HygroMatik FlexLine Plus, FLP15, FLP05, FLP25, FLP30 Series Manual

...

FlexLine Plus

Electric Heater Steam Humidifiers

ÁFLP.ENcÈ

FLP.EN

E-8881170

Manual

Certain computer programs contained in this product [or device] were developed by HygroMatik

GmbH ("the Work(s)").

Copyright © HygroMatik GmbH [03.12.2018]

FlexLine FLP 05/08/15/25/30/40/50 EN

All Rights reserved.

Current version of this manual can be found at: www.hygromatik.co.uk

HygroMatik GmbH grants the legal user of this product [or device] the right to use the Work(s)

solely within the scope of the legitimate operation of the product [or device]. No other right is

granted under this licence. In particular and without prejudice to the generality of the foregoing,

the Work(s) may not be used, sold, licensed, transferred, copied or reproduced in whole or in

part or in any manner or form other than as expressly granted here without the prior written consent of HygroMatik GmbH.

Information in this manual is subject to change or alteration without prior notice.

:$51,1*

Risk of electrical shock!

Hazardous electrical high voltage!

All electrical work to be performed by certified expert staff (electricians or expert personnel with

eqivalent training) only.

Page 2

1. Introduction ....................................................................................................................... 5

1.1 Typographic Distinctions ................................................................................................... 5

1.2 Documentation .................................................................................................................. 5

1.3 Symbols in Use ................................................................................................................. 5

1.3.1 Specific Symbols related to Safety Instructions ............................................................. 5

1.3.2 General Symbols ............................................................................................................ 5

1.4 Intended Use ..................................................................................................................... 6

2. Safety Instructions ............................................................................................................ 7

2.1 Guidelines for Safe Operation ........................................................................................... 7

2.1.1 Scope ............................................................................................................................. 7

2.1.2 Unit control ..................................................................................................................... 7

2.1.3 Unit Operation ................................................................................................................ 7

2.1.4 Mounting, dismantling, maintenance and repair of the unit ............................................ 8

2.1.5 Electrical ......................................................................................................................... 8

2.2 Disposal after dismantling ................................................................................................ 8

3. Transport ............................................................................................................................ 9

3.1 Overview ........................................................................................................................... 9

3.2 Packing .............................................................................................................................. 9

3.3 Interim Storage .................................................................................................................. 9

3.4 Check for Complete and Correct Delivery of Goods ......................................................... 9

4. Functional Description and Device Composition .......................................................... 10

4.1 Mode of Action .................................................................................................................. 10

4.2 Operational sequence ....................................................................................................... 11

4.3 Internal Output Setting ...................................................................................................... 11

4.4 Mechanical Construction ...................................................................................................11

4.4.1 FlexLine Plus .................................................................................................................. 11

4.4.2 FlexLine Process ............................................................................................................ 11

4.5 Thermal fuses .................................................................................................................... 12

5. Mechanical installation ..................................................................................................... 13

5.1 Environment Parameters to be met and Mounting Recommendations ............................. 13

5.1.1 Dimensions and Mounting Directions ............................................................................. 14

5.2 Unit Installation Check ....................................................................................................... 17

5.3 Absorption Distance BN ....................................................................................................18

5.3.1 Determining the Absorption Distance ............................................................................. 18

5.3.2 Absorption Distance Nomogram .................................................................................... 19

5.4 Steam Manifold ................................................................................................................. 20

5.4.1 General installation guidelines ....................................................................................... 20

5.4.2 Recommendations for dimensioning .............................................................................. 20

5.5 Steam line and condensate hose layout .......................................................................... 23

5.5.1 Guide lines for steam line design .................................................................................. 23

5.5.2 Condensate hose layout ................................................................................................. 23

5.5.3 Steam line and condensate hose installation types ....................................................... 24

Page 3

6. Water connection .............................................................................................................. 25

6.1 Water supply ..................................................................................................................... 25

6.2 Water discharge ................................................................................................................ 27

6.3 Water connections final check ........................................................................................... 28

7. Electrical connection ........................................................................................................ 29

7.1 Electrical installation approach ..........................................................................................29

7.2 Cable connections ............................................................................................................. 30

7.3 Safety interlock .................................................................................................................. 31

7.4 Connection diagrams ........................................................................................................ 31

7.5 Electrical installation check list .......................................................................................... 31

8. Commissioning ................................................................................................................. 32

9. Maintenance ....................................................................................................................... 33

9.1 General .............................................................................................................................. 33

9.1.1 Service messages .......................................................................................................... 33

9.1.2 Service messages for preventive maintenance .............................................................. 33

9.1.3 Safety instructions for maintenance ............................................................................... 34

9.2 Maintenance frame work when unit is operated with fully demineralised water and condensate

................................................................................................................................................. 35

9.3 Maintenance when unit is operated with tap water or partially softened water ................ 35

9.4 Removing and cleaning the steam cylinder ....................................................................... 36

9.4.1 Perform leakage check ...................................................................................................37

9.5 Cylinder base and strainer cleaning .................................................................................. 37

9.6 Steam cylinder and heater element cleaning .................................................................... 37

9.7 Cleaning Connection Hoses, Cylinder Base Connections, Steam Hose Adapter Nozzle . 38

9.8 Level control device cleaning ............................................................................................ 39

