Hy-Gain T-2XX Instructions

Starkville, MS 39759 US

A

TAILTWISTER

y

b

,

Ph: (662) 323-9538 FAX: (662) 323-6551

INSTRUCTION MANUAL

GENERAL DESCRIPTION

T-2X / T-2XX

TM Rotator

T-2X has 110 VAC Controller

T-2XX has 220 VAC Controller

The Tailtwister rotator consists of an extra heav

duty rotator and the control unit. The rotator is

designed to be mounted on a plate inside a tower.

A mast to support and turn large communications

beams is then attached to the top of the rotator.

However, in some instances, mast mounting is

desired. The Lower Mast Support Kit, PN

5146710, contains a lower mast support and the

necessary hardware to facilitate mounting the

Tailtwister rotator on top of a mast.

New features in the Tailtwister include an 8 pin

Cinch® connector on the rear panel of the

control, a chassis ground connection on the 120

VAC model, a high-strength drive gear, a weather

proof AMP connector at the rotor unit, and RF

eads on the potentiometer lines.

CinchTm a Division of Labinal Components & Systems

The rotator unit must be wired to the control unit

with an 8-wire cable. The control unit must be

placed inside the house or other protected location.

Included in the shipping box are:

A. Instruction Manual

B. Rotator Unit

C. Controller Unit

D. Mounting Hardware Pack

E. Connector Parts Pack

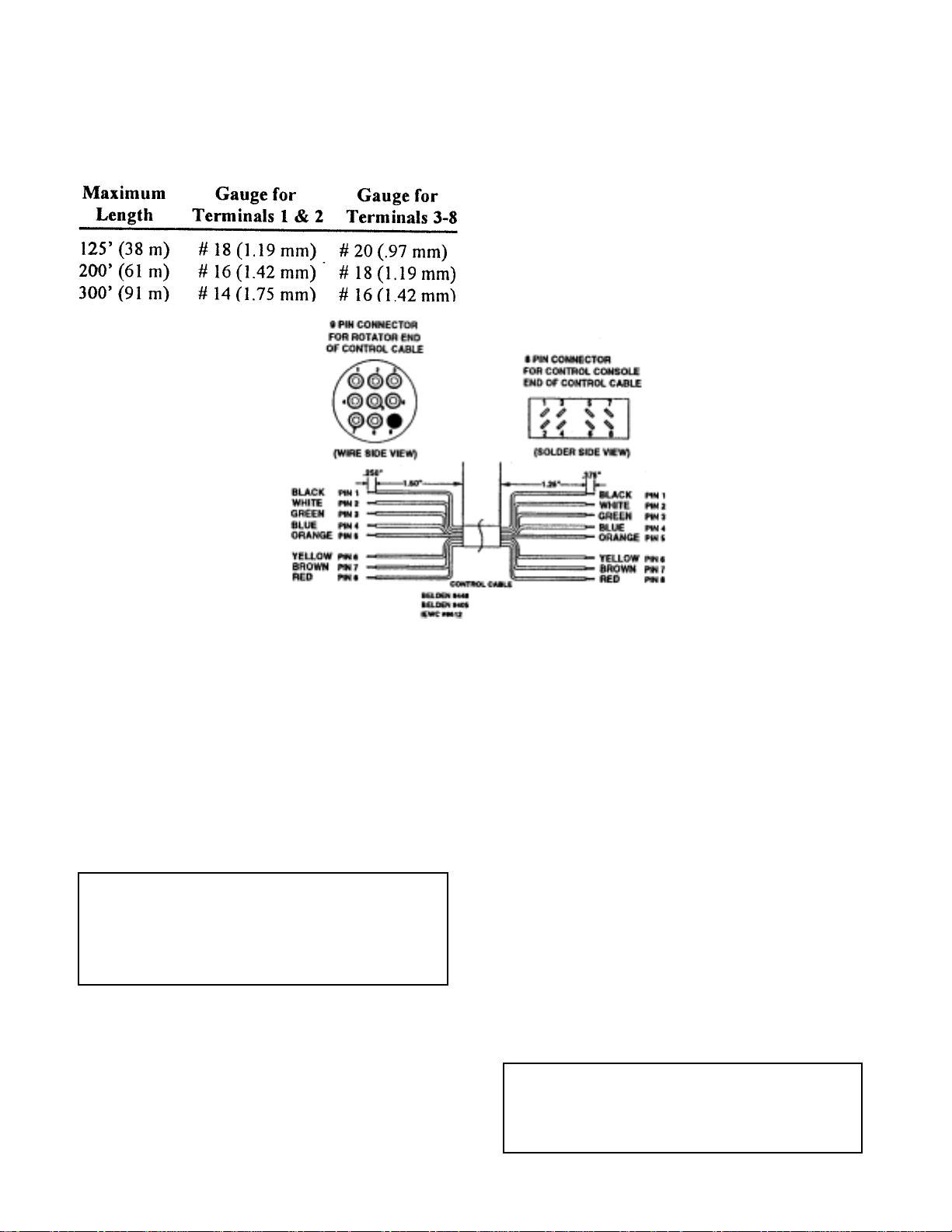

Due to the wide variety of towe rs available, each

installation will have different requirements. The

gauge of the 8-wire cable to connect the control

unit to the rotator depends upon the distance

between the rotator and control. The longer the

distance, the larger the diameter of the wire

required. Various antennas or beams require

different installation methods. (See Table 1).

Figure 1

Control Unit - Front Panel

prop

y

,

CAUTIONS

Install

Towers, often the highest metal parts in the vicinity, require caution during

erection and placement. Extreme care must be taken during erection so that

metal towers and beams do not contact power lines even if the beams slip or

rotate

Metal towers or other position mechanisms must be placed so that if they

fracture or blow over in high winds, they cannot contact power lines, be a

hazard to individuals, or endanger property.

When not mounted within a tower with a thrust bearing, as shown in Figures 6

and 7, the rotator must be DEBATED.

erly and safel

towers fall or fracture or metal wires blow in the wind, etc.

Metal towers must be grounded properly at the tower location before the tower is

p

y

g

SSU

;

erected. This is to minimize electrical hazard and the possibility of lightning

damage. DO NOT bury bare aluminum wires or stakes in the ground. Use copper

ground stakes. The service entrance ground should be checked. The household

convenience outlet should be the 3-prong type (grounded back to the service

entrance).

• The Control Box is not weatherproof and must be located in the house, ham

shack or other protected location.

• Read this manual com

letely before proceeding.

