Page 1

MERCURY TL Laundry Dispensing System

!

Reference Manual LM-700 Series

Online and downloadable

Product Manuals and Quick Start

Guides are available at

www.HydroSystemsCo.com

Please check online for the latest

version of this Reference Manual.

WARNING:

The LM-700 dispensing system

is intended to be installed

by experienced installers, in

accordance with all applicable

electrical and plumbing codes.

NOTE: Always use proper

lockout tagout procedures

when installing and servicing

dispensing systems. Please

disconnect all washer and

dispenser power sources any

time the dispenser cabinet

is open.

Preface

This manual has been written and illustrated to present the basic

installation, operation, and servicing instructions of the LM-700 Laundry

Dispensing System. Guidelines will be suggested in reference to the

preferred method of installation, however, the variety of equipment and

the surrounding environment will dictate the actual installation of

the LM-700.

All machine and dispenser power

must be disconnected during

installation and/or any time the

dispenser cabinet is opened.

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 1

Page 2

Table of Contents

1 Theory of Operation

Overview .......................................................................................................................................... 3

Automatic Mode...............................................................................................................................3

Push Button Mode ........................................................................................................................... 3

Relay Mode ...................................................................................................................................... 4

2 Mechanical Installation

3 Electrical Installation

4 User Mode Operation

5 Programming

6 Troubleshooting

7 Maintenance and Repair

8 Maintenance and Specifications

Index

Wall Mounting Unit ...........................................................................................................................4

Supply and Discharge Hoses ........................................................................................................... 4

Main Power ...................................................................................................................................... 5

Trigger Signal Wiring ........................................................................................................................ 5

Auto Formula Select Wiring .............................................................................................................5

User Mode Screens .........................................................................................................................6

Formula Selection ............................................................................................................................ 6

Start Formula (Push Button Mode Only) .......................................................................................... 6

View Load Counter...........................................................................................................................6

ID/Mode ........................................................................................................................................... 6

Prime Pumps (when enabled) .......................................................................................................... 7

Password Access to Program Mode ...............................................................................................7

Introduction ...................................................................................................................................... 8

Key Descriptions .............................................................................................................................. 8

Password Access to Program Mode ...............................................................................................8

Prime Pump “P-1”............................................................................................................................9

Clear Load Counter “CLr” ................................................................................................................ 9

Operating Parameters “oP’ .............................................................................................................. 9

Lockout Period “LP” ........................................................................................................................ 9

Formula Program “F-1” .................................................................................................................... 9

Pump Amount “P1A” .......................................................................................................................9

Delay Time “D1A” ............................................................................................................................9

Assign Pump “A1A” (only in Occurrence Mode) .............................................................................. 9

Finish Program “Fin” ........................................................................................................................ 9

Filter Duration “Fd” ........................................................................................................................10

User Prime “uPr” ............................................................................................................................ 10

Password Edit “Pin” ....................................................................................................................... 10

Exit Program Mode “End” .............................................................................................................. 10

Dead Unit (No Display) Troubleshooting ........................................................................................ 11

Spare Parts Listing ......................................................................................................................... 12

Dimensions ....................................................................................................................................13

Power Requirements ...................................................................................................................... 13

General Specifications ................................................................................................................... 13

Limited Warranty ............................................................................................................................13

Limitation of Liability ...................................................................................................................... 13

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 2

Page 3

Theory of Operation

Overview

The Mercury offers four operating modes for maximum flexibility in small OPL and Top Load washer laundry

applications. Automatic Formula Selection may be used in all modes whenever a spare washer supply signal

output is available that may be programmed to the second. The following sections describe each mode’s

unique operation specifications in detail.

Automatic Mode

Automatic Mode is a basic mode of operation similar to Timer Mode in our Eclipse and Orion dispensers.

