HydroTherm KN-16, KN-26, KN-30 Field Assembly Instructions

KN-FAI2-0313

Gas-Fired Cast Iron Boilers

42-9552

Models

KN-16, -26, and -30

Field Assembly

Instructions

Also read and follow:

KN Series Gas Boiler

Installation and Operating

Instructions

and

KN HeatNet Control Manual

is manual is intended only for use by a quali ed heating installer/technician. Read and follow this manual, all supplements and related

instructional information provided with the boiler. Install, start and service the boiler only in the sequence and methods given in these

instructions. Failure to do so can result in severe personal injury, death or substantial property damage.

Do not use the boiler during construction. Construction dust and particulate, particularly drywall dust, will cause contamination of

the burner, resulting in possible severe personal injury, death or substantial property damage. e boiler can only be operated with a dustfree air supply. Follow the instruction manual procedures to duct air to the boiler air intake. If the boiler has been contaminated by operation

with contaminated air, follow the instruction manual guidelines to clean, repair or replace the boiler if necessary.

A x these instructions near to the boiler/water heater. Instruct the building owner to retain the instructions for future use by a quali ed

service technician, and to follow all guidelines in the User’s Information Manual.

10/12 Copyright 2010 Hydrotherm

G

as-Fired Direct Vent Cast Iron Boilers – Field Assembly Instruction

s

INFORMATION

This manual is intended only for the fi eld assembly of

a KN-16, -26 or -30 boiler. Follow the assembly

instructions in sequence. Also follow all requirements

of the KN Boiler manual and the KN HeatNet manual.

BLOCK ASSEMBLY SEQUENCE

These instructions show block assembly

beginning with the front section and fi nishing

with the back section.

If job conditions make this impractical, the bloc k

can be built beginning with the back section and

fi nishing with the front.

Hazard Icons

You will fi nd the following icons throughout this manual.

(English/French)

The WARNING icon indicates a hazard that

can cause severe personal injury, death or

substantial property damage.

The CAUTION icon indicates a hazard that

will or can cause minor personal or property

damage.

The NOTICE icon calls out special instructions

that are important, but are not related to hazards.

READ BEFORE PROCEEDING

Customer Service And Technical Support

Direct all questions to your HydroTherm distributor or

contact the HydroTherm Customer Service Department at:

260 North Elm Street, Westfi eld, MA 01085. Always include

the model and serial numbers from the rating plate of the

boiler in question.

Claims for damage or missing components must be fi led

immediately against the transportation company by the

consignee.

CODES AND STANDARDS

Code compliances

All aspects of the boiler installation must conform to the

requirements of the authority having jurisdiction, or, in the

absence of such requirements, to the National Fuel Gas

Code, ANSI Z223.1/NFP A 54-latest re vision. Where required

by the authority having jurisdiction, the installation must

conform to the Standard for Controls and Safety Devices

for Automatically Fired Boilers, ANSI/ASME CSD-1.

In Canada, the installation must be in accordance with the

requirements of CSA B149.1 or .2, Installation Code for

Gas Burning Appliances and Equipment.

BEFORE ASSEMBLING THE BOILER . . .

Other Manuals

You must read and follow this manual, the KN

Series Gas Boiler Installation and Operating

Instructions, the KN HeatNet Control manual

and all additional materials supplied with the

boiler. Failure to do so can result in severe

personal injury, death or substantial property

damage.

Boiler/Control Installation And Setup

After completing assembly of the KN boiler, follow all

instructions in the Installation and Operation Instructions

and Control Manual for installation, start-up and testing.

Verify Boiler Rating And Gas Supply

• Before assembling and installing the boiler, check the

ratings to ensure that the unit has been sized properly

for the job.

• Ensure that the boiler will be set up for the type of gas

available at the installation site.

Verify Location Is Suitable

• Ensure the availability of an adequate electrical supply,

uncontaminated air for combustion, and that vent (and

air) piping can be correctly installed.

• Ensure the boiler can be connected to system water

piping and gas supply.

• The boiler must not be exposed to dripping or spraying

water or to rain.

• If replacing an existing boiler, fi nd out what caused the

boiler to fail before installing a new boiler. Correct the

problems that led to failure, or the failure may happen

to the new boiler.

2

G

as-Fired Direct Vent Cast Iron Boilers – Field Assembly Instruction

s

ATTENTION:

Use of an approved dust respirator is

strongly recommended when handling the

insulating components of the boiler.

Electrical shock hazard — Disconnect all

electrical power sources to the boiler before

making any electrical connections.

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation! Verify

proper operation after servicing.