9.9 Heater element replacement ............................................................................................. 40

9.10 Releasing the thermical safety devices ........................................................................... 40

9.10.1 Variety of thermal protection devices in use ................................................................. 40

9.10.2 Unlocking of a thermo switch on the cylinder cover ..................................................... 41

9.10.3 Unlocking of the Klixon thermo switch .......................................................................... 41

9.11 Thermo switch replacement (for heater element) ............................................................ 41

9.12 Inspection of wiring connections and heater element wiring ........................................... 42

9.13 Removal and reinstallation of the twin solenoid valve including fine filter cleaning ........ 43

9.14 Removal and reinstallation of the quadruple solenoid valve including fine filter cleaning (Flex-

Line Process) .......................................................................................................................... 44

9.15 Cleaning of blow-down pump .......................................................................................... 45

9.16 Inspection of hoses ......................................................................................................... 45

9.17 Functional check ............................................................................................................. 45

9.18 Completion of maintenance ............................................................................................. 45

10. Dismantling ..............................................................................................................

11. Declaration of Conformity .............................................................................................. 47

........ 46

12. Spare Parts ...................................................................................................................... 48

13. Technical specifications ................................................................................................. 50

14. Exploded view ................................................................................................................. 52

15. View of housing ............................................................................................................... 53

Page 4

3OHDVHQRWH

'$1*(5

:$51,1*

127,&(127,&(

3OHDVHQRWH

1. Introduction

Dear Customer,

Thank you for choosing a HygroMatik steam

humidifier.

HygroMatik steam humidifiers represent the

latest in humidification technology.

In order to operate your HygroMatik steam

humidifier safely, properly and efficiently,

please read these operating instructions.

Employ your steam humidifier only in sound

condition and as directed. Consider potential

hazards and safety issues and follow all the

recommendations in these instructions.

If you have additional questions, please contact your expert dealer.

For all technical questions or spare parts

orders, please be prepared to provide unit

type and serial number (see name plate on

the unit).

Versions in Other Languages

These operating instructions are available in

several languages. If interested, please contact HygroMatik or your HygroMatik dealer.

1.3 Symbols in Use

1.3.1 Specific Symbols related to Safety Instructions

According to EN 82079-1 (and ANSI Z535.6),

the following signal words are used within

this document:

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

1.1 Typographic Distinctions

• preceded by a bullet: general specifications

» preceded by an arrow: Procedures

for servicing or maintenance which

should or must be performed in the

indicated order

Installation step which must be

checked off.

italics Terms used with graphics or draw-

ings

1.2 Documentation

In addition to this manual, the appropriate

FlexLine Control documentation is mandatory

for the operation of the unit.

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

&$87,21

CAUTION indicates a hazardous situation

which, if not avoided, could result in minor or

moderate injury.

NOTICE is used to address practices not

related to physical injury.

1.3.2 General Symbols

This symbol is used whenever a situation

requires special attention beyond the scope

of safety instructions.

Retention

Please retain these operating instructions in

a secure, always accessible location. If the

product is resold, turn the documentation

over to the new operator. If the documentation is lost, please contact HygroMatik.

Page 5

1.4 Intended Use

HygroMatik electric heater steam humidifiers

serve for steam production based on tap

water, partially softened water or fully desalinated water/cleaned condensate.

Proper usage also comprises the adherence

to the conditions specified by HygroMatik for:

• installation

• dismantling

• reassembly

• commissioning

• operation

• maintenance

• disposal.

Only qualified personnel may operate the

unit. Persons transporting or working on the

unit must have read and understood the corresponding parts of the Operation and Maintenance Instructions and especially the

chapter 2. „Safety Notes“.

Additionally, operating personnel must be

informed of any possible dangers by the provider. A copy of this manual is to be placed at

the unit‘s operational location.

By construction, HygroMatik steam humidifiers are not qualified for exterior application.

:$51,1*

Risk of scalding!

Steam with a temperature of up to 100 °C

(212 °F) is produced.

Do not inhalate steam directly!

Page 6

127,&(127,&(

2. Safety Instructions

These safety instructions are required by law.

They promote workplace safety and accident

prevention.

2.1 Guidelines for Safe Operation

2.1.1 Scope

Comply with the accident prevention regulation „DGUV Regulation 3“ to prevent injury to

yourself and others. Beyond that, national

regulations apply without restrictions.

2.1.2 Unit control

Do not perform any work which compromises

the safety of the unit. Obey all safety instructions and warnings present on the unit.

Risk of material damage!

The unit may be damaged if switched on

repeatedly following a malfunction without

prior repair.

Rectify defects immediately!

The unit must not be operated on a DC

power supply.

The unit may only be used connected to a

steam pipe that safely transports the steam.

Regularly check that all safety and monitoring devices are functioning normally. Do not

remove or disable safety devices.

In case of a malfunction or electrical power

disruption, switch off the unit immediately and

prevent a restart. Repair malfunctions

promptly.

:$51,1*

Restricted use.

