Page 1

FreshPoint™ U440

Service Manual

IMPORTANT: Fill in Pertinent Information on Page 3 for Future Reference

Page 2

Table of Contents

Installation & Start-Up Checklist ............................................................................................................................ 3

Product Specications & Important Information .................................................................................................... 4

Safety, Cautions, & Warnings ................................................................................................................................ 5

Flushing Schedule & Installation Instructions ........................................................................................................ 6

Installation Instructions .......................................................................................................................................... 7

Basic Programming Quick Reference Guide ....................................................................................................... 22

Programming ....................................................................................................................................................... 23

Service & Maintenance........................................................................................................................................ 29

Troubleshooting ................................................................................................................................................... 31

Flow Rate vs. Driving Pressure ........................................................................................................................... 33

IMPORTANT PLEASE READ:

The information, specications and illustrations in this manual are based on the latest information available at the time of printing.

•

The manufacturer reserves the right to make changes at any time without notice.

This product should be installed by a plumbing professional.

•

This unit is designed to be installed on potable water systems only.

•

This product must be installed in compliance with all state and municipal plumbing and electrical codes. Permits may be required

•

at the time of installation.

If daytime operating pressure exceeds 80 psi, nighttime pressures may exceed pressure limits. A pressure reducing valve must be

•

installed.

Do not install the unit where temperatures may drop below 32°F (0°C) or above 104°F (40°C).

•

Do not place the unit in direct sunlight.

•

Do not strike any of the components.

•

Warranty of this product extends to manufacturing defects of the vessel and controller, not the membrane. Misapplication of this

•

product may result in failure to properly condition water, or damage to product.

A prelter should be used on installations in which free solids are present.

•

In some applications local municipalities treat water with Chloramines. High Chloramine levels may damage system components.

•

Correct and constant voltage must be supplied to the controller to maintain proper function.

•

Page 3

Installation & Start-Up Checklist

Use this form to record initial system hardware, site conditions, and controller programming information.

•

Retain a copy for future reference.

•

Fill in the appropriate data (if available).

•

Checklist data should be collected and logged on this form for each system installed.

•

Start-up Data:

Installation Date: ___________________________

Installer: _________________________________

Installation Site: ___________________________

Application: _______________________________

System Model/Serial Number: ______________

Water Source: ___________________________

Water Analysis:

Turbidity: _____________________________

Total Iron: _____________________________

Water Temperature: _____________________

System Inlet Pressure (if available): ________

System Outlet Pressure: (if available):_______

Flow Rate During Pressure Reads: _________

Chlorine: _____________________________

Pretreatment Installed: ______________________

Back-ush Kit Installed: Yes ________ No _______

Set Volume Between Flushes: ____________

Set Flushing Duration: __________________

Set Day Override: __________________________

Initial Product Water Flow Rate: _______________

_________________________________________

Other Program Details: ______________________

_________________________________________

General Notes:

_________________________________________

_________________________________________

_________________________________________

_________________________________________

_________________________________________

_________________________________________

Checklist of Installation/Start-Up Steps

Installation location allows access to membrane ___

1.

Mounting provision accommodates system weight ___

2.

Listed components/ttings present ___

3.

Loose components assembled to system ___

4.

System securely mounted ___

5.

Solenoid valve/ow meter signal connections ___

6.

Plumbing connections completed ___

7.

Initial ush w/o leaks ___

8.

Electrical power connected ___

9.

System sanitized ___

10.

Back-up battery installed in controller ___

11.

Controller display okay ___

12.

Time of day set ___

13.

All programming steps completed ___

14.

Proper operation veried ___

15.

Installation/Set-Up information entered onto form ___

16.

Specic Installation Notes

(Problems/Suggestions/Comments):

_________________________________________

_________________________________________

_________________________________________

_________________________________________

_________________________________________

_________________________________________

Page 3

Page 4

Product Specications & Important Information

Introduction to the FreshPoint™ Ultraltration System

The FreshPoint™ ultraltration system is an advanced Point of Entry (POE) water treatment device designed to

improve the water quality in the entire home. It uses ultraltration membrane technology to provide a physical barrier

to particles, large dissolved molecules, most colloids, and microbes down to 0.025 um in size. The FreshPoint™ is not

designed to removed ions or other elemental forms such as hardness and heavy metals, or small organic molecules

such as pesticides.

The FreshPoint™ should only be installed by a qualied professional. The installation must comply with all local codes

and state or provincial laws and regulations.

In addition to meeting codes, laws, and regulations, the home owner should understand the care and maintenance of

the FreshPoint™. Please read the information found in this service manual.

SAFETY NOTICE: Read all safety precautions before installing, operating, or servicing the FreshPoint™.

Product Specications

Technical Data and Specications

pH Range During Operation ............................. 3-10

Free Chlorine .............................................. Max. 200 mg/L for cleaning, 4 mg/L for service

Maximum Continuous Flow .............................. Recommended 1.2 gpm (surface waters) to 2.9 gpm (well water)

Maximum Intermittent Flow .............................. 10 gpm

Recommended Operating Pressure ................. up to 60 psig

Maximum Operating Pressure ......................... 120 psig

Minimum Operating Temperature ..................... 33°F (Do Not Freeze)

Maximum Operating Temperature .................... 104°F

Contaminant Removal Size .............................. 150,000 daltons molecular weight cut-off

0.025 um nominal pore size

Multibore® Capillaries

Capillaries per Fiber ............................................................................7

Outer Diameter ......................................................... Inch ...................0.17

Inner Diameter .........................................................Inch ...................0.04

Material ...............................................................................................PESM

Molecular Weight Cutoff (MWCO) ............................ k Daltons ...........100-150

Active Membrane Surface ........................................ ft2 .......................48.50

IMPORTANT! READ THIS FIRST

Read this service manual thoroughly before rst use.

All plumbing and electrical codes must be complied with when installing this product.

•

Only qualied personnel should install this product.

•

Check the FreshPoint™ periodically to ensure proper operation (i.e.: ushing, ow rate, pressure drop, etc)

•

Do not allow the FreshPoint™ to be exposed to freezing temperatures. Freezing may damage the system.

•

Ensure the membrane does not dry out. Opened membranes should be preserved with a 0.1% sodium bisulte

•

solution.

The FreshPoint™ will continue to operate as a lter during power loss. However, when power returns after an

•

extended outage, the timer may need reprogramming.

Keep this service manual near the FreshPoint™ system for future reference.

•

The FreshPoint™ is intended to treat only potable quality water. It is not intended as the permanent primary

•

treatment of water from a source that is contaminated, such as from radon, pesticides, insecticides, sewage, or

wastewater.

Use lubricants (such as silicone) sparingly.

•

Page 4

Page 5

Safety, Cautions, & Warnings

Safety

The FreshPoint™ must be wired according to local electrical codes to prevent the possibility of

•

electrical shock.

Do not modify the power supply cord.

•

The FreshPoint™ must be installed in compliance with local plumbing codes and any other applicable codes.

•

The FreshPoint™ has been designed and tested to offer reliable service when installed by a qualied

•

professional and operated and maintained according to the instructions in this service manual.

For safety reasons, the FreshPoint™ is furnished with a low voltage power transformer to plug into the

•

electrical outlet. Do not replace this transformer with another power supply (except as supplied by the

manufacturer), as this may cause damage to the electronics.

Install the FreshPoint™ only for its intended use as described in this service manual.

•

Do not use corrosive chemicals in the FreshPoint™.

•

Do not install the FreshPoint™ if it has a damaged cord or plug, if it is not working properly, or if it has been

•

damaged or dropped.

Do not immerse the cord or plug in water.

•

Keep the cord away from heated surfaces.

•

Disconnect the FreshPoint™ from the power source before performing any service or maintenance on the

•

controller, meter, or solenoid valves.

Do not plug in the controller transformer if there is water on the electrical wiring or the power supply.

•

Always shut off the water ow and release water pressure before cleaning or maintaining the FreshPoint™.

•

The FreshPoint™ is intended for indoor use only. The power supply and controller must not be exposed to

•

weather elements.

The outlet used for power to the FreshPoint™ should be an unswitched outlet.

•

NOTE: This product should be installed by a qualied professional. Comply with all plumbing and

electrical codes when installing this product.

Page 5

Page 6

Flushing Schedule & Installation Instructions

Flushing Schedule

The FreshPoint™ is ushed on a schedule dependent on the quality of water being treated.

