HydroTherm KN-20 Field Assembly Instructions

Hydrother m

®

-Series

KN

Gas-fired direct vent

Cast iron boilers

Model KN-20 only

Field assembly

instructions

Also read and follow:

KN Series Gas Boiler

Installation & Operating

Instructions and KN

HeatNet Control Manual

is manual is intended only for use by a qualied heating installer/technician. Read and follow this manual, all supplements and re-

lated instructional information provided with the boiler. Install, start and service the boiler only in the sequence and methods given in

thi

s manual and the documents listed above. Failure to do so can result in severe personal injury, death or substantial property damage.

Do not use the boiler during construction. Construction dust and particulate, particularly drywall dust, will cause contamination

the burner, resulting in possible severe personal injury, death or substantial property damage. e boiler can only be operated with a

of

du

st-free air supply. Follow the instruction manual procedures to duct air to the boiler air intake. If the boiler has been contaminated by

op

eration with contaminated air, follow the instruction manual guidelines to clean, repair or replace the boiler if necessary.

P/N 42-9551 Copyright 2011 Mestek, Inc.

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

Contents and information

Read before beginning the installation. . . . . . . . 5

Boiler ratings and specifications . . . . . . . . . . . . 6

Installation site preparation . . . . . . . . . . . . . . . 7

Prepare the boiler . . . . . . . . . . . . . . . . . . . . 10

Water piping. . . . . . . . . . . . . . . . . . . . . . . . 11

Gas piping . . . . . . . . . . . . . . . . . . . . . . . . . 18

Wiring a single boiler . . . . . . . . . . . . . . . . . . 20

Control setup . . . . . . . . . . . . . . . . . . . . . . . 25

Vent piping (and air piping when used) . . . . . . 28

Condensate drain line. . . . . . . . . . . . . . . . . . 29

Fill and test the system . . . . . . . . . . . . . . . . . 30

Hazard icons

You will find the following icons

throughout this manual.

(English/French)

The WARNING icon indicates

a hazard that can cause severe

personal injury, death or

substantial property damage.

The CAUTION icon indicates a

hazard that will or can cause minor

personal or property damage.

The NOTICE icon calls out special

instructions that are important, but

are not related to hazards.

Starting the boiler . . . . . . . . . . . . . . . . . . . . 32

Annual start-up . . . . . . . . . . . . . . . . . . . . . . 41

Maintenance . . . . . . . . . . . . . . . . . . . . . . . 42

Replacement parts. . . . . . . . . . . . . . . . . . . . 46

Appendix A — suggested wiring. . . . . . . . . . . 48

Other manuals

You must read and follow this

manual, the KN Series Gas Boiler

Installation and Operating

Instructions, the KN HeatNet

Control manual and all additional

materials supplied with the boiler.

Failure to do so can result in severe

personal injury, death or substantial

property damage.

Boiler/control installation and setup

After completing assembly of the

KN boiler, follow all instructions

in the Installation and Operation

Instructions and Control Manual for

installation, start-up and testing.

2

P/N 42-9551

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

Read before proceeding

Customer service and technical support

Direct all questions to your HydroTherm distributor or contact the HydroTherm Customer Service Department at:

260 North Elm Street Westfield, MA 01085.

Always include the model and serial numbers from the rating plate of the boiler in question.

Claims for damage or missing components must be filed immediately against the transportation company by the

consignee.

Codes and standards

Code compliances

All aspects of the boiler installation must conform to the requirements of

the authority having jurisdiction, or, in the absence of such requirements,

to the National Fuel Gas Code, ANSI Z223.1/NFPA 54-latest revision.

Where required by the authority having jurisdiction, the installation must

conform to the Standard for Controls and Safety Devices for Automatically Fired Boilers, ANSI/ASME CSD-1.

In Canada, the installation must be in accordance with the requirements

of CSA B149.1 or .2, Installation Code for Gas Burning Appliances and

Equipment.

Before assembling the boiler . . .

Verify boiler rating and gas supply

• Before assembling and installing the boiler, check the ratings to ensure that the unit has been sized properly for the job.

• Ensure that the boiler will be set up for the type of gas available at the

installation site.

Verify location is suitable

• Ensure the availability of an adequate electrical supply, uncontaminated air for combustion, and that vent (and air) piping can be correctly installed.

• Ensure the boiler can be connected to system water piping and gas

supply.

• e boiler must not be exposed to dripping or spraying water or to

rain.

• If replacing an existing boiler, nd out what caused the boiler to fail

before installing a new boiler. Correct the problems that led to failure,

or the failure may happen to the new boiler.

Attention:

Use of an approved dust respirator is strongly

recommended when handling the insulating components of the boiler

Electrical shock hazard — Disconnect all electrical

power sources to the boiler before making any electrical

connections.

Label all wires prior to disconnection when servicing

controls. Wiring errors can cause improper and dangerous

operation! Verif y proper operation aer servicing.

Failure to comply with the above could result in severe

personal injury, death or substantial property damage.

e electrical connections to this boiler must be made in

accordance with all applicable local codes and the latest

revision of the National Electrical Code, ANSI /NFPA-70.

Installation should also conform to CSA C22.1 Canadian

Electrical Code Part I if installed in Canada. Install a separate 120 volt 15 amp circuit for the boiler. A properly rated

shut-o switch should be located at the boiler. e boiler

must be grounded in accordance with the authority having

jurisdiction, or if none, the latest revision of the National

Electrical Code, ANSI/NFPA-70.