Each trigger signal input number matches the corresponding pump number (i.e. trigger 1 = pump 1, trigger 2

= pump 2, etc.). Pumps can be delayed after trigger signals for occasions where pump delays are required to

prevent dosing on dry linen, etc. Pump delay times are programmable in seconds. Pumps 1 and 2 have two

product levels, A and B. The A level dispenses on the first occurrence of the trigger signal in a formula. The

B level dispenses on the second occurrence of the same trigger signal within the same formula. Pump 3 only

has one product level. The Pump Lockout feature, when turned on, prevents any unwanted pump activations

due to false signals from washers that send noisy or multiple output supply signals. Loads are counted each

time the highest pump number with an amount programmed (unique to each formula) is run. The Pump

Lockout timer and (pumps 1 and 2) A/B levels will be reset 5 minutes after the count pump runs or the

Lockout period ends, whichever comes first. If the load needs to be restarted for any reason, the dispenser

wash formula may be terminated early by pressing the Enter key for two seconds.

Push Button Mode

Push Button Mode is intended for manual operation where the machine operator selects a formula and

presses the Enter key to start and run the dispenser wash formula. A dispenser wash formula consists of

up to 5 programmed pump amounts (1a, 1b, 2a, 2b, and 3 are the five programmable pump amounts from

three physical pumps). Pump Delay times (programmed in minutes) stagger the programmed pump doses

throughout the wash load. The Pump Lockout feature (programmed in minutes) prevents the machine

operator from starting multiple doses in the same wash load. If the load needs to be restarted, the dispenser

wash formula may be terminated early by pressing the Enter key for two seconds. Loads are counted each

time the highest pump number with a programmed amount is run.

Occurrence Mode

Occurrence Mode paces the dosing of products off the washer fill valves by counting each time the machine

fills to identify the occurrence-sequence of machine steps. This mode of operation is ideally suited for

machines with no chemical supply signal outputs, such as domestic style top load washers. While all three

of the trigger signal inputs are active and may be used, typically only two will be used. Typical trigger signal

wiring would be one of the available trigger signal inputs wired to one fill valve, and another trigger signal

input to the other fill valve (typically the hot and cold fill valves). Since the dispenser responds to any of the

trigger inputs, it does not matter which input goes to which fill valve. The dispenser counts the machine fill

occurrences and runs pumps based on an assignment of the pumps to the machine step sequence.

NOTE: Careful attention must be paid when programming the signal Filter Duration time to account for any

spurious fills resulting from level and/or temperature controls in the washer. For more information, please

see section 4.8, Filter Duration.

A dispenser wash formula consists of up to 5 programmed pump amounts (1a, 1b, 2a, 2b, and 3 are the

five programmable pump amounts from three physical pumps). Any of these available amounts may be

programmed to any (up to 9) machine step. The Lockout feature is available to be sure that each programmed

pump amount only runs one time per dispenser wash formula. The dispenser wash formula is terminated

5 minutes after the last pump programmed in a sequence runs, or the Lockout period (when on) ends,

whichever comes first. If the load needs to be restarted for any reason, the dispenser wash formula may be

terminated early by pressing the Enter key for two seconds.

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 3

Page 4

Theory of Operation

Relay Mode

Relay Mode runs pumps for the duration of washing machine supply signals. This mode is typically used

on fully programmable microprocessor controlled washing machines where the installer opts to control

the dispensing equipment from the washing machine control system instead of the dispenser’s control

system. The load counter increments each time pump one is run in Relay Mode.

