HydroTherm R-180C, R-210C, R-250C, R-300B Installation, Operation & Maintenance Manual & Replacement Parts List

MMOODDEELL RR SSEERRIIEESS

IINNSSTTAALLLLAATTIIOONN,,

OOPPEERRAATTIIOONN &&

MMAAIINNTTEENNAANNCCEE

MMAANNUUAALL &&

RREEPPLLAACCEEMMEENNTT

PPAARRTTSS LLIISSTT

RRCC22--1100004

4

4422--99115599

GGaass--FFiirreedd WWaatteerr CCaasstt IIrroonn BBooiilleerrss

118800,,000000 ttoo 330000,,000000 BBttuuhh IInnppuut

SSttaannddiinngg PPiilloott,, IInntteerrmmiitttteenntt PPiilloott &

VVeenntt DDaammppeer

SSEECCTTIIOONN 11:: BBOOIILLEERR IINNSSTTAALLLLAATTIIOON

Introduction............................................................ 2

Step 1: Locating & Setting Boiler........................... 3

Step 2: Installing/Purging Water Piping................. 5

Step 3: Venting Boiler............................................ 8

Step 4: Installing/Testing Gas Piping..................... 10

Step 5: W

SSEECCTTIIOONN 22:: SSTTAARRTT--UUPP&& OOPPEERRAATTIIOON

Safety Controls......................................................

Start-Up & Adjustments.........................................

iring Boiler.............................................. 11

r

N

N

t

&

17

17

SSEECCTTIIOONN 33:: MMAAIINNTTEENNAANNCCE

Water Treatment.................................................... 20

Freeze Protection................................................... 20

Before Each Heating Season................................

o Change Orifices........................................

How T

Troubleshooting..................................................... 21

(French V

Appendix

Replacement Parts List.......................................... 23

A

E

20

21

ent Damper Translation)..... 22

TES: 260 NOR

A

UNITED

IN

IN CANADA: 5211 CREEKBANK ROAD, MISSISSAUGA, ONT. L4W IR3 (905) 625-2991/FAX (905) 625-6610

ST

TH ELM ST., WESTFIELD, MA 01085 (413) 564-5515/FAX (413) 568-9613

AANNSSII//AASSMMEE CCOODDEE CCOOMMPPLLIIAANNCCEE:

D

*LOCATED IN FRONT ON MODELS R-180C

AND R-210C

PRESS. RELIEF VALVE

TEMP./PRESS. INDICATOR

HI-LIMIT AQUASTAT

7"

GAS VALVE

*

2" SUPPLY

BOILER

MODEL

R-300B

R-250C

R-210C

R-180C 28-1/4" 58-5/8" 7"21-7/8"

DIMENSIONS

ABCD

28-1/4"

32-1/4"

28-7/8"

61-7/8"

65-5/8"7"7"

8"

32-1/4"

29-3/8" 66-1/8"

25-1/8"

B

2" RETURN

9-1/2"

9-1/2"

12"

SPILL SWITCH

ROLLOUT

SWITCH

NOTE: SPILL & ROLLOUT

SWITCHES USED ON

R-180 THRU R-250.

VENT DAMPER

3 5/8"

C

36 3/4"

21 1/4"

A

25 1/2"

:

Installation must

conform to requirements of authority having jurisdiction

or, in absence of such requirements, to National Fuel

as Code ANSI Z223.1-latest edition and to National

G

Electric Code NFPA-70-latest edition. Where required by

authority having jurisdiction, installation must also conform to Standard for Controls and Safety Devices for

utomatically Fired Boilers, ANSI/ASME CSD-1.

A

BBOOIILLEERR SSHHIIPPMMEENNTT::

Each boiler is shipped in a single

carton. There is a vent damper packed separately with

the boiler (for model R-300 vent damper is optional)

WWAARRNNIINNGG:: IInnssttaalllleerrss mmuusstt ffoollllooww llooccaall rreegguullaattiioonns

wwiitthh rreessppeecctt ttoo tthhee iinnssttaallllaattiioonn ooff CCOO ddeetteeccttoorrss aannd

ffoollllooww tthhee mmaannuuffaaccttuurreerr''ss ssttaatteedd mmaaiinntteennaanncce

sscchheedduullee ffoorr tthhiiss bbooiilleerr!

!

s

d

e

For Canada, the installation must be in accordance with

Standards CAN/CGA-B149 (.1 or .2) Installation Codes

for Gas Burning Appliances and Equipment and with

Standard C.S.A. C22.1 Canadian Electrical Code, Part 1

and Part 2, and/or local codes.

AATTTTEENNTTIIOONN:: OObbsseerrvveerr lleess rrèègglleemmeennttss rrèèggiioonnaall àà ll''eeggaarrdd ddeess ddéétteecctteeuurrss ddee mmoonnooxxyyddee ddee ccaarrbboonnee eet

oobbsseerrvveerr eennttrreettiieenn ddee mmaannuuffaaccttuurriieerr ppoouurr cceetttte

cchhaauuddiièèrree!

!

t

e

The following terms are used throughout this manual to bring attention to the presence of potential hazards or to

important information concerning the product:

DDAANNGGEERR:: IInnddiiccaatteess aann iimmmmiinneennttllyy hhaazzaarrddoouuss ssiittuuaattiioonn wwhhiicchh,, iiff nnoott aavvooiiddeedd,, wwiillll rreessuulltt iinn ddeeaatthh,, sseerriioouuss iinnjjuurryy oorr ssuubbssttaannttiiaall pprrooppeerrttyy ddaammaaggee.

WWAARRNNIINNGG:: IInnddiiccaatteess aa iimmmmiinneennttllyy hhaazzaarrddoouuss ssiittuuaattiioonn wwhhiicchh,, iiff nnoott aavvooiiddeedd,, ccoouulldd rreessuulltt iinn ddeeaatthh,, sseerriioouuss iinnjjuurryy oorr ssuubbssttaannttiiaall pprrooppeerrttyy ddaammaaggee.

MMOODDEELL RR BBOOIILLEERR DDIIMMEENNSSIIOONNSS

.

.

CCAAUUTTIIOONN:: IInnddiiccaatteess aa iimmmmiinneennttllyy hhaazzaarrddoouuss ssiittuuaa-

-

ttiioonn wwhhiicchh,, iiff nnoott aavvooiiddeedd,, mmaayy rreessuulltt iinn mmiinnoorr iinnjjuurry

-

oorr pprrooppeerrttyy ddaammaaggee.

NNOOTTEE:: UUsseedd ttoo nnoottiiffyy ooff ssppeecciiaall iinnssttrruuccttiioonnss oon

-

iinnssttaallllaattiioonn,, ooppeerraattiioonn oorr mmaaiinntteennaannccee wwhhiicchh aarre

-

iimmppoorrttaanntt ttoo eeqquuiippmmeenntt bbuutt nnoott rreellaatteedd ttoo ppeerrssoonnaal

iinnjjuurryy hhaazzaarrddss.

.

.

