Page 1

INSTALLATION

OPERATION &

MAINTENANCE

MANUAL

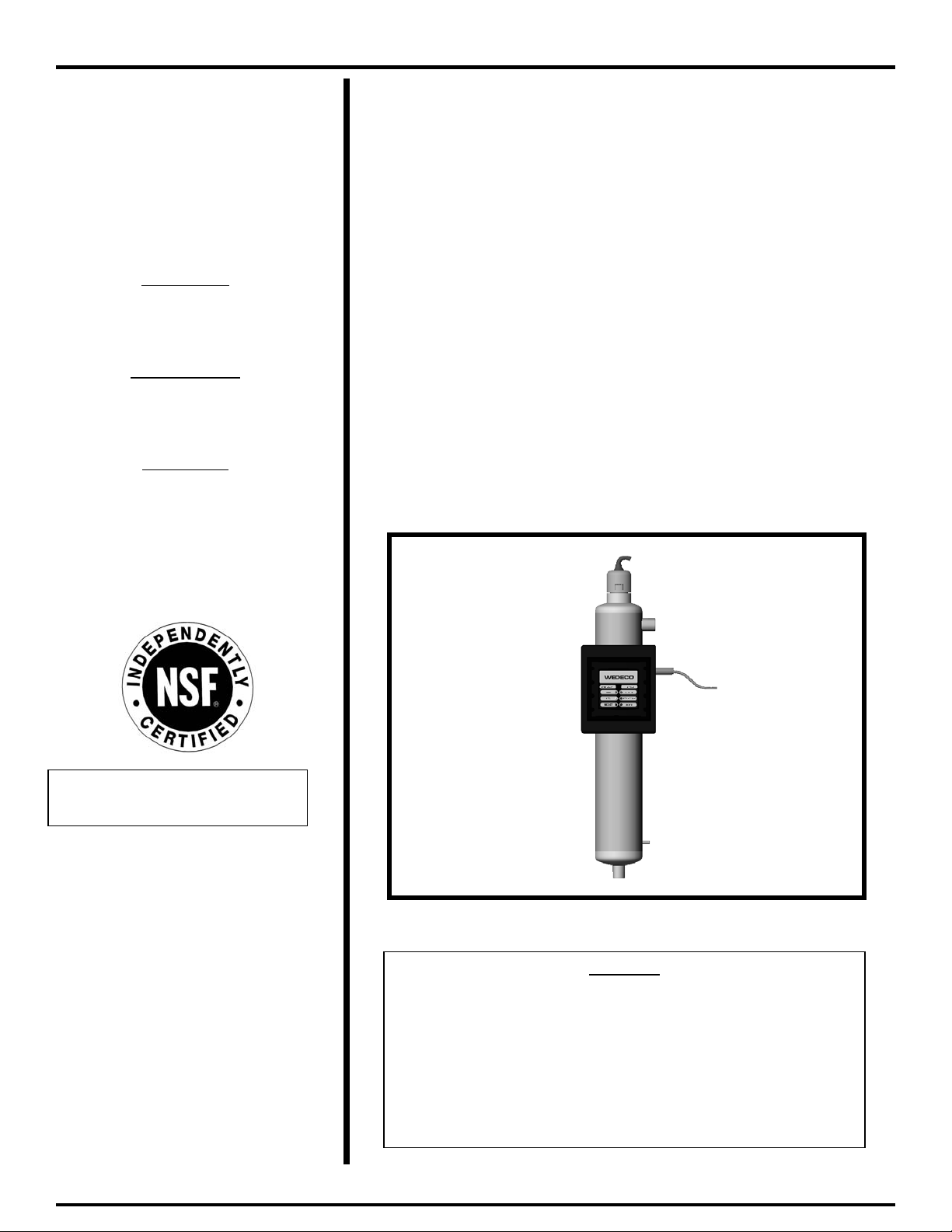

WEDECO

SERIES

DLR

VERSION

M

MODEL

4-M

7-M

ULTRAVIOLET

WATER

DISINFECTION UNIT

DLR SERIES

System Tested and Certified by NSF

International against NSF/ANSI Standard

55 for Disinfection Performance, Class A.

Manufactured by:

WEDECO UV Technologies, Inc.

14125 South Bridge Circle

South Point Business Park

Charlotte, NC 28273

Main:704-716-7600

Fax: 704-409-9838

www.wedeco.us

CAUTION

IT IS VERY IMPORTANT THAT THOSE RESPONSIBLE FOR

THE INSTALLATION OF THIS EQUIPMENT, AS WELL AS THE

OWNER/OPERATOR, READ THIS MANUAL AND CAREFULLY

FOLLOW THE INSTRUCTIONS AND GUIDELINES.

INSTALLATION OF THIS SYSTEM MUST COMPLY WITH ALL

APPLICABLE STATE AND LOCAL REGULATIONS.

Page 2

Table of Contents

Important Safety Instructions...................................................................................................................... 3

Pre-Installation Instructions ..................................................................................................................... 4-6

Installing the Disinfection Unit................................................................................................................... 7

Mounting Electrical Control Box................................................................................................................ 8

Installing the UV Lamp .........................................................................................................................9-10

Pre-Start Up Sequence .............................................................................................................................. 11

Start-Up Sequence .................................................................................................................................... 12

Maintenance.........................................................................................................................................13-16

Maintenance Log ...................................................................................................................................... 17

Parts List ................................................................................................................................................... 18

Alarms.................................................................................................................................................. 19-20

Troubleshooting ........................................................................................................................................ 21

Technical Specifications: DLR Series ................................................................................................. 22-23

Warranty ................................................................................................................................................... 24

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

2

Page 3

Important Safety Instructions

WARNING!

CAUTION! Use disinfection unit only for its intended purpose as described in the Owner’s Manual. The use

ELECTRIC SHOCK! To avoid possible electrical shock, take special care when using water with this

ELECTRIC SHOCK! Do not operate any disinfection unit if it has a damaged cord or plug, if it is

ELECTRIC SHOCK! Always unplug disinfection unit from outlet when not in use, before putting on or

CAUTION! Shut down system before servicing:

EYE PROTECTION MUST BE WORN! Never look at an operating UV light with the naked eye. The light

To guard against injury, basic safety precautions must be observed.

