HygroMatik WaterLine Single, WaterLine Double Plus, WaterLine Double Operating Manual

Softener devices

WaterLine Single

WaterLine Double

WaterLine Double Plus

ÁWLSDP.ENUÈ

WLSDP.EN

Operating manual

Page 2

Warning! Hazardous Voltage: All work to be performed by trained personnel only.

All electrical installation and servicing of the electrical components of this unit to

be performed by qualified electricians only. Disconnect power supply before installation and servicing!

Copyright © HygroMatik GmbH [04.05.2015]

WL-S/D/DP EN

All rights reserved

Page 3

1. Introduction ....................................................................................................................... 5

1.1 Intended Use ..................................................................................................................... 5

1.2 Typographic markings .......................................................................................................6

1.3 Documentation .................................................................................................................. 6

2. Safety instructions ............................................................................................................ 7

2.1 General information ........................................................................................................... 7

2.2 Safety instructions for the installation and start-up of the softener device ........................ 7

2.3 Safety regulations for the operation of the softener device ............................................... 8

2.4 Safety instructions for working on electrical equipment .................................................... 9

2.5 Disposal upon disassembly ............................................................................................... 9

3. Transport ............................................................................................................................ 10

3.1 General Information ........................................................................................................... 10

3.2 Temporary storage ............................................................................................................ 10

3.3 Inspecting for correctness and completeness ................................................................... 10

3.4 Scope of delivery ............................................................................................................... 10

3.5 Packaging and return consignement ................................................................................. 10

4. Functionality and device composition ............................................................................ 11

4.1 Principle of operation ......................................................................................................... 11

4.2 WL-S and WL-D/DP device composition ........................................................................... 11

4.3 Use of optional chlorine cell ..............................................................................................14

4.4 Operating cycles ................................................................................................................ 14

4.4.1 Softening ........................................................................................................................ 14

4.4.2 Regenerate ..................................................................................................................... 14

4.5 Brine .................................................................................................................................. 17

5. Installation ......................................................................................................................... 18

5.1 Basic prequisites for operating the WaterLine softener device ......................................... 18

5.2 Selecting the correct installation location of the Waterline softener device

within the house installation scenario ................................................................................ 18

5.3 Requirements on the installation site of the WaterLine softener device ............................ 19

5.4 Set-up of the WaterLine pendulum devices WL-D/DP ...................................................... 19

5.5 Attaching the tubing for raw water and soft water ............................................................. 19

5.5.1 Prerequisites for the correct connection of the tubing on the softener device ............... 19

5.5.2 Connecting the control valve to the house water installation ......................................... 20

5.5.3 Connecting the control valve to the optional mounting block ......................................... 21

5.6 Connecting of brine tube ...................................................................................................21

5.7 Make waste water connection ........................................................................................... 21

5.8 Connecting the brine tank overflow ................................................................................... 22

6. Start-up ............................................................................................................................... 23

6.1 Operating the control valve for the first time ...................................................................... 23

6.2 Run forced regeneration ....................................................................................................24

6.3 Filling the brine tank with salt tablets ................................................................................. 24

6.4 Programming the control valve .......................................................................................... 24

6.5 Setting of the optional external blendingvalve ................................................................... 26

Page 4

7. Programming of the control valve ................................................................................... 27

7.1 General information ........................................................................................................... 27

7.2 Overview on the display and operating options for the device operator

(normal operation) ............................................................................................................. 27

7.3 Programming steps for the control valve ........................................................................... 28

7.3.1 Deactivating and re-activation of the valve lock ............................................................. 28

7.4 Settings ............................................................................................................................. 28

8. Maintenance ....................................................................................................................... 30

8.1 General information ........................................................................................................... 30

8.2 Maintenance work to be carried out by the device operator .............................................. 30

8.2.1 Daily check of proper device operation .......................................................................... 30

8.2.2 Periodical inspection ...................................................................................................... 32

8.2.3 Minor Maintenance ......................................................................................................... 32

8.3 Full maintenance ............................................................................................................... 34

8.4 Troubleshooting ................................................................................................................. 34

9. Removal from service, storage and recommissioning .................................................. 35

9.1 Removal from service ........................................................................................................ 35

9.2 Storage .............................................................................................................................. 35

9.3 Recommissioning .............................................................................................................. 35

10. Optional chlorine cell ...................................................................................................... 36

10.1 Functional description and design ................................................................................... 36

10.2 Mounting the device ........................................................................................................ 36

10.3 Setting-up the control device ........................................................................................... 37

10.4 Operating ......................................................................................................................... 37

10.5 Chlorine cell maintenance ............................................................................................... 37

10.6 Technical specifications ..................................................................................................38

10. Technical Specifications ................................................................................................ 39

11. Spare parts ....................................................................................................................... 42

Page 5

1. Introduction

Dear customer,

thank you very much for choosing a HygroMatik cabinet ion

exchanger device (softener device).

