Hydrotec HYDROION VAS 75-CS 1-A, HYDROION VAS 25-CS 1-B, HYDROION VAS 75-CS 1-B, HYDROION VAS 125-CS 1.5-A, HYDROION VAS 125-CS 1.5-B Operating And Maintenance Manual

...

Last change 10/2018 E-P | Subject to technical modifications

Operating and Maintenance Manual

®

HYDROION

Type: VAS – CS

Serial number: ____________________

HYDROTEC UK Ltd. Telephone 01494 796040

Hydrotec House

5 Manor Courtyard, Hughenden Avenue

High Wycombe, Bucks. HP13 5RE Fax 01494 796049

Web: www.hydrotec.co.uk

1/98

Last change 10/2018 E-P | Subject to technical modifications

Index

The individual chapters are listed in the survey below. More detailed information is shown in

the respective overlays.

Preface

Chapter I General information

Chapter II Transport and storage

Chapter III System description / Technical data

Chapter IV Assembly and installation

Chapter V Micro processor control

Chapter VI Start up / Taking out of service

Chapter VII Troubleshooting

Chapter VIII Monitoring and maintenance

Appendices 1 Installation schematic softener

Appendices 2 Calculation soft water capacity

Appendices 3 Calculation sodium content

Appendices 4 Start up and training record - Softener HYDRO ION®

Appendices 5 Log book

Appendices 6 Commissioning request

Appendices 7 PUROLITE - ION EXCHANGE RESIN - Safety data sheet

Imprint

2/98

Last change 10/2018 E-P | Subject to technical modifications

Preface

The HYDROION® Softener are constructed and manufactured with respect to and in consideration

of all current standards as well as further technical specifications, and corresponds to the latest

state-of-the-art technology, allowing for maximum safety under all operating conditions.

System safety in operation can only be assured if all necessary measures are taken beforehand. It

is part of the operator’s diligence to plan and monitor such measures and implement them with due

care.

The operating and maintenance manual includes important information for a save installation,

operation and commissioning. Please make yourself familiar with all details prior to start operation.

For any additional information or problems encountered in conjunction with operation, please

contact our Customer Service Department at the following address:

Hydrotec (UK) Ltd

Hydrotec House

5 Manor Courtyard, Hughenden Avenue

High Wycombe, Bucks HP13 5RE

Tel: 01494 796 040

Email: services@hydrotec.co.uk

3/98

Last change 10/2018 E-P | Subject to technical modifications

Index Chapter I – General information

Page

1. Documentation 5

2. Safety information 5

2.1 Operator’s duty of care 5

2.2 Appropriate use 6

2.3 Basic safety measures 6

Maintenance, repair and electric work 7

Start up after maintenance and repair work 7

Environmental regulations 7

2.4 Risk in the event of safety instructions being disregarded 8

2.5 Operational and ancillary materials 8

2.6 Used safety signs and instruction symbols 8

3. Warranty 9

4/98

Last change 10/2018 E-P | Subject to technical modifications

1. Documentation

The following information is included for the operator in the operation and maintenance manual:

• Safety information

• Information and instructions for assembly

start-up

operation

maintenance

troubleshooting

• Technical Data

The operation and maintenance manual together with all other technical information and documents

must always be kept readily accessible.

The O&M includes several chapters marked with roman numerals (see global index). The page

reference is shown right below on each page.

Information about the chapter contents see index on page 1 of each chapter.

For any additional information or problems encountered in conjunction with operation, please

contact our Customer Service Department at the following address:

Hydrotec (UK) Ltd.

Hydrotec House

5 Manor Courtyard, Hughenden Avenue

High Wycombe, Bucks HP13 5RE

Tel: 01494 796 040

Email: services@hydrotec.co.uk

2. Safety information

2.1 Operator’s duty of care

The system is constructed and manufactured with respect to and in consideration of all current

standards as well as further technical specifications, and corresponds to the latest state-of-the-art

technology, allowing for maximum safety under all operating conditions.

System safety in operation can only be assured if all necessary measures are taken beforehand. It

is part of the operator’s diligence to plan and monitor such measures and implement them with due

care.

The operator must ensure that:

- The system is used in accordance with the specified purpose

- The system is maintained in a serviceable condition, with the safety facilities being monitored

for correct function in regular intervals

- The operation and maintenance manual is always in a legible condition and available next

to the unit

- The operation, maintenance and repair work is carried out by qualified and authorised

personnel only

- All safety and warning information attached to the system must not be removed and must be

kept in a legible condition

5/98

Last change 10/2018 E-P | Subject to technical modifications

2.2 Appropriate use

The system is manufactured to the latest German technical safety standards employing the latest

state-of-the-art technology.

If incorrectly treated, not maintained properly at regular intervals or not used for the correct purpose

according to the specifications, the softener may incur risks and/or damage.

Operation of system shall be within the technical parameters and limit values in chapter III.

The softener unit is to be operated and maintained in good working order and according to the

specification it was designed for only.

Important! Any other use of the system, other than described, is deemed to be not in

accordance with the specification.

The manufacturer / supplier does not accept any liability resulting from the

improper use of the system. Such risks are borne by the operator alone.

All regulations and instructions in the operating and maintenance manual and

such regulations as are applicable locally must be strictly adhered to.

Any malfunctions must be corrected immediately.

2.3 Basic safety measures

Prior to starting the system it must be guaranteed that:

- No-one can suffer injury due to the system operation

- All safety facilities are in a perfectly serviceable condition

The system must be operated in perfect condition only. All faults must be notified to the person

responsible immediately after being noticed.

In order to avoid flooding of installation site, there is a drainage and / or leak control with alarm to be

provided locally.

6/98

Last change 10/2018 E-P | Subject to technical modifications

Maintenance and repair work

- All inspection and maintenance intervals specified in the operation and maintenance manual

must be adhered to

- Prior to any repair work, the system must be disconnected from mains

- Prior any repair and electrical work the system is to be disconnected from the piping system

(the system must be de-pressurised) and shall be protected from accidental restart

- Only suitable and correctly functioning load-supporting devices shall be used when replacing

heavy components or system elements

- Hose lines shall be replaced regularly (preventive maintenance) even if no damage is visible

- During work at the plant suitable and corresponding protective clothing shall be worn (e.g.

when handling with liquids such as acids and bases/alkalis)

Electrical work

- Prior to any work on electric components the system must be disconnected from the mains

- Electric equipment must be checked in regular intervals

- Any possible loose connections must be re-secured and damaged electric cabling replaced

immediately

- Casings of electric equipment and system components must never be cleaned with a water

hose (spray)

- Electric components must never be touched with wet hands

- Valid VDE regulations must be adhered to, especially the regulations for the required

potential equalisation

- EMC interferences must be avoided and if necessary a mains filter protection shall be

applied

- Cable connections shall always be kept as short as possible

- Sensor and low voltage cables shall never be laid parallel to current-carrying wires (230 V or

400 V).

Start-up after maintenance and repair work

- Check screw connections for tight fit

- Ensure that any components removed beforehand (e.g. tank lid, screen or filter) are installed

and restored to their correct operational position

- It is to be ensured that all material, tools and other appliances which were necessary for

maintenance and repair work are removed from the working area of the system

- Any liquid that has leaked is to be removed

- Ensure that all safety equipment is in a perfectly serviceable condition

Regulations in respect of environmental protection

When working on and with the system, all legal regulations in respect of waste minimisation and

proper disposal (if appropriate) must be observed and respected.

The water-endangering substances listed below in particular must not be allowed to contaminate the

soil or enter the drainage system during installation, maintenance and repair work:

7/98

Last change 10/2018 E-P | Subject to technical modifications

This icon indicates general information which must be observed during the

operation of water treatment systems.

This warning symbol indicates information which shall be observed for the

purpose of your own personal safety and to prevent any cause of damage to the

systems.

This warning symbol indicates work which shall only be carried out by qualified

electricians according to VDE regulations or by responsible institutions or

specialized companies.

This symbol indicates information which must be observed for handling of

environmentally hazardous and water-endangering substances.

This icon indicates information to be observed during any maintenance and repair

work and for maintenance intervals.

- Grease and lubrication oils

- Hydraulic oils

- Cooling agents

- Acids and alkalis (bases)

- Disinfection agents

- Cleaning materials containing solvents

Such substances must be stored, transported and collected in suitable tanks and disposed

of in accordance with the applicable regulations.

2.4 Risk in the event of safety instructions being disregarded

The consequences of disregarding safety instructions can be dangerous to the system, material and

personnel, and the loss of any warranty claims.

We shall accept no liability for possible water damage caused due to disregard of the safety

instructions.

2.5 Operational and ancillary materials

All materials shall be handled in accordance with the COSHH regulation (the Control of Substances

Hazardous to Health 2002). Material Safety Data Sheets are provided in the Appendices.

Safety datasheets

The operating media used:

- Highly acidic cation exchange resin

- Regeneration salt

are not considered to be hazardous substances in the meaning of the legal provisions.

2.6 Safety and warning symbols

8/98

Last change 10/2018 E-P | Subject to technical modifications

3. Warranty

The warranty period for the system is 12 months, calculated from either the date of commissioning

by Hydrotec (UK) Ltd. or 15 months from the date of supply in the event that commissioning is not

included with the supply agreement, whichever is the shorter. The plant must be operated and

maintained in accordance with Hydrotec (UK) Ltd’s requirements. It is recommended that a service

contract is taken out for the unit.

Claims under warranty will only be accepted in the meaning of our General Conditions of Sale and

Supply subject to the following conditions:

- The system is used and operated in accordance with information and instructions in the

operation and maintenance manual

- The system is treated properly

- Repair work is to be carried out exclusively by authorised specialists

- Original spare parts or parts recommended by Hydrotec (UK) Ltd. shall be used

exclusively

- No modifications are carried out on the system by users themselves

- The stipulated operation parameters (pressures, flow volume) are maintained and a

water temperature of 30°C is not exceeded

- Start-up of the system has been carried out by our service personnel

- That after installation and longer standstill periods a chemical disinfection has been

effected

- A yearly maintenance is carried out by our service personnel

Excluded from warranty claim are all parts subject to wear and tear such as:

- All moving parts, motors, seals, membranes, filter etc.

Warranty claims cannot be accepted in cases of:

- Operation and installation errors

- Faulty maintenance

- Deliberate damage or negligent handling

Any unauthorised modifications are not permitted for safety reasons. Original spare parts and

accessories are especially designed for the softener series HYDROION®.

Original spare parts shall be used exclusively!

Important information for any queries and spare parts orders:

- Softener type (model number)

- Serial number

- Date of manufacture

9/98

Last change 10/2018 E-P | Subject to technical modifications

Chapter II – Transport and storage

All system parts of the HYDROION® softener unit should be secured against jolting and

falling during transport and storage.

Appropriate means must be used in order to avoid and exclude any damage during transport.

The entire delivery must be checked for completeness and possible transport damage immediately

upon receipt at the warehouse / site.

Any transport damage must be notified to the supplier immediately.

Important!

Pressure tanks get damaged by shock load!

In order to protect the feet, the tanks shall be lifted for transport (not tilted!).

The system and resin must be protected from frost during transport and storage

(recommended temperature 5-40°C). Storage outside these conditions can damage and

destroy the resin and resin vessel.

Components, fittings and pipes shall never be used for fixing of conveyor belts or other

supporting means of transport!

Do not lift the system via the components, fittings or pipes!

If disregarded, system components can easily get damaged and break/crack!

Regeneration material

Common salt (sodium chloride) supplied in tablet form according to EN 973 (DIN19604) is to be

used as the regenerant. Typically the salt is supplied in 25 kg plastic sacks which must be stored in

clean and dry areas only.

Hydrotec (UK) Ltd. is not a salt supplier. Supply of salt is the responsibility of the operator.