The Tailtwister rotator has been carefully designed and manufactured to give man

years of trouble-free service when carefully and professionall y installed. It consists

of the strongest and best commercially available components.

TYPES OF INSTALLATION

There are three general types of installations (see

Figures 4, 5 and 6).

l. The recommended Installation is an "Inside"

Tower Mount with a thrust bushing or bearing

to provide support and resist high wind loads.

When the rotator is properly mounted this

way, it can be rotated to turn an antenna or

beam of 20 square feet (1.86 m2) wind surface

area. The wind loading during storms, the

rotational inertia of the beam and unbalanced

weight are more important than the dead

weight of the beam. It is important to

minimize the height of the beam above the

rotator to minimize the overturning force

induced in a high wind (see "Unbalanced

ht" and "Wind Pressure").

Wei

2. An "outside" Tower Mount (see Figure 6) is

optional. The rotator is not well protected

but the installation is simpler. With an

"Outside"Tower Mount, the rotator must be

derated to 10 square feet (.93 m2).

UNBALANCED WEIGHT AND WIND

PRE

RE

Unbalanced Weight: Weight should be as

closely balanced as possible. Unbalanced

weight creates a bending moment of force

which is concentrated on the mast at the point

where it is clamped to the rotator. This

moment tends to strain the mast at that point

and also to bind the ball bearings by creating

excessive downward pressure on one side and

upward pressure on the other. Such unbalance

places additional stress on the motor gear

train. Unbalanced weight becomes critical as

the distance from the antenna boom to the

clamping point at the rotator is increased.

Wind Pressure: Wind pressure against the

boom and elements produces a bending force

on the mast which can cause the same stresses

as unbalanced weight. To strengthen the

installation to withstand unbalanced weight

and wind pressure the top mast should be as

short and as strong as possible. In multiple

arrays the antenna with the most wind area

should be closest to the rotator.

,

3. A telescoping or other type mast (see Figure

7) can also be used. This installation is

similar to Number 2 above and requires the

optional Heavy Duty Lower Mast Support

Kit and must be derated to 10 square feet

In order to distribute the bending stress and

prevent fracture of the mast, the T2X rotator

includes a specially designed steel clampin g plate

to clamp the mast to the rotator

After procuring the type of tower or other

positioning mechanism of the owner's choice, the

next step is to wire the rotator to the control box

and check out its operation prior to installation.

WIRING AND CHECK-OUT

A. Decide the wire gauge (size) required and

procure the number of feet of the proper

cable (see Table 1).

Table 1

E. Turn the power switch on. The meter should

be illuminated.

F. Depress the "Brake Release" (center) lever,

then release it. An audible click should be

heard in the rotator. This is the solenoid

operating the brake wedge.

