g

g

g

g

S

INSTRUCTION MANUAL

Model EXP-14

Broadband Tribander 10, 15,

20 Meter

Hy-

Hy-

Hy-

308 Industrial Park

tarkville, MS 39759 USA

323-9538 FAX: (662) 323-6351

ain

ain

ainHy-

ain

Ph: (662)

Table of Contents

Table of Contents

Table of Conten tsTable of Conten ts

Page CHAPTER

1............. ...... .. ... ...... ………….. …. ..... ..... .. ...... ... ...... .. ... ...... .. ...... .. ... ...... .. ..... .... ..... ... .. ...... ... ........... .. .... .... 1-1

General Description... ..... ...... …..... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...... ..... ......... ..... ..... . ...... .......... . ... ... .1 - 1

Driven Element Description….…………………………………………………………………..1-1

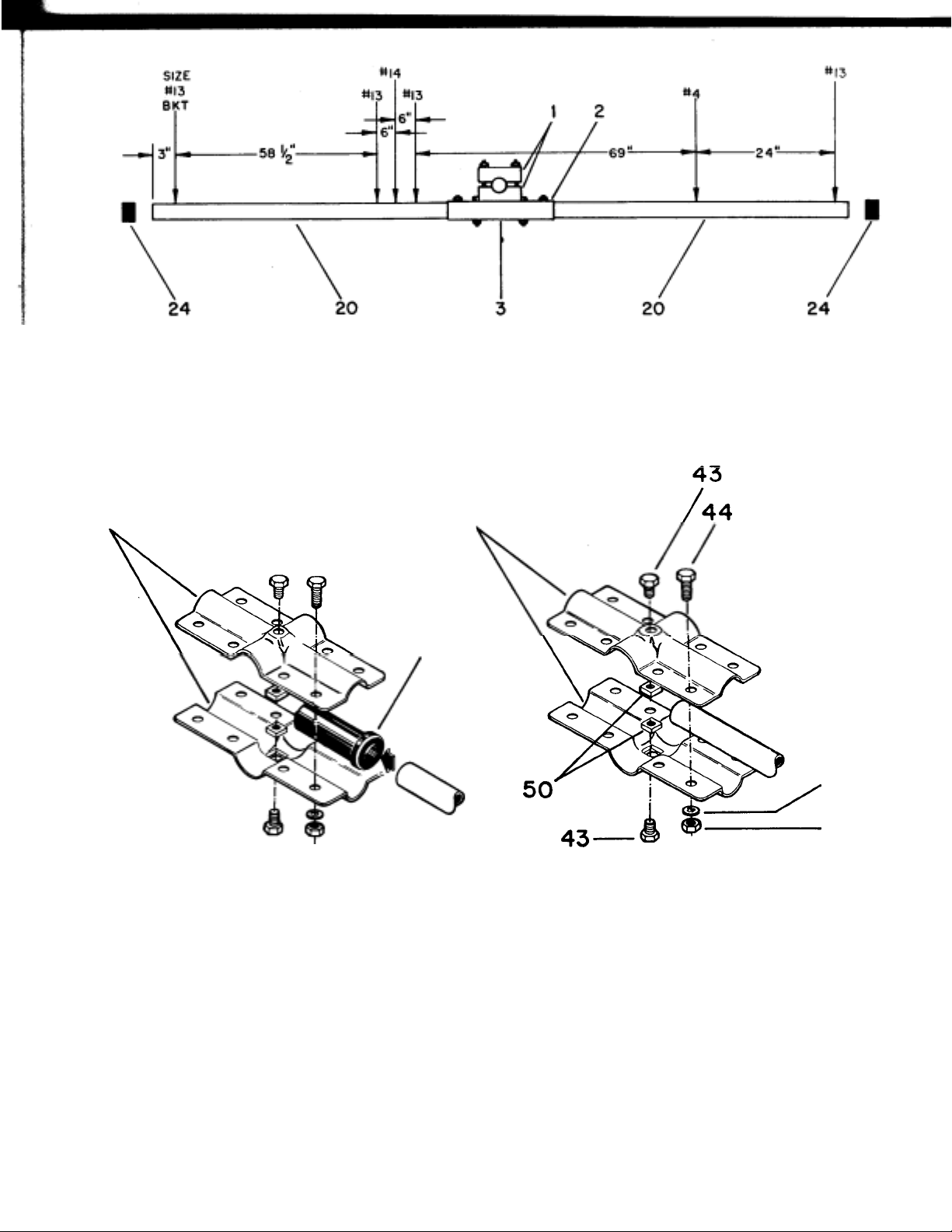

Specifications .....................................................................................….................:................................ 1-2

CHAPTER 2......: ..... ..... .:.... ...... ..... ...... ..... ...... ..... ...... .:... ..... ...... ..... ...... ..... .... ....... ...... ..... ........... ... ... ..... ... .2 -1

Preparation for Asse mbly ...... ..... ...... ..... ...... ..... ...... .. ......... ..... ..... ...... .…. ......... ..... ...... ..... ...... ........... .. ..2- 1

Option QK-710........ .... ....... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ...... ........ …. ....... ..... ...... ..... .............. .... ...2 -1

Assembly of the Boom-to-Mast Br acke ts and Boom..... ...... ..... ..…. .....… .. ......... ........ ...... ..... ...... ... ....2-2

Element-to-B oom Brac kets.... ...... ..... ...... ..... ..... ...... ..... ...... ..... .... …....... .... …. ......... ..... ...... ..... ...... .........2- 2

