HygroMatik HC09P, HC09, HC06, HC03, HC12 User Manual

...

Electric Heater Steam Humidifier

HeaterCompact

Installation yellow

Plumbing blue

Electrics red

Maintenance green

General Information white

ÁHC.EN0È

HC.EN

E-8881110

Manual

Page 2

Certain computer programs contained in this product [or device] were developed by HygroMatik

GmbH ("the Work(s)").

© Copyright HygroMatik GmbH

HeaterCompact [21.07.2017]

Current version of this manual can be found at: www.hygromatik.co.uk

All rights reserved.

HygroMatik GmbH grants the legal user of this product [or device] the right to use the Work(s)

solely within the scope of the legitimate operation of the product [or device]. No other right is

granted under this licence. In particular and without prejudice to the generality of the foregoing,

the Work(s) may not be used, sold, licensed, transferred, copied or reproduced in whole or in

part or in any manner or form other than as expressly granted here without the prior written consent of HygroMatik GmbH.

Information in this manual is subject to change or alteration without prior notice.

Risk of electrical shock!

Hazardous electrical high voltage!

All electrical work to be performed by certified expert staff (electricians or expert personnel with

equivalent training) only.

Page 3

1. Introduction ....................................................................................................................... 5

1.1 Typographic Distinctions ...................................................................................................5

1.2 Documentation .................................................................................................................. 5

1.3 Intended Use .....................................................................................................................6

2. Safety Instructions ............................................................................................................7

2.1 Guidelines for Safe Operation ........................................................................................... 7

2.1.1 General ........................................................................................................................... 7

2.1.2 Unit control ..................................................................................................................... 7

2.1.3 Unit operation .................................................................................................................7

2.1.4 Mounting, dismantling, maintenance and repair of the unit ............................................ 8

2.2 Electrical ............................................................................................................................9

2.2.1 Disposal after dismantling ..............................................................................................9

3. Transport ............................................................................................................................ 10

3.1 Overwiew ........................................................................................................................... 10

3.2 Transport Size and Weigth ................................................................................................ 10

3.3 Packing .............................................................................................................................. 10

3.4 Interim Storage ..................................................................................................................10

3.5 Check for Complete and Correct Delivery of Goods .........................................................10

3.6 Included in the Delivery .....................................................................................................11

4. Operation and Device Construction ................................................................................ 12

4.1 Mode of Action .................................................................................................................. 12

4.2 Installation and Method of Operation ................................................................................ 13

4.3 Internal Output Setting ...................................................................................................... 15

5. Installation ......................................................................................................................... 16

5.1 Steam Humidifier - environmental conditions .................................................................... 16

5.1.1 Equipment Dimensions HC ............................................................................................18

5.1.2 Fitting Measures .............................................................................................................20

5.2 Absorption Distance BN ....................................................................................................21

5.2.1 Determining the Absorption Distance ............................................................................. 21

5.2.2 Absorption Distance Nomogram .................................................................................... 23

5.3 Fan Unit (optional) ............................................................................................................. 24

5.4 Steam Manifold .................................................................................................................26

5.4.1 Notes on Installation ....................................................................................................... 26

5.5 Steam Line ........................................................................................................................ 30

5.6 Cover Plate ........................................................................................................................ 31

5.7 Condensate Hose .............................................................................................................. 32

5.8 Types of Installation ..........................................................................................................32

5.9 Steam Solenoid Valves .....................................................................................................34

5.10 Unit Installation Check ..................................................................................................... 34

6. Water installation ..............................................................................................................35

6.1 Water Quality ..................................................................................................................... 36

6.2 Water Supply (For Operation with Demineralized Water or Purified Condensate) ........... 36

Page 4

6.3 Water Supply (For Operation with Tap Water or Partially/Fully Softened Water) ............. 37

6.4 Feed from Holding Tank ....................................................................................................38

6.5 Water Treatment ...............................................................................................................39

6.6 Water Discharge ................................................................................................................ 39

6.7 Water Connection Installation Checklist ............................................................................ 40

7. Electrical Installation ........................................................................................................ 41

7.1 Electrical Installation .......................................................................................................... 42

7.2 Safety Interlock .................................................................................................................. 42

7.3 Control Connection ............................................................................................................ 43

7.4 Control Connection - Steam Bath Application ...................................................................43

7.4.1 Temperature Sensor Connection ...................................................................................43

7.5 Control Connection - Air Conditioning Application ............................................................ 44

7.5.1 1-step control .................................................................................................................. 44

7.5.2 Proportional Control with an external control signal ....................................................... 45

7.5.3 Proportional Control with Built-In PI-Controller ...............................................................46

7.6 Cable Connections ............................................................................................................ 47

7.7 Fan Unit .............................................................................................................................47

7.8 Wiring Diagram .................................................................................................................. 48

7.9 Electrical Installation Checklist ..........................................................................................48

8. Maintenance ....................................................................................................................... 49

8.1 Maintenance for Operation with Demineralized Water / Condensate ............................... 50

8.2 Maintenance for Operation with Tap Water or Partially Softened Water ...........................51

8.3 Access to Control Unit .......................................................................................................52

8.4 Removing and Cleaning the Steam Cylinder .................................................................... 53

8.5 Maintenance of the Control Cylinder ................................................................................. 58

8.6 Replacing Heater Elements ............................................................................................... 59

8.7 Replacing the Heater Element Sealing ............................................................................. 60

8.8 Replacing Thermo Sensor (for Heater Element) ............................................................... 61

8.9 Unlocking of a Released Thermo Sensor (for heater element) ......................................... 62

8.10 Unlocking of a Released Thermo Sensor (for Solid State Relay) ................................... 62

8.11 Removing Inlet Solenoid Valve and Cleaning Fine Mesh Filter ...................................... 63

8.12 Cleaning Blow-Down Pump .............................................................................................64

8.13 Cleaning connecting hoses and cylinder base ................................................................ 65

8.14 Checking Cable Screw Connections, Heater Element Wires .......................................... 65

8.15 Functional Check ............................................................................................................. 65

8.16 Dismantling ...................................................................................................................... 66

9. Commissioning ................................................................................................................. 67

10. EC-Declaration of Conformity ........................................................................................ 69

11. Spare Parts ...................................................................................................................... 70

12. Technical Specifications ................................................................................................ 74

13. Exploded View ................................................................................................................. 76

14. View of Cabinet ................................................................................................................ 77

Page 5

1. Introduction

Dear Customer,

Thank you for choosing a HygroMatik steam humidifier.