IEC 60335-1 stipulates as follows:

This device may be used by children of eight

years of age and above as well as by persons

with reduced physical, sensory or mental capabilities or lack of experience and knowledge

so long as they are supervised or have been

instructed regarding the safe use of the device and understand the hazards that may result from it. Cleaning and user maintenance of

the unit must not be undertaken by children

without supervision.

2.1.3 Unit Operation

:$51,1*

Risk of scalding!

Uncontrolled hot steam escape in case of

leaking or defective components possible.

Switch off unit immediately.

Page 7

127,&(127,&(

127,&(127,&(

127,&(127,&(

2.1.4 Mounting, dismantling, maintenance and repair of the unit

Use only original fuses with the appropriate

amperage rating.

The HygroMatik steam humidifier is IP20 protected. Make sure that the unit is not object to

dripping water in the mounting location.

Installing a humidifier in a room without water

discharge requires safety devices to protect

against water leakages.

• Use genuine spare parts only

• After any repair work, have qualified

personnel check the safe operation of

the unit

• Attaching or installing of additional

components is permitted only with the

written consent of the manufacturer

Regularly check the unit‘s electrical equipment. Promptly repair any damage such as

loose connections or burned wiring.

Responsibility for intrinsically safe installation

of the HygroMatik steam humidifiers is

incumbent on the installing specialist company.

2.2 Disposal after dismantling

The operator is responsible for the disposal

of unit components as required by law.

2.1.5 Electrical

:$51,1*

Risk of electrical shock!

Hazardous electrical voltage!

Any work on the electrical system to be performed by certified expert staff (electricians

or expert personnel with comparable training)

only.

Disconnect unit components from electrical

power supply prior to work.

After electrical installation or repair work, test

all safety mechanisms (such as grounding

resistance).

Page 8

3OHDVHQRWH

3OHDVHQRWH

3OHDVHQRWH

3. Transport

3.1 Overview

Proceed carefully when transporting the

steam humidifier in order to prevent damage

due to stress or careless loading and unloading.

3.2 Packing

Pay attention to the icons affixed to the packing box.

Time limits for filing freight claims with shipping companies are*:

Shipping company

Carriers no later than 4 days

Parcel service immediately

* Time limits for some services subject to

change.

After receipt of

goods

3.3 Interim Storage

Store the unit in a dry place and protect from

frost and strong sunlight.

3.4 Check for Complete and Correct Delivery of Goods

Upon receipt of the unit, confirm that:

• model and serial number on the

name plate match those specified in

the order and delivery documents

• the equipment is complete and all

parts are in perfect condition

In case of damage from shipment and/or

missing parts, immediately notify the carrier

or supplier in writing.