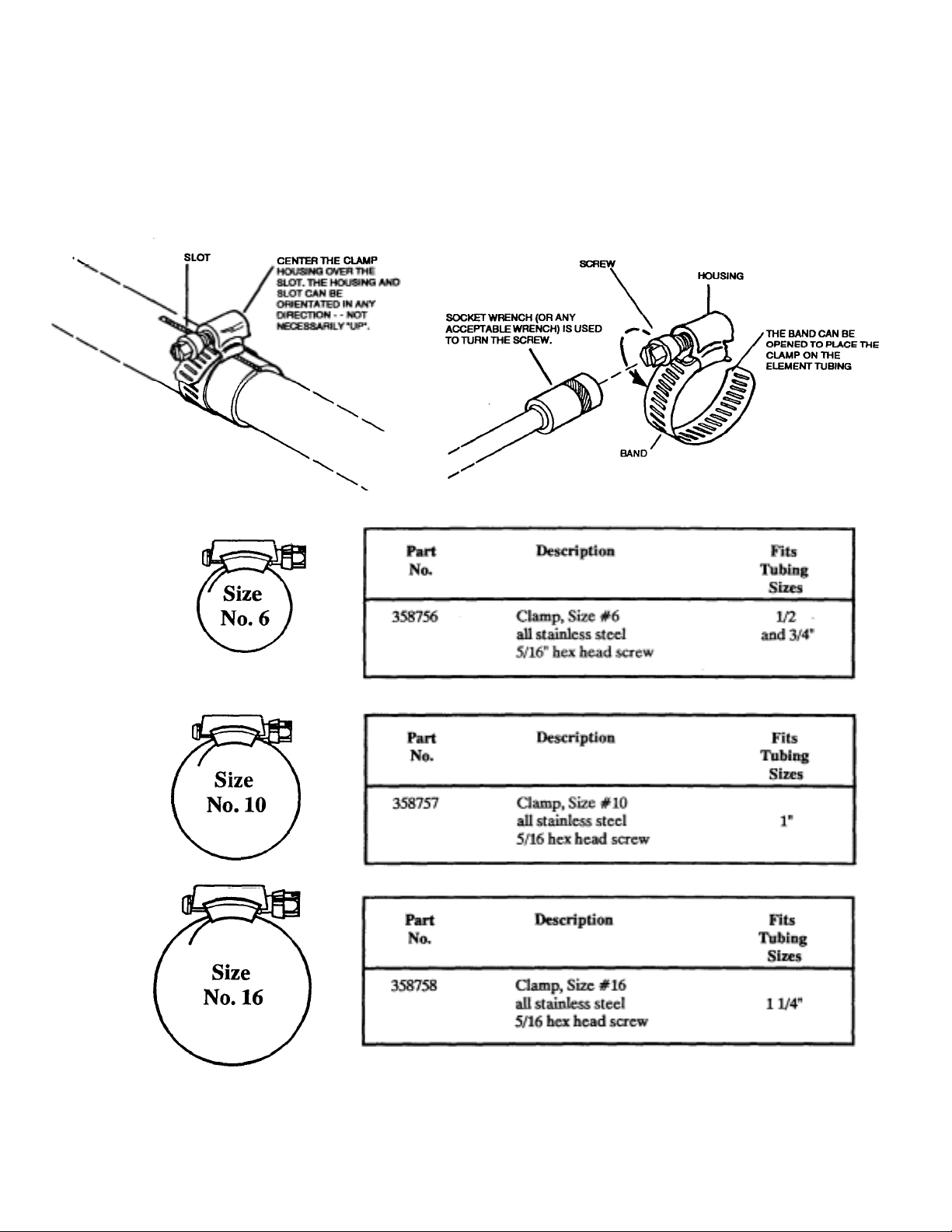

Installation of Tubing Clamps .. ...... ..... ..... -..... ..... ...... ..- ..-....... .... ...... ...... .... ….. .......... ...... ..... ........... . ...2 -4

Element Assembly ... .... ....... ..... ...... ..... ..... ...... ...... ........ ..... ..... ...- -. -. ............. .... ….. .......... ...... ....... ......... ..2 -5

10-15-20 Me te r Dir ec tor E le me n t.... ... .. ... ... ... .. .. .... ... .. ... ... .. ... ... …. .... ... ... .. ... ... . … . . ........ ... .. ... ... ... .. ...... .2- 6

Front Sleeve Element...............................................................….........................…...............................2 -7

Center Driven El emen t..... ...... ..... ..... ...... ..... ...... ..... ...... ..... .... …. ......... ..... .:.... ..... ...…. ....... ...... ........... .. ..2 -8

Rear Sleeve El eme nt.... ....... ...... ..... ...... ..... ..... ...... .... ....... .… .. .......... ...... ..... ...... ..... .... …. ......... ................ .2 -7

10-Meter R efl e c tor Ele me n t.. ... .. ... ... ... .. ... ... ... .. ... ... .. ... ... ... . …. . ........ .. ... ... .. . ..... ... .. ... ... … . . ...... ... .. ...........2- 9

15-20 Meter R eflec tor Ele men t..... ...... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ..... ...... ..... .... ……. .............. 2-10

Element Alig nment... ..... ...... ..... ...... ..... ...... ..... ...... ..... ..... --. .......... ..-. ....... ..... ...... ..... ...... ..... ...…............. 2-10

Final Assembly Para-Sleeve Driven Element System ............................................................……..... 2-13

Beta Match Assembly... ....... ..... ...... ..... ...... ..... ...... ..... ..... ...... ..... ...... ..... ........ ...... ..... ...... ..... ........... .... 2 -1 3

Para-Sleeve S pa c er Asse mbl y .. ... .. ... ... ... .. ... ... ... .. ... ... .. ... ... ... .. ... ... ... .. ... ... ... .. ... ... .. ... ... ... .. ... ... ... ..... ... 2 -1 3

Final Assembly Rope Dampening................................................................................................... 2-15

Final Assembly Chec kli st...... ..... ...... ..... ...... ..... .... ....... ...... ..... ..... ...... ..... ...... ..... ...... ..... ...... ........ ... .. .. 2 - 1 5

CHAPTER 3..................................................--..................................................................................... ..... 3- 1

Installation........ ... ..... ... ...... .. ... ..... ... ...... .. ... ...... .. .... .... ...... ... .. ...... ... ..... ... ... ..... ... ..... ... ........... ... ..... ... .. ...... 3- 1

Installation on a Crank- Up Towe r....... ..... ...... .... ....... ..... ..... ......... ..... ...... ... ....... ...... ..... ...... ..... ........... 3- 1

Attaching the Antenna to the Ma st ....... ..... ..... ...... ..... ......... ..... ..... ...... ..... ...... ..... ...... ..... ...... ........... .. .3- 1

Other Types of Towers.... ...... ..... ...... ..... ...... ........ ..... ...... ..... ...... ..... ..... ...... ..... ...... ..... ...... ..... .............. ..3- 1

Lightning Protection.............................................................................................................................3-1

Attachment of Feedli ne ....... ...... ..... ...... ..... ..... .... ....... ...... ..... ...... ..... ...... ...... ....... ...... ..... ...... ........... ..... 3- 2

VSWR Curves.... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...... ..... ...... .... ....... ..... ...... .... ....... ..... ...... .......... ... ... ..... . 3-2

CHAPTER

4............. ... ..... ... ... ..… …. ..... ...... .. ... ..... ... ...... .. ... .... .... ... ...... .. ... ..... ... ...... .. ... .... .... ... ..... ........... ...... .. 4- 1

Operation………... ...... .. ... .... .... . ....... ... ...... .. ... ...... .. ...... .. ... ...... .. ... ...... .. ...... .. ... ...... .. ... ...... .. ...... ... .4- 1

Maintenance .............................……............................................................................................4-1

CHAPTER 5....... ... .. ... .. .... .. ... .. …………... ... ...... .. .. .. .. ... ... ... .. ... ... . .. ... ... .. ...... . .. ..- 5 - 1

Troubleshooting .......... ... ... .. ... ... ... .. ...... .. ... ... . .... .. .... ... .. ... ... ... .. ... ... .. ...... ... .. .. .... ... .. ... ... .. ..5-1

CHAPTER 6....... ..... ..... ...... ...... ..... ...... ..... ...... ..... ...... ..... ..... ...... ..... ...... ..... .... ....... ...... ..... .............. ... ...6 - 1

Service Inform ation ...... .. .... ...... ..... ...... ..... -..- ...- -. .......... ...... ........ ...... ..... ..... ...... ..... ...... ........... ..... ... 6- 1

Parts List.............………….................................................................................................................6-1

Converting America n Mea sureme nts to Metr ic..... ..... ...... ..... ...... ..... ..... .... ....... ...... ..... ...... ..... ...... ...6 -3

-i-

LIST OF ILLUSTRATIONS

Figure

e

1 Overall View ................. ... ... ... ....... ... ... ... ....... ... ... ...... .... ... ... ...... .... ... ... ....... ... ... ...... .... .......1-1