-

y

n

e

l

2

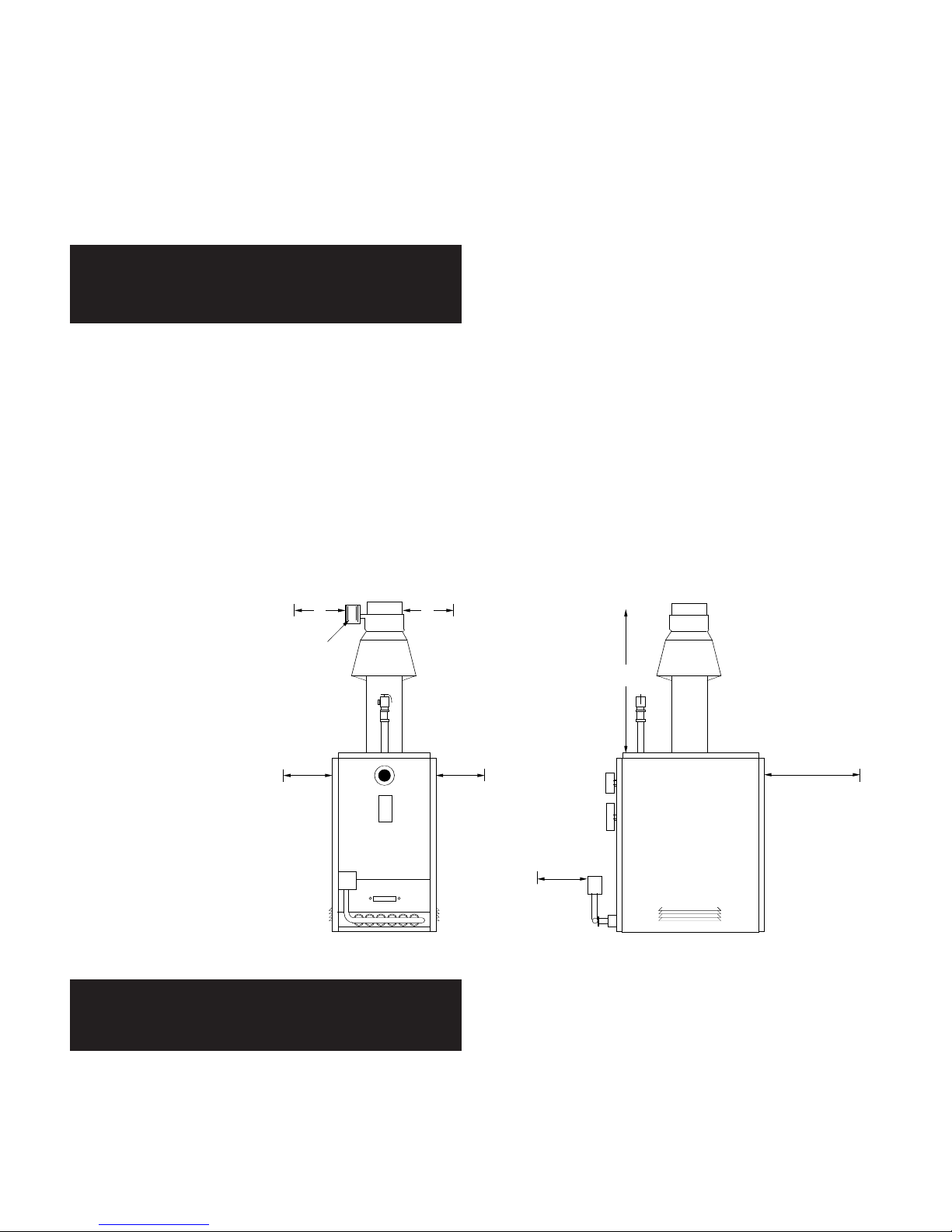

SSEECCTTIIOONN 11:: BBOOIILLEERR IINNSSTTAALLLLAATTIIOON

FRONT

ALCOVE

REAR

(6")

W/O CIRC.

24" WITH

CIRCULATOR

(RECOMMENDED

FOR SERVICING)

RECOMMEND

MORE FOR

ACCESS TO

VENT DAMPER

POSITION

INDICATOR

VENT

DAMPER

6" 6"

LEFT

6"

SIDE

VIEW

FRONT

VIEW

TOP

38"

RIGHT

6"

N

SSTTEEPP11:: LLOOCCAATTIINNGG && SSEETTTTIINNGG TTHHEE BBOOIILLEER

R

PPRROOCCEEDDUURREE AA:: CChheecckk tthhaatt pprroovviissiioonnss ffoorr ccoommbbuussttiioonn aaiirr aarree iinn aaccccoorrddaannccee wwiitthh NNaattiioonnaall FFuueell GGaass CCoodde

AANNSSII ZZ222233..11--llaatteesstt eeddiittiioonn aanndd aallll aapppplliiccaabbllee llooccaall ccooddeess.. IInn CCaannaaddaa,, ffoollllooww CCAANN//CCGGA

BB114499((..11 oorr ..22)) iinnssttaallllaattiioonn ccooddeess.

.

WWAARRNNIINNGG:: AAddeeqquuaattee ffrreesshh aaiirr mmuusstt bbee pprroovviiddeedd ffoor

ccoommbbuussttiioonn.. OOtthheerrwwiissee,, iimmpprrooppeerr bbooiilleerr ooppeerraattiioon

aanndd iinnaaddeeqquuaattee vveennttiinngg ooff ddeeaaddllyy fflluuee ggaasseess mmaay

.

rreessuulltt.

When communicating directly with the outside, each

r

opening must have a minimum free area of one square

n

inch per 4000 Btu/hr of gas input. When ventilation air is

y

provided by openings in doors, etc. to adjoining spaces

A

having adequate infiltration, each opening must have a

IIff bbooiilleerr iiss iinnssttaalllleedd iinn aann uunnccoonnffiinneedd ssppaaccee,

,

adequate

air will be available via normal infiltration.

IIff bbooiilleerr iiss iinnssttaalllleedd iinn aa ccoonnffiinneedd ssppaacce

e

(a space with

a volume of less than 50 cubic feet per 1000 Btu/hr of

gas input for all fuel burning equipment) or building construction is unusually tight, adequate air for combustion

must be provided by two openings: one located about 6”

minimum free area of one square inch per 1000 Btu/hr of

gas input.

NNOOTTEE:: BBooiilleerr eemmppllooyyss aattmmoosspphheerriicc ccoommbbuussttiioonn.

CCoommbbuussttiioonn aaiirr mmuusstt nnoott bbee ccoonnttaammiinnaatteedd wwiitthh hhaallooggeennaatteedd hhyyddrrooccaarrbboonn vvaappoorrss,, aaeerroossooll pprrooppeellllaannttss oor

ffrreeoonn;; ootthheerrwwiissee,, hheeaatt eexxcchhaannggeerr wwiillll bbeessuubbjjeecctt tto

ccoorrrroossiioonn,, rreedduucciinngg bbooiilleerrlliiffee.

.

below the ceiling, the other about 6” above the floor.

e

.

-

r

o

PPRROOCCEEDDUURREE BB:: CChheecck

mmiinniimmuumm cclleeaarraanncceess tto

ccoommbbuussttiibblleess aarree pprrooppeer

aass sshhoowwnn.. LLooccaall rreeqquuiirreemmeennttss mmaayy ssppeecciiffy

ggrreeaatteerr cclleeaarraanncceess && mmuusst

bbee aadd--hheerreedd ttoo.

BBooiilleerr sshhaallll bbee iinnssttaallll--eed

ssuucchh tthhaatt tthhee ggaass iiggnniittiioon

ssyysstteemm ccoommppoonneennttss aarre

pprrootteecctteedd ffrroomm wwaatteer

((ddrriippppiinngg,, sspprraayyiinngg,, rraaiinn,

eettcc..)) dduurriinngg aapppplliiaanncce

ooppeerraattiioonn aanndd sseerrvviiccee ((cciirrccuullaattoorr rreeppllaacceemmeenntt,, ccoonnddeennssaattee ttrraapp,, ccoonnttrrool

rreeppllaacceemmeenntt,, eettcc..)).

