Page 1

Item #26117

#51450 Rev. 8/08

ULTRA 2 UNDER SINK FILTER INSTALLATION INSTRUCTIONS

Ultra 2 Parts include:

1 Two housing bracket c/w housing and cartridges

1 5 foot length 1/4” OD blue tubing (product water)

1 5 foot length 1/4” OD white tubing (feed water)

Package A

2 Phillips #10 x 3/4” stainless steel screws

2 1/4” plastic tubing inserts

2 Elbow, 1/4” x 1/4”, QC x MNPT

1 Filter housing wrench

1 SV9 self tapping feed water saddle c/w quick connect tube

fitting

Package B

1 Long reach faucet assembly c/w quick connect tube fitting

Limited Warranty

• This warranty is valid for twelve months from date of purchase.

If this product is found to be defective in the judgement of the

manufacturer, a like or similar product will be provided at no

charge.

• The manufacturer shall not be liable for damages or delays

caused by defective material or workmanship or by failure due

to normal wear.

• Retain for your records along with your proof of purchase.

Precautions

• This filter is designed to operate at water pressure up to 100

psi. Normal municipal water pressure is 40 - 60 psi.

• Plastic housing parts must not be subjected to freezing,

excessive heat or direct sunlight. These conditions may cause

failure.

• Install filter with a minimum of 3” clearance - top, bottom and

sides.

• Do not overtighten fittings when installing this unit.

Replacement Cartridges

Carbon Filter #26006

- Replace a minimum of every six months or as

required.

- Carbon filters require some rinsing to remove

carbon fines before installation.

Post-filter #26118 - 0.5 Micron Carbon Briquette

Cartridge

- Replace a minimum of every 12 months or if

production or quality of water diminishes.

Page 2

ULTRA 2 UNDER SINK FILTER INSTALLATION INSTRUCTIONS

This unit is not intended for use where water is microbiologically unsafe or with

water of unknown quality without adequate disinfection before or after the unit.