READ AND FOLLOW ALL SAFETY INSTRUCTIONS AND SAFE THESE

INSTRUCTIONS

CAUTION! Denotes a potentially dangerous situation. Failure to observe this

warning may lead to minor or serious personal injury and material damage.

CAUTION! Ultraviolet light (UV-C) is harmful to eyes and skin. Use UV lamps only inside the disinfection

chamber with the appropriate protective covering. Avoid exposure to UV-C radiation.

of attachments not recommended or sold by WEDECO may cause an unsafe condition.

CAUTION! Disinfection unit must be properly installed in accordance with the Owner’s Manual and in

compliance with all applicable local and state regulations before use. Read and observe all important notices

on the disinfection unit.

CAUTION! The UV disinfection unit is intended for indoor use only.

equipment. Always shut off and disconnect power to the unit before:

• Making repairs (We strongly recommend that a qualified individual who fully understands the Owner’s

Manual perform service and/or repairs.)

• Cleaning

• Replacing a UV lamp

malfunctioning, or if it is dropped or damaged in any way.

ELECTRIC SHOCK! The power cord of disinfection unit is equipped with a 3-prong grounding plug that

mates with a standard 3-prong grounded wall outlet to minimize the possibility of electric shock. Be sure the

outlet for the disinfection unit is wired and grounded properly.

remove the third prong from the power cord.

taking off parts, and before cleaning. Never unplug by pulling on the power cord. Always grip plug firmly

and pull straight out of the outlet.

• Turn off water supply to the UV disinfection unit.

• Disconnect all power to the UV disinfection unit.

• Drain water from the system.

will burn and irritate unprotected eyes and skin.

EYE PROTECTION MUST BE WORN! Never operate the UV lamp outside of the UV disinfection unit.

ELECTRIC SHOCK! Warning — Dangerous electric voltage. Failure to

observe this warning may lead to serious injury or death.

EYE PROTECTION MUST BE WORN!

IMPORTANT! Denotes a useful tip and other information.

Do Not under any circumstances, cut or

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

3

Page 4

Pre-Installation Instructions

Before you

begin

Perform the following pre-installation steps:

Step Action

1 Ensure that your DLR-M system is correct for your flow capacity (see Flow Rate

Tables in Technical Specifications.)

2 Ensure that your water supply meets water quality standards as shown in the table

below. If any of the elements exceed the recommended maximum, we strongly

suggest, at a minimum, that you install a 5-micron sediment filter as particles in the

water can reduce UV light intensity and affect performance. Contact the distributor for

additional information about testing and pretreatment equipment.

Suspended solids <5 mg/l

Color None

Iron 0.3 mg/l

Manganese 0.05 mg/l

pH 6.5 to 9.5

Hardness <120 ppm

3 Check the pressure of the water supply. The WEDECO UV system is designed to

Less than 148 psi Proceed to step 4

Greater than 148 psi Install a suitable pressure-reducing valve in

Element Recommended

Note: All models are rated for a minimum UV transmittance of 70%. If your

transmittance is lower, consult the distributor.

operate at pressures up to 148 psi.

If the pressure is… Then…

4

5 Select a location that meets the following guidelines.

Fill in the following information and retain for future reference.

Series________________ Model_____________________

Date Purchased:_______________ Date Installed:_________________

Water pressure (psi):___________ Water flow rate (gpm):__________

• The unit must be installed between the cold water source and the water heater as

inlet temperature must not exceed 100

sequence.)

• The disinfection unit can be installed either horizontally or vertically. (See Figure

3 for water flow direction.)

• There must be enough clearance to remove the UV lamp and the quartz sleeve for

replacement and regular maintenance. Recommended clearance is length of unit

plus four inches. (See Figure 4 for additional clearance requirements.)

• The unit must be within 7 feet of a properly grounded, dedicated 110V electrical

outlet. A 7'5" cord is included with the unit.

• The unit must be protected from freezing. Freezing damage will void the warranty.

• The unit should be placed where a potential leak will not cause water damage.

WEDECO is not responsible for water damage.

Actual

maximum levels

(1mg/l = 1ppm)

the water inlet pipe to the disinfection unit.

o

F. (See Figure 1 for proper installation

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

4

Page 5

Pre-Installation Instructions, Continued

Figure 1:

Installation

Sequence

HOT W ATER

Figure 2:

Installation

Planning

HEATER

Figure 1 shows a typical installation sequence. Note that all items may not be

necessary for water treatment.

OPTION AL EQUIPM ENT

UV DISINFECTION

UNIT

OPTIONAL EQUIPMENT

SUCH AS SOFTENER,

SUCH AS SOFTENER, OR

OR ODOR FILTER

OTHER FILTER

You must determine how to run pipes in and out of your disinfection unit.

Figure 2 shows one method of installation (with chamber mounted control

box). Use this diagram to determine the materials needed for your installation.

WATER

SEDIM ENT

FILTER

NOTE: PRETREATMENT EQUIPM ENT

MUST BE INSTALLED PRIOR TO

UV DISINFECTION UNIT

SOURCE

! IMPORTANT!

Check local plumbing codes

for sizes and types of pipes

to be used.

ELECTRIC SHOCK!

Check for hidden electrical

wiring before drilling holes.

The disinfection chamber must

be properly grounded prior to

powering up the system. Refer

to the section “Installing the

Disinfection Unit” on page 7 of

this manual for details.

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

Installation of this system must comply

with all applicable state and local

regulations.

5

Page 6

Pre-Installation Instructions, Continued

Figure 3: Unit

Positioning

Figure 3 shows proper water flow for horizontal or vertical installation. Make

certain that your unit and the inlet and outlet pipes are in the right position for

either horizontal or vertical installation.

Correct Installation

IMPORTANT!