Line voltage eld wiring of any controls or other devices

must use copper conductors with a minimum size of

#14awg. Use appropriate wiring materials for units

installed outdoors.

DO NOT open any gas valve, or aempt to re the boiler,

until all boilers have been set up and veried following the

instructions in the KN Series Gas Boiler Installation &

Operating Instructions.

Failure to comply could cause a boiler failure, leading to

possible severe personal injury, death or substantial property damage.

.

P/N 42-9551

3

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

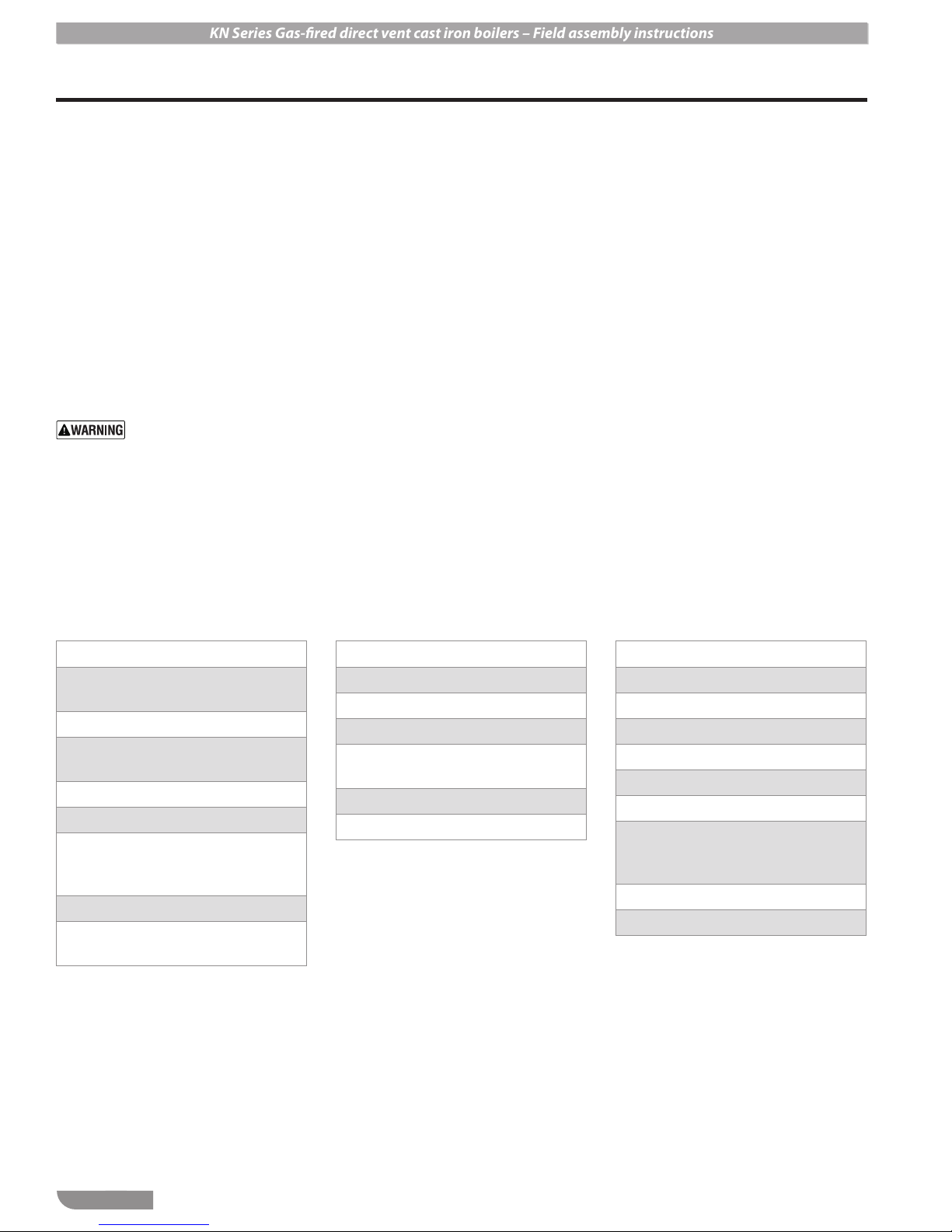

Components and special tools required

Special equipment/materials required for assembly

1. One quart 30-wt motor oil

2. Rubber and leather gloves

3. Rubber or leather mallet

4. Two 2”x4”x12” boards (used for

cushioning when seating push nipples)

5. Two 18-inch pipe wrenches

6. Torque wrench (at least 30 foot-pound

capacity)

7. Deep socket, 11/16” for use with torque

wrench

8. Standard hand tools, wire, nuts, electrical

hand tools

9. 2”x2” steel square stock x 6 inches long,

for driving square-socket pipe plugs

(supplied with boiler in hardware box)

Sealants, lubricants and adhesives supplied with boiler (in hardware box)

Use gloves when working with

these products as specied in

these instructions and in the

product instructions.