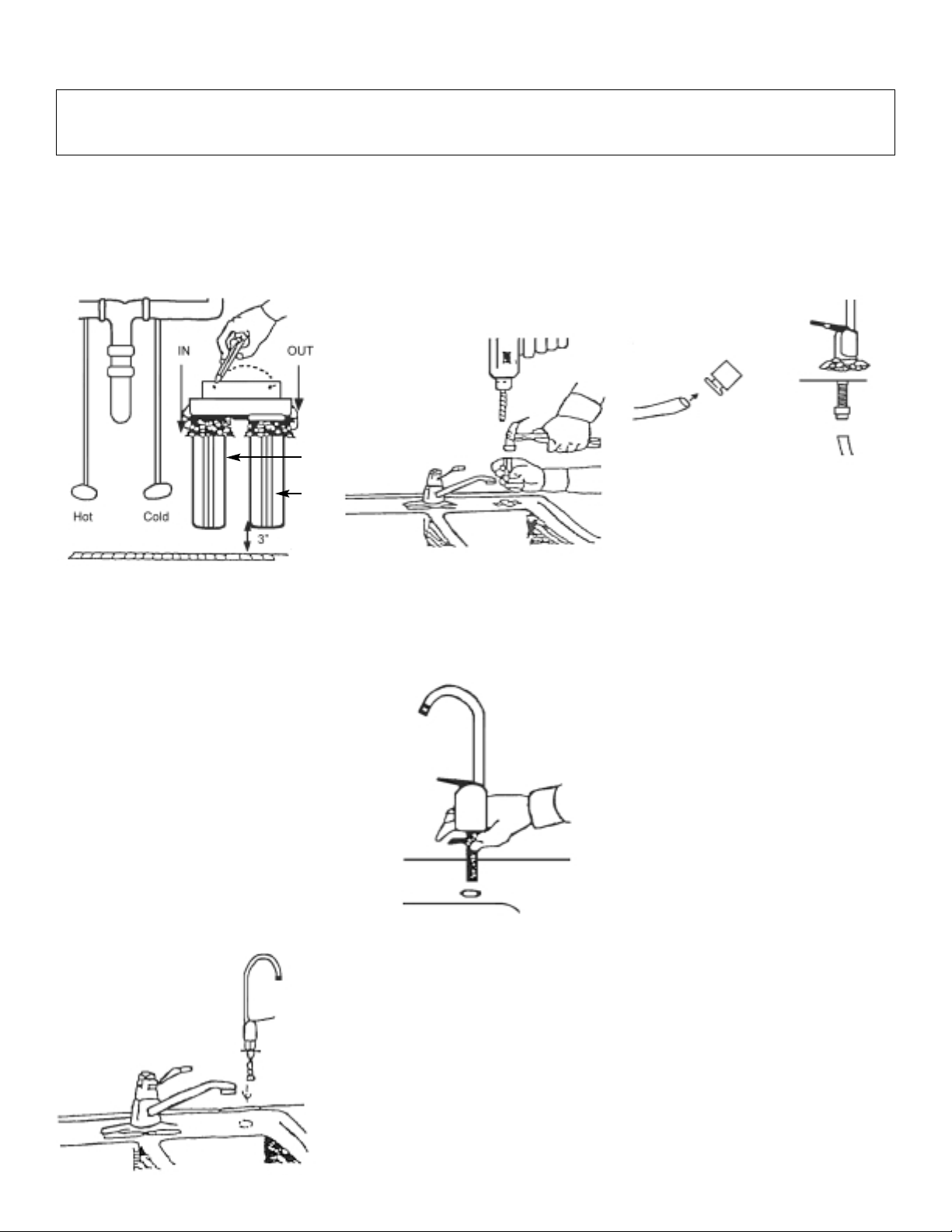

Step 1 - Choose a Location

Position the filter housing bracket on wall

of cabinet nearest cold water line

beneath sink. Leave at least 3” clearance

between the bottom of the filter housing

and the floor. Mark bracket slots on the

wall.

Step 2 - Install Filter Cartridges

For sanitization procedures, refer to

Instructions #1. Install the Carbon filter in

the (1) sump and 0.5 Micron Carbon

Briquette cartridge in the (2) sump.

Step 3 - Install Screws - Package A

Drill a 1/8” hole on each mark, then insert

the screws. Leave each screw

approximately 1/4” out from the wall for

mounting the head assembly later in the

installation.

Step 4 - Installing the Ultra 2 Faucet

The faucet may be installed into the hole

normally used for the sink sprayer. If you

have a sink sprayer installed and plan to

use it or do not have a hole, you will

have to drill a hole for the faucet. The

faucet will fit through a 7/16” hole or

larger.

For drilling through a metal sink, first

make a small indentation with a punch

where you want to install the faucet.

(Caution - Wear Eye Protection When

Drilling)

For drilling through porcelain, place a

piece of masking tape over the location,

then score with a punch before drilling.

Step 5 - Insert the Faucet - Package B

Remove the hardware from the faucet

stem for later use. Slide the large chrome

plated washer onto the stem, then the

large plastic washer. Place the faucet

stem through the hole on the sink.

Step 6 - Secure the Faucet

Slide the small rubber washer, then the

large metal washer and lock nut onto the

faucet stem. Tighten the lock nut to

secure the faucet in place.

Step 7 - Install Faucet Connector

Apply NSF 61 grade tape over the

threads of the faucet and install the

faucet connector. Do not overtighten.

Step 8 - Connect the Product Water

Tubing

Firmly push one end of the blue product

water tubing into the quick connect fitting

of faucet connector as shown below. For

more details on quick connect fitting, see

instruction #2.

Step 9 - Install Feed Water Saddle Package A

Locate a suitable area on the cold line.

Following the instructions #3 supplied,

attach the self tapping feed water saddle

to the cold water line.

Step 10 - Install Connector and the

Feed Water Tubing

Install the connector (PACKAGE A) to the

valve body of the saddle valve as shown

in step 7 (If not using compression nut

fittings). Firmly push the one end of the

white tubing to the quick connect fitting of

the connector as shown in Step 8.

Step 11 - Install White 90 Degree

Elbows

Apply NSF 61 grade tape to the threads

of the white 90 degree elbow fitting and

install them in the filter inlet and outlet

ports.