In order to operate your HygroMatik softener device safely, properly and economically please carefully study this operation manual.

Only use your HygroMatik softener device when in flawless condition as well as according to its intended use, safety and hazard

conscious and in compliance with all hints and restriction given

in this operation manual.

For any further questions please contact HygroMatik as follows:

Tel.: +

41 (0)31 932 01 11 (Main offi

ce)

Tel

.: +41 (0)31 932 01 11 (

Technical Hotline)

Fax: +41 (0)31 931 08 67

e-mail: info@badgermeter.ch

For any queries or ordering of sp

are parts please have your

device data ready!

1.1 Intended Use

The HygroMatik cabinet ion exchanger device (softener device)

is ment for the production of soft water. It may only be used

according to its intended use.

Caution: Proper use includes fulfilment of the assembly, disassembly, reassembly, start-up, operating and maintenance conditions specified by us as well as disposal measures.

Only appointed qualified staff may work on or with the system.

Persons transporting or working on or with the system must

have read and understood the relevant parts of this operating

manual, particularly the 'Safety instructions' section. Staff must

also be informed of possible hazards by the operating company.

Please keep a copy of the operating manual at the location

where the device is being used.

Any additional equipment may only be built into any parts of

the softener device with the written permission of the HygroMatik

GmbH.

WaterLine softener device utilization

• The intended case of application is the operation within the

area of drinking water supply.

• All TVO (Trinkwasserverordnung = Drinking Water Ordinance) limit and guide values must be respected. The

Page 6

iron (Fe) content limit is 0.2 mg/l, max. manganese (Mn) is

0.05 mg/l

• For use with raw water with a iron and/or manganese

content exceeding these limits, only HygroMatik WaterLine

softeners of the WL-DP family type are suited

• The softener device must not be operated outside in the

exterior

• Frost protection and humidity protection must be ensured

• Allowable environmental temperature is 5 - 40 °C with a

max. r.h. of 60 percent

• Use of a system separator according to EN 1717 (former

DIN 1998, part 4) is obligatory

• Optimum flow pressure of teh device is 4.0 bar

Please note: For protection of the softener device, a water filter according to DIN 13443-1 implemented in front of the water

intake is obligatory. Without such a filter the ion exchanger resin

might silt-up within short periods of time. Also, the control valve

might get damaged by dirt ingress.

1.2 Typographic markings

• lists with items beginning with bullets: general lists

» lists with items beginning with arrows: work or operating

steps which should or must be carried out in the specified order

installation steps which must be checked

italics figure and plan names

1.3 Documentation

Storage

Please keep this operating manual in a safe place where it is

accessible at all times. If you sell the product, be sure to include

this manual. Please contact HygroMatik if the documentation is

lost.

Language versions

This operating manual is available in different languages. Please

contact your HygroMatik dealer or HygroMatik for details.

Page 7

2. Safety instructions

2.1 General information

The safety instructions are prescribed by law. They are intended

to ensure health and safety at work and accident prevention.

Warnings and safety symbols

The following safety symbols are used in this manual to indicate

hazard and risk warnings. Please familiarise yourself with these

symbols

Caution: Failure to heed this warning may result in injury or danger to life and limb and/or damage to the device.

.

Caution:Voltage: Dangerous electrical voltage! Failure to heed

this warning may result in injury or danger to life and limb.

Indicates materials and consumables which must be handled

and/or disposed of in accordance with statutory requirements.

Please note: precedes explanations for or cross-references to

other places in the text. Also, information is marked in this way

that requires particular observance.

General safety instructions for working on the HY-EKB20

softener device

Caution: Prior to working on the softener device water supply

must be cut

Caution: The device may be under pressure. Prior to working

on the device pressure must be released.