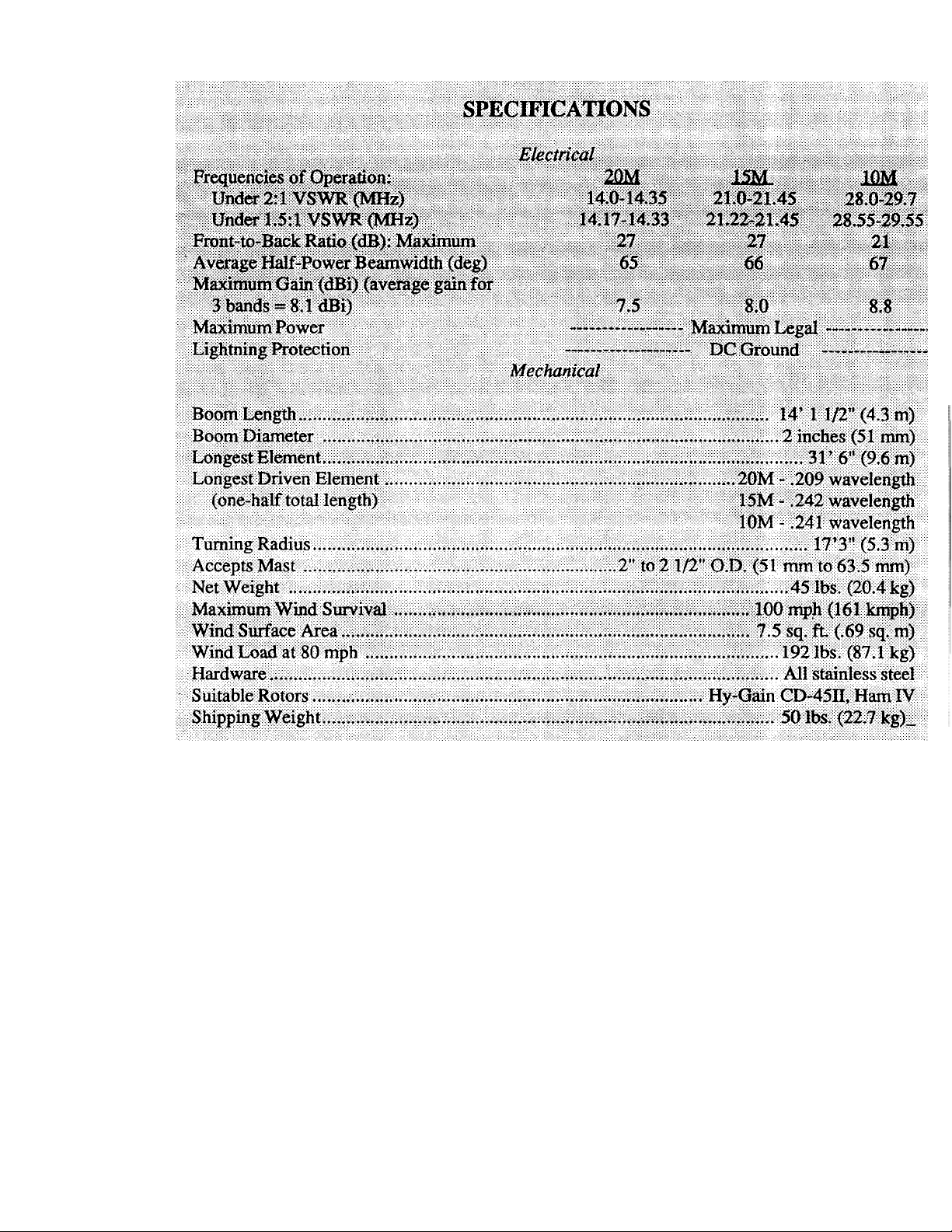

2 Boom-to-Mast Bracket....... ...... .... ... ...... .... ... ...... ... .... ...... ... ... .... ...... ... ... ....... ... ... ....... ... ...2 -2

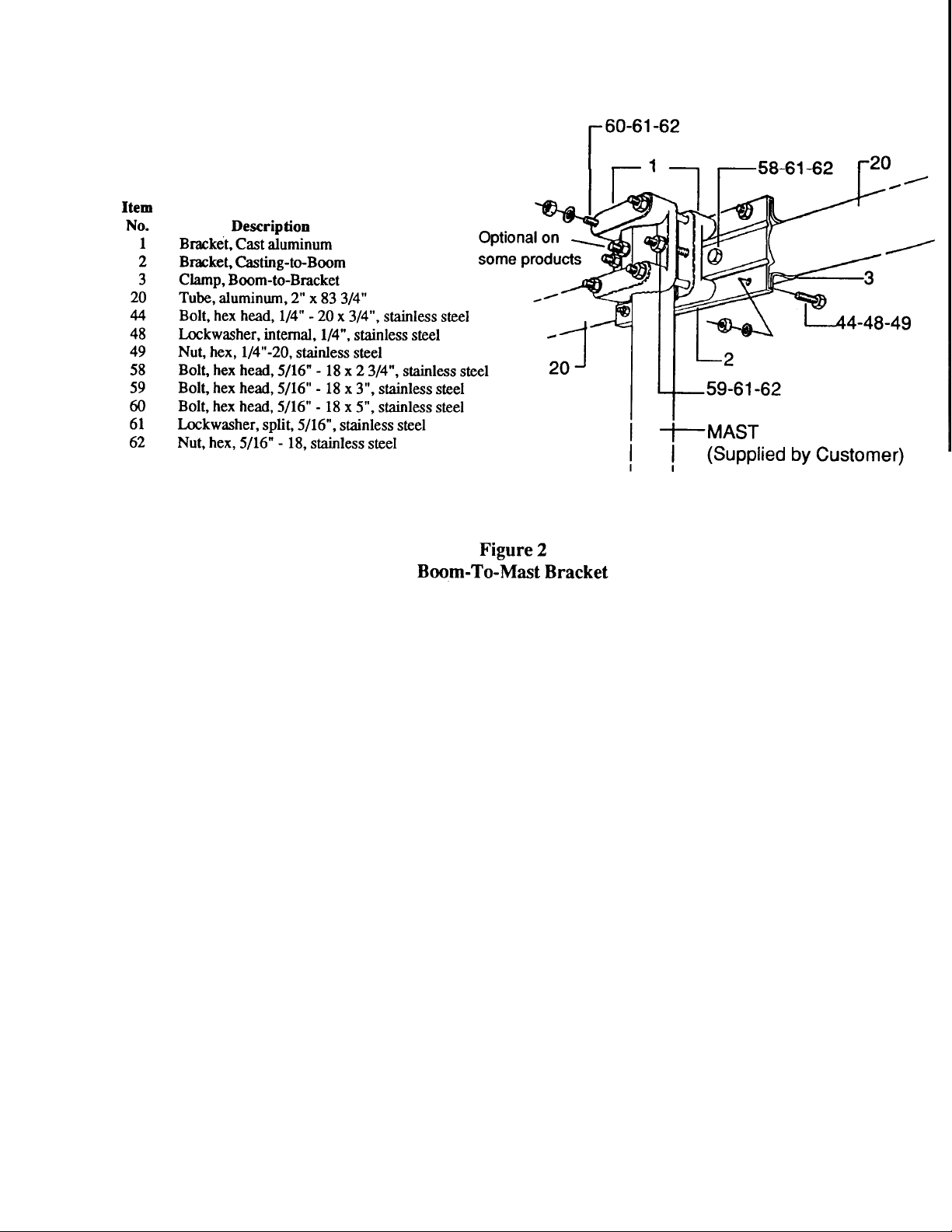

3 Assembly of Boom .......... ... ....... ... ... ... ....... ... ... ....... ... ... ... ....... ... ... ... ....... ... ... ....... ... ... ... ....2-3