Default Factory Settings

Flush Frequency: 100 gallons

Flush Duration: 0.5 minutes

Day Override: 1 Day

These settings may need to be adjusted based on the analysis for the water treated and practical experience

with fouling. The FreshPoint™ will automatically initiate a ush if 24 hours (for each 1 day of the Day Override

setting) has elapsed since the last ow initiated ush. This setting is adjusted in the day override setting in master

programming.

A post-ultralter pressure tank is recommended to ensure sufcient ow and pressure to the home during a ush

cycle. The backush surge tank (where installed) will perform the same function.

Refer to Table 1 below for initial set up.

Table 1: Initial Recommended Flushing Parameters by Water Source and Treatment

Water Source Typical Water Quality to Filter

Surface Water

(Municipally Treated)

Surface Water (Private

Multi Barrier Treatment)

(with recommended pretreatment)

• Chlorine < 4.0 mg/l

• Turbidity < 1.0 NTU

• TOC < 2.0 mg/L

• SDI15 < 6.67

• Metals (Fe, Mn, Cu, etc.) < 1 mg/l

• Chlorine > 2mg/l, < 4.0 mg/l

• Turbidity < 5.0 NTU

• TOC < 10.0 mg/L

• SDI5 < 20

• Metals (Fe, Mn, Cu, etc.) < 1 mg/l

Recommended

Pretreatment

• 200 micron prelter Recommended 100 30

• In-Line coagulation and

ltration with multimedia

lter

• Disinfection with chlorine

• 200 micron prelter

1

Backush Kit Flush Frequency

(Gallons

Throughput)

Recommended 50 60

Flush

Duration

(Seconds)

Well (Municipally

2

Treated)

Well (Private)

2

• Chlorine < 4.0 mg/l

• Turbidity < 1.0 NTU

• TOC < 2.0 mg/L

• SDI15 < 6.67

• Metals (Fe, Mn, Cu, etc.) < 1 mg/l

• Chlorine < 4.0 mg/l

• Turbidity < 1.0 NTU

• TOC < 2.0 mg/L

• SDI15 < 6.67

• Metals (Fe, Mn, Cu, etc.) < 1 mg/l

• Iron removal ltration

(if iron over 1 mg/l)

• 200 micron prelter

• Iron removal ltration

(if iron over 1 mg/l)

• Disinfection – optional

• 200 micron prelter

Recommended with

high turbidity,

suspended solids,

colloids, or ferric iron

Recommended with

high turbidity,

suspended solids,

colloids, or ferric iron

200 30

100 30

1

In all cases, a disposable pre-lter cartridge is recommended to protect the FreshPoint™ from large particles,

plumbing debris, etc.

2

Some shallow wells may have serious contamination problems, hazy water, high TOC, color and high bacterial

loads. The backush kit is recommended to avoid fouling in these installations.

NOTE: It is important to understand the water quality and fouling potential to determine the type of

ushing required when installing the FreshPoint™.

Flow Capacity

Assess the household water use, especially peak water draw. The standard single-element FreshPoint™ is

•

sized for 10 gpm peak capacity ow. Water draw in the house that exceeds peak capacity will have the effect

of reduced pressure and volume delivery at the open taps.

Maximum recommended continuous ow for the FreshPoint™ system is 1.2 gpm for surface water, and 2.9

•

gpm for well water.

Page 6

Page 7

Installation Instructions

Plumbing

The system and installation piping should be cleaned before the system is started so that no impurities,

•

abrasive materials, or oily materials are washed into the membranes. The piping must be purged of air to

prevent water hammer which can damage the system.

A bypass system is strongly to permit the most efcient service of the FreshPoint™ over its life. Additionally,

•

some local plumbing codes may require a bypass.

All three FreshPoint™ housing ports on the system (inlet, ltrate or outlet, and drain) are 3/4” NPT

•

connections.

A 10 gpm ow control is included to be installed on the inlet of the FreshPoint™ to ensure the membrane

•

operates in an efcient manner.

A 7 gpm ow control is included to be installed on the drain line to maximize water efciency and ensure

•

proper ushing rates are achieved. Ensure the drain selected has the capacity for this ow rate.

Private wells often have higher levels of turbidity or suspended solids that can shorten membrane life without

•

adequate ushing. If fouling potential is high, a backush kit should be installed. The installation of a pressure

tank and solenoid valve switches the system from forward ushing to backushing, thereby extending the

membrane life in high fouling potential waters.

For standard installations, a post-ultralter pressure tank is recommended to maintain pressure during a ush

•

cycle.

The system must be protected from possible back contamination by the installation of an air gap between the

•

FreshPoint™ drain connection and the drain line.

Electrical Requirements

The FreshPoint™ controller requires a constant electrical supply to ush correctly (120 VAC).

Pretreatment

Pretreatment of the FreshPoint™ with a 200 µm lter is recommended. Some installations may require additional

pretreatment. Reference the Flushing Schedule (Table 1) or the FreshPoint™ Ultraltration Systems Applications

Guide for more information.

FreshPoint™ Location

Note the location of the water supply, drain and an electrical outlet when choosing a mounting location.

•

The FreshPoint™ is a point-of-entry (POE) device designed to treat water distributed throughout the entire

plumbing system. The installation should be located near the point of entry, but ahead of where plumbing

splits for distribution.

The system mounting bracket has been designed to mount the FreshPoint™ sufciently off the wall to

•

accommodate installation of a pre/post lter inline with the water inlet and/or water outlet of the system.

Remember to allow for visual and physical access to the meter/programming controls.

•

Do not mount the FreshPoint™ above any electrical equipment, or above items that may become damaged if

•

they get wet.

Install the FreshPoint™ in a location that will allow for easy service access. Service and maintenance requires

•

access to the unit and removal and replacement of the membrane element.

Mount the FreshPoint™ to a wall in a vertical orientation using appropriate mounting hardware (not included)

•

capable of supporting 51 pounds (23.1 kilograms).

The FreshPoint™’s footprint is 12” x 12”, exclusive of plumbing connections. The FreshPoint™ requires 85”

•

of vertical room to allow for removal of the membrane, unless plumbing accommodations are made (e.g.:

unions). See Figure 3 for a typical installation with dimensions.

The backush tank, in the backush kit, requires an additional 16” by 16” of level oor space.

•

Plumbing Options

There are two options for plumbing in the FreshPoint™ system:

Standard Installation (Forward Flush only)

1.

Backush Kit Installation

2.

Page 7

Page 8

Installation Instructions

Drain Flow Control

(Note Flow Direction)

Flow Meter Housing

(Note Flow Direction)

Drain

Piping Must

Include

Code-Compliant

Air Gap

1/4” Ball Valve Pressure Tap

for Membrane Integrity Testing

(Recommended)

Inlet Flow Control

(Note Flow Direction)

Pre-filter (Recommended)

Inlet Valve

Bypass Valve

Inlet

Outlet

Outlet Valve

Standard Installation (Forward Flush only)

A standard installation clears the membrane periodically by opening a drain port, and allowing the feed stream

ow in its normal direction, but at a faster rate. The ow goes in and out of the end of the ber instead of through

the membrane, and the foulant is cleaned off the membrane and out of the unit to drain.

Connect the FreshPoint™ to the household plumbing supply as shown in Figure 1. It is recommended that the

plumbing include a system bypass for future service. A 200 um sediment pre-lter is recommended. For ease of

membrane element replacement, unions are recommended as indicated on Figure 1.

NOTE: Installations without a pressure tank may experience drops in pressure/ow to the home during a

ush cycle.

Figure 1: Tankless Installation

Page 8

42605_REVA

Page 9

Installation Instructions

Drain Flow Control

(Note Flow Direction)

Flow Meter Housing

(Note Flow Direction)

Drain

Piping Must

Include

Code-Compliant

Air Gap

1/4” Ball Valve Pressure Tap

for Membrane Integrity Testing

(Recommended)

Backflush Inlet Shut-Off Valve

Pre-filter (Recommended)

Inlet Valve

Bypass Valve

Inlet

Outlet

Outlet Valve

Tank Isolation Valve

Backush Kit Installation

Installations with high fouling potential will require plumbing in a pressurized surge tank and inlet solenoid

valve (See Flushing Schedule Table 1). In the backush mode, the ltered water from a pressure tank ows

backward through the membrane from the ltrate side during the ushing cycle. This removes the foulant from the

membrane surface as well as material that may have entered into the porous structure.