Mechanical Installation

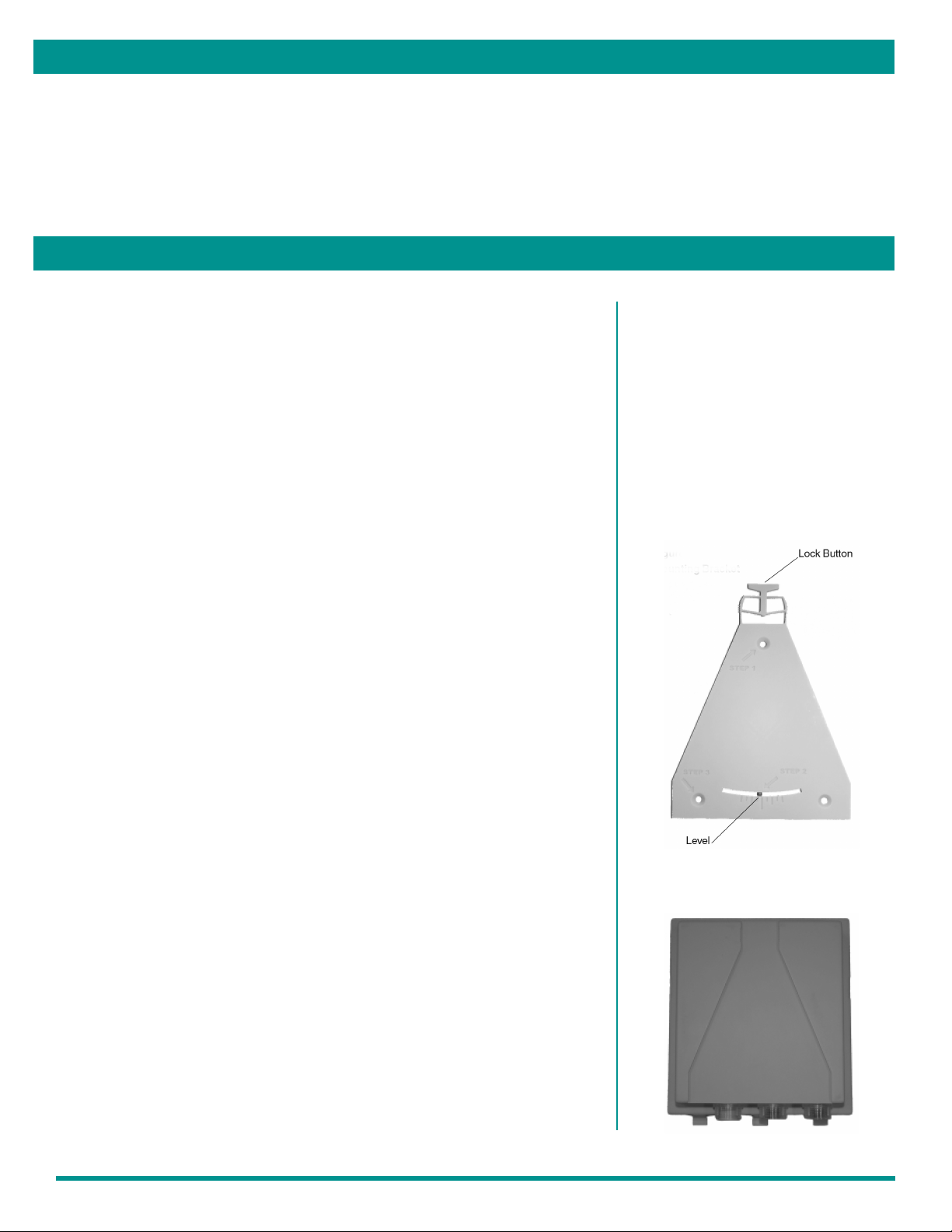

Wall Mounting Unit

To determine a suitable location to install the dispenser, keep the

following in mind: Install close to product containers at a reasonable

height for easy service access. When intended for Push Button Mode

operation, be sure to allow easy front panel access for the machine

operator.

• Drill one hole in wall for upper mounting bracket screw wall anchor.

• Install wall anchor and temporarily attach bracket to the wall

(do not tighten screw all the way).

• Level bracket using built-in level and mark drill locations for lower

mounting screw holes.

• Swing bracket out of the way, drill lower holes, and install lower

wall anchors.

• Screw bracket into place.

• Lower unit onto wall mount bracket and press down until unit locks

into place. To remove unit from bracket, depress lock button on the

top of the bracket as you lift the unit from the mounting bracket.

Supply and Discharge Hoses

We recommend use of 3/8” ID hose for supply and discharge hoses.

Use of smaller size ID hose/tube may results in reduced flow rates,

premature pump tube failure, or both.