NOTE: The specifications call for heavier

gauge wire in two locations. Leads #1 and #2

must be heavier gauge and less total lead

B. Assemble the rotor cable as shown in Figure

1.

CAUTION

Shorts between terminals or grounded leads may

damage the rotator. Pay strict attention to the pin

numbers on the connectors!

C. Temporarily attach the 6 5/16"-18 x 1 5/8"

screws (Item 140) to the bottom of the rotor

unit.

D. With the rotator sitting in the upright position

and connected to the control unit by the 8wire cable, plug the control unit power cord

into a receptacle.

Figure 2

Depress the "Brake Release" (center) lever,

hold it, and simultaneously depress the CCW

direction switch (left). The rotator should

turn CCW (looking from the top). This is SE-N-WS. Release the CCW direction switch;

the rotator wil lcoast down and stop. Now

release the brake switch. The rotator is now

locked into position.

Repeat the previous step for CW direction

by depressing the brake switch first, then the

CW direction switch (right). The red lamps

I. Return the rotator to full CW position.

CAUTION

It is best to release the direction switch just prior to

the end of rotation (extreme CW or CCW position) in

order not to cause undue stress on the stop arm

and/or the gears.

ATTACHING CONTACTS TO WIRES AND

CONNECTOR

Since these contacts will be inserted into

connector blocks, their tabs mustbe carefully

rounded. Unless you have a crimpinmg tool for

installing connectors, use the following

procedure.

Repeat for each contact. Pa y close attention to the

numbered holes in the connector! Pull back

lightly on each conductor to be sure each contact

is locked in each cavit y. Once locked in place, the

contacts may only be safely removed with an

extraction tool. (Extraction tool not included).

This tool consists of a tube with an O.D. of 0.129

and an I.D. of 0.115. When inserted over the

contact from the front side, this tool compresses

the locking tabs, permitting easy removal.

MOUTING INSIDE TOWER

y

r

p

p

w

ed.