Connect the FreshPoint™ to the plumbing supply as shown in Figure 2. It is recommended that the plumbing

include a system bypass for future servicing, etc. A 200 um sediment pre-lter is recommended. For ease of

membrane element replacement, unions are recommended as indicated on Figure 2. The backush tank should

be installed on a tee before the ow meter. The backush tank precharge pressure should be set to 20 psig.

NOTE: Installation of the backush tank after the meter will cause reverse ow through the meter and

could have a detrimental effect on meter performance.

Figure 2: Backush Kit Installation

42606_REVA

Page 9

Page 10

[1250.89]

49.25

[184.09]

7.25

[266.41]

10.57

[90.66]

3.57

[1350.61]

53.17

[2159]

85.00

Vertical Clearance

Required to

Remove Membrane

[357.51]

14.08

[299.82]

11.80

[187.96]

7.40

[6.35]

Ø.25

[250.70]

9.87

Installation Instructions

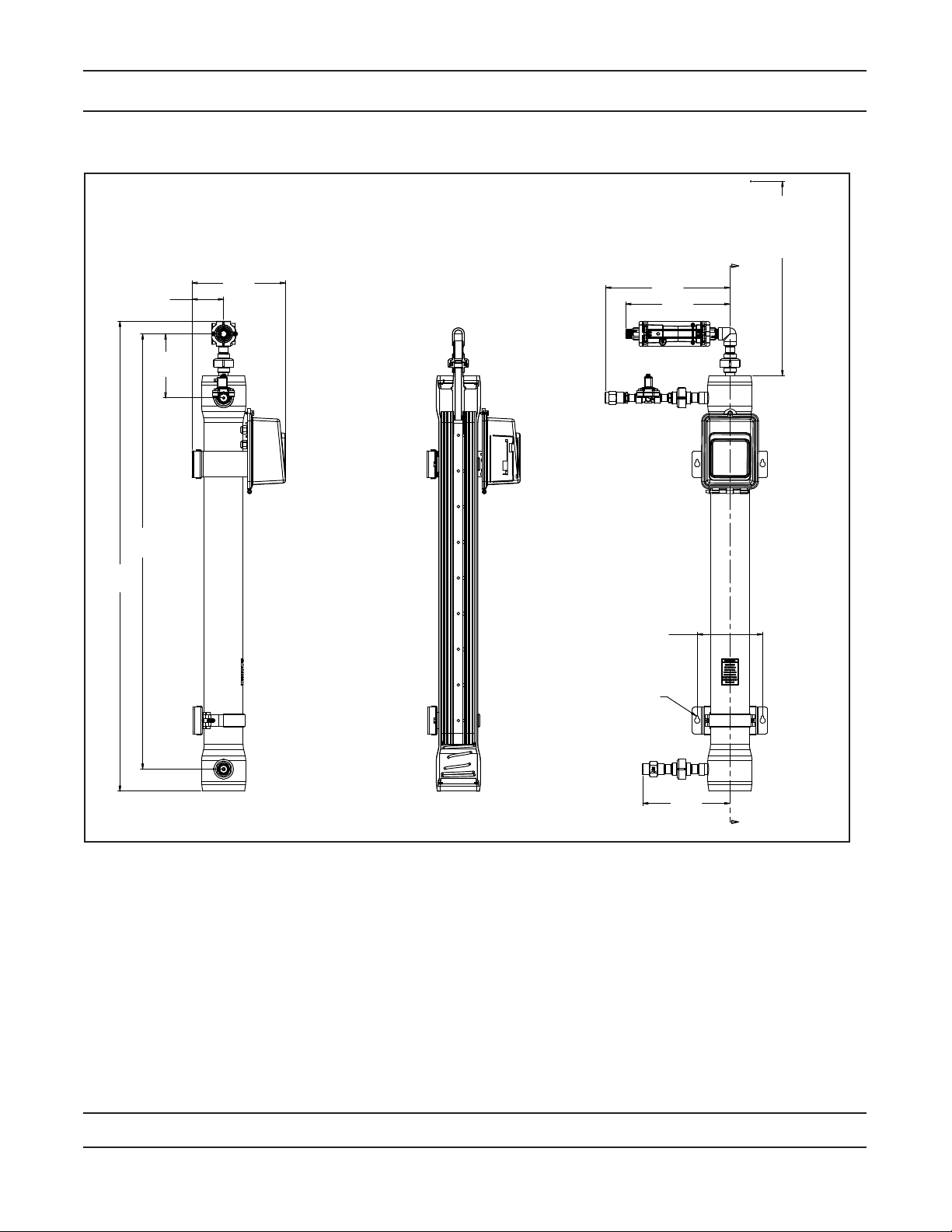

Figure 3: Dimensional Drawing for the FreshPoint™ Ultraltration System

NOTE: Dimensions are in inches. Metric (mm) dimensions are in brackets.

61593_REVJ

Page 10

Page 11

FreshPoint™ Assembly

2

3

9

1

10 6

11

12

11

13

5

7

8

5

4

5

1

Open End of

Membrane Assembly

Faces Up

Figure 4: FreshPoint™ Assembly and Included Parts

61593_REVJ

Item No. Quantity Part No. Description

1 .................. 1 .....................61594-02 ..................Codeline Vessel Assy, UF-Filter

2 .................. 1 .....................61595-03 ..................UF Filter Element Assy, 4”

3 .................. 1 .....................42335 ....................... Spring, Codeline, U440 Filter

4 .................. 2 .....................41972 ....................... Bracket, Mounting, UF Filter

5 .................. 2 .....................41976 ....................... Saddle & Clamp Assy

6 .................. 1 .....................61592-01 ..................Timer Assy, UF, ET, 120VAC

.................... 1 .....................61592-03 ..................Timer Assy, UF, ET, 230VAC, EU

.................... 1 .....................61592-04 ..................Timer Assy, UF, ET, 230VAC, AU

7 .................. 1 .....................61650 ....................... Fitting Kit, Inlet

8 .................. 1 .....................60700-10 ..................DLFC, 3/4”F x 3/4”F, NPT, 10 GPM, Brass

9 .................. 1 .....................61663 ....................... Fitting Kit, Outlet

10 ................ 1 .....................61560-11 ...................Meter Assy, 3/4”, Inln, NPT, Elec

11 ................ 1 .....................61652 ....................... Fitting Kit, Drain

12 ................ 1 .....................42556 ....................... Bracket, Solenoid, 1/2”, NPT, NC

13 ................ 1 .....................60699-70 ..................DLFC, 3/4”F x 3/4”F, NPT, 7.0 GPM, Brass

Page 11

Page 12

Installation Instructions

Additional Water Treatment Devices

It is preferable to install the FreshPoint™ ahead of softeners and carbon lters, as the removal of particulates

•

generally improves their performance. The FreshPoint™ should be installed after equipment such as iron lters,

sediment lters, or multimedia lters.

Installation downstream of a chlorinator runs the risk of oxidative attack of the membrane, shortening the membrane

•

life depending on chlorine level, time of contact and temperature. The FreshPoint™ can withstand a continuous

dose of up to 4.0 mg/L (or ppm) of free chlorine, but continuous exposure to higher level of free chlorine or other

oxidizing chemicals can shorten the life of the membrane.

When installed on a chlorinated water supply of less than 4.0 mg/L free chlorine, it is preferable to allow the chlorine

•

to pass through the FreshPoint™.

FreshPoint™ Installation Instructions

Tools and Supplies needed:

Teon® thread tape or paste for leak free assembly of the pipe thread connections.

1.

CAUTION: Ensure that the paste is compatible with plastic ttings.

Lubricant for seals (a packet of silicone is supplied)

2.

NOTE: Silicone (supplied) should be applied sparingly to avoid fouling the membrane.

Four ¼” bolts to mount the system to the wall.

3.

½” open end wrench to tighten saddle clamp.

4.

7/16” open end wrench to tighten ¼” wall mount bolts.

5.

Crescent wrench that can open to 1 ½” to grip ow control.

6.

Pipe wrench to grip the vessel’s side port.

7.

Flat head screw driver and pliers to remove the vessel’s vessel retaining ring.

8.

Unpacking (Refer to Figure 4, FreshPoint™ Assembly)

Open the box with the hardware and verify that all of the components pictured on the FreshPoint™ Assembly page

1.

are present and undamaged.