The maximum combined distance for supply and discharge hoses must

not exceed 50 feet. The maximum supply side hose distance must

not exceed 15 feet. The maximum vertical height from product

container to pump must not exceed 10 feet.

CAUTION:

The Mercury dispensing system is

intended to be installed by

experienced installers in

accordance with all applicable

electrical and plumbing codes.

Disconnect power to laundry

machine and dispensers during

installation and/or any time the

dispenser cabinet is opened.

Figure 1 Mounting Bracket

Use hose clamps to secure supply and discharge hoses to pump tube

hose barbs. Route supply hose to product pails and discharge hose to

washer per industry standard practices.

HydroSystemsCo.com Toll Free: 1.800.543.7184 4

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

Figure 2 Unit Rear Bracket Slot

Page 5

Electrical Installation

The Mercury is available in two different wiring versions: terminal block,

or wiring cable. The following instructions apply to cable versions.

Terminal Block versions include an additional wiring information label

adjacent to the terminal blocks inside the unit enclosure.

The Mercury includes two separate wiring cables for Main Power and

Input Trigger Signal connections. These cables may route through either

one or two conduit fittings, as required.

Main Power

Main Power is a universal power input that accepts any AC voltage

from 90-249 VAC, 50/60 Hz. Typical sources include a wall outlet, or

washing machine incoming power terminals. For wall outlet connections

use a wall plug, sourced locally, that fits outlets in your region. Main

Power Cable color coding is as follows: Blue + Brown 90-249 VAC,

50/60 Hz.

NOTE: In cases where a Neutral wire exists, connect Neutral to

the Blue wire.

Green with yellow stripe is Earth Ground.

Trigger Signal Wiring

CAUTION:

The Mercury dispensing system

is intended to be installed

by experienced installers in

accordance with all applicable

electrical and plumbing codes.

All laundry machine and dispenser

power is to be disconnected

during installation and/or any time

the dispenser cabinet is opened.

CAUTION:

Always verify all voltage sources

with a meter.

NOTE:

Failure to use watertight conduit

for electrical cables will impair

water resistance of the

unit enclosure.

All trigger signal inputs are optically isolated high impedance input circuits. Washer supply signal voltages

may range from 24-249 VAC, 50/60 Hz (20 mA maximum draw) or 12-24 VDC (5 mA maximum draw) that

accommodate the range typically found in most washing machines. Each signal input connects to a pair of signal

input wires (solid color and white with colored stripe). In cases where the washing machine has a single

common for supply signals, connect all the signal input common wires (white with colored stripes) to the machine’s

signal common wiring location. In Automatic or Relay Mode trigger inputs match pump numbers (i.e. trigger 1 =

pump 1, etc.). In Occurrence Mode connect wire pairs from each machine fill valve to two trigger inputs (it does not

matter which two of the three available trigger inputs are used for Occurrence Mode).

Signal Input wire colors are as follows:

Trigger Signal 1 = Black

Signal Common 1 = White w/Black Stripe

Trigger Signal 2 = Brown

Signal Common 2 = White w/Brown Stripe

Trigger Signal 3 = Red

Signal Common 3 = White w/Red Stripe

Auto Formula Select Wiring

Input specifications are the same as trigger inputs. The Auto Formula Select signal must be programmable to the

second on the washing machine control system. Program the washer to send this signal at the start of the wash

load (prior to any chemical supply signals) for a duration of 2 seconds times the desired formula number (i.e. for

formula 2 program for 2s * F2 = 4 seconds signal time).

Auto Formula Select input wire colors are as follows:

Auto Formula Select Signal = Orange

Auto Formula Select Signal Common = White w/Orange

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 5

Page 6

User Mode Operation

The Mercury dispensers four modes of operation are described in this section.

Automatic Mode runs each pump program (program = delay time + run time) upon qualified input to the

respective signal input. When on (not set to 000), the Lockout Timer begins at start of first pump program

(beginning of delay time). During this lockout period, no pump amount may run more than once regardless of

the number of times the signal input occurs. Display indicates signal status, pumps running, and lockout status.

