Hydro systems SuperDos 20, Model 0.3%, Model 0.3% PAA, Model 2.5%, Model 2.5 % WSP Operating Manual

...

20

Operating Manual•Mode D'Emploi

Bediehnungs Handbuch •Manual de Operación

Manual de operação • Manuale d'uso

Model 0.3%

Model 0.3% PAA

Model 2.5%

Model 2.5 % WSP

Model 5%

Model 10%

Fluid Flow Range:

Débit d'eau:

Durchussmenge:

Caudal de trabajo:

Vazão Operativa:

Velocità di usso:

0.04 gpm to 20 gpm

0,15 l/mn to 76 l/mn

Injection Range

Dosage:

Dosierung:

Dosicación:

Injeção:

Dosaggio:

0.025% to 10%

1:4000 to 1:10

Operating Pressure:

Pression:

Druck:

Presión operativa:

Pressão operativa:

Pressione operativa:

5 to 100* psi

0,34 to 6,9 bar

*Specications vary by model.

*Les données techniques varient

selon les modèles.

* Technische Daten sind je nach

Modell unterschiedlich.

* Características técnicas varían

según modelo.

* Características técnicas variam

conforme o modelo.

* Le speciche variano a seconda

del modello.

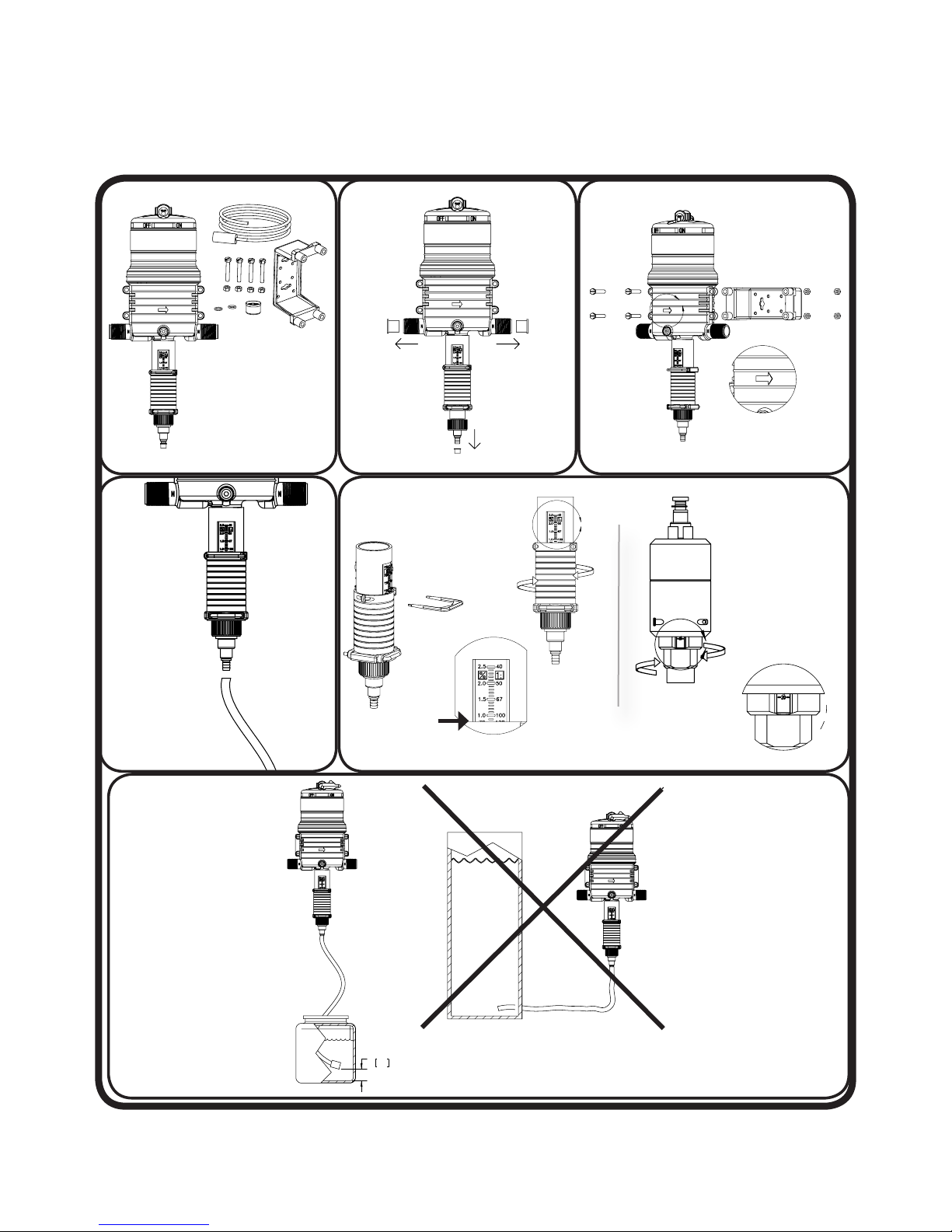

Quick Start Up

A

C

A

Puesta en marcha rápida

Démarrage Rapide

Schnell Antrieb

Inicialização rápida

A

A

↓

C

→

2

51

Part # 013825 Rev. G

English: 2

English....................................................3-21

Français................................................22-32

Deutsch.................................................33-43

Español.................................................44-54

English

Português.............................................55-65

Italiano..................................................66-83

Hydro Systems Company Ofces:

North America &

Global Headquarters:

Hydro Systems Company

3798 Round Bottom Road

Cincinnati, OH 45244

Phone: 513-271-8800

Fax: 513-271-0160

Toll Free: 800-543-7184

Asia Pacic:

Hydro Systems Asia Pacic

Unit A

1 Kelham Place

Glendenning, NSW 2761

Australia

Phone: 612-9625-8122

Fax: 612-9625-8177

Europe, Middle East,

Africa, & India

Hydro Systems Europe

Unit 3, The Sterling Centre,

Eastern Road

Bracknell, Berkshire

RG12 2PW

Europe

Phone: +44 1344 488880

Fax: +44 1344 488879

South America:

Hydro Systems South America

Rua Mogiana, 172,

Chacarras Reunidas,

Sao Jose Dos Campos,

Brasil

Phone: +55-12-3201-7707

Fax: +55-12-3201-7739

English: 3

Operating Principle

Accurate and Reliable

Installed directly in the uid supply line, the injector operates without electricity, using uid (water)

pressure as the power source. The uid drives the injector, which pulls the required percentage of

concentrate directly from the chemical solution container. Inside the Hydro Systems patented mixing

chamber, the concentrate is mixed with the uid, and the uid pressure forces the mixed solution

downstream. The amount of concentrate will be directly proportional to the volume of uid entering

the injector, regardless of variations in ow or pressure.

Chemical does not

→

come in contact

with the motor.

→

Fluid ow drives

motor piston.

*MiniDos model shown, example only.

SuperDos 20 is not equipped with on/

off lever.

Chemical is mixed

→

in the patented

mixing chamber.