WWAARRNNIINNGG:: NNeevveerr iinnssttaallll bbooiilleerr oonn ccoommbbuussttiibbllee fflloooorriinngg oorr ccaarrppeettiinngg aass hheeaatt ddaammaaggee aanndd//oorr ffiirree mmaay

rreessuulltt.

.

.

.

k

o

r

-

y

t

d

n

e

r

,

e

-

l

NNOOTTEE:: DDoo nnoott lloooosseenn ttiiee rrooddss oonn aabbssoorrppttiioonn uunniitt.

-

TThheeyy aaccccoommmmooddaattee tthheerrmmaall eexxppaannssiioonn.. LLoossss ooff bbooiill-

y

eerr ssttrruuccttuurraall iinntteeggrriittyy aanndd wwaatteerr lleeaakkss//ddaammaaggee mmaay

.

rreessuulltt.

CCAAUUTTIIOONN:: LLooccaattee bbooiilleerr ssoo hhoorriizzoonnttaall ccoonnnneeccttiinng

fflluuee ppiippee iiss aass sshhoorrtt aass ppoossssiibbllee.. MMaaxxiimmiizzee hheeiigghhtt oof

vveerrttiiccaall fflluuee ccoonnnneeccttoorr.

.

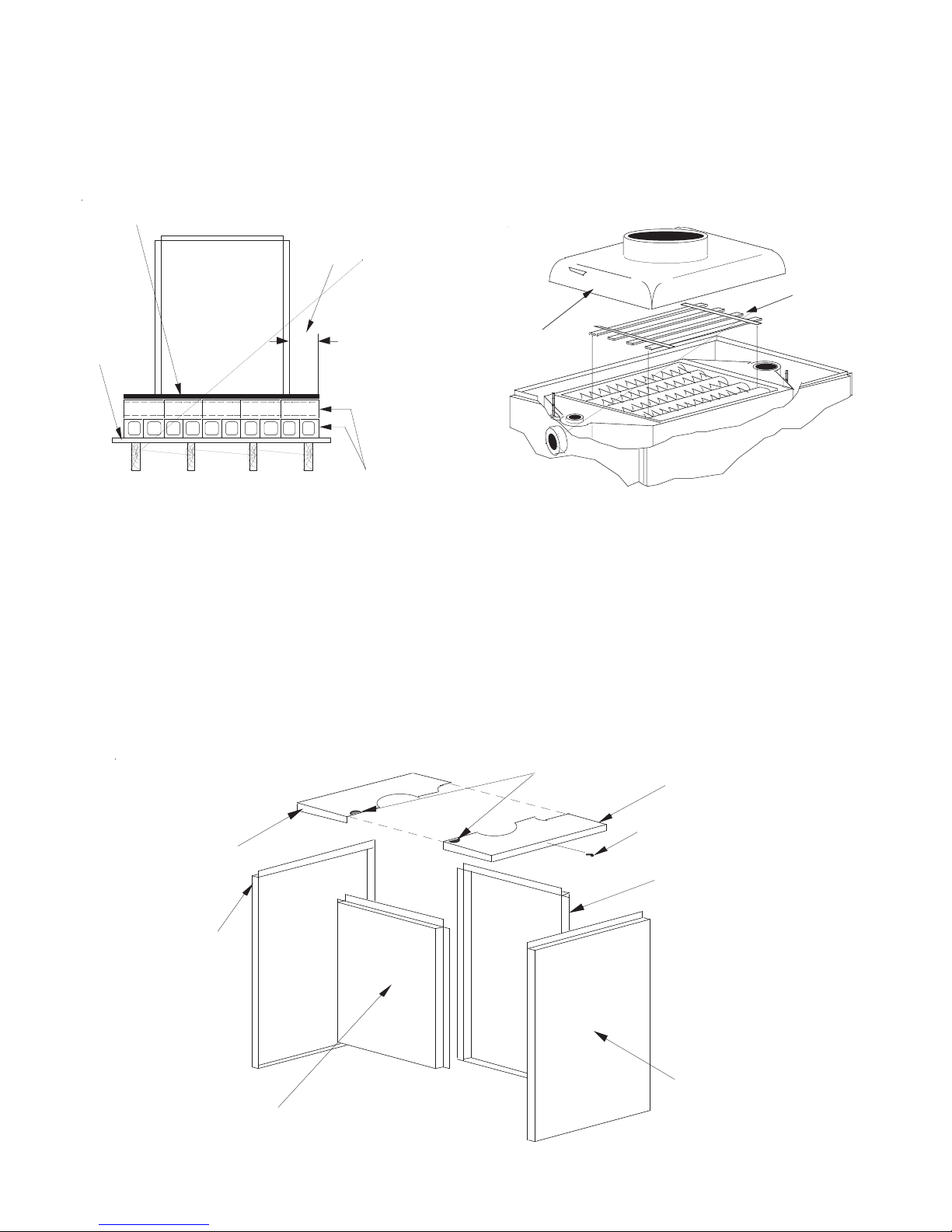

FIGURE 1.1

.

-

y

g

f

3

BAFFLE

GRID

DOME

6"

4

" HOLLOW CLAY TILE (TWO COURSES) OPENINGS THRU

B

LOCKS IN TOP COURSE TO BE AT 90 ANGLE TO OPENINGS

THRU BOTTOM COURSE

0

22 GAUGE

SHEETMETAL

FLOOR

6" OVERHANG

OF BLOCK AND

SHEETMETAL

A

LL AROUND

LEFT TOP PANEL

FRONT PANEL

(BOILER MOUNTED)

RIGHT SIDE PANEL

RIGHT TOP PANEL

LEFT SIDE PANEL

REAR PANEL

REMOVE KNOCK-OUT

ASSEMBLY SCREW

PPRROOCCEEDDUURREE CC:: CChheecckk ccoommppoonneenntt ppoossiittiioonniinngg..

1. Remove all packing material from boiler.

. Install boiler on non-combustible flooring only, unless

2

local codes permit use and fabrication of a recommended fireproof base (see Figure 1.2A).

FIGURE 1.2A FIGURE 1.2B

3. Check that burners and controls are in the proper

position.

. Check proper seating of baffle grid inside of dome

4

opening (see Figure 1.2B).

PPRROOCCEEDDUURREEDD:: IInnssttaallll jjaacckkeett.

.

1. Unpack jacket parts from carton and check that quantity is correct: two side panels, one rear panel, one left

top panel and one right top panel (see Figure 1.3).

2. Stand left and right side panels in place and fasten to

front panel with screws provided. Fasten side panels to

rear panel in same manner.

3. Lock left and right halves of top panel together and fasten to side panels with screws provided.

FIGURE 1.3

4

SHUT-OFF

VALVE

VERTICAL EXPANSION TANK

ARRANGEMENT (PREFERRED)

DRAIN VALVE

SHUT-OFF

VALVE

PRESS.

