HygroMatik HyLine User Manual

Electrode Steam HumidifierElectrode Steam Humidifier

Manual

Copyright HygroMatik GmbH

HyLine, March 2010

Information in this manual is subject to change or alteration without prior notice.

A Word about Water Quality

The mode of operation of all electrode steam humidifiers is based on the fact that water contains

minerals and is therefore conductive.

• "normal" tap water is ideal.

• but what is "normal" tap water exactly?

Users of HygroMatik units in the most diverse areas consider their tap water "normal."

HygroMatik typically defines "normal" as feed water with a conductivity between 200 and 500 µS/

cm (microSiemens per centimeter) at 15° C.

Some areas, however, are supp lied with tap water whose quality is outside the paramet ers specified by HygroMatik. If the HygroMatik steam humidifier's control is not adjusted correctly in these

areas, the unit cannot perform optimally. For example, the electrodes could wear out particularly

quickly or the steam production could be too low.

The operational parameters set by HygroMatik in the factory are intended for normal tap water.

However, they can very easily be reprogrammed to fit the special requirements of a particular

area. In addition, it is possible to install a plastic star in the cylinder in order to increase the life

span of the electrodes or to provide a flushing mechanism to extend maintenance intervals.

Because of this you should monitor your new unit during initial operation. Make sure that it has

been properly installed and is operating to your satisfaction.

Consult your HygroMatik specialists. We will test the quality of your water and advise you on

installation and initial operation. Your HygroMatik steam humidifier will be carefully adapted to

your particular application.

Warning, Hazardous Voltage: All work to be performed by trained personnel only.

All electrical installation and servicing of the electrical components of this unit to be

performed by qualified electricians only. Disconnect power supply before inst allation

and servicing!

Page 2

1. Introduction ....................................................................................................................... 5

1.1 Directions for Use ..............................................................................................................5

1.2 Typographic Distinctions ...................................................................................................6

1.3 Documentation ..................................................................................................................7

2. Safety Notes ....................................................................................................................... 8

2.1 Overview ...........................................................................................................................8

2.2 Guidelines for Safe Operation ...........................................................................................8

2.3 Disposal after Dismantling .................................................................................................9

3. Transport ............................................................................................................................ 10

3.1 Overview ...........................................................................................................................10

3.2 Carton outer Size and Weight ...........................................................................................10

3.3 Packing ..............................................................................................................................11

3.4 Interim Storage ..................................................................................................................11

3.5 Check for Complete and Correct Delivery of Goods .........................................................11

3.6 Included in the Delivery .....................................................................................................11

4. Operation and Installation ................................................................................................ 12

4.1 Mode of Operation .............................................................................................................12

4.2 Installation and Operation .................................................................................................12

5. Installation ......................................................................................................................... 15

5.1 Steam Humidifier Operating Environment ......................................................................... 15

5.1.1 Fitting measures .............................................................................................................16

5.1.2 Unit Dimensions HY05-HY45 ......................................................................................... 18

5.1.3 Unit Dimensions HY60-HY116 ....................................................................................... 19

5.2 Fan Unit (optional) ............................................................................................................. 20

5.2.1 Fan Unit Type VG ...........................................................................................................20

5.2.2 Fan Unit Cover ............................................................................................................... 21

5.3 Absorption Distance BN ....................................................................................................22

5.3.1 Determining the Absorption Distance ............................................................................. 22

5.3.2 Absorption Distance Nomogram .................................................................................... 24

5.4 Steam Manifold .................................................................................................................25

5.4.1 Notes on Installation ....................................................................................................... 25

5.5 Steam Line ........................................................................................................................ 29

5.6 Cover Plate ........................................................................................................................30

5.7 Drill Pattern ........................................................................................................................31

5.8 Condensate Hose ..............................................................................................................33

5.9 Types of Installation ..........................................................................................................33

5.10 Steam Solenoid Valves ...................................................................................................35

5.11 Unit Installation Check ..................................................................................................... 35

6. Water Installation .............................................................................................................. 36

6.1 Operation with Softened Water .........................................................................................36

6.2 Water Supply .....................................................................................................................37

Page 3

6.3 Water discharge ................................................................................................................ 38

6.4 Water Installation Check ...................................................................................................39

7. Electrical Connection ........................................................................................................ 40

7.1 Electrical Installation .......................................................................................................... 40

7.2 Cable Connections ............................................................................................................ 42

7.3 Fan Unit .............................................................................................................................43

7.4 Safety Interlock .................................................................................................................. 44

7.5 Wiring Diagram .................................................................................................................. 44

7.6 Electrical Installation Checklist ..........................................................................................44

8. Commissioning ................................................................................................................. 45

9. Maintenance ....................................................................................................................... 46

9.1 Maintenance Work ............................................................................................................46

9.2 Access Electrical Enclosure .............................................................................................. 47

9.3 Removing and Cleaning the Steam Cylinder .................................................................... 48

9.4 Electrode wear ..................................................................................................................53

9.4.1 Original Electrode Lengths .............................................................................................54

9.4.2 Uneven Electrode Lengths .............................................................................................54

9.5 Replacing Electrodes ........................................................................................................54

9.6 Cleaning the Blow- Down Pump ........................................................................................56

9.7 Cleaning the Water Inlet Solenoid Valve ........................................................................... 57

9.8 Checking Cable Connections and Electrode Cables .........................................................57

9.9 Checking Hoses ................................................................................................................58

9.10 Checking Operation ......................................................................................................... 58

9.11 Dismantling ......................................................................................................................58

10. EC-Declaration of Conformity ........................................................................................ 59

11. Spare Parts ...................................................................................................................... 60

12. Fax Form - Order for spare parts ................................................................................... 65

13. Technical Specification .................................................................................................. 66