For vertical

installation, the

inlet is at the

bottom and the

outlet is near the

top of the

disinfection

chamber. For

horizontal

installation pay

careful attention to

the diagram for

flow direction.

Figure 4:

Clearance

Requirements

OUTLET

FLOW

DIRECTION

INLET

INLET INLET

DIRECTION

FLOW

OUTLET OUTLET

DIRECTION

DIRECTION

OUTLET

FLOW

INLET

FLOW

OUTLET

FLOW

DIRECTION DIRECTION

DIRECTION

FLOW

OUTLET

INLET

INLET

INLET

INLET

OUTLET

FLOW

DIRECTION

FLOW

OUTLET

Incorrect Installation

Figure 4 provides the clearance requirements needed for proper installation of

the disinfection chamber.

Model Min. Clearance

M-1 22.5

M-2 30.4

M-4 30.4

M-7 44.5

The disinfection chamber must

be properly grounded prior to

powering up the system. Refer

to the section “Installing the

Disinfection Unit” on page 7 of

this manual for details.

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

6

Page 7

Installing the Disinfection Unit

Attaching unit

to wall

Follow these steps to attach WEDECO UV disinfection chamber to the wall.

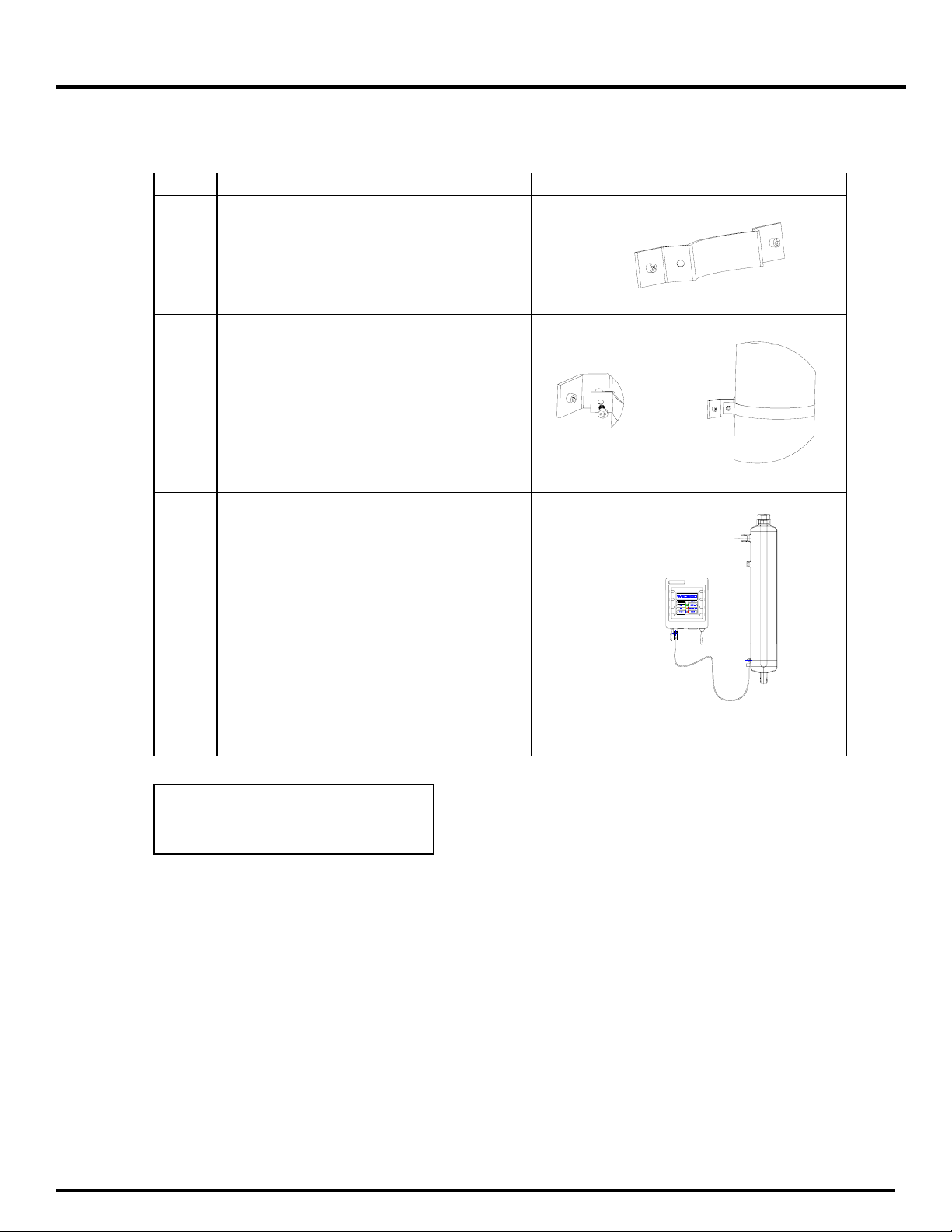

Step Action Diagram

1 Install the two wall mount brackets on the

wall using the proper screws for your wall

type (screws not included).

2 Place disinfection chamber in the brackets

and secure with the wall mount bracket

straps. Use the wall mount bracket strap

screws provided to tighten the wall mount

bracket straps to the wall mount brackets.

3 The disinfection chamber must be properly

grounded prior to powering up the system.

Attach the ground wire to the stud and nut

located on the lower area of the

disinfection chamber and connect it to the

earth strap that is located at the bottom left

of the electrical box. (Grounding wire

included.)

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

Installation of this system must comply

with all applicable state and local

regulations.

7

Page 8

Mounting Electrical Control Box

Option A: Wall

mount

Option B:

Chamber

mount

IMPORTANT!

The electrical control box can be mounted on the wall (Option A) or on the

disinfection chamber (Option B), according to the following instructions.

Follow these steps to mount the electrical control box on the wall.

Step Action

1 Attach the optional wall mount bracket to the wall using suitable hardware for your wall

surface.

2 Position the keyhole slots on the back of the electrical control box over the tabs on the

wall mount bracket and slide into place.