→

Blended solution

English: 4

Intake from chemical

→

container

English

Contents

Operating Principle ...................................................................................................................... 4

Package Contents ........................................................................................................................ 6

Specications .............................................................................................................................. 6

Safety Precautions ....................................................................................................................... 7

Warranty Compliance ................................................................................................................... 7

General Tips ................................................................................................................................7

Operations ...................................................................................................................................8

Installation and Start-up .............................................................................................................. 9

Suggested Installation Diagram ................................................................................................... 9

Maintenance ............................................................................................................................. 10

Remote Injecting ........................................................................................................................ 10

Routine Maintenance Instructions .............................................................................................. 11

0.3%, 2.5%, 5% ........................................................................................................................ 11

Routine Maintenance Instructions - 10% .................................................................................... 12

Troubleshooting ......................................................................................................................... 13

Injector Repair Parts .................................................................................................................14

Lower end & wear parts kits 0.3% PAA(Rotating): .......................................................................15

Lower end & wear parts kits 0.3% (Rotating): ............................................................................ 16

Lower end injector & wear parts kits 2.5%: ................................................................................17

Lower end injector & wear parts kits 2.5% WSP: ........................................................................18

Lower end injector & wear parts kits 5%: ...................................................................................19

Lower end injector & wear parts kits 10%: ................................................................................. 20

Warranty .................................................................................................................................... 21

English

Please read this manual carefully before putting the Hydro Systems injector into operation.

This booklet has the information you will need for the use and care of your new Hydro Systems

injector. If you have any further questions about your injector, the warranty, routine maintenance or

proper usage, please contact your nearest distributor or Hydro Systems customer service.

These models are designed to inject liquid concentrate or soluble powder that are recommended

and approved for injection into uid systems.

lt is the responsibility of the operator to determine the correct dosage settings of the unit using the

chemical manufacturers’ recommendation for dispensing their product, and to assure that proper

dosage is being maintained.

Maintenance and Warranty

Hydro Systems offers a three year limited warranty from the original date of purchase for

manufacturing or materials defects only. With proper use and care, your injector should provide you

long-term performance. Please review the complete warranty information on page 21.

For Your Records

The serial number of your Hydro Systems injector is located

on the injector body. Please record this number in the space

below and reference it when calling your distributor or Hydro

Systems for information, parts and service.

Serial #..............................................................................

Date Purchased ................................................................

This document does not form a contractual engagement on the part of Hydro Systems and is for

information only. Hydro Systems reserves the right to alter product specications or appearance without prior notice.

English: 5

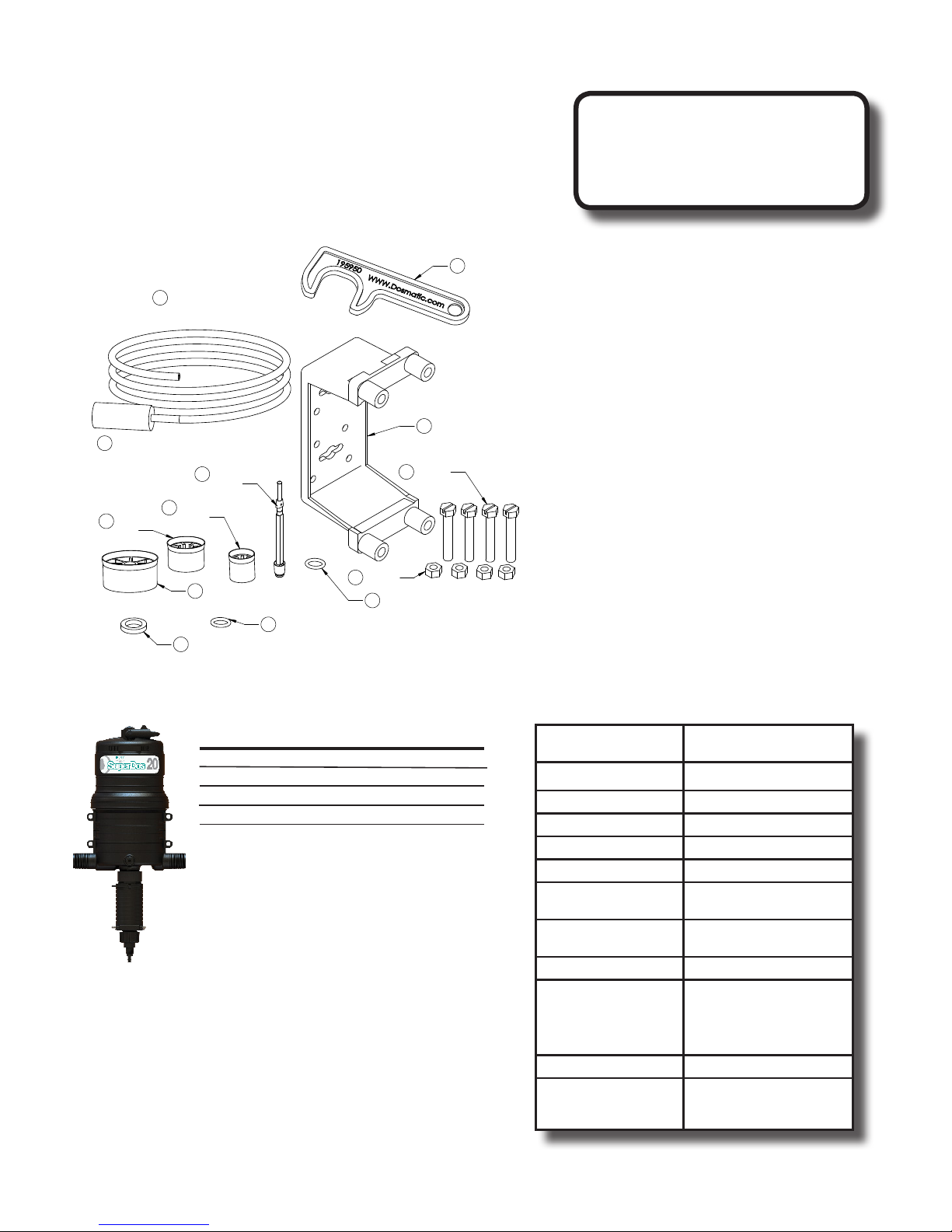

Package Contents

The injector is packaged

with the following items:

Injector (not shown) Mounting Bracket

Dosage Piston Mounting Nuts and Bolts

O-ring Filter

Manual (not shown) Suction Tube

Lower End Wrench (0.3% only)

95

195950

25

5% 011025

2.5% 010025

0.3% 010025

56

194006

27

10% 011849M

5% 011018

2.5% 011017

0.3% 003067

194309

2.5%

44

5%

51

0.3%

44

010044

44

10%

44

194022

2.5% WSP

011803

194909

58

14

212005V on the 2.5% & 5%

212007V on the 10%

57

194016

194017

17

212005VH (black)

Certied ISO 9001:2008 QMS

for the Hydro Systems Brand

Model NPT BSP

0.3% Rotating 113228R 113728R

0.3% PAA Rotating 113228RK 113728RK

2.5% 113205 113705

2.5% WSP 113205WSP 113705WSP

5% 113206 113706

10% 113207 113707

10% Remote

Injection

113232 113233

Specications

SuperDos 20 gpm

(

100 max. psi

Model 0.3% 0.025% - 0.30% (1:4000 - 1:333)

Model 2.5% 0.20% - 2.5% (1:500 - 1:40)

Model 5%** 0.4% - 5% (1:250 - 1:20)

Model 10%* 2% - 10% (1:50 - 1:10)

Flow Rate: 0.04 - 20 gpm (0,15 - 76 l/mn)

Operating Pressure: 5 - 100 psi** (0,34 - 6,9 bar)

Pipe Coupling: 1” NPT/BSP

* 10% model maximum operating pressure is

65psi (4,5 bar)

**5% with remote injection kit maximum

operating pressure is 60 psi (4bar).

