Hy-Gain UB-7030SAT Instruction Manual

S

ill

39759 USA

UB-7030SAT

yp

d

b

308 Industrial Park Road

tarkv

Ph: (662) 323-9538 FAX: (662) 323-

e, MS

INSTRUCTION MANUAL

GENERAL DESCRIPT ION

The Hy-Gain Model 70-30 SAT is a highperformance "OSCAR" (Orbiting Satellite

Carrying Amateur Radio) satellite antenna for the

432-438 MHz frequency band. It features

polarization switching circuitry for manual

selection of either Right Hand Circular

Polarization (RHCP) or Left Hand Circular

Polarization (LHCP). This flexible design is

suitable for worldwide applications with any of

the amateur satellites having either an uplink or

downlink in the 432-438 MHz frequency range

such as AO-10, FO-12, AO-13, UO-14, AO16,

LO-19, AO-21, UO-22, KO-23, etc. These include

modes B, J, JA, JD, JL, L and S.

The 70-30 SAT antenna features 30 elements (total) on a 4.2 wavelength boom. Each set of 15

elements is designed to give 14.0 dBd gain based

upon the NBS Tech Note 688. The 70-30 SAT

also features high efficiency "Delta" matched

driven elements for easy assembly and rugged

durability. True RF 50 ohm switching relays are

rated at 200 watts and contribute to improved

VSWR. Feed points are encapsulated for lo ng life

in all t

es of climates.

UHF 432 - 438 MHz

Satellite Antenna

Most hardware is stainless steel including the element pushnuts. All insulators are UV protected.

The coaxial assemblies are made from high-quality Polytetrafluoroethylene (PTFE) dielectric and

Fluorinated Propylene (FEP) jacketed coax cable.

The 70-30 SAT "OSCAR" antenna can be use

with the Hy-Gain 216 SAT 2-meter "OSCAR"

antenna and the 217S fiberglass 5 foot boom, or it

can be used with other commercial or homebrew

"OSCAR" antennas. The 70-30 SAT antennas may

e stacked for more gain.

PREPARATION FOR ASSEMBLY

FOR OUR OVERSEAS CUSTOMERS: If you

use the Metric System, see the Americ an-to- Metric Conversion Table in the rear of this manual.

Most illustrations in this manual will provide both

Choose a moderate-sized clear area to assemble

the 70-30 SAT Oscar Beam. The area must be at

least 24" x 63" for each boom section.

Boom Length ...................................................................................................134 in. (340.4 cm)

Maximum Boom O.D. ....................................................................................1.125 in (28.6 mm)

Turning Radius (Max).......................................................................................71.25 in (181 cm)

Total Number of Elements ......................................................................................................30

Longest Element .....................................................................................................13 in. (33 cm)

Wind Survival ..............................................................................................80 mph (128.7 km/h)

Mast/Boom Diameter Accepted ..............................................1.250 - 1.625 in (32 mm - 41 mm)

Wind Area ................................................................:............................. 0.75 sq. ft. (.0697 sq. m)

Net Weight ................................................................................................... 4 lbs 14 oz (2.21 kg)

Stacking Distance (Min) ......................................................46 inches (1.17m) (1.7 wavelengths)

SPECIFICATIONS

Mechanical

SPECIFICATIONS

(

Electrical

Frequency Range...................................................................….................................432-438 MHz

Gain ...............................................................................…..............................................14.0 dBdc

Beamwidth...................................................................………............................................28-30 degrees

Front-to-Back Ratio.....................................................…..................................................... 25 dB

Ellipticity ...................................................................................................................... 3 dB Max.

Power Rating .............................................................................................................. 200 W/PEP

Connector .......................................................................................................................... Type N

Polarity Switch Voltage and Current Requirements …………………… 9-15 VDC @ 30-60 mA

VSWR (435-437 MHz) .............................................. Less than 1.5 when using fiberglass boom

A bench-vise with jaws no wider than 6 inches is

recommended to hold the booms while the elements are being installed. An alternate method is

to drive a 5' (1.5 m) length of mast material into

the ground and attach the entire boom and boomto-mast bracket to this mast temporarily during

assembly. If you assemble this antenna over a

grassy area, protection should be taken so that

hardware is not accidentally lost during assembl y.

A concrete driveway is an excellent area for assembly.

Tools: The following tools are required for

easy assembly of the 70-30 SAT OSCAR

Beam:

Make all measurements to the given dimensions,

plus or minus, no more than 1/16 inch! The assembly of this antenna will be easier if you read

this manual completely through at least twice and

follow the recommended directions. Allow at least

4 hours for assembly.

