Hydrotec HY-MAG Competition Operating Instructions Manual

- 1 -

Operating Instruction

HY-MAG

Competition

Serial number: _______________

HYDROTEC

Hydrotec House

4-5 Manor Courtyard

Hughenden Avenue

High Wycombe

HP13 5RE

Tel. 01494 / 796040 Fax 01494 / 796049

- 2 -

General

Our control box type HY-MAG Competition is a high-quality menu and micro-processor controlled

control box providing maximum efficiency for the HY-MAG Water Conditioning Units sizes DN20

to DN65. The control box is set ex works to the individual water conditioning units.

The instruction render a survey on the menu guide and the individual programming possibilities

for the operator.

The control box shall only be started if the Harting plug connection between control box itself and

water conditioning unit is closed! Insert Harting connection of the control box into the corresponding bushing at the water conditioning unit and close safety bracket.

NOTE : The HY-MAG Competition control box is provided with a transparent

plastic glass. To be able to change or set control operations, the plastic

cover must be opened with the right-hand closure.

Once setting has been finished, the glass must be closed again with an

audible noise.

Initiating phase

Once the control box was connected to the mains power and switched on, the initiating phase

and an initial system check is started automatically. Every individual and actually running operating sequence is shown in the LCD – display.

Standard display :

Control box test :

Short-circuit test :

Operation - test: Technical operation check of complete HY-MAG system (control box and

water conditioning unit). The below individual sequences are shown

Test current to water conditioning unit See

list of individual current rates for units

(nom. width)

Pre-set water conditioning unit –

example HY-MAG DN20/25

Check remanence clearance

H Y D R O T E C

Competition V. 1.00

Short-circuit - test

Test OK

Control box - test . . . .

Control box OK

Actor – test

current: xxx mA

Actor – test

Hydromag type: DN 20/25

Actor – test

Time reman. clearance: OK

- 3 -

Normal operation

The control box automatically switches to normal operation once the initiating phase has elapsed,

whereby the individual actual operation sequences are shown in the display and by the LED lights.

The individual operation phases are shown optically. The below display monitoring is shown during continuous operation.

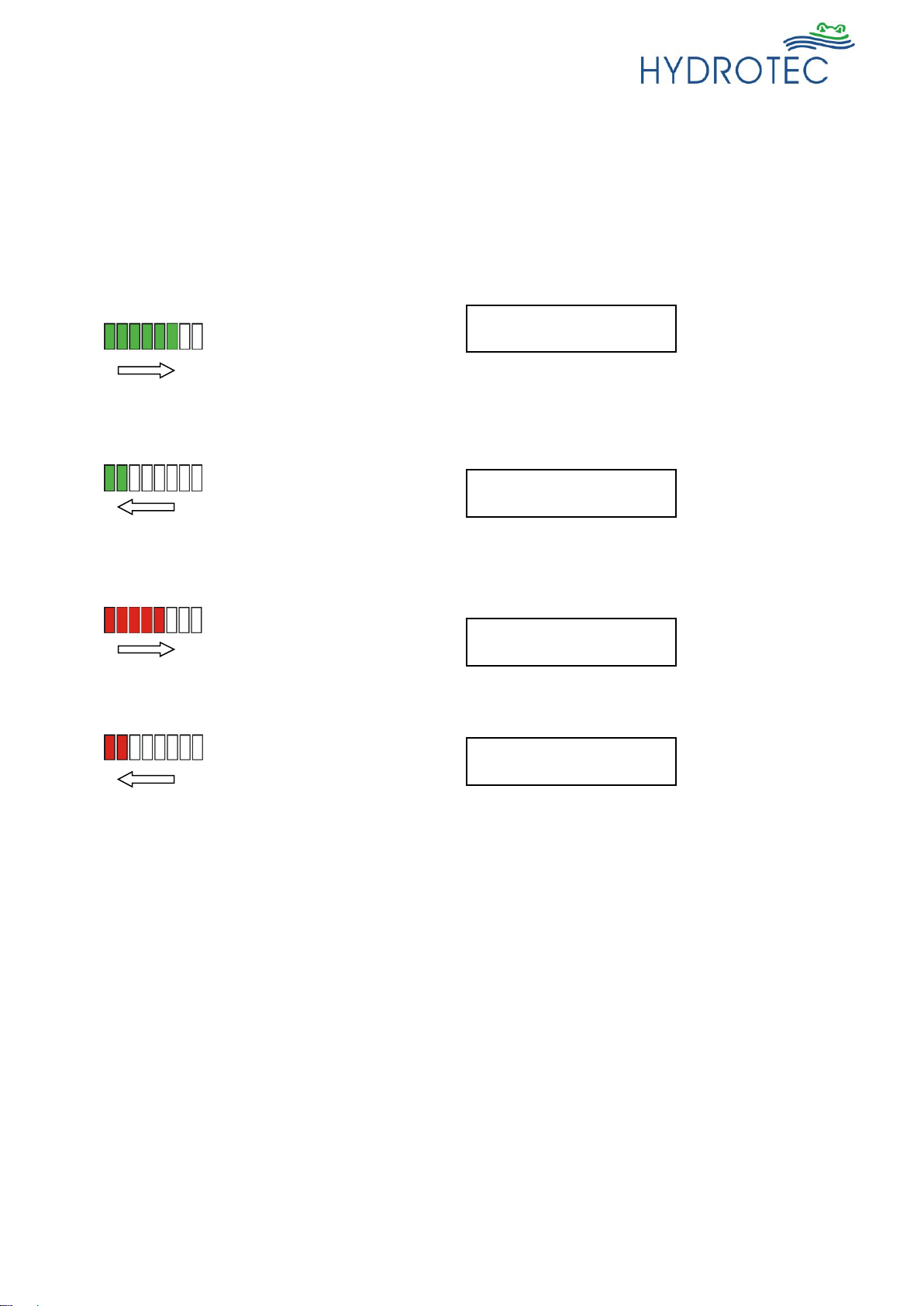

LED – light sequence Display monitor

All 8 LED’s light successively (GREEN phase),

positive d.c. (approx. 100 V) is released to the

water part

Duration about 8 s

Monitoring of day, date and time

Operation state Monitoring current

The current ratings for the corresponding HY-MAG types are

shown in the below list

REFIT® – Phase

Duration about 2 s (magnetic remanence clearing, LED extinguishes successively to the left

within 2 seconds – GREEN LED)

All 8 LED’s light successively (RED), negative

d.c. (approx. 100 V) is released to the water part

Duration about 8 s

REFIT® – Phase

Duration about 2 s (magnetic remanence clearing, LED extinguishes successively to the left

within 2 seconds – RED LED)

The shown current rating is dependent on the type of water conditioning unit.

HY-MAG DN20 / DN25 235 mA ± 10%

HY-MAG DN32 / DN40 345 mA ± 10%

HY-MAG DN50 / DN65 465 mA ± 10%

Thu 11.10.2001 10:30

Cont. operation + xxx mA

Thu 11.10.2001 10:30

Cont. operation + 0mA

Thu 11.10.2001 10:30

Cont. operation - xxx mA

Thu 11.10.2001 10:30

Cont. operation - 0mA

Loading...

Loading...