10/98

Last change 10/2018 E-P | Subject to technical modifications

Index Chapter III – System description / Technical Data

Page

1. System description 12

1.1 General 12

1.2 Function 13

1.3 Water pressure 14

2. Technical Data 15

2.1 HYDRO ION® VAS – CS – A 15

2.2 HYDRO ION® VAS – CS – B 16

2.3 Installation schematic 17

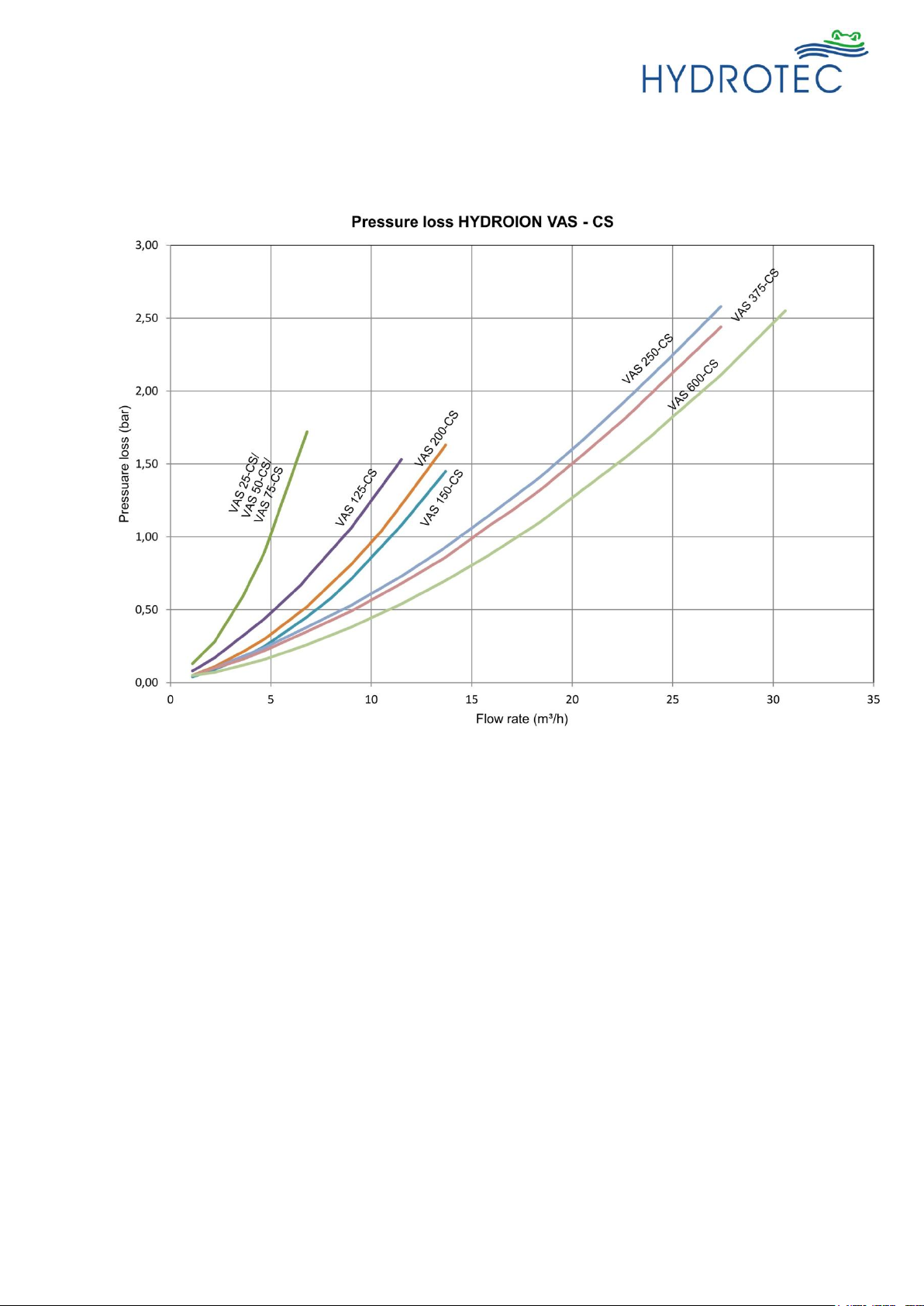

2.4 Pressure loss 18

3. Scope of supply 19

3.1 Components 19

- Resin vessel 19

- Resin 20

- Control valve 20

- Micro processor control 21

- Water volume counter 21

- Brine tank 22

- Brine exhaust 22

- Brine lack sensor 22

- Chlorinator 23

- Measuring kit total (permanent) hardness 23

3.2 Accessories 24

- System separator 24

- Assembly mounting 24

- External blending 25

- Flexible hoses 25

- Regenerant 25

11/98

Last change 10/2018 E-P | Subject to technical modifications

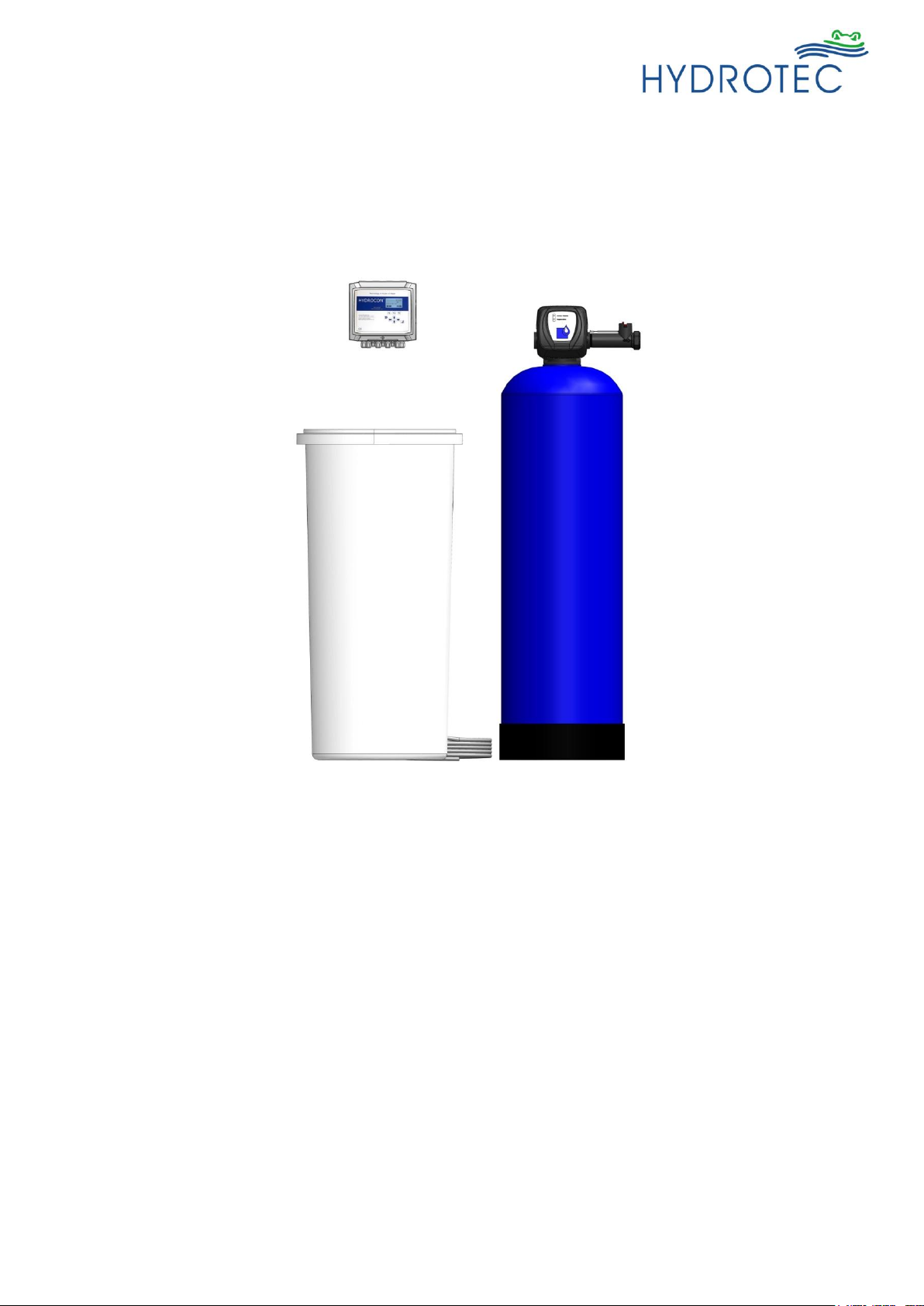

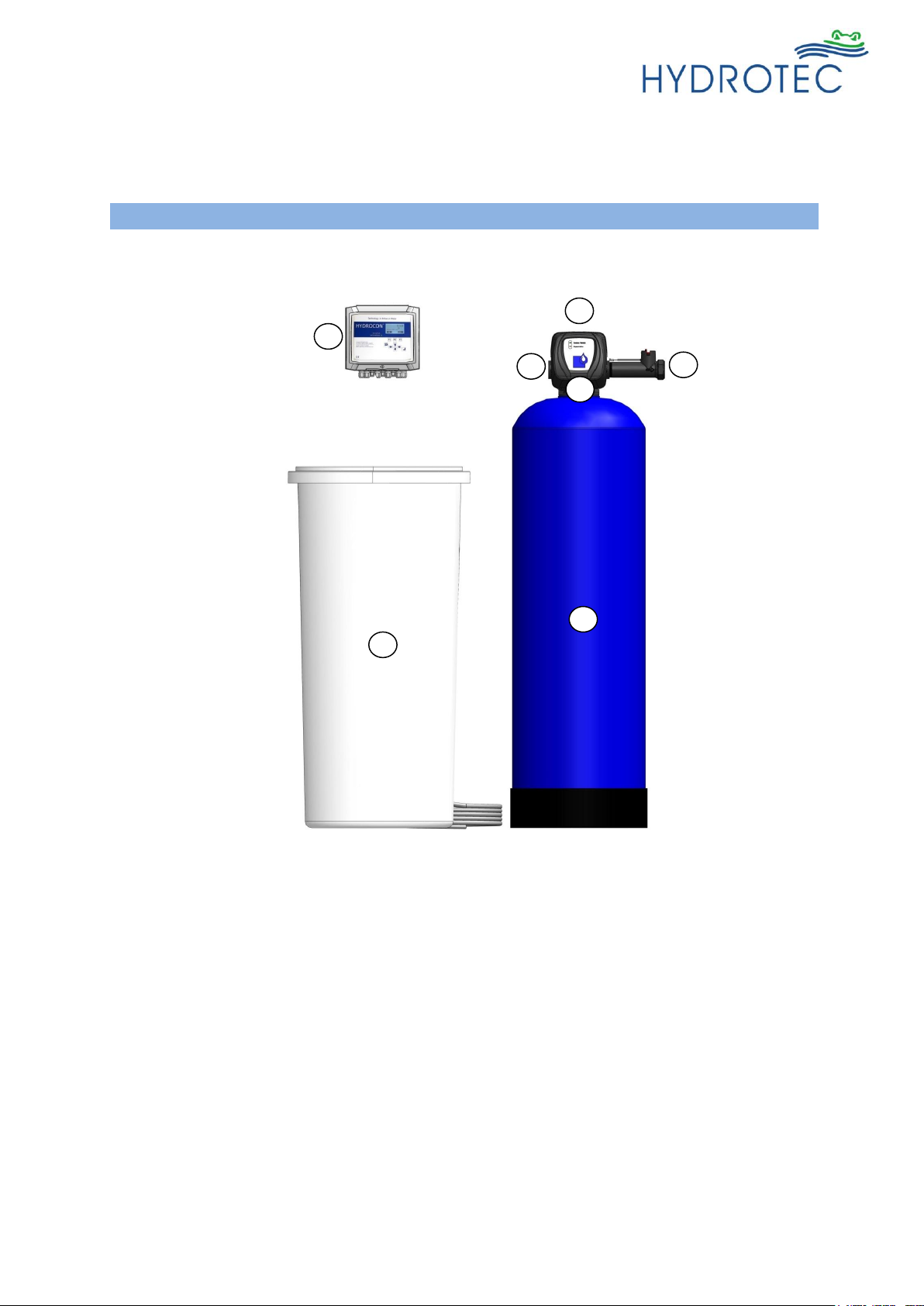

fig.1

1. System description

1.1 General

Simplex softener HYDRO ION® VAS – CS

HYDROION® VAS softeners are designed and used to chemically transform hard water into soft

water. The treatment process is via the ‘ion-exchange’ method, whereby the hard water flows over

the resin media in the pressure vessel. The elements responsible for hardness, calcium and

magnesium ions present in the water are bound reversibly to the ion exchange resin and in return,

sodium ions are released into the water. The accumulation of calcium and magnesium ions

(hardness) on the resin is periodically removed by a regeneration process using sodium chloride

(common salt) solution or brine.