Open the Plumbing Kit bags, and verify that all of the components listed on the parts list (found in the Plumbing Kit

2.

bags) are present and undamaged.

The membrane is packed in a preservative solution, and should not be opened until it is to be installed in the

3.

housing.

Hardware Assembly (Standard Assembly):

Assembly is most easily done on a horizontal surface.

1.

Position a mounting bracket (Item 4), a saddle, and a saddle clamp (Items 5) about 10” from the top of the vessel

2.

(Item 1). Leave the bolts loose. Note: The smaller diameter portion of the mounting bolt holes in the mounting

bracket must be positioned toward the top of the vessel.

Position the bracket of the timer (Item 6) between the mounting bracket and the saddle clamp. Ensure timer is

3.

oriented correctly.

Rotate the vessel so that the side ports are oriented in the direction compatible with the site plumbing and tighten

4.

the saddle clamp bolts with the ½” wrench.

Install the remaining mounting bracket, saddle, and saddle clamp at a convenient location near the bottom of the

5.

vessel, and tighten the saddle clamp bolts with a ½” wrench.

Vessel Head Removal

Remove the top end closure, bottom end closure, and two square cross section seals from the vessel.

1.

a. Remove the retaining rings by prying the tabbed end out of the stainless steel groove with the tip of the

screwdriver. Once the end of the retaining ring is clear of the groove, grasp the tab with the pliers and pull it toward

the end of the vessel until the end of the ring is resting in the end margin of the shell.

b. Remove the 4” retaining ring from the stainless steel groove in the shell by rotating your nger behind the ring as

it continues to exit the groove.

c. Once the retaining ring has been removed, examine the area for burrs or dings which could damage the head or

membrane. If necessary, use Scotch-Brite® or 600 grade sandpaper to smooth the area.

d. Grasp the adapter and pull the head straight out. A small amount of side-to-side movement may be necessary to

start the head moving.

Page 12

Page 13

Installation Instructions

Outlet Fittings

Apply thread sealant to the ¾” NPT thread of the adapter (Item 1) of the top end closure and securely thread the

1.

male half of the union (Item 9, Outlet Fitting Kit) to it.

Apply thread sealant to both ends of the ¾” NPT nipple (Item 9, Outlet Fitting Kit), and securely thread it to the

2.

female portion of the union (Item 9, Outlet Fitting Kit) and the elbow (Item 9, Outlet Fitting Kit). If installing with the

backush kit, substitute the backush kit for the elbow (see Figure 2).

Remove the red retainer clips and the adapters from the ends of the meter assembly (Item 10).

3.

Apply thread sealant to the 3/4” NPT thread of the meter assembly adapters.

4.

Securely thread one of the meter assembly adapters into the elbow (Item 9, Outlet Fitting Kit). If installing with the

5.

backush kit, substitute the tee from the backush kit for the elbow (see Figure 2).

Drain Fittings

Apply thread sealant to the NPT nipples and reducer bushings (Items 11, Drain Fitting Kit).

1.

Securely thread the male half of the union (Item 11, Drain Fitting Kit) to the ¾” NPT nipple.

2.

Securely thread a reducer bushing (Item 11, Drain Fitting Kit) to the female half of the union (Item 11, Drain Fitting

3.

Kit) and a reducer bushing to the inlet end of the DLFC (Item 13). The ow direction is indicated on the body of the

ow control.

Securely thread one of the 1/2” NPT nipples (Item 11, Drain Fitting Kit) into each reducer bushing (Item 11, Drain

4.

Fitting Kit).

Securely thread the inlet port of the solenoid valve (Item 12) onto the 1/2” nipple which is connected to the union.

5.

The valves ow direction is indicated on the valve.

Securely thread the outlet port of the solenoid valve (Item 12) onto the 1/2” nipple which is connected to the 7 gpm

6.

DLFC. The ow direction is indicated on the body of the ow control.

Securely thread the 3/4” NPT nipple (Item 11, Drain Fitting Kit) into the top port of the vessel (Item 1).

7.

NOTE: Use a wrench to hold the vessel’s side port when tightening a tting, movement of the port could

damage the shell and/or the port.

Inlet Fittings

Apply thread sealant to the 3/4” NPT nipples (Items 7, Inlet Fitting Kit).

1.

Securely thread one of the nipples into the outlet of the 10 GPM ow control (Item 8). The ow direction is indicated

2.

on the body of the ow control.

Securely thread female half of the union (Items 7, Inlet Fitting Kit) into the nipple extending from the 10 GPM ow

3.

control. If installing with the backush kit, insert the backush kit inlet solenoid valve between the union and the

ow control (see Figure 2). If installing the recommended ttings for integrity testing, install immediately prior to the

union (see Figures 1 and 2).

Securely thread the male half of the union (Items 7, Inlet Fitting Kit) onto the other 3/4” NPT nipple (Items 7, Inlet

4.

Fitting Kit).

Securely thread the 3/4” NPT nipple (Items 7, Inlet Fitting Kit) into the bottom port of the vessel (Item 1).

5.

NOTE: Use a wrench to hold the vessel’s side port when tightening a tting, movement of the port could

damage the shell and/or the port.

Insert Vessel Top Head

Install the square cut seal into the groove below the stainless steel ring at the top end of the vessel. The seal should

1.

be lubricated lightly on the ID surface only with the supplied silicone.

Installing the head into the vessel.

2.

a. Install the top closure into the vessel. Using both thumbs, apply equal pressure on opposite sides of the head

to force it into the vessel so that it clears the retaining ring groove.

b. Carefully insert the retaining ring into the groove. This is done by inserting the lead end of the spiral ring

(end without bent tab) into the stainless steel retaining ring groove located in the shell, slowly pushing the

remaining turns into the shell.

c. Check that the spiral retaining ring is fully seated in the groove. If it is not, remove it and check for foreign

materials that would cause the spiral ring to not fully seat.

Page 13

Page 14

Installation Instructions

Connect Fittings to the Vessel

Connect the inlet end of the ow meter (Item 10) to the meter adapter which is threaded into the outlet elbow (Item

1.

9), and secure it with the red clip. The ow direction is indicated on the body of the meter.

Connect the drain valve union (Item 11) to the union at the sideport near the top of the vessel (Item 1).

2.

Connect the inlet union (Item 7) to the union at the bottom of the vessel (Item1).

3.

NOTE: Use a wrench to hold the vessel’s side port when tightening a tting, movement of the port could

damage the shell and/or the port.

Position the hardware assembly and vessel bottom head against the wall and mark the four mounting bolt locations.

4.

Installing the Membrane Element (Item 7):

Lay the assembled vessel and ttings on a horizontal surface.

1.

Cut open the sealed bag of the lter element at the end where the center tube is open. Lightly lubricate the center

2.

tube with the supplied silicone.

Insert the lter element into the bottom of the vessel, with the open end of the center tube rst, and removing the

3.

plastic bag as it goes in. A slight resistance will be felt at the last inch of insertion, as the seals on the adapter are

compressed into the center tube of the element.

Install the square cut seal into the groove below the stainless steel ring at the bottom end of the vessel. The seal

4.

should be lubricated lightly on the ID surface only.

Insert the spacer spring (Item 3). About ¼” of compression is required to compress it beyond the square cut seal.

5.

Install the bottom closure.

6.

a. Using both thumbs, apply equal pressure on opposite sides of the head to force it into the vessel, clearing the

retaining ring groove.

b. Carefully insert the retaining ring into the groove. This is done by inserting the lead end of the spiral ring (the end

without the bent tab) into the stainless steel retaining ring groove located in the shell, slowly pushing the remaining

turns into the shell.

c. Check that the spiral retaining ring is fully seated in the groove. If it is not, remove it and check for foreign

materials that would cause the spiral ring to not fully seat.

Mounting the Assembly on the Wall:

Install four ¼” bolts at the positions previously marked. Leave enough clearance between the wall and the bolt

1.

heads to permit the mounting brackets to be slid into place.

NOTE: Bolts larger than ¼” may not t through the keyhole openings in the mounting brackets.

Tighten the four wall mounting bolts.

2.

Install the other meter adapter into the meter assembly and fully insert the red clip.

3.

Plumbing Connection:

Connect the supply water to the inlet ow control, and complete supply plumbing. Couple the inlet union.