HygroMatik steam humidifiers represent the latest in humidifica-

tion technology.

They will impress you with their safety, ease of use and econo-

mical operation.

In order to operate your HygroMatik steam humidifier safely, pro-

perly and efficiently, please read these operating instructions.

Employ your steam humidifier only in sound condition and as

directed. Consider potential hazards and safety issues and follow all the recommendations in these instructions.

If you have additional questions, please contact us:

Tel.: +49-(0)4193 / 895-0 (Main Number)

Tel.: +49-(0)4193 / 895-293 (Technical Support Hotline)

Fax: +49-(0)4193 / 895-33

e-mail: hotline@HygroMatik.de

For all technical questions or spare parts orders, please be prepared to provide unit type and serial number (see name plate on

the unit).

1.1 Typographic Distinctions

• preceded by a bullet: general specifications.

» preceded by an arrow: Procedures for servicing or

maintenance which should or must be performed in the

indicated order.

Installation step which must be checked off.

italics Terms used with graphics or drawings.

1.2 Documentation

Retention

Please retain these operating instructions in a secure, always

accessible location. If the product is resold, turn the documentation over to the new operator . If the document ation is lost, please

contact HygroMatik.

Versions in Other Languages

These operating instructions are available in several languages.

If interested, please contact HygroMatik or your HygroMatik dealer.

Page 6

1.3 Intended Use

The HygroMatik steam generator serves for steam production

based on various water qualities or partially softened water

(valid for all of the HygroMatik humidifier models). With the HeaterLine, HeaterCompact/Kit and HeaterSlim familiy of products,

also fully desalinated water/cleaned condensate may be used.

Risk of scalding!

Steam with a temperature of 100°C is produced.

Do not inhalate directly.

Only qualified and authorised personnel may operate the unit.

Persons transporting or working on the unit must have read and

understood the respective parts of the Operation and Maintenance Instruction and especially chapter 2, „Safety Notes“. Additionally, operating personnel must be informed of any possible

dangers. You should place a copy of the Operation and Maintenance Instruction at the unit‘s operational location (or near the

unit).

The steam humidifier is not qualified for exterior installation.

Page 7

2. Safety Instructions

These safety instructions are required by law. They promote

workplace safety ans accident prevention.

2.1 Guidelines for Safe Operation

2.1.1 General

Comply with the accident prevention regulation „DGUV Regulation 3“ to prevent injury to yourself and others. Beyond that,

national regulations apply without restrictions.

2.1.2 Unit control

Do not perform any work which compromises the safety of the

unit. Obey all safety notes and warnings present on the unit.

In case of a malfunction or power grid disruption, switch off the

unit immediately and prevent a restart. Repair malfunctions

promptly.

Restricted use.

This unit is not designed for the use by persons (also children)

with limited physical, sensory and mental abilities - or without

knowledge and experience - unless they are supervised or trained by a person, who is responsible for their safety.

Supervise children in order to ensure that they will not play with

the unit.

2.1.3 Unit operation

Risk of scalding!

In case of leaking or defective components, hot steam may exit

in an uncontrolled manner.

In case of malfunction or electrical power disruption, switch off

the unit immediately and prevent from restart.

Page 8

Risk of material damage!The unit may be damaged if switched

on repeatedly following a malfunction without prior repair.Rectify

defects immediately!

The unit must not be operated on a DC power supply.

The unit may only be used connected to a steam pipe that safely

transports the steam (not valid device type MiniSteam).

Regularly check that all safety and monitoring devices are func-

tioning normally. Do not remove or disable safety devices.

2.1.4 Mounting, dismantling, maintenance and repair

of the unit

The HygroMatik steam humidifier is IP20 protected. Make sure

that the unit is not object to dripping water in the mounting location.

When installation is made in a room without a drain, safety precautions must be taken in order for to shut off the humidifier‘s

water supply in event of a leak.

Use genuine spare parts only.

After any repair work, have qualified personnel check the safe

operation of the unit.

Attaching or installing of additional components is permitted

only with the written consent of the manufacturer.

Page 9

2.2 Electrical

Risk of electrical shock!Hazardous electrical high voltage.Any

work on the electrical system may only be performed by qualified personnel.Disconnect unit components from electrical

power supply prior to work.After electrical installation or repair

work, test all safety mechanisms (such as grounding resistance).

Use only original fuses with the appropriate amperage

rating.Regularly check the unit‘s electrical equipment. Promptly

repair any damage such as loose connections or burned

wiring.Responsibility for intrinsically safe installation of the

HygroMatik steam humififiers (steam generators) is incumbent

on the installing specialist company.

2.2.1 Disposal after dismantling

The operator is responsible for the disposal of unit components

as required by law.

Page 10

3. Transport

3.1 Overwiew

Proceed carefully when transporting the steam humidifier in order

to prevent damage from rough or careless loading and unloading.

If the transport of this unit is attempted by only one person there

is a risk that the unit will drop down. We propose to transport the

unit by two persons.