Plant type: HYDRO ION® VAS - CS – A / B (Salt saving mode)

Treatment normally for

- Drinking water application according to DIN 19636

- Preparation of cooling water according to VDI 3803

Softener designed as Simplex system.

12/98

Last change 10/2018 E-P | Subject to technical modifications

1.2 Function

System HYDRO ION® VAS exclusively suited to soften hard water having drinking water

characteristics.

That means the water must be clear, colourless, free from chlorine, iron, manganese and oil in order

to avoid a damage of the exchange material by blocking.

The feature of hard water is substantial for the efficiency of the ion exchange material and the

operation of the system.

The ambient temperature for the system must be free from frost and not exceed 40°C since

otherwise the ion exchange resin will be irreversibly damaged and/or the pressure resistance of

used materials is reduced.

The HYDRO ION® VAS water softener is controlled by a water meter.

The softening of the water is by means of the ion exchange resin in the pressure vessel. The

process of ion exchange is the exchange of the hard minerals (calcium and magnesium ions) with

sodium ions. Water treated in this manner is called softened water.

The ion-exchange resin becomes exhausted after a certain water volume has passed and at this

point it must be regeneration with sodium chloride (common salt).

Operation / regeneration of the softener in the different stages in accordance with the following

processes:

Operation = soft water production

The water to be treated passes through the iron exchange resin bed from top to bottom and goes to

service as soft water via a riser tube.

Backwash

Water passes through the ion exchange resin bed from bottom to top, to fluidise and aerate the bed.

The back wash is sent to drain.

Brining / slow rinse

Brine is drawn by means of an injector, diluted, and fed through the ion exchange resin from top to

bottom. Whilst the process is taking place, the calcium and magnesium ions attached to the resin

are exchanged for sodium ions, thus regenerating it. Effluent goes to drain.

13/98

Last change 10/2018 E-P | Subject to technical modifications

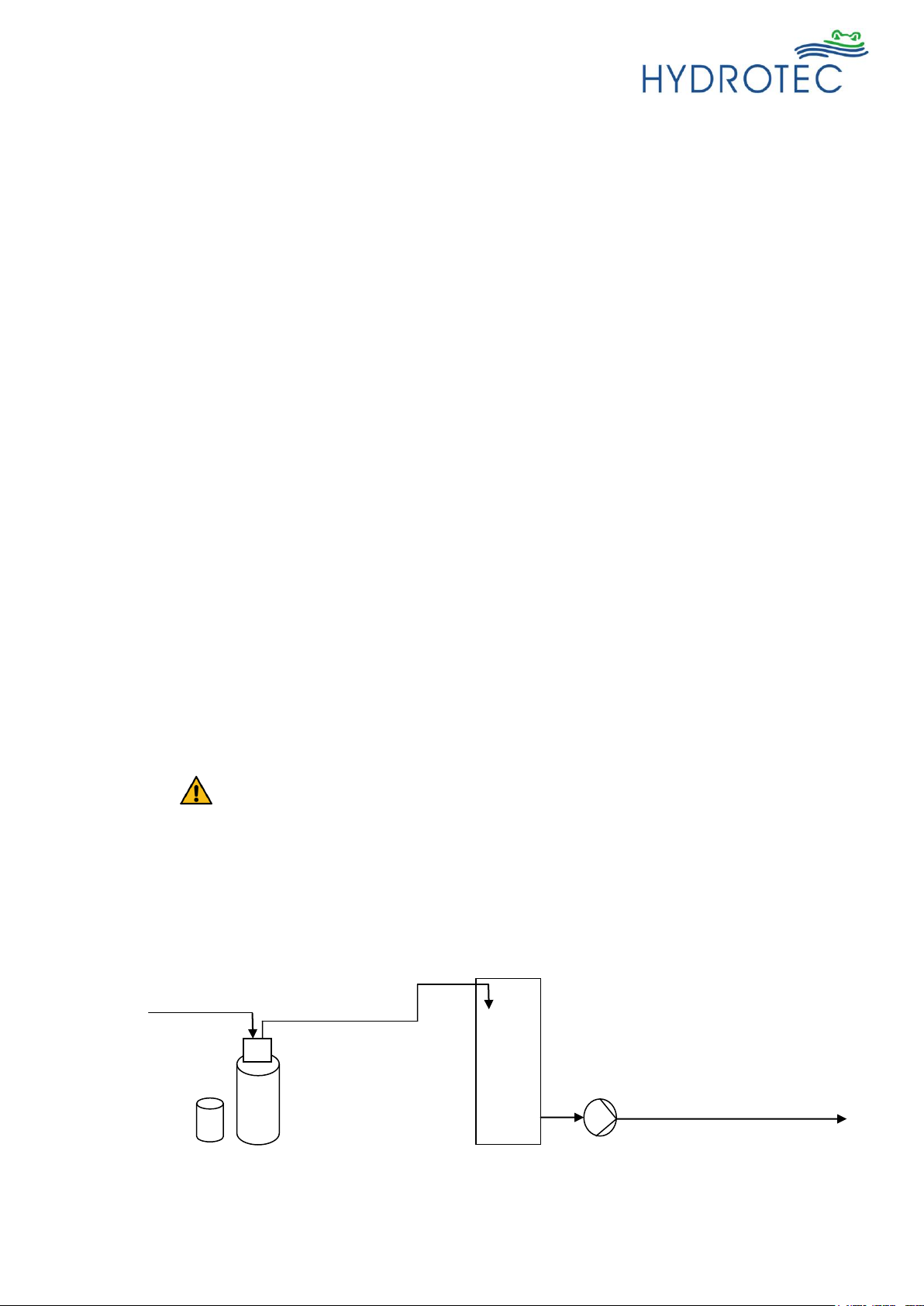

water

incoming

to the consumer

reservoir

pressure

booster

system

softener

fig.2

Fast rinse

Hard water flows from top to bottom through the ion exchange resin, driving out the excess residues

of brining process. Effluent goes to drain.

Brine tank fill

After brining and rinsing, water is fed to the brine tank, via the brine draw line, filling it again up to

the normal water working level, this is to ensure that concentrated brine available for the next

regeneration process.

The softener is returned to service!

1.3 Water pressure

In order to guarantee optimum and economic operation of the system, the water pressure should be

adjusted to between 2.0 bar and 8.0 bar.

The water pressure should not fall below 2.0 bar, in order not to impair the functional performance of

the softener.

Regular maintenance avoids the increase of pressure loss and guarantees correct system

operation.

The water pressure must not exceed 8 bar, doing so may pose a safety risk and cause operational

problems, it is recommended that a pressure reducing valve be fitted upstream of the water

softener.

Caution!

Pressure booster systems must not be installed in flow direction directly after a water treatment

system into the piping.

In case a pressure booster system is required for the transport to the consumer the system shall

only transport soft water into a pressure-less vessel which is used for the subsequent pressure

booster system.

14/98

Last change 10/2018 E-P | Subject to technical modifications

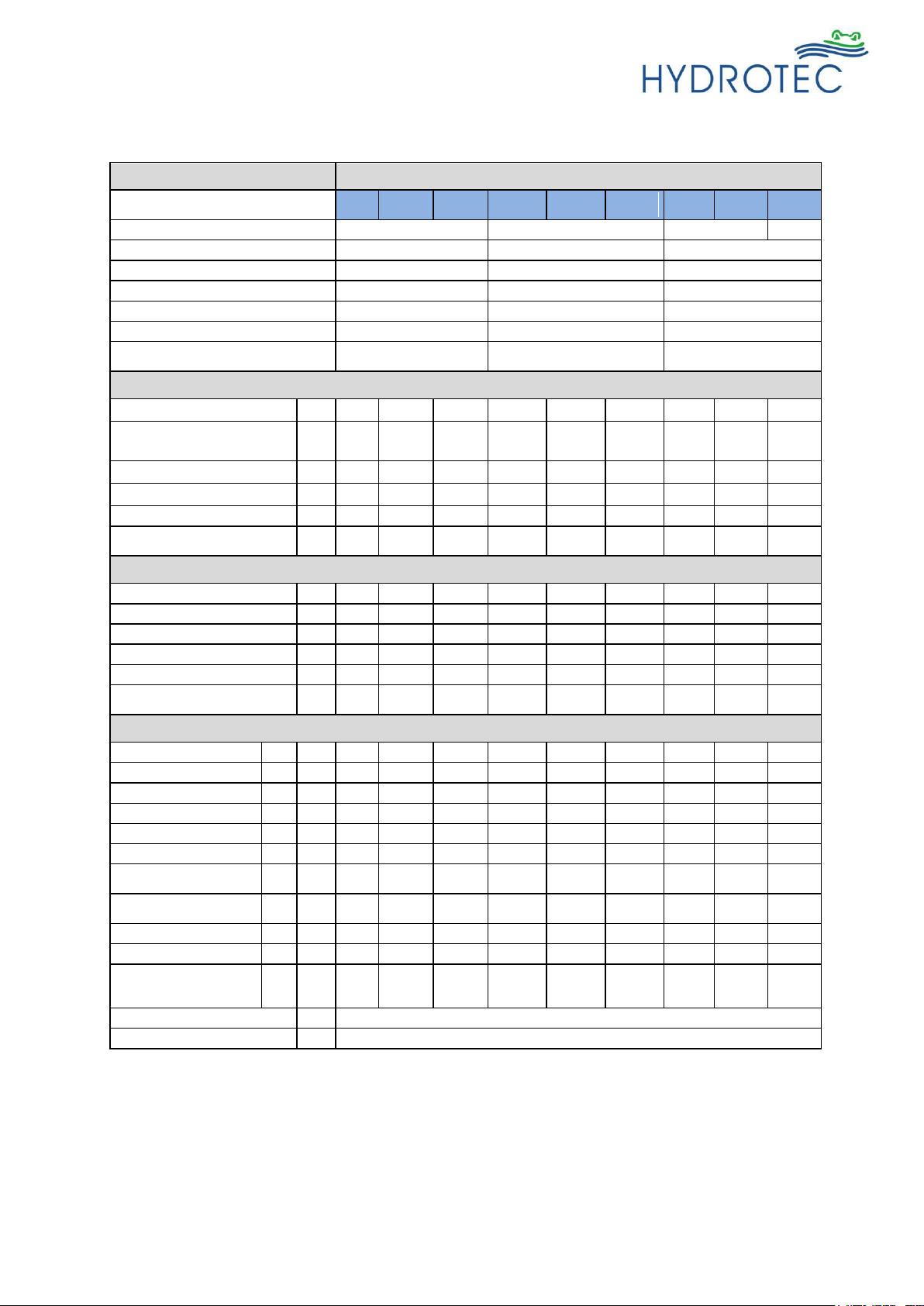

2.1 Technical data

HYDROION® VAS – CS – A

Systems with full salting

(Type A)

25-CS

1 - A

50-CS

1 - A

75-CS

1 - A

125-CS

1,5 - A

150-CS

1,5 - A

200-CS

1,5 - A

250-CS

2 - A

375-CS

2 - A

600-CS

2 - A

Connection mains / soft water line

DN 25 (1")

DN 40 (1 1/2")

DN 50 (2")

DN 80

Drain line (mind.)

DN 50

DN 50

DN 70

Mains electrical connection

230 V / 50 Hz AC

230 V / 50 Hz AC

230 V / 50 Hz AC

Electrical connection (secondary)

12 V AC

12 V AC

12 V AC

Water temperature (min./max.)