Keyhole Slots

Follow these steps to mount the electrical control box on the disinfection chamber.

Step Action Diagram

1

2 Position the electrical control box on the UV

Feed the electrical control box straps through the

upper and lower recessed areas on the back of the

electrical control box.

disinfection chamber: Wrap the electrical box straps

around the chamber, push loose end through high

side of Q-Clip, and pull through to tighten.

If it is necessary to remove the electrical control box strap, lift the pawl to

release the Q-Clip. You may need to use a screwdriver to lift the pawl.

PAWL

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

8

Page 9

Installing the UV Lamp

CAUTION

Hg

Insert lamp in

chamber

UV lamp is very fragile. Do not handle it with bare hands. Use clean cotton

gloves or cloth when handling lamp to keep it free of dust or fingerprints. If

dust or fingerprints get on the lamp, wipe it with a clean cloth and alcohol.

UV lamps contain mercury.

DO NOT PUT IN TRASH.

Recycle or dispose as hazardous waste.

www.lamprecycle.org

Follow these steps to install the UV lamp in the disinfection chamber.

Step Action

1

Insert the lamp into the headpiece. Gently pinch the two large tabs on the

transparent lamp clip and push until the tab locks into the groove (see step 2).

2 Make sure that the transparent tab is properly snapped into the headpiece and is

not pushed down too far.

GROOVE

1-866-457-6697

WARNING

This product contains a chemical

known to the State of California to cause

birth defects or other reproductive harm.

TRANSPARENT

LAMP CLIP

HEAD PIECE

DISINFECTION

CHAMBER

HORIZONTAL TAB

TAB PROPERLY

LOCATED IN GROOVE

TAB NOT PROPERLY

LOCATED IN GROOVE

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

9

Page 10

Installing the UV Lamp, Continued

Position GloCap

Attach sensor

The Glo-Cap must be properly placed on the headpiece for the UV

disinfection unit to work. Follow the steps below to position the Glo-Cap.

Step Action

1 Align the tab on the Glo-Cap with the middle tab on the transparent clip.

2 Lower the Glo-Cap onto the headpiece until it clicks into place. If it does not

click into place, make sure that the tabs on the Glo-Cap are not over the raised

tabs on the headpiece. If they are, turn the Glo-Cap. When properly installed, the

Glo-Cap will not separate from the headpiece.

GLO-CAP

ALIGNMENT TAB

MIDDLE

TAB

The UV system includes a sensor port and sensor assembly. Attach the

sensor assembly to the sensor port on the disinfection chamber, as shown

below. Hand-tighten the sensor assembly onto the threaded nipple by

rotating clockwise until you have a proper seal. Do not use tools on the sensor

assembly. (Note: Ensure O-ring is seated properly against lens before

installing sensor assembly to sensor port.

TAB

HEADPIECE TAB

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

SENSOR

ASSEMBLY

SENSOR

PORT

O-RING

10

Page 11

Pre-Start Up Sequence

Before using

the unit…

Follow these steps before operating your WEDECO disinfection unit.

Step Action

1 Check your plumbing:

• Make sure that new plumbing has no leaks.

• Flush pipes to purge soldering residue or other debris from the system.

• Expel air from the system to avoid pressure damage to the unit.

Before initial use of your UV system and after routine maintenance procedures, you should

2

sanitize your water system to ensure that no organisms are present. (See Maintenance section for

instructions)

Flush the UV system for 5 minutes prior to start-up.

3 Insert the solenoid valve plug into the solenoid valve receptacle located on the bottom of the

electrical box.

Note: Solenoid is optional. WEDECO recommends installing the solenoid valve, which will shut

off water supply in the event that certain alarms are triggered (see Alarms & Troubleshooting

sections).

4 Check that the grounding is properly installed before powering up the system.

Plug one end of power cord into receptacle on the bottom of electrical control box, making sure

plug is pushed in completely.

OPTIONAL

IMPORTANT! Do not plug power

cord into wall outlet until you

begin the start-up sequence.

SOLENOID

RECEPTACLE

SOLENOID

PLUG

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

11

Page 12

Start-Up Sequence

Before using

the unit…

If your unit has… Then…

UV sensor and no

solenoid valve

UV sensor and

solenoid valve

UV Sensor

Calibration and

Sanitization

Follow the start-up procedures below.

The UV sensor is self-calibrating on initial start-up. Proper calibration requires

water flow through the unit.

• Sanitize your system before using your household water (see maintenance

section for instructions.)

• Slowly fill the unit with water.

• Flush the UV system for 5 minutes prior to start-up.

• Plug power cord into wall outlet.

• Within the first 5 seconds of applying power, press and hold the RESET

button for 5 seconds to set internal "Days" counter to 365. The alarm buzzer

will beep three times and all LEDs will blink three times to indicate that the unit

has been reset. Release the reset button.

• Wait 30 seconds. If the lamp is functioning properly, the "Lamp On" LED will

light and the internal "Days" counter will begin counting down from 365.

• Wait at least 30 minutes, then the UV intensity “High” (green) LED will light

up.

The UV sensor is self-calibrating on initial start-up. Proper calibration requires

water flow through the unit.

• Sanitize your water system before using the disinfection unit (see maintenance

section for instructions).

• Slowly fill the unit with water.

• Flush the UV system for 5 minutes prior to start-up.

• Plug power cord into wall outlet.

• Within the first 5 seconds of applying power, press and hold the RESET

button for 5 seconds to set the internal "Days" counter to 365. The alarm buzzer

will beep three times and all LEDs will blink three times to indicate that the unit

has been reset. Release the reset button.

• Wait 30 seconds. If the lamp is working, the "Lamp On" LED will light and the

internal "Days" counter will begin counting down.

• Wait 30 minutes. The sensor will be set to 100% and the UV Intensity "High"

(green) LED will light up.

• Note: The Normally Closed Solenoid Valve is energized when power is

applied to the control box.

***IMPORTANT NOTE***

The 30-minute time period before the High UV intensity LED lights is provided to

inhibit alarms during the sanitization process.