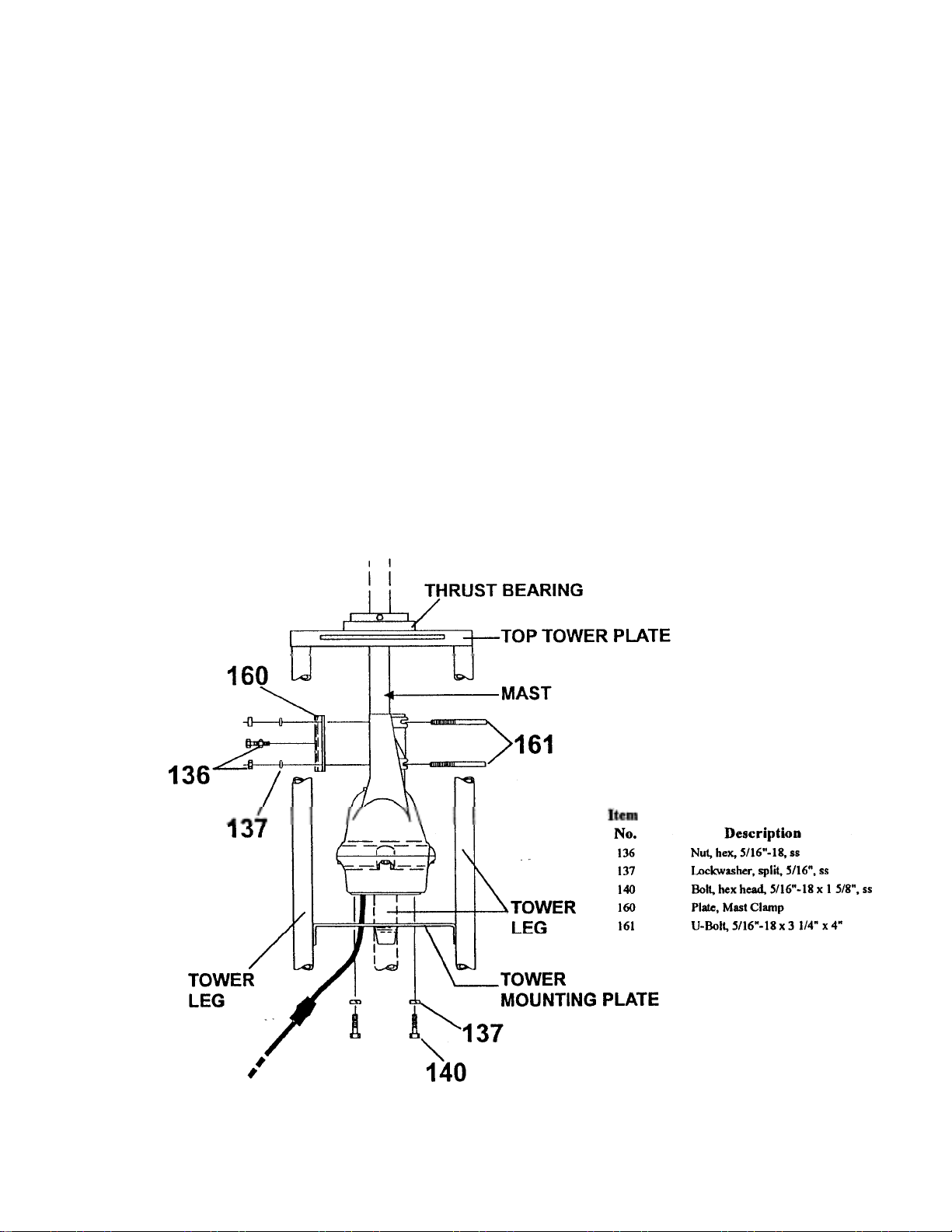

The rotator is mounted inside a tower (see Figure

4) to the flat tower plate by means of six (6) bolts

furnished in the hardware kit. Use the following

procedure:

1. Locate the rotator in the tower directl

the bushing. Note that the tower plate must be

cut out to allow the connecting 8-wire cable to

ass through the plate.

Use the tem

2. Plug the cables together and secure the cable

to the tower in such a manner that the cable

ill not be strain

3. The rotator is attached to the tower plate by

means of six (6) bolts and lockwashers (see

Figure 4). The flat tower plate must be drilled

in six (6) places using the template provided

with this manual unless the tower plate is already properly drilled.

late in the back of the manual.

unde

4

Tighten the six (6) bolts, but not to final tightness. Observe how the rotator turns. It must

rotate in such a manner as to turn the mast

concentrically in the thrust bearing.

Trial assemble the mast to the top of the rotator

5

using the U-bolts nuts and lockwashers

through the rotator and clamp plate as shown

in Figure 4. The maximum mast diameter that

may be used is 2 1/16" O.D. We recommend

1 1/2" nominal steel pipe with 1.9" O.D. in

standard wall thickness of .145". For stacked

arrays or very large beams, we recommend

extra heavy-duty wall thickness of .200".

Both steel pipes can be purchased to

specification ASTM120.

NOTE: Apply a coating of heavy-duty motor oil

or grease to the threads of the st ainless steel bolts

and U-bolts to prevent seizing.

Figure 4

Rotator Mounting in a Tower

On any inside tower installation, care must be

exercised to get the antenna mast shimmed to the

exact rotational center of the rotator. The

geometry is such that a mast of 2.062" (2 1/16"

[52 mm]) O.D. pipe will be exactly centered. If

the O.D. of your mast is less than this, you should

shim out to these dimensions.

9. Return the rotator to the full CW "S"

position. Mount the beam on the mast

pointing South. The coaxial cable should be

looped in such a manner that it will not foul

or tangle when the beam turns around in a

circle to the full 360° counterclockwise

position.

OUTSIDE TOWER

6. If the rotator, top bushing and mast are

properly aligned, there should be unrestricted

rotation through 360°. If not, the rotator may

have to be moved slightly on the flat plate. If

a high quality bearing is used in the top of

the tower (recommended), the shimming

procedure must be done more carefully as

closer tolerances.are required. It is important

that the rotator does not try to turn the mast

eccentrically with the top bushing or bearing.

7. Tighten the mounting bolts carefully - to approximately 175 inch-pounds of torque.

8. Drill through the antenna mast and rotator

casting, using a 5/16" drill. Locate the hole in

the clamp plate that is furnished. Insert the

bolt through the clamp plate, mast, and

rotator and tighten all bolts to 150 inchpounds. Refer to Figure 4.

Referring to Figures 5, 6, and 7, an outside tower

or pole mount is made in the same manner except

that the rotator is fastened by four (4) bolts only

(not six) to the Lower Mast Support, PN 51467

10. Since the eccentricity of the rotator turning in

reference to the tower is no longer important, the

shimming procedure is not necessary. The four (4)

screws must be torqued to the same specification

and the 8-wire cable securel y fastened. The lower

mast should be pinned with the 5/26"-18 x 4" bolt

as shown in Figure 6.

CAUTION

The rotator is designed for vertical operation with

the bell shaped housing in the up position. Water

and other contamination will get into the motor

unit if it's mounted horizontally or upside down.

Figure 5

Rotator Mounted On Tower Top Plate

Loading...

Loading...