Failure to comply with the abov e could result in

severe personal injury, death or substantial

property damage.

The electrical connections to this boiler must be

made in accordance with all applicable local

codes and the latest revision of the National

Electrical Code, ANSI /NFPA-70. Installation

should also conform to CSA C22.1 Canadian

Electrical Code Part I if installed in Canada.

Install a separate 120 volt 15 amp circuit for the

boiler. A properly rated shut-off switch should

be located at the boiler. The boiler must be

grounded in accordance with the authority

having jurisdiction, or if none, the latest revision

of the National Electrical Code, ANSI/NFPA-70.

Line voltage fi eld wiring of any controls or other

devices must use copper conductors with a

minimum size of #14 awg. Use appropriate

wiring materials for units installed outdoors.

DO NOT open any gas valve, or attempt to fi re

the boiler, until all boilers ha ve been set up and

verifi ed following the instructions in the KN

Series Gas Boiler Installation & Operating

Instructions.

Failure to comply could cause a boiler failure,

leading to possible severe personal injury,

death or substantial property damage.

COMPONENTS AND

SPECIAL TOOLS REQUIRED

Recommended Assembly Crew

The assembly crew should be a minimum of

3experienced technicians.

Equipment/Materials Required For Assembly

1. One quart 30-wt motor oil

2. Flexible leather work gloves

3. Dead-blow hammer with plastic face (DO NOT use a

sledge hammer)

4. Four 2" x 4" x 12" boards (used for cushioning when

seating push nipples)

5. Two 18 inch pipe wrenches (plus 2 inch x 2 feet

cheater pipe)

6. Crescent wrenches, 18 inch or larger, may be used for

tightening the draw rod nuts (NOT tie rods). (See

Step 16, page 10 for draw rod instructions.)

7. Torque wrench (at least 30 foot-pound capacity)

8. Deep socket, 11/16 inch for use with torque wrench

9. Standard hand tools.

10. Wire, wire nuts, electrical hand tools (crimper , stripper,

etc.).

Boiler Components And Shipping Information

Check the contents of the skids against the

Bill of Materials/Checklist shipped with the

boiler. Use the Checklist to locate specifi c items

throughout the assembly process. Content

your Hydrotherm supplier if you discover any

components damaged or missing.

The boiler is shipped in two skids and one crate. See the

contents of the crates and skids in Figure 2, page 23.

Sealants, lubricants and adhesives supplied with

boiler (see Figure 2, page 23 for location)

Use gloves when working with these products

as specified in these instructions and in the

product instructions.

1. Silicone RTV-6500 HiTemp: 10-oz caulk tubes (for

sealing between sections)

2. Loc-Tite 30557 pipe dope: (1) 16-oz can (for water and

gas piping connections)

3. Hercules Pro Dope: 8-oz jar (for mixing with 30-wt

motor oil, used as lubricant for push nipples)

4. Fast-Tack 87: (1) 13-oz spray can (for securing fl ue

baffl es to sections)

3

G

as-Fired Direct Vent Cast Iron Boilers – Field Assembly Instruction

s

FRONT END

(legs extend longer at

front than at rear)