5 °C / 30 °C

5 °C / 30 °C

5 °C / 30 °C

Ambient temperature (min./max.)

5 °C / 40 °C

5 °C / 40 °C

5 °C / 40 °C

Operational pressure

(min./max.) 2)

2 bar / 8 bar

2 bar / 8 bar

2 bar / 8 bar

Performance data

Nominal flow

1)

m³/h

2.5

3.5

4.5

6.5

8.0

10.5

13.5

17.0

24.0

Flow rate at blending

(300 ppm to 60 ppm)

m³/h

3.1

4.4

5.6

8.1

10.0

13.1

16.9

21.3

30.0

Pressure loss at rated flow 1)

bar

0.43

0.66

0.88

0.78

0.65

1.14

1.05

1.34

1.94

Capacity at 300 ppm CaCO3 1)

m³

5.3

10.8

16.2

27.3

32.2

43.5

54.9

82.8

132.3

Salt consumption

kg 5 10

15

25

30

40

50

75

120

Waste water volume per

regeneration

m³

0.17

0.36

0.55

0.88

1.06

1.40

1.73

2.62

4.20

Volume and weights

Resin vessel volume

Ltr.

38.4

79.5

115

153

277

277

344

473

704

Quantity of resin

Ltr.

25

50

75

125

150

200

250

375

600

Quantity of gravel

kg 4 7

10

17

40

40

40

58

40

Brine tank volume

Ltr.

140

190

340

460

460

670

920

1000

1500

Regeneration salt supply

kg

50

75

125

175

162

250

325

375

525

Operational weight

(complete unit) max.

kg

125

210

325

465

620

740

925

1210

1750

Dimensions

Height (max.)

mm

1235

1530

1600

1600

1700

1700

2000

2200

2220

Ceiling height (min.)

H

mm

1800

1800

1900

1900

2000

2000

2200

2400

2500

Width (max.)

B

mm

910

960

1160

1360

1550

1730

1980

2050

2480

Depth (max.)

T

mm

600

600

725

850

850

1000

1150

1150

1500

Clearance tank/tank (ca.)

A1

mm

510

530

630

760

820

900

1020

1070

1340

Diameter pressure tank

D1

mm

258

310

363

413

555

555

555

635

779

Diameter brine tank

(min. / max.)

D2

mm

460 /

565

460 /

565

594 /

723

703 /

833

703 /

833

847 /

973

997 /

1123

1015 /

1120

1050 /

1150

Height pressure tank

(incl. foot)

H1

mm

897

± 6

1232

± 6

1344

± 6

1341

± 15

1434

± 15

1434

± 15

1721

± 15

1918

± 15

1892

± 15

Height top control valve

H2

mm

1080

1420

1530

1570

1665

1665

1930

2130

2160

Height brine tank

H3

mm

843

1123

1200

1196

1196

1196

1206

1340

1500

Height feed (mains

water) / discharge

(softwater)

H4

mm

960

1295

1400

1430

1520

1520

1810

2010

2040

Control box (W x H x D)

mm

240 x 170 x 110

Mounting board (W x H x D)

mm

330 x 200 x 10

2. Technical Data

1)

Parameters are dependent on operation mode and water input quality.

2)

At operating pressure min. the flow pressure is decisive, at operating pressure max. the static

pressure is decisive

For the use in the field of boiler feed water, preliminary treatment and reverse osmosis a project

planning is always required performed by our Applications engineering department!

15/98

Last change 10/2018 E-P | Subject to technical modifications

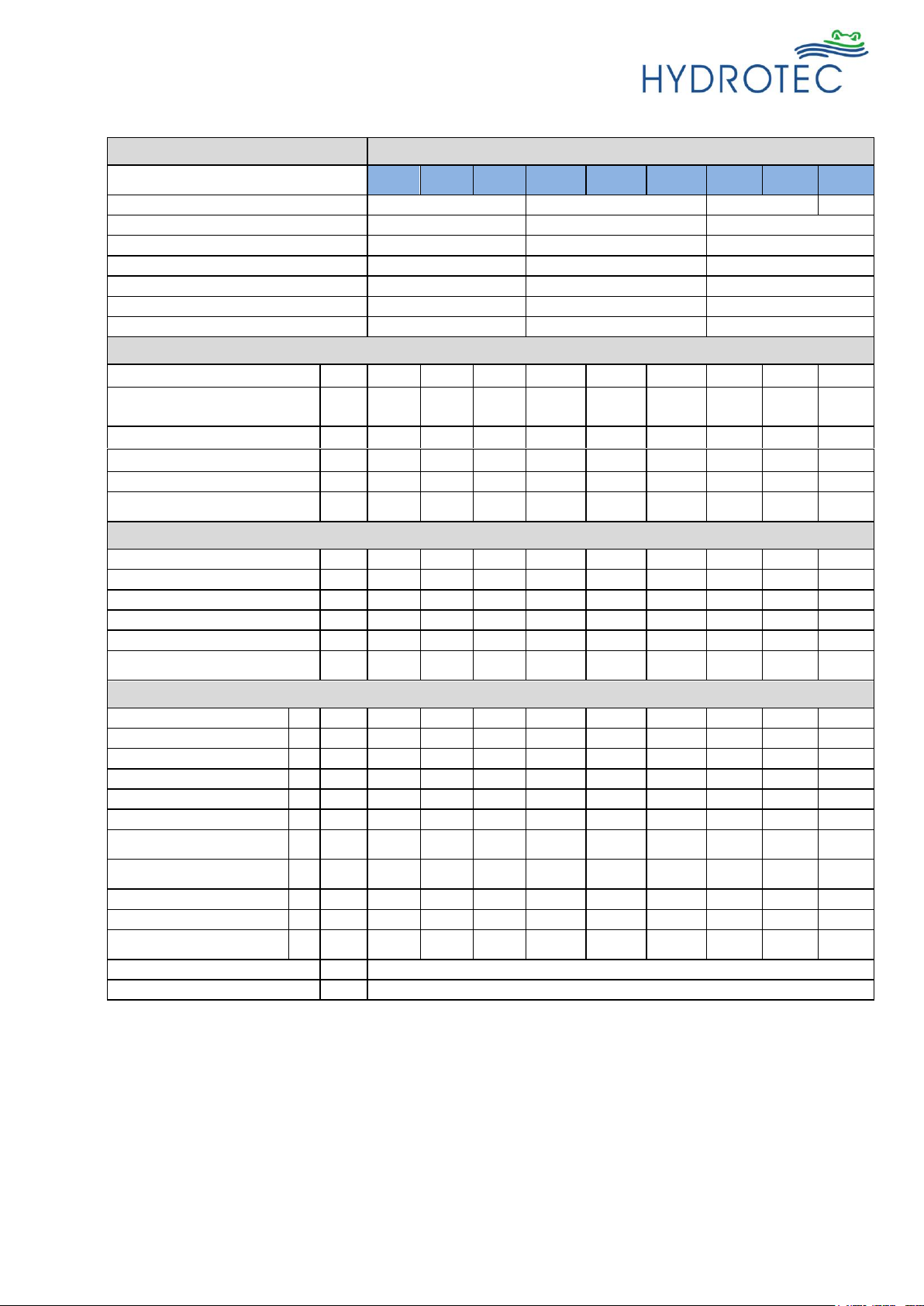

2.2 Technical data

HYDROION® VAS – CS – B

Systems with economise

salting (Type B)

25-CS 1

- B

50-CS 1

- B

75-CS 1

- B

125-CS

1,5 - B

150-CS

1,5 - B

200-CS

1,5 - B

250-CS

2 - B

375-CS

2 - B

600-CS

2 - B

Connection mains / soft water line

DN 25 (1")

DN 40 (1 1/2")

DN 50 (2")

DN 80

Drain line (mind.)

DN 50

DN 50

DN 70

Mains electrical connection

230 V / 50 Hz AC

230 V / 50 Hz AC

230 V / 50 Hz AC

Electrical connection (secondary)

12 V AC

12 V AC

12 V AC

Water temperature (min./max.)

5 °C / 30 °C

5 °C / 30 °C

5 °C / 30 °C

Ambient temperature (min./max.)

5 °C / 40 °C

5 °C / 40 °C

5 °C / 40 °C

Operational pressure (min./max.) 2)

2 bar / 8 bar

2 bar / 8 bar

2 bar / 8 bar

Performance data

Nominal flow

1)

m³/h

2.5

3.5

4.5

6.5

8.0

10.5

13.5

17.0

24.0

Flow rate at blending

(300 ppm to 60 ppm)

m³/h

3.1

4.4

5.6

8.1

10.0

13.1

16.9

21.3

30.0

Pressure loss at rated flow 1)

bar

0.43

0.66

0.88

0.78

0.65

1.14

1.05

1.34

1.94

Capacity at 300 ppm CaCO3 1)

m³

3.9

7.8

11.8

19.9

23.4

31.6

39.9

60.2

96.2

Salt consumption

kg 2 4 6 10

12

16

20

30

48

Waste water volume per

regeneration

m³

0.15

0.31

0.46

0.76

0.92

1.22

1.52

2.28

3.66

Volume and weights

Resin vessel volume

Ltr.

38,4

79,5

115

153

277

277

344

473

704

Quantity of resin

Ltr.

25

50

75

125

150

200

250

375

600

Quantity of gravel

kg 4 7

10

17

40

40

40

58

40

Brine tank volume

Ltr.

140

190

190

340

340

460

460

670

920

Regeneration salt supply

kg

50

75

75

125

125

175

175

250

337

Operational weight

(complete unit) max.

kg

125

210

270

410

580

660

765

1080

1550

Dimensions

Height (max.)

mm

1235

1530

1600

1600

1700

1680

2000

2200

2220

Ceiling height (mind.)

H

mm

1800

1800

1900

1900

2000

2000

2200

2400

2500

Width (max.)

B

mm

910

960

1020

1250

1400

1500

1540

1760

2060

Depth (max.)

T

mm

600

600

600

750

750

850

850

1000

1150

Clearance tank/tank (ca.)

A1

mm

510

530

560

700

770

830

870

980

1130

Diameter pressure tank

D1

mm

258

310

363

413

555

555

555

635

779

Diameter brine tank

(min. / max.)

D2

mm

460 /

565

460 /

565

460 /

565

594 /

723

594 /

723

703 /

833

703 /

833

847 /

973

997 /

1123

Height pressure tank (max.)

H1

mm

897

± 6

1232

± 6

1344

± 6

1341

± 15

1434

± 15

1434

± 15

1721

± 15

1918

± 15

1892

± 15

Height top control valve

H2

mm

1080

1420

1530

1570

1665

1665

1930

2130

2160

Height brine tank

H3

mm

843

1123

1123

1200

1200

1196

1196

1196

1206

Height feed (mains water) /

discharge (softwater)

H4

mm

960

1295

1400

1430

1520

1520

1810

2010

2040

Control box (W x H x D)

mm

240 x 170 x 110

Mounting board (W x H x D)

mm

330 x 200 x 10

1)

Parameters are dependent on operation mode and water input quality.

2)

At operating pressure min. the flow pressure is decisive, at operating pressure max. the static

pressure is decisive

For the use in the field of boiler feed water, preliminary treatment and reverse osmosis is this model

series not suitable!