)

Housing Proprietary Engineered

Dosing Accuracy +/- 10% of ratio

Repeatability +/- 3% of ratio

Pressure Loss Available upon request

Maximum Temp. 100ºF (38ºC)

Minimum Temp. 34ºF (1ºC)

Maximum vertical suction

of concentrate

Maximum horizontal

suction of concentrate

Self-Priming Yes

Seal Material Available:

*Contact your representative for

specic chemical information

Maximum Viscosity 1,500 cP (Ex. Honey)

Recommended

Accessories

Composite Material

13 Feet (3.6 Meter)

49 Feet (15 Meter)

Aas

Viton

EPDM

FFKM

Teon Coated

140 mesh (104 micron)

lter, check valve, pressure

regulator, ow restrictor.

English: 6

Safety Precautions

Warranty Compliance

Warning, Please read precautions thoroughly before operation. Must meet all applicable

!

local codes and regulations.

Remove Red Caps Prior to Installation

Your injector is 100% factory tested before delivery and

may contain a small amount of water. The three red

plastic caps are tted after testing to ensure cleanliness

of the injector.

Before Applying Aggressive Chemicals

Please consult your distributor, chemical manufacturer

or contact Hydro Systems's customer service to conrm

compatibility with your injector. Always wear proper safety

protection as recommended by chemical supplier.

Label all Fluid Lines, Valves and Connections

If the solution that is being injected is not suitable for

drinking, all uid lines should be labeled:

Warning not for human consumption!

Monitor Outlet Flow

It is the user's responsibility to monitor the output of

chemical injected.

A Filter is Recommended and Required

Install a lter of 140 mesh (104 micron) or ner

depending on your uid quality to prolong the working

life of the injector and for the warranty to be valid. A

lter is imperative since most uid contains impurities or

particles, especially if the uid source comes from a well,

pond or lake.

Avoid a Potentially Hazardous Chemical Accident

Select a safe location. Chemical container should be

kept away from children and/or high usage areas and

the location must also not be susceptible to freezing

temperatures.

Avoid Solution Contamination

Use only clean FILTERED uid. Do not allow contaminants

to enter the solution container. They can be pumped into

the uid line and may cause the spread of disease. Dirt,

debris and other contaminants in the solution container

may cause excessive wear to the unit.

Fluid Temperature

Min: 34°F (1°C) Max: 100°F (38°C)

Maximum Fluid Pressure

0.3%, 2.5%, 5% - 100 psi (6,9 bar)

10% - 65 psi ( 4,5 bar)

5% model with remote injection kit has maximum operating

pressure of 60 psi (4 bar).

Install a pressure regulator and/or pressure relief valve to

ensure operating pressure does not exceed the maximum

specication.

Before Removing An Injector From The System

Release uid pressure. While the system is in operation, turn

off the incoming uid valve. Leave the out going valve open

this will relieve the pressure at the injector and all parts of

the system after the injector. Injector is now safe to remove.

English

Please read this instruction manual thoroughly.

Following the procedures, will increase the life of your injector.

For A Long Service Life

Start with clean uid by using an inline lter to reduce

impurities. Keep the solution container covered and

clean. Keep the suction tube lter 2" (5 cm) from

the bottom of the container. Perform maintenance

procedures as recommended (see Maintenance page 10).

Liquid Concentrate, Soluble Product, Soluble and

Wettable Powder use

Ensure that the chemical, when mixing with water, is

thoroughly mixed and or completely dissolved before

using injector. For soluble and wettable powder injection,

it is recommended to use a Hydro Systems WSP injector

or install a WSPL lower end conversion kit to an existing

Hydro Systems dosage piston model injector.

General Tips

Keep From Extreme Temperature

Protect the injector from freezing temperatures or excessive heat.

Rinse Injector After Each Use

Additive allowed to remain in injector can dry out, foul

or damage the lower end at the next start-up (see

Maintenance page 10).

Injector Not in Use for an Extended Period

If the injector has not been stored properly deposits may have

dried onto the motor (see Maintenance page 10). Before

operation, soak entire unit into room temperature water

approx. 72°F (22°C) for an eight hour period.

English: 7

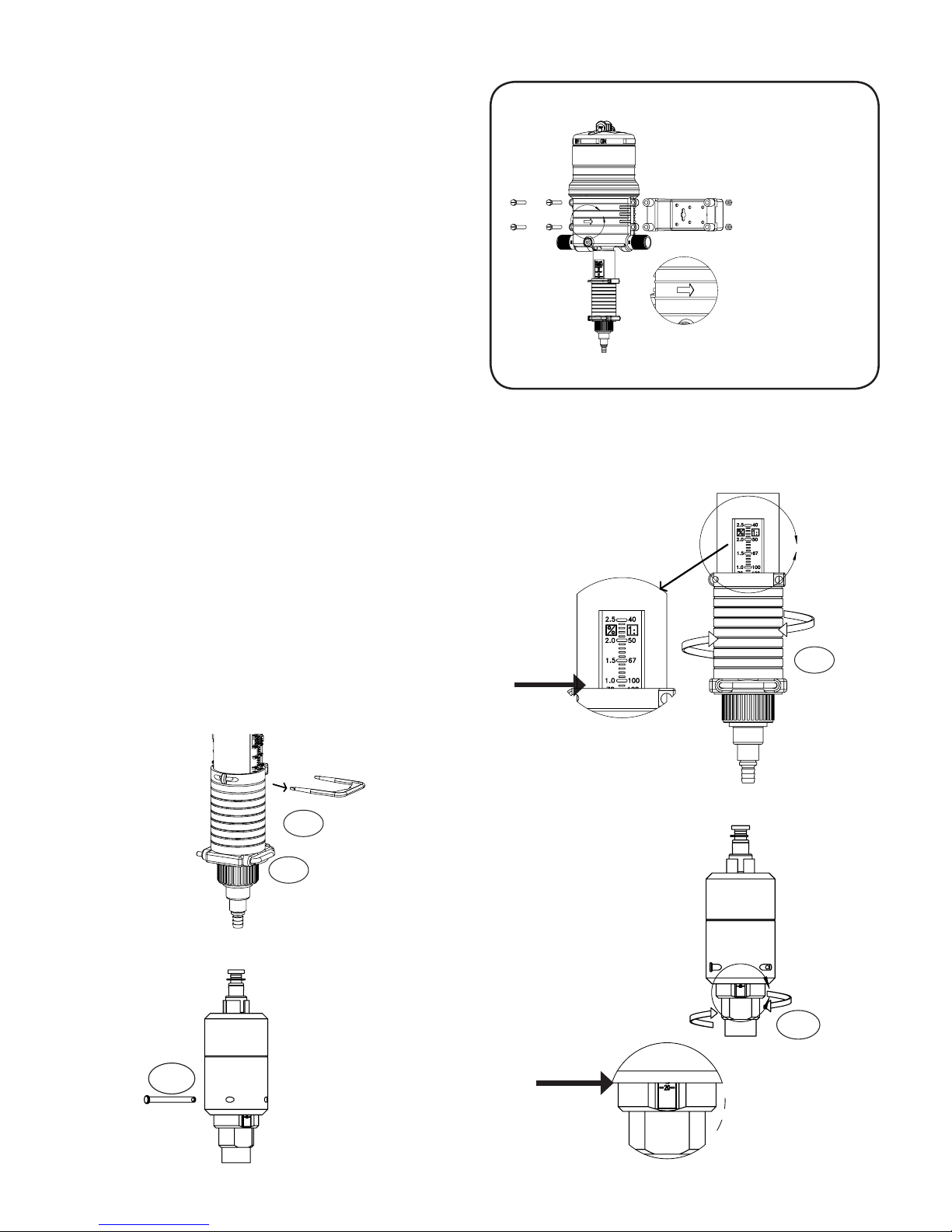

Operations

A

C

A

A

Clicking Sound is Normal

Fluid owing through the injector will automatically cause

the injector to “click” and inject a set amount of solution

into the uid line. The higher the ow rate the more

frequent the "clicking". The injector is designed to inject

solution proportionally (at the same set ratio) regardless

of uid ow.