Step 12

Firmly push the other end of white tubing

and the other end of the blue tubing into

the quick connect fittings of elbow at the

inlet and outlet side respectively. For

more details on quick connect fittings,

see instructions # 2.

Step 13 - Activating the System

Open feed water saddle and faucet.

Flush unit for 2 - 3 minutes or until all the

air has been expelled and the water

appears clear at the faucet.

(1)

(2)

Page 3

Instruction #1 - Cleaning, Sanitizing and Cartridge Replacement Procedure

1. Mix mild cleaning solution of dish

soap and clean potable water in

plastic bowl.

2. Relieve presure by closing feed water

supply valve and open product water

faucet.

Icemaker:

Transfer ice cubes from

bin/tray to clean freezer container for

storage until procedure is done.

3. CAUTION: Do not attempt to remove

filter housings until water flow stops.

This reduces pressure inside

the system so housings may safely

be removed.

CAUTION: Additional point-of-use

devices (i.e., icemakers) may use

filters along their supply line. Remove

any filter or treatment device installed

between module and device before

proceeding.

Remove each filter/membrane

housing by turning it counterclockwise. Remove each filter

cartridge as its housing is removed.

Discard filters.

4. CAUTION: Use sanitary rubber

gloves for this procedure to avoid

contaminating sanitizing solution,

filters, or membrane. Wear gloves

whenever cleaning/ sanitizing system

components or handling new

filter/membrane cartridges.

5. Remove filter housing "O" rings and

wash them with cleaning solution.

Rinse them well with clean potable

water. Inspect them for damage (i.e.,

nicks, scratches). Replace damaged

"O" rings.

6. Clean filter housings ports, inside and

outside, with washcloth and cleaning

solution. Do not use abrasive

materials.

7. Rinse manifold/housings with clean

potable water.

8. Inspect manifold and filter housing

"O" ring groove area for damage (i.e.,

nicks or scratches). Replace

damaged components.

9. Place a small amount of "O" ring

lubricant over surface of filter housing

"O" ring. Install "O" ring into filter

housing groove.

TO SANITIZE THE SYSTEM: Complete

Steps 12-20.

TO INSTALL FILTERS: Complete Steps

19-20.

WARNING: WEAR SAFETY GLASSES

WHILE PERFORMING THIS

PROCEDURE.

READ "WARNINGS" INFORMATION

ON BLEACH CONTAINER BEFORE

USING CONTENTS.

HANDLE SANITIZING SOLUTION

CAREFULLY. AVOID CONTACT WITH

UNPROTECTED AREAS.

10. CAUTION: Excessive concentrations

of bleach will damage plastic and

rubber components. Rinse all parts

that contact bleach thoroughly with

clean potable water.

Mix sanitizing solution of 1.5 ml (1/3

teaspoon) of household bleach and

3.8 L (1 gallon) of clean, potable

water in the bucket. Mix solution well.

11. CAUTION: Tighten filter housings by

hand only. Do not use tools as they

will over-tighten and damage

housings. Take care not to cut or

pinch o-rings.

Add 236 ml (one cup or 8 oz.) of

sanitizing solution to each filter

housing and install them onto the

manifold (do not install filters or

membrane at this time). Tighten each

filter housing by hand only.

12. Slowly open source water supply

valve.

13. Open product water faucet. Close

faucet as soon as water begins to

flow from spout.

14. Wait 5 minutes, then close source

water supply valve.

15. Wait 25 minutes, then open product

water faucet and let water flow to

drain.

16. CAUTION: Do not attempt to remove

filter housings until water flow stops.

This reduces pressure inside the

system so housings may be removed

safely.

Remove filter housings and dispose

of water. Rinse filter housings and

manifold ports thoroughly with clean

potable water.

17. CAUTION: Do not remove protective

plastic bag from replacement filter

cartridges until so instructed.

Install "O" rings into filter housings.

Open top of filter bag enough to

expose filter cap and "O" ring

grooves. Place a small amount of "O"

ring lubricant on surface of each "O"

ring.

18. CAUTION: TIGHTEN FILTER

HOUSINGS BY HAND ONLY. Do not

use tools as they will over-tighten and

damage housings. Take care not to

cut or pinch o-rings.