1. Silicone RTV-6500 HiTemp: (3) 10oz caulk tubes (for sealing between

sections)

2. Loc-Tite 30557 pipe dope: (1) 16-oz can

(for water and gas piping connections)

3. Hercules Pro Dope: (1) 8-oz jar (for

mixing with 30-wt motor oil, used as

lubricant for push nipples)

4. Res Bond 2300: (1) 11-oz caulk tube (for

sealing burner assembly)

5. Fast-Tack 87: (1) 13-oz spray can (for

securing flue baffles to sections)

Boiler components and shipping information

Skid 1

Cast iron sections (front, rear and

intermediate)

Push nipples

3” x 8” supply nipple and return

nipple

Pipe plugs

Draw rods and hardware

All-thread rods (7/8”) and cast-iron

draw-up plates for assembling boiler

block

Ceramic flue baffles

Hardware box (bolts, nuts, etc., individually packed/labeled by usage)

Base

Burner kit

Ceramic combustion chamber

Drain pan (with inspection cover

plate pre-attached)

Upper casting

4” x 6” boards for section assembly

Skid 2

Jacket components

Jacket insulation

Blower and filter box assembly

Control box assembly

Gas train assembly

Gas train shroud

Components box (igniter, sight

glass, supply and return sensors,

LWCO assembly, etc.)

Flue adapter assembly

Condensate trap assembly

Skid 3

4

P/N 42-9551

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

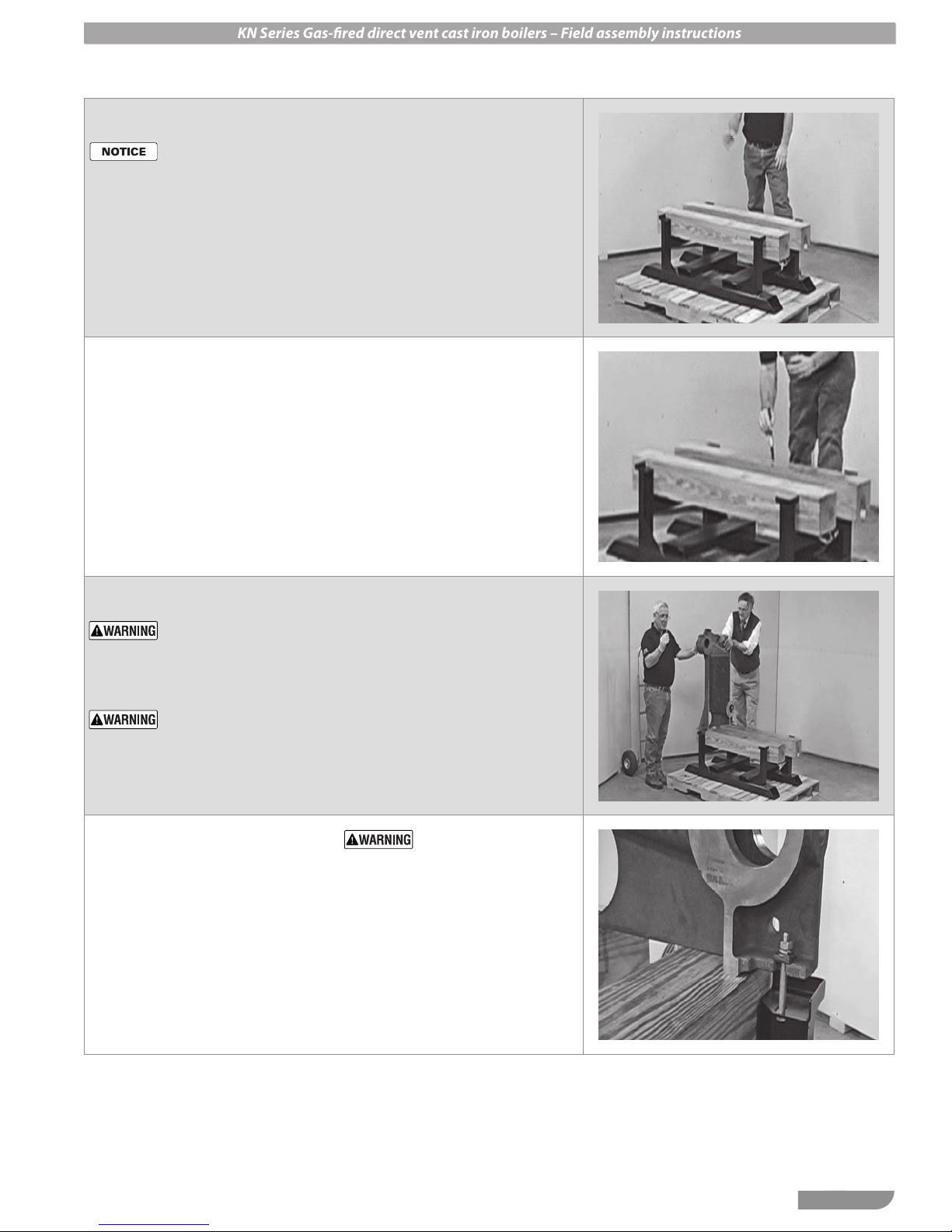

Step 1 Place 4x6 boards on base

Ignore the palee under the

boiler in the manual images

— it is le in place during

assembly for demonstration

purposes only.

Step 2 Oil top surface of runner

boards

1. Use a brush to spread 30-wt motor

oil on the runner boards. This will

allow sections to move easily during

draw-up.

1. Remove base from skid.

2. Place a 4x6 board (supplied) against

each side as a runner shown.

3. Space runner boards with about even

amounts off of each end of the base.