RELIEF

VALVE

AIR VENT

SHUT-OFF

VALVE

PRESSURE

REDUCING

(FILL) VALVE

SHUT-OFF

VALVES

CIRCULATOR

DRAIN VALVE

HORIZONTAL EXPANSION

TANK ARRANGEMENT

DRAIN VALVE

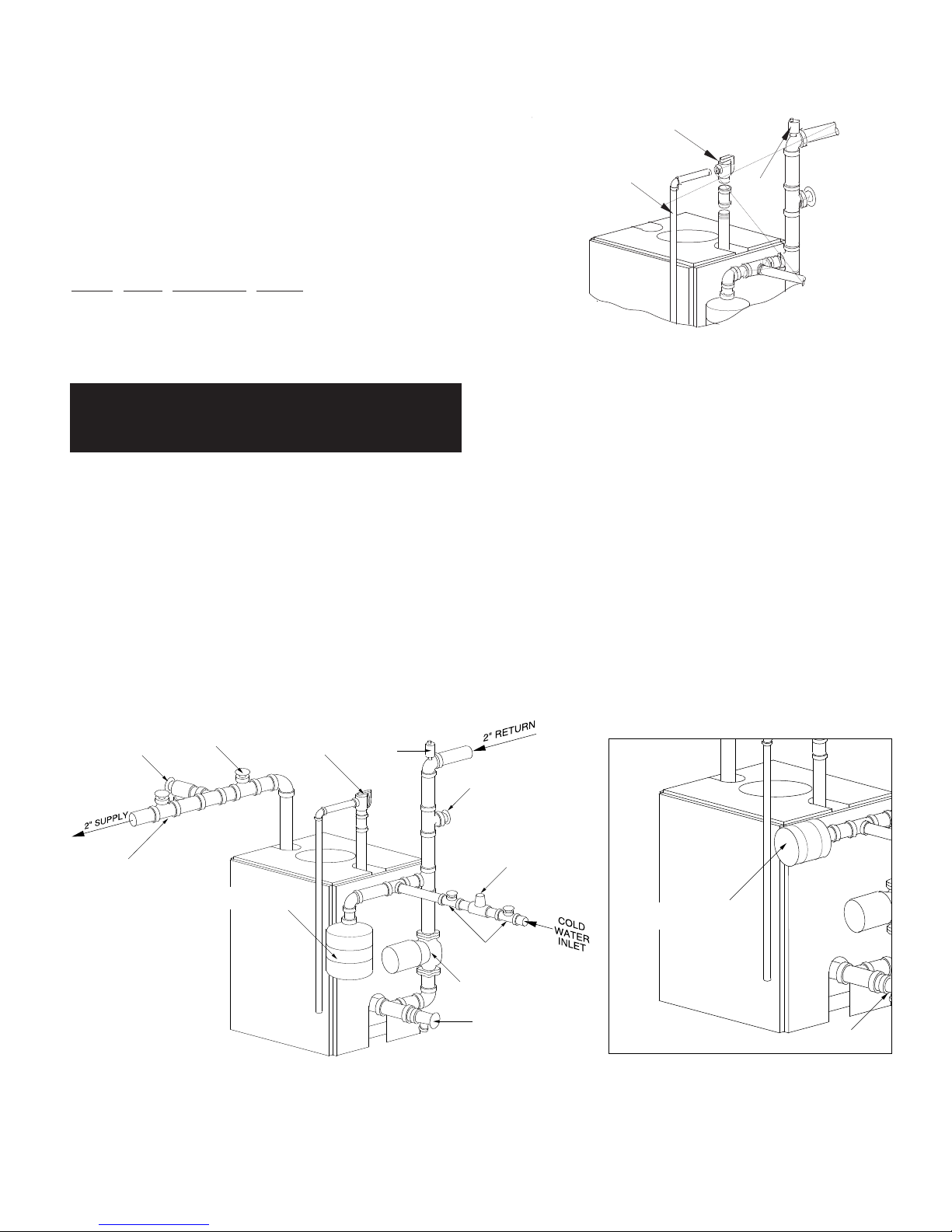

SSTTEEPP22:: IINNSSTTAALLLLIINNGG && PPUURRGGIINNGG WWAATTEERR PPIIPPIINNG

PRESS. RELIEF VALVE

AIR

VENT

RELIEF VALVE DISCHARGE

PIPING

G

NNOOTTEE:: BBooiilleerr mmuusstt nnoott bbee uusseedd wwiitthhoouutt ffoorrccee cciirrccuullaattiioonn,, aass oovveerrhheeaattiinngg oorr ffaaiilluurree ooff ccaasstt iirroonn

sseeccttiioonnss mmaayy rreessuulltt.

PPRROOCCEEDDUURREE AA:: IInnssttaallll pprreessssuurree rreelliieeff vvaallvvee aannd

rreelliieeff vvaallvvee ddiisscchhaarrggee ppiippiinngg.. FFoorr MMooddeell RR--330000B

ssuuppppllyy oouuttlleett iiss aatt rreeaarr aanndd rreelliieeff vvaallvvee ppiippiinngg iiss aat

ffrroonntt ooff bbooiilleerr.

.

d

B

t

.

RReelliieeffVVaallvveeDDiisscchhaarrggeePPiippiinngg:: MMuusstt tteerrmmiinnaattee 66”

aabboovvee fflloooorr && bbee ssaammee ssiizzee oorr llaarrggeerr tthhaann vvaallvvee oouuttlleett.

WWAARRNNIINNGG:: NNoo vvaallvvee ooff aannyy ttyyppee mmaayy bbee iinnssttaalllleed

bbeettwweeeenn bbooiilleerr && rreelliieeff vvaallvvee ttoo pprreevveenntt aacccciiddeennttaal

eexxpplloossiioonn ffrroomm oovveerr--pprreessssuurree..

PPRROOCCEEDDUURREE BB:: IInnssttaallll ssuuppppllyy aanndd rreettuurrnn wwaatteer

ppiippiinngg.. FFoorr MMooddeellss RR--118800CC && 221100CC ssuuppppllyy oouuttlleett iis

aatt ffrroonntt ooff bbooiilleerr aanndd rreelliieeff vvaallvvee ppiippiinngg iiss aatt rreeaarr oof

.

bbooiilleerr.

-

”

.

CCAAUUTTIIOONN:: PPiippiinngg mmuusstt bbee iinnssttaalllleedd ffrroomm rreelliieeff vvaallvve

d

ddiisscchhaarrggee ssoo tthheerree wwiillll bbee nnoo ddaannggeerr ooff ssccaallddiinngg ppeerr-

l

ssoonnnneell.

r

IIff bbooiilleerr iiss iinnssttaalllleedd aabboovvee lleevveell ooff rraaddiiaattiioonn,, aa lloow

s

wwaatteerr ccuutt--ooffff mmuusstt bbee uusseedd.

.

.

f

AALLLLEEXXTTEERRNNAALLPPIIPPIINNGG MMUUSSTT BBEE SSUUPPPPOORRTTEEDD BBY

HHAANNGGEERRSS,, NNOOTT BBYYBBOOIILLEERR AACCCCEESSSSOORRIIEESS.

FIGURE 1.4

e

-

w

Y

.