ASSEMBLY OF THE BOOM-TO

MAST BRACKETS AND BOOM

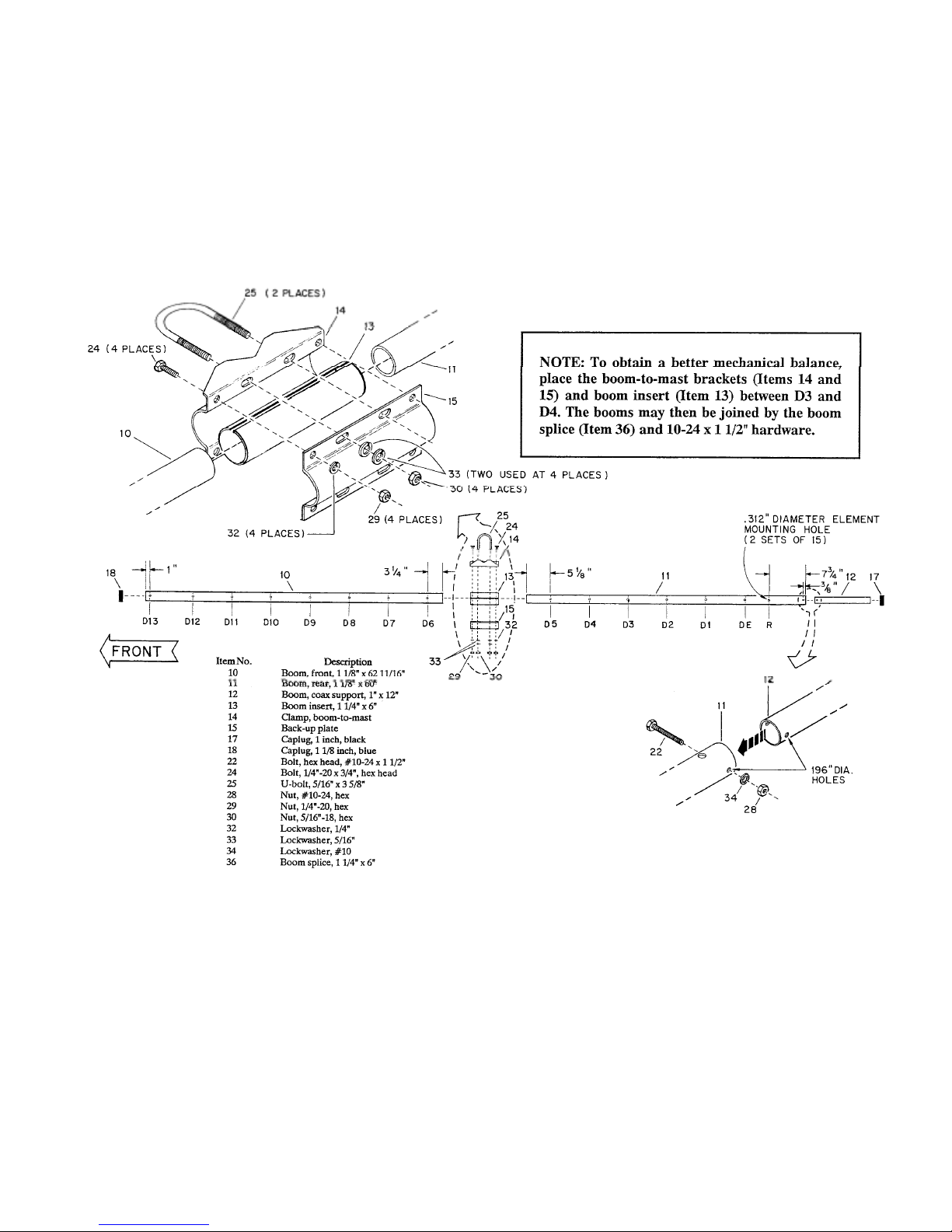

Select the boom-to-bracket parts, boom sections

and mast bracket parts as shown in Figure 1. Lineup the holes in the 3 boom sections as shown. The

front and rear boom sections should meet at the

center of the boom insert (Item 13).

NOTE: Another complete set of element mounting holes exist in the vertical plane and is not

shown in Figure 1. This set has identical spacings

between holes but is offset approximately 6 3/4

inches towards the rear of the boom assembly.

This is 1/4 wave

90 degrees) at 435 MHz.

A 3/8 inch by 6 inch tube (Item 35) is supplied to

help install the insulators and pushnuts. Standard

wrenches or adjustable wrenches may also be

used in place of nut drivers.

When unpacking your antenna, check inside of all

tubing for small parts and elements. To conserve

space, these smaller articles are sometimes put

inside larger pieces. Check all parts against the

parts list in the rear of this manual to ensure no

parts are missing.

After assembly, the boom-too-mast bracket may

be rotated on the boom so that after mounting, the

elements are in an "X" configuration. Securely

tighten the 1/4" - 20 x 3/4" hardware when the

bracket is in the desired position. Securely tighten

the #10 - 24 x 1 1/2" bolt which holds the coax

support boom to the rear boom.