Example: When chlorine is used to sanitize the system, the 30 minute period allows

for initial system sanitization and subsequent flushing of the piping with fresh water

without causing a UV alarm.

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

12

Page 13

Maintenance

Required

maintenance

Hg

Replacing the

lamp

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

Periodically, you will need to perform routine maintenance procedures on

your WEDECO UV disinfection unit. This section provides directions for:

• Replacing the lamp (every 365 days or in the event of a lamp-out alarm).

• Cleaning the quartz sleeve (as needed).

• Replacing the headpiece O-ring (every 365 days or when needed, based

• Cleaning the sensor quartz (every 365 days).

Recycle or dispose as hazardous waste.

www.lamprecycle.org

The UV lamp is rated to provide 365 days of continuous use. After this time,

it must be replaced for the disinfection unit to operate effectively.

Step Action

1 Turn off the water supply to the UV disinfection unit.

2 Disconnect all power to the UV disinfection unit and wait several minutes for the lamp to

3 Drain the system: Have a bucket large enough to hold the water in the chamber, close both

4 Remove the Glo-Cap: Rotate the Glo-Cap so that the tabs line up with the raised tabs on the

5 Remove the lamp: Gently pinch together the two large tabs on the transparent clip and pull

6 Insert the new UV lamp (refer to directions for installing the UV lamp).

7 Restart your disinfection unit according to the start-up sequence for your model specifications.

8 Record the date in the maintenance log.

9 Sanitize your water system (see directions in this section).

on visual inspection).

UV lamps contain mercury.

DO NOT PUT IN TRASH.

1-866-457-6697

cool.

shutoff valves, and open the drain to draw off the water.

headpiece and pull the cap away from the headpiece to remove it.

lamp assembly straight up until it is completely removed.

IMPORTANT! Lamp must be disposed of properly. Check your local regulations for

disposal of hazardous materials.

This product contains a chemical

known to the State of California to cause

birth defects or other reproductive harm.

WARNING

13

Page 14

Maintenance,

Cleaning the

quartz sleeve,

headpiece, ORing, & sensor

quartz

The quartz sleeve must be kept clean to kill bacteria effectively. Your water

quality and mineral content will determine cleaning frequency. Perform a

visual inspection after thirty (30) days of operation. If the sleeve is dirty,

shorten cleaning intervals. If the sleeve is clean, lengthen cleaning intervals.

At this time, clean the headpiece, O-Ring, and sensor quartz assembly also.

Step Action

1 Fill bucket or other receptacle with warm, soapy water.

2 Follow Steps 1 through 5 for replacing the lamp (see previous page).

3 Unscrew the headpiece and carefully remove the quartz sleeve from the disinfection chamber.

3 Take the headpiece and O-ring off the quartz sleeve. Clean the headpiece, O-Ring, and quartz

4 Push the O-Ring a few inches down on the quartz sleeve and lower the sleeve into the

5 Screw the headpiece onto the disinfection chamber to secure the quartz sleeve and O-Ring in

6 Carefully reinstall the UV lamp and the Glo-Cap (see directions for installing the UV lamp).

7 Clean the sensor quartz (see directions in this section).

8 Restart your disinfection unit according to the start-up sequence for your model specifications.

9 Record the date in the maintenance log.

10 Sanitize your water system (see directions in this section).

Continued

IMPORTANT! The quartz sleeve may stick to the headpiece. Be sure to hold both pieces

carefully so they don’t separate during removal.

sleeve with a mild soap and hot water solution. If the sleeve is still not clean, use a mild acid

(citric acid or Lime-Away), then rinse with hot water.

chamber.

place.

HEADPIECE

HEADPIECE

O-RING

QUARTZ

SLEEVE

O-RING SEAT

QUARTZ

SEAT

HEADPIECE

O-RING

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

14

Page 15

Maintenance, Continued

Replacing the

O-Ring

Cleaning the

sensor quartz

Sanitizing the

system

General maintenance for the O-Ring requires that you replace it every 365 days. If,

however, during routine cleaning of the quartz sleeve, you find the O-Ring cut,

damaged, or extremely dirty, then it should be replaced at this time. To replace the

O-Ring, follow the directions for cleaning.

Clean the sensor quartz during routine cleaning of quartz sleeve and at least every

365 days.

Step Action

1 Fill a bucket or other receptacle with warm, soapy water.

2 Turn off the water supply to the disinfection unit.

3 Disconnect all power to the disinfection unit.

4 Drain the system: Have a bucket large enough to hold the water in the chamber,

close both shutoff valves, and open the drain to draw off the water.

5 By hand, carefully turn the sensor assembly counter-clockwise to remove it from

the sensor port on the disinfection chamber. Do not disassemble the sensor unit.

6 Clean the sensor quartz (quartz window) and O-Ring with warm soapy water.

Mild acid (such as citric acid or Lime-Away) may be used on the sensor quartz, if

needed. Rinse well.

7 Make sure that all surfaces of the sensor quartz are clean to ensure a good seal and

replace the sensor assembly on the sensor port, turning clockwise on the threaded

nipple. Hand-tighten only.

8 Restart your disinfection unit according to the start-up sequence for your model

specifications.

9 Record the date in the maintenance log.

10 Sanitize your water system (see directions in this section).

Before initial use of your UV unit and after routine maintenance procedures, you

should sanitize your water system to ensure that no organisms are present.

Step Action

1 Pour household bleach into your water system. If you have a filter container, fill it

with bleach. If you have no filter then introduce chlorine directly into your well.

The amount of chlorine depends upon the diameter and depth of your well.

(Generally, use ½ gallon to treat an 8” diameter/80’ deep well and one gallon for

anything larger.) You may contact your State Extension Service or a water

treatment specialist for additional information.

2 Open hot and cold water taps throughout the house and let the water run until you

detect a chlorine odor. To ensure that the hot water heater is also purged, allow

the hot water to run until the water becomes cold.