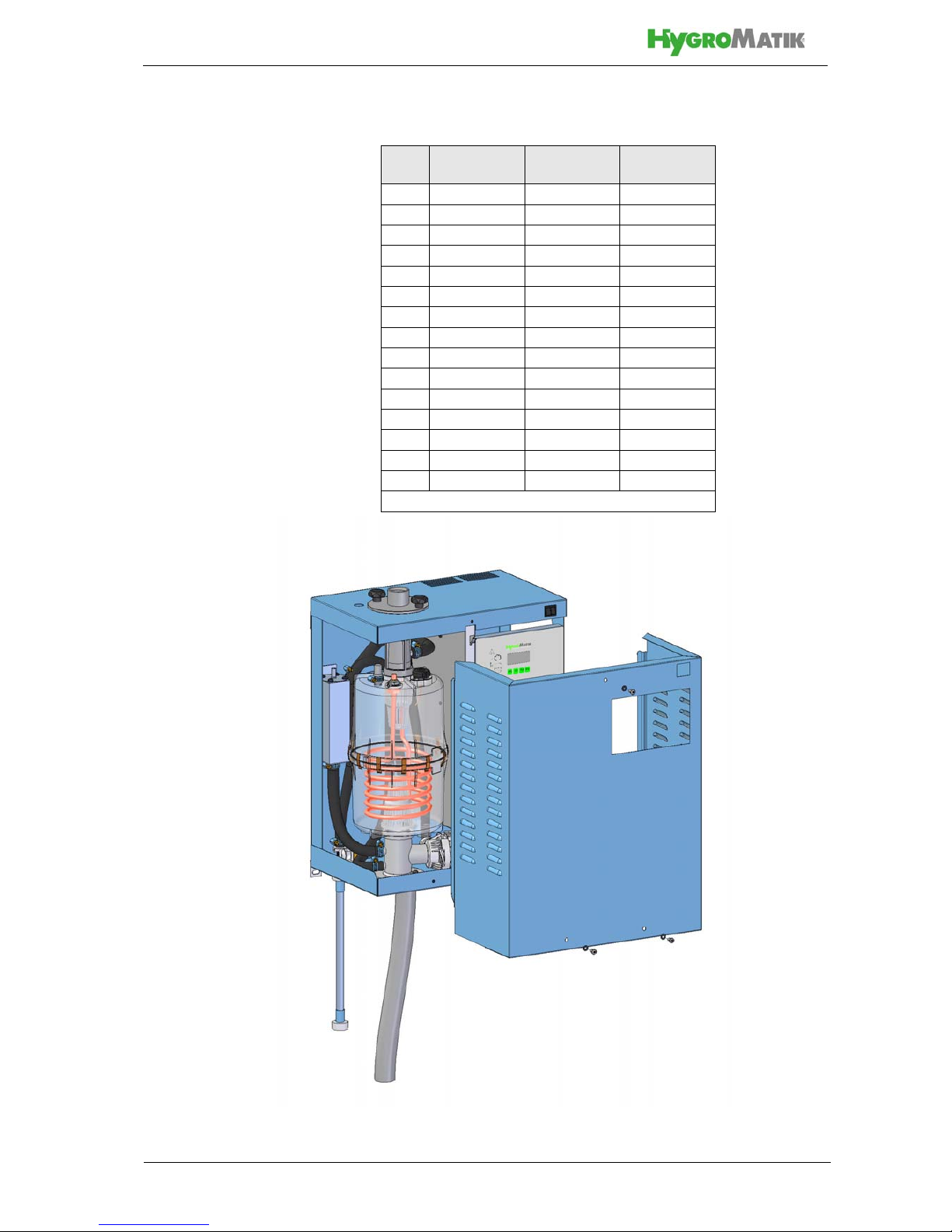

3.2 Transport Size and Weigth

* Dimensions and weigths can vary insignificantly

3.3 Packing

Observe the symbols affixed to the box.

3.4 Interim Storage

Keep the unit dry and protect from frost.

3.5 Check for Complete and Correct Delivery of

Goods

Upon receipt of the unit, make sure that:

• type and serial number on the name plate match what

is in the purchasing and delivery documents,

• equipment is complete and in perfect condition.

In case of damage during shipment and/or missing parts, imme-

diately file a written claim with your carrier or supplier.