16/98

Last change 10/2018 E-P | Subject to technical modifications

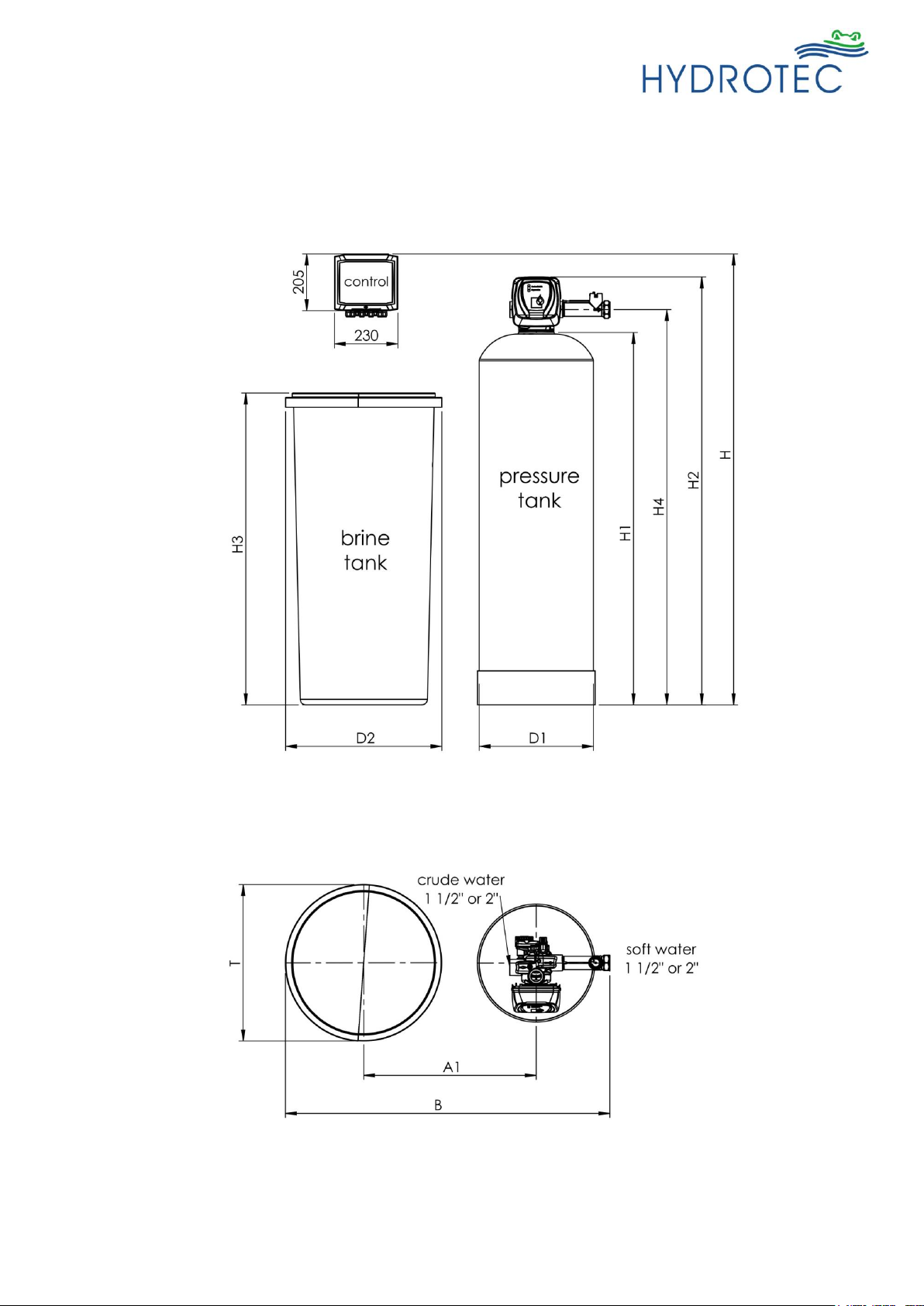

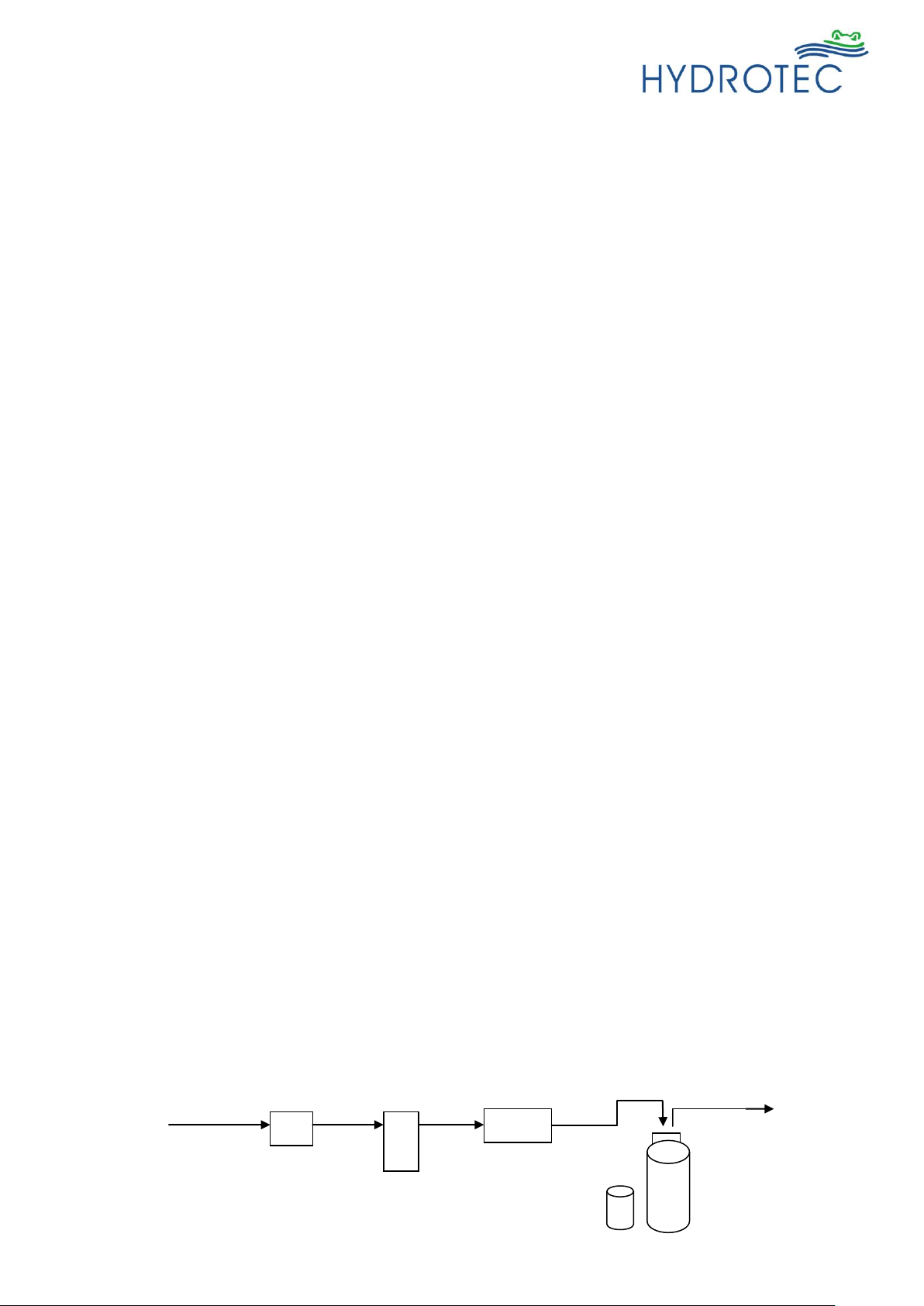

2.3 Installation schematic

Height feed (mains water) / discharge (softwater)

17/98

Last change 10/2018 E-P | Subject to technical modifications

2.4 Pressure loss curve

18/98

Last change 10/2018 E-P | Subject to technical modifications

Equipment

Description

HYDRO ION® VAS – CS 1,5

(example)

1 = Resin vessel 1 (pressure tub)

2 = Control valve

3 = Brine tank

4 = Electronic control

5 = Input

6 = Output (softened water)

7 = Wash water drain

Resin vessel

Pressure tank of corrosion-resistant glass-fibre

reinforced plastics with PE-inliner (approved

for foodstuffs) with nozzle (jet) system.

Number: 1

Top threaded connection:

2 1/2“ HYDRO ION® VAS – CS 1

4” HYDRO ION® VAS – CS 1.5

4“ HYDRO ION® VAS – CS 2

6“ flanged HYDRO ION® VAS 600 – CS 2

1 2 3 4 5

6

7

fig.3

3. Scope of supply

3.1 Components

19/98

Last change 10/2018 E-P | Subject to technical modifications

Resin media

Strong acid cat-ion exchange resin to be suited

for drinking water application PFC100E grade.

Control valve

Microprocessor controlled, menu driven

system for control of operating modes,

functions and display.

Number: 1

Operating pressure: 2,5 to 8 bar

Operating temperature: 5 to 40 °C

HYDRO ION® VAS – CS 1

Material: Plastics (Noryl)

With top nozzle and

system pcb CB 204

Connections:

Incoming/soft water: 1“ (male)

Brine intake: 3/8“

Waste water: DN 20

Tank connection: 2 1/2“ – 8 NPSM

HYDRO ION

®

VAS – CS 1.5

Material: Brass with epoxy resin

coating and

system pcb CB 204

Connections:

Incoming/soft water: 1 1/2“ (female)

Brine intake: 1/2“

Waste water: DN 20 / DN 25

Tank connection: 4“ – 8 NPSM

HYDRO ION

®

VAS – CS 2

Material: Brass with epoxy resin

coating and

system pcb CB 204

Connections:

Incoming/soft water: 2“ (female)

Brine intake: 3/4“

Waste water: DN 25

Tank connection: 4“ – 8 UN

fig.4

fig.5

fig.6

20/98

Last change 10/2018 E-P | Subject to technical modifications

Micro processor control

Micro processor control in wall-mounted

casing, menu driven for different operation

modes such as:

- volume control with temporally priority circuit

- time control

- quality control in combination with

hardness control

- forced regeneration

- water refresh

- automatic disinfection

- external release

- external regeneration

- “brine alarm” - sensor in brine tank

(Function even at 2 brine tanks)

- “pressure alarm” - sensor

Hygienic operation of softener in two steps:

Phase 1: Refresh

(Interval rinsing / water-refresh)

For prevention of stagnation phases a switch

between both vessels takes place in short

intervals. Stagnated water is minimized in

stand-by.

Interval rinsing: At this setting the stagnated

water (defined volume) is led directly into the

drain line.

Water-refresh: In contrast to interval rinsing

the stagnated water (defined volume) is led

into the soft water system instead.

Phase 2: Disinfection

Is possible during regeneration.

Functions and messages:

- Diagnostic mode

- Error list (emBrick list) for errors

occurring during operation of the

controller

- Information mode with display on

monitor

- LED signal malfunction / operation

- universal output (maintenance /

regeneration / brine lack)

The electronic controller is pre-installed and

pre-assembled on a mounting plate and ready

for wall mounting.

Water meter

HYDRO ION® VAS – CS 1

The water meter 1” is integrated in the casing

of the control valve.

fig.7

21/98

Last change 10/2018 E-P | Subject to technical modifications

HYDRO ION® VAS – CS 1,5

Water meter as external installation unit,

mounted direct to the soft water output.

Connection: input 1 ½“ external thread

output 1 ½“ internal thread

Voltage: 12 V AC

Cable suited to connect the control to the central

control valve 1.

HYDRO ION® VAS – CS 2

Water volume meter as external installation unit,

mounted direct to the soft water output.

Connection: input 2“ external thread

output 2“ internal thread

Voltage : 12 V AC

Cable suited to connect the control to the central

control valves 1.

Brine tank

Storage tank for regeneration salt, designed as

tank with sieve base, brine tube and overflow.

Number: 1 off

Material: Polyethylene

Brine exhaust

Installed in the brine tube of the brine tank,

consisting of:

Brine safety valve

Float switch

Brine hose

Brine alarm sensor

Brine alarm sensor to control the brine level in

the tank, installed in the brine tube and consisting

of:

- float switch

- protective tube

- electric connection cable to micro processor

control

Switching capacity: max. 10 W/VA

Voltage: max. 12 V

Currency: max. 0.5 A

Connection cable

Connection cable

fig.8

fig.9

fig.10

22/98

Last change 10/2018 E-P | Subject to technical modifications

Chlorinator (Option)

Chlorinator used for the automatic disinfection

during regeneration phase of softener, consisting of:

- electrodes installed in PVC assembly element

- control cable for the connection to the micro

processor control

Control voltage: max. 15 V

Connection: 3/8“ (VAS – CS 1)

1/2“ (VAS – CS 1,5/ 2)

The electrodes are activated automatically once the

brine intake cycle of the regeneration phase starts.