FIGURE 1.5

5

S

UPPLY

R

ETURN

50%

120° F

100%

140° F

1

00%

160° F

50%

160° F

50%

160° F

SYSTEM

BYPASS

SUPPLY

RETURN

50%

120° F

100%

140° F

100%

160° F

50%

160° F

50%

160° F

PUMP AWAY

BYPASS

SUPPLY

RETURN

100%

120° F

200%

140° F

200%

160° F

100%

160° F

100%

160° F

PUMPED

BYPASS

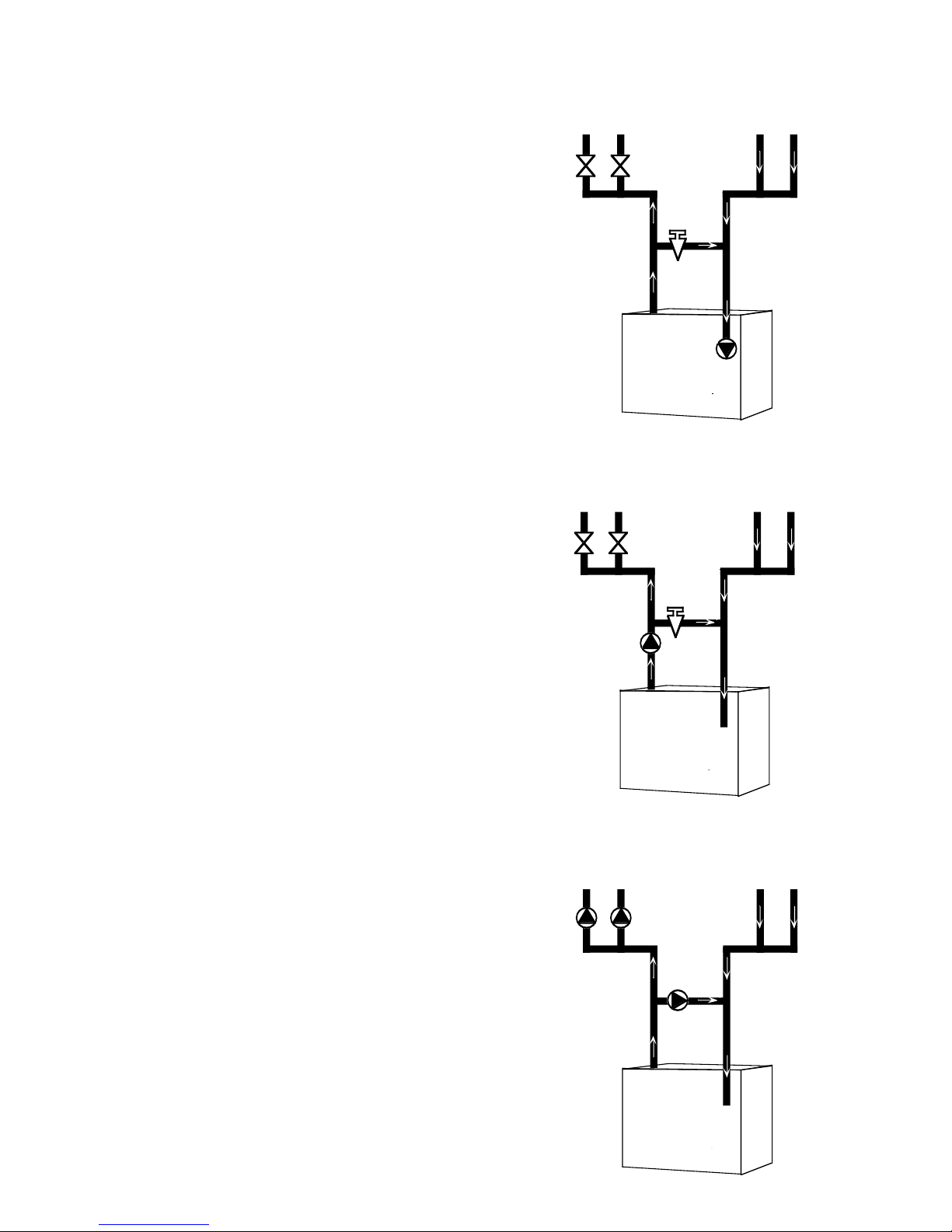

CCAAUUTTIIOONN:: TToo pprreevveenntt ddaammaaggee dduuee ttoo eexxcceessssiivvee ccoonnddeennssaattiioonn,, oonnee ooff tthhee ffoolllloowwiinngg ppiippiinngg ooppttiioonnss sshhoouulld

bbee uusseedd.

.

-

d

SSYYSSTTEEMM BBYYPPAASSS

S

For systems using a circulator on the return as either a

single zone, or multiple zones with zone valves, install a

system bypass line between the supply and return on the

suction side of the circulator (see Figure 1.6). Install a

etering valve in this bypass line to regulate the amount

m

of flow that will be diverted to the return. A plug valve

offers the best control for this application. Although other

valves may be less expensive, a plug valve will be easier

to set accurately.

In the absence of a flow indicator, set the metering valve

using temperature as a guide. The accompanying diagram suggests one scenario. This addition requires only

two tees, a plug valve, and a small amount of pipe and

offers the simplest approach to reliably control condensation. For this system and those that follow, be aware that

you are using a percentage of the pump capacity to

blend, but the friction loss for the entire pump flow has

been reduced. In most cases, the standard pump packaged with the boiler has enough capacity to feed the

baseboard distribution system and the bypass line.

PPUUMMPPAAWWAAYYBBYYPPAASSS

S

For systems that use a single circulator to pump away

from the boiler, the bypass should be installed on the discharge side of the circulator (see Figure 1.7). Full temperature water supplies the baseboard distribution system as before. Half of the circulator’s volume moves

through the bypass, blending and heating the cooler

return water. Again, the cost of installing the bypass is

small and setting it by temperature can be accomplished

with a contact thermometer.

FIGURE 1.6

PPUUMMPPEEDD BBLLEENND

D

An additional circulator can also be used to provide a

return water temperature blend. This method works well

with systems with multiple zones with circulators (see

Figure 1.8). The dedicated bypass circulator provides a

strong blending flow without diminishing the flow available to any heating zone. Any residentially sized circulator is adequate for this purpose.

Each of these bypass solutions also has the added benefit of increasing circulation in the boiler which will maxi

mize tankless coil output and increase the accuracy of

temperature sensing controls.

FIGURE 1.7

-

FIGURE 1.8

6

VALVE “C”

VALVE “B”

VALVE “A”

VALVE “D”

VALVE “E”

VALVE “F”

NOTE: VALVES "H" OPENED ON HEATING WITH "C" VALVES

CLOSED REVERSE PROCEDURE ON COOLING.

EXP. TANK

VENT

ROOM

UNIT

DRAIN

CHILLER

BOILER

HCP

UMP

RELIEF

VALVE

FILL

VALVE

DRAINCH

BOILER

reverse

aquastat

N.O.

T

T

t'stat

G

V

115 volts

24 volts

circulator

operating

aquastat

N.C.