Machine operator selects desired formula number with the Scroll key. Auto Formula Select is always active, but

may be overridden by machine operator input.

Push Button Mode relies on a user push button press to start the wash formula program. Auto Formula Select

is always active, but may be overridden by machine operator input. The machine operator selects the formula

number with the Scroll key, and then starts the wash formula program by pressing and releasing the Enter key

for less than 2 seconds. Pumps run as programmed via programmed delay and run times. During the lockout

time, all button presses to start the formula program are ignored except, Password input. The display indicates

pumps running and lockout status.

Occurrence Mode is an alternate automatic logic where signals from input numbers 1, 2 and 3 act as a

single logic input signal. Signal occurrences are counted (simultaneous input signals count as one signal

occurrence) to determine when each pump runs, based on pump-assignments in the Assign Pump “A1A”

screen in the programming menu. Pumps 1 and 2 have two programmable amounts, A and B, which are treated

in Occurrence Mode as separate pump programs. Display indicates signal status, pumps running, and lockout

status. Auto Formula Select is always active, but may be overridden by machine operator input.

Relay Mode requires no machine operator interaction since all dispensing system control is turned over to the

washing machine control system.

NOTE: Password input and/or power failure resets the lockout timer and ends the wash load in all modes.

User Mode Menu Screens

Use the Next key to step through all available User Mode menu screens. The display will revert to the User Mode

Home Screen after 30 seconds of inactivity.

Formula Selection

From the Home Screen, press the Scroll key to select programmed formulas (1-4).

NOTE: Formulas with no amounts programmed may not be selected.

Start Formula (Push Button Mode Only)

From the Home Screen press and release the Enter key for less than 2 seconds to trigger manual dispensing.

NOTE: To terminate wash formula before end of lockout period press and hold the Enter key longer than 2

seconds, release, and wait 30 seconds for screen to revert to idle screen.

View Load Counter

From the Home Screen press the Next key once to display “L”. Load counter (all formulas) will toggle between “L”

and load count since last clear.

ID/Mode

From the Home Screen press the Next key twice to display the operating firmware ID number and currently selected

operating mode. The first two digits indicate a firmware ID number we may ask you when troubleshooting. The right

digit indicates the current Operating Parameter (oP) selection (1= Automatic, 2 = Push Button, 3 = Occurrence,

and 4 = Relay).

HydroSystemsCo.com Toll Free: 1.800.543.7184 6

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

Page 7

User Mode Operation

Prime Pumps (when enabled)

From the Home Screen press the Next key three times to display “P 1”. Press the Scroll key to select

pump number to prime. Press the Enter key to turn selected pump on or off.

NOTE: Prime Pumps is only available when unit is not in a lockout timer period. If the dispenser is in a lockout

timer period the display will indicate P-0 and the Scroll key will not select a pump number.

Password Access to Program Mode

From the Formula Selection screen only, press and hold the Enter Key for 2 seconds to access the Password

input screen. Press the Scroll Key to change the blinking digit to the desired value. Press the Next Key to

move the blinking digit. Press the Enter Key when the desired number is present in all digits to enter Program

Mode. The password factory setting is 123.

Figure 3 User Mode Display

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 7

Page 8

Programming

Introduction

Use the menu screen illustrations as a guide when learning to program

the Mercury. We suggest that you power up a unit and become familiar

with the programming steps in a quiet environment, with the manual,

prior to the first installation. Use the Next key to move to all available

main menu screens in Program Mode.

Key Descriptions

• Next Key-Move to the next item or task.

- User Mode: Move through the available User Mode screens.

- Program Mode: Move through Program Mode menu screens.

- Input Screens: Move blinking digit to the right.

• Scroll Key-Change the blinking digit value.

- User Mode: Selects formula. Change values of blinking digits

(Password entry).

- Program Mode: Change values of blinking digits.

- Input Screens: Change values of blinking digits.

• Enter Key-Perform a task or set a value.

- User Mode: Momentary press starts Push Button Mode wash formula.