Page 9

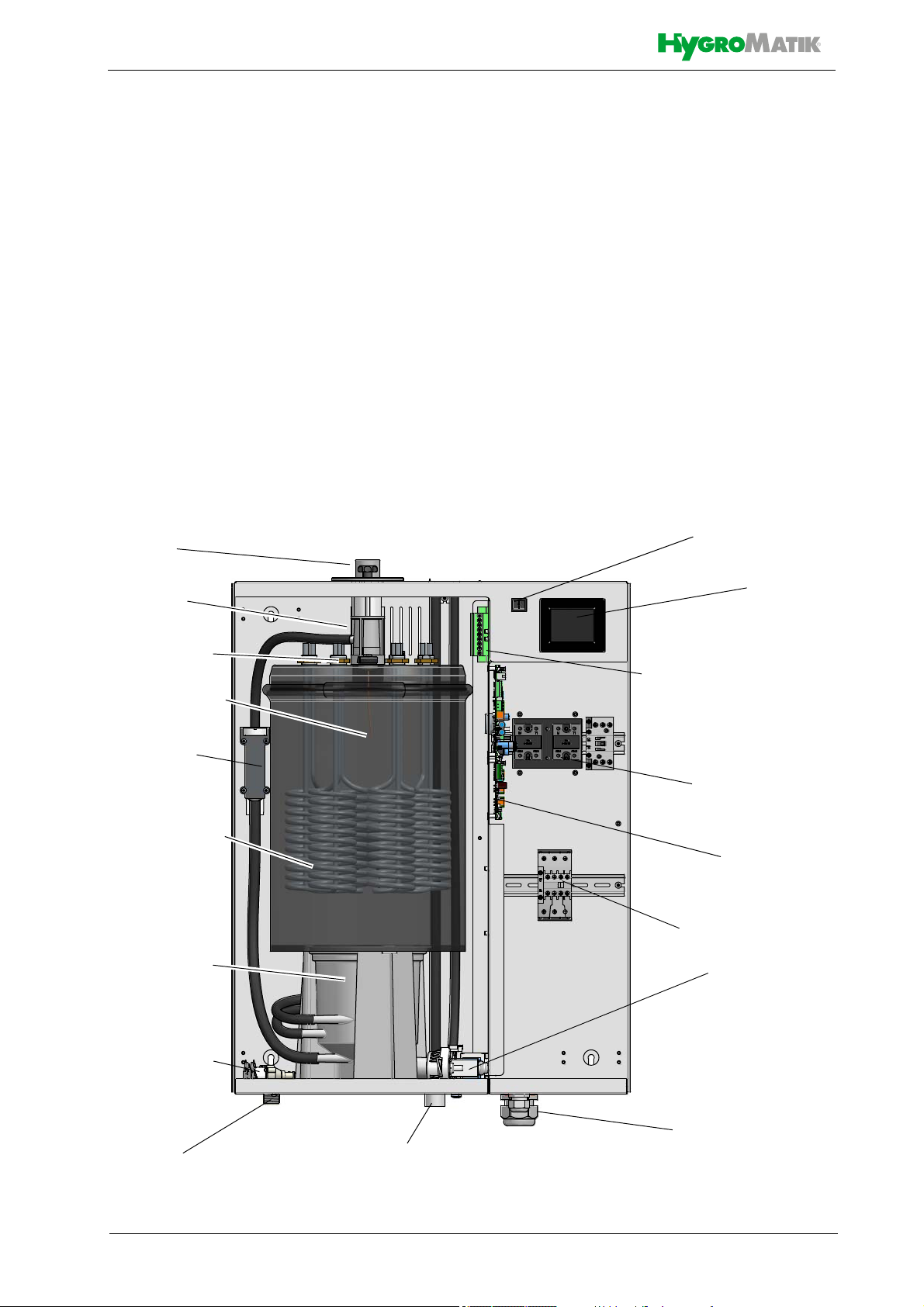

Control switch

Display

Main contactor

Blow-down

pump

Cable bushings

Waste water

outlet

Mainboard

(control)

Connector for heater

element wiring

Solid state relay

on heatsink

Water inlet

Solenoid valve

Cylinder base

Heater elements

Steam cylinder

Steam hose

adapter

Steam exit

Thermo switch

Level control

4. Functional Description and Device Composition

4.1 Mode of Action

The immersion heater principle

Depending on the output rating, one, three or

six heater elements are arranged within a

closed cylinder. Examplary given, the figure

below shows the heater elements and other

main components of a heater element steam

generator of the FLP series with 6 heater elements.

The cylinder(s) are filled with either tap water

of varying quality, fully desalinated water or

partially softened water.

The heat introduced by the heater elements

heats up the cylinderwater to approx. 100 °C

(212 °F), transforming the water into steam

with a temperature of approx. 100 °C (212 °F)

This steam is virtually mineral-free and germfree.

When fully desalinated water is used, the cylinder water is almost totally clear of minerals.

This situation guarantees a long lifetime of the

cylinder(s) and the heater element(s), since

virtually no hardeners will fall-out and no mineral deposits will occur. Such, the number of

inspections and/or maintenance operations

required will be reduced to a minimum.

When tap water is used for operation, some of

the minerals dissolved in the water are likely to

settle in the cylinder in form of solids of various

compositions. However, most of the solids are

flushed out by cyclic blow-down with the help

of a heavy-duty blow-down pump.

Page 10

4.2 Operational sequence

The steam humidifier is switched on by

pressing the control switch on the front panel

to the „I“ position. If the safety chain is

closed, the inlet multiple solenoid valve (twin

solenoid valve (25)

*)

in case of FLPxx-T and

FLPxx-TSPA units, 4-fold solenoid valve

*)

(71)

with FLPxx-TPRO units)* opens and

water is fed into the steam cylinder.

Filling level in the cylinder is controlled by a

level control device (27)

*)

. In a plastic cylinder, connected to the steam cylinder via

hoses in the way communicating tubes are

connected, a sensor for continous proportional water level survey is located.

The cylinder water is periodically blown

down. For usage of the unit with fully deselinated water, the blow-down function may be

blocked.

Water blow-down is achieved by means of

*)

the blow-down pump (32)

that is continously

monitored during unit operation. In case of

pump disruption, the HygroMatik steam

humidifier is shut off.

With normal water quality, blow-down loss is

in the range of 7 to 15% of the steam amount

produced. Depending on water quality, a full

steam cylinder blow-down is run every 3 to 8

days.

Mineral deposits settle in the open area

below the heater element(s) and are

removed through periodic maintenance. The

blow-down pump itself has wide openings

and can flush out smaller pieces of mineral

deposit. This extends the service life of the

unit and reduces the required maintenance

interval.

On blow-down, water flows from the pump

into the drain hose system.

4.3 Internal Output Setting

Continuous control is achieved by proportional driving (pulse width modulation) of the

heater elements via one or both solid state

relays. In this way the humidifier can be proportionally operated across the entire output

range of 5% - 100% of the nominal capacity.

A power setting of 0% to 5% of the nominal

output is possible, but not technically feasible

due to condensate losses in the steam line.

If the unit is equipped with more than 3

heater elements, the output power provision

is accomplished in 2 stages. As long as a

certain threshold was not reached, the heating power necessary is solely controlled via

the solid state relays and the 3 heater elements in a propotional manner (stage 1). If

the output power requested lies beyond what

is available in stage 1, three additional heater

elements are activated via a main contactor

in a one-step operation mode (stage 2). Any

power requirement in excess of the stage 2

rating is then proportionally supplied via the

solid state relays by the stage 1 operational

mode.

4.4 Mechanical Construction

The type of housing is designed for wall

mounting. The steam cylinder is made from

stainless steel. Depending on the power output range, one, three or six heater elements

are encorporated.

4.4.1 FlexLine Plus

Freshwater supply is accomplished by

means of a twin solenoid valve that is also

used for the SuperFlush functionality.