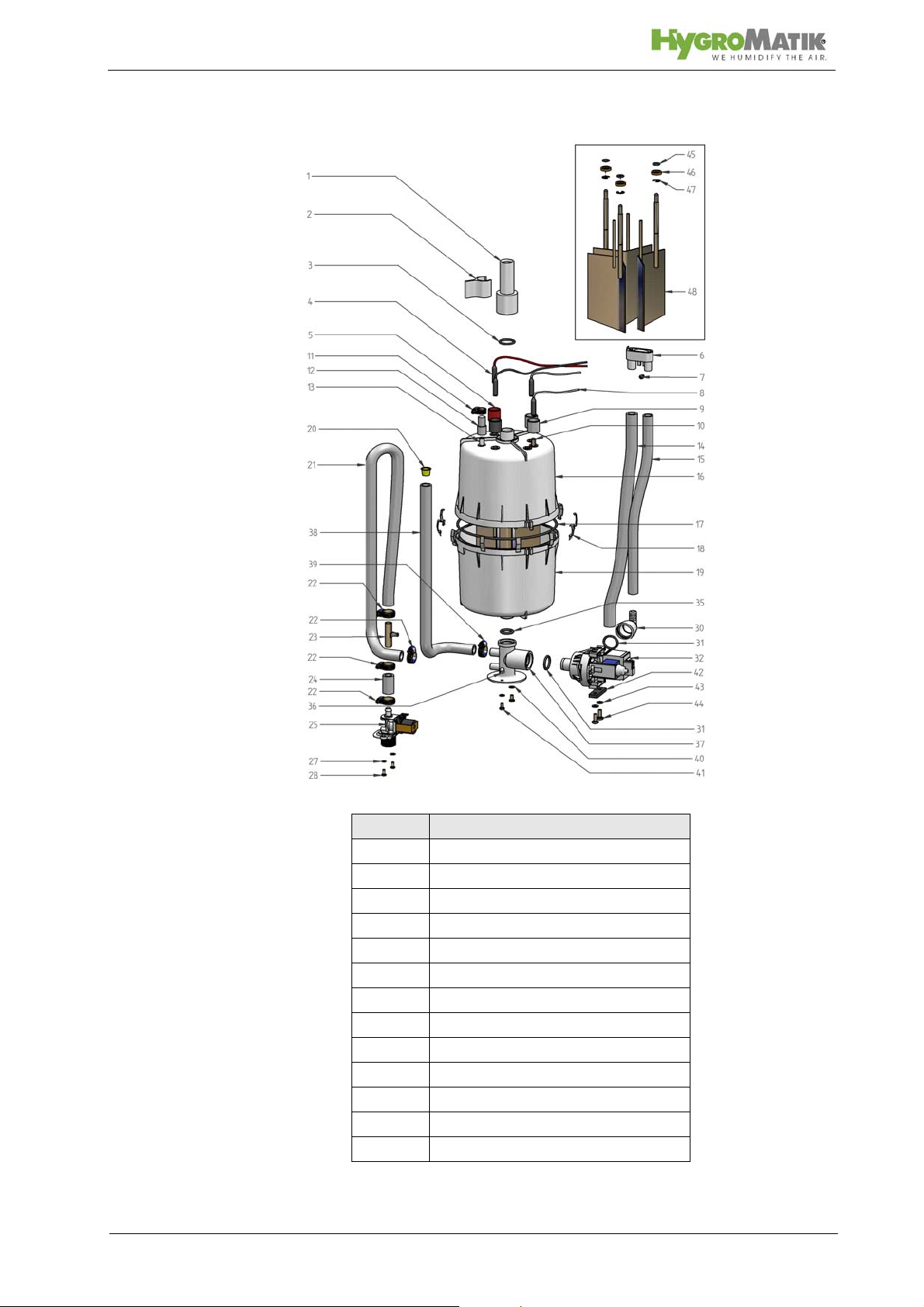

14. Exploded View ................................................................................................................. 68

15. View of housing ............................................................................................................... 69

Page 4

1. Introduction

Dear Customer,

Thank you for choosing a steam humidifier.

HygroMatik steam humidifiers represent the latest in humidifica-

tion technology.

They will impress you with their safety, ease of use and econom-

ical operation.

In order to operate your HygroMatik steam humidifier safely,

properly and efficiently, please read these operatin g instructions.

Employ your steam humidifier only in sound condition and as

directed. Consider potential hazards and safety issues and follow all the recommendations in these instructions.

If you have additional questions, please contact us:

Tel.: +49-(0)4193 / 895-0 (Main Number)

Tel.: +49-(0)4193 / 895-293 (Technical Support Hotline)

Fax: +49-(0)4193 / 895-33

e-mail: hot1@HygroMatik.de

For all technical questions or spare parts orders, please be prepared to provide unit type and serial number (see name plate on

the unit).

1.1 Directions for Use

The HygroMatik steam humidifier is intended for steam production.

Proper usage also entails following HygroMatik's instructions for

installation, dismantling, reassembly, initial operation and operation and maintenance, as well as disposal procedures.

Only qualified, authorized personnel may operate or service the

unit. Workers who transport or service the unit must have read

and understood the relevant sections of the operating instructions, especially the section "Safety Notes." In addition, staff

must receive safety training about potential hazards from the

operator. Place a copy of the operating instructions at the location where the unit is operated.