1.

Connect the drain line plumbing to the drain ow control and couple the drain union.

2.

Connect the meter adapter to the outlet plumbing and couple the outlet union.

3.

NOTE: If installing with the backush kit, complete the plumbing between the outlet tee and the backush

tank (see Figure 2). The backush tank pre-charge should be adjusted to 20 psi. If installed, the backush

tank isolation valve should be closed.

Page 14

Page 15

Installation Instructions

2

4

1

5

3

6

1

B

T

B

24 VAC Transformer

Solenoid Harness

Black

Black

Green

White

White

Black

Yellow

White

Wt/Blk

Meter/Solenoid Electrical Connection (Refer to Figure 5)

Connect the drain solenoid wire harness to the solenoid valve.

1.

Insert the ow meter cable into the socket on the ow meter

2.

If installing with the backush kit:

3.

a. Remove the two transformer leads from the terminal strip (terminals 4 and 5) and replace them with the leads

from the higher-rated transformer provided in the kit.

b. Install inlet solenoid’s wiring harness (backush kit) to the control board. The inlet solenoid leads should be

installed in the same terminal locations as the drain solenoid (1-green, 2-black, 3-white). DO NOT connect the

wiring harness to the solenoid at this time.

Plug the power cord transformer into a 120V GFI outlet.

4.

Figure 5: Meter/Solenoid Electrical Connection Diagram

42209_REVB

Page 15

Page 16

Installation Instructions

System Startup Guidelines

Electrical

Follow the instructions in the programming section of this service manual to setup the timer.

Check the FreshPoint™ For Leaks

Ensure that all new plumbing connections, the three ports from the housing, and the two end cap perimeters

•

have no leaks. Correct if needed.

Manually initiate a ush cycle by pressing the Extra Cycle button. Ensure the drain solenoid valve opens and

•

that a robust ow goes to the drain, and that the drain can handle the ow.

Flushing

Flush the membranes prior to placing the system in service to remove the membrane storage solution.

NOTE: If installed, the backush tank isolation valve should be closed. If there is a tank and no isolation

valve, ensure that each ush cycle lls and empties the backush tank.

NOTE: If installed with the backush kit, the inlet solenoid valve should not be connected to the wiring

harness for ushing, as it will not permit easy removal of air from the system if operating.

Rinse the preservative solution from the membrane as follows:

Close the bypass valve of the bypass plumbing arrangement.

1.

Open the outlet valve of the bypass plumbing arrangement.

2.

Slowly open the inlet valve of the bypass plumbing arrangement. This will ll the module with water without

3.

creating a water hammer effect.

To expel air from the feed side of the membrane initiate at least two successive ush cycles by pressing the

4.

Extra Cycle button on the timer.

Rinse Cycle 1:

Open the service water faucet closest to the FreshPoint™ installation to permit a ow of ve gallons per

1.

minute. Allow the system to ush for twenty minutes.

Initiate two successive ushes to drain by pressing the Extra Cycle button on the timer.

2.

If a backush tank is installed and not isolated, ensure that it is emptied by initiating successive ushes by

3.

pressing the Extra Cycle button on the timer.

Rinse Cycle 2:

Allow the service water to continue to ow at ve gallons per minute. Permit the system to ush for an

1.

additional twenty minutes.

Initiate two successive ushes to drain by pressing the Extra Cycle button on the timer.

2.

If a backush tank is installed and not isolated, ensure that it is emptied by initiating successive ushes by

3.

pressing the Extra Cycle button on the timer.

Rinse Cycle 3:

Allow the service water to continue to ow at ve gallons per minute. Permit the system to ush for an

1.

additional twenty minutes.

Initiate two successive ushes to the drain by pressing the Extra Cycle button on the timer.

2.

If a ush tank is installed, ensure that it is emptied by initiating successive ushes by pressing the Extra Cycle

3.

button on the timer.

While the system is ushing check all plumbing connections for any possible leaks.

4.

Page 16

Page 17

Installation Instructions

System Sanitizing - With Prelter Installed

The unit should be sanitized/disinfected after the initial start up rinsing procedure, or in the case of biological

fouling. The system should be disinfected after ushing but prior to use. Disinfect after the integrity test, if

performed.

CAUTION: Sodium hypochlorite (bleach) is used for disinfection. The user should acquaint themselves

with the appropriate safety precautions for storage and handling of the chemicals being used. USE ONLY

SODIUM HYPOCHLORITE. DO NOT USE BLEACHES CONTAINING ANY OTHER COMPOUNDS.

Close the inlet valve of the bypass plumbing arrangement. If installing with backush kit, disconnect the wiring

1.

harness from the inlet solenoid valve.

If the FreshPoint™ system is equipped with a backush or product tank, initiate successive ushes by

2.

pressing the Extra Cycle button on the timer until the ush tank is empty. Isolate the backush tank by

closing the tank isolation valve. CAUTION: Any product or backush tank needs to be isolated during

disinfection. The chemicals use in disinfection are at a higher concentration than recommended for

these tanks, and are likely to cause damage to the tanks if exposed.

Open a faucet near the FreshPoint™ system to ensure that the plumbing system is depressurized.

3.

Remove the prelter sump.

4.

Remove the lter cartridge.

5.

Add unscented bleach to the lter sump as follows:

6.

Filter Size Teaspoons of Unscented Bleach

10” x 2.5” 3/4

20” x 2.5” 1 1/2

10” x 4” 1 1/2

20” x 4” 3

Open the inlet valve, purge air from the cartridge lter sumps, and allow the water to ow until a chlorine smell

7.

can be detected in the water owing from the open service faucet.

Close the service faucet and allow the system to soak for one hour.

8.

Initiate a system ush by pressing the Extra Cycle button on the timer.

9.

Open the service faucet and allow the water to ow until the chlorine smell is not detected.

10.

Use a test kit to conrm that the chlorine level is below 4 ppm (ideally below 1 ppm).

11.

Close the inlet valve, depressurize the plumbing, and replace the lter cartridge.

12.

Repressurize the system by opening the closest faucet, and slowly opening the inlet valve of the bypass

13.

plumbing arrangement. Expel air from the feed side by pressing the Extra Cycle button several times.

Close the faucet. Open the tank isolation valve and reconnect the inlet solenoid valve to the wiring harness, if

14.

applicable.

Page 17

Page 18

Installation Instructions

Add Sanitizing Solution

System Sanitizing - No Prelter Installed

CAUTION: Sodium hypochlorite (bleach) is used for disinfection. The user should acquaint themselves

with the appropriate safety precautions for storage and handling of the chemicals being used. USE ONLY

SODIUM HYPOCHLORITE. DO NOT USE BLEACHES CONTAINING ANY OTHER COMPOUNDS.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

Close the inlet valve of the bypass plumbing arrangement. If installing with backush kit, disconnect the wiring

harness from the inlet solenoid valve or product tank.

If the FreshPoint™ system is equipped with a backush tank, initiate successive ushes by pressing the

Extra Cycle button on the timer until the ush tank is empty. Isolate the backush tank by closing the tank

isolation valve. CAUTION: Any product or backush tank needs to be isolated during disinfection. The

chemicals use in disinfection are at a higher concentration than recommended for these tanks, and

are likely to cause damage to the tanks if exposed.

Open a faucet near the FreshPoint™ system to ensure that the plumbing system is depressurized.

Separate the drain plumbing from the FreshPoint™ housing at the union.

Drain the FreshPoint™ housing into a bucket by loosening the supply port union or using the recommended

integrity test port.

Tighten the supply port or close integrity test valve.

Through the drain port ll the FreshPoint™ housing with a solution containing chlorine at 100 mg/l (1 1/2

teaspoons of unscented bleach in 1 gallon of clean water). See gure 6.

Reconnect the drain plumbing union.

Open the inlet valve of the bypass valve arrangement and allow water to ow until a chlorine smell is detected

in the water owing from the open faucet.

Close the open faucet and allow the

system to soak for one hour.

Initiate a system ush by pressing the

Extra Cycle button on the timer.

Open the service faucet and allow the

water to ow until the chlorine smell is not

detected.

Use a test kit to conrm that the chlorine

level is below 4 ppm (ideally below 1 ppm).

Repressurize the system by opening the

closest faucet, and slowly opening the inlet

valve of the bypass plumbing arrangement.

Expel air from the feed side by pressing

the Extra Cycle button several times.