2.2 Safety instructions for the installation and

start-up of the softener device

• Integration of the softener device into the house water

installation scenario must only be carried out by an expert

company for drinking water treatment. Local and regional

regulations must by obeyed without exemption

• The electrical connection and programming of the softener

device may only be made by trained personnel

Page 8

• Please also consider water flow pressure in your supply

situation. The allowable pressure range is 2.5 to 7.0 bar. If

pressure lies above that, a pressure reducer must be

installed

•As a protection against water damage, a gully is recommended. If not available, alternatively a water-stop may

be used

• The installation ground must be imperatively level and dry.

The device is to be placed in a way that tilting by accidental impact is not possible

• Please consider adequate distance to heat sources

• We recommend the sole use of pipes made from plastic

or stainless steel. Zinc plated water pipes are note suited

for use with zero hardness water

2.3 Safety regulations for the operation of the

softener device

General

• Any form of using the device that impaires the safety of

the device must be refrained from

• Please observe all safety and hazard signs on the device

• On functional failures switch-off the device immediately

and secure against switching on again. Clear any faults on

the spot

• After repair work operational safety must be assured by

expert staff

• Only use orignal spare parts

• All other national regulations beyond the a.m. coverage

apply without restriction for operating the device

Use by persons not entitled

This device is not intended for the use by persons (including children) with limited physical, sensoric or mental capabilities or

lacking experience and/or non-existing knowledge unless supervised by a person responsable for the user‘s safety or prior

instructions given in the use of the device. Children should be

kept an eye on to make sure that no playing with the device

happens.

Operational safety

• For your own safety regularly inspect connecting pipes

and hoses to minimize the risk of flooding

• Check the brine tank in a regular time frame to make sure

that regeneration salt is always available in sufficient

volume in order not to limit the functional capability of the

device

Page 9

• To avoid contamination by dust or pest, the brine tank

should always be closed with the appropriate cover

• Even when not in use for a longer period of time, the

device should remain switched on since hygienic regenerations are run in stand-by also

2.4 Safety instructions for working on electri-

cal equipment

Warning: Only expert personnel is permitted to work on the

electrical system and the control cabinet (if applicable).

Risk of electrical shock! Prior to working on the electrical

equipment of the softener device always cut the mains connection by unplugging the power adaptor. Make sure never to touch

electrical components with wet hands.

Switch off the system immediately if faults in the electrical

energy supply occur.

Only use original fuses with the specified amperage.

Inspect the system's electrical equipment at regular intervals.

Promptly eliminate deficiencies, such as loose connections or

melted cables. After carrying out the corresponding electrical

assembly or maintenance work, test all protective measures

used (e.g. earth resistance).

Accident prevention regulations

Caution: Heed the HSW (Health and Safety at Work) regulations

for electrical installations and equipment (VBG4/BGVA3).

By doing so you protect yourself and others from harm.

2.5 Disposal upon disassembly

The operating company is responsible for disposal of the system

parts in accordance with statutory requirements.

Page 10

3. Transport

3.1 General Information

Please note: Take care when transporting the HygroMatik sof-

tener device to prevent the device and packaging from being

damaged.

Warning: Pressure tanks are very impact sensitive und must not

be rolled.

3.2 Temporary storage

Store the device in a dry and frost-free place.

3.3 Inspecting for correctness and complete-

ness

When you receive the goods, ensure that the equipment is complete and all parts are in perfect condition.

Please note: Any transport damages and/or missing parts must

be reported immediately to the shipper or supplier.

The periods in which notification of the transport company must

occur for the purposes of identifying the damage are as follows*:

* Periods are subject to change without notice.

3.4 Scope of delivery

The following items are included in the delivery:

• Softener device (in case od a device featuring two pres-

sure tanks, the second tank is separately packaged)

• Operating manual(s)

• Accessories ordered

3.5 Packaging and return consignement

Should return consignment be necessary, please consider the

following:

• Preferably use euro pallet for packaging

• Ensure frost and humidity protection during transport

• Take care when handling pressure tanks

Transport company Time after receipt of

goods

Post no later than 24 hours

Rail 7 days at the latest

Rail and road transport

companies

4 days at the latest

Parcel services immediately

Page 11

4. Functionality and device composition

4.1 Principle of operation

The HygroMatik softener device makes use of the ion exchange

method for replacing magnesium and calcium as well as strontium and barium by natrium, thus producing so called soft water.

The device works using the concurrent process and was

designed for normal salting.

The raw water fed to the softener must be iron- and maganinefree. For use with raw water not complying to this prerequisite,

the WaterLine double softener device family WL-DP featuring a

special compatible resin filling may be used .