Page 5

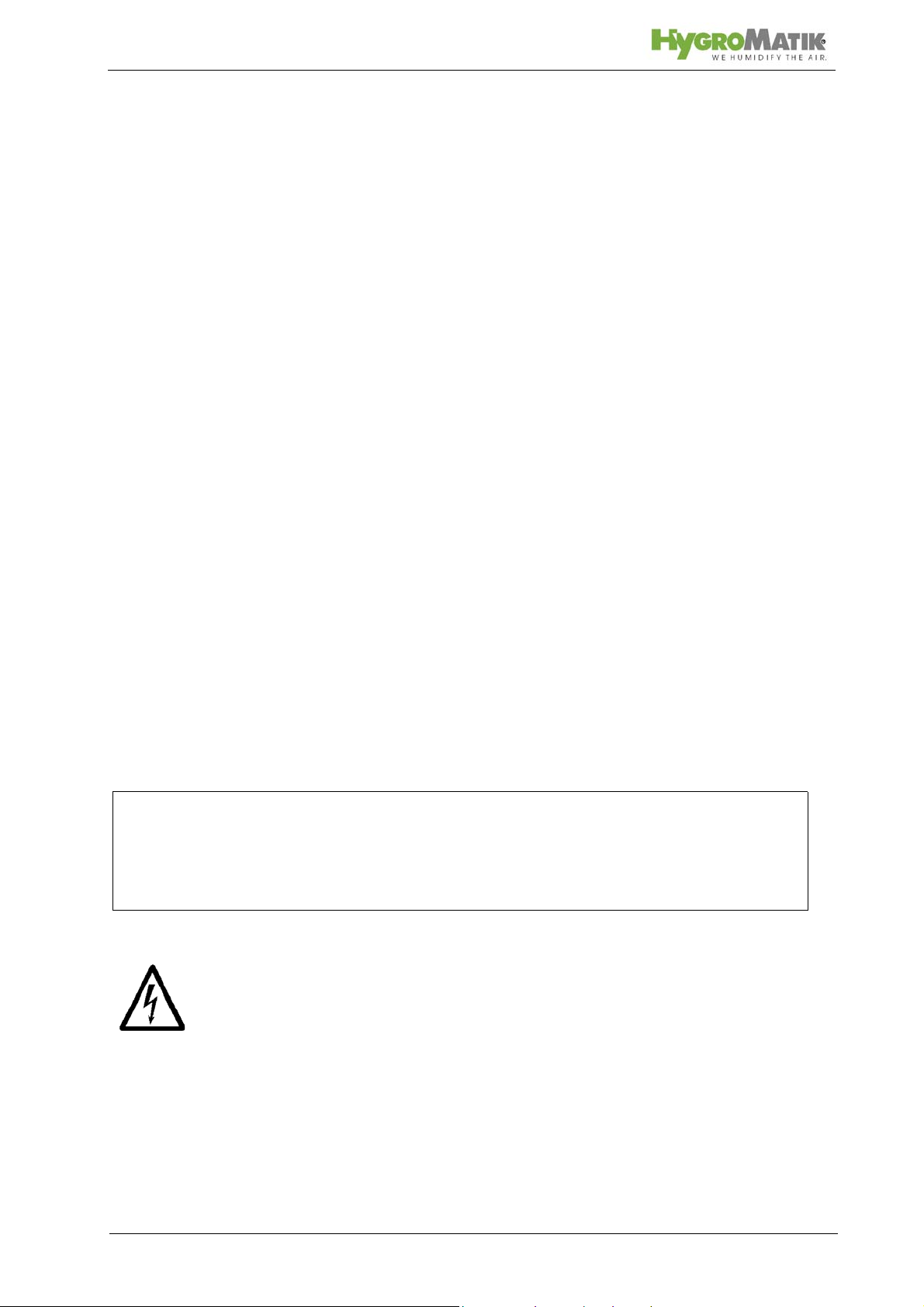

Use feed water with a conductivity between 125 and 1250 µS/

cm only

D1: Lower threshold

C1: Range of reduced conductivity (adjustments recommend ed)

A: Normal tap water

B: Range of heightened conductivity

C2: Range of high conductivity (adjustments recommended)

D2: Upper threshold

Warning: HygroMatik steam humidifiers emit steam with a temperature of 100° C. The steam may not be inhaled directly.

The HygroMatik Steam Humidifier is not designed for out door fitting

1.2 Typographic Distinctions

preceded by a bullet: general specifications.

» preceded by an arrow: Procedures for servicing or

maintenance which should or must be performed in the

indicated order.

Installation step which must be checked off.

italics Terms used with graphics or drawings..

Page 6

1.3 Documentation

Retention

Please retain these operating instructions in a secure, always

accessible location. If the product is resold, turn the documentation over to the new operator . If the document ation is lost, please

contact HygroMatik.

Versions in Other Languages

These operating instructions are available in several languages.

If interested, please contact HygroMatik or your HygroMatik

dealer.

Page 7

2. Safety Notes

2.1 Overview

These safety notes are required by law. They promote workplace safety and accident prevention.

Warnings and Safety Symbols

The safety symbols below identify sections containing warnings

about hazards or potential dangers. Please familiarize yourself

with these symbols.

Warning: Failure to observe this warning may result in serious

injury or death and/or damage to the unit.

Danger, Hazardous Voltage: Hazardous electrical current!

Failure to observe this warning may result in injury or even seri-

ous injury or death.

Warning: Failure to follow these instructions may result in dam-

age to the unit due to electrostatic discharge. The electronic

components of the humidifier control are very sensitive to electrostatic discharges. In order to safeguard these components

during installation and servicing, steps must be taken to protect

against ESD.

Reminder: Materials and consumables must be handled and/or

disposed of as required by law.

Note: Appears before explanations or cross-references which

refer to other sections of the operating instructions.

2.2 Guidelines for Safe Operation

Overview

Obey all safety notes and warnings present on the unit. In case

of a malfunction, switch off the unit immediately and prevent a

restart. Repair malfunctions promptly. After any repair work,

have qualified personnel check the safe operation of the unit.

Use original spare parts only. Additional national safety regulations also fully apply to the operation of this unit.

This unit is not designed for the use by persons (also children)

with limited physical, sensory and mental abilities - or without

knowledge and experience. Unless they are supervised or

trained by a person, who is responsible for their safety.

Supervise children in order to ensure that they will not play with

the unit.

The unit is only allowed to work with connected steam hose that

safely leads the steam.

Page 8

HygroMatik steam humidifiers are IP20-protected. Make sure

that the unit is protected from drips in its installed location.

Installing a humidifier in a room without water discharge requires

safety devices to protect against water leakages.

Accident Prevention Regulations

Comply with the accident prevention regulationAccident Prevention Regulation Electrical Systems and Equipment to prevent

injury to yourself and others.

Operation of the Unit:

Do not perform any work which compromises the safety of the

unit. Regularly check that all safety and monitoring devices are

functioning normally. Do not remove or disable safety devices.

Installation, Di smantling, Maintenance and Re pair of the

Unit:

Disconnect unit components from power supply prior to maintenance or repair work.

Attaching or installing additional components is permitted only

with the written consent of the manufacturer.

Electrical

Work on the electrical system must be performed by qualified

personnel.

Disconnect unit components from power supply prior to work.

It is not allowed to connect the unit to DC voltage supply.

In case of a malfunction in the electrical power supply, switch off

the unit immediately. Use only original fuses with the appropriate

amperage rating. Regularly check the unit's electrical equipment. Promptly repair any damage, such as loose connections,

burned wiring or defective electrical insulation. After proper e lectrical installation or repair, test all safety mechanisms (such as

grounding resistance).

2.3 Disposal after Dismantling

Note: The operator is responsible for the disposal of unit compo-

nents as required by law.

Page 9

3. Transport

3.1 Overview

Note: Proceed carefully when transporting the steam humidifier

in order to prevent damage due to stress or careless loading and

unloading.