4 Element-to-Boom Brackets ........ ... .... ...... ... ... ....... ... ... ... ....... ... ... ....... ... ... ....... ... ... ... ....... 2-3

5 Tubing Clamps .......... ... .... ... ...... .... ... ... ...... .... .... .. ...... .... ... ... ...... .... ... ...... .... ... ... ...... .... ... ....2-4

6 10-15-20 Meter Director Element........ .... ... ...... .... ... ...... ... .... ...... ... ... ....... .... .. ....... ... ... ..2-6

7 Front Sleeve Element............ ...... ... .... ...... ... .... ...... ..... . ....... ... ... ... ....... ... ... ....... ... ... ....... ... 2-7

8 Rear Sleeve Element ............. ... ....... ... ... ....... ... ... ... ....... ... ... ...... .... ... ...... ... .... ... ...... .... ... ...2 -7

9 Center Driven Element ............ ... ...... .... ... ...... ... .... ..... .... ... .... ...... ... .... ...... ... ... .... ...... ... ... .2-8

10 10 Meter Reflector Element ............... .... ... ...... .... ... ...... ... ... ....... ... ... ....... ... ... ....... ... ... ....2-9

11 15-20 Meter Reflector Element......... ...... .... ... ...... ... ....... ..... . ....... ... ... ....... ... ... ...... .... ~ 2-10

12 Element Assembly and Antenna Dim e nsions ... ... ... ....... ... ... ....... ... ... ...... .... ... ...... ... . 2-11

13 Para-Sleeve Driven Element Connection s.. ... ....... ... ... ....... ... ... ....... ... ...... ... .... ...... ... 2-12

Pag

Detail A Beta Support Clamps and Insulator Assembl y ...... .... ...... ... ... ....... ... ...... .... .. 2-12

Detail B Beta Shorting Clamp Assembly ....... ... ... .... ...... ..... .. ...... ... ... ....... ... ... ....... ... ... ... 2-12

14 Para-Sleeve Spacer Detail....... ...... ... ... ....... ... .... ...... ... ... ....... ... ... ...... .. 2-14

Detail A 5/8" Clamp on Open-Sleeve Spa cer Insu lator.. ...... ... ... ....... ... ... ....... ... ...... ... .... . 2-14

Detail B 11/4" Clamp on Open-Sleeve Spacer I nsulator. ... ....... ... ... ....... ... ... ...... ..... .... 2-14

15 Rope Dampening .......... .... ...... ... ... ....... ... ... ... ........ .. ... ....... ... ... ... ....... ... ... ........ .. ... ... ...... 2-15

16 VSWR Charts ............... ..... .... ... ... ...... .... ... ... ...... ..... .. ...... ... .... ... ...... .... ... ... ....... ... ... ...... .....3-

2 Attachment

1 VSWR Record................. ... .... ... ...... ... .... ...... ... .... .... ..... ... .... ...... ... ... .... ...... ... .... ...... ..... .6 -4

Insert Element Assembly and Antenna Dimensions

CHAPTER 1

General Description

The Hy-Gain Explorer 14 is a very unique 4-element, three band beam antenna designed for

broadband, high performance, high efficiency

operation on the Amateur 10, 15, and 20 meter

bands. The boom length of 14 feet 11/2 inches

(4.17 m) and a longest element of 31 feet 6 inches

(9.6 m) combine for a modest 17 foot 3 inch

turning radius, small enough for most city lots.

Broadbanding is accomplished through the use of

a monoband reflector on 10 meters, a duoband

reflector on 15 and 20 meters and a very unique

driven element system called the Para-Sleeve

Stainless steel hardware and clamps are used on

all electrical and mechanical connections. HyGain's 50 ohm BN-86 balun and new Beta MultiMatch are supplied. Add-on kits for a 30 or 40

meter driven element are available as option QK-

710. The antenna is designed to fit masts from 2"

to 2 1/2" in diameter and can be rotated with Hy-

'

-

-

-

-

Driven Element

The Explorer 14 utilizes a new concept in driven

element design, called the Para-Sleeve System

(Patent No. 4,604,628). Basically, the design consists of on *open-sleeve dipole that has been optimized for maximum bandwidth and directivity

within a Yagi-Uda configuration of parasitic elements. The open-sleeve dipole has evolved from

the coaxial sleeve dipole; however, it is much

easier to tune and exhibits less wind loading. The

ParaSleeve System consist of a trapped driven

element for 15 and 20 meters, electrically

connected to the balun and Beta-Match; and a set

This driven element system allows half element

lengths of 0.209 wavelength on 20 meters, 0.242

wavelengths on 15 meters and 0.241 wavelength on

of two parallel sleeve element for 10 meters.

For more information on the open-sleeve dipole, see H.E. King and

*

J.L.

of a Balun-Fed Open-Sleeve Dipole in Front of a Metallic Reflector", IEEE Trans. Antennas Propagation,

Vol. AP-20,201-204,

March

1972. Also

see: Roger

Cox,

"The Open-Sleeve Antenna", CQ Magazine,

Figure 1

Wong, "An Experimental Study

Vol. 39,

CHAPTER 6

p

361/

.

Preparation For Assembly

FOR OUR OVERSEAS CUSTOMERS: If you

use the Metric System, see American-to-Metric Conversion Table in the rear of this

manual. The United States uses American

units of weights and measures.

Choose a large, clear area to assemble the

EX14. The area must be at least 14' x 32' (4.3

m x 9.7 m). You may wish to use sawhorses or

chairs to support the boom during assembly.

An alternate method involves driving a 5' (1.5

m) leng th of mas t ma te ri al in t o th e gr ound

and attaching the boom and boom-to-mast

bracket to this mast temporarily during

assembly. This permits eye level installation

of parts and allows easy alignment of

elements after assembly. If you assemble this

antenna over a grassy area, precautions

should be taken so that hardware is not

accidentally lost during assembly. A concrete

The assembly of this antenna will be easier if

you read this manual completely through at

least three (3) times before beginning

assembly. Allow at least 5 hours for assembly.

Double and tri

NOTE: An

in this manual for use when assembling the

Option QK-710

The Hy-Gain Model QK-710 is an optional kit

that will allow you to add 30 or 40 meter

operation to your Explorer 14 antenna. The

kit supplies all the necessary hardware and

instructions to add an extension onto the

Para-Sleeve driven element for either 30 or 40

If you anticipate adding this kit to your

Explorer 14, you may make the following

adjustments before adding the QK 710.

le check ALL dimensions

extra Figure 12 has been inserted

Whenunpackingyou antenna, check inside of

all tubing parts (traps, smaller tubing, etc.).

To conserve space, these smaller articles are

sometimes put inside larger pieces. Check all

parts against the Parts List to make sure no

parts are missing. The hardware supplied

with this antenna is bagged by thread size for

All tubing supplied with the EX-14 telescopes

together. Make all measurements to the given

dimensions, plus or minus, no more than 1/8

- Disassemble the Para-Sleeve spacers from

the sleeve elements (FS-1 and RS-1).