For maintainence purposes, the cylinder

4.4.2 FlexLine Process

water may be pumped out by pressing and

holding the control switch in the „II“ position.

The units featuring the TPRO-control allow

the exceedingly precise steam control via a

fourfold solenoid valve. For this to work, the

*)

numbers indicated correspond with those in

the exploded view in the „Exploded view“

use of fully demineralized water is mandatory.

chapter.

Page 11

4.5 Thermal fuses

The devices of the FLP series have several

thermal fuses which are electrically connected in series. After one of the fuses has

tripped, the device switches to the fault status. A device restart is required but is possible only if the relevant thermal switches have

cooled down or the thermal sensors have

been unlocked.

The following fuses are available:

on the cylinder cover

• 1 thermal switch (Klixon) to protect

against overheating of the steam cylinder; the switch has a pin for manual

reset after cooling down

• 1 or 2 (for devices with six radiators)

thermal sensors with capillary tube for

direct thermal monitoring of the radiators. One capillary tube each is connected to 1 to 3 radiators (depending

on the device type). After a thermal

sensor has been triggered, it must be

reset manually (see maintenance

description)

on solid state relays

The solid state relay (or two solid state relays

on devices with higher power) is (are) thermally protected by a bimetal switch. The

bimetal switch returns to its initial position

during the cooling process.

Page 12

:$51,1*

:$51,1*

5. Mechanical installation

Risk of foot injuries!

Prevent unit from dropping during installation!

Helping hand of a second person is advisable.

Risk of electrical shock!

Hazardous electrical voltage.

During installation, the unit must be disconnected from power supply.

5.1 Environment Parameters to

be met and Mounting Recommendations

When selecting the installation site for the

steam humidifier, take the following into

account:

• The minimum clearances indicated in

the fitting measures section must be

observed in order to ensure adequate

unit ventilation and allow for unobstructed access in case of maintenance

• Protection class IP20

• Installation in a closed room requires

aeration and, eventually, temperature

conditioning in order to meet the a.m.

environmental conditions

• The steam humidifier should be

installed as close as possible to the

steam manifold. Optimum performance is only guaranteed when steam

and condensate hoses are kept short

• Make use of existing water connections

for supply and draining

• Hoses must be laid at a consistent 5 to

10 % incline/decline; sagging and kinking prevention is a must

• Mount the unit on a stable, preferably

solid wall offering the bearing capacity

required (s. unit technical specifications). If such a wall is not at hand, the

unit may be attached to a stand bracket

firmly bolted to the floor

• For proper functioning of the level control, plumb and level installation of the

unit is required

• The steam humidifier rear panel heats

up during operation to a maximum of

70 °C (158 °F). Take care that the construction on which the unit is to be

mounted is not made of temperaturesensitive material

• By design, HygroMatik steam humidifiers are not qualified for outdoor installation (electronical components and

water-bearing parts may be damaged)