Figure 1

Assembly of Boom and Boom-To-Mast Bracket

ASSEMBLY OF DRIVEN ELEMENTS

p

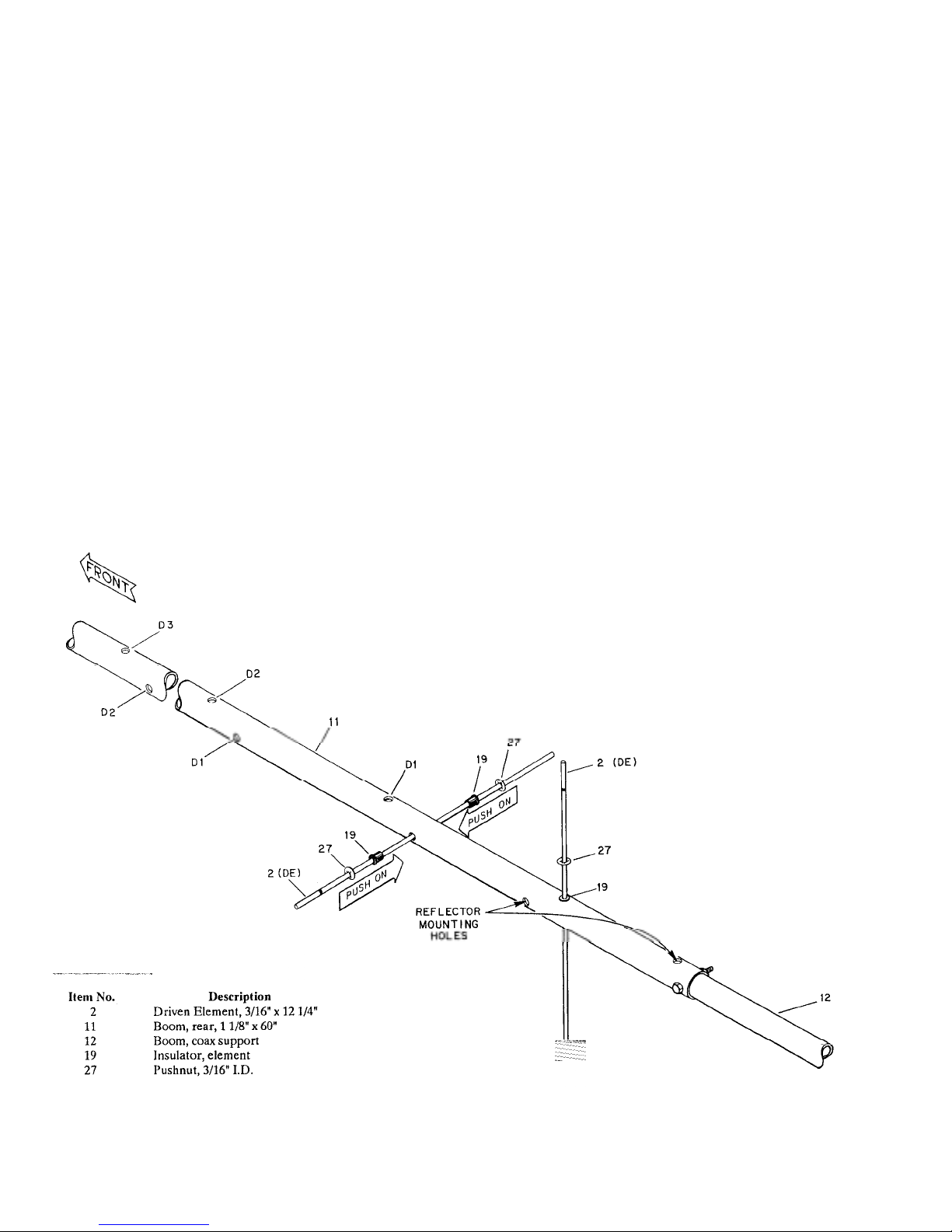

Select the two (2) driven elements, 3/16" x 12

1/4", marked with a single black color band

need one end of each. Also select the insulators

and pushnuts as shown in Figure 2.

Push one of the element insulators (Item 19)

onto each Driven Element (DE) so that its

shoulder is 5 9/16" from the nearest end (as

shown in Figure 3). I nsert t he long end of eac h

DE into the driven element moun ting holes on

the rear boom section, as shown in Figure 2.

Slide another element ins ulator (Item 19) over

the other end of the DE's, and push it onto each

element until it seats into the mounting hole.

Recheck the exposed length of the DE's and

reposition if necessary.

Carefully slip the 3/16 inch pushnuts (ite m 27)

over each end of the t wo (2) driven elements,

and push them along each element until they

are snug against each element insulator. Check

the exposed length of each DE during this

process, to ensure the correct dimensions.

NOTE: You may wish to use the sho rt length

of tubing to help push the element insulators

and pushnuts. If you accidentally slide a

pushnut on too far, then you should cut it off

the element and tr y again wit h one of the s pare

Select the DE T-Bars ( Item 20), and 3/16 inch

tubing clamps (Item 21), and associated

hardware. Assemble these parts to the driven

elements as shown in Figures 3 and 4. When

the coax assembly is installed later you will

decide on either LHCP or RHCP for the unswitched

olarization. See Figures 6 and 7.

Driven Element Location and Assembly

Figure 2

Loading...

Loading...