Figure 14.

Increase the distance between the central

driven element and both sleeve elements

from 6" to 7" . This wil l redu ce th e

distance to the director and 10 meter

reflector by 1" each. See Figure 12.

Increase the length of the DE-2 from

2" to 37 1/2"

Slide the 15 meter DE trap all the way

Adjust FS-2 to 48" and RS-2 to

Remove DE-3 and the 1/2" element

tubing clamps from the center driven

element. Save the compression clamps.

An extension to the spacers

-

See

Assembly of the Boom-to-mast Brack-

tighten the bolts unt

ucted to do so.

g

Select the boom-to-bracket clamp parts (Item

Nos. 2 and 3). Loosely assemble them on the

boom ends (Item No. 20), as shown in Figure 2.

Line up the holes on both brackets and both

boom ends. Secure the two brackets together

with four (4) 1/4"-20 x 3/4" bolts, lockwashers

and nuts. Secure the brackets to the boom ends

using the 5/16"-18 x 2 3/4" bolts, lockwashers

and nuts. Tighten these six (6) bolts securely.

Assemble the two cast aluminum brackets (Items

No. 1) on the mast at the desired height above

your tower. Secure the two brackets together

using the two (2) 5/16"-18 x 3" bolts,

lockwashers and nuts. You may wish to drill a

hole through your mast so that a 5/16"-18 x 3

1/2" bolt may be inserted through the cast

brackets and the mast and tightened. This bolt

will prevent the antenna from twisting on the

mast in high winds. See Figure 2. The four (4) 5inch bolts will be installed when the antenna is

installed on the mast.

-

-

To save time, loosely assemble all of the

elementto-boom brackets and their appropriate

hardware before beginning further installation of

the antenna. See Figure 4. The different size

brackets can be identified by a number stamped

into the surface of each bracket half DO NOT

il instr

NOTE: Bracket size #14 is used on the center

driven element. Bracket size #13 is used on the

driven element sleeves and on the director and

15/20 reflector. Each size number is stamped into

At this time, slide each el ement-to-boom bracket

over a boom end and position all of the brackets

close to their final attachment points. See Fi gure

3 and Fi

Hand-tighten the hardware on each element-toboom bracket to prevent losing small parts, and

to prevent bracket movement on the boom.

-

ure 12.

Ite Item

No. Description No. Description

1 Bracket, Cast Aluminum 20

2 Bracket, Casting-to-Boom 24 Caplug, 2", black

3 Clamp, Boom-to-Bracket

Tube, aluminum, 2"x 83

Figure 3 Assembly

of Boom

Driven/Sleeve Detail

NOTE: The #4, # 13 and # 14 brackets use the same size

bolts, lockwashers and nuts - in identical locations.

Item Item

No. Description No. Description

4 Bracket, Element-to-Boom, #4 43

5 Bracket, Element-to-Boom, #13 44

6 Bracket, Element-to-Boom, #14 48 Lockwasher, internal, 1/4", stainless steel

25 Insulator, Front & Rear Sleeves, 5/8" I.D. 49 Nut, hex, 1/4"-20, stainless steel

28 Insulator, Driven Element, 11/4" I.D. 50 Nut, square, 1/4"-20, stainless steel

Bolt, hex head, 1/4"-20 x 3/8", stainless

Bolt, hex head, 1/4"-20 x 3/4", stainless

Figure 4

Element -T o- Boo m B ra ck ets

-

48

Installation of Tubing Clamps

Select the proper size tubing clamp as shown

in the chart. When installing the clamps, place

the clamp near the tube end with the top of the

clamp over the slot in the tube as shown in

Figure 5.

After adjustment of the tubing length, tighten

the clamp with a 5/16 inch nut driver, socket,

or open end wrench until the tubing will not

-

-

-

Element Assembl

y

Because of the broadband nature of the EX 14, it is supplied with only one setting for use

on all modes on all of the 20, 15, and 10 meter

bands. If assembled and installed correctly,

the VSWR should be below 2:1 on any

frequency on these bands.

The following steps will be in singular form.

Do each element assembly step, first for one

side of the boom and then for the other side.

The dimensions shown in Figure 12 are in

American units on the right side and Metric on

the left side.

The elements may be assembled indoors, perhaps in the garage or basement work area,

especially if the weather is cold, wet or windy

outside. Take your time, and recheck all

element dimensions. The elements should be

attached to the boom outside, at a location

near your tower.

After each element is assembled to the boom,

tighten the eight (8) 1/4"-20 x 3/4" bolts. After

all elements are assembled, make sure that

they all lie in a horizontal plane at 90 degrees

to the mast, then securely tighten the two (2)

anchor bolts on each element.

-

y

-

Item

Assemble the 10-15-20 meter director as

No. Description

shown in Figure 6 and 12. Use trap part

numbers 878749 and 878694 and install with

the tubing slots and trap drain holes facing

16 Tube, aluminum, 11/4" x 48", D1

17 Tube, aluminum, 11/8" x 30", swaged, D2

the ground and the labeled trap ends toward

the boom. Use Figure 6 and Detail "A" as

guides. Tighten all element tubing clamps

Detail A Trap Detail -

NOTE: Make sure that all trap caps are

firml

seated while measuring dimensions.

Figure 6 10-15-20 Meter

Select the FS-1 section (5/8" x 48") and a small

y

driven element insulator (Item No. 25). Slip the

insulator on the unslotted end of the FS-1 section, completely.

Install a #6 tubing clamp on the slotted end of

the FS-1 section and in sert one end of the FS-2

section (7/16" x 53") to the dimension shown in

Figure 7. Tighten the tubing clamp securely

Figure 7

Item

No.

13

14

22

25

AO-3955-B-

Description

Tube, al umi nu m, 5/ 8" x 48", swa ged, RS- 1, F S1 Tube, aluminum, 7/16" x 53"

Caplug , 7/ 16" , bl ac k

Front Sleeve Element

Rear Sleeve Element

Select the RS-1 section (5/8" x 48") and a

small driven element insulator (Item No. 25).

Slip the insulator on the unslotted end of the

RS-1 section, completely.

Assemble the remainder of the Rear Sleeve

Element using a #6 tubing clamp and the RS-2

section (7/16" x 53"). Set it to the dimension

shown in Figure 8. Tighten the tubing clamp

securel

and recheck the RS-2 dimension.

Item

No.

13

14

22

25

Description

Tube, al umi nu m, 5/ 8" x 48", swa ged, RS- 1, F S1 Tube, aluminum, 7/16" x 53"

Caplug , 7/ 16" , bl ac k

Figure 8 Rear Sleeve

-

TUBING CLAMP

p

easu

t

SIZE N0. 16 SIZE N0. 10

-

-

-

N

Select the DE-1 section (11/4" x 83") and a

Item

No. Description

large driven element insulator (see Figure 4).

Slip the insulator on the unslotted end of the

DE-1 section, com

letely.

7 T ube Assembly, aluminum, 11/4" x 83", R1,

DE-1

Install a #16 tubing clamp onto the slotted end

of the DE-1 and insert the unslotted end of the

DE-2 (1 1/8" x 42") to the dimension shown

in Figure 9. Tighten the tubing clamp securely

and recheck the DE-2 dimension.