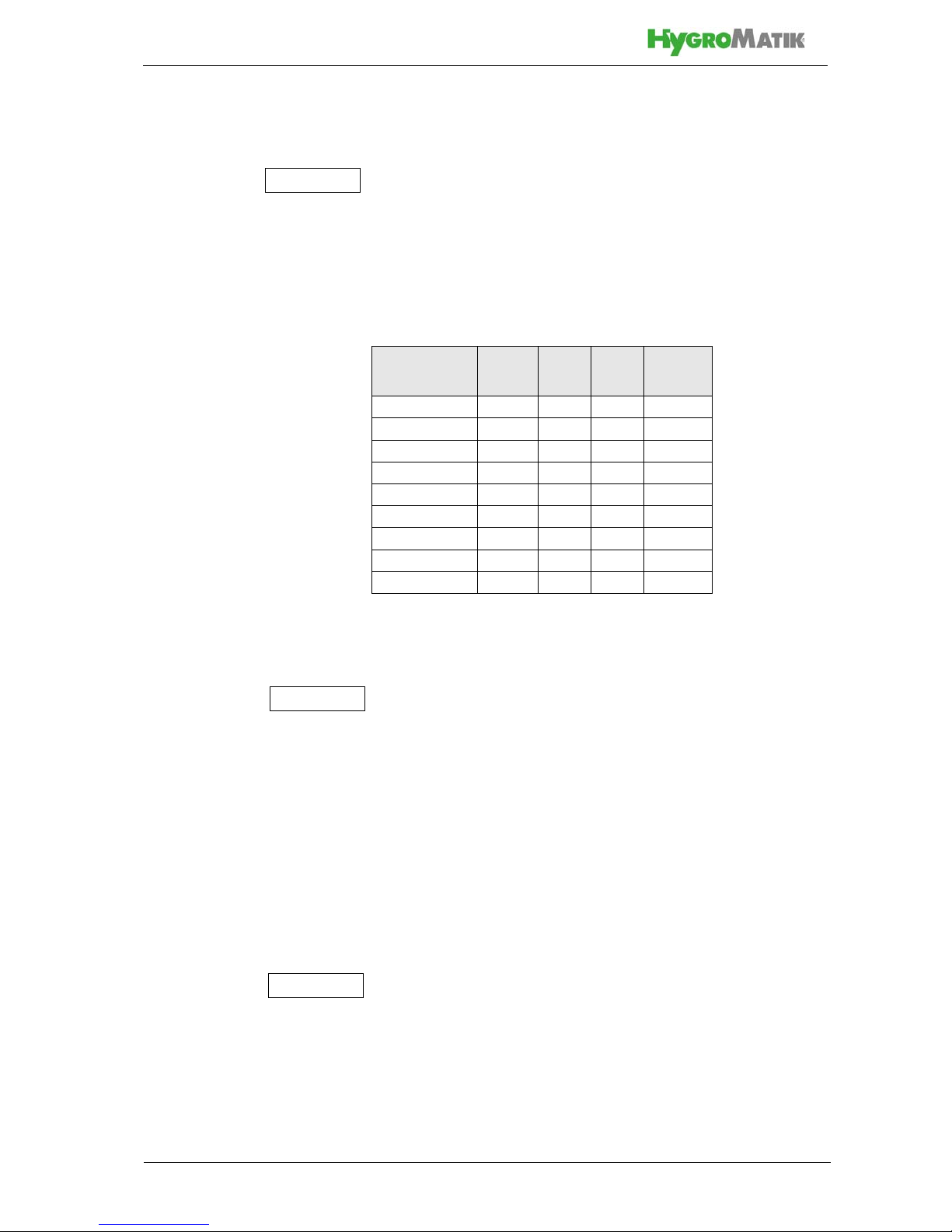

Type* depth

[cm]

higth

[cm]

width

[cm]

weigth

[kg]

HC02 33 47 46 14

HC03 36 65 51 16

HC06 36 65 51 16

HC09 36 65 51 16

HC06P 41 78 59 25

HC09P 41 78 59 25

HC12 41 78 59 26

HC18 41 78 59 26

HC27 41 78 59 27

Please note

Please note

Please note

Page 11

Time limits for filing freight claims with shipping companies are*:

* Subject to change without prior notice.

3.6 Included in the Delivery

The delivery includes:

• Unit of the selected humidifier type including selected control.

• Water installation hose.

• Manuals for the steam humidifier and the control.

• Ordered accessories (steam manifold, steam hose, condensate hose, etc.).

• Maintenance o-ring set for steam cylinder.

Transport Company After Receipt of Goods

Carriers 4 days at the latest

Parcel Service immediatly

Page 12

4. Operation and Device Construction

4.1 Mode of Action

The Imersion Heater Principle

One to three heater elements (Pos. 8 in the exploded view,

please see cover foldout) are placed in a closed cylinder and

connected to alternating current. The cylinder is filled with tap

water, fully demineralized water or partially softened water. Heat

generated by the heater element increases water temperature to

approx. 100°C.

When fully demineralized water is used, the feed water is practically free of minerals. This ensures long life for the cylinder and

heater elements since virtually no mineral deposits can settle or

build up. Fully demineralized water minimizes the number of service / maintenance checks.

When tap water is used, some of the minerals dissolved in the

water will settle in the cylinder as solids of various compositions.

Most of these scale deposits are removed by periodic flushing or

use of a heavy-duty blow-down pump. See section "Servicing

During Operation with Tap Water".

The generated steam has a temperature of about 100°C and

minimal positive pressure ("pressureless” steam). It is virtually

demineralized and germ-free.

Page 13

4.2 Installation and Method of Operation

By pressing the control switch („Pos. I”) the humidifier is turned

on. When the hygrostat or controller signals a demand for

humidification, the inlet solenoid valve (14) opens. The solenoid

valve is designed for pressures from 100 x 10

3

to 100 x 104 Pas-

cals (1 to 10 bar).

Water is fed into the cylinder.

The water level in the cylinder must be maintained within a spec-

ified range. If the water level is too high, the ellbow acts as a

safety overflow for water drainage. If the water level is too low, it

could cause the heater element (8) to overheat. Therefore,

power supply to the heater element is shut off when water levels

are too low.

The cylinder water level is controlled by a level control (27). The

level control consists of a stainless steel cylinder with two float

switches and three reed contacts. The float switches indicate the

water level in the steam cylinder: "Dry Run", "Humidification"

and "Max. Level". The control capsule is pressure-equalized.

At the standard setting, the inlet solenoid valve (14) opens when

the water level remains below “humidification” level for 10 seconds. The water level then rises again to “humidification” level.

The steam cylinder consists of a top (16) and lower (9) part

joined with a cylinder flange. The seal between the cylinder and

cylinder base (11), as well as between the top and lower part of

the cylinder, is maintained using an o-ring.

Page 14

General survey

The heater elements are equipped with a mechanical high temperature safety. This mechanism provides a redundant safety

system in the event of excessively low water levels (“Dry Run”).

The cylinder water is periodically flushed out with a heavy-duty

blow-down pump (10).

Steam is fed into air-conditioning ducts through special steam

hoses and steam manifolds. Under normal conditions, this

steam has virtually no heating effect on the air to be humidified.

Accumulated condensate can be returned to the steam cylinder

via a condensate hose.

Direct room humidification (without ducts) is performed using fan

units (with blower and nozzle). The steam generator is connected to the fan unit with steam and condensate hoses.

Steam lines in steam bath cabins employ special steam hoses

and piping (if required). Accumulated condensate is normally

routed into the steam cabin. At a relative humidity of 100%, the

supplied steam is used to heat up the steam bath. The mou nting

location of the humidifier must always be outside of the steam

cabin.

Page 15

For maintenance purposes, the cylinder water may be drained

by pressing and holding the control switch in the „II“ position.

Risk of electrical shock!

Hazardous electrical high voltage.

In case of leakage from the humidifier, switch off the unit and

eliminate leakage.

Risk of scalding!

During blow down hot water with a temperature of about 95°C is

being drained. Avoid any contact with skin.

4.3 Internal Output Setting

Continuous control of the HeaterCompact Type steam humidifier

is achieved by proportional control of the heater element s. In this

way the humidifier can be proportionally operated across the

entire output range of 5% - 100% nominal capacity.

Page 16

5. Installation

Installation of this unit to be accomplished only by qualified

personnel (persons with completed training in the plumbing

field and in the field of electrical installation work, respectively) !

Obey all safety notes and warnings present on the unit.

Risk of electrical shock!