REAR END

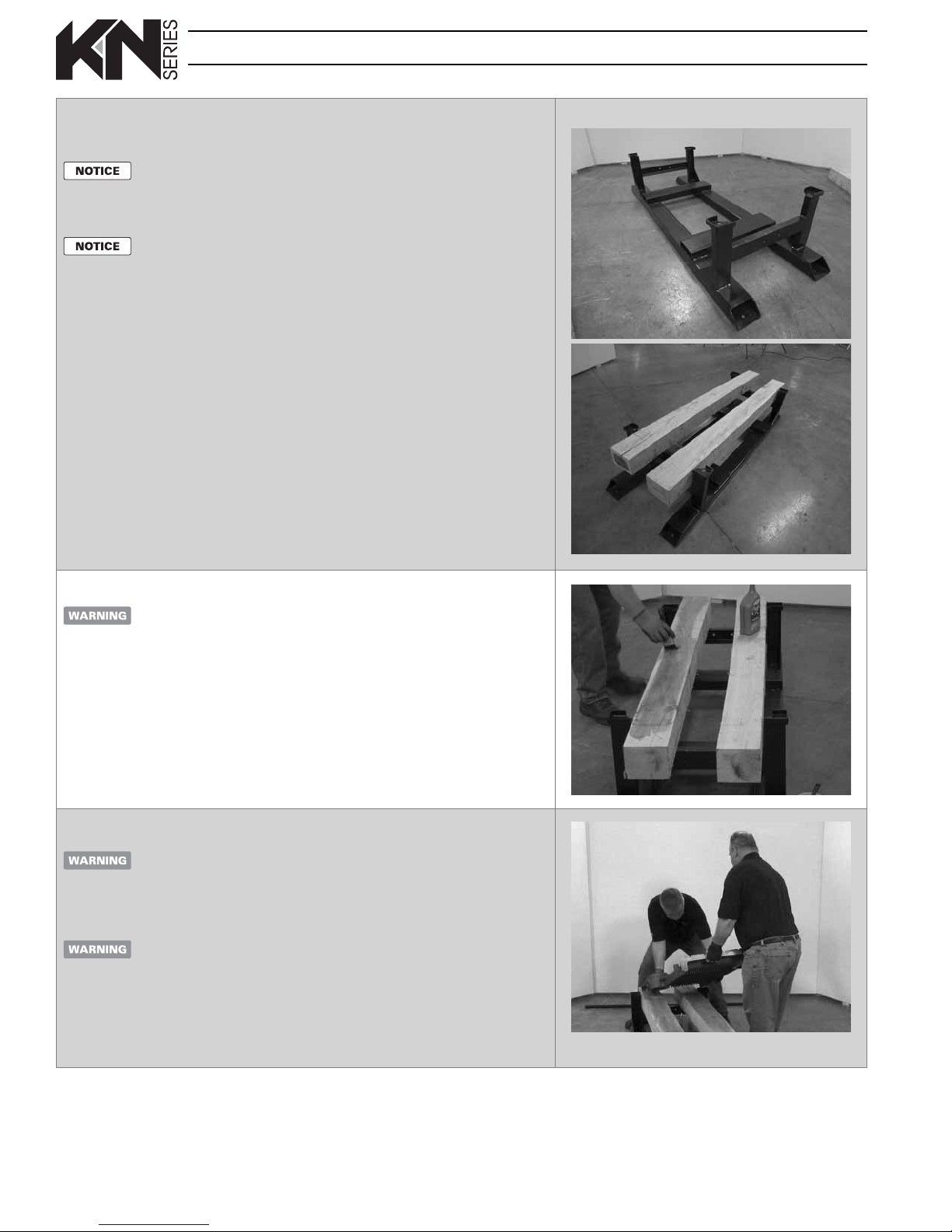

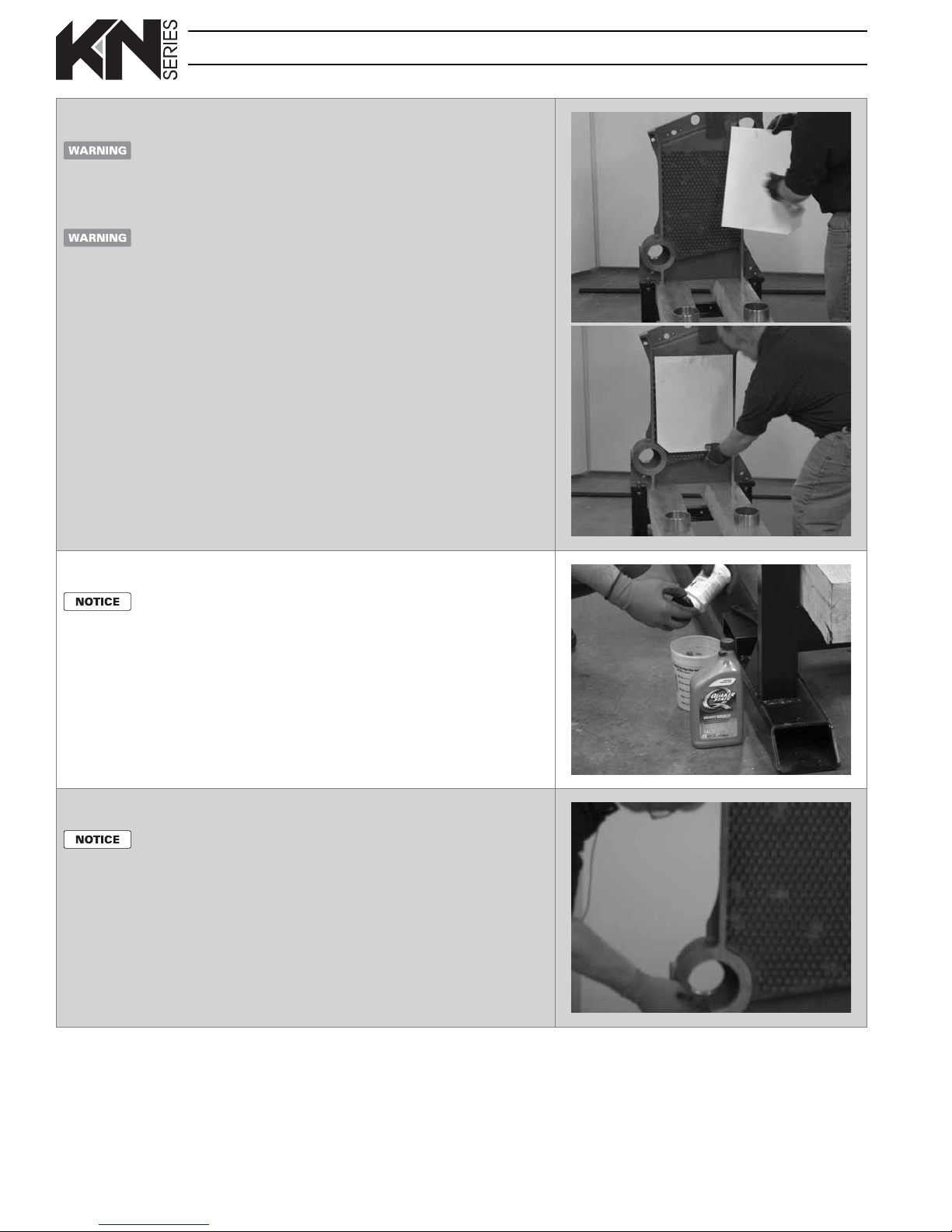

Step 1 Place runner beams on base (see BLOCK ASSEMBLY SEQUENCE NO-

TICE on page2 — assembly can be from back to front if necessary)

Make sure the boiler base is in the correct position before

starting. The legs extend longer on the FRONT end of the base

than on the rear end (approximately 9-1/2 inch at front and 6-3/4

inch at rear — use a tape measure if necessary to compare).

FRONT END

(legs extend longer at

front than at rear)

LOCATE BOILER TO

PROVIDE MINIMUM

CLEARANCES FOR

ASSEMBLY AND AS

REQUIRED BY KN BOILER

MANUAL:

e boiler must be installed

in accordance with the KN

Instruction Manual — the

boiler location must maintain

all required clearances for

service and spacing from

combustible surfaces.

In addition, provide:

AT LEAST 60 INCHES

clearance at the front of

the boiler to allow room for

block and condensate pan

assembly.

Step 2 Oil top surface of runner beams

DO NOT allow oil to drip

on the oor

Make sure the oor is free

of any slick spots and that

there is no debris or any

obstruction in the work area

or walk path to boiler parts.

.

1. Remove base from skid.

2. The base is symmetrical, so either end

can be placed as the front end.

3. Place a beam (supplied) against each

side as a runner as shown at right.

4. The planed surface of the beam must

be on top.

5. If beam has any curvature, place the

beam with the curvature toward the

OUTSIDE of the frame.

6. Space runner beams with about even

lengths extending o of each end of

the base.

7. The runner beams will be used to

support the boiler block during

assembly, then removed afterward.

1. Use a paint brush to spread 30-wt

motor oil on the runner boards. This

allows sections to move easily during

draw-up.

REAR END

Step 3 When lifting the sections

Use leather gloves when

li ing or moving boiler

sections. Sections are heavy

and can cause severe personal

injury or death if mishandled.

Lift section using two

people. Then place in

position on the runner

beams. Make sure

the section is always

supported to prevent

tipping or falling.

4

1. Lift section with each person lifting at

the bottom of the section.

2. Move onto the runners and slide into

position.

3. Handlers should lift with their legs to

avoid back strain.

G

as-Fired Direct Vent Cast Iron Boilers – Field Assembly Instruction

s

.

3. The adhesive is required to secure th

e

y

.