3.2 Carton outer Size and Weight

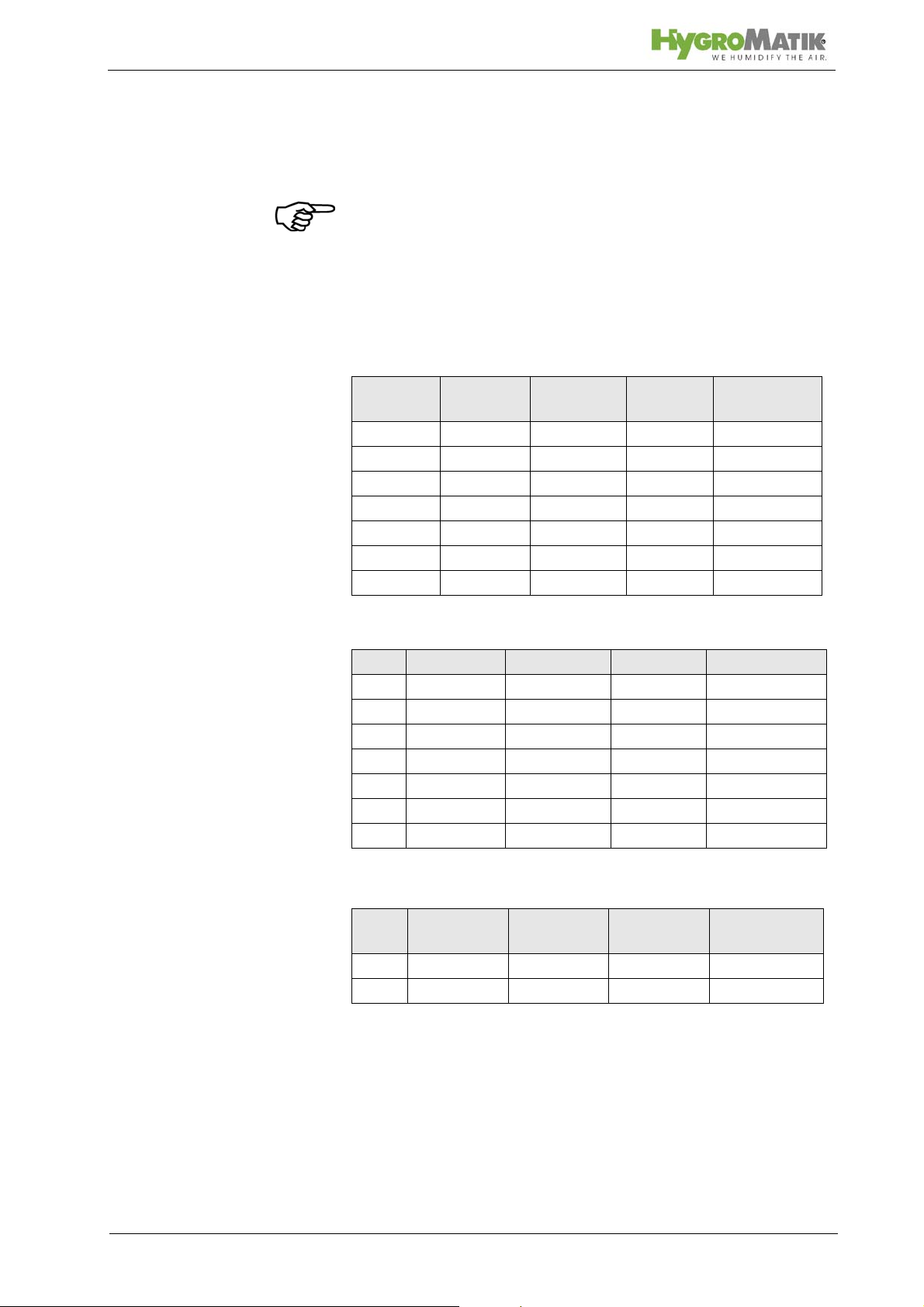

HyLine:

Type* Height

[cm]

HY05- 08 58 56 32 16

HY13- 17 75 63 37 24

HY23 75 63 37 25

HY30 81 67 41 33

HY45 88 76 48 46

HY60 80 104 41 54

HY90- 116 90 117 48 77

CompactLine:

Type* Height [cm] Width [cm] Depth [cm] Weight [kg]

C6 52 50 28 13

C10 58 51 31 14

C17 75 54 37 22

C22 75 54 37 22

C30 75 58 37 23

C45 81 63 41 25

C58 90 72 48 36

Width

[cm]

Depth

[cm]

Weight

[kg]

MiniSteam:

Type**Height [cm] Width [cm] Depth [cm] Weight[kg]

MS 5 59 48 28 13

MS 10 68 51 31 15

* Dimensions and weights may vary slightly.

Page 10

3.3 Packing

Note: Notice the symbols affixed to the packing box.

3.4 Interim Storage

Store the unit in a dry place and protect from frost.

3.5 Check for Complete and Correct Delivery of Goods

Upon receipt of the unit, confirm that:

the type and serial number on the name plate match

those specified in the order and delivery documents

and

the equipment is complete and all parts are in perfect

condition

Note: In case of damage during shipment or missing parts,

immediately notify the carrier or supplier in writing.

Time limits for filing freight claims with shipping companies are*:

Shipping Companies After Receipt of Goods

Mail no later than 24 hours

Rail no later than 7 days

Truck and Rail Carriers no later than 4 days

Parcel Service immediately

* Time limits for some services subject to change.

3.6 Included in the Delivery

The delivery includes:

Unit of the selected humidifier type including selected

control.

Water installation hose 0,6m, 3/4".

Mounting set with anchors and screws. For HyLine

types HY45 to HY116, extra mounting bar.

Operating Instructions for the unit and the control.

Ordered accessories (steam manifold, steam hose,

condensate hose, etc.).

Maintenance o-ring set for steam cylinder.

Page 11

4. Operation and Installation

4.1 Mode of Operation

The HygroMatik steam humidifier utilizes the conductivity normally present in tap water for steam production. Electrodes

inside an enclosed steam cylinder are immersed directly into the

tap water. They are connected to the alternating current.

The conductivity of the water generates an electric current

between the electrodes. In this way, the electric power supplied

is converted directly into heat without energy loss.

The amperage is a function of the available voltage, the

immersed electrode surface area, the average distance between

the electrodes and the water conductivity. The steam output of

the humidifier is determined by electric power usage, which is

regulated by increasing or decreasing the immersed surface

area of the electrodes.

Concurrently, a self-regulating control keeps conductivity within

a specified range.

The steam produced has a temperature of about 100°C with

minimal excess pressure ("pressureless steam"). It is largely

free of minerals and germ-free. Mineral deposits typically remain

behind in the cylinder.

4.2 Installation and Operation

By pressing the control switch („Pos. I”) the humidifier is turned

on. When the controller specifies an increase in humidity, the

main contactor is switched on and the electrodes (48) are supplied with power. The water inlet solenoid valve (25) feeds water

into the steam cylinder (16+19).

As soon as the electrodes are immersed, the current begins to

flow. The water is now heated. When the pre-selected output is

reached, the control turns off the solenoid valve and interrupts

the water supply.

After a short heating up period, the water between the electrodes begins to boil and vaporize. The vaporization lowers the

water level in the steam cylinder, reducing the output provided.

The inlet solenoid valve, equipped with a fine mesh filter, intermittently admits fresh water.

Humidifier power usage is continuously monitored. With a cold

start-up, the nominal current increases to 125% in order to

achieve quick-start output parameters. This activates the electronic overflow limiter which causes a partial draining of the cylinder . This reduces the immersed surface area of the electrodes,

lowering power usage.

Page 12

Please also see Section „Exploded View“.

Location Designation

1 adapter

6 vent pipe

10 max. water level sensor electrode

14 water drain, discharge

16 top part of steam cylinder

17 o-ring cylinder flange

18 cylinder flange and o-ring

19 lower part of cylinder

25 solenoid valve water inlet

32 blow-down pump

35 o-ring

37 cylinder base

48 electrodes

Page 13

The concentration of dissolved salts increases over time, which

can lead to a rise in the conductivity of the water. If this continues, conductivity may increase until a short circuit occurs. This

could damage the unit, but in any case would significantly

reduce the life span of the electrodes.