4. The runner boards will be used to

support the boiler block during assembly, then removed afterward.

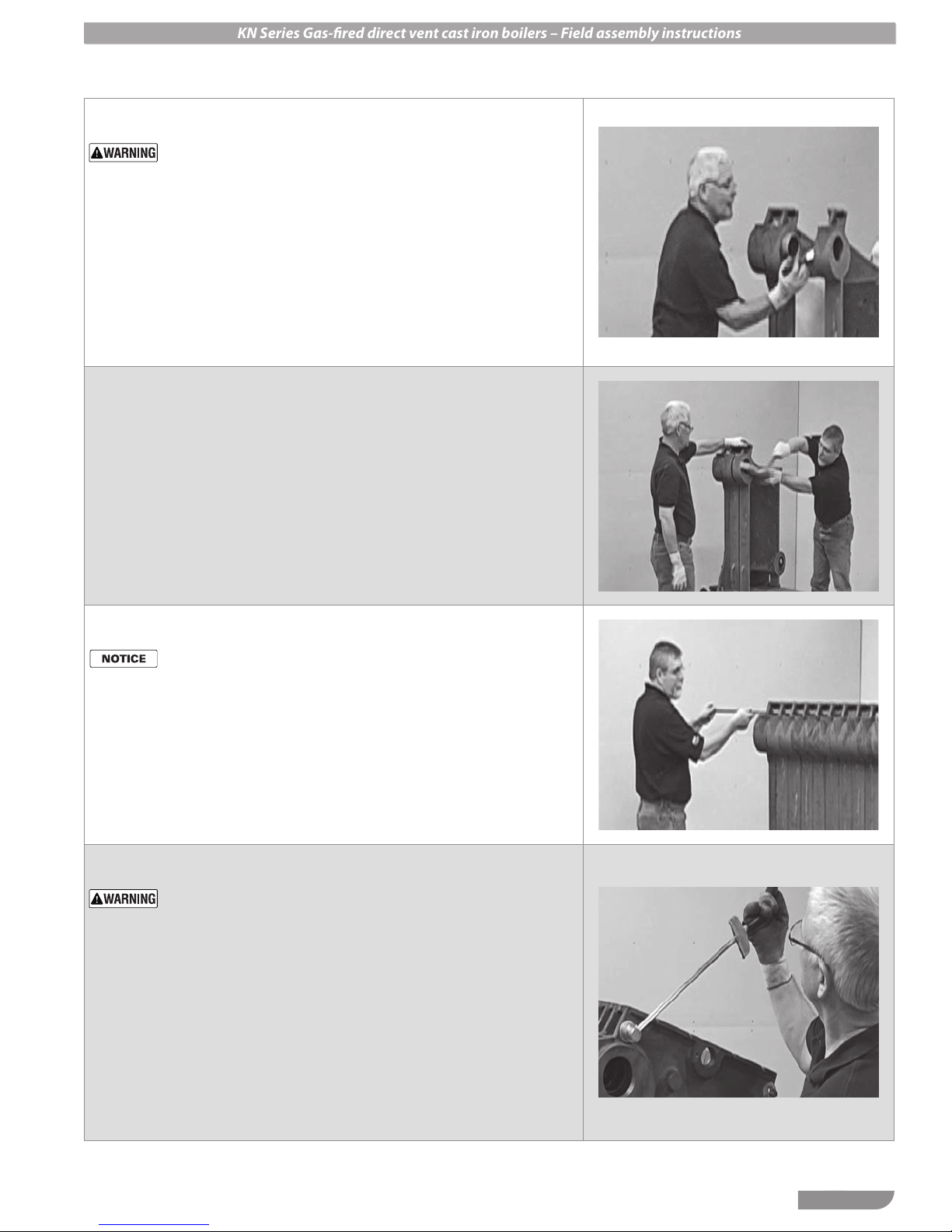

Step 3 Position the rear section

Use leather gloves when li-

ing or moving boiler sections.

Sections are heavy and can

cause severe personal injury

or death if mishandled.

Li section using two

people, following the

recommendations shown in

Step13,page8.

Step 4 Bolt rear section to base

1. Use 3/8 x 3½” bolts, wedges, split

lock washer and nut on each side as

shown.

2. Point the wedge narrow edge toward

the section.

1. Identify the rear section — its lower

nipple port is on the right side when

looking at the inside of the section, as

in this photo.

2. Slide the rear section to the end of

the base. Have someone support the

section during the next step.

Tighten bolt rmly, but DO

NOT over-tighten — the

cast iron ange could be broken if too tight. Tighten only

until the split lock washer has

just aened.

