

Grease Gun

Lithium Grease

Congratulations on your purchase of the Hyline Offroad Gen II Swingout Tire

Carrier. Our Products are completely manufactured in our facility located in

Perkasie, PA. They are designed and engineered by Offroad enthusiasts just like

you to be rock solid at an affordable price. Hyline Offroad would like to thank

you for your recent purchase and look forward to serving you in the future.

½” Wrench

¾” Wrench

7/16” Wrench

Wire Cutters

Hyline Offroad Staff

Vehicle Fitment:

1987-2006 Jeep Wrangler &

Unlimited

5 lb. Hammer

Or Heavy Duty Vise

Generation II Swingout Tire Carrier Installation

PLEASE READ INSTRUCTIONS BEFORE BEGINNING

INSTALLATION

Step 1 – If you have not already installed your Hyline Offroad Rear Bumper that accepts this tire carrier please do

so using the Installation Instructions for P/n 250.200.110.

***BEFORE INSTALLING TIRE CARRIER ON THE BUMPER COMPLETE STEPS 2 & 3***

Step 2 – Remove the stock tire carrier housing by unbolting the four bolts using the ½” socket. Then remove the 3 black

rubber mounts that the stock tire pressed against using the torx socket. Cut wire for third brake light as long as

possible for rewiring if desired.

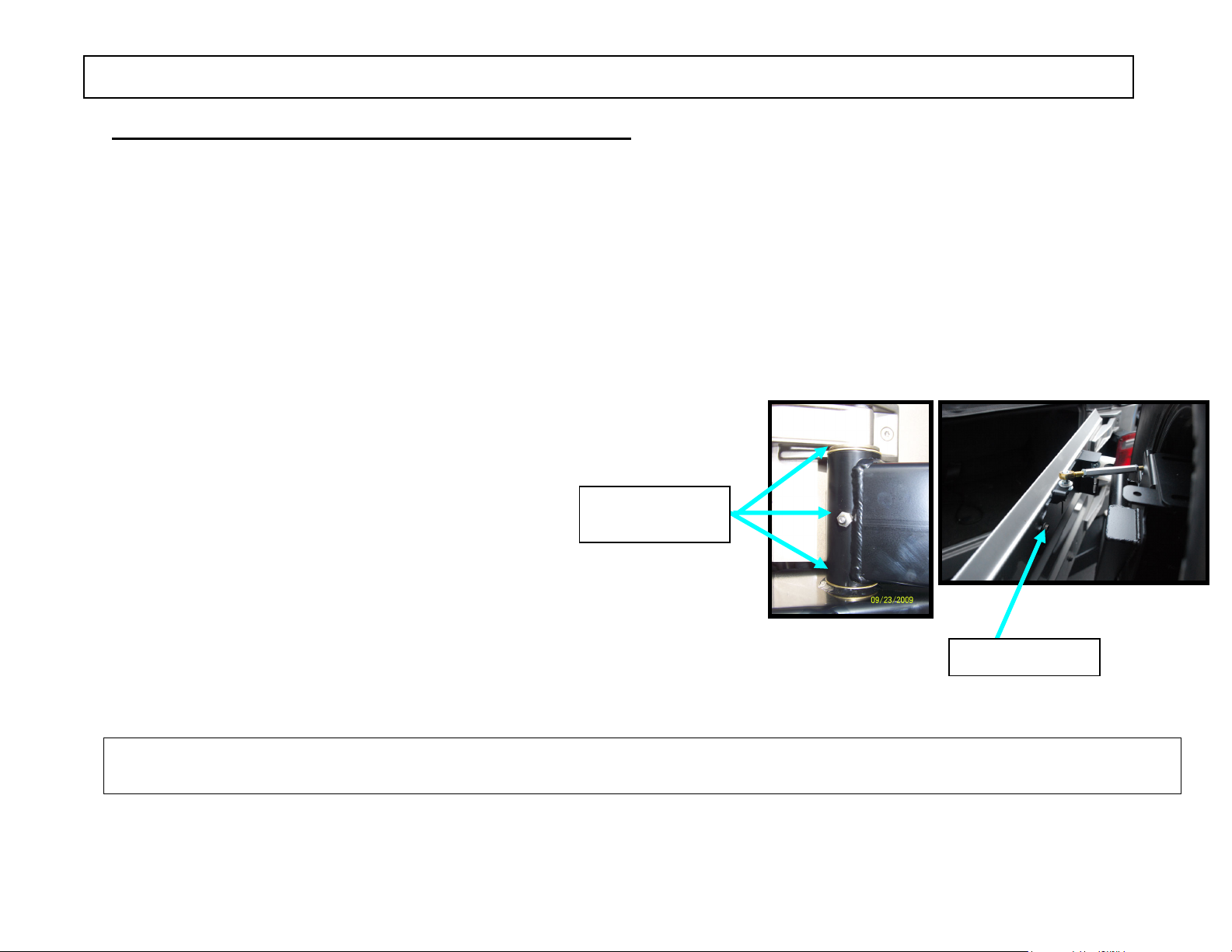

Step 3 – Install the Stainless Steel Grease Fitting using the 7/16” Wrench.

The grease fitting has pipe threads which are tapered to obtain

a leak free seal. Because of the tapered threads you may not

be able to completely screw in the grease fitting. Note: Location of

fitting might vary from picture in Figure 1.

Step 4 – Install the supplied tailgate bracket using 3 bolts that were previously

removed from stock tire carrier (Do Not Tighten Yet). Install Rod End

Fitting using 3/8” flat washers & 3/8”-24 Locking Hex Nut & tighten.

Also install the white plastic Alignment block using two-5/16-18” bolts,

four-5/16” flat washers & two-5/16-18” hex lock nuts (Do Not Tighten Yet).

See Figure 2 – Photo May Vary By Model

Note: Two Plastic Alignment Blocks have been provided. Use whichever block works best to align swingout carrier parallel to the tailgate.

Typically all models will use the shorter block.

Brass Washers

& Grease Fitting

Figure 1

Figure 2

Tailgate Bracket

Loading...

Loading...