After the production of a set volume of soft water, regeneration

occurs on a regular base. For that purpose brine water is sucked

from the brine tank into the exchanger (pressure tank). Because

of the extremely high concentration of natrium in the brine the

hardness components bound are exchanged again with natrium.

The regeneration waste water is drained to a canal. On finishing

the regeneration cycle, the brine tank is filled-up again with

water to allow for the production of new brine.

Besides the volume based regeneration, forced regeneration is

carried out on a regular base to ensure proper hygienic conditions. Otherwise, the softener may be prone to microbial contamination if no water flow exists due to longer periods of nonusage (e.g. during holiday periods) Pre-setting for forced regeneration is 3 days. This setting may be changed by the operator.

Since the WaterLine WL-S softener device features only one

pressure tank, the device is not available for soft water production during regeneration. In contrast to this, the WaterLine softener devices WL-D and WL-DP are equipped with two pressure

tanks each, allowing for soft water production in the one tank

while - in parallel - the resin in the other tank is regenerated.

Because of this mechanism, these devices are designated as

„pendulum systems“. When the resin in the active pressure tank

is dead, the control valve switches to the other pressure tank

holding freshly regenerated resin of full capacity.

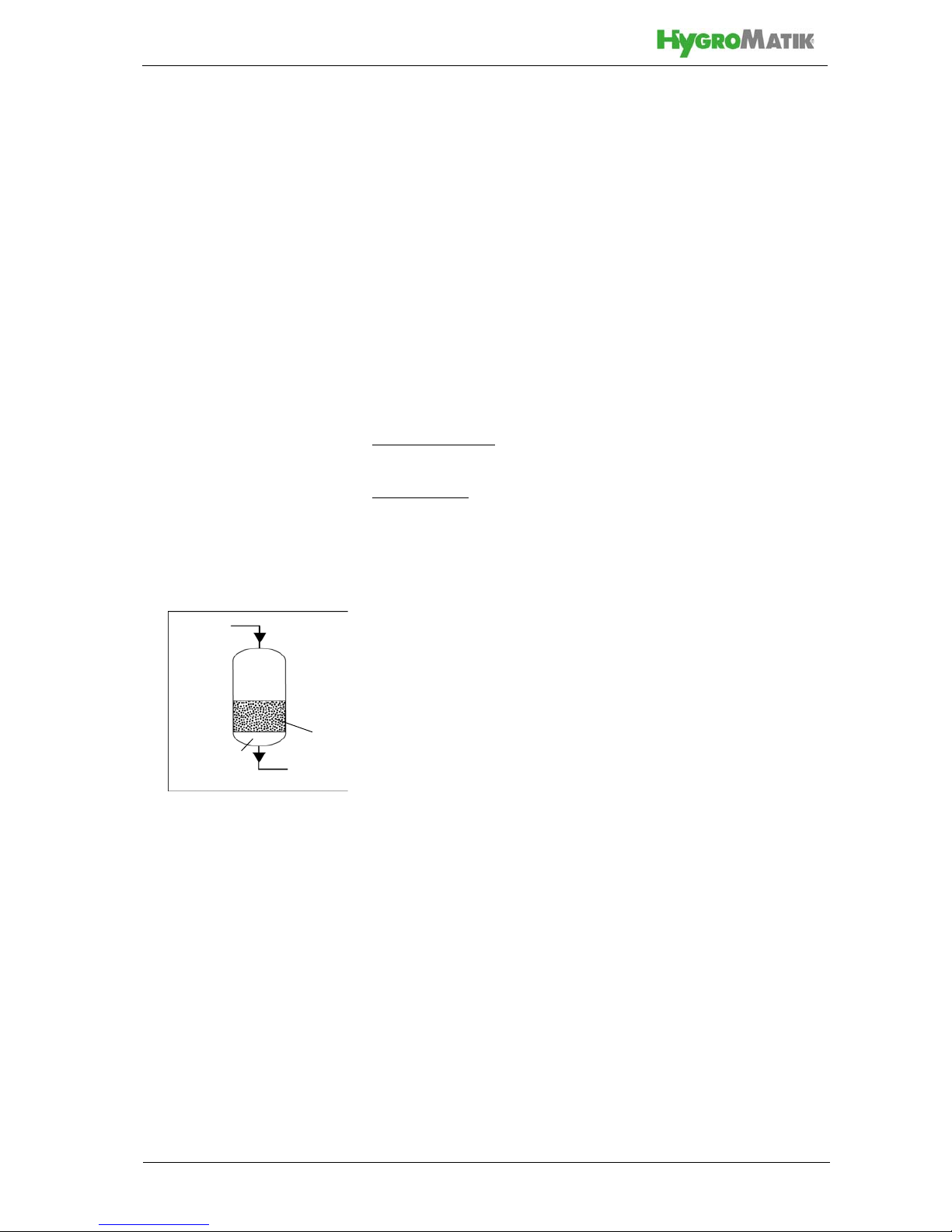

4.2 WL-S and WL-D/DP device composition

The systems are composed of a brine tank and one or two

exchangers. The resin-filled exchangers are pressure tanks

made from GRP. On top of the pressure tank (or one of the pressure tanks in case of the WaterLine WL-D/DP systems) sits the

control valve. The control valve holds a displaceable piston for

supporting all of the steps of the ion exchanger and regeneration

processes and the microprocessor-based control logic.

Control valve for WL-S, view

Control valve for WL-D/DP,

view

Page 12

Arranged in the brine tank is a stand pipe holding a riser pipe for

brine sucking. The bottom end of the riser pipe features a ball

valve that blocks sucking when the brine level has sunk accordingly. The riser pipe top end is connected to the control valve

through a brine tube.

The control valve is connected to the house water installation

either directly or via a (optionally available) mounting block

through hoses for water inlet and water outlet (optionally available water connection set including titration kit may be used).

Hose connections make use of the provided BSPT adaptors

(BSPT = British Standard Pipe Thread).