REVERSE

AQUASTAT

SET AT 120° F

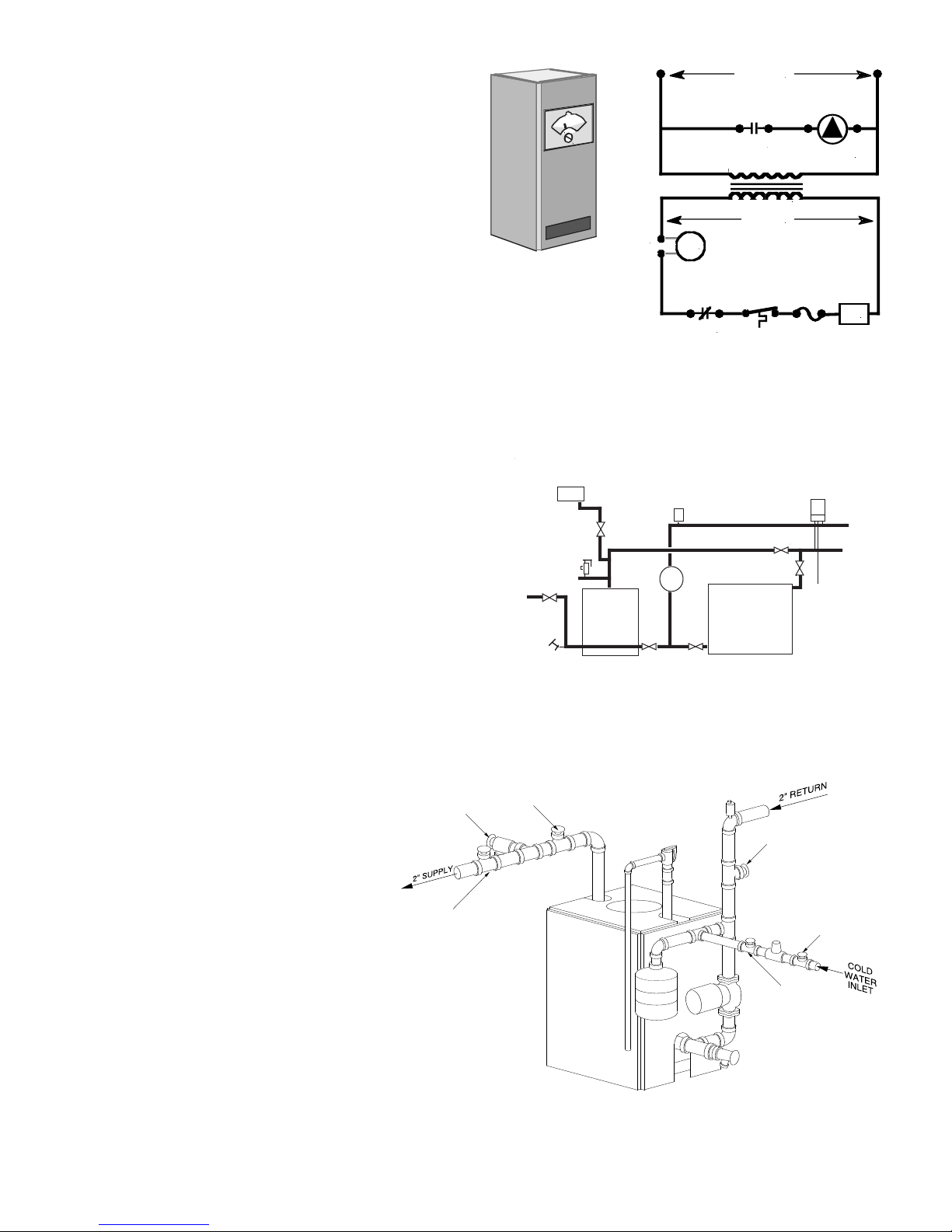

RREEVVEERRSSEE AACCTTIINNGG AAQQUUAASSTTAATTS

S

An alternative for existing systems experiencing condensation that does not require re-piping the boiler utilizes a

reverse acting aquastat, one that makes on temperature

ise. This approach works best in single zone systems.

r

Wired in series with the circulator, this control holds the circulator off until the boiler reaches an acceptable temperature and then starts system circulation (see Figure 1.9).

he most commonly available reverse acting aquastat is

T

a Honeywell L4006B. The aquastat should be mounted in

an immersion well directly installed in the boiler. The use

of heat conductive grease (Honeywell part # 972545) in

the immersion well is strongly recommended for fast and

accurate temperature response. Set this adjustable

aquastat to make at no less than 130° F. While this

method can cause the circulator to cycle more frequently,

setting the aquastat’s differential to the maximum (2530°F) will minimize short cycling.

FIGURE 1.9

PPRROOCCEEDDUURREE CC:: FFoorr ccoommbbiinnaattiioonn hheeaattiinngg aanndd ccoooolliinngg iinnssttaallllaattiioonnss oonnllyy.

.

If a hot water boiler is installed in connection with a water

chiller, the chilled water must be piped in parallel with the

boiler, using appropriate valves to prevent the chilled

medium from entering the boiler (see Figure 1.10). When

boilers are connected to heating coils located in air handling units where they may be exposed to refrigerated air

circulation, such boiler piping system shall be equipped

with flow-control valves or other means to prevent gravity circulation of the boiler water during the cooling cycle.

PPRROOCCEEDDUURREE DD:: CCoommpplleetteellyy ffiillll && ppuurrgge

hheeaattiinngg ssyysstteemm.. MMaakkee ssuurree tthhaatt aallll hheeaattiinngg ssyysstteemm mmaannuuaall aaiirr vveennttss aarree cclloosseedd.

e

.

1. Check flow direction arrows on hydronic

components are facing in proper direction.

Attach hose to drain valve “B” and close

2.

valve “A”. Open valves “C”, “D”, “E” and “F”

and drain valve “B”. Fill system with water

until water runs out of the hose in a steady

stream (no visible air bubbles).

3. Close valves “C” and “D”. Open valve “A”.

When water runs out of the hose in a steady

stream (no visible air bubbles), close drain

valve “B”.