P/N 42-9551

5

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

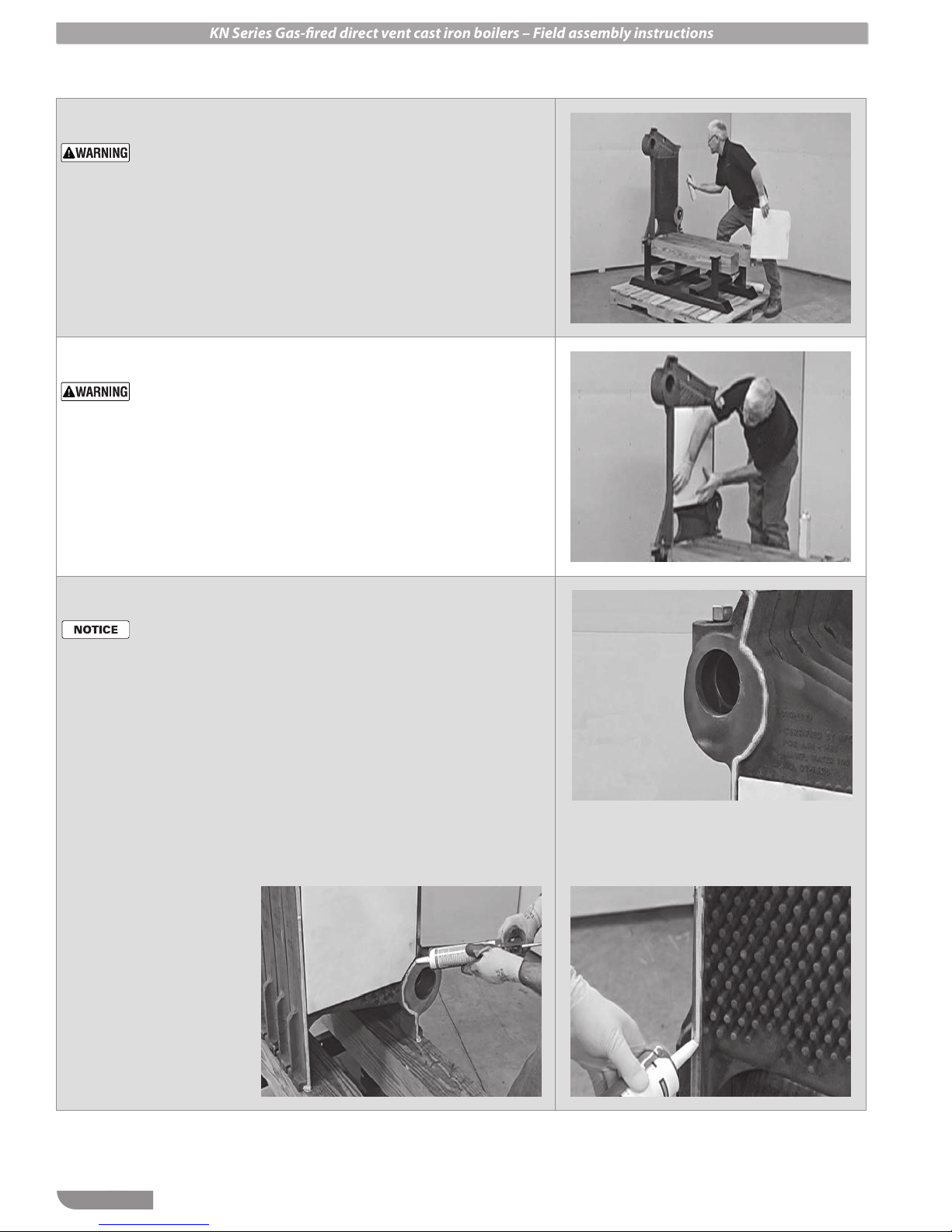

Step 5 Prepare section for baffle

Use of an approved dust

respirator is strongly recommended when handling the

insulating components of the

boiler.

Step 6 Install baffle

Do not use baes if they

have been broken, cracked,

folded or frayed. Obtain replacements before proceeding with the boiler assembly.

Step 7 Apply RTV to perimeter

1. Spray cast iron heat pin section liberally with spray adhesive supplied with

the boiler.

2. Avoid spraying on the nipple port

machined surfaces.

1. Place a baffle in the heat pin area of

the front section as shown.

2. The cut-off corner must go to the

lower right.

3. Press into place.

4. Make sure the baffle does NOT

overlap onto the perimeter surfaces

of the section. This would prevent the

section from drawing up correctly.

Rubber gloves are recom-

mended for this procedure.

1. Apply a bead of silicone RTV (supplied with boiler) on the perimeter

surfaces of the section and around

the INSIDE edges of the nipple ports.

2. This is necessary to form a seal between the sections. The seal prevents

flue gases from escaping.

3. Extend the bead all the way from the

top of the section to the bottom.

4. Keep the bead of silicone close to the

INSIDE edge of the nipple ports.

5. This will protect the machined nipple

port surfaces from condensation that

may occur in the flueways.