Chlorine is produced that starts the disinfection of

the resin bed.

The process is finished automatically once the

programmed time period for disinfection is elapsed.

The electrodes are de-activated again.

Measuring kit permanent hardness

The below measuring kits shall be available for

setting and control of the system:

Determination of permanent hardness:

Measuring range up to 760 ppm

Control cable

T-fitting

Chlorinator

fig.11

23/98

Last change 10/2018 E-P | Subject to technical modifications

Back flow prevention device

Connection size dependent on

customer’s request

(Nom. flow to be considered!)

To separate drinking water from non drinking water up to

and including liquid category 4 (DIN 1988, part 4) for

systems according to DIN 1717 with controlled

separation (installation type 2 according to DIN 1988)

with integrated differential pressure controlled and

maintenance friendly safety cartridge, non-return system,

three test valves and drain connection.

Material: red brass

without dead space, noise

tested as per ISO 38222, with

SVGW/DVGW-certificate

Temperature: max. 60 ° C

Nom. pressure: PN 10 (connection screwing

with external thread)

Pressure loss: 1.0 bar

Back flow prevention to be in accordance with local

regulations.

Connection local incoming/

soft water pipe

Assembly mount

HYDRO ION® VAS – CS 1

With blending

Art.-No.

Excluding blending

Art.-No.

The mount replaces the by-pass line to be provided

locally. Two valves stop the supply and discharge and

allow service work. The fitting can be used including or

excluding blending.

Material: corrosion resistant

red brass as per DIN 1705

Water temperature: max. 90 ° C

Pressure step: PN 10

Connections : R 1“

Installation length: 166 mm

HYDRO ION® VAS – CS 1,5

With blending

Art.-No

Excluding blending

Art.-No.

Material: corrosion resistant

red brass as per DIN 1705

Water temperature: max. 90 ° C

Pressure step: PN 10

connections: R 1 1/2“

installation length: 200 mm

HYDRO ION® VAS – CS 2

There is no mount available for such sizes. Installation of

softener has to be realized in rigid pipe work.

3.2 Accessories

24/98

Last change 10/2018 E-P | Subject to technical modifications

External blending

Blending unit DN 32

Art.-No.

Blending unit DN 50

Art.-No.

Fully automatic operating blending valve for installation

in bypass.

Material: corrosion resistant

red brass as per DIN 1705

Water temperature: max. 90 °C

Pressure step: PN 10

Connections : R 1 1/4“ (DN 32)

Installation length: 130 mm

Installation length: R 2“ (DN 50)

Installation length: 139 mm

Flexible hose

HYDRO ION® VAS – CS 1

Flexible hose - Art.-No.

HYDRO ION® VAS – CS 1,5

Flexible hose - Art.-No.

2 flexible hoses for system connection

Dimensions: 2 x 1“ (ÜM)

Length: 800 mm

2 flexible hoses for system connection

Dimensions : 1 1/2“ (AG) x 1 1/2“ (ÜM)

Length: 1000 mm

Regenerant

Art.-No.

In form of tablets (not granular!)

25 kg PE bag (Not available from Hydrotec UK Ltd.)

25/98

Last change 10/2018 E-P | Subject to technical modifications

Index chapter IV – Installation and assembly

Page

1. General information 27

2. Installation location 28

3. Work prior to assembly 28

Control of shipment 28

Drain connection 28

Incoming and soft water pipe 28

3.1 Filling of filter vessel with quartz gravel and exchange resin 29

4. Hydraulic connections at control valve 31

Control valve 1“ HYDRO ION® VAS – CS 1 31

Control valve 1 1/2“ HYDRO ION® VAS – CS 1.5 31

Control valve 2“ HYDRO ION® VAS – CS 2 31

Brine line 32

Brine lack sensor 32

Chlorinator 32

Wash water connection (drain) 32

5. Electric connections 33

Mains connection 33

Connection pcb control valve 33

Connection water volume meter 34

26/98

Last change 10/2018 E-P | Subject to technical modifications

Fine filter

System sep.

Water meter

Incoming

water

Softener

fig.12

1. General information

The HYDRO ION ® VAS – CS softener is designed as Simplex system consisting of one resin vessel

(pressure vessel) with ion exchange resin and support quartz gravel as well as one control valve on

top of the filter vessel each. All operation modes are realized by means of a micro processor control.

The softener system HYDROION® VAS 25 is filled with exchange resin ex works. The system

up to “VAS 600” has to be filled with exchange resin in situ (chapter IV section 3.1).

The resin vessel for the HYDROION® VAS range is dispatched empty for handling purposes

and must be filled with the gravel and ion exchange resin on site (see Chapter 6.5.1.). The resin

will be supplied separately in 25l bags.

It is the responsibility of the commissioning engineer to fill the resin vessel with the gravel and

resin. Hydrotec (UK) Ltd. will perform this service during commissioning visit.

Necessary pipe connections to the central control valve must be performed on site.

Softener is controlled via water flow meter installed in the soft water pipe.

The control settings are programmed in the microprocessor control unit.

Information and parameters such as time, regeneration status, residual capacity, water

consumption, operation days, functions and actual state for inputs and outputs are shown in the

display of the microprocessor control unit.

The brine container / salt bin which holds the tablet salt regenerant must be located immediately

adjacent to the resin vessel.

The supply of the regenerant to the control valve of the respective vessel is by float valve and

hose line into the vessel.

Wash water (waste water) is discharged to drain.

Incoming water is drinking water

According to standard EN1717 (DIN 1988), water softeners have to be provided with the

following safety fittings:

- Black flow prevention device

Due to the installation of a back flow prevention device, the pipe work is protected against

the return of treated drinking water into the drinking water system.

Please consult local regulation.

- Protective filter

Suited for the protection of the pipe installation and the softener against malfunction and

corrosion damage that can arise by foreign particles such as rust, sand etc.

According to standard DIN 13443-1, a filter has to be installed in the pipe before the system

separator and just after the water meter in case of metal pipe work.

The installation of a protective filter is recommended for plastic pipe work as well.

27/98

Last change 10/2018 E-P | Subject to technical modifications

Delivery check

Prior to starting assembly, the equipment must be

checked for completeness and possible transport

damage.

Any deviation must be notified immediately.

Waste water connection

The local waste water connection must be provided as

free discharge as per EN1717 (DIN 1988).

The cross section of the drain must be sufficiently

dimensioned (DN 50 at least).

Mains / incoming and soft

water pipes

The mains water and soft water pipes must be designed

locally in the required cross section and in the necessary

position in relation to the system.

Materials for soft water pipes should be plastic or

stainless steel.

Furthermore DIN 19636 (section: “protection against bacterial contamination”) must be observed:

“As water softening systems, especially at discontinuous operation, are vulnerable to bacterial

contamination, this must be prevented by means of suitable constructive or chemical-physical

measures.”

In order to keep that DIN 19636, a forced regeneration after 4 days (96 hours) has to be

programmed in the controller of the HYDRO ION ® VAS – CS softener system.

Installation of a chlorine producer into the brine hose is provided ex works for the system designs

VAS CS – A (systems with full salting) and B (systems with economic salting).

The chlorinator is actuated via the micro processor control unit.

The installation of the system must be carried out by trained and qualified personnel.

DIN 1988, DIN EN 12506 and DIN EN 806 are to be observed during installation.

2. Installation location

The below has to be guaranteed in respect of the installation and operation of a softener:

The HYDRO ION® VAS - CS softener is to be installed in a frost-protected area.

The ambient temperature must not drop below 5°C and not exceed 40°C.

A free discharge to the drainage system as per EN 1717 (DIN 1988) for waste water and

overflow of brine tank in accordance with the discharge volume is to be provided locally.

Installation should be located on even floor with level tolerances as per DIN 18202.

The minimum installation dimensions are shown in the dimensional drawings and table (see

chapter III).

An electrical connection of 230 V, 50 Hz, 3 A fused spur is to be provided locally for the

operation of the micro processor control.

In order to avoid flooding by leakage, the installation location must be provided with ground

drainage discharge or leakage monitor with corresponding alarm.

3. Work prior to assembly

28/98

Last change 10/2018 E-P | Subject to technical modifications

Seal the upper pipe opening of the riser with

insulating tape in order to prevent resin or

quartz gravel entering the riser tube during

filling of the resin tank.

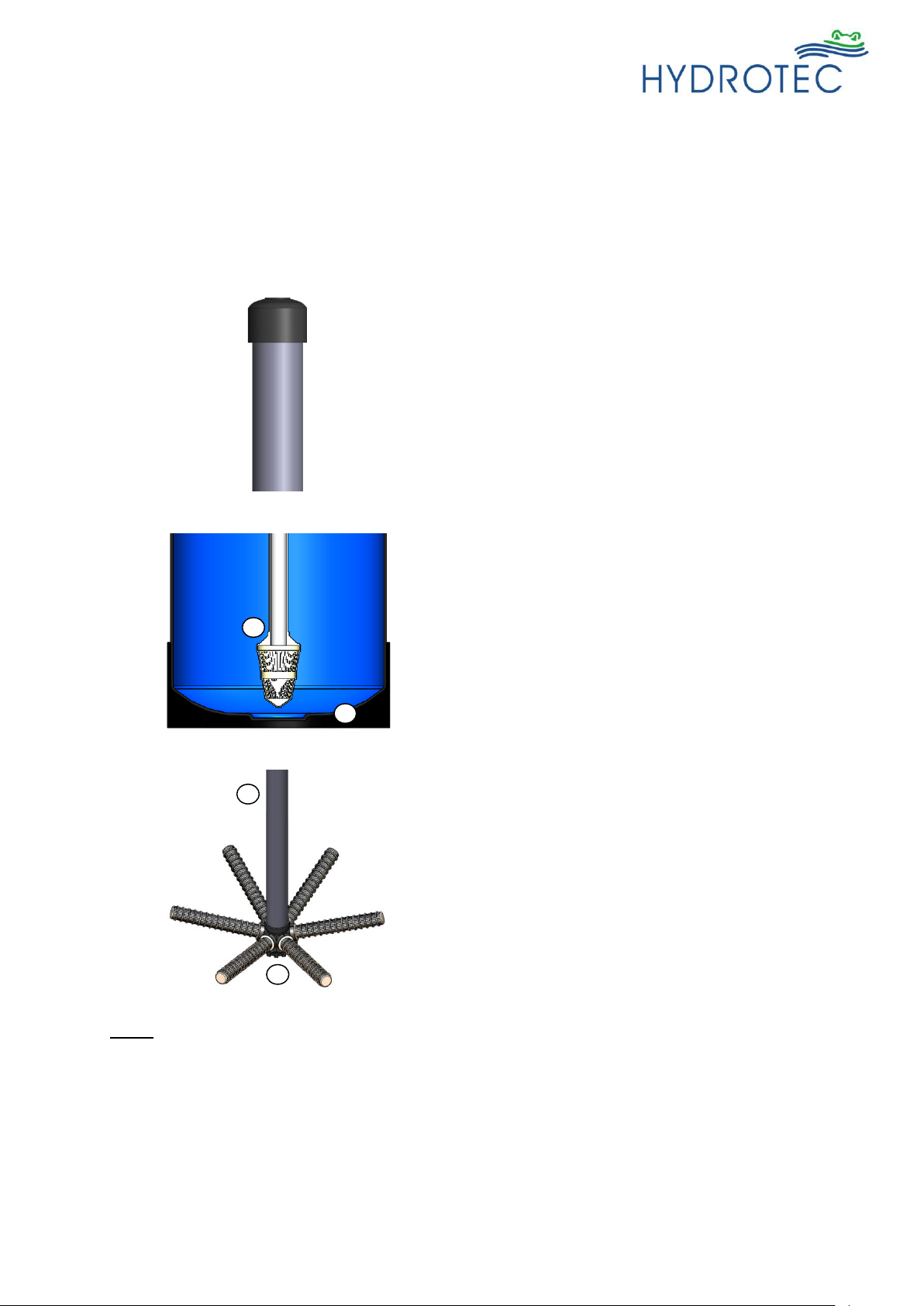

Lower distributor (1“ systems)

1 = filter on end of riser tube

2 = resin vessel base

Position the riser tube in the resin vessel in

such a way, that the riser tube stands in the

middle of the container base.