Hazardous electrical voltage.

During installation the unit must be disconnected from power

supply.

HygroMatik accepts no liability for damage due to faulty installation.

Attaching or installing additional components is permitted only

with the written consent of the manufacturer, or else the warranty is void.

Risk of foot injuries!

Unit may drop during mounting involving a single person.

Helping hand of a second person is required.

5.1 Steam Humidifier - environmental conditi-

ons

When selecting the location for steam humidifier installation, be

aware of the following:

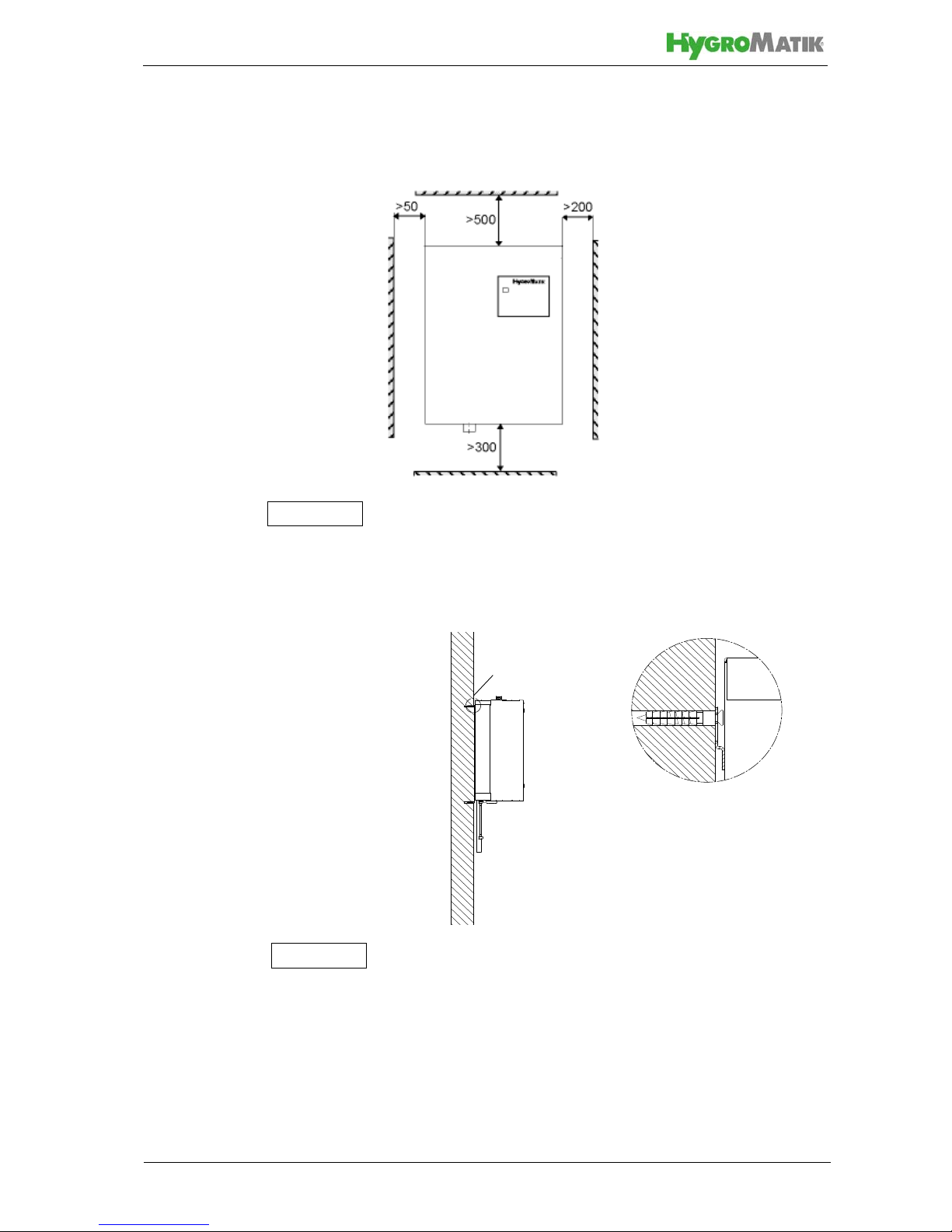

• Ambient temperature must be between +5 and +40 °C

• Observe clearances specified in the diagrams below to

ensure adequate ventilation

• An Installation in a closed room requires aeration and if

neccessary temperature conditioning in order to reach the

above mentioned environmental conditions

• HygroMatik humidifiers are not suitable for direct outdoor

installation

Please note

Page 17

• Install the steam humidifier as close as possible to the

steam manifold. Use only short lengths of steam and condensate hose to ensure optimal performance

• The back surface of the steam humidifier heats up during

operation (to max. 70°C). Take care that the construction

on which the unit is mounted is not made of temperaturesensitive material

• Place the steam humidifier so that the unit is easily accessible with sufficient space to perform maintenance