Service Fluid Flow

Fluid ow and pressure must be within the established

specications (see Specication on page 6) for your

model.

Change Feed (Injection) Rate

The feed rate on the injector is adjustable EVEN WHILE

OPERATING AND UNDER PRESSURE. To change feed

rate see (Fig. 1 and Fig. 2). Do not remove #79 when

injector is under pressure.

SuperDos 20 0.3%, 2.5% 5%

1. Remove Upper Interlock Pin (#65) (Fig. 1).

2. Rotate Ratio Adjuster Sleeve (#61) up or down to the

desired setting (Fig. 2). Use the top of the Ratio Adjuster

Sleeve to line up with the desired feed rate on the

setting (Fig. 2a).

3. Re-insert Upper Interlock Pin (#65). Clip must be

parallel with settings to be able to re-insert.

SuperDos 20 10%

1. Remove Ratio Locking Pin (#79) (Fig 1a.).

2. Rotate Outer Cylinder (#7) up or down to the desired

setting (Fig. 2b). Use the bottom of the Ratio Adjuster to

line up with the desired feed rate setting (Fig 2c)

Fig. 3

Typical wall

mounting

A

Fig. 2

A

NOTE: Do not screw Ratio Adjuster Sleeve below lowest

setting line. Measure outlet uid to assure desired feed

rate is being delivered.

Fig. 1

#65

#79

Fig. 1a

#79

Fig. 2a

Fig. 2c

#61

Fig. 2b

C

#7

English: 8

Installation and Start-up

Refer to Fig. 3 and Fig. 4

Fluid Filter (Required)

Install a lter of 140 mesh (104 micron) or ner depending

on your uid quality to prolong the working life of the injector

and for the warranty to be valid. Hydro Systems recommends a

Twist II Clean® lter that can be ordered with your injector.

Mounting Injector

Securely fasten your injector to a solid object such as a wall or in

a cold uid line. Note arrow on injector indicates uid ow.

Backow Preventor (Recommended)

Install one that meets local code requirements.

Pressure Safety Release Device (Recommended)

Prevents pressure from exceeding specications of the unit.

Bypass Valve Set-up (Recommended)

Allows the injector to be taken off-line for maintenance

or storage when not in use.

Fluid-Hammer Arrester (Recommended)

Prevents uid-hammer damage to the injector when operating

quick closing solenoid, pneumatic or hand-operated ball valves

on the uid system.

Anti-Siphon Valve (Optional)

To prevent solution from being siphoned out (from the solution

container) into the feed lines when the upstream valve is shut off.

The anti-siphon valve must be installed on the downstream outlet.

Additional Siphoning Prevention

Place solution container on a level below the injector suction tube

tting. Using the inlet side as a shut-off valve could cause full

strength solution to siphon into the feed line.

Solution Container

Use any size container. A lid or cover is recommended. To connect

your solution container, gently push the end of the suction tube

onto the bottom of the suction tube tting assembly.

Place the lter into the solution container at least 2" (5cm) from

the bottom and ll with at least 2" (5cm) of chemical solution.

Never Use Petroleum Based Lubricants

The injector is shipped with a thin coat of silicone around the

seals for ease-of-assembly. Petroleum based lubricants such as

Vaseline©, baby oil, WD40©, or motor oil on the O-rings or any part

of the injector should never be used as this can cause particles to

adhere and clog or damage the injector.

Check System for Leaks and Start-Up Procedures

Open the bypass valve (A), close inlet valve (B) and outlet

!

valve (C) to prevent uid ow into the injector. SLOWLY

turn on the main uid line. Run uid ows between 5 -12

gpm (11-45 l/m) through the plumbing system. Turn on all of the

valves located downstream from your injector to release trapped

air. SLOWLY turn on the inlet valve (B). Open the outlet valve (C)

and close valve (A). As uid travels through the injector, you will

hear a “clicking” sound. Check for leaks and correct if necessary.

English

Suggested Installation Diagram

ANTI-SIPHON

VALVE

(OPTIONAL)

FLOW CONTROL

VALVE @ OUTLET

(OPTIONAL)

PRESSURE

REGULATOR

(OPTIONAL)

BACK FLOW

PREVENTOR

(RECOMMENDED)

INLET FILTER

140 MESH / 104 MICRON

(MINIMUM REQUIRED)

PRESSURE

GAUGE

(OPTIONAL)

FILL

VALVE

(OPTIONAL)

INLET VALVE

(RECOMMENDED)

PRESSURE SAFETY

DEVICE

(RECOMMENDED)

Fig. 4

DIRECTION OF FLOW

(B)

FLOW INDICATOR

BYPASS

(A)

FLUID HAMMER

ARRESTER

(RECOMMENDED)

BYPASS VALVE

(RECOMMENDED)

OUTLET VALVE

(RECOMMENDED)

SUCTION TUBE

COVERED CONTAINER

SOLUTION FILTER

(C)

6" minimum

152.4 mm

2" REQUIRED

50 MM

English: 9

Remote Injecting

Fig. 5

Remote Injector

Kit shown on a

single injector.

0.3%, 2.5% & 5%

Models

10% Models

Maintenance

Reference numbers refer to Pages 14 - 20

RINSE INJECTOR AFTER EACH USE

Additive allowed to remain in injector can dry, foul or

damage the lower end at the next start-up. Place suction

tube into a 1 qt. (0.95 liters) or more container of fresh

ltered water. Flow fresh water through the injector by

operating until container is empty. This procedure is not

needed for continuous operation.

CLEAN SOLUTION CONTAINER

Keep covered to prevent dirt, debris from entering the

container. Rinse container thoroughly and often. Do not

mix chemicals together that might react and cause a

precipitate. Use FILTERED uid when lling container.

Remote Injector Kit (not included)

Is recommended for the following:

Kit Part Numbers

012705

Single Injector:

To prevent mineral buildup within the body of the unit.

Use when injecting chemicals that cause minerals to

precipitate from uid (see Fig. 5)

NOTE: when mixing more than one chemical, always refer

to your chemical manufacturer information guide for

proper application. Contact your local distributor or Hydro

Systems customer service for information or to order.

Perform these maintenance

procedures to extend the life of your unit.

Refer to page 15 & 16

SuperDos 20 (0.3%) Model (Including PAA)

Every 3 - 6

Months

1. Clean seal areas (#13).

2. Check #17 O-ring,

#68 Cylinder, clean

and/or replace as

necessary.

Every 6 - 12

months

1. Replace #17 O-ring

and #51 Dosage Piston

Shaft Assembly.

2. Clean and/or replace

#13 Check Poppet, #11

Suction Tube Fitting.