Star-type distributor (1 ½“ and 2“systems)

1 = nozzle rod

2 = star-type distributor

The star-type distributor shall be put together

and placed in the vessel in a way that it

stands on the vessel base.

The pipe cover must not be forgotten!

nozzle rod

protection cap

2 1 1

2

fig.13

fig.14

fig.15

3.1 Filling of resin vessel with quartz gravel and exchange resin

Assembly of resin vessel (pressure vessel) and brine tank, whereby a sufficient area must be

available for operation and maintenance as well as supply and discharge lines.

(Installation schematics see appendices 1)

Note:

The quartz gravel volume is sufficient for both filter vessels and packed in the respective required

quantity.

It is recommended to wash the quartz gravel prior to being filled into the vessel in order to eliminate

any possible contamination.

(Best in a bucket under flowing water and constant stirring)

29/98

Last change 10/2018 E-P | Subject to technical modifications

Upper distributor

HYDRO ION® VAS – CS 1

Upper distributor

HYDRO ION®

VAS – CS 1,5

(Di 50 mm)

VAS – CS 2

(Di 63 mm)

Filling of filter vessel as below:

Step 1:

Fill the resin vessel to approximately one quarter

of its volume with clean water.

Step 2:

Fill the quartz gravel in the resin vessel.

A good distribution must be guaranteed!

Step 3:

Separate the resin and fill it in the vessels.

A good distribution must be guaranteed!

The respective quantity to be filled into the

vessels are shown in chapter III / point 2.1 and

2.2 (table with technical data).

Step 4:

Clear any contamination, such as resin off the

threaded opening to the vessel, with clean water.

Step 5:

The closure of the nozzle rod must be removed

again.

Step 6:

The control together with top distributor must be

mounted on the vessels and the unit be aligned.

It has to be guaranteed that the nozzle rod can

be inserted into the opening of the control valves

without problem.

Step 7:

The prepared connections for incoming and soft

water must be connected.

Note:

All sealings (O-Ringe) at the vessel

connection of the control valves must not be

damaged and fit straightly.

to control valve

to control valve

nozzle rod

nozzle rod

fig.16

fig.18

fig.17

30/98

Last change 10/2018 E-P | Subject to technical modifications

Control valve 1“ - HYDRO ION® VAS CS 1

1 = Mains water connection (inlet)

2 = Soft water connection (outlet)

3 = Connection for brine line

4 = Waste water connection

Control valve 1 1/2“ - HYDRO ION® VAS CS 1.5

Control valve 2“ - HYDRO ION® VAS CS 2

3

1 2 4 3 2 1 4 2 1

4

fig.18

fig.19

fig.20

Water meter

4. Hydraulic connections at control valve

31/98

Last change 10/2018 E-P | Subject to technical modifications

Brine line

The brine is taken from the brine tank by means of a hose.

Brine is drawn in by the control valve and flows through the

intake pipe to the injector, passing the injector, before

reaching the filter media. The injector is used to limit the

brine quantity that is dependent on the quantity of filter

media.

The brine intake hose has to be fixed to the hose connection

of the brine valve (in brine tank). The hose must be fixed to

the connections of the control valve.

HYDRO ION® VAS - CS 1

Control valve 1“: connection 3/8“

HYDRO ION® VAS - CS 1.5

Control valve 1.5”: connection 1/2“

HYDRO ION® VAS - CS 2

Control valve 2“: connection 3/4“

The waste water hose that is included in the delivery scope

must be connected in an appropriate length and size to the

local drain.

Brine lack sensor

The brine lack sensor is mounted already in the brine tube of

the brine tank and has to be connected electrically to the

micro processor control.

Chlorinator

If necessary and ordered, the

chlorinator is already

mounted in the brine intake

pipe.

Waste water connection

Waste water connection of control valve 1“: 3/4“

Waste water connection of control valve 1 1/2“: 3/4“ or 1“

Waste water connection of control valve 2“: 1“

The waste water hose must be fixed in an appropriate length

to the connection leading into drain.

It must be guaranteed that discharge of waste water into the

local drain (channel) is without any pressure applied.

Otherwise, regeneration takes place whereby no brine is

drawn in.

To control valve

From brine tank

fig.21

32/98

Last change 10/2018 E-P | Subject to technical modifications

Mains connection

The control in wall mount casing must

be installed at eye level and easily

accessible!

A safety socket must be provided locally next to

the mains cable of the micro processor control.

Permanent voltage must be provided

(230 V / 50 Hz).

Do not use the lighting circuit!

Figure 23 shows all electrical supplies and

control lines to the micro processor control unit.

1 = Power supply

2 = Connection cable chlorinator

3 = Connection cable brine level sensor

4 = Connection cable control valve 1 (A)

5 = Connection cable control valve 2 (B)

Connection pcb control valve

Connections to terminal of pcb of control valve

(from top to below)

Terminal

Magenta 29 / 38

Grey 28 / 37

Black 27 / 36

Red 26 / 35

Blue 25 / 34

Brown 24 / 33

White 23 / 32

Yellow 22 / 31

Green 21 / 30

1 = Connection motor control valve

2 = Connection water flow meter

1

1

2

fig.23

3

2

4

5

fig.22

Important!

All pipe connections must be done without any tension applied on. If necessary, the

subsequent pipes must be provided with corresponding mounts or supports.

Hoses must not be bent and hose connections must be screwed tight.

Waste water, overflow and discharge lines must be provided from the connections at the

control valve until waste water drain with an appropriate inclination.

The waste water must be allowed to drain without backflow.

Backflow is not allowed for hygienic reasons!

5. Electrical connections

33/98

Last change 10/2018 E-P | Subject to technical modifications

Connection water flow meter

HYDRO ION® VAS – CS 1

The water meter is firmly installed in the soft water

output of the valve in case of control valves 1” and

is electrically connected to the pcb by means of

plug cable (see figure 18).

HYDRO ION® VAS – CS 1,5

HYDRO ION® VAS – CS 2

The water meter is installed in the output of the soft

water line in case of control valves 1.5“ and 2“.

Electrical connection is realized by means of plug

cable at the control valve.

Water meter

Control valve

fig.24

All work at electrical equipment of the softener shall be

carried out by an authorized expert only!

Note!

Since there is the risk of germ formation, it is recommended to disinfect the softener after

vessel filling and short before commissioning.

34/98

Last change 10/2018 E-P | Subject to technical modifications

Index Chapter V – Micro processor control

Page

1. HC - SOFTENER 36

1.1 Display / LED’s / Operating keys 37

1.2 Display content whilst the controller is run up 37

1.3 Main display – view 38

1.4 Access levels 40

2. Menu survey 41

3. Alarm 42

3.1 Acknowledge alarm 42

3.2 Alarm records 44

4. Total hardness 45

5. Operation mode 45

6. Protocol settings 46

7. SD-Card (messaging) 46

8. Language 47

9. System time 46

10. System date 47

11. Information 47

12. Menu structure 48

13. Electrical installation / wiring / terminal posts 51

13.1 Installation and commissioning 52

13.2 Technical data HC – softener controller 53

13.3 PCP equipment and terminal charge 54

13.4 Fine fuses 60

14. Parameter settings HYDROION® VAS – CS 61

35/98

Last change 10/2018 E-P | Subject to technical modifications

1. HC – SOFTENER

Our HC SOFTENER controllers ensure a regulation and control of operating process and

regeneration of single unit.

Regeneration can be released by different modes. Volume controlled with time priority (e.g. forced

regeneration after 4 days). A hundred percent time controlled with a pre-set regeneration interval.

Quality controlled regeneration, for example in conjunction with a hardness control device that

supplies an external contact input in case of hardness break, is possible as well.

Different VFC outputs are given to control the operation of the softener:

External regeneration release

Salt lack in brine tank

Pressure shortage

The universal VFC output can be programmed for the below functions:

Warn signal

Regeneration active

Brine lack

An additional VFC relay output confirms possible failure records.

Both relay outputs are designed as VFC alternator.

Several VFC-affected outputs are available for power supply and for the approach of possible

additional plant components:

Brine pump

Circulation pump

36/98

Last change 10/2018 E-P | Subject to technical modifications

HC – Applikation

SOFTENER = softener controller

Software-Version

Arrow keys

Input key/

Enter/CR

Function keys(charge

acc. below display)

Escape

LED operation

LED error

1.1 Display/LED’s/ Operating keys

1.2 Display content whilst the controller is run up

The controller is switched-on with the ON/OFF button (left side at casing) and supplied with mains

voltage. The below display is shown when the controller is run up:

37/98

Last change 10/2018 E-P | Subject to technical modifications

LED green – ON – Vessel in operation

Vessel number –

Vessel 1 in front view

1.3 Main display / view

Two or three different main displays / views exist dependent on plant construction, in between the

controller is switching automatically.

Main display with date, time and software version

Display for filter in operation – identical for all plant constructions

- total capacity that can be treated

- available residual capacity

- actual flow

- time remaining until release of forced regeneration (option)

Ready for operation display – in case of Duplex system only

38/98

Last change 10/2018 E-P | Subject to technical modifications

LED green – OFF – Vessel in regeneration

Regeneration display

- actual regeneration phase

- time remaining of regeneration phase

At the beginning of regeneration the following messages are shown on display.

- Pre-regeneration filter 1

- Pre-operation filter 1

These messages are displayed on the screen until the control valve is in their correct end position.

39/98

Last change 10/2018 E-P | Subject to technical modifications

Regeneration display – release of regeneration locked

- brine formation time not yet finished/elapsed

- lock time active

1.4 Access levels

The controller has four access levels to avoid access by unauthorized persons.

Example for input of password:

Passwords

There are 4 access levels with the below passwords:

Level 1 [user password]: 1111 plumber

Level 2 [admin password]: 2222 supplier

Level 3 [engineer password]: plant engineer

Level 4 [super password]: plant engineer

40/98

Last change 10/2018 E-P | Subject to technical modifications

2. Menu survey

The main menu is called via the keys F3 or Enter. Different functions and settings can be called

from the main menu as below:

Main menu

Alarms

Settings

Total hardness

Service

Operation mode

Protocol Setting

SD-Card

Language

System Time

System Date

Information

The desired menu point can be achieved and selected via the keys F3 or Enter.

The controller returns to any higher menu via the keys F1 or Escape. If any setting was modified,

confirmation is required prior returning to main view that the new setting must be stored.

The respective necessary release must be confirmed to select the different menu points

(see topic 1.4).

These are:

Alarm no password required

Settings Level 1 > plumber

Total hardness no password required

Service Level 3 > plant engineer

Operation mode no password required

Protocol Setting no password required

SD-Card nor password required

Language no password required

System time no password required

System date no password required

Information no password required

41/98

Last change 10/2018 E-P | Subject to technical modifications

LED red - ON

3. Alarm

3.1 Acknowledge alarm

Immediately upon release of an alarm, the below display is shown with the number of actual alarms

and the reason for the record.

The controller returns to main menu view via the keys F1 or Escape.

The alarm record is maintained and can be called anew via the main menu.

The failure LED lights red for the duration of an alarm record.

The alarm is acknowledged via the keys F3 or Enter.

NOTE: Any failure must be eliminated prior being acknowledged.

Example 1:

Alarm „brine lack“

That is caused if regeneration is released but no saturated brine is available or

if salt must be added to the brine tank

Salt must be refilled into brine tank

A brine formation time (ca. 2 to 3 hours) must be allowed to pass

The alarm is automatically acknowledged by the controller once saturated brine is available

as the float in the brine tank rises and thus, closes the input contact

The number of alarms is reduced to zero / the red LED extinguishes

42/98

Last change 10/2018 E-P | Subject to technical modifications

Example 2:

Pre-warn „power failure“

“power failure“ warning is shown in the controller

The warning record is shown even after the controller has been switched off and on again

If power supply was interrupted for a longer time period, no flow was determined during such

period and the capacity was not reduced

Manual regeneration is worthwhile then to avoid overriding the plant capacity

The warning record is acknowledged via the keys F3 or Enter

NOTE:

If several failures and alarms are evident, these must be eliminated and acknowledged all

one after the other.