Close the faucet. Open the tank isolation

valve and reconnect the inlet solenoid

valve to the wiring harness, if applicable.

Figure 6: Adding Sanitizing Solution

Page 18

42614_REVA

Page 19

Installation Instructions

Membrane Integrity Test (Recommended)

All membrane elements are factory-tested, and pass integrity tests before they are shipped. However, a full

system integrity test should be done upon startup and then routinely (once per year minimum) thereafter.

The integrity is used to check for:

Internal leaks, such as cut or misaligned O-rings

•

Damaged membranes

•

The preferred integrity test is the pressure decay test. Air pressure is applied to the membrane when it is fully

wet-out (the pores are full of water), which is the membrane’s condition when it has been properly ushed after

start up. The amount of pressure loss is measured over a set period of time. If the pressure declines too fast, it

indicates that there is a seal leak in the system or membrane ber damage.

General Test Information

The test requires that the membrane be fully “wet-out” (all pores full of water).

•

The membrane assembly should be drained of all excess water.

•

This test does not require the visual detection of a bubble. Instead it measures the loss of pressure or vacuum

•

over time via a gauge.

A certain amount of pressure loss will occur in an intact system from diffusion of air through the trapped water

•

in the membrane pores (“baseline decay”). But a higher pressure loss will occur from membrane aws or

broken seals.

To prevent contamination, use a clean air source, preferably ltered through a 0.2 micron lter on the air

•

source.

Equipment (See Figure 7)

Pressurized air source (~20 psig, 3+ scfm capacity) with pressure regulator, a small portable air tank, or a

•

portable compressor.

Pressure gauge (0-20 or 0-30 psig) with accuracy to 0.1 psi.

•

Positive shut off valve (a bubble tight ball valve) to isolate the FreshPoint™ membrane inlet, and one to

•

isolate the air source.

Stopwatch, or watch with a second hand.

•

Integrity Test Procedure

Ensure that the membrane is fully “wet-out” by operating the system at its maximum ow rate for at least 20

1.

minutes by opening the nearest tap downstream.

Isolate the system by closing the inlet valve of the bypass plumbing arrangement.

2.

If the system is installed with the optional ush tank, close the valve to the ush tank.

3.

If installed with a backush kit, disconnect the wiring harness from the inlet solenoid valve.

4.

Depressurize the system by pressing the Extra Cycle button.

5.

Open the nearest downstream faucet to allow air to escape during the test, or crack open the outlet union.

6.

Drain the module by opening the 1/4” ball valve at the bottom of the module and pressing the Extra Cycle

7.

button on the timer to open the drain solenoid valve.

The drain solenoid valve will need to be opened repeatedly using the Extra Cycle button until there is no

8.

further evidence of water draining from the module.

Connect the Technician’s Decay Test Components, Figure 7, with the quick connect tting to the valve at the

9.

bottom of the module (see Figure 8).

Page 19

Page 20

Installation Instructions

Air Compressor

Quick-Disconnect Fitting

0.2 Micron Air Filter

Shut-Off Valve

Tee

Pressure Gage

Air Fill Valve

NOTE: Test the system rst for plumbing leaks by closing the downstream faucet and/or connecting

the outlet union, and performing steps 11 through 13. Pressure decay with outlet plumbing closed

indicates a leak in the plumbing or valves, and the plumbing connections should be tightened or

replaced and the system retested until the plumbing passes. In the event a drain solenoid is leaking,

actuating a ush a few times may cause it to seat. If not, it should be replaced.

Turn on the air compressor.

10.

With the drain solenoid valve closed, carefully pressurize the feed side (the inside of the ber lumens) to 15.1

11.

psig to 15.4 psig by pressing the air compressor hose chuck onto the air supply valve on the Technician’s

Decay Test Components, Figure 7. DO NOT PERMIT THE MODULE TO BE PRESSURIZED TO GREATER

THAN 16 PSIG.

Turn off the air compressor.

12.

Begin timing the pressure decay when the pressure falls to 15.0 psig.

13.

Record the pressures at 30, 60, 90, and 120 seconds.

14.

Once the plumbing has passed the test, test the membrane and membrane seals by opening the nearest

15.

downstream faucet to allow air to escape during the test, or crack open the outlet union.

NOTE: A membrane that is not properly wet-out or has been sitting for some time may cause a false

failure. Ensure that the membrane has been ushed properly before performing the Integrity Test.

Acceptance Criteria: After two minutes, the system should not have decayed from 15.0 psig to less than

14.5 psig.

If the system fails to hold pressure, replace the membranes and/or seals.

16.

When the testing is complete, depressurize the modules by pressing the valve core in the air supply valve on

17.

the Technician’s Decay Test Components, and by pressing the Extra Cycle button.

Close the ¼” valve at the bottom of the module.

18.

Page 20

Figure 7: Technician’s Decay Test Assembly

42613_REVA

Page 21

Installation Instructions

Remove the Technician’s Decay Test Components.

19.

Repressurize the module with water by slowly opening the inlet valve of the bypass plumbing arrangement.

20.

Close the downstream faucet was opened for the test, or reconnect the outlet union, when air is no longer

21.

being expelled.

Press Extra Cycle button to ush trapped air from the feed side of the module.

22.

Open the ush tank valve, if present.

23.

Reconnect the inlet solenoid valve wiring harness, if applicable.

24.

Figure 8: Integrity Test Simplied Diagram

42613_REVA

Page 21

Page 22

Basic Programming Quick Reference Guide

Basic Programming Quick Reference Guide

1. Plug in the system

2. The display will alternate between Time and Flush Volume (Default 100 gallons)

3. Set the time to 12:01 PM by moving the Set Up button and/or the Set Down button

4. Press and hold the Program button to for 5 seconds to enter the programming menu

5. Once in the programming menu, continue to press the Program button to toggle through the various settings listed below

6. Use the Set Up button and/or the Set Down button to adjust the setting as desired

* In typical applications, only the Flush Duration, Flush Volume, and Time of Day would need adjustment

During cold weather, it is recommended that the installer warm the system up to room temperature before operating.

A 9V alkaline battery is recommended to be installed at all times for proper controller operation. The system will indicate when the

battery needs to be replaced by turning on the Low Battery LED.

Page 22

Default Settings

1--- 0.5 Flush Duration- minutes (eg. 30 seconds = 0.5) (default 0.5 minutes)

Fr --- .0 Flow rate

d --- 0 Days since last regeneration

E ---0 Prior volume used

Pd ---0 Previous day usage

y --- OFF Time Aux off

r --- OFF Cancel setting

n --- OFF Chem pump off

A --- 1 Time override - days (default 1 day)

b --- 100 Flush volume - gallons (default 100 gallons)

u --- 1 US gallons

7 --- 2 Meter immediate ush

F --- 6 Allows for pulse setting of ow meter

F - 6 - 80.0 80 pulses per gallon

PL --- OFF Lock OFF

Page 23

Regeneration

Signal

Low Battery

Water Hardness

System Capacity

Regeneration Time

Extra

Totalizer

Flow

Rate

Program

S

E

T

Cycle

Program Display Indicator

Extra Cycle Button

Program Button

Set Up Button

Set Down

Button

Regen

Service Time Reserve Totalizer Meter

Lockout Volume

Remaining

Program Flow

Rate

Sensor

Timer Display

Programming

Page 23

Page 24

Programming

Controller Operation During Service

1. In normal operation the Time of Day and Volume Remaining displays will alternate. Set the

Time of Day display by pressing the Set Up or Set Down buttons to the correct time.

Example:

12:59 A.M.

(System in Service)

2. The Volume Remaining display is the volume of water (in gallons) remaining prior to ushing. Without

any water usage, the Meter Arrow should be either off or on but not changing. Open a tap. The Meter Arrow

should begin ashing at a rate that varies with ow rate. Close the tap after 3-5 gallons of water ow.

Example:

125 Gallons of Water

Remaining

(System in Service)

(No Water Flow)

Example:

0 Gallons of Water

Remaining

(System in Service)

(Water Flowing, Meter

Arrow Flashing)

Timer Operation During a Flush Cycle

1. Manually initiate a ush cycle and allow water to run to the drain. To initiate a ush, press and release the

Extra Cycle button. The system will go into ush mode immediately.