Replace as

necessary

1. #68 Cylinder

2. #51 Shaft

Assembly

CLEAN SUCTION TUBE FILTER SCREEN

Inspect each time new solution is added. Clean lter

screen (#27) and suction tube (#25) as necessary by

rinsing in fresh water. Replace if necessary. Keep lter

screen off bottom of solution container to prevent dirt

and precipitate from clogging lter.

CLEAN INLET FILTER

Clean or replace inlet lter as required to increase the life

of the unit as well as reduce pressure loss.

BYPASS INJECTOR

When not in use place the injector in bypass mode by

using the three valve bypass.

STORAGE

For extended storage, rinse injector (see "Rinse Injector

After Each Use") and place underwater in a container.

Apply monthly, <0.1 oz. (29 ml) of chlorine bleach to

avoid algae growth. KEEP FROM FREEZING.

Refer to page 17, 18 & 19

SuperDos 20 (2.5% & 2.5% WSP), (5%) Models

Every 3 - 6

Months

1. Clean seal areas

(#14 & #13, #44 WSP).

2. Check #17 O-ring,

#7 Cylinder, clean

and/or replace as

necessary.

Every 6 - 12

months

1. Replace #17 O-ring

and #44 Dosage Piston/

gasket (WSP model).

2. Clean & inspect #13

Check Poppet , #11

Suction Tube Fitting.

1. #7 Cylinder

2. #14 (#44 - WSP)

O-ring

Refer to page 20

SuperDos 20 (10%) Models

Every 3 - 6 Months Every 6 - 12

months

1. Clean seal areas (#14).

2. Check #17 O-ring, #7

Cylinder, clean and/or

replace as necessary.

1. Replace #17 O-ring

and #44 Dosage Piston.

Clean and/or replace.

2. Replace #60 hose kit.

Replace as

necessary

Replace as

necessary

1. #7 Cylinder

2. #14 O-ring

English: 10

Routine Maintenance Instructions

0.3%, 2.5%, 5%

↓

↓

English

Step 1.

Unscrew LOWER END

CYLINDER ASSEMBLY from

body. Remove LOWER END

CYLINDER ASSEMBLY

Step 4. For 2.5% & 5%

Replace #44 DOSAGE PISTON

ared-end up and #14 O-RING.

Step 2.

Rotate #51 SHAFT 90º and pull

from body.

↓

Step 5. For 2.5% WSP

Pinch and pull #44 DOSAGE

GASKET over the retainer lip. Slide

off the #51 SHAFT ASSEMBLY.

Step 3.

Pry the #15 SEAL RETAINER from

the injector. Pry #17 O-RING from

the unit. NOTE: O-ring may still be

seated at the base of the unit.

Step 5a. For 0.3%.

Replace LOWER SHAFT ASSEMBLY

#51 into upper shaft.

Step 6.

Reinsert #15 SEAL RETAINER

and #17 O-RING onto # 51

SHAFT ASSEMBLY.

Step 7.

Reinsert #51 SHAFT ASSEMBLY into

body and rotate 90º to lock. Conrm

the shaft is locked in by gently

tugging on the shaft. Shaft should

remain inserted.

Step 8.

Screw LOWER END CYLINDER

ASSEMBLY onto body. Ensure

#16 GASKET is seated on the top

of cylinder assembly.

English: 11

Routine Maintenance Instructions - 10%

↓

Step 1.

Unscrew LOWER END

ASSEMBLY from body.

Step 4.

Remove the #73 DOSAGE PISTON

GUIDE and replace #44 DOSAGE

PISTON and #14 O-ring.

Step 2.

Remove LOWER END ASSEMBLY .

↓

Step 5. Unscrew #72 ADAPTER and

remove.

Step 3.

Remove #93 CAPSCREW from the

end of the shaft using a wrench

and nut driver.

Step 6.

Remove and replace #17 O-RING

Step 7.

Re-install the new #44 DOSAGE

PISTON and #73 DOSAGE PISTON

GUIDE. Tighten snug using a nut

driver.

English: 12

↓

Step 7a.

NOTE: #44 DOSAGE PISTON must

be installed ared end up.

↓

↓

Step 8.

Screw LOWER END ASSEMBLY

onto body. Hand tighten only.

Troubleshooting

New Install - Always Pressure Up Slowly (Follow start up on page 9)

Problem Cause Solution

Are the red plugs at the inlet, outlet and suction tube tting openings removed?

Is the unit installed backward? The arrow on the unit must point in the

Fluid not owing through system

No Clicking

Sound

Fluid owing through system

Injector in Operation or After Scheduled Maintenance

Problem Cause Solution

Main Piston Assembly #9 worn Replace # 9 Main Piston Assembly. Clean uid lter.

Cover #1 or main body #40 worn

No Clicking

Sound

or scored

By-Pass Valve (A) not closed Set By-pass valve (A) to the closed position.

Dirty or plugged inlet lter Ensure mesh size is correct for proper ltration. Clean lter.

#17 Worn or not seated properly Re-seat #17 or replace.

direction of the uid ow.

If still not clicking, do not open the upper body. Call Hydro Systems

Customer Service.

Fluid rate is below or exceeds rated service ow of injector. (see

Specications page 6).

Has the new injector been stored for an extended period. If so, submerge

the injector in room temperature uid for 24 hours so that the working

parts can reabsorb uid and swell back to the proper size.

If below increase ow rate, if above, reduce ow rate.

Operating pressure exceeds maximum limit. Install a pressure reducer

valve. (see Specications page 6).

By-Pass Valve (A pg.9) not closed. Check and set valve to the OFF

position.

Replace and install or clean uid lter.

English

Problem

Clicking

Sound

No Suction Of

Solution

Cause

Cylinders #7 or #68 worn. Replace.

Dosage piston/gasket (WSP model)

#44 (0.3% model #51) worn or

installed incorrectly

O-ring retainer #15 installed

incorrectly

O-ring seat #14 or dosage piston/

gasket #44 (0.3% model #51)

damaged

#17 O-ring worn and/or loose Replace.

Suction tube #25 or suction tube

tting #11 cracked, leaking or

clogged suction tube lter

Check valve #13 leaking Clean & replace as necessary.

Replace. Ensure during maintenance replacement that #44 was

installed correctly ared-end up.

Install correctly.

Replace.

Replace and/or clean as necessary.

Solution

Problem Cause Solution

Clicking

Sound.

Under

Injecting

#44 (0.3% model #51) Dosage

Piston/gasket (WSP model) worn

#7 (#68 - 0.3%) Inner Cylinder worn Replace.

Unit operates at high-ow and not

at low ow

Main Piston Assembly #9 worn Replace # 9 Main Piston Assembly. Clean uid lter.

Cover #1 or main body #40 worn

or scored

Replace.

Replace #17 O-ring.

Replace and install or clean uid lter.

Problem

Fluid

Re-lling

Solution Tank

Check valve #13 leaking Check seat area on suction tube tting #11. Check valve and seal must

Washer seal on #13 is swollen or

chemical attack

Cause

Solution

t loose in the suction tube tting. Clean seal and inside tting for debris.

Replace with new check valve assembly.