IMPORTANT! You may get a low UV alarm buzzer after introducing chlorine into

your water system. Press the RESET button until the buzzer stops. This will

disable the buzzer for 5 days. The UV system will reset automatically once all

chlorine has been flushed through the UV vessel with fresh water.

3 Turn off the taps and allow the water to stay in the pipeline for about six hours or

overnight but not more than 36 hours to avoid corrosion.

4 Open hot and cold water taps throughout the house and let the water run until the

chlorine odor disappears.

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

15

Page 16

5 Flush the UV system for 5 minutes prior to start-up.

Maintenance Log

Note

Replace lamp

(every 365 days)

You must perform routine maintenance in order to achieve optimum performance

levels from your WEDECO UV disinfection unit. As you perform routine

maintenance or necessary service on your unit, record the dates in the maintenance

log. The maintenance section of the Owner’s Manual provides instructions for

servicing and maintenance procedures.

Replace O-Ring

(every 365 days)

Clean quartz

sleeve (as needed)

Clean sensor

quartz (as

Reset lamp counter

(with lamp change)

needed)

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

16

Page 17

Parts List

KEY # PART # QTY. DESCRIPTION

1 * 1 Electrical Control Box

8

7

6

5

4

3

2 * 1 Disinfection Chamber

3 * 1 Quartz Sleeve

4 *** 1 Ult raviol et Lamp

5 AQ35492 1 Head Piece O-Ring

6 AQ36538 1 Head Piece

7 AQ36617 1 Glo-Cap O-Ring

8 AQ36799 1 Glo-Cap

9 AQ37250 1 Sensor Assembly

10 AQ36942 2 Electrical Control Box Strap

10A AQ36992 2 Electrical Control Box Strap Buckle

11 * 2 Wall Mount Bracket

12 * 2 Wall Mount Bracket Strap

13 * 4 Wall Mount Bracket Strap Screw

14** * 1 Flow Control

15** * 1 Solenoid Val ve (OPT IONAL)

16** AQ36944 1 Power Cord

Contact the distributor for r epl acement parts

* Determined by serial number

11

** Not shown

*** Refer to data plate for part number

13

For replacement parts and service or

12

13

10

9

to find out who your local water

treatment distributor is contact:

WEDECO UV Technologies, Inc.

Aftermarket Services Department

14125 South Bridge Circle

1

South Point Business Park

Charlotte, NC 28273

Main:704-716-7600

11

Fax: 704-295-9080

www.wedeco.us

The warranty requires the use of

WEDECO UV Technologies, Inc.

authorized replacement parts only.

2

13

12

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

17

Page 18

Alarms

Displays

Alarm

activation

What Happens Cause How to Resolve

• The REPLACE

LAMP LED blinks.

• The internal ALARM

beeps once every 5

minutes.

• The LAMP ON LED

is no longer

illuminated.

• The REPLACE

LAMP LED is

illuminated

continuously.

• The ALARM LED

blinks

• The internal ALARM

buzzer beeps

continuously.

The front panel of the electrical control box has the following LED displays:

LED Displays Diagram

LED Displays:

• LAMP ON: green

• REPLACE LAMP: red

• ALARM: red

• UV intensity HIGH: green

• UV intensity LOW: yellow

The WEDECO UV disinfection unit has built in alarms to warn of inefficient

performance or lamp failure.

The internal counter has reached 30

days of lamp life remaining.

IMPORTANT! Water to the

house is being disinfected and

the solenoid valve (optional)

will remain open.

The internal counter has reached 0

(zero) days of lamp life. Or, lamp

has failed due to another problem.

(See Troubleshooting section.)

WARNING! Disinfection may

be insufficient to ensure safe

drinking water. Do not drink

water without boiling or

disinfecting through some

other means.

• Press the RESET button once to

silence the alarm buzzer for 5

days. The alarm buzzer will begin

to beep again 5 days after pressing

the RESET button and continue

until lamp has been replaced and

the unit reset.

• Replace UV lamp within 30 days

to ensure optimum performance

from the unit.

• Press the RESET button once to

silence the alarm buzzer for 5

days. The alarm buzzer will begin

to beep again 5 days after pressing

the RESET button and continue

until lamp has been replaced and

the unit reset.

• Replace lamp immediately. Follow

instructions on lamp replacement

in the manual.

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

18

Page 19

Alarms, Continued

What Happens Cause How to Resolve

• The UV intensity

HIGH LED blinks.

• The internal

ALARM buzzer

beeps once every 3

minutes.

• The UV intensity

HIGH LED is no

longer illuminated.

• The UV intensity

LOW LED blinks.

• The internal

ALARM buzzer

beeps continuously.

• The UV intensity

HIGH LED is no

longer illuminated.

• The UV intensity

LOW LED blinks.

• The REPLACE

LAMP LED is

illuminated

• The ALARM LED

blinks.

• The internal

ALARM buzzer

beeps continuously.

• If the unit has an

optional solenoid

valve, it will shut off

water supply.

The UV intensity has dropped

below 70%. Quartz sleeve or

sensor may be dirty.

IMPORTANT!

house is being disinfected

The UV intensity has dropped

below 50% indicating that there

may be a potential problem within

the UV disinfection unit. Quartz

sleeve or sensor may be dirty.

WARNING! Disinfection

may be insufficient to ensure

safe drinking water. Do not

drink water without boiling or

disinfecting through some

other means

The UV intensity has dropped to

zero.

WARNING! UV system is not

operational. Do not drink

water without boiling or

disinfecting through some

other means.

Water to the

.

.

• Press the RESET button once to

silence the alarm buzzer for 5

days. The alarm buzzer will begin

to beep again 5 days after pressing

the RESET button and continue

until the problem is resolved and

the unit reset.

• Perform routine maintenance as

indicated in the manual.

• Clean quartz sleeve and UV sensor

quartz.

• If the problem persists, have local

water treatment dealer check the

water quality.

• Press the RESET button once to

silence the alarm buzzer for 5

days. The alarm buzzer will begin

to beep again 5 days after pressing

the RESET button and continue

until the problem is resolved and

the unit reset.

• Perform routine maintenance as

indicated in the manual.