Pendulum systems feature a single control valve with the

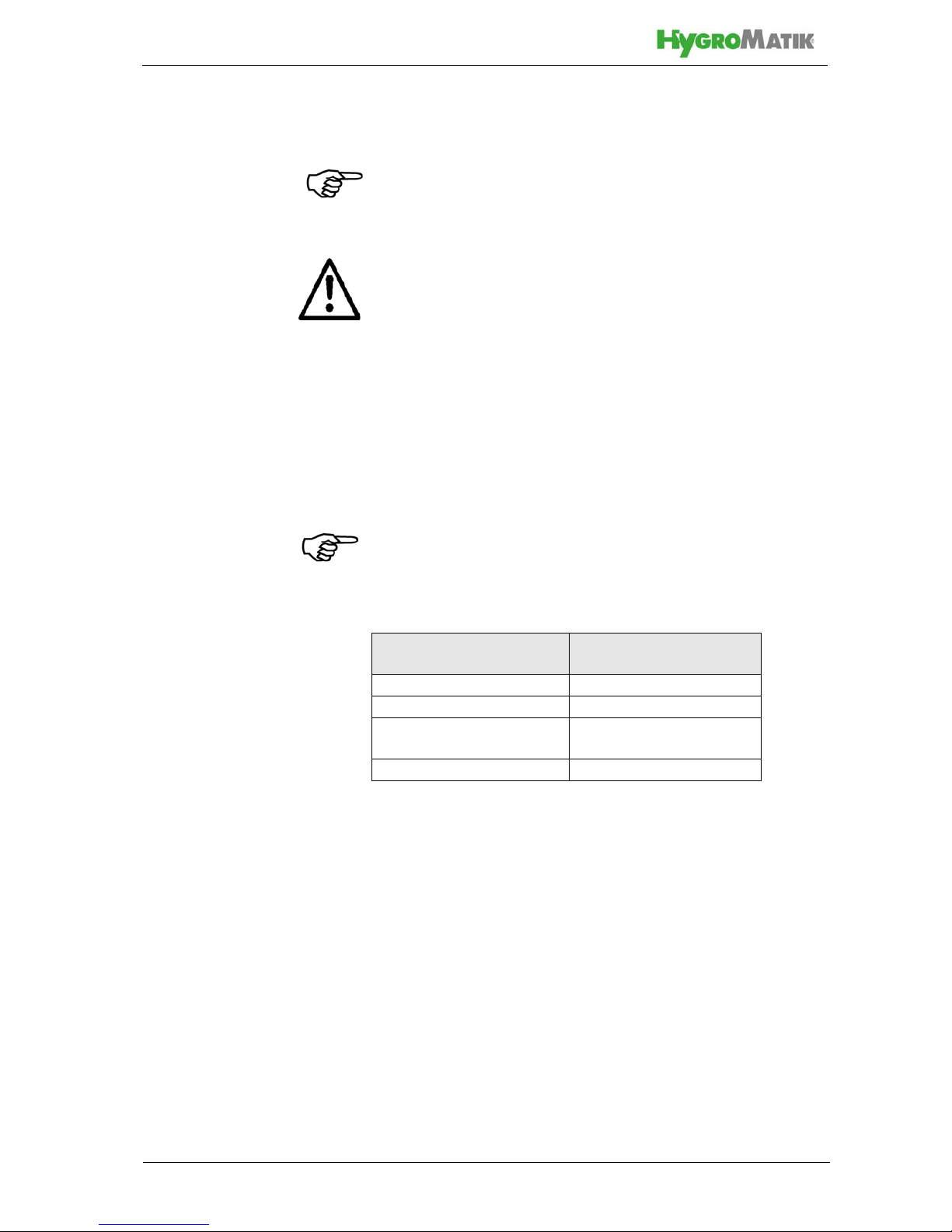

Principle design of WaterLine softener device WL-S

Control valve

Regenerations waste water connection

Soft water

connection

Brine tank

Brine tube

Raw water

connection

Resin filling

Riser pipe

Overflow

Floor drain

Riser pipe

w. ball valve

Pressure tank

Inserted

Riser pipe

Top nozzle

Bottom nozzle

*) Inserted floor screen only when resin capacity is 100 m3 x °dH or higher

floor screen *)