43/98

Last change 10/2018 E-P | Subject to technical modifications

Record

Failure

Reason / background

Action

Pre-warn

Maintenance

necessary

Maintenance interval

soon running out

Arrange for maintenance soon and

confirm in menu

Alarm

Maintenance

necessary

Maintenance interval ran

out

Arrange for immediate maintenance

and confirm in menu

Pre-warn

Power failure

Separated for mains of

power failure

Acknowledge failure

Pre-warn

Brine lack

No saturated brine in

brine tank

Add salt into brine tank

Alarm

Brine lack

No saturated brine in

brine tank and a

regeneration is due to be

released

Add salt into brine tank

Pre-warn

Chlorinator

Blockage

The actual current is

outside the tolerance for

nominal current

Deposit on chlorine electrode

clean or replace

Pre-warn

Chlorinator

Blockage

The duration of the

chlorine production is

higher than the brine

intake period

Check brine intake period and

chlorine production duration and

adjust if necessary. Alarm delay set

too low

Alarm

Chlorinator

Saturation

The required current

cannot be achieved

even with quite high

voltage

Too low brine saturation

add salt tablets

possibly check hydraulics of brine

intake

Alarm

Chlorinator

Short circuit

Hardware error or false

terminal charge

Check installation

Alarm

head 1/2 time

exceeded

Move time of valve

motor too long

Check plug connections at valve and

terminals in the controller

Alarm

head ½ time

increments

Piston position not

reached

Check plug connections at valve and

terminals in the controller

Alarm

head 1/2 stdby current

Hardware error

Check pcb’s and terminals

Alarm

head 1/2 tract. current

Hardware error

Check pcb’s and terminals

Alarm

head 1/2 high current

Hardware error

Check pcb’s and terminals

Alarm

head 1/2 low voltage

Hardware error

Check pcb’s and terminals

Alarm

head 1/2 high voltage

Hardware error

Check pcb’s and terminals

Alam

Alternator low current

Hardware error

Check pcb’s and terminals

Alarm

Alternator high current

Hardware error

Check pcb’s and terminals

Alarm

Alternator time

exceeded

Move time of valve

motor too long

Check plug and socket contacts on

valve and terminal clamps on the

control unit

Alarm

Alternator low voltage

Hardware error

Check pcb’s and terminals

Alarm

flow fallen below

Too less flow

Increase removal

Alarm

flow exceeded

Too high flow

Reduce removal

Alarm

lack of pressure

Too low input pressure

Check input pressure

3.2 Alarm records

Below is a survey of possible alarm or warning records:

44/98

Last change 10/2018 E-P | Subject to technical modifications

LED red - OFF

The below display is shown when calling the menu point „alarm“ in case of troublefree operation:

No record, warning and no alarm actually evident.

4. Total hardness

The local mains water hardness is programmed in the menu point total hardness.

Setting range 5°dH to 80°dH (89 ppm to 1430 ppm)

5. Operation mode

The main menu item „Operation mode“ is used for release of regeneration. Furthermore

regeneration steps can be skipped under this menu item. It is displayed by a message if a menu

item should not be selectable due to technical reasons.

45/98

Last change 10/2018 E-P | Subject to technical modifications

Datentransfer

All Data > SD-Card

PAR Data > SD-Card

SYS Data > SD-Card

PROC-Data > SD-Card

SD- Card > All Data

SD- Card > PAR Data

SD- Card > SYS Data

SD- Card > PROC Data

Calib. > SD- Card

SD- Card > Kalib.

Delimiter

6. Operation settings

In the main menu item „Protocol settings“ the currently

programmed protocol settings can be accessed via “Info

Protocol”. For this purpose, no password is required.

In the second menu item you can change the protocol

settings. Access-Level 3 is required.

Under the menu item „Single recording“, the following

information will be stored on the SD card at the execution

time.

- Logging - Protocol (Systemtime, Date, … )

7. SD-Card (messaging)

The menu item „SD-Card“ is used for

transfer of data of the SD-Card to the

controller, and vice versa.

Description:

All data - PAR, SYS, PROC

PAR - Parameter Data

SYS - System Data

PROC - Process Data

Calib. - Calibration Data

An access level is not required for this

menu item in the Main menu!

46/98

Last change 10/2018 E-P | Subject to technical modifications

8. Language

The unit for mains (permanent) hardness as well as the unit for resin capacity is altered in

conjunction with the language setting.

Unit total hardness in German: °dH

Unit total hardness in English: ppm

Unit resin capacity in German: m³x°dH

Unit resin capacity in English: m³

The actual values and figures are converted and shown in the respective unit after the language has

been selected.

Example:

German display:

Total hardness - 20°dH Kapazität - 65 m³x°dH

English display:

Total hardness - 356 ppm Capacity - 1157 m³

9. System time

47/98

Last change 10/2018 E-P | Subject to technical modifications

Menu point

Display

Regeneration

Total number of regenerations

In case of Duplex or parallel system the sum of both vessels

Regen. F1

Number of regenerations Vessel 1

Regen. F2

Number of regenerations Vessel 2

Total volume

Total water volume treated in m³

Volume F1

Water volume treated in Vessel 1

Volume F2

Water volume treated in Vessel 2

Last regeneratioin

Date and time of last regeneration

Last regeneration F1

Date and time of last regeneration Vessel 1

Last regeneration F2

Date and time of last regeneration Vessel 2

Flow

Maximum determined flow since last regeneration of the Vessel in

operation

Save Information

The above mentioned informations – technical data will be stored on

the SD-Card (.csv file). For this action, access level 3 is required.

10. System update

11. Information

All operation and regeneration parameters can be called in the information menu.

48/98

Last change 10/2018 E-P | Subject to technical modifications

Alarms

Settings

Design

Single / Double / Parallel Unit

Rinsing

Refresh mode

Interval rinsing

Interval

Volume

Flow

Inputs

Brine cure

Ext. regeneration

Brine alarm

Pressure lack

Brine tank

1 brine tank

Regeneration mode

Amount

Time

Chlor. gen.

Chlor. gen. active

Selection Chlorine gen. A

Start delay

Target current

Tolerance

Period

Alarm delay

Blockage limit

Saturation lim.

Circulation

Minimum flow

delay

Capacity

Clack valve

Clack type

t-backwash

t-brine dr:/sl.

t-fast rinse

t-fill

t-brine format.

Forced regenerat.

Lock times

Operation valve

1st lock time

2nd lock time

3rd lock time

4th lock time

Universal out

Brine alarm, Regeneration, Warning

Cont. Type

Alarm sound

Total hardness

Service

System info

SW Version

Syspar-Vers.

Par-Vers

Cali.-Vers

Com. Module

Auto DLS time

Firmware Update

Op. time

Maintenance type

Maint. bef.

Maint. (Warn)

Maint. (Alarm)

Maintenance done

Reset

Reset brine timer

Diagnosis

Calibration

emBrick List

Operation mode

operation1

regeneration 1

regeneration step

12. Menu structure

49/98

Last change 10/2018 E-P | Subject to technical modifications

Protocol settings

Info Protocol

SD Card

Recording

Delimiter

Number. Of Elem.

Rec. Intervall

New.File Intervall

Settings Protocol

Recording

Delimiter

Rec. Intervall

New.File-Interval

Single recording

SD card

All Data > SD-Card

PAR Data > SD-Card

SYS Data > SD-Card

PROC-Data > SD-Card

SD- Card > All Data

SD- Card > PAR Data

SD- Card > SYS Data

SD- Card > PROC Data

Calib. > SD- Card

SD- Card > Kalib.

Delimiter

Language

German / English

System Time

System Date

Information

Regenerations

Regen. F1

Total capac.

Amount F1

Last Reg. (Date)

Last Reg. (Time)

Last Reg. F1 (Date)

Last Reg. F1 (Time)

max. flow

Save information

50/98

Last change 10/2018 E-P | Subject to technical modifications

13. Electrical installation / wiring / terminal posts

Work at electric equipment

- Prior any work at electric equipment, the system/machine must be set de-energized.

- All respective regulations (DIN, VDE, UVV) must be observed for installation and operation

of the controller.

- Repair work at electrical equipment must be carried out by skilled experts only!

- Electric equipment must be controlled in regular intervals!

- Any loose connections must be fixed!

- Damaged cable/wiring must be replaced immediately!

- Switchboard / controller casing must always be kept closed and locked! Access is reserved

to authorized staff!

- Switchboard / controller casing of electric equipment must never be cleaned by using a water

hose!

Any negligence of the information can result in damage of the controller as well as the total

system and, as a consequence loss of warranty claim!

51/98

Last change 10/2018 E-P | Subject to technical modifications

13.1 Electrical installation / wiring / terminal posts

Installation requirement

- The maximum admissible load of switching outputs as well as the total system capacity must

not be exceeded by the connected consumer.

- All inductive consumers (valves, motors, contactors, transformers) must be equipped with

suitable suppressors (RC-unit, varistor (VDR), diode etc.).

- High line disturbance levels of any external units (frequency converter, motors, inductive

furnaces etc.) existing next to the controller must be reduced by suitable measurement or

otherwise, respective external suppressors (mains filter) provided at the supply voltage input

of the controller.

- Transmitting (data) systems of any type, including mobile transmitting units must not be

operated next to the controller to avoid possible EMC influences.

Assembly direction

The below direction must be observed in view of PCB wiring:

- The clamps must be handled carefully and the wires clamped/inserted with minimum power

only.

- The connection clamps (without screws) are suited to take flexible wiring (without wire end

sleeve) up to 0.5 mm² (at sensor inputs) or flexible wiring (without wire end sleeve) 1.00 mm²

or 1.5 mm² rigid wire. Using wire end sleeves is not admissible in accordance with

supplier information.

- The screw connection terminals (PE 1 – PE 6) can take the following wires:

> rigid wires 0.14 – 2.5 mm²

> flexible wires 0.14 – 1.5 mm² or 0.25 – 1.5 mm² (with wire end sleeves)

- Prior putting into the clamp, the wire must be insulated over a length of min. 5 mm. It is

recommended to turn the wire end somewhat or to apply tin coat.

- The respective VDE regulations must be observed in view of all assembly work.

- Work at electric equipment must be carried out by skilled experts only.

Installation of controller

Installation shall be in the below sequence:

- Fixing of controller: the controller must be wall mounted in a dry, well accessible and well

visible area.

- The sensors / initiators must be connected (flow record).

- The actors must be connected (e.g. pumps, valves).

- Subsequently, the controller must be connected to mains.

The correct connected voltage must be observed!

52/98

Last change 10/2018 E-P | Subject to technical modifications

minimum

typical

maximum

Unit

Nom. operating voltage (AC)

205

230 250

V

Mains frequency

47

50 63

HZ

Nom. apparent power (excluding consumer)

6 8

15

VA

Ambient temperature (operation)

0

40

°C

Ambient temperature (storage)

- 10

60

°C

Rel. humidity (not condensing)

15

80

%

Inputs

Switching current

15

mA

Switching voltage

25

V

Outputs

Disruptive strength

250

V

Load AC

4

A

Load DC

1

A

Dimensions

Length 230

mm

Width

205

mm

Height

83

mm

13.2 Technical Data HC – softener controller

The controller must be operated in accordance with the below conditions:

53/98

Last change 10/2018 E-P | Subject to technical modifications

Input 24 VDC

clack board

Inputs and Outputs for

the control valves

Output 24 VDC for

the clack board

Output 24 VDC for

the chlorine board

Power supply

230 V / 50 Hz

Output

230 V / 50 Hz

Outputs with potential

230 V / 50 Hz

Relay outputs

potential free

Digital Inputs

potential-free

Output for

chlorinator

Input 24 VDC

chlorine board

PE-terminal 1-6

13.3 PCP equipment and terminal charge

Main board and wiring