English: 13

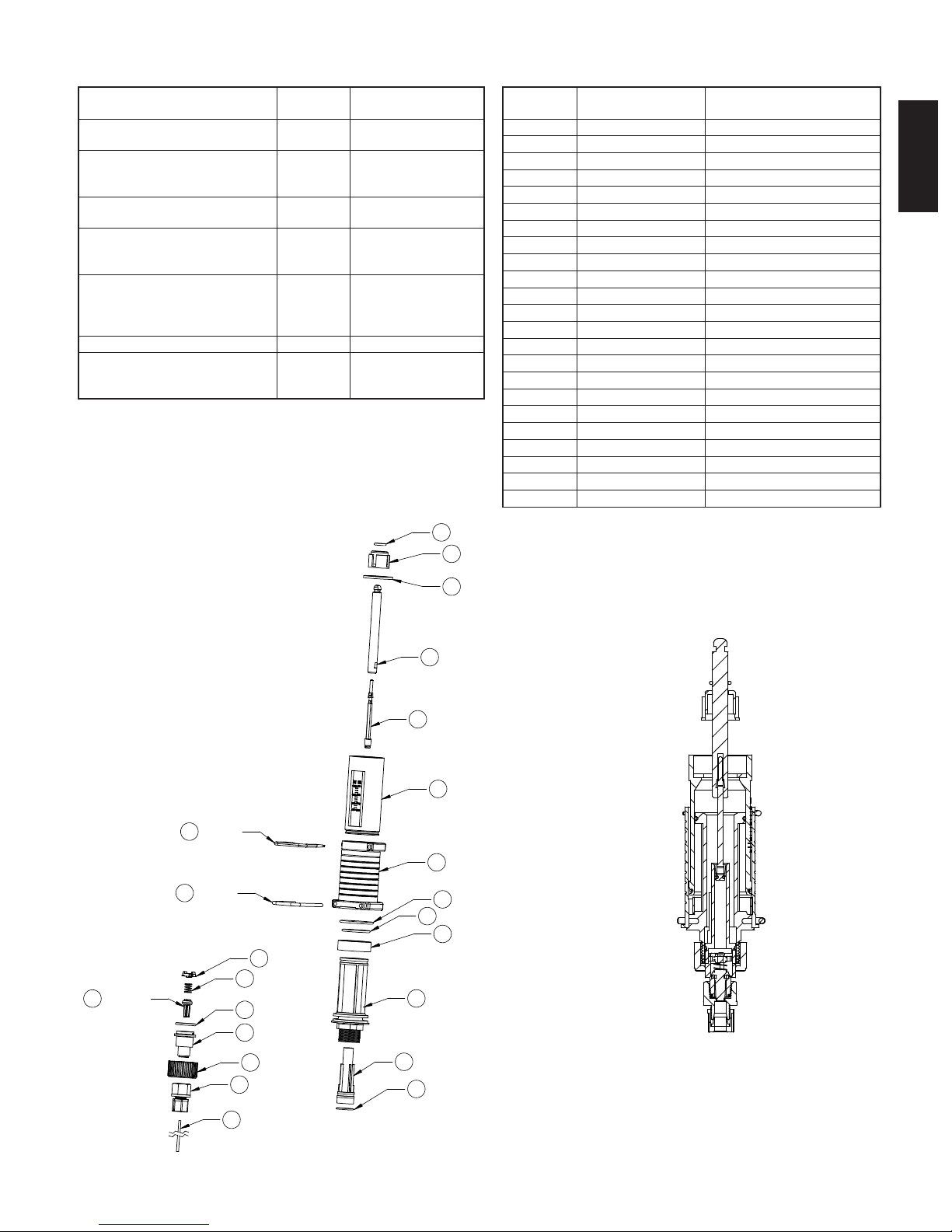

Injector Repair Parts

Ref. # Part # Description

1 194610 Upper Body (Must Order W/#88)

3 194605 Mixing Chamber Gasket

9 011876VH Piston Assembly (Must Order With #21)

9 011879T Piston Assembly 10% (Must Order With #21)

21 011172 Shaft Assembly

34 004014 Hairpin

40 011031 Lower Body NPT 1"

40 011031B Lower Body BSP 1"

85 194612 Upper Shaft Pin

88 194615 Non Bypass Plug

89 197090 Washer

85

194612

1

194610

89

197090

88

21

194615(2x)

34

004014

011172

9

011876

011879T 10%

3

194605

English: 14

40

011031 NPT

011031B BSP

Lower end & wear parts kits 0.3% PAA(Rotating):

Kit A – Wear Parts Kit (shaft assy,

O-ring)

Kit C – Wear Parts Kit (Kit A, inner

cylinder, O-ring)

Kit D – Suction Tube Fitting Assy

(O-ring, spring, tting, twistlock,

check poppet)

Kit E – Wear Parts Kit (Kits C & D,

gasket)

Kit F – Lower End Cylinder Kit (inner

& outer cylinder, ratio adjuster,

O-rings, pins, gasket, lower end stop)

Kit G - Complete Lower End, solution

tube, compression tting

Kit H – Motor Piston Assy 011863 9, 21

Kit M – Mounting Bracket Kit

(mounting bracket, 4 hex caps &

nuts)

012310K 17, 51

012311RK 17, 51, 63, 68

011463RK 10, 11, 12, 13, 80

012312RK 10, 11, 12, 13, 16, 17,

51, 63, 68, 80

012313RK 7, 16, 61, 63, 64, 65,

66, 67, 68, 78,79

012314RK 7, 10, 11, 12, 13, 15,

16, 17, 25, 27, 51, 52,

61, 63, 64, 65, 66, 67,

68, 71, 78, 79, 80

011432 56, 57, 58

Manual

Reference

7 194408 Cylinder, inner

10 194418H Spring

11 011452 Suction tube tting

12 212120X O-ring

13 011453F Check poppet

15 194004 Seal retainer, O-ring

16 010016S Lower End Gasket

17 212005K O-ring

25 010029 Suction tube, 1/4” ID x 5ft

27 005230 Compression tting

51 011803K Lower shaft Assy.

52 194007 Upper shaft

61 194406P Ratio adjustment sleeve

63 212516X O-ring

64 212017X O-ring, inner cylinder, lower end

65 194310D Pin, upper interlock

66 212025V O-ring, outer cylinder, lower end

67 194611 Cylinder, outer

68 194030 Cylinder, inner for #7

71 194414 Nut, suction tube tting

78 194620 Lower end stop

79 194410SS Pin, narrow interlock

80 194415 Twistlock

Part # Description of Part

English

13

011453F

65

79

194310

194410

10

12

11

80

194415

194418

212120X

011452

52

51

64

7

17

212005K

15

16

194007

011803K

67

194611

61

194406

66

212025V

212017X

78

194620

194408

194004

010016

71

194414

27

005230

25

010029

68

194030

63

212516X

Lower End

Assembly

English: 15

Lower end & wear parts kits 0.3% (Rotating):

Kit A – Wear Parts Kit (shaft assy, O-ring) 012310 17, 51

Kit C – Wear Parts Kit (Kit A, inner cylinder,

012311R 17, 51, 63, 68

O-ring)

Kit D – Suction Tube Fitting Assy (check

poppet, O-ring, spring, tting, twistlock)

011463V 10, 11, 12, 13,

80

Kit E – Wear Parts Kit (Kits C & D, gasket) 012312R 10, 11, 12, 13,

16, 17, 51, 63,

68, 80

Kit F – Lower End Cylinder Kit (inner & outer

cylinder, ratio adjuster, O-rings, pins, gasket,

lower end stop)

Kit G - Complete Lower End, lter, solution

tube

012313R 7, 16, 61, 63,

64, 65, 66, 67,

68, 78,79

012314R 7, 10, 11, 12,

13, 15, 16, 17,

25, 27, 51, 52,

61, 63, 64, 65,

66, 67, 68, 71,

78, 79, 80

Kit H – Motor Piston Assy 011863 9, 21

Kit M – Mounting Bracket Kit (mounting

011432 56, 57, 58

bracket, 4 hex caps & nuts)

17

212005

15

194004

16

010016

25

010025

52

194007

Manual

Part # Description of Part

Reference

7 194408 Cylinder, inner

10 194418H Spring

11 194417 Fitting, suction tube, ¼”

12 212120

O-ring

*Must specify material

13 011453A Check poppet

15 194004 Seal retainer, O-ring

16 010016 Lower End Gasket

17 212005

O-ring

*Must specify material

25 010025 Suction tube, ¼” x 5’

27 003067 foot valve ¼” ID

51 011803

Lower shaft assy.