• Ambient temperature must lie between

+5 and +40 °C (+41 and +104 °F) in

order to protect the unit electronics

against damage; frost may damage the

steam cylinder, the solenoid valve and

pump, as well as make hoses burst

• Relative humidity must not exceed

80 % r.h., since values beyond may

lead to electronic malfunction or damage

Page 12

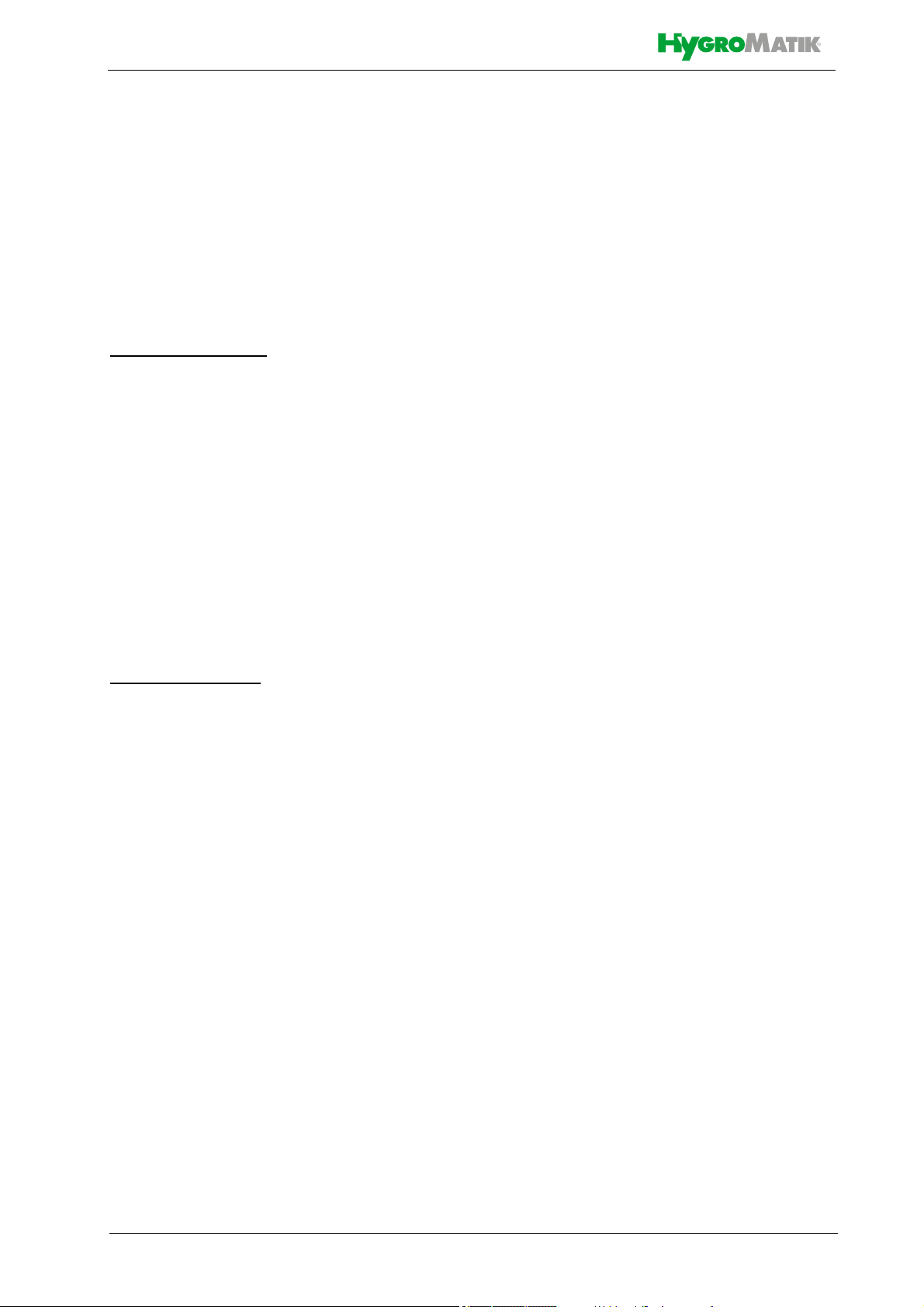

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

PP

LQFK

View from below

View from top

Front view

3D model under

https://www.hygromatik.com/en/downloads

5.1.1 Dimensions and Mounting Directions

Page 14

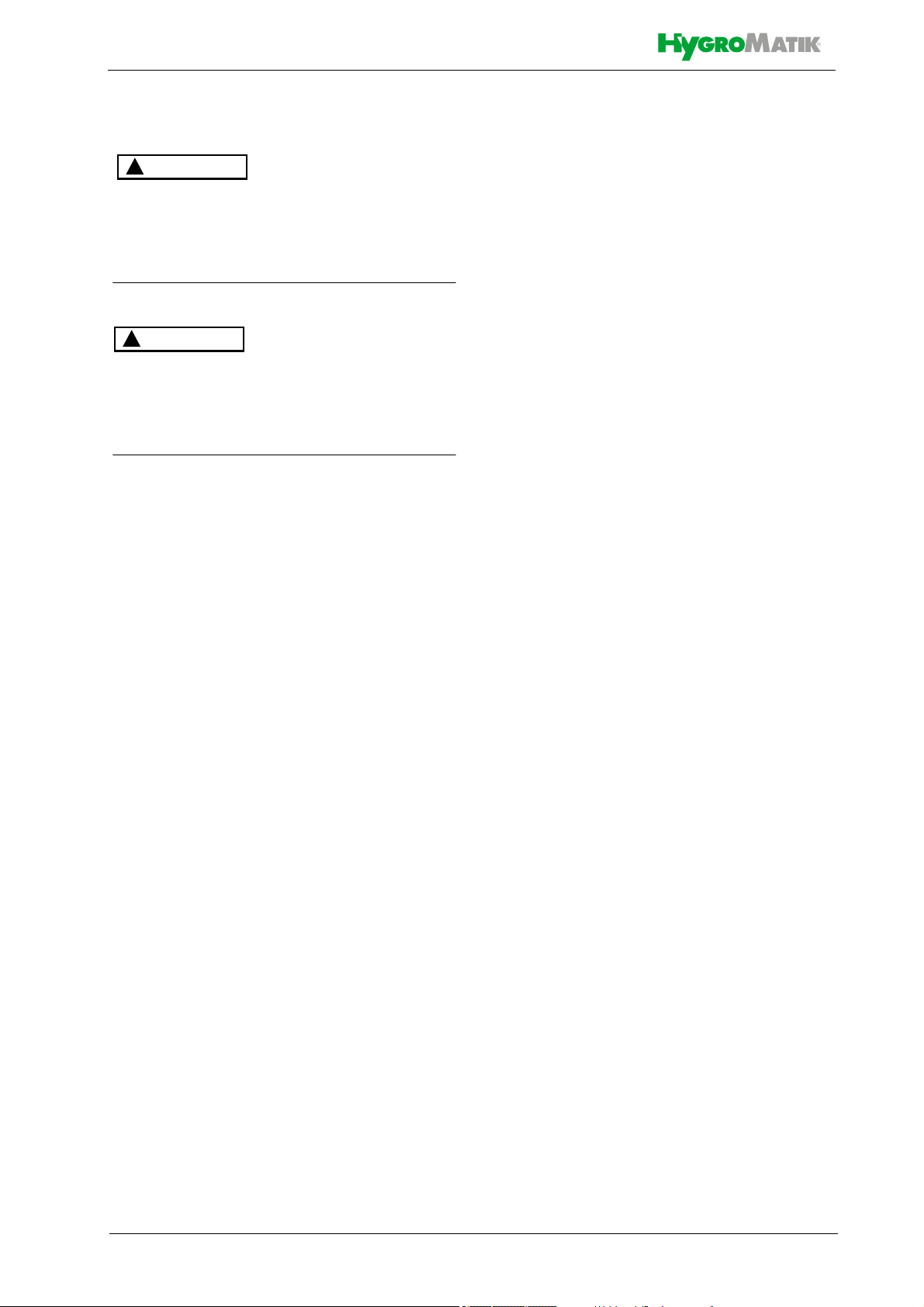

>500/19.7

>200/7.8

>300/11.8

>50/2.0

device rear

suspension

brackets

Wall clearances

When mounting the steam humidifier, the

wall clearances shown in the fig. below must

be obeyed:

all measures in mm/inch

For wall mounting drill measures, please

consult the table above (measure A and B).

In case of no suitable wall available for

mounting the unit, it is recommended that

installation is made on brackets firmly

anchored in the floor.

» mark the holes for the upper sus-

pension brackets

screws

» drill holes and dowel

» screw in the supplied mounting

screws; let the screws protrude

approx. 12 mm

/.5 inch from wall

» ensure firm fixation and load-carry-

ing capacity of the mounted screws!

» hook in the unit and ensure safe

suspension

» mark the holes for the lower suspen-

sion brackets screws

» remove the unit

» drill holes and dowel

» hook in the unit and mount the lower

screws firmly

To function properly, the steam humidifier

must hang level and plumb.