A. During Flushing: The the system will display the time remaining.

Example:

(System is sending

0.5 minute regen signal)

(Regeneration Arrow)

B. Pushing the Set Up or Set Down button during the ush cycle will adjust the time remaining in that cycle.

The programmed ushing time will not be changed.

C. After the ush cycle, the system returns to in service and will resume normal operation.

Regeneration

Signal

Page 24

Page 25

Programming

Control Operation During Programming

The system will only enter the Program Mode when it is in service and operating on line power. While in the

Program Mode the system will continue to operate normally, monitoring water usage and keeping all displays up

to date. System programming is stored in memory permanently with or without line or battery backup power.

Keypad Operation

Extra Cycle Button

Pushing this button will initiate a ush immediately, independent of the actual system conditions.

Totalizer/Flow Rate Button

This button is used to view the Totalizer and Flow Rate displays. Pressing the button once will display ow rate.

Pressing the button again will display the total accumulation of water ow through the system since it was last

reset. Pressing the button once more will return the display to the Time of Day or Volume Remaining screen. The

Totalizer display is reset by pressing and holding the Totalizer button for 25 seconds. During the 25 seconds, the

Totalizer Arrow will ash, indicating the display is being reset properly.

Program Button

This button is used by the installer to program those settings indicated on the front panel by red LEDs.

Set Up Button

This button is used to set the current time of day, adjust time remaining in a ush cycle step, and in system

programming. The Set Up button will increment a display setting.

Set Down Button

This button is used to set the current time of day, adjust time remaining in a ush cycle step, and in system

programming. The Set Down button will decrement a display setting.

Low Battery Indicator

When the system is operating on line power, the red LED will turn on whenever the 9V alkaline battery (not

included) used for memory backup needs to be replaced. The battery is stored against the valve backplate. In

the event of a power outage, the battery will maintain current operating displays for approximately 24 hours at

maximum battery capacity.

Page 25

Page 26

Programming

Changing Flushing Duration

While the system is in service, press and hold the Program button for 5 seconds.

1.

The Flush Duration Time will be displayed. Use the Set Up and Set Down Set Buttons to adjust the time.

2.

Note: The time can be set in 0.1 minute increments.

Example:

(Timer is sending 0.5

minute regen signal)

(Regeneration arrow on)

Changing Flushing Frequency

Press the Program button. The next display is used to set the maximum amount of water that can be used before

a ushing cycle is called for.

Examples: Flush every 100 Gallons [ b - - - 100]

Override cancelled [ b - - - OFF]

— Use the Set Up and Set Down buttons to adjust these settings.

Flushing Day Override

Press the Program button. The next display is used to set the ushing day override option setting. This setting

sets the maximum number of days the lter can be in service without a ush, regardless of water usage.

Examples: Override every 1 day [ A - - - - -1]

Cancel setting [ A - - - OFF]

— Use the Set Up and Set Down buttons to adjust these settings.

General Timer Programming

Using the Set Up and Set Down buttons, adjust the time on the controller to 12:01 P.M.

1.

Press and hold the Program button for 5 seconds.

2.

The rst display is the Flush Duration Time. This can also be adjusted on this display using the Set Up and

3.

Set Down buttons. To skip this display, press the Program button.

Example: 0.5 minutes [1----0.5]

Flow Rate Display (Fr)

4.

The rst display is the current ow rate of treated water through the system. The unit of measurement is

gallons/liters per minute.

Example: 8.5 Gallons Per Minute [Fr - - - 8.5]

Days Since Last Regeneration Display (d)

5.

Press the Program button. The number of days since the last regeneration is recorded in this display by the

control.

Example: 4 days [d - - - - - 4]

Page 26

Page 27

Programming

Prior Service Volume Used Display (E)

6.

Press the Program button. This displays the amount of water treated since the last system ush recorded.

The unit of measurement used is gallons/liters/cubic meters.

Example: 850 Gallons - [ E - - - 850]

Previous Days Water Usage Display (Pd)

7.

Press the Program button. This displays the previous days water usage in gallons/liters/cubic meters.

Example: 200 gallons - [ P d - - 200 ]

Timed Auxiliary Output Window #1 Setting (y)

8.

This setting should be set to OFF.

Cancel setting [ y - - - OFF]

Timed Auxiliary Output Window #2 Setting (r)

9.

This setting should be set to OFF.

Cancel setting [ r - - - OFF]

Chemical Pump Output (n)

10.

This setting should be set to OFF.

Cancel setting [ n - - - OFF]

US/Metric Display Format (U)

11.

Press the Program button. This display is used to set the US or Metric format.

There are ve possible settings:

1. The U.S. Format uses gallons for volume and gallons per minute for ow rate related data/displays with a

12-hour timekeeping format.

Example: [U - - - - - 1 ]

2. The European Metric Format uses liters for volume and liters per minute for ow rate related data/displays

with a 24 hour timekeeping format.

Example: [U - - - - - 2 ]

3. The Standard Metric Format uses liters for volume and liters per minute for ow rate related data/displays

with a 24 hour timekeeping format.

Example: [U - - - - - 3 ]

4. The Cubic Meter Metric Format uses m3 for volume and liters per minute for ow rate related data/

displays with a 24 hour timekeeping format.

Example: [U - - - - - 4 ]

5. The Japanese Metric Format uses liters for volume and liters per minute for ow rate related data/displays

with a 24 hour timekeeping format.

Example: [U - - - - - 5 ]

— Use the Set Up and Set Down buttons to adjust these settings.

Regeneration Type (7)

12.

Press the Program button. This display is used to set the type of ushing initiation. The default setting of

meter immediate is highly recommended for proper ushing and operation of the FreshPoint™ system.

Page 27

Page 28

Programming

There are three possible settings:

1. Timeclock Delayed

The timer will determine when ushing is required based on the set ushing time and day override settings.

Example: [7 - - - - - 1 ]

2. Meter Immediate (Recommended)

The timer will determine when ushing is required based on when the volume of treated water exceeds the

ush frequency volume. Flushing begins immediately.

Example: [7 - - - - - 2 ]

3. Meter Delayed

The control will determine when ushing is required based on when the volume of treated water exceeds the

ush frequency volume. Flushing begins immediately at the set ush time only when service ow has not

been detected. Flushing is delayed in two, 10-minute sections, for up to an additional 20 minutes with

service ow.

Example: [7 - - - - - 3 ]

Flow Meter Size (F)

13.

Press the Program button. This display is used to set the size of the system ow meter. This setting will not be

displayed on non-metered systems.

Examples: [ F - - - - - 0 ] Option Not Typically Used

[ F - - - - - 1 ] Standard 3/4” Flow Meter

[ F - - - - - 2 ] Standard 1.0” Flow Meter

[ F - - - - - 3 ] Standard 1.5” Flow Meter

[ F - - - - - 4 ] Standard 2.0” Flow Meter

[ F - - - - - 5 ] Standard 3.0” Flow Meter

[ F - - - - - 6 ] Non-Standard Flow Meter, Enter Pulses Per Gallon/Liter

(used for FreshPoint™)

— Use the Set Up and Set Down buttons to adjust these settings.

NOTE: The standard meter on the FreshPoint™ has a pulse count of 80.0.

Program Lock (PL)

14.

Press the Program button. This option prevents certain displays from being viewed or set.

There are two possible settings:

Examples: [ PL - - OFF ] Lock Cancelled (Recommended)

[ PL - - - ON ] Lock Active

NOTE: It is strongly recommended that the program lock remain set to OFF.

Exiting the Option Setting Level

Press the Program button once per display until all have been viewed.

Resetting the Permanent Programming Memory

Press and hold the Program button for 50 seconds. This erases all previous display settings, and resets them

to default values. Reset the timer programming if necessary.

Page 28

Page 29

Service & Maintenance

When to call the Dealer

If problems are experienced with the installation or operation of the FreshPoint™, refer to the troubleshooting

guide in this service manual, or contact your FreshPoint™ Distributor for assistance.

Monitoring

If changes to the ow rate or pressure are noticed, contact the installer to get recommendations on changing

ushing settings, and/or have the system evaluated by the installer. Many factors can cause a change in pressure.

As water temperature decreases, the ow available from the FreshPoint™ system will also decrease for the

same inlet pressure. The ow rate will drop or rise approximately 3% for a corresponding 1° (1.8°F) drop or rise

in water temperature. Prelter plugging will cause a decrease in available pressure. Additionally, if a noticeable

loss of pressure is detected over time, the current ushing schedule may not be sufcient to prevent fouling, and

additional ushing will be required. Refer to the Troubleshooting section in this service manual to address this and

other issues.