6

P/N 42-9551

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

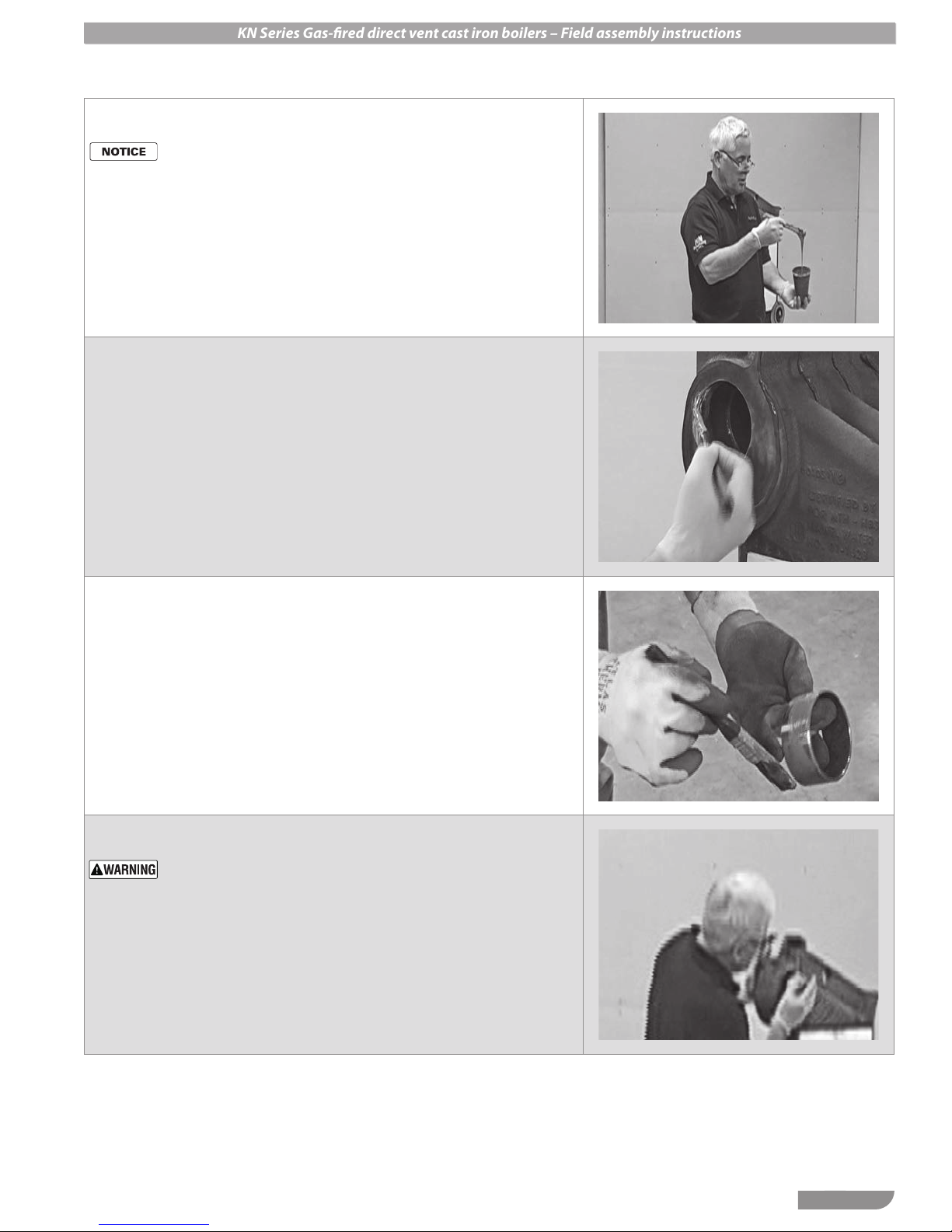

Step 8 Push nipple lubricant

Rubber gloves are recom-

mended for this procedure.

Step 9 Lubricate nipple ports

Step 10 Lubricate push nipples

1. In a disposable container, mix some

30-wt motor oil with some of the

Hercules Pro Dope supplied with the

boiler.

2. The consistency should be similar to

thick paint and should flow easily.

3. You will need enough to lubricate all

nipple ports and all push nipples —

probably about ½ pint is enough.

1. Brush the pipe dope/oil mixture on

the inner machined surfaces of the

nipple ports.

2. Avoid getting lubricant on the silicone RTV or on the face of the nipple

ports.

Step 11 Insert push nipples

Avoid scarring or damaging

the push nipple or nipple

port surfaces. e push nipple makes a metal-to-metal

seal with the nipple port. Any

surface defects could cause a

leak.

1. Brush the entire outside surface of

each nipple port with the lubricant.

1. Insert a push nipple into each of the

two nipple ports.

2. Seat each nipple firmly but squarely.

3. Make sure the nipple face is parallel

to the section surface as closely as

possible.