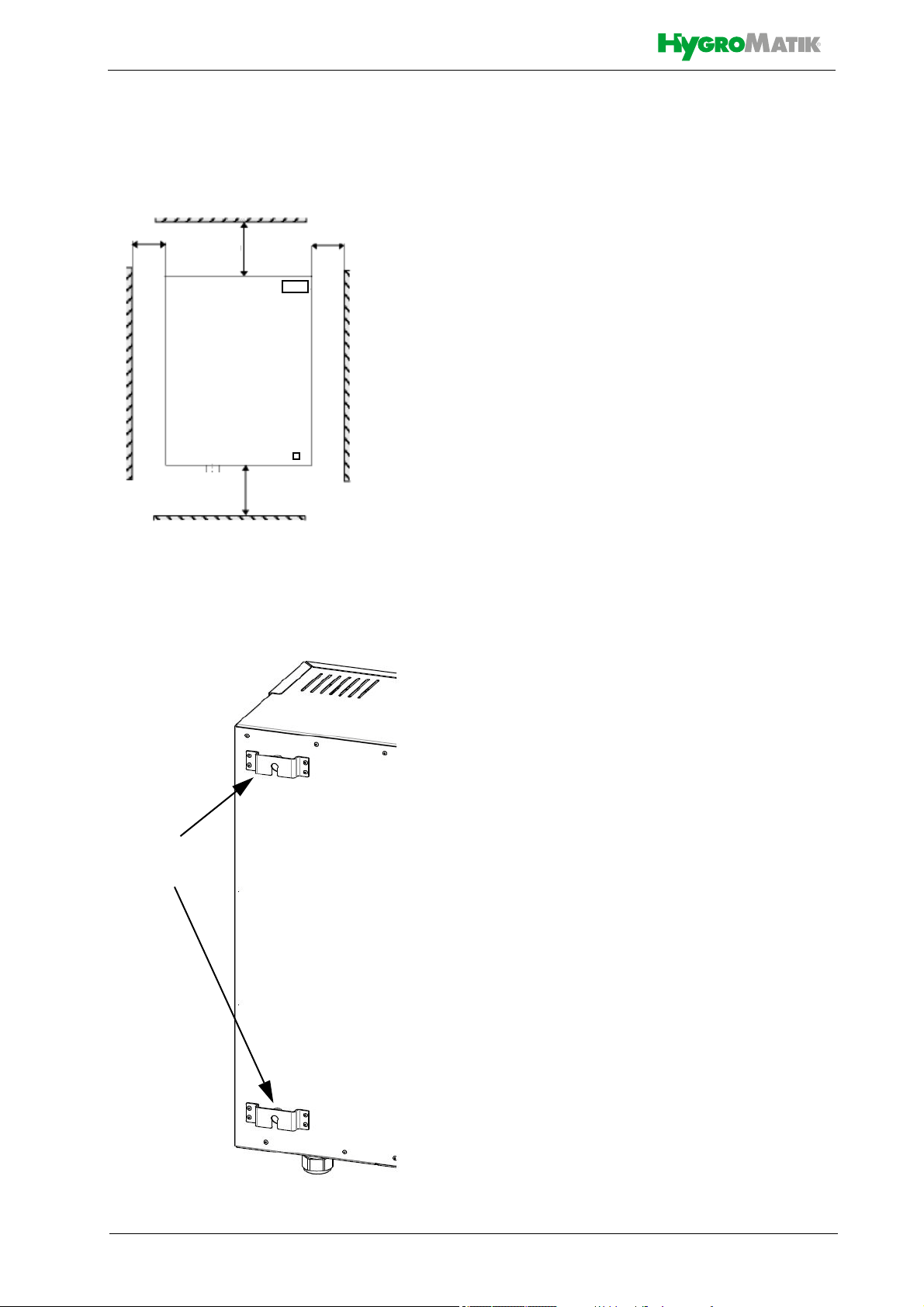

Mounting principle

Page 15

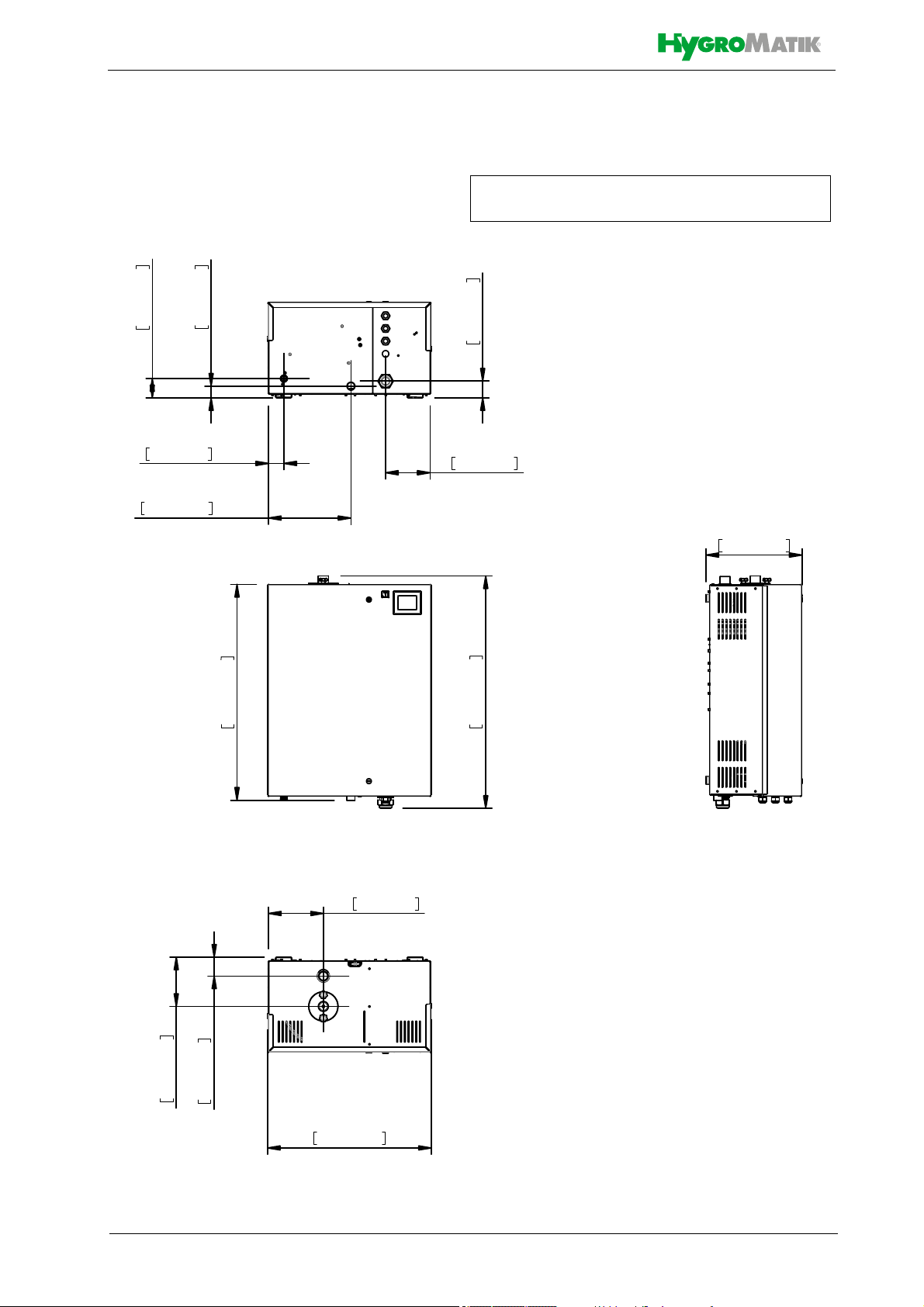

Cable entries

1¼“ Waste water connection

¾“ Water inlet

DN25, DN40 Steam outlet

Device connections:

Page 16

5.2 Unit Installation Check

Before start-up, pls. check proper unit installation following the list below:

Unit perpendicularly aligned in both

the vertical and horizontal axis ?

All clearances obeyed?

Steam hose installed with a 5 - 10 %

minimum incline/decline (see chapter "Steam line“) ?

Condensate hose features a loop

functioning as a steam barrier (see

chapter „Condensate hose“) ?

Steam manifold(s) properly positio-

ned?

All bolts and clamps properly tighte-

ned?

Steam manifold(s) horizontally mon-

ted and suspended on the free end,

if required ?

All seals (o-rings) in place?

All ventilation slots on housing top

unobscured?

Page 16

Loading...

Loading...