• The unit’s protection class is IP20

Page 18

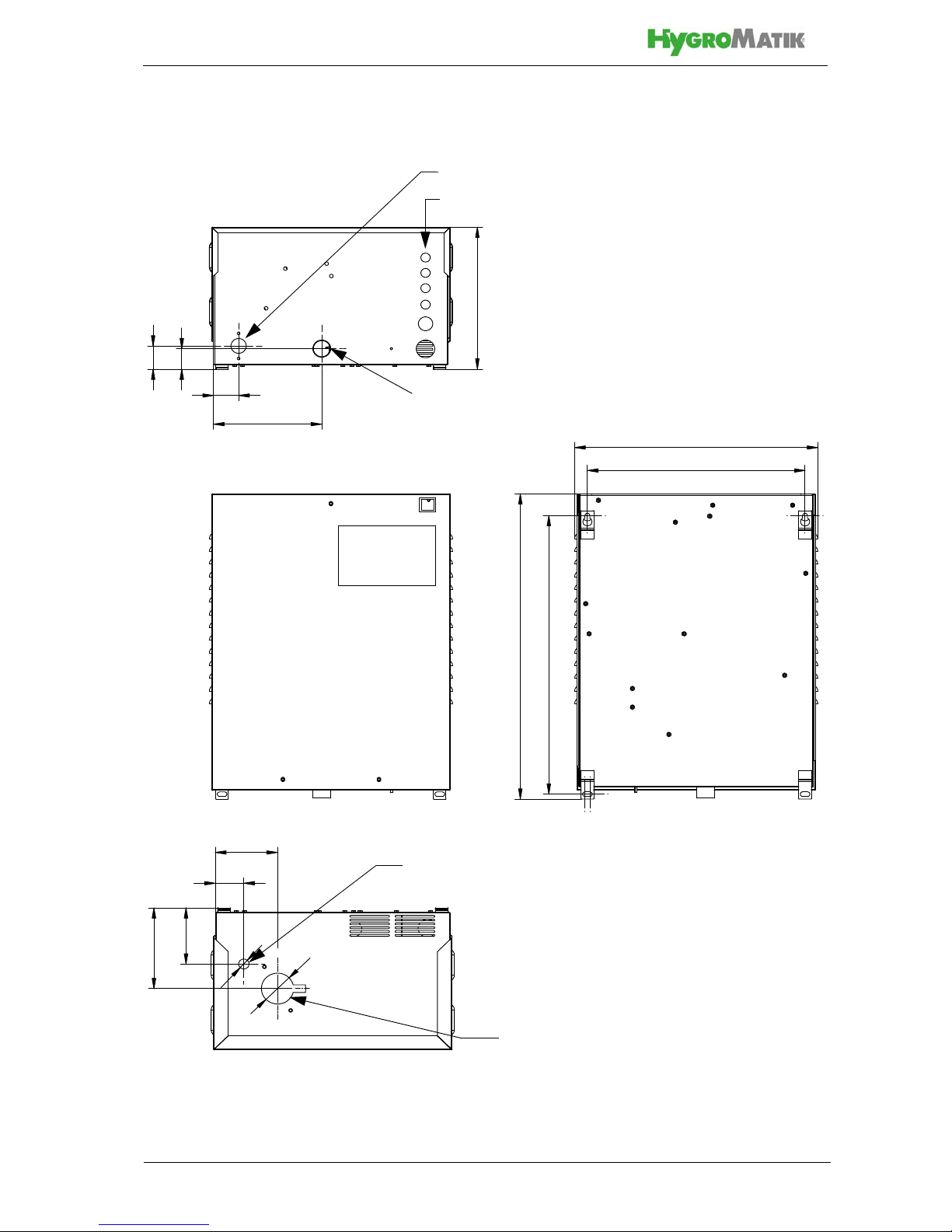

5.1.1 Equipment Dimensions HC

c

a

e

l

j

m

k

o

n

d

b

h

f

i

g

View from below

Rear view

View from top

Water inlet

Waste water connection

Steam outlet

Condensate inlet

Cable entries

Page 19

HC02 HC03-09 HC06P-09P

HC12-HC27

a 390 562 707

b 394 427 490

c 260 257 306

d 320 382 445

e 351 513 657

f33 30 30

g 170 190 250

h48 35 50

i80 44 50

j 158 145 162

k 110 109 138

l 178 100 81

m 167 50 86

n43 56 56

o18 18 18

all dimensions in mm

General Survey

Page 20

5.1.2 Fitting Measures

Wall clearance

When determining the steam humidifier positioning, make use of

existing water connections (feed and drain).

Wall Mounting

To function properly, the steam humidifier must be installed vertically.

Measures for drills for wall mounting please see table (measures

d and e) in chapter „Equipment Dimensions”.If there is no suitable wall, it is recommended that the equipment is installed on

brackets which can be embedded in the floor.

(all dimensions in mm)