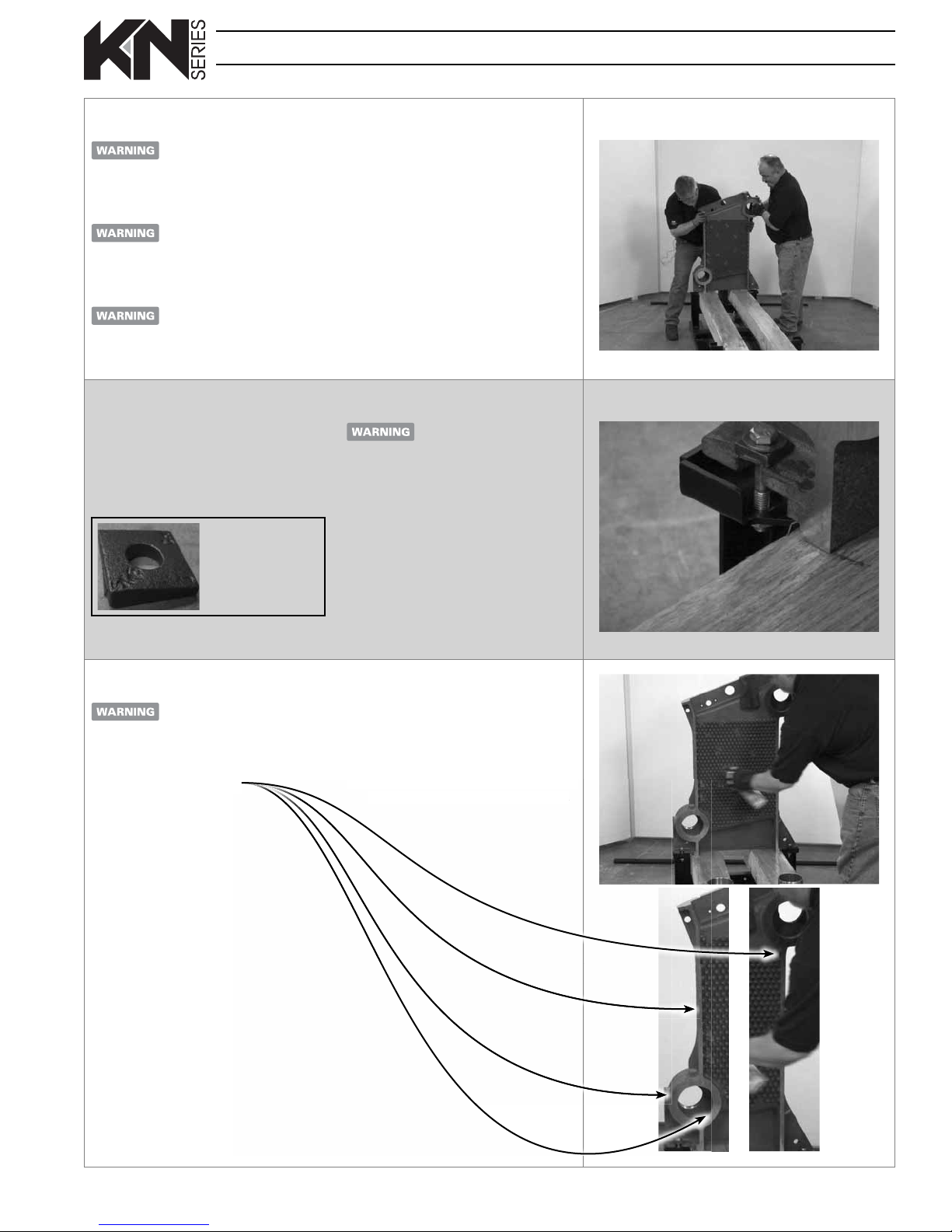

Step 4 Place the FRONT section

Use leather gloves when

li ing or moving boiler

sections. Sections are heavy

and can cause severe personal

injury or death if mishandled.

Have someone support the

section during this step and

the next. e sections are

top-heavy and could easily

fall if not supported.

Handle all sections with

care to prevent any

damage to machined

surfaces.

Step 5 Bolt front section to base

1. Use a 3/8 x 6 inch bolt, wedge, at

washer, split lock washer and nut on

each side as shown.

2. Point the wedge narrow edge toward

the section.

1. Identify the FRONT section — its

lower nipple port is on the LEFT side

when looking at the inside of the

section, as in this photo.

2. Slide the front section to the end of

the base.

3. Lift into position and have someone

hold securely.

Tighten bolt rmly, but DO

NOT over-tighten — the

cast iron ange could be

broken if too tight. Tighten

only until the split lock

washer has just a ened.

e bolt must be secure to

Wedge —

Point thin edge

toward the section.