• Clean quartz sleeve and UV sensor

quartz.

• If the problem persists, have local

water treatment dealer check the

water quality.

• Press the RESET button once to

silence the alarm buzzer for 5

days. The alarm buzzer will begin

to beep again 5 days after pressing

the RESET button and continue

until the lamp is replaced and the

unit reset.

• Perform routine maintenance as

indicated in the manual.

• Clean quartz sleeve and UV sensor

quartz.

• Replace lamp and quartz sleeve, if

necessary.

• If the problem persists, have local

water treatment dealer check the

water quality.

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

19

Page 20

Troubleshooting

Determining

problem

If… Then…

The unit is leaking water

Glo-Cap is not lit or has

gone out

Poor bacterial

performance

Power Failure

Display screen is blank

Unit gives faulty alarms

You miss the 5 second

window for resetting unit

and/or unit does not beep

or LED’s blink three

times

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

The troubleshooting guide gives you suggestions for resolving problems.

• Ensure that the headpiece is tight.

• Verify that inlet water pressure is not >148 psi.

• Ensure that headpiece O-ring is seated properly.

• Lubricate O-ring (use food-grade silicone).

• Check O-ring for cracks or rips. Replace if necessary.

• Check quartz sleeve for possible cracks. If sleeve is cracked, call distributor for

replacement.

• Verify that all electrical connections are correct.

• Replace lamp. If problem is solved, resume unit operation.

• If lamp still does not light, electrical control box may need to be replaced. Call distributor

for replacement information.

• Replace lamp if it is more than 365 days old or nearing the end of its lamp life.

• Perform routine maintenance.

• Check water quality. If water quality has changed then you may need to install filters or

other disinfection units to ensure that water supply does not exceed recommended

maximum concentration levels (shown in Step 1 of Pre-Installation Instructions).

• Verify flow rate using the flow rate table found in the Technical Specifications at the back

of the manual.

• The unit will restart automatically and the internal Days counter will resume counting

down as before the power failure. The UV intensity will remain the same as before the

power failure, unless actual water conditions change. If the unit has an optional solenoid

valve installed, the valve will immediately open after power is restored to the unit.

• In the event of a system failure you must disinfect the system. Refer to maintenance

instruction on page 16 of this manual. “Sanitizing the system”.

Note: The unit is designed for continuous operation. Never connect the unit to a timer or other

device, which will cause the unit to cycle on and off. Excessive cycling of the power will

reduce lamp life.

• Ensure that the unit is assembled and installed correctly. In the case of improper handling

or assembly during installation and/or servicing, the unit will turn off power to the lamp

and display a blank screen.

• Check for damage to the lamp filament elements, quartz sleeve, or electrode connectors.

Applying power to a unit with such damage will cause a blank display screen. Damage

may be caused from shipping, overheating the lamp by operating the unit with no water in

the chamber, introducing debris into the unit from the water source, or improper handling

or assembly during service or installation.

Note: Units with the optional solenoid valve installed will turn off. In most cases, replacing

the lamp, and/or quartz sleeve will return the unit to proper operation. If the unit fails to

resume operation, notify your distributor.

• The ballast or control circuit may be faulty. Call distributor for replacement information.

• Disconnect the power for 30 seconds, and then reapply power. Within 5 seconds of

reapplying power press and hold the reset button for 5 seconds, As stated in the start-up

sequence on page 12. Do not release the reset button until the LED’s blink 3 times and the

alarm beeps 3 times.

20

Page 21

Technical Specifications: DLR-M

All prices and specifications are subject to change without notice.

Technical Description

Description The UV system is designed with a single low pressure high intensity UV lamp centered

inside a protective quartz sleeve. The disinfection chamber is either 304 or 316L stainless

steel and is electro-polished with male NPT Inlet/Outlet. The UV lamp and quartz jacket

assembly are easily removable from one side of the disinfection chamber.

UV disinfection chamber

UV lamp High output low pressure UV lamp

UV sensor One selective sensor, selectivity > 99% at 254 nm, non-aging

Control Box

Application The UV system is engineered to disinfect clear fresh water to meet drinking water

Operational capacity Clear fresh water up to 13 US GPM (Refer to Flow Rate Table below.)

Options

The DLR-M is available in different sizes based on flow capacity.

Flow Rate Table: Valid for water with minimum UV transmittance > 70% @ 1cm (254nm)

Model 4-M 7-M

• Material: stainless steel electro-polished

• UV sensor

• Mounting: vertical or horizontal

• Inlet/Outlet connections: Male NPT thread

• Mounting brackets included

• Material: ABS, designed for wall or UV chamber mounting

• Electronic power supply (ballast)

• LED readout

• Solenoid valve activator outlet

• Cable length UV chamber/control box: 4.9’

standards.

• Voltages 230 Volt / 50 or 60 Hz (CE conforming)

• Solenoid inlet valve (NPT size corresponding to reactor NPT connection for each unit)

¾”, 1”, and 1 ½” normally closed.

Flow rate (gpm) at UV dose of 40 mJ/cm2 at the end of lamp lifetime*

* 40 mJ/cm

Notes: (1) Flow rates based on flow restrictor installed in line.

2

= 40,000 µWs/cm

2

51 131

UV Reactor, Stainless Steel 304 (1.4301) Electro-polished

Reactor connections, male NPT thread ¾” 1”

Width (inches) 5 5

Height (inches) 26.38 40.55

Diameter (inches) 4.02 4.02

Weight (lb.) approx. 7.06 11.03

Operating pressure (psi) max. 148 148

Operating pressure (psi) min. 0 0

Operating temperature (°F) min. 33 33

Operating temperature (°F) max. 100 100

Water inlet temperature (°F) min. 33 33

Water inlet temperature (°F) max. 100 100

Pressure loss (psi) approx. 2 2

UV Lamp, Low Pressure High Output

Lamp Part Number NLR1845 WS NLR1880 WS

Lamp Power (Watt) 40 80

Quantity 1 1

Lamp lifetime (days) 365 365

1

The certified flow rates listed here apply to units shipped after 11/01/05 (Date Code 300-05).