For this reason, regular, periodic blow-downs of some of the

concentrated water are very important. Following this procedure

as recommended provides stable cylinder water conductivity as

well as minimal water loss for the expected service life of the cylinder.

Water blow-down is performed by a blow-down pump (32). The

functioning of the blow-down pump is continuously monitored

during operation. If the pump is damaged, the steam humidifier

shuts down.

With normal water quality, the blow-down loss rate is between

7% and 15% of the amount of steam produced. The steam cylinder requires complete drainage every 3-8 days, regardless of

the water quality.

Mineral deposits settle in the open area below the electrodes

and are removed through periodic maintenance. The blow-down

pump itself has wide openings and can flush out smaller pieces

of mineral deposit. This extends the service life of the unit and

reduces the required maintenance interval.

During blow-downs, water flows from the pump into the drainage

system.

A sensor electrode (10) monitors the maximum

water capacity

of the cylinder. When the water level reaches the sensor electrode, the water supply is interrupted. This can occur when the

water has low conductivity or when the electrodes are worn out.

In the case of low water conductivity, however, this state usually

lasts only a short time. The built-in control and the large area

electrodes combine to produce a rapid rise in conductivity by

increasing the concentration of the water.

The steam cylinder consists of a top (16) and lower (19) part

joined with a cylinder flange. The seal between the cylinder and

cylinder base (37), as well as between the top and lower part of

the cylinder, is maintained using an o-ring (35+17).

For maintenance the cylinder can be drained by pressing the

control switch „Pos.II”.

Page 14

5. Installation

Warning: Installation of this unit to be attempted only by quali-

fied personnel. We accept no liability for damage due to faulty

installation.

Obey all safety notes and warnings present on the unit.

During installation the unit must be disconnected from its power

supply.

Attaching or installing additional components is permitted only

with the written consent of the manufacturer, or else the warranty is void.

Warning: If the installation of this unit is attempted by only one

person there is a risk that the unit drops down. We propose to

carry out the installation by two persons.

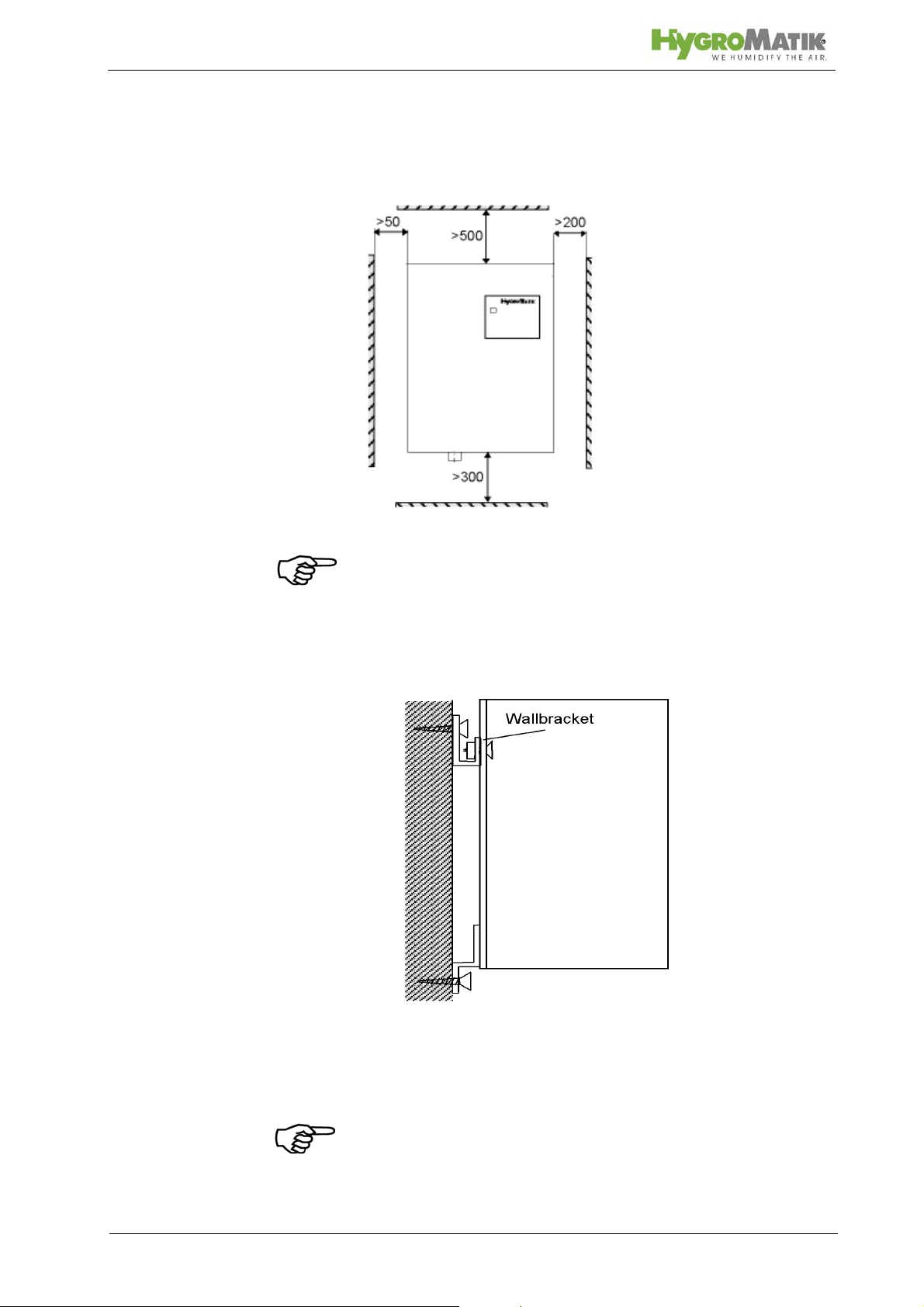

5.1 Steam Humidifier Operating Environment

Note: When selecting the installation site for the steam humidi-

fier, note that:

Ambient temperature must be between +5° and +40° C.

Relative humidity must not exceed 80% RH.

An Installation in a closed room requires aeration and if

neccessary temperature conditioning in order to reach

the above mentioned environmental conditions.

The minimum clearances indicated in the diagram

below must be observed; these are necessary to

ensure adequate ventilation for the housing.

HygroMatik humidifiers are not suitable for direct out-

door installation.

The steam humidifier should be installed as close as

possible to the steam manifold. Optimal performance is

guaranteed only with short lengths of steam and condensate hose

.

Hoses must be laid at a consistent 5-10% incline to pre-

vent sagging and kinking

.

The rear panel of the steam humidifier heats up during

operation (to a maximum of 60°C).

Take care that the

construction on which the unit is mounted is not made

of temperature-sensitive material.

Place the steam humidifier so that the unit is easily

accessible with sufficient space to perform maintenance.