Brine

filling

Waste water

hose

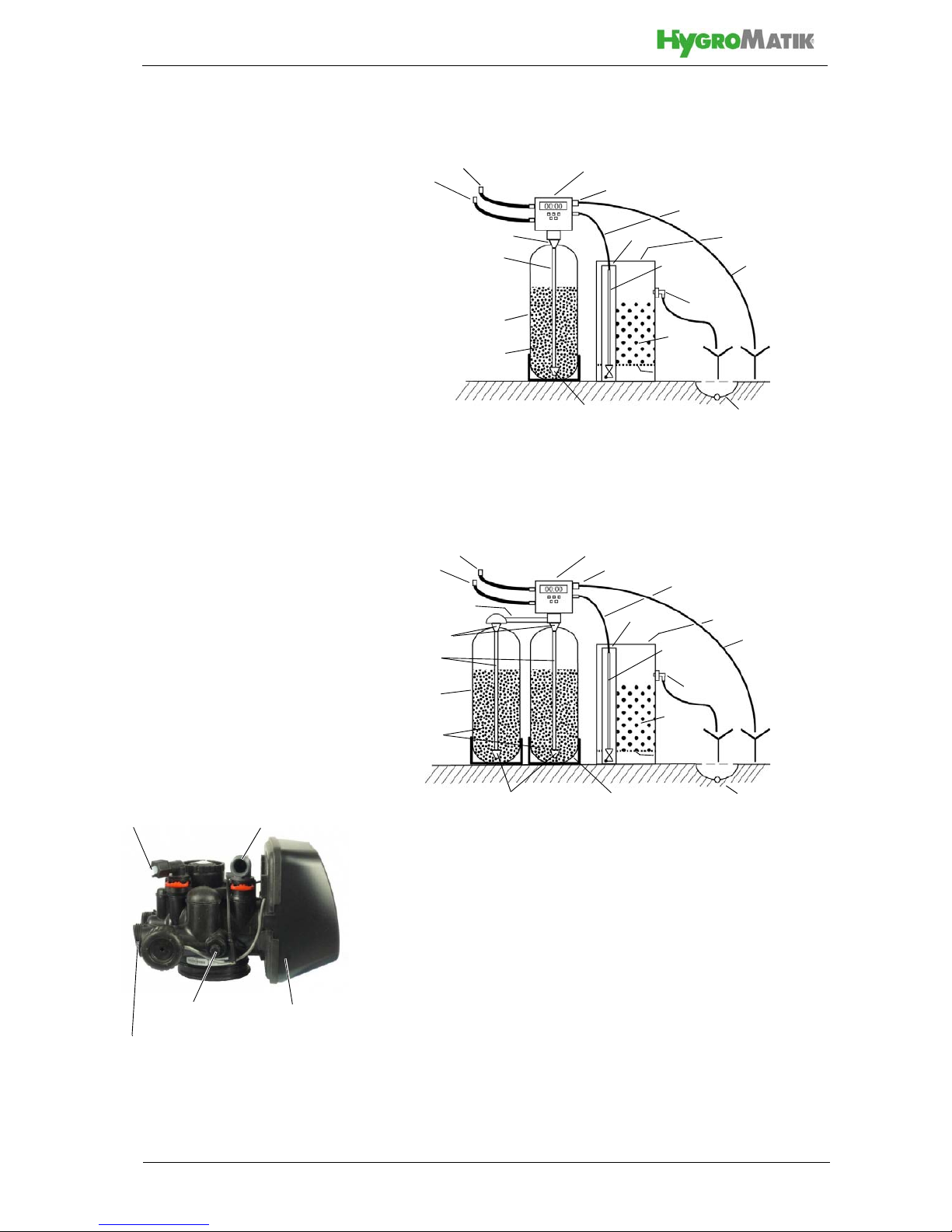

Principle design of WaterLine softener device WL-D/DP

Brine tank

Brine tube

Raw water

connection

Resin filling

Riser pipes

Overflow

Floor drain

2

nd

pressure

Control valve

Riser pipe

w. ball valve

Soft water

connection

Pressure tank

Tubing

Top nozzles

Bottom nozzles

Stand pipe

Regeneration waste water connection

*) Inserted floor screen only when resin capacity is 100 m3 x °dH or higher

Inserted

floor screen *)

tank

Brine

filling

Waste water

hose

connection

Water inlet

and outlet

Wastewater

Brine tube

Blending

valve

Electronic control

with Display and

Control valve for WL-S,

connections

control panel

connection

Page 13

expanded functionality for automatic switching between pressure tanks. The tank without a control valve is connected to the

control valve on the other pressure tank via tubings for raw and

soft water.

The waste water hose is connected to a 3/4 inch elbow on the

control valve. Draining must feature an open outlet in order to

prevent microbiological contamination.

The control logic comprises a display for time-of-the-day presentation as well as the preset and programmable parameters of the

ion changer process. Operating and programming is accomplished by use of the 5 keys designated „SET CLOCK“, „NEXT“,

„REGEN“as well as „

Δ“ und „∇“ (up/down-arrows for increasing/

decreasing settings).

Control valve for WL- D/DP, connections

Brine tube

connection

Waste water

Connection head for

2

nd

pressure tank

Soft water

Raw water

Tubing for 2

nd

pressure tank

outlet

connection

Electronic control with

display and control panel

inlet

SET

CLOCK

NEXT

REGEN

Δ

∇

(Up)

(Down)

Display and control panel

of control valve for WL-S

and WL-D/P

Page 14

4.3 Use of optional chlorine cell

Periodical chlorination of the raw water feed to a softener device

is meaningful in order to fight microbiological contamination in