-

FIGURE 1.10

4. Open valves “C” and “D”.

FFOORR WWAATTEERR TTRREEAATTMMEENNTT && FFRREEEEZZEE PPRROOTTEECCTTIIOONN RREEQQUUIIRREEMMEENNTTSS,,

SSEEEE ““SSEECCTTIIOONN 33:: MMAAIINNTTEENNAANNCCEE”” IINN TTHHIISS MMAANNUUAALL

FIGURE 1.11

7

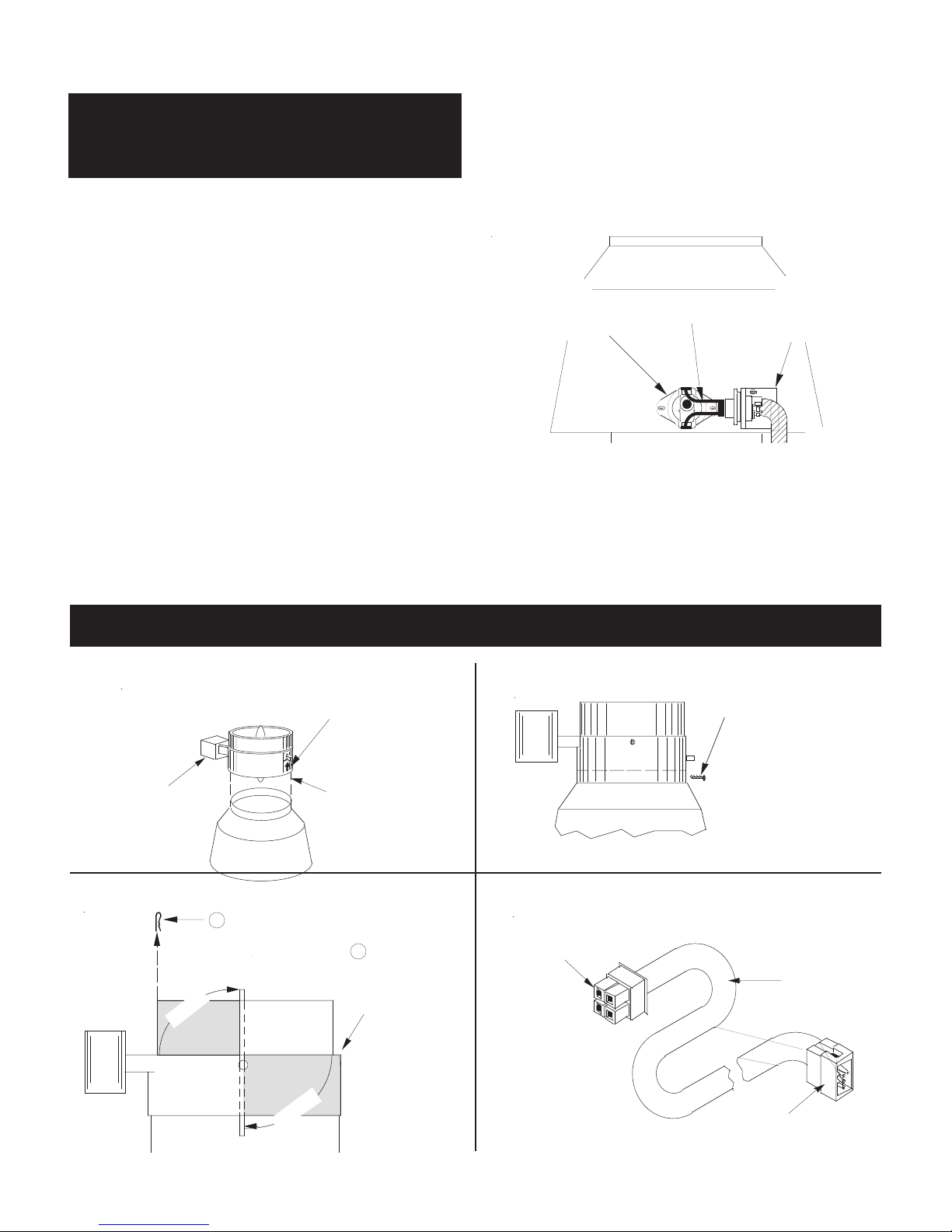

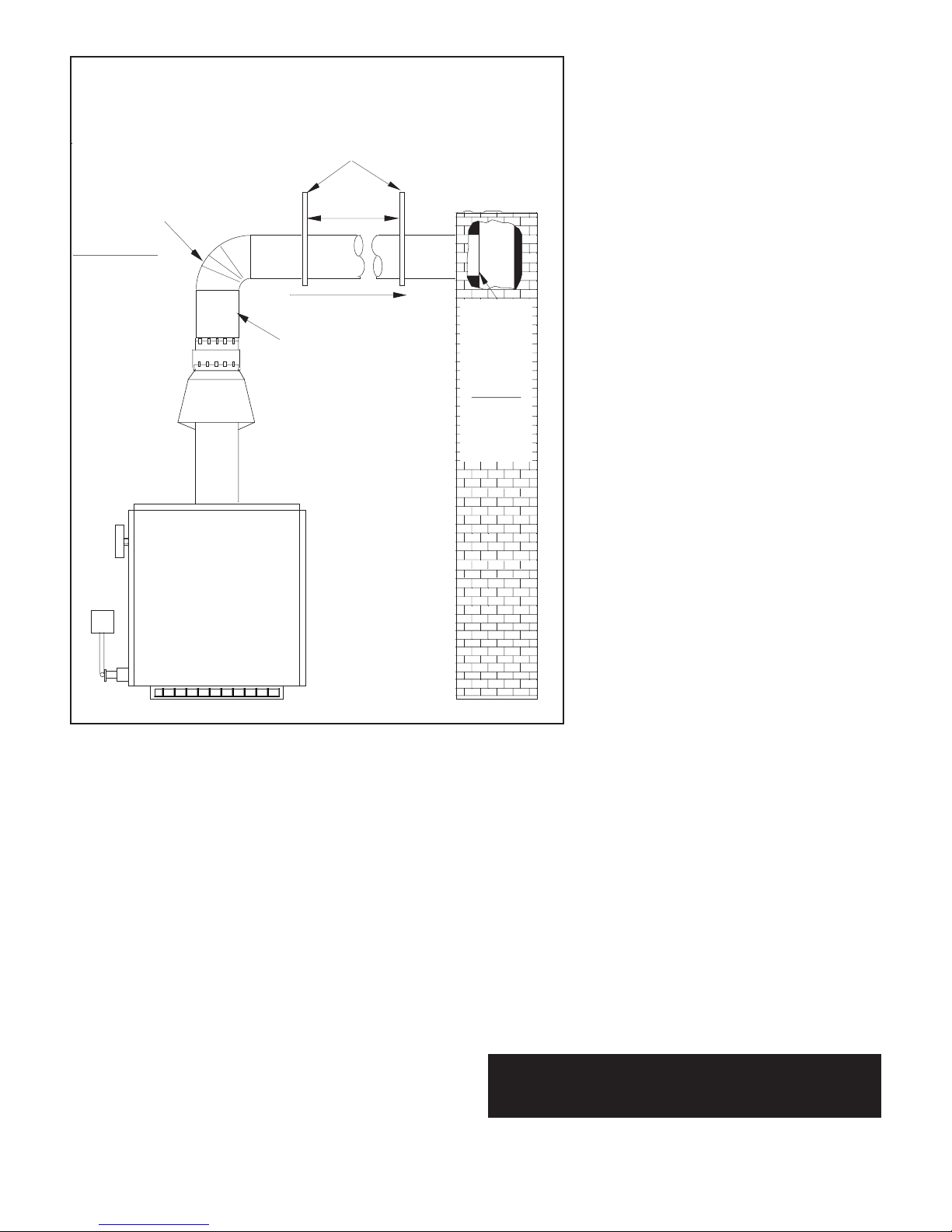

SSTTEEPP33:: VVEENNTTIINNGG TTHHEE BBOOIILLEER

FLOW DIRECTION

ARROW POINTS UP

MOUNT

VENT DAMPER

OVER

DRAFTHOOD

MAKE SURE

MOTOR IS

LOCATED

ON LEFT SIDE

ATTACH LOWER

PORTION OF

VENT DAMPER

TO DRAFTHOOD

WITH 1/2" OR

SHORTER SCREWS

OR POP RIVETS

OPEN

OPEN

1

REMOVE

SHIPPING

CLIP

2

OBSERVE

DAMPER

ROTATES

TO OPEN

POSITION

WITHOUT

OBSTRUCTION

PLUG INTO MOLEX

RECEPTACLE ON FRONT

OF BOILER

PLUG INTO MOLEX

RECEPTACLE INSIDE

DAMPER MOTOR

VENT

DAMPER

WIRE

HARNESS

I

NSTALL

SWITCH

IN OPENING

ON DRAFTHOOD

C

ONNECT

WIRE

LEADS

I

NSTALL

MOUNTING

BRACKET

ON DRAFTHOOD

R

DDAANNGGEERR:: DDrraafftt hhoooodd aanndd vveenntt oouuttlleett mmuusstt nnoott bbe

aalltteerreedd,, aass pprrooppeerr ooppeerraattiioonn wwoouulldd bbee jjeeooppaarrddiizzeedd;

ffllaammee rroolllloouutt,, ffiirree oorr ccaarrbboonn mmoonnooxxiiddee ppooiissoonniinng

wwiillll rreessuulltt.