The steam humidifier is not qualified for exterior appli-

cations.

Page 15

5.1.1 Fitting measures

Clearances

Note: When choosing the site for the steam humidifier, consider

the location of existing water installations (feed and drain lines).

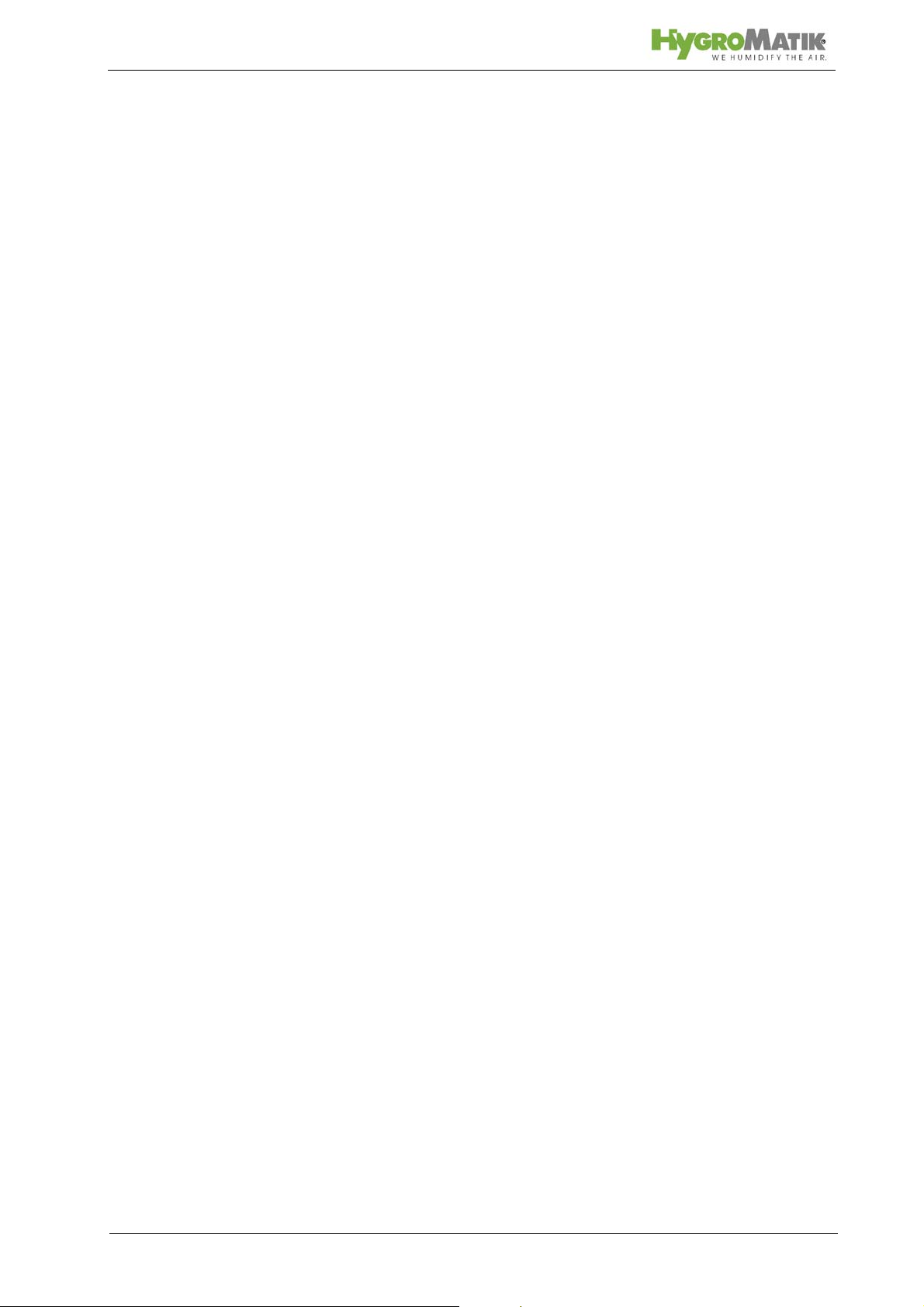

Mounting Fixtures (for HY45 to HY116)

The unit should be mounted on a stable wall.

Note: To achieve a uniform immersed surface area for the electrodes, the humidifier must be installed plumb and level.

Page 16

to Install Units Type HY05- HY30:

» Place the steam humidifier in its intended location, use

a level to adjust position, and secure. See chapter "Unit

Dimensions".

» Attach the unit to the lower mounting fixtures.

to Install Units HY45- HY116:

» Fix bracket at the intended location. See chapter "Unit

Dimensions".

» Mount the unit, adjust position using a level, and screw

tightly into the mounting fixtures.

» Attach the unit to the lower mounting fixtures.

If no suitable wall is present, we recommend construction of a

free-standing console anchored to the floor.