*Must specify material

52 194007 Upper shaft

61 194406P Ratio adjustment sleeve

63 212516

*Must specify material

64 212017

*Must specify material

O-ring, inner cylinder

(#68)

O-ring, inner cylinder,

lower end

65 194310D Pin, upper interlock

66 212025

*Must specify material

O-ring, outer cylinder,

lower end

67 194611 Cylinder, outer

68 194030 Cylinder, inner for #7

71 194414 Nut, suction tube tting

78 194620 Lower end stop

79 194410SS Pin, narrow interlock

80 194415 Twistlock

13

011453A

65

79

194310

194410

27

10

11

003067

80

194418

12

194417

68

71

63

194415

212120

194030

194414

212516

78

51

67

61

64

7

011803

194611

194406

66

212017

194620

194408

212025

Lower End

Assembly

English: 16

Lower end injector & wear parts kits 2.5%:

Kit A – Wear Parts Kit (dosage

piston and O-rings)

Kit B – Wear Parts Kit (Kit A &

shaft)

Kit C – Wear Parts Kit (Kit A,

inner cylinder and O-ring)

Kit D – Suction Tube Fitting Assy

(check poppet, O-ring, spring,

tting, twistlock)

Kit E – Wear Parts Kit (Kits C &

D, shaft, gasket)

Kit F – Lower End Cylinder Kit

(inner & outer cylinder, ratio

adjuster, O-rings, pins, gasket)

Kit G - Complete Lower End,

lter, solution tube

Kit H – Motor Piston Assy 011863 9, 21

Kit M – Mounting Bracket Kit

(mounting bracket, 4 hex caps

& nuts)

011850V 14, 17, 44

011945V 14, 17, 44, 51

011850CV 7, 14, 17, 44, 64

011463V 10, 11, 12, 13, 80

011833PV 7, 10, 11, 12, 13,

14, 16, 17, 44, 51,

64, 80

011961V 7, 16, 61, 64, 65, 66,

67, 79

011843PV 7, 10, 11, 12, 13, 14,

15, 16, 17, 25, 27,

44, 51, 61, 64, 65,

66, 67, 71, 79, 80

011432 56, 57, 58

17

16

212005

15

44

194004

010016

010044

Manual

Reference

7 194404P Cylinder, inner

10 194418 H Spring

11 194 417 Fitting, suction tube,

12 212120

13 011453A Check poppet

14 212005

15 194004 Seal retainer, O-ring

16 010016 Lower End Gasket

17 212005

25 010025 Suction tube, 1/4” x 5’

27 011017 Filter, for suction tube,

44 010044P Dosage Piston

51 194301F Shaft

61 194406P Ratio adjustment sleeve

64 212017

65 194310D Pin, upper interlock

66 212025

67 194407P Cylinder, outer

71 194414 Nut, suction tube tting

79 194410SS Pin, narrow interlock

80 194415 Twistlock

Part # Description of Part

1/4”

*Must specify material

*Must specify material

*Must specify material

*Must specify material

*Must specify material

O-ring

O-ring

O-ring

1/4” ID

O-ring, inner cylinder,

lower end

O-ring, outer cylinder,

lower end

English

11

13

194417

011453A

194413

194416

65

79

194310

194410

010025

011017

80

10

194418

12

25

27

194415

212120

14

51

67

66

64

212005

194301

194407P

212025

61

194406

212017

7

194404

71

194414

Lower End

Assembly

English: 17

Lower end injector & wear parts kits 2.5% WSP:

Kit A – Wear Parts Kit (dosage

011850WSP 17, 44

gasket and O-rings)

Kit B – Wear Parts Kit (Kit A,

011945WSP 17, 44, 51

& shaft)

Kit C – Wear Parts Kit (Kit A,

011850CWSP 7, 17, 44, 64

inner cylinder and O-ring)

Kit D – Suction Tube Fitting

011463V 10, 11, 12,13, 80

Assy (check poppet, O-ring,

spring, tting, twistlock)

Kit E – Wear Parts Kit (Kits C &

D, shaft, gasket)

011833WSP 7, 10, 11, 12, 13,

16, 17, 44, 51,

64, 80

Kit F – Lower End Cylinder Kit

(inner & outer cylinder, ratio

011961WSP 7, 16, 61, 64, 65,

66, 67, 79

adjuster, O-rings, pins, gasket)

Kit G - Complete Lower End,

lter, solution tube

011843WSP 7, 10, 11, 12, 13,

15, 16, 17, 25, 27,

44, 51, 61, 64, 65,

66, 67, 71, 79, 80

Kit H – Motor Piston Assy 011863 9, 21

Kit M – Mounting Bracket Kit

011432 56, 57, 58

(mounting bracket, 4 hex caps

& nuts)

17

16

212005

15

010016

194004

Manual

Part # Description of Part

Reference

7 194023 Cylinder, inner

10 194418 H Spring

11 194 417 Fitting, suction tube,

1/4”

12 212120

O-ring

*Must specify material

13 011453A Check poppet

15 194004 Seal retainer, O-ring

16 010016 Lower End Gasket

17 212005

O-ring

*Must specify material

25 010025 Suction tube, 1/4” x 5’

27 011017 Filter, for suction tube,

1/4” ID

44 194022 Dosage Gasket

51 194019 Shaft

61 194406P Ratio adjustment sleeve

64 212027

*Must specify material

O-ring, inner cylinder,

lower end

65 194310D Pin, upper interlock

66 212025

*Must specify material

O-ring, outer cylinder,

lower end

67 194407WSP Cylinder, outer

71 194414 Nut, suction tube tting

79 194410SS Pin, narrow interlock

80 194415 Twistlock

13

011453A

194413

194416

79

65

194310

194410

25

10

11

71

27

80

12

010025

011017

194415

194418

212120

194417

194414

44

64

7

51

194022

67

66

61

194023

194019

194407WSP

194407P

212025

194406

212027

Lower End

Assembly

English: 18

Lower end injector & wear parts kits 5%:

Kit A – Wear Parts Kit (dosage

011852PV 14, 17, 44

piston and O-rings)

Kit B – Wear Parts Kit (Kit A, &

011950V 14, 17, 44, 51

shaft)

Kit C – Wear Parts Kit (Kit A, inner

cylinder and O-ring)

Kit D – Suction Tube Fitting Assy

(check poppet, O-ring, spring, tting,

011856PV 7, 14, 17, 44,

64

011462V 10, 11, 12, 13,

77, 80

twistlock, barb)