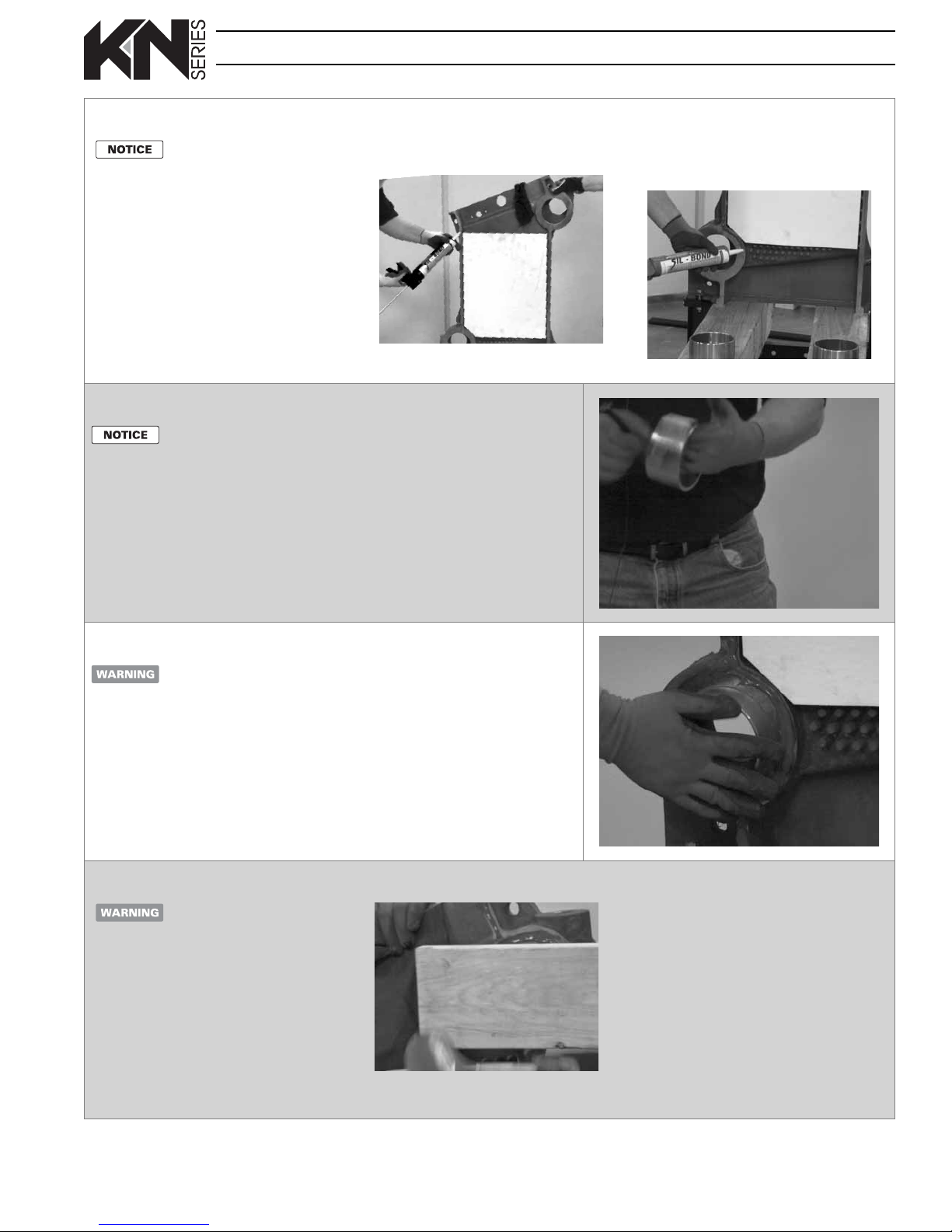

Step 6 Apply adhesive for ceramic ber ue ba e

DO NOT SPRAY adhesive

on the nipple port

machined surfaces

. is

would prevent proper sealing

with the silicone sealant

applied later.

1. Obtain the spray adhesive supplied in

the hardware box.

2. Spray ONLY the heat pin area of the

casting with the spray adhesive.

3. The adhesive is required to secure the

ue ba e (next step) in the ueway.

ue ba e (next step) in the uewa

prevent movement of the

front section during the next

steps of assembly.

5

G

as-Fired Direct Vent Cast Iron Boilers – Field Assembly Instruction

s

Step 7 Place ceramic ber ba e in ueway

Use of an approved dust

respirator is strongly

recommended when

handling the insulating

components of the boiler.

Do not use ue ba es if

they have been broken,

cracked, folded or frayed

Obtain replacements before

proceeding with the boiler

assembly.

1. The cut-o corner of the ba e must

go to the lower left corner. Align the

ba e in this position to determine

which side to spray with adhesive.

2. Apply spray adhesive to the back side

of a ceramic ber ba e.

3. Place the ba e in the heat pin area of

the front section as shown.

.

4. Press ba e into place.

5. Position the ba e so that it does

NOT overlap onto the edge

surfaces of the section. This would

prevent the section from drawing up

correctly.

Step 8 Mix push nipple lubricant

Work gloves are

recommended for this

procedure.

Step 9 Lubricate nipple ports

DO NOT get oil on the

FACES of the nipple ports

— apply lightly and ONLY

on the inside machined

surfaces.