.

e

;

g

PPRROOCCEEDDUURREE AA:: MMoouunntt ddrraafftt hhoooodd aanndd ssppiillll sswwiittcchh oon

.

bbooiilleerr.

1. Install draft hood on boiler. If draft hood shroud has a

hole near the relief opening, mount draft hood so hole

faces to the front of the boiler.

2. R-C boilers are equipped with factory-mounted spill

switch harness/mounting bracket as-sembly; spill switch

is provided in bag on boiler front.

3. Install mounting bracket on outside surface of draft

hood shroud with the screws provided (HARNESS MUST

BE ON OUTSIDE OF SHROUD). Install spill switch in

hole in shroud (on outside surface) with the screws provided.

NNOOTTEE:: FFoorr bbooiilleerrss eeqquuiippppeedd wwiitthh iinntteerrmmiitttteenntt ppiilloot

iinnssttaallll pplluugg ssuupppplliieedd iinn ddaammppeerr ppaacckkaaggee iinnttoo ddaammppeer

vvaannee hhoollee.. FFoorr ssttaannddiinngg ppiilloott bbooiilleerrss ddiissccaarrdd pplluugg.

AAddddiittiioonnaall vveennttiinngg aanndd cchhiimmnneeyy rreeqquuiirreemmeennttss aarre

pprroovviiddeedd oonn ppaaggee 99.

.

n

4. Plug wiring leads from harness/bracket assembly onto

flat terminals on spill switch.

NNOOTTEE::BBooiilleerr wwiillll nnoott ooppeerraattee uunnlleessss wwiirriinngg lleeaaddss tto

ssppiillll sswwiittcchh aarree ccoonnnneecctteedd.

.

t

r

.

e

FIGURE 1.8

o

PPRROOCCEEDDUURREE BB:: IInnssttaallll vveenntt ddaammppeerr.. ((FFoorr FFrreenncchh vveerrssiioonn,, sseeee AAppppeennddiixx AAaatt rreeaarr ooff mmaannuuaall..)

)

DDAANNGGEERR:: OOnnllyy tthhee bbooiilleerr mmaayy bbee sseerrvveedd bbyy tthhee vveenntt ddaammppeerr.. DDoo nnoott uussee iitt ttoo vveenntt aann aaddddiittiioonnaall aapppplliiaannccee;

tthhiiss wwiillll ccaauussee ffiirree oorr ccaarrbboonn mmoonnooxxiiddee ppooiissoonniinngg.

11.. MMoouunntt ddaammppeerr oonn ttoopp ooff ddrraafftt hhoooodd.

FIGURE 1.13

33.. CChheecckk ddaammppeerr ooppeerraattiioonn.

.

.

.

22.. SSeeccuurree ddaammppeerr ttoo ddrraafftt hhoooodd.

44.. CCoonnnneecctt wwiirree hhaarrnneessss.

.

FIGURE 1.14

.

;

FIGURE 1.15

FIGURE 1.16

8

MAXIMUM

6-FT

APART

PITCH 1/4"

P

ER FOOT

S

ECURE

FLUE PIPE

TO VENT

DAMPER

USE VENT SUPPORT(S) AS REQUIRED TO PREVENT SAGGING

INSTALL

F

LUSH

WITH

I

NSIDE

CHIMNEY

LINER

SEAL

WITH

FURNACE

CEMENT

SINGLE WALL

OR TYPE B

FLUE PIPE

R

-180 = 7"

R-210 = 7"

R

-250 = 7"

R-300 = 8"

PPRROOCCEEDDUURREE CC:: IInnssttaallll fflluuee ppiippee bbeettwweeeenn vveenntt ddaammppeerr aannd

cchhiimmnneeyy ((66”” mmiinniimmuumm cclleeaarraannccee rreeqquuiirreed

bbeettwweeeenn fflluuee ppiippee aanndd ccoommbbuussttiibblleess)).

d

.

d

ing system.

2. Visually inspect the venting system for proper size and horizontal pitch and determine

there is no blockage or restriction, leakage,

corrosion and other deficiencies which could

cause an unsafe condition.

3. Insofar as is practical, close all building

doors and windows and all doors between the

space in which the appliances remaining con-

1. Seal all unused openings in common vent-

ected to the common venting system are

n

located and other spaces of the building. Turn

on clothes dryers and any appliance not connected to the common venting system. Turn on

any exhaust fans, such as range hoods and

bathroom exhausts, so they will operate at

maximum speed. Do not operate a summer

exhaust fan. Close fireplace dampers.

4. Place in operation the appliance being in-spected. Follow the lighting instructions. Ad-just thermostat so appliance will operate continuously

.

5. Test for spillage at draft hood relief opening

after 5 minutes of main burner operation. Use

the flame of a match or candle, or smoke from

cigarette, cigar or pipe.

FIGURE 1.17

AADDDDIITTIIOONNAALLVVEENNTTIINNGG RREEQQUUIIRREEMMEENNTTSS:

:

When connecting

to gas vents or chimneys, vent installations shall be in accordance with Part 7, Venting of Equipment, of the National Fuel

Gas Code, ANSI Z223.1-latest edition, or applicable provisions

of the local building codes.

Vent connectors serving appliances vented by natural draft

shall not be connected into any portion of mechanical draft systems operating under positive pressure.

When two or more appliances vent into a common flue, the

area of the common flue should be at least equal to the area of

the largest flue plus 50% of the areas of the additional flue or

vent connectors.

When an existing boiler is removed from a common venting

system, common venting system is likely to be too large for

proper venting of appliances remaining connected to it.

of removal of existing boiler

, following steps shall be followed

with each appliance remaining connected to the common vent-

ing system placed in operation, while other appliances remaining connected to common venting system are not in operation:

At time

6. After it has been determined that each ap-pliance remaining connected to common venting

system properly vents when tested as outlined

above, return doors, windows, exhaust fans,

fireplace dampers and any other gas-burning

appliance to previous conditions of use.

7. Any improper operation of the common venting system should be corrected so installation

conforms with the National Fuel Gas Code,

ANSI Z223.1-latest edition. When resizing any

portion of the common venting system, the

common venting system should be resized to

approach the minimum size as determined using the appropriate tables in Appendix G in the National Fuel Gas Code, ANSI

Z223.1-latest edition. For Canada, the provisions of CAN/CGA

B149(.1 or .2) shall apply.

AADDDDIITTIIOONNAALLCCHHIIMMNNEEYYRREEQQUUIIRREEMMEENNTTSS:

:

Chimney condition is of paramount importance for a safe and efficient boiler

installation.

All installations must include a chimney inspection

by a qualified individual or agency. Chimney construction materials must be compatible with the fuel being used.

Particular attention should be paid on all oil-to-gas conversions.

Soot may have accumulated in chimney and/or degraded chim

ney liner. Most utilities require complete chimney cleaning.

Others may require installation of new liner, spill switches or

other chimney upgrades. Check with local utility for required

safety precautions.

DDAANNGGEERR:: AAcchhiimmnneeyy wwhhiicchh ddooeess nnoott mmeeeett mmooddeerrn

ssaaffeettyy ssttaannddaarrddss wwiillll rreessuulltt iinn aa ffiirree oorr ddeeaaddllyy ccaarrbboon

mmoonnooxxiiddee ppooiissoonniinngg ooff tthhee bbuuiillddiinngg rreessiiddeennttss.

9

-

n

n

.

Loading...

Loading...