Press and hold 2 seconds to access Password input screen. Starts

and stops prime. Performs actions as prompted in User Mode

menu screens.

- Program Mode: Access all input screens from main menu loop screens

(selected with the Next key). Performs actions in certain screens.

- Input Screens: Set the displayed value in all input screens (selected

with the Scroll key), and exit back to main menu loop.

Password Access to Program Mode

Figure 4 Mercury TL Keypad

Figure 5 Key Icons

Figure 6 Set Numerical Display

Press and hold the Enter key for 2 seconds to access the Password input

screen. The password factory setting is 123. Any three-digit number may

be used. Press the Scroll key to change the blinking digit to the desired

value. Press the Next key to move the blinking digit. Press the Enter key

when the desired number is present in all digits to enter Program Mode.

The Prime Pumps screen, P-1, will appear once you are in Program Mode.

An incorrect password entry returns you to the home screen.

NOTE: You have 30 seconds to input a password. After 30 seconds,

the display reverts to the User Mode idle home screen.

Figure 7 Password Input

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 8

Page 9

Programming

Prime Pump “P-1”

Press the Scroll Key to select pump number. Press the Enter Key to turn pump on. Press the Enter Key

again to turn the pump off. Pump prime automatically ends after 5 minutes, if pump is left on.

Clear Load Counter “CLr”

Every two seconds, the screen alternates between CLr and load count (all formulas). Press and hold the

Enter key for two seconds to reset the Load Counter.

Operating Parameters “oP”

Every two seconds, the screen alternates between oP and the current selection. Press the Enter key to

select the desired mode of operation: Au (Automatic), Pb (Push Button), oc (Occurrence), or r (Relay).

NOTE: The four operating modes, Lockout Period, and other related operational details are described in more

detail under Theory Of Operation.

Lockout Period “LP”

Press the Enter key to display/edit Lockout Period value in minutes. Input method is the same as Password

input. 00.0 = Lockout off. The range of adjustment is 00.0-99.9 minutes.

NOTE: In Occurrence and Push Button Modes, the programmed Lockout Period must be longer than the total

time of all programmed pump run times and delay times. The Lockout Period should approximate the washer

cycle time for a complete load.

Formula Program “F-1”

Press Scroll key to select the formula number (1-4) you wish to program. Press the Enter Key to move to the

Program Formulas menu loop for the selected formula number. This menu loop is not available in Relay Mode.

If data is input in this loop and Relay Mode is later selected, all values will be retained for later use if Relay

Mode is cancelled. Use the Next key to step through all available menu screens in this loop.

Pump Amount “P1A”

Every two seconds, the screen alternates between the stored run time (in seconds) for the selected pump

number and Pxx. Press the Scroll key to select the desired pump number (P1A, P1B, P2A, P2B, and P3 are

the available pump numbers). To set a pump run time, press and hold the Enter key for two seconds to start

the pump (display will increment seconds and pump will run). When desired time/volume is reached, press

the Enter key again to stop the pump and set the value. Repeat for all desired pumps. The adjustment range

is 000-240 seconds.

Delay Time “D1A”

Press the Scroll key to select the pump number (P1A, P1B, P2A, P2B, and P3) to be delayed. Press the

Enter key and input delay time in the same manner as Password input. In Push Button Mode, program

Delay Times in minutes (display will read 00.0). In all other modes, Delay Times are seconds (display

will read 000).

Assign Pump “A1A” (only in Occurrence Mode)

Assigns pump numbers to signal sequence occurrences. At the A1A screen, press the Scroll key to select

the pump number (P1A, P1B, P2A, P2B, and P3) you wish to assign to a machine step occurrence. Press the

Enter key to access occurrence input screen (oc). Press the Scroll key to assign the previously selected pump

number to the machine step occurrence (1-9) in which you desire that pump to run. Press the Enter key to set

this assignment and return to the formula programming sub-menu loop. Repeat for all pumps/occurrences.

Finish Program “Fin”

Press the Enter key at this screen to return to the F-1 formula number selection screen in the main menu loop.