CAUTION: Refer to Installation

Instructions for the location of each

cartridge.

Install filter cartridges. Hold cartridge

by its protective plastic bag and insert

cartridge into manifold turning it 1/4

turn as it enters the port. Slide bag

from cartridge and discard. Replace

each filter housing as each cartridge

is installed.

19. Turn feed water valve slowly to open

position.

20. Confirm system is producing water.

Unit will be sending rinse water to

drain.

Page 4

Instruction #2 - Install Tubing to Quick Connect Fittings

PLASTIC TUBING

1. Cut tube ends square and straight.

Do not deform tube (i.e., cause tube

to compress its diameter so it is no

longer round).

2. Make sure outer surface of tube is

clear of marks or scratches for a

length equal to twice tube diameter.

This allows "O" ring to seat properly

against tube.

3. Avoid sharp changes in direction

when routing tubing. Sharp turns

cause tubing to flex and deform,

which reduces its flow capacity and

may increase lateral stress on the

fittings, causing leakage.

QUICK-CONNECT FITTINGS

Fittings consist of two parts: a Body and

a collet.

1. To install a tube, push it through

Collet until it seats firmly at bottom of

fitting (Figure A and B.).

2. To remove a tube, push and hold

Collet against Body while pulling tube

out (Figure C).

A. Push tube through Collet into Body.

B. Tube must seat firmly at bottom

of fitting.

C. Push Collet against Body to

release tube.

Instruction #3 - Saddle Tapping Valve Installation on Copper Tube

CAUTION: This saddle-tapping valve is

not designed for installation on flex line

tubing.

NOTE: State, provincial and local

plumbing codes may prohibit use of

saddle-tapping valves.

1. CAUTION: If no shut off valve is

installed under sink, close main water

valve during this Installation.

Locate shut off valves on water lines

under sink. To identify hot supply pipe

and cold supply pipe, turn both

faucets on and let water run. As water

flows, hot water pipe becomes

noticeably warmer.

2. CAUTION: Do not install feed water

assembly on hot water line.

Turn off cold water supply by closing

shut off valve. Drain line by opening

sink faucet. Some mixing type faucets

may require hot water supply be shut

off as well.

NOTE: All instructions refer to

components shown in Figure 1 unless

otherwise noted.

3. CAUTION: Do not turn valve handle

before or while installing saddletapping valve. Make sure piercing

lance does not protrude beyond

rubber gasket before installing valve.

Assemble saddle-tapping valve

assembly on tube.

a. Hold back plate against tube.

• 3/8" copper tubing use back

plate smaller radius.

• 1/2" copper tubing, use back

plate larger radius

b. Hold valve saddle against tubing

in a position directly opposite

back plate.

c. Tighten screw enough so valve

saddle and back plate are held

securely against tube.

d. Rotate assembly so tubing

connection is aligned toward RO

Module feed port.

e. Tighten screw firmly. Do not

crush tube.

4A. Connect source water feed tubing to

valve body using compression fitting.

a. Slide nut and sleeve onto tubing

(in that order).

b. Install insert into plastic tubing.

c. Install tube with insert and

sleeve into valve body.

d. Thread compression nut onto

valve body, tighten.

4B.Connect source water feed tubing to

valve body using connector.

a. Apply NSF 61 grade Teflon tape

over the threads of valve body.

b. Install the connector (Do not

overtighten)

c. Firmly push the white tubing into

the quick connect fitting of

connector.

5. Turn saddle-tapping valve handle

clockwise until it is firmly seated and

piercing lance is fully extended.

6. CAUTION: Supply line is pierced and

valve is closed.

Do not open valve until system is

activated.

Turn on cold water supply. Check

saddle-tapping valve installation for

leaks. Allow water to run from faucet

for a few minutes to clear any debris

in the line caused by installation.

NOTE: If flow from sink faucet is

reduced, clean faucet aerator.

Figure 1: Saddle-Tapping Valve Assembly

P/N 92276 installed on 1/2”

Copper Tubing

7. Trim ¼” white tube to desired length.

Install ¼” white tube into ¼” white

collet as shown in Figure 1.

Compression

Nut Fitting

Connector

Loading...

Loading...