If oil gets on a port face, wipe

o with a clean rag dipped

in a solvent such as mineral

spirits. Oil will prevent the

silicone sealant from sealing

properly.

1. In a disposable container, mix some

30-wt motor oil with some of the

Hercules Pro Dope supplied with

the boiler. Mix about 1part of oil to

20parts of the pipe dope.

2. The consistency should be similar to

thick paint and should ow easily.

3. You will need enough mixture to

lubricate all nipple ports and all push

nipples — about 1/2 pint.

1. Use a clean rag to wipe o all

machined surfaces on both sides

of the section before proceeding.

2. Also wipe clean the inside machined

surfaces of both nipple ports on fornt

and back of section.

3. After cleaning the ports, brush pipe

dope/oil mixture on the INNER

machined surfaces of the nipple ports

ONLY.

6

G

as-Fired Direct Vent Cast Iron Boilers – Field Assembly Instruction

s

Step 10 Apply RTV to machined surfaces

Rubber gloves are

recommended for this

procedure.

1. Apply a bead of silicone RTV (supplied

with boiler) on the perimeter surfaces

of the section and around the INSIDE

edges of the nipple ports.

2. This is necessary to form a seal between

the sections. The seal prevents ue

gases from escaping.

3. Extend the bead all the way from the

top of the section to the bottom.

4. Keep the bead of silicone close to the

INSIDE edge of the nipple ports.

Step 11 Lubricate push nipples with oil/pipe dope mixture (see Step 8)

Inspect push nipples carefully

before using. DO NOT use

a nipple if it is gouged or

scarred.

DO NOT apply excessive

lubricant to the nipple

ports

. Lubricant can drip

onto the machined sealing

surface, preventing the

RTV sealant used later from

sticking.

1. Obtain two push nipples.

2. Inspect carefully and wipe o the

nipples with a clean cloth.

3. Brush the outside surface of each

push nipple VERY LIGHTLY with the

push nipple lubricant.

4. Wipe o any excess lubricant.

5. This will protect the machined nipple

port surfaces from condensation that

may occur in the ueways.

Step 12 Insert push nipples

Avoid scarring or damaging

the push nipple or nipple

port surfaces. e push

nipple makes a metal-tometal seal with the nipple

port. Any surface defects

could cause a leak.

Step 13 Seat the push nipples

Use only a dead blow hammer

to seat the push nipples. DO

NOT use a sledge hammer.

1. Place a 2x4 board across the nipple and

strike rmly with a dead-blow hammer.

2. Make sure to strike in the center of the

nipple to prevent rotating it.

3. Do this with several strokes, just so the

push nipple is rmly started.

1. Insert a push nipple into each of the

two nipple ports.

2. Seat each nipple rmly but squarely.

3. Make sure the nipple face is parallel

to the section surface as closely as

possible.

4. DO NOT attempt to assemble sections

if any nipple port is mis-aligned.

4. Look into the nipple ports from the end

of the boiler. When properly seated at

this point, the push nipple edge should

be slightly inside the nipple port. It

should also be parallel with the inside

surface.