4. DO NOT attempt to assemble sections if any nipple port is mis-aligned.

P/N 42-9551

7

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

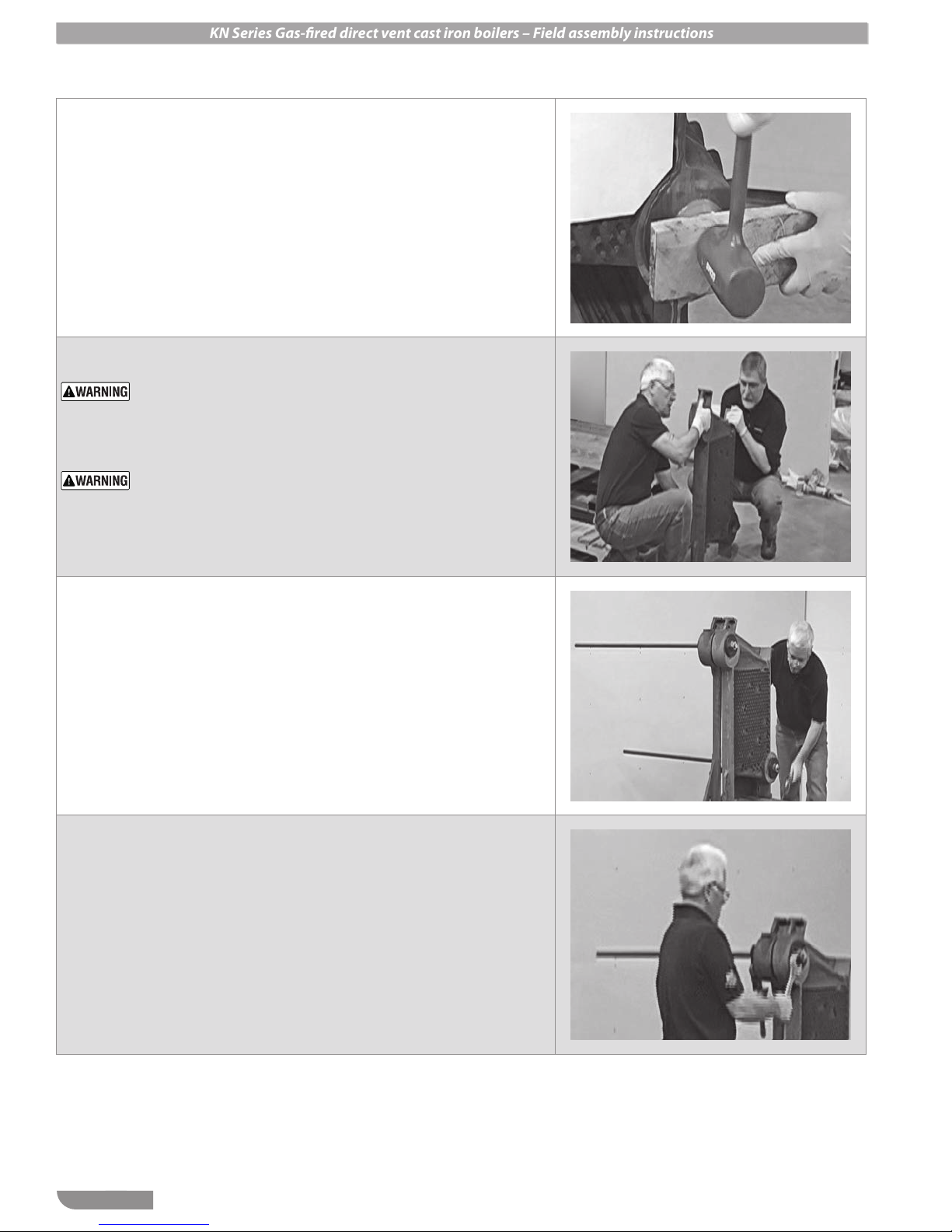

Step 12 Seat the push nipples

Step 13 Lifting the sections

1. Place a 2x4 board across the nipple

and strike firmly with a mallet.

2. Do this with several strokes, just so

the push nipple is firmly started.

3. Make sure the board is parallel to the

nipple port surface to prevent rolling

the push nipple.

Use leather gloves when li-

ing or moving boiler sections.

Sections are heavy and can

cause severe personal injury

or death if mishandled.

Li section using two

people, following the

recommendations shown in

Step13,page8.

Step 14 Draw up sections

1. Carefully slide the first intermediate

section up to the front.

2. Before pulling the intermediate

section up fully, brush lubricant on

the inside machined surfaces of the

nipple ports as in Step 9, page 7.

3. Use a 2x4 board and mallet to start

the section in place as shown in

Step 17, page 9.

Step 15 Pull sections together

1. Lift section, with each person holding

at the bottom of the section.

2. Handlers should lift with their legs to

avoid back strain.

4. Wipe a small amount of motor oil on

the ¾-inch all-thread rods supplied

with the boiler to make pull-up easier.

5. Place a ¾” nut and washer plus a cast

iron plate (supplied with boiler) on

the ¾” rod on each side as shown.

6. Snug finger tight.

1. Use box wrenches (preferred) to pull

2. Alternate from one side to the other

3. When the sections are properly

8

the sections together.

during pull-up to avoid cocking the

nipple ports.

pulled up, they will be nearly metalto-metal.

P/N 42-9551

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

Step 16 Install baffle

Do not use baes if they

have been broken, cracked,

folded or frayed. Obtain replacements before proceeding with the boiler assembly.

Step 17 Use 2x4 and mallet

1. Before adding additional sections,

install a baffle in the flueway as in

Step 5, page 6 and Step 6, page 6.

2. Place a baffle in the heat pin area of

the front section as shown.

3. The cut-off corner must go to the

lower right.

4. Press into place.

5. Make sure the baffle does NOT

overlap onto the perimeter surfaces

of the section. This would prevent the

section from drawing up correctly.

1. To initially seat the push nipple into

the next section, rap with a mallet

and 2x4 at each nipple port.

2. Repeat, alternating from right nipple

port to left to avoid cocking the push

nipples.

Step 18 Install draw rods

e draw rods ARE NOT

used to pull the sections

together, only to keep them

rmly in position.

Step 19 Use a torque wrench

DO NOT exceed 30foot-

pounds when tightening

nuts. Higher torque could

cause breakage of the cast

iron.

1. When the section assembly is completed, slide a draw rod through each

of the four draw rod holes.

2. Apply a washer and nut on each end

and pull up finger tight.

1. Use a torque wrench to tighten the

nuts on the draw rods.

2. Start with the upper left corner rod

first.

3. Tighten the nut to 15 foot-pounds.

4. Move to the lower right rod. Tighten

the nut to 15 foot-pounds.

5. Repeat with the lower left, then the

upper right rod, both tightened to

15 foot pounds.