Page 17

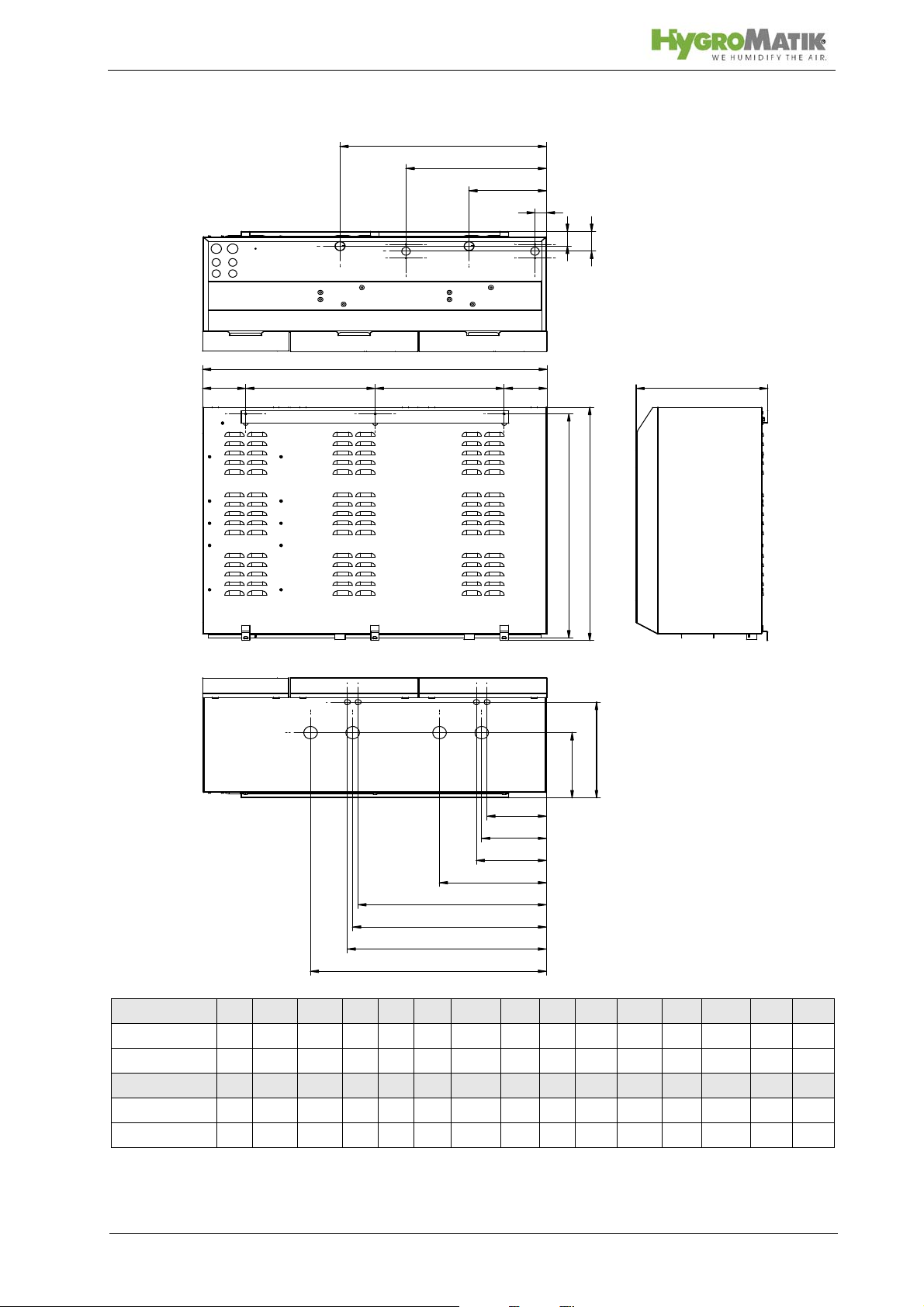

View from below

Rear view

5.1.2 Unit Dimensions HY05-HY45

View from top

Dimensions

HY05-HY08 481 449 216 415 438 43 35 35 120 120 103 - 147 65 HY13-HY23 654 520 284 486 619 63 35 38 210 152 136 - 184 96 -

Specifications in (mm)

Type /

HY30 710 560 327 515 665 58 50 38 250 172 156 - 197 106 HY45 788 653 405 588 742 68 50 48 300 209 200 330 227 153 283

a b c d e f g h i j k1 k2 m n1 n2

Page 18

c

g1

i1

g2

i2

h

f

d4 d2 d1 d3

b

j

m

n1

k1

n2

k2

n3

k3

n4

k4

e

a

5.1.3 Unit Dimensions HY60-HY116

Type / Dims. a b c d1 d2 d3 d4 e f g1 g2 h i1 i2 j

HY60 712 927 336 327 371 95 133 680 67 46 368 50 195 525 186

HY90-HY116 792 1061 404 398 398 132 132 758 67 35 432 50 238 635 220

Type / Dims k1 k2 k3 k4 m n1 n2 n3 n4

HY60 157 488 - - 204 110 441 - HY90-HY116 199 329 597 727 324 183 216 580 613

Specifications in (mm); * HY60 only one steam outlet

Page 19

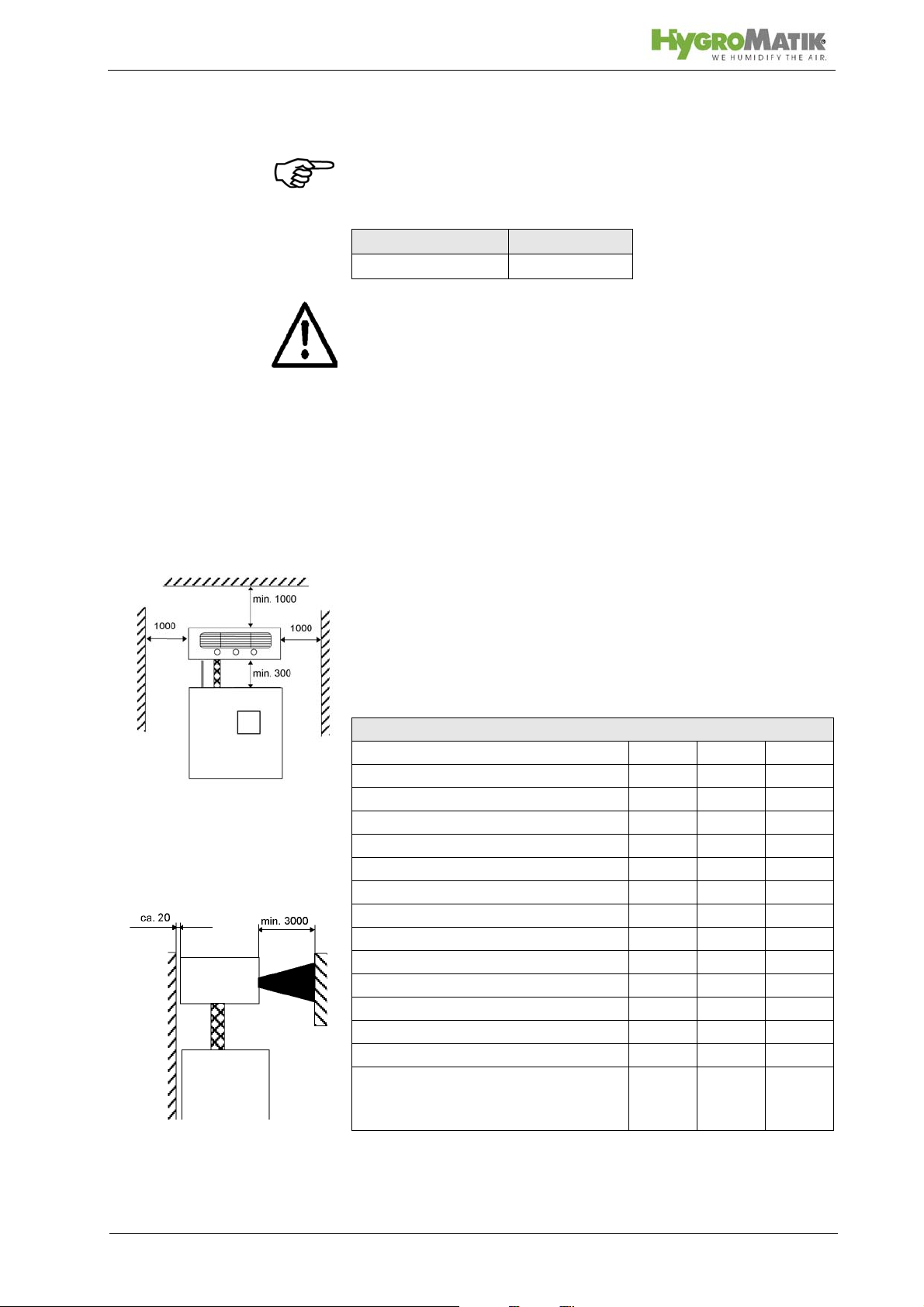

Steam

Front View Wall Installation

Side View Wall Installation

5.2 Fan Unit (optional)

Note:

The fan unit should be positioned to avoid drafts. In gen-

eral, a minimum height of 2 m is sufficient.