7

G

as-Fired Direct Vent Cast Iron Boilers – Field Assembly Instruction

s

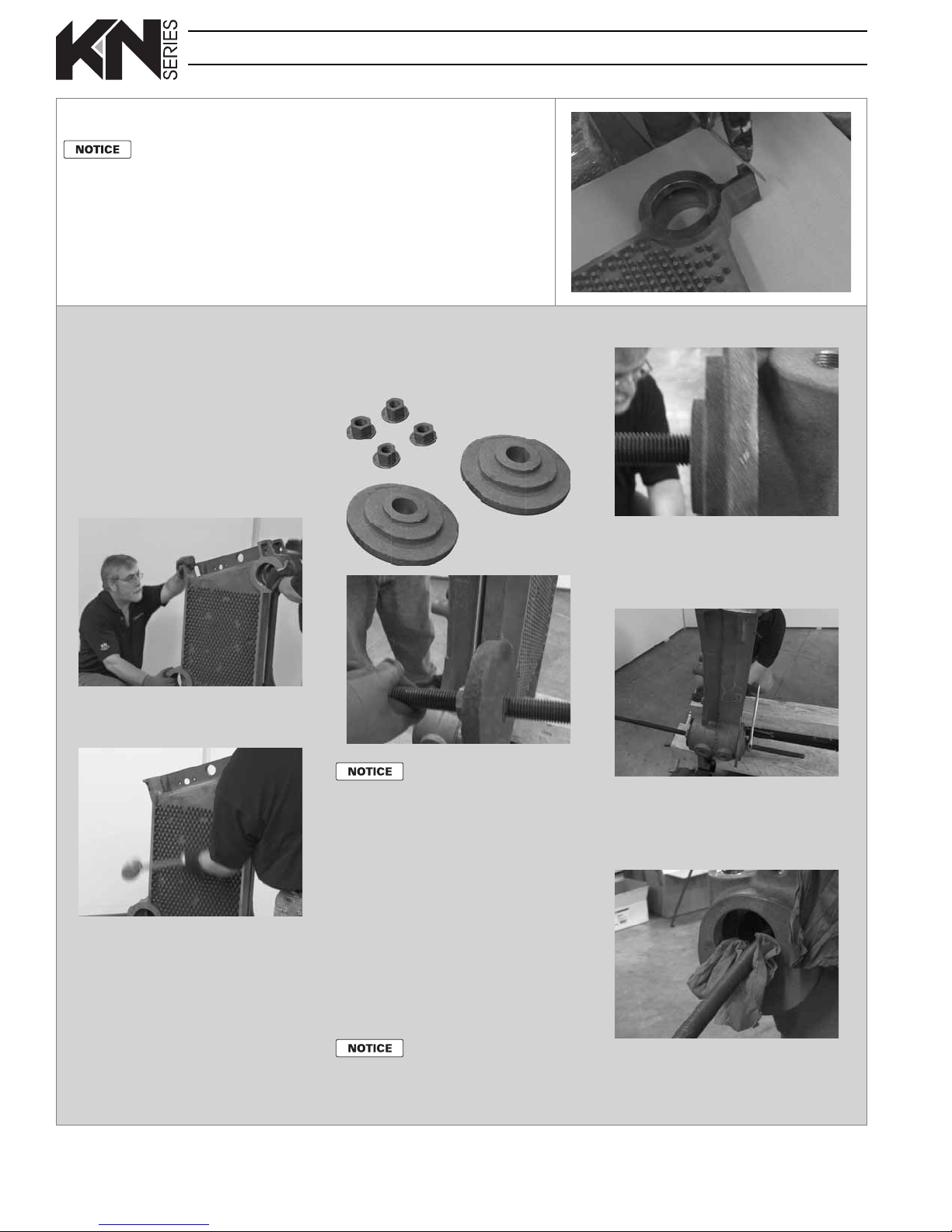

Bearing

plates

Place bearing plate with fl at side

away from the nut.

Step 14 File lower edges of next section

Work gloves are

recommended for this

procedure.

1. Use a at le to ease o the front

lower edge on both sides of the next

section.

2. This step will prevent the sharp edges

from gouging the runner beams as

the section is drawn up.

Step 15 Install next section and prepare draw rods

1. Carefully slide the rst intermediate

section up to the front.

2. Before pulling the intermediate section

up fully, clean the nipple ports and

brush lubricant on the inside machined

surfaces of the nipple ports as in Step9.

3. Align the intermediate section to the

front section and slowly move into

position so both push nipples just

enter the intermediate section.

nuts). The ribbed side of the bearing

plate (shown in the photo below) must

face the nut.

7/8-inch nuts and washers

Bearing

plates

Place bearing plate with fl at side

away from the nut.

11. Thread a washer and nut onto the

back end of each draw rod and snug

against the bearing plate. Make sure

the bearing plates are centered on the

nipple ports.

4. To initially seat the push nipple into the

next section, rap with a dead blow

hammer and 2x4 at each nipple port.

5. Repeat, alternating from right nipple

port to left to avoid cocking the push

nipples.

6. Wipe a small amount of motor oil on

the 7/8 inch all-thread rods supplied

with the boiler to make pull-up easier.

7. Place a 3/4 inch nut and washer plus

one of the bearing plates one each of

the two draw rods. The back sides (large

surface) of the bearing plates must face

toward the sections (away from the

When block assembly is

completed with the rear section,

use a small bearing plate on the

rear section as well, with the

ribs pointed inward.

8. Thread the nut far enough that about

24inches of draw rod extends beyond

the bearing plate.

9. Carefully insert the draw rods through

the front nipple ports. (Most of the draw

rod length will extend to the front.)

10. Slide one of the bearing plates over the

back end of each draw rod until ush

with the intermediate section port. The

bearing plate ribs should be toward the

nut, with at side against the section.

Hold the draw rods up while

positioning to prevent the draw

rod threads from gouging the

nipple port machine surfaces.

12. As additional sections are added, lay a

rag in the bottoms of the nipple ports

to prevent damaging the machined

surfaces as the draw rods are passed

through.

8

Loading...

Loading...