6. Repeat this sequence again, but finish

the tightening to 30 foot-pounds for

each nut.

P/N 42-9551

9

KN Series Gas-fired direct vent cast iron boilers – Field assembly instructions

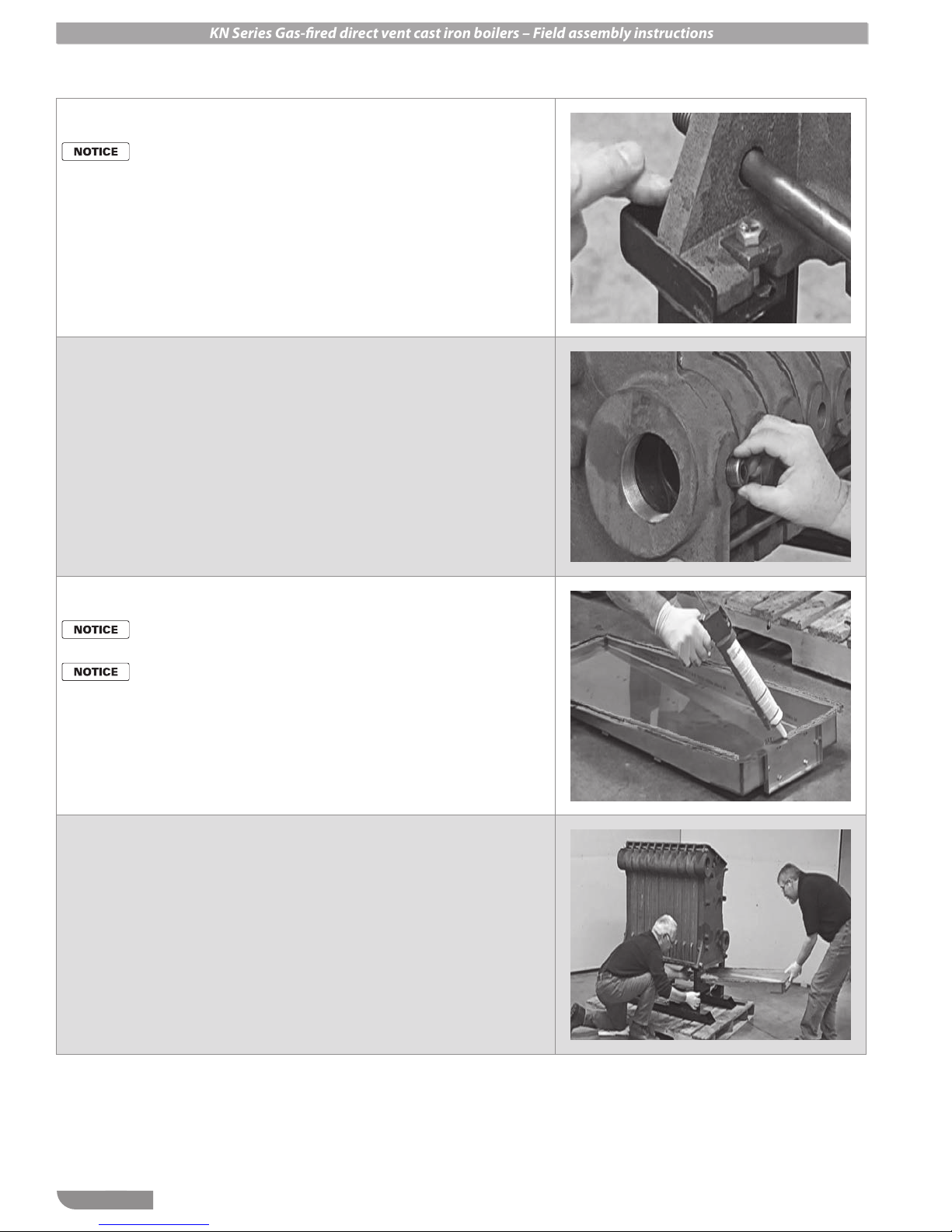

Step 20 Bolt boiler to base

Before bolting the boiler to

the base, knock the two 4x6

boards out from under the

block. If necessary, loosen the

two bolts that secure the back

section to the base.

Step 21 Inspection port plugs

Step 22 Prepare condensate pan

1. Install a bolt, wedge, washer and nut

on side of the front section as done in

Step 4, page 5.

2. Tighten only until the split lock

washer has just flattened.

3. Make sure the back section bolts are

tightened as well.

1. Apply pipe dope (supplied with

boiler) to plugs (supplied) and install

in each of the inspection ports at the

lower right side of each section.

Rubber gloves are recom-

mended for this procedure.

e condensate drain pan

is shown here with the

inspection plate and gasket

installed. is can be done

before or aer the condensate drain pan is bolted to the

boiler.

Step 23 Install condensate drain

pan

1. This procedure requires two people

to do correctly.

2. Guide the condensate drain pan

through the front of the base as

shown.

3. When in position, lift the pan straight

up and hold firmly against the bottom of the section assembly.

1. Use the silicone RTV supplied with

the boiler to apply a bead on the

condensate pan flange around the

complete perimeter.

2. At each of the four corners, apply a

bead on the flange where the sheet

metal edges meet.

4. Install each bolt with two flat washers,

one split lock washer and nut (provided). Insert the bolts from the top.

5. Tighten just until the split lock washer

has flattened.

10

P/N 42-9551

Loading...

Loading...