Install the fan unit directly on a wall.

Fan Unit Type

for wall installation VG 08, 17, 30

Warning:

During operation and a soon afterwards the steam

nozzle is hot! If touched this can cause burns to the

skin.

During operation the cross-flow fan rotates. Do not

touch the fan during operation.

During operation hot steam discharges from the nozzle.

In the field of the visible steam cloud contact can cause

burns to the skin.

During operation the cross-flow fan rotates. Do not

touch the fan during operation.

5.2.1 Fan Unit Type VG

Install the fan unit over the steam humidifier.

When employing multiple fan units, do not exceed a

maximum distance of 5 m from the steam humidifier.

Observe the clearances specified in the diagram below:

Technical Specifications Fan Unit VG

Fan Unit VG08 VG17 VG30

Quantity of Steam [kg/h] 8 17 30

Steam Inlet [mm]25 25 40

Condensate Outlet [mm]12 12 12

Airflow Capacity [cbm/h] 185 185 350

Nominal Output [W] 35 35 67

Nominal voltage [V] 230 230 230

Dimensions W [mm] 441 507 550

H [mm] 171 171 171

D [mm] 180 237 277

Weight [kg] 4,5 6 7

Sound Level (1m dis-

[dB(A)] 50 57 59

tance to the source of

noise)

Page 20

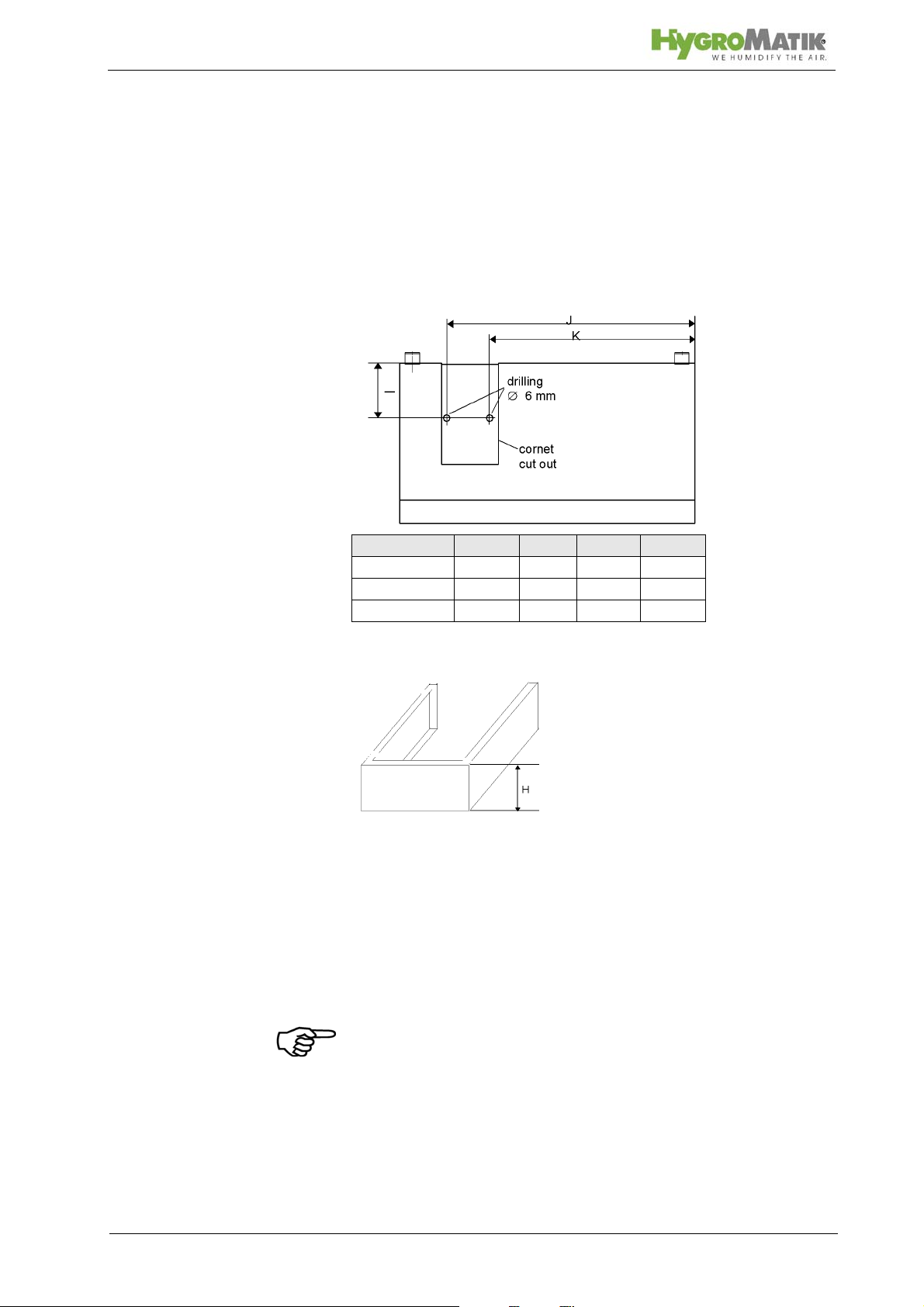

5.2.2 Fan Unit Cover

Covers (optional) for T ypes HY05 and HY30 are available to protect the steam and condensate hoses between the steam

humidifier and the fan unit. The vertical distance between the

humidifier and the fan unit is determined by the height of the

cover (see Table of Dimensions H).

» Drill two holes in the housing as specified in the fol-

lowing diagram.

Type H [mm] I [mm] J [mm] K [mm]

HY05- HY08 175 80 373 266,5

HY13-HY23 280 105 422 310

HY30 280 105 452 340

» Install the steam humidifier and fan unit on the wall (dis-

tance H). Diameter ofbore 6 mm Panel cutout

» Secure the steam hose between the humidifier and fan

unit with hose clamps

» Also using a hose clamp, attach the condensate hose

to the fan unit.

» Run condensate hose along the rear of the unit to the

water discharge. (Also see chapter "Water Discharge".)

» Lay the loop of condensate hose 200 mm directly

above the drain. The loop acts as a vapor barrier.

Note: Condensate cannot be fed directly back into the steam

cylinder.

» Slide cover between humidifier and fan unit.

» Fasten cover with the two screws supplied. Screw from

the steam panel outwards.

Page 21

Loading...

Loading...