Prelter Changes

The prelter should be changed as recommended by the manufacturer. Generally, change the cartridge when a

decrease in pressure is noted, or after 6 months installed.

Membrane Maintenance

The FreshPoint™ membrane must be kept in a wetted condition. Once installed or during service and

maintenance activities, do not allow the FreshPoint™ membrane to sit completely drained for extended periods

(greater than 12 hours). Failure to do so may damage the system. If the FreshPoint™ is drained or out of

service for an extended period of time, the installer/dealer should put a preservative into the system to keep

the membrane wetted and prevent microbial growth. A 0.1% sodium bisulte solution is recommended. A 0.1%

sodium bisulte solution would be 1 gram of sodium bisulte added to one liter of water (approximately ten liters

are required).

Prior to putting the FreshPoint™ back into service, the system should be ushed and sanitized per the

instructions in the Installation section of this service manual.

Membrane Cleaning

Membrane cleaning is required when the surface of the membrane and membrane pores become fouled. This

is most often detected by a loss of ow rate. The FreshPoint™ membranes should be maintained in a clean

condition, unfouled by particulate matter, precipitates or biological growth. Contact your FreshPoint™ Distributor

for cleaning.

Page 29

Page 30

Service & Maintenance

Membrane Storage After Use

After initial use the membranes need to be kept wet at all times. To avoid biological growth during shutdowns or

storage, wet membranes should be treated with a compatible biocide.

Downtime up to 24 hours - no measures required.

Downtime 1 to 15 days – Automatic ushing

Systems that are equipped with automatic time based ush systems (and feed water is available) can

continue to ush automatically provided the ush cycle occurs at least every 24 hours for a minimum of 30

seconds.

Downtime Over 15 days – Automatic ushing

Systems that are equipped with automatic time based ush systems (and feed water is available) can

continue to ush automatically provided the ush cycle occurs at least every 24 hours for a minimum of 60

seconds.

Downtime > 7 days – No Automatic ushing / Membranes stored in place

Membranes should be cleaned and disinfected. The system should be put in bypass. Then ll with a 0.1%

sodium bisulphite solution. Leave membranes installed in the system.

NOTE: DO NOT FREEZE! Take precautions to ensure the FreshPoint™ system is not exposed to

freezing temperatures.

In all cases the membranes must be stored hydraulically lled.

CAUTION: Any time a storage solution is used the membranes must be ushed and sanitized prior to use.

See Membrane Flushing & Disinfection guidelines. An integrity test is recommended.

To replace the membrane element:

Use the bypass valve to bypass the system. Isolate the backush tank, if applicable.

1.

Run a manual ush by pressing the Extra Cycle button until water no longer comes out of the drain port.

2.

If installed, use the integrity test port to drain the system. It may be useful to open the drain by pressing the

3.

Extra Cycle button to help draining.

Unplug the power cord leading to the system and gently disconnect the cord leading to the ow meter and the

4.

wire harness(es) leading to the solenoid valve(s).

Slowly disconnect the three unions starting with the union located closest to the oor (this will allow any

5.

remaining water to drain from the system).

Loosen the four mounting bolts which fasten the FreshPoint™ to the wall. Lift the system up slightly and pull

6.

away from the wall.

Open the end caps (see page 10 for instructions on installing the vessel head), and slide the membrane

7.

element out of the membrane housing (both end caps may need to be removed so the element can be

pushed out of the housing).

Lubricate the O-rings sparingly with silicone. Replace the end cap on the bottom port.

8.

Install the spacer spring.

9.

Gently slide the new membrane element into the housing.

10.

NOTE: The open distributor tube of the membrane should be oriented up.

NOTE: DO NOT DROP THE MEMBRANE ELEMENT INTO HOUSING-THIS COULD DAMAGE THE

MEMBRANE ELEMENT.

Gently and rmly slide the top adaptor with O-rings into the membrane elements center tube, and fasten the

11.

end cap (See page 13 for instructions on installing the vessel head).

Remount the FreshPoint™ and reattach plumbing. Reconnect the meter cable and wire harness(es).

12.

Put the unit back into service with the bypass valve. Before using system, perform ushing and sanitizing

13.

procedures as listed in the Installation section of this service manual.

Page 30

Page 31

Problem Possible Cause Correction

1.System controller does not have

power.

2. There is no product water ow to

the house.

3. There is low ow or pressure

available.

4. System is ushing continuously. A. Drain solenoid valve is stuck

5. System is not ushing. A. The system is not plugged

6. Meter is not reading ow. A. Meter cable is not secured

A. The system is not plugged

in.

A. Bypass valves are not in the

correct positions to allow water

ow to the house, or supply

water is unavailable.

B. Cartridge in prelter is

plugged.

C. FreshPoint™ membrane is

fouled.

A. FreshPoint™ is ushing. A. Wait for ush to end. If desired, have

B. Unit is not ushing

frequently enough.

C. Inlet water pressure is too

low.

D. Cartridge in prelter is

plugged.

E. FreshPoint™ membrane is

fouled.

F. Incoming water temperature

is too low.

open.

B. System controller circuit

board is sending ush signal

continuously.

in.

B. Drain solenoid valve is stuck

closed.

C. Meter is not reading ow. C. Check the connection of meter cable

D. System controller circuit

board is not sending ush

signal.

to meter body.

B. Meter or controller are

malfunctioning.

A. Plug the system controller in.

A. Restore supply ow to the system.

B. Replace or clean the lter cartridge.

C. Contact your FreshPoint™ dealer for

service.

a pressure tank installed after system

to maintain pressure during ush. If

ushing continuously, see #4 below.

B. Decrease the volume between

ushes, and/or increase the ush time.

C. Boost the inlet water pressure.

D. Replace or clean the lter cartridge.

E. Contract your FreshPoint™ dealer for

service.

F. Contact your FreshPoint™ dealer for

options to compensate for low water

temperature.

A. Replace the drain solenoid valve.

B. Contact your FreshPoint™ dealer for

service.

A. Plug the system controller in.

B. Replace the solenoid valve.

to meter, secure if necessary.

D. Contact your FreshPoint™ dealer for

service.

A. Check the connection of meter cable

to meter, and secure if necessary.

B. Contract your FreshPoint™ dealer for

service.

Troubleshooting

Page 31

Page 32

Troubleshooting

Problem Possible Cause Correction

7. Water leaks at the end of the

lter cartridge after changing

cartridge.

8. System controller display is

blank.

9. Water has an unpleasant taste

and/or suds when being drawn.

10. Water splashes at drain during

ush.

11. Backush ow stops before end

of ush cycle.

12. Water leaks at the end of the

membrane housing.

A. Cartridge end connections

are not tight enough.

B. O-rings are not properly

lubricated.

C. O-rings are cut, or

deformed.

A. The system controller is not

plugged in.

B. System controller circuit

board is malfunctioning.

A. Unit has not been ushed

sufciently at startup.

A. Drain line not positioned

properly.

A. High ush tank precharge

pressure.

B. Backush tank is too small

for ush and service usage.

A. Seal missing or damaged. A. Replace seal.

B. Sealing surface is rough,

has burrs or dings.

A. Tighten with wrench if necessary.

B. Lubricate O-rings.

C. Replace O-rings.

A. Plug the system controller in.

B. Contract your FreshPoint™ dealer for

service.

A. Open all faucets in the house, and let

water ow for 20 minutes, starting at the

faucet closest to the system.

A. Reposition the end of the drain line.

Adjust ush tank precharge pressure to

20 psig.

B. Install a larger backush tank.

B. Use Scotch-Brite® or 600 grit sand

paper to smooth area.

Page 32

Page 33

Flow Rate vs. Driving Pressure

40 F 60 F 80 F 100 F

FreshPoint Flow vs. Pressure curves

0

5

10

15

20

25

30

0 5 10 15 20 25

psid

gpm

Figure 9: FreshPoint™ Flow Vs. Pressure Drop

NOTE: Curves are shown for a clean membrane at various water temperatures.

NOTE: Flow decreases 3% for each 1.8°F (1°C) decrease in feed water temperature.

Page 33

Page 34

Notes

Page 34

Page 35

Notes

Page 35

Page 36

P/N 42264 Rev. B

Loading...

Loading...