Please note

B

B

Please note

Page 21

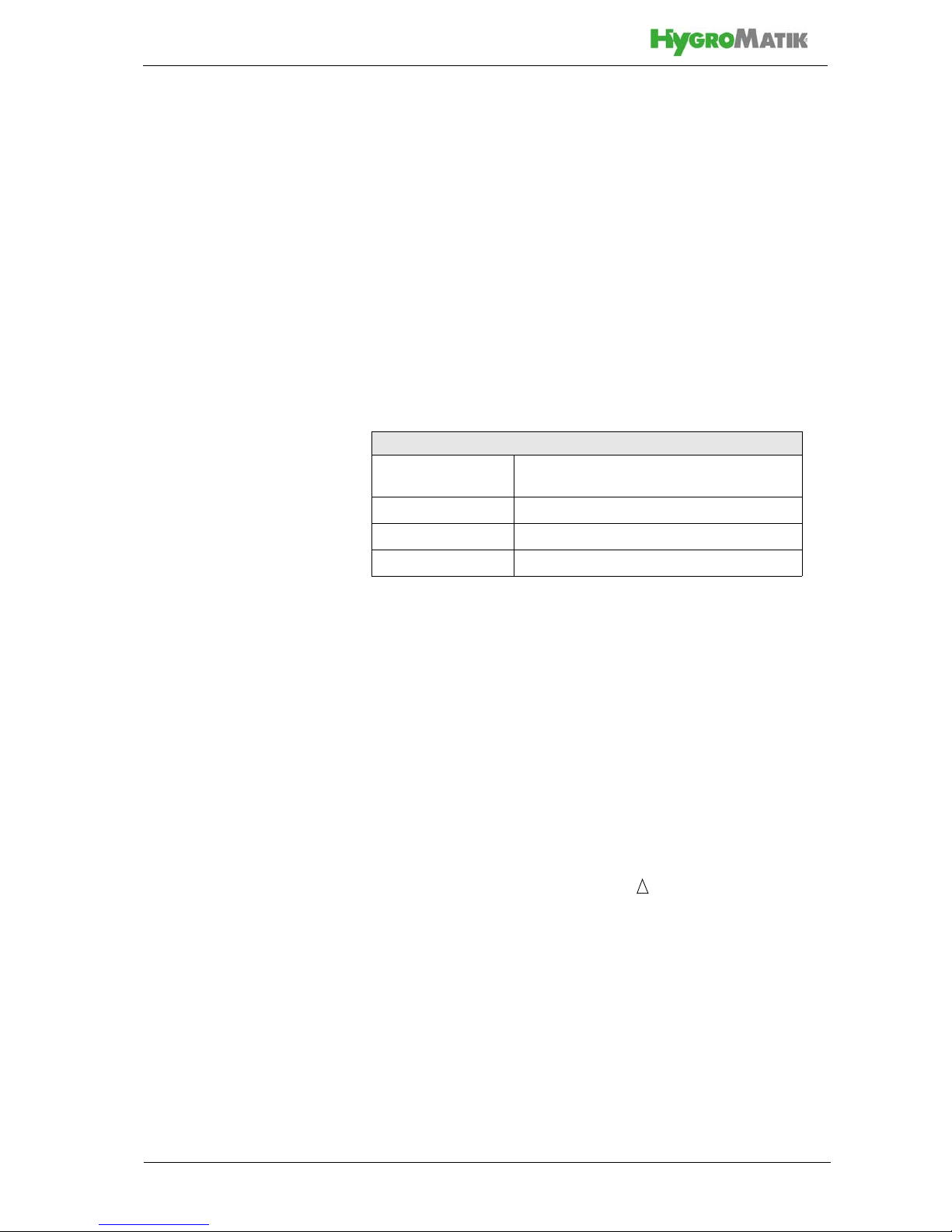

5.2 Absorption Distance BN

The "absorption distance" (BN) is defined as the distance from

the steam feed to where the steam is completely absorbed in the

treated air. Within the absorption distance, steam is visible as

mist in the air stream.

Condensation may occur on anything installed within the

absorption distance.

Although steam outside the absorption distance (B

N

) is com-

pletely absorbed, it is not yet evenly diffused in the duct. If you

plan to install any parts or devices inside the absorption distance, such as sensors or elbows, we recommend increasing

the absorption distance using the formulae below. The absorption distances required for certain installed fittings are distinguished by separate symbols and calculated as a multiplier of

the absorption distance B

N

.

The absorption distance has no fixed value, but depends on

many factors. These are depicted in the absorption distance

nomogram below.

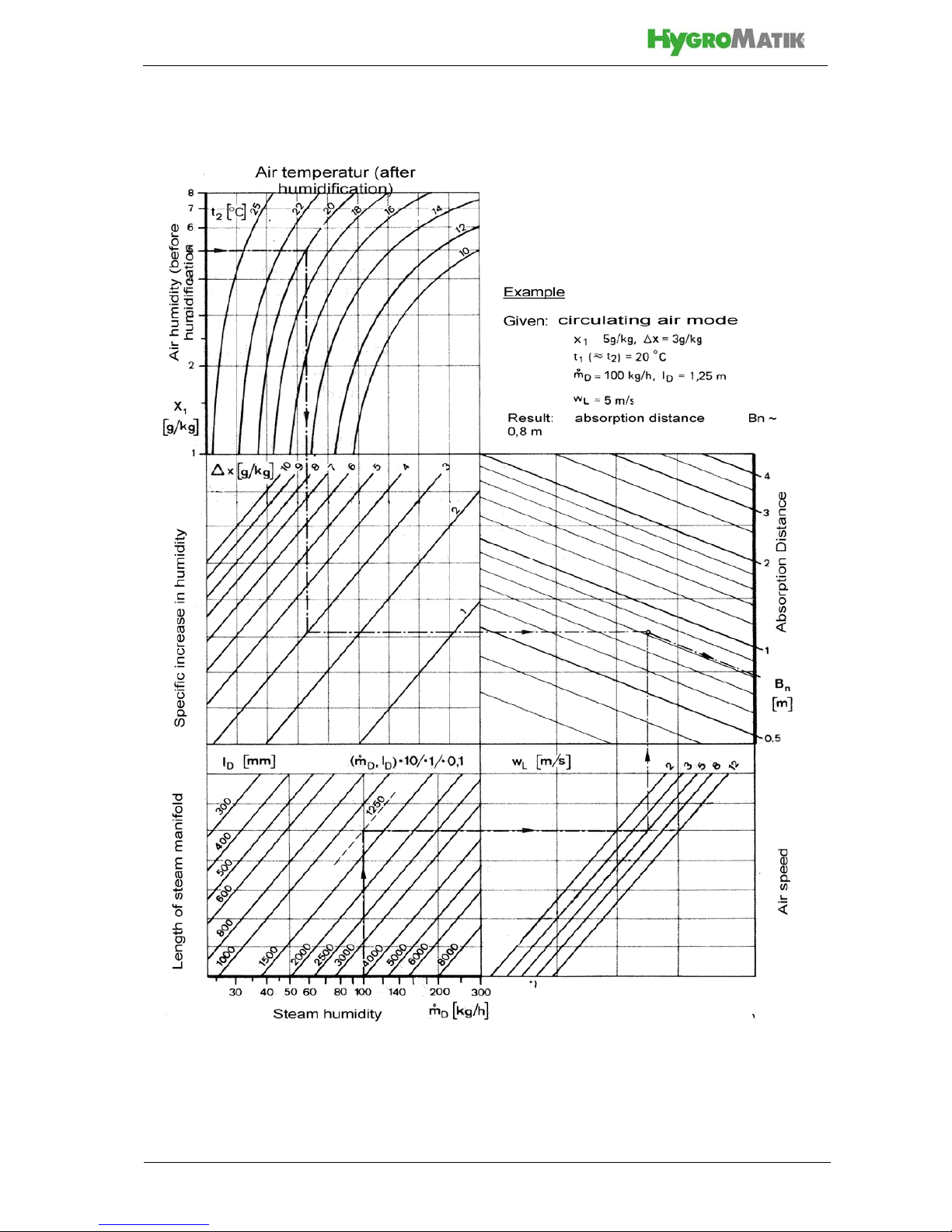

5.2.1 Determining the Absorption Distance

To determine the absorption distance, the following parameters

are required:

• Air humidity before humidification x

1

in g/kg.