Assemble the remainder of the center driven

element in the same manner using dimensions

NOTE: ON ALL TRAPS MAKE SURE ALL DRAIN

HOLES ARE FACING THE GROUND, ALL L ABELED

ENDS ARE TOWARDS THE BOOM AND ALL

INSULATORS AND TRAP CAPS ARE FIRMLY

SEATED. ALSO ON ALL TUBING ATTACHED TO

TRAPS, MAKE SURE ALL SLOTS ARE FACING THE

GROUND AND THE SMALL DRAIN HOLES ARE

ALIGNED WITH THE SLOTS.

Detail A Trap Detail -

M

ring Poin

from Figure 9. Use 15 meter trap Part Number

---

-

Assemble the 10-meter reflector as shown in

Figure 10, using #6 tubing clamps. Tighten all

element tubing clamps with the slots facing

the ground and recheck all dimensions.

Figure 10 10 Meter

Reflector Element

Item

No. Description

10 Tube, aluminum, 7/8" x 55", swaged, R21

11 Tube, aluminum, 5/8"x 26", swaged, R22

12 Tube, aluminum, 7/16" x 42 3/4", R2-3

22 Caplug, 7/16", black

N

p

-

Assemble the 15-20 meter reflector, as shown

in Figure 11, using # 16, # 10 and # 6 tubing

clamps. Use trap Part Number 878694 and

install with tubing slots and trap drain holes

facing the ground and the labeled trap end

toward the boom. Use Figure 11 and Detail

"A" as guides. Tighten all element tubing

clam

s and recheck all dimensions.

Element Alignment

Item

No.

7 8

9 22

65

Description

Tube Assembly, aluminum, 11/4" x 83", Rl, DE1 Tube, aluminum, 11/8" x 54", swaged, R2

Tube, aluminum, 7/16" x 37", R3,

DE-3 Caplug, 7/16", black

After

all elements

all elements in the horizontal plane at 90

from the mast. Also, recheck all dimensions

have been installed, align

°

Detail A Trap Detail -

between element centers as shown in Figure

12. Securely tighten each set of eight (8) 1/4 "-

Figure 11 15-20 Meter

20 x 3/4" bolts on every element-to-boom

bracket, then tighten both anchor bolts on

each bracket. See Figure 4. The anchor bolts

should be tightened flush to the al

bracket.

uminum

*NOTE: THESE MEASUREMENTS ARE

LONGER THAN THE MEASUREMENTS

OF THE TUBE ITSELF DUE TO THE

DEPTH OF THE BOOM-TODRIVEN

ELEMENT INSULATORS.

DO NOT INSTALL THE ANCHOR BOLT,

-

-

-

Final Assembly Para-sleeve Driven

Sy

y

eta Matc

ssembly

g

Element

stem

Do not allow the pigtail wires to touch either

the boom or the element-to-boom bracket.

Select the two (2) 1 1/4" aluminum tubing

clamps, four (4) 5/8" aluminum tubing clamps,

two (2) 1/4"-20 x 11/4" bolts, two (2) 1/4"-20

hex nuts, six (6) 1/4" lockwashers, four (4)

#10-24 x 1" bolts, and four (4) # 10-24 hex

nuts. Assemble the two (2) 11/4" tubing clamps

onto the center driven element and the f our (4)

5/8" tubing clamps onto the sleeve elements as

shown in Figure 13. Tighten these clamps

Select the two (2) boom jumper straps, four (4)

# 10 lockwashers and four (4) # 10 hex nuts.

Assemble these straps to the sleeve elements as

shown in Figure 13. The front boom jumper

strap is installed below the boom, and the rear

boom jumper strap is installed above the

boom. DO NOT allow these straps to short out

against the boom. Tighten the hardware

Select the BN-86, 50 ohm balun, U-bolt, four

(4) 7" pigtail wires and associated hardware

and assemble as shown in Figure 13. Tighten

all hardware securely. The balun sh ould slope

down towards the rear end, when i nstalled, so

that water may drain out during rain showers.

Para-sleeve Spacer Assembl

Select the remaining four (4) 1 1/4" aluminum

tubing clamps, four (4) 5/8" aluminum tubing

clamps, four (4) sleeve spacer insulators, four

(4) 1/4"-20 x 1 1/4" bolts, four (4) 1/4"

lockwashers, four (4) 1/4"-20 hex nuts, four (4)

#10-24 x 1" bolts, four (4) #10 lockwashers,

and four (4) #10-24 hex nuts and assemble as

shown in Figure 14. The sleeve spacers should

be installed near the ends of the FS-1 and RS-1

sections. Tighten all bolts securely.

NOTE: If the QK-710 option is used, do not

attach the spacers to the sleeve elements un til

the extension is added.

B

NOTE: The Beta Match Assembly is not used

in the 40-meter conversion of the Explorer 14,

therefore, it need not be assembled if you plan

to add 40-meter operation. Also, the two

pigtail wires going to the Beta Match need n ot

be installed for 40 meters.

Select the two (2) beta match tubes (3/4" x

60"), beta support clamp, beta support

insulator, beta top insulator, and associated

hardware and clamps, as shown in Figure 13

and Details "A" and "B". Assemble as shown

in Figure 13 and Details "A"and "B".

The shorting clamp should be flush with the

ends of the beta match tubes. The opposite

ends of the beta tubes should be even with the

front edge of the center driven element-toboom bracket. Ti

h A

-

hten all hardware securely.

-

---

---

Detail A 5/8" Clamp on

Open-Sleeve Spacer

Insulator

Item

No. Description

7 Tube Assembly, aluminum, 11/4" x 83", R1, DE1

13 Tube, aluminum, swaged, 5/8" x 48", RS-1, FS-1

14 Tube, aluminum, 7/16" x 53", RS-2, FS-2

29 Insulator, Open-Sleeve Spacer

Figure 14 Para-Sleeve

Detail B 11/4" Clamp on

Open-Sleeve Spacer

Insulator

Item

No. Description

45 Bolt, hex head, 1/4"-20 x 11/4", stainless

steel

48 Lockwasher, internal, 1/4", stainless steel

49 Nut, hex, 1/4"-20, stainless steel

Spacer Detail

-

Final Assembly Rope Dampening

)

g

g

Final Assembly Checklist

Select the dampener rope and cut it into two

equal lengths of six feet each. Slip a rope in to

the end of each 10 meter reflector element.

With abou t a 1/2" of rope extending from the

element end, separate the fibers and fold

them back over the element end. Refer to

Figure 15. Now slip a 7/16" caplug over the

element and rope. The rope inside the element

will dampen vibrations caused by low wind

speeds. Place a 7/16" caplug on each end of

the trapped elements. Select the 2" caplugs

and place one on each boom end. Check all

element spacings and dimensions and tighten

all of the bolts before continuing.

-

-

-

1. - Check the distance between elements, 58

1/2", 6", 6", 69" and 24". (Distances

will be 57 1/ 2", 7" , 7" , 68" and 24" if

option QK-710 is used.

2. - Check the exposed element lengths

against the dimensions shown in Figure

12. Check both sides of each element.

Ensure that the trap caps are firmly

seated. (Note differences if option QK-

3. - Check the tightness of each element

tubing clamp. You should not be able to turn

an element that is securely clamped

within a lar

er element.