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

21

Page 22

Technical Specifications: DLR-M, Continued

Control Box

MODEL 4-M 7-M

Width (inches) approx. 6.61 6.61

Height (inches) approx. 7.87 7.87

Depth (inches) approx. 2.6 2.6

Weight (lb) approx. 5.51 5.51

Voltage (V/Hz) 120V/60Hz 120V/60Hz

Cable length chamber/cabinet (ft) 4.9 4.9

Ambient temperature (ºF) 100 100

Power consumption (W) 55 95

The technical features are described below.

Model Characteristics

Features

Effective microbiological protection

Electro-polished stainless steel disinfection chamber

High output low pressure UV lamp

High efficiency electronic ballast power supply

Lamp operation indicator

Safety lamp connector (no lamp removal without lamp shut-off)

Micro-computer control

Audible alarm plus visual alarm display (lamp failure and end of lamp life)

Lamp change reminder with internal counter

Alarm and computer reset button

Selective UV monitoring system

LED UV intensity display: high-low alarm (with separate UV intensity audible alarm)

Power connection for optional automatic solenoid safety shut-off valve

System Tested and Certified

by NSF International against

NSF/ANSI Standard 55 for

Disinfection Performance,

Class A.

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

The DLR-M Ultraviolet Water Disinfection Unit is an NSF Class A Certified System that

conforms to NSF/ANSI 55 for the disinfection of microbiologically contaminated water that

meets all other public health standards. The system is not intended to convert wastewater

or raw sewage to drinking water. The system is intended to be installed on visually clear

water.

NSF/ANSI 55 defines wastewater to include human and/or animal body waste, toilet paper,

and any other material intended to be deposited in a receptacle designed to receive urine

and/or feces (blackwaste); and other waste materials deposited in plumbing fixtures

(greywaste).

Class A system without a general cyst inactivation/reduction device in conformance to the

appropriate NSF/ANSI Standard:

If this system is used for the treatment of untreated surface waters or ground

water under the direct influence of surface water, a device found to be in

conformance for cyst reduction under the appropriate NSF/ANSI Standard shall

be installed upstream of the system

Manufactured by:

WEDECO UV Technologies, Inc.

14125 South Bridge Circle

South Point Business Park

Charlotte, NC 28273

Main: 704-716-7600

Fax: 704-409-9838

www.wedeco.us

.

●

●

●

●

●

●

●

●

●

●

●

●

●

22

Page 23

Warranty

Note

FULL ONE-YEAR WARRANTY ON UV DISINFECTION UNIT: For one (1) year from date of purchase, when this

UV water disinfection unit is installed and maintained in accordance with our instructions, WEDECO UV Technologies,

Inc. will repair, free of charge, defects in material or workmanship in this UV water disinfection unit.

FULL TEN-YEAR WARRANTY ON DISINFECTION CHAMBER: For ten (10) years from date of purchase,

WEDECO UV Technologies, Inc. will furnish a new current model pressure vessel, free of charge, if the pressure vessel

fails because of a manufacturing defect.

FULL TWO-YEAR WARRANTY ON ELECTRICAL PARTS: For two (2) years from date of purchase, WEDECO

UV Technologies, Inc. will provide, free of charge, parts and factory labor to repair or replace electrical parts that fail

because of defects in material or workmanship.

FULL ONE-YEAR WARRANTY ON ULTRAVIOLET LAMP: For one (1) years from date of purchase, WEDECO

UV Technologies, Inc. will provide, free of charge, an ultraviolet lamp to replace a lamp that fails because of defects in

materials or workmanship. This does not include lamps that are broken by the consumer.

FULL ONE-YEAR WARRANTY ON EXPENDABLE ITEMS: For one (1) year from date of purchase, WEDECO

UV Technologies, Inc. will provide, free of charge, expendable items such as quartz, viewport assemblies, gaskets, flow

controls, and O-rings that fail because of defects in materials or workmanship.

Save sales slip or cancelled check for proof of original purchase date to

establish warranty period.

ULTRAVIOLET DISINFECTION UNIT WARRANTY

This warranty is void if equipment is not installed and operated according to instructions in the Owner’s Manual. It does

not apply to damage caused by abuse, accident, neglect, freezing, fire, floods, or acts of God. This warranty is void on

any part from which the original manufacturing date code decal has been removed or made illegible. This warranty

requires the use of WEDECO UV Technologies, Inc. authorized replacement parts. All models must be operated and

maintained in accordance with the Owner’s Manual.

This warranty shall be void if the ultraviolet system is moved from the original point of installation, if the operating

pressure exceeds 148 psi, or if the influent water temperature exceeds 100oF or goes below 33 oF.

All defective parts must be returned to WEDECO UV Technologies, Inc., for inspection and repair or replacement.

Contact the factory for a Return Goods Authorization Number prior to shipment. Defective parts must be sent prepaid

freight. WEDECO UV Technologies, Inc. will inspect, test, and determine cause of defective component parts.

WEDECO UV Technologies, Inc. will not be liable for any labor charges other than factory repairs. Incidental or

consequential damages are not covered by this warranty. Warranty DOES NOT cover freight costs.

The customer must order replacement parts as a standard purchase until the defective part is returned to the factory and

evaluated. The factory will determine the extent of warranty coverage and proper warranty credit to be applied.

This warranty gives you specific legal rights and you may have other rights that will vary from state to state. Some states

do not allow limitations on implied warranties or exclusion of incidental or consequential damages.

All claims must be submitted in writing to your ultraviolet equipment supplier within thirty (30) days from the discovery

of the defect. Your ultraviolet equipment supplier will correct defective parts and/or workmanship within sixty (60) days

from the time of receiving this notice.

Warranty Forms must be filled out and sent back to WEDECO UV Technologies, Inc. for this warranty to be valid.

WEDECO UV Technologies, Inc. will keep Warranty Forms on file.

O & M Manual DLR-M, 4-7

08/05 – Rev. 6

23

Loading...

Loading...