the exchangers and pipes by chemical means. For this purpose,

a chlorine cell may be inserted in the brine tube by use of a tpiece connector that produces active chlorine. Any excessive

chlorin is washed out with the regeneration waste water. How to

use the chlorine cell is described in a chapter of its own.

4.4 Operating cycles

Normal operation mode of the WaterLine softener devices is

„softening“ . Alternating to this (in case of single systems) or in

parallel (with double systems), then in the currently not active

exchanger, „regenerating“ is carried out. The following operating

cycles can be distinguished in detail:

Normal operation

• Softening

Regeneration

• Backwash

• Brine and Slow wash

•Rinse

• Fill (brine tank)

4.4.1 Softening

This is the normal operation mode of the WaterLine softener

device. The control valve guides raw water into the pressure

tank filled with exchanger resin. Raw water flows top down

through the resin while the resin absorbes magnesium and calcium ions, exchanging them with sodium ions. By this mechanism, softened water is generated. The product water enters the

rise pipe in the pressure tank through the bottom nozzle and is

subsequently propagated to the control valve and, finally, to the

consumer through the product water pipe.

4.4.2 Regenerate

Since the exchange capacity of the resin is exhausted after a

certain volume of soft water produced, regeneration is required

on a regular time frame. For this purpose, NaCl brine is used

that is produced by dissolving salt tablets in the brine tank.

Regeneration point of time is determined by the control valve. To

enable this, „soft water capacity“ with respect to the Waterline

device capacity and local raw water hardness must be programmed into the the control valve logic. On reaching the

threshold set, automatic regeneration will result. The number of

regeneration occurences is only restricted by resin life time.

Softening

Soft water

Raw water

resin

Exchanger

Loading...

Loading...