Kit E – Wear Parts Kit (Kits C & D,

shaft, gasket)

011836PV 7, 10, 11, 12,

13, 14, 16, 17,

44, 51, 64,

77, 80

Kit F – Lower End Cylinder Kit (inner

& outer cylinder, ratio adjuster,

011963PV 7, 16, 61, 64,

65, 66, 67, 79

O-rings, pins, gasket)

Kit G - Complete Lower End, lter,

solution tube

011846PV 7, 10, 11, 12,

13, 14, 15, 16,

17, 25, 27, 44,

51, 61, 64, 65,

66, 67, 71, 77,

79, 80

Kit H – Motor Piston Assy 011863 9, 21

Kit M – Mounting Bracket Kit

011432 56, 57, 58

(mounting bracket, 4 hex caps &

nuts)

212005

194004

010016

194309

212005

Manual

Reference

Part # Description of Part

English

7 194405P Cylinder, inner

10 194 418H Spring

11 011452 Suction Tube Ftting

12 212120

O-ring

*Must specify material

13 011453A Check Poppet

14 212005

O-ring

*Must specify material

15 194004 Seal retainer, O-ring

16 010016 Lower End Gasket

17 212005

O-ring

*Must specify material

25 011025 Suction tube, 1/2” x 5’

27 011018 Filter, for suction tube, 1/2” ID

44 194309 Dosage Piston

51 194301F Shaft

61 194406P Ratio adjustment sleeve

64 212017

O-ring, inner cylinder, lower end

*Must specify material

65 194310D Pin, upper interlock

66 212025

O-ring, outer cylinder, lower end

*Must specify material

67 011918P Cylinder, outer

17

15

16

44

14

71 194414 Nut, suction tube tting

77 003039 Hose Barb 1/2” x 3/8”

79 194410SS Pin, narrow interlock

80 19 4415 Twistlock

13

011453A

194413

194416

65

79

194310

194410

194415

194418

212120

011452

194414

003039

194301

51

011918P

67

66

212025

194406

61

80

10

12

11

71

77

212017

194405

64

7

25

011025

27

011018

Lower End

Assembly

English: 19

Lower end injector & wear parts kits 10%:

Kit A - Wear Parts Kit (Dosage Piston,

011138 14, 17, 44

O-rings)

Kit B – Wear Parts Kit (Hose kit) 011849M 60

Kit C - Wear Parts Kit (Kit A, O-ring) 011107 7, 14, 17, 44, 91

Kit H – Motor Piston Assy 011879T 9, 21

Kit M – Mounting Bracket Kit

011432 56, 57, 58

(mounting bracket, 4 hex caps &

nuts)

51

011908

194343

(#51 is part of the

011879T piston assy)

17

212005

15

194004

68

212002

72

194830

194342

212010

194832

53

194344

Manual

Part # Description of Part

Reference

7 011921P Outer Cylinder

14 212007

O-ring, Dosage Piston Guide

*Must specify material

15 194004 Seal Retainer, O-ring

17 212005

O-ring

*Must specify material

44 194909 Dosage Piston

51 011908 Shaft Assembly, Stainless Steel

53 194344 Klipring

61 194831 Ratio Adjuster

66 212402

O-ring, Outer Cylinder, Lower End

*Must specify material

68 212002

O-ring, Cylinder Adapter, Lower End

*Must specify material

72 194830 - Standard

Adapter

190830 - Remote Injection

73 194833 Dosage Piston Guide

79 195911 Ratio Locking Pin

93 193003 Capscrew 10-32 X 1/2” Ss Hex

92 195861 Shaft Cap

94 212012

O-ring, Outer Cylinder

*Must specify material

91 212518

O-ring, Dosage Piston Guide

*Must specify material

60 011849M

Hose Kit

*Must specify material

60

011849M (Kit)

79

195911

61

66

194831

94

7

011921P

212402

44

14

73

91

92

93

212012

194909

212007

194833

212518

195861

193003

Remote Injection Kit

(Factory Installed)

Remote Injection Port

7

53

68

72

190830

44

14

73

91

92

93

94

212012

011921P

194344

17

15

212002

194909

212007

194833

212518

195861

193003

212005

194004

51

011908

194343

194342

212010

194832

(# 51 is part of the

011879T piston assy)

English: 20

60

011849M (Kit)

79

195911

61

66

194831

212402

Lower End

Assembly

Warranty

English

Congratulations on Your Purchase

We make the best and most reliable uid-driven injectors

available. Our warranty provides the best coverage in the

industry. Hydro Systems will provide for replacement of all

parts proven to be defective in material or workmanship

from the date of purchase for the following periods:

3 years The cover and body

2 years The motor piston assembly

1 year The lower end (Chemical pump)

Hydro Systems products are warranted to be free from

defects in materials and workmanship for the above time

frames. Hydro Systems will at its sole option repair or

replace any component that fails in normal use. Any repairs

made under warranty shall not extend the initial warranty

period.

To Maintain Your Warranty

Your only responsibility is ordinary maintenance - ltering

incoming uid, replacing the O-ring and dosage piston when

worn. Seals and O-rings are not covered under the warranty.

This warranty is not valid if the defects are found to be

due to the product’s misuse, lack of maintenance, uid

continued...

impurities such as sand or iron, defective installation, freezing,

uid hammer, abuse, unwanted side effects due to the

chemicals you choose to inject or service provided by anyone

who is not an authorized service provider. Hydro Systems

declines any responsibility if the product is not used in

compliance with the operating instructions and specications

as indicated in this owner’s manual.

Warranty may be void if injector body is disassembled. If

you suspect you are having a problem in the motor piston

assembly or inside the body please contact Hydro Systems or

any authorized repair center to arrange to send the injector in

to be evaluated and/or repaired.

IN NO EVENT SHALL Hydro Systems BE LIABLE FOR ANY

INCIDENTAL, SPECIAL; INDIRECT, OR CONSEQUENTIAL DAMAGES,

WHETHER RESULTING FROM THE USE, MISUSE OR INABILITY TO

USE THIS PRODUCT OR FROM DEFECTS IN THE PRODUCT.

There is no warranty expressed or implied relating in any way

to products used in conjunction with Hydro Systems.

Hydro Systems or authorized distributor shall not be liable for

incidental or consequential damage, such as any economic loss.

Hydro Systems retains the exclusive right to repair or replace the

product. Such remedy shall be your sole and exclusive remedy

for any breach of warranty. There are no warranties, expressed

or implied, which extend beyond those described above.

To Return an injector for Warranty or Non-Warranty repair:

See page 3 for Hydro Systems contact information.

1. Thoroughly ush the injector with water of any chemical and drain. Ensure proper packing for shipment.

2. To EXPEDITE warranty evaluation and repair or non-warranty product repair, please include the following:

a copy of the original invoice, serial number of the unit, chemical used, contact information and a Return

Authorization (RA) number, contact your country's Hydro Systems Customer Service to obtain.

3. Send freight prepaid and ship to Hydro Systems or your local distributor. For the name of your local distributor or if

returning to Hydro Systems, contact your country's Hydro Systems Customer Service.

4. For a WARRANTED injector: upon inspection and determination that the unit has defects in materials or

workmanship, the unit will be repaired or replaced at Hydro Systems’s option, free of charge and shipped back

freight prepaid.

5. For a NON-WARRANTED injector: upon inspection Hydro Systems or a local distributor will call the customer

with a repair estimate.

English: 21

Loading...

Loading...