• Air temperature after humidification t

2

in °C (with steam

humidifiers the change in air temperature due to humidification may be disregarded t

1

or t2).

• Specific increase in humidity x in g/kg (can be determined in the h,x diagram)

• quantity of steam introduced in kg/h.

• air speed w

L

in m/s in air duct

• Total length l

D

of the steam manifold installed in the air

duct

Absorption Distance

B

N

for normal obstructions, such as sensors, ventilators, outlets

B

c

= (1,5...2) x BNfor fine filters, heat registers

B

s

= (2,5...3) x BNfor particle filters

B

d

= (3...5) x B

N

for humidity sensors, duct humidistats

o

D

m

Page 22

Length ID of the usable steam manifold depends on the dimensions of the air duct. The length of the absorption distance can

be reduced by using multiple steam manifolds (also see section

on the steam manifold).

Method:

Graphically determine absorption distance B

N

using the absorp-

tion distance nomogram (also see Section „Absorption Distance

Nomogramm“). Enter the value of the parameters enumerated

above into the respective quadrants. The resulting point of intersection indicates the value of the desired absorption distance

B

N

.

Notes:

x

1

: _______________________________[g/kg]

t

2

: _______________________________[°C]

x:_______________________________[g/kg]

:_______________________________[kg/h]

w

L

: _______________________________[m/s]

l

D

: _______________________________[mm]

Air humidity before humidification

Air temperature after humidification

Specific increase in humidity

quantity of steam introduced

air speed t

Total length of the steam manifold

o

D

m

Page 23

5.2.2 Absorption Distance Nomogram

Source: Henne, Erich: Luftbefeuchtung (Air Humidification), 3rd Edition 1984 (Page 101), Oldenbourg Industrieverlag, Munich

Page 24

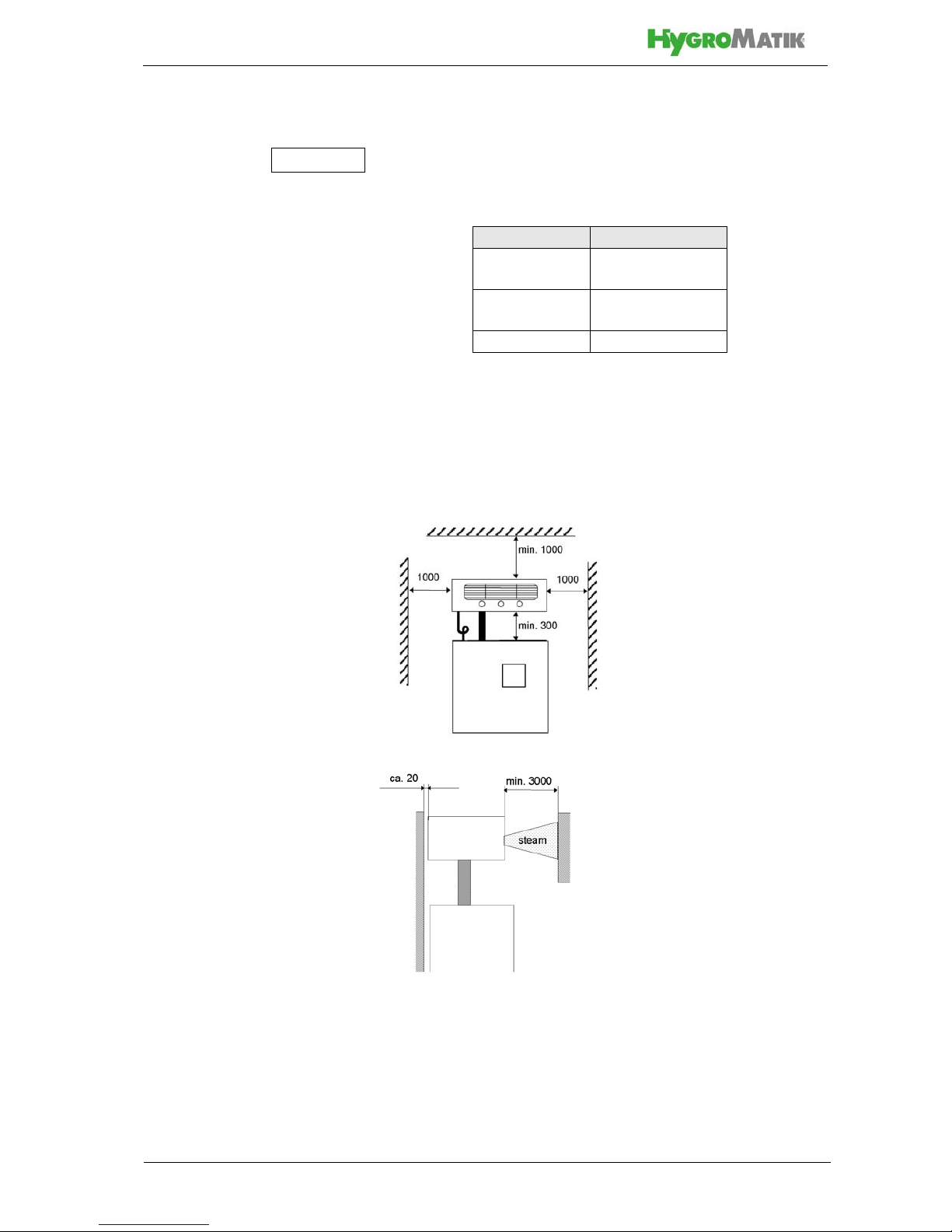

5.3 Fan Unit (optional)

The fan unit should be positioned to avoid drafts. A minimum

height of 2 m is generally sufficient.

• Install the fan directly on the wall

• The fan unit is installed above the steam humidifier

• When using multiple fan units, do not exceed a maximum

distance of 5 m from the steam humidifier

• Observe the clearances specified in the diagrams below

Fan unit, wall installation

Side view, wall-mounted fan unit

Model Fan unit

HC02, HC03

HC06(P)

VG 08

HC09(P),

HC12

VG 17

HC18 - 27 VG 30

Please note

(all dimensions in mm)

Loading...

Loading...