4. - Check to ensure all elements lie in the

same pl ane and will be perpendicu lar (at

°

5. -Ensure that all trap drain holes and all

tubing slots will b e fa ci ng the g round wh en

Figure 15 Rope

Dampenin

6.-Securely tighten all bolts used in the ele-

-

-

7. -Securely tighten all bolts used in the

-

-

In

stallatio

g

n

Attaching the Antenna to the Mast

IMPORTANT

The Explorer 14 is a moderately large antenna

and requires some consideration as to how you

are going to get it to the top of the tower.

Thoroughly read this section before beginning to

install yo ur an te nna.

Installation on a Crank-Up Tower

Crank the tower down completely or as low as

it will go, and block all sections from moving

by using a 2" x 4" piece of wood or a solid

iron bar for heavier towers. The block should

be inserted through the lattice structure

before the tower is completely down, then the

tower can be cranked down until the block

takes the weight off the winch.

Use a ladder to reach the top of the tower.

NEVER CLIMB THE LATTICE

STRUCTURE OF ANY CRANK-UP

TOWER! Attach the mast to the tower and

rotator. (The cast aluminum boom-to-mast

brackets should be installed on the mast as

shown in Figure 2. See Chapter 2.) Attach a

gin pole to the tower to assist in lifting the

Explorer 14.

Attach the lifting rope to the balance point of

the antenna. Be careful not to damage the

rear sleeve assembly next to the boom-to-mast

clamp. The lifting rope should be fed through

the gin pole or other pulley arrangement attached to the tower. The other end should be

at ground level, available to the ground crew

for lifting. Guide ropes may be loosely looped

over the boom ends and used by the ground

crew to guide the antenna away from the

tower and ladder. Each guide rope's two loose

ends should be held by the ground crew, so

that the guide rope can be retrieved. Always

use a nonconductive type of rope if working

near power lines.

When the antenna reaches the mast bracket,

the four (4) 5" bolts should be inserted

through the holes in the mast brackets and

secured using 5/16"-18 lockwashers and nuts.

Tighten all bolts securely. You may wish to

use a deep well socket set to tighten these

bolts.

Other Types Of Towers

When installing the Explorer 14 on a guyed

tower, you may wish to use a different guide

system. If you have insulators on your guy

wires, y ou will need to keep th e antenna away

from the guy wires as well as the tower. You

may wish to use two ropes attached together

at the top of the tower and attached to the

gound about 15 feet apart. These two ropes

can then be used to slide the antenna on as it

is also being lefted. The two ropes will need to

be far enough from the tower base to allow

some sag and still support the antenna away

from the guy wires.

WARNING

Installation of this product near power

lies is dangerous. For your safety, follow

the instructions.

Lightning Protection

For proper lightning protection, you must

ground your antenna supporting structure.

Grounding will ensure noise-free operation

and low SWR. A proper ground consists of a

1/2" x 8" co pper clad steel groun d rod d riven

into the ground approximately 12" away from

the concrete tower base. Connect the tower to

the ground rod using #8 copper wire and

commercial noncorrosive

round clamps.

Attachment of Feedline

,

Use a good quality 50 ohm coaxial

transmission line such as Times Wire and

Cable RG-213/u or Belden 8214 (foam) or

Belden 8237, 8267 or 9251 (solid). Take extra

care when soldering connectors to foam

dielectric coaxial cable. Weatherproof all

connectors which will be exposed to rain or

ice, with Coax-Seal® or another similar

substance. There is no need to make the

feedline any multiple of wavelengths long.

Attach the transmission line to the BN-86

balun and tighten the connector securely. Tape

the coax to the boom and mast to ensure good

strain relief.

These VSWR curves are typical for this

antenna mounted 70 feet above the ground,

horizontally polarized. Similar curves can be

expected for this antenna mounted between 30

and 100 feet above the ground. DO NOT TRY

TO TUNE THIS ANTENNA FOR LOW

VSWR AT GROUND LEVEL. Higher VSWR

can be expected if mounted at less than 30 feet

or above a roof or large metallic structure.

Forty (40) and eighty (80) meter wire dipoles

should be kept at least 6 feet below this

antenna.

Guy wires should be broken up into

nonresonant lengths (less than 12 foot lengths)

and insulated from the tower if mounted

within 10 feet of the top of the tower.

Coax-Seal(R) is a registered trademark of Universal Electronics

-

Operatio

CHAPTER 4

Connect the other end of your transmission line

to a good quality SWR meter or Thruline@

wattmeter and then to your radio. While using

lower power (less than 200 watts output), check

the VSWR across each band from 14.0 to 29.7

MHz. Record this information for future

reference. See Attachment 1 on the last page of

this manual. Check the VSWR periodically to

ensure proper operation.

The front-to-back ratio may be checked by using

a steady carrier transmitted by a local station (at

least a half mile away). The front-to-back ratio

may be affected by the proximity of metallic

structures or guy wires less than 10 feet below

the antenna.

This completes your installation of the Explorer

14. Happy DX'ing!

Maintenanc

The Explorer 14 antenna is designed to be

relatively maintenance free. All hardware, except

for seven (7) long bolts used in the boom-to-mast

bracket, are made of passivated stainless steel.

The seven (7) long bolts are plated with a thick

layer of cadmium with a protective coating of

clear chromate. The internal tooth-type

lockwashers used in this antenna are made of a

slightly magnetic grade of stainless steel. The

element tubing clamps are made of all stainless

steel. All other metallic parts are aluminum. All

insulators are made of either black polyethylene

or black Cycolac®.

Hy-Gain now recommends genuine Penetrox-A©

from Burndy Corporation for use as an antielectrolytic compound within element

assemblies. This prevents aluminum oxide from

forming on the aluminum surface, thereby

maintaining high electrical conductivity between

element sections, especially in coastal

environments. No other type of conductive paste

should be used. Penetrox-A© may be obtained

from any electrical supply store.

A light amount of clear lacquer or an acrylic

spray may be used to coat the exterior surface of

the element assemblies if heavy oxidation is

likely to occur. Do not use any coating on trap

assemblies. Heavy oxidation of aluminum may

occur if the antenna is installed within 5 miles of

salt water.

When storing this antenna (or if awaiting

installation), care should be taken not to damage

any trap assembly or allow any dirt or insects to

enter any trap assembly. Do not leave the

elements in a grassy area, as wet grass will stain

the aluminum.

Optional

If you use a 1500 watt continuous duty power

amplifier or if you use RTTY at 1500 watts on

this antenna, the BN-86 balun should be replaced

with a suitable high power balun or RF choke.

Hy-Gain makes a new high-power current-type

balun rated at 2000 watts continuous, Model

/BN-4000B for beams.

Thruline® is a registered trademark of Bird Electronics.

Cycolac® is a registered trademark of Borg-Warner.

Pentroz-A® is a registered trademark of Bumdy

-

-

CHAPTER 5

g

y

Troubleshootin

If you encounter problems with the operation

of your Explorer 14, follow these steps to

isolate the cause.

Usually you can isolate problems that occure

in either

our antenna or feedline/feedpoint.

If you experience high VSWR on all bands,

your problem is probably in the feedline or

balun. If you experience high VSWR on some

bands but not all bands, look for problems in

the antenna element lengths or traps or nearby

resonant structures.

-

-

CHAPTER 25

p

g

,

If you are unable to resolve technical

problems, you should contact the Telex/HyGain Customer Service Department in

Minnea

You should fully research your problem by

going through the Troubleshooting Guides in

Chapter 5 before you contact the Customer

Service Department. You should also record

your VSWR across all three bands before

calling.

You should retain your sales receipt or other

proof of purchase for antennas that are still

under warranty. (See separate sheet for Telex

Warranty.)

olis, Minnesota.

All requests, inquiries or warranty claims

Amateur Department Telex

Communications, Inc. 9600 Aldrich

Avenue South Minneapolis, MN 55420

Phone: (612) 884-4051 or (612) 8875528

For orderin

Telex/Hy-Gain

Telex Communications, Inc.

8601 East Cornhusker

Highway P.O. Box 5579

Lincoln, NE 68505-5579

replacement parts

PARTS LIST (continued

)

plug, 7/

(

)

, 5/8",

pp

p

p

p

p

g

p

p

p

(

)

,

,

, sq

,

, 5/

Item

No. Part No. Description

Qty

22 455644 Ca

23

24 455625 Caplug, 2", black............................................................................... 2

25 461057 Insulator

26 465595 Insulator, beta support (bottom) ...................................................1

27 465600 Insulator, beta su

29 470486 Insulator, open-sleeve spacer ....................................................... 4

872222 Parts Pack, 395S, Straps .....................................................................1

30 168695 Clam

31 171329 Clam

32 170483 Stra

33 171077 Stra

34 171131 Sleeve, beta shortin

35 171162 Stra

36 177888 Clamp, beta support ........................................................................1

37 871508 "Pigtail" wire, 7" ................................................................................ 4

878682 Parts Pack, 395S, Clamps...................................................................1

38 358756 Clam

39 358757 Clam

40

41 358758 Clamp, tubing #16, stainless steel................................................. 6

-42 541363 U-bolt, # 10-24 x 2 1/2" x 2 3/4" ......................................................1

16", black .......................................................................12

NOT USED

I.D., front and rear sleeves................................... 4

ort (top) ..........................................................1

, tubing, 11/4 "

, tubing, 5/8............................................................................. 8

, boom jumper.........................................................................2

, boom-to-beta, 2" I.D. ...........................................................1

......................... ... .... ... ... .... ... ... .... ... ... .... ... ... .... l

, beta shorting, 3/8" radius ..................................................... 2

, tubing #6, stainless steel ................................................. 14

, tubinyg #10, stainless steel .............................................10

NOT USED

872224-1 Parts Pack, 395S, 1/4" Hardware....................................................... l

43 500156 Bolt

44 505266 Bolt, 1/4"-20 x 3/4", hex head, stainless steel .............................. 56

45 506518 Bolt, 1/4"-20 x 11/4", hex head, stainless steel ............................. 6

46 504098 Bolt, 1/4"-20 x 11/2", hex head, stainless steel ............................. 2

47 505763 Bolt, 1/4"-20 x 13/4", hex head, stainless steel ............................. 2

48 562961 Lockwasher, internal, 1/4", stainless steel ..................................72

49 554099 Nut

50 551367

872225-1 Parts Pack, 395S, #10 and 5/16" Hardware..................................... l

51 500160 Bolt

52 504069 Bolt, #10-24 x 1", hex head, stainless steel ................................. 10

53 500159 Bolt, # 10-24 x 11/2", hex head, stainless steel ............................ 2

54 500157 Bolt, #10-24 x 2", hex head, stainless steel................................... 2

55 565697 Lockwasher, internal, #10, stainless steel.................................. 28

56 554071 Nut, # 10-24, hex, stainless steel .................................................. 24

57 555792 Nut, #10-24, square, stainless steel............................................... 2

58 506968 Bolt

1/4"-20 x 3/8", hex head, stainless steel ..............................14

hex, 1/4"-20, stainless steel ................................................... 64

Nut

uare, 1/4"-20, sstainless steel ............................................

# 10-24 x 5/8", hex head, stainless steel ............................... 4

16"-18 x 2 3/4", hex head, stainless steel........................... 2

-

14

Item

y

No.

Part No.

500392

Bolt, 5/16"-18 x 3", hex head, stainless steel .................................. 2

Description

59

60 500349 Bolt, 5/16"-18 x 5", hex head, stainless steel .................................4

61 564792 Lockwasher, split, 5/16", stainless steel....................................... 13

62 555747 Nut, 5/16"-18, hex, stainless steel .....................................................9

63 873424 Balun, BN-86 .................................................................................... 1

64 878637 Trap, 15M, driven element................................................................ 2

65 878694 Trap, 15M .........................................................................................4

66 878749 Trap, 10M .........................................................................................2

67 850050 Coax-Seal ©.......................................................................................1

68 691138 Rope, 12 ft., black poly .....................................................................1

Qt

Converting American

Measurements To Metric

Use this scale to identify lengths of bolts,

diameters of tubes, etc. The American inch (1 ")

and foot (1') can be converted to centimeters in

1 inch (1 ") = 2.54 cm

1 foot (1') = 30.48 cm

Example:

42" x 2.54 - 106.7 cm

Coax-Seal® is a registered trademark of Universal Electronics Inc.

-

VSWR RECORD

Attachment

6-

hy-gains

prop

p

g

LIMITED WA RRANTY

by gain

and purchased from an authorized dealer or directly from

defects in material and workmanship for a period of 12 months for rotator products and

24 months for antenna products from date of purchase provided the following terms of

this warranty are satisfied.

The purchaser must retain the dated proof-of-purchase (bill of sale, canceled check,

1.

credit card or money order receipt, etc.) describing the product to establish the validity

of the warr ant y claim and subm it th e o rig i na l o r ma c hi ne re pr o duct io n of su ch pr oofof-

purchase to

to deny warranty without dated proof-of-purchase. Any evidence of alteration, erasure,

or forgery shall be cause to void any and all warranty terms immediately.

2. hygain

owner any defective product under warranty, provided the product is returned postage

prepaid

covering postage and handling.

Under no circumstances is

3.

Warrants to the original owner of this product, if manufactured by

by gain

by gain

agrees to repair or replace at

hygain

to

erty by the use of any

with a personal check, cashiers check, or money order for $8.00

at the time of warranty service.

hygain's

hygain

hygain

liable f or co n se q ue ntial dama ge s t o pe rs o n or

roducts.

hygain

option without charge to the original

to be free from

shall have the discretion

by gain

Out-of-warranty Service:

4.

the unit is shipped prepaid. All repaired units will be shipped COD to the owner. Repair

charges will be added to the COD fee unless other arrangements are made.

This warranty is

5.

6. hygain

without incurring any obligation to install such changes upon any of the products

previously manufactured.

All

7.

reserves the right to make changes or improvements in design or manufacture

hygain

iven in lieu of any other warranty expressed or implied.

products to be serviced in-warranty or out-of-warranty should be

hygain will

Mississippi 3975 9, USA

the problem in detail along with a copy of your dated proof-of-purchase.

This warranty gives you specific rights, and you may also have other rights which vary

8.

from state to state.

repair any out-of-warranty product provided

and must be accompanied by a letter describing

Loading...

Loading...