HydroSystemsCo.com Toll Free: 1.800.543.7184 9

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

Page 10

Programming

Filter Duration “Fd”

Press the Enter key to view/set Signal Filter Duration (same input method as Password input). The available

range is 0-19 seconds; the default is 3 seconds).

NOTE: In Occurrence Mode, set the Filter Duration time long enough to filter out excess fill valve signals that

may occur as the washer level control calls for more water, etc. Automatic and Relay modes typically use the

default setting.

User Prime “uPr”

Every 2 seconds, the screen alternates between UPr and current User Prime setting (on or off). Press the

Enter Key to change this setting.

Password Edit “Pin”

Any three-digit number may be input. Press the Scroll Key to change the blinking digit to the desired value.

Press the Next Key to move the blinking digit. Repeat for all digits and press the Enter Key when the desired

password is present.

NOTE: Note any password changes! Access to Program Mode is not available if the password is lost!

Exit Program Mode “End”

Press the Enter key to exit Program Mode and return to User Mode.

NOTE: To clear all values and restore factory settings, press and hold the Scroll key for two seconds, then

press the Enter key (while still pressing the Scroll key). “FAC” will appear to indicate that you have restored

factory settings and cleared the dispenser’s memory (including counter reset to zero). Press the Enter key

again to return to User Mode.

Figure 8 Program Mode Screens Figure 9 Key Icons

Figure 10 Set Numerical Display

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 10

Page 11

Troubleshooting

Dead Unit (No Display) Troubleshooting

1. Verify Main Power (between 90 VAC and 249 VAC, 50/60 Hz) is present on Main Power Cable (or

Terminals) and Power Switch (located behind cover in upper left corner) is On.

Yes? Go to step 2.

No? Restore Main Power source.

2. With a volt meter capable of reading AC voltages between 90VAC and 249 VAC, and DC voltages

around 20 VDC to 30 VDC, perform the following measurements on the Power Supply PCB:

2a. Recheck Main Power source, if Main Power present, replace Logic PCB.

Problem Possible Cause Solution

1. Tripped breakers or blown fuses at

No voltage to main power terminals

Voltage at main power terminals, but LED display

is not lit (see additional troubleshooting info above)

Pumps run slowly or not at all

Password will not access program mode 1. Password has been changed

Pump runs but will not deliver product

power source

2. Main power wires

1. Power supply failure 1. Replace power supply

2. Damaged logic circuit board 2. Replace logic circuit board

1. Pumps not plugged in properly

2. Pump failure 2. Replace failed pump

1. Squeeze tube failure 1. Replace squeeze tube

2. Product tubing plugged 2. Replace product tubing

3. Pump roller failure 3. Replace pump roller

1. Squeeze tube failure 1. Replace squeeze tube

1. Reset breakers or replace fuse at

power source

2. Check connections at plug or washer

power terminals

1. Verify pump electrical connectors are

plugged in properly

1. Call Hydro Systems Customer Service for

new Logic PCB

Poor results

Dispenser not dispensing upon request from washer

2. Product tubing plugged 2. Replace product tubing

3. Pump roller failure 3. Replace pump roller

1. Incorrect Operating Mode (Op)

selected from programming menu

2. Signal wires are loose or

wired incorrectly

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

1. Select appropriate Operating Mode under

(Op) in the programming menu

2. Check signal wiring to washer

HydroSystemsCo.com Toll Free: 1.800.543.7184 11

Page 12

Maintenance and Repair

Spare Parts Listing

Reference # Part # Description

1 13-07265-00 Power Supply

2

3 13-06524-00 Pump Motor Detergent (2-Pin Plug)

4 13-06398-06 Kit, Pump Cover, Teal

5 13-07028-368 Pump Tube, Epdm, w/ 3/8" Barb, Ea.

6 13-06396-00 Pump Spinner Assembly

* 13-07266-00 Power Cable

* 13-07267-00 Signal Cable

* 37-07087-02 Cabinet Front

* 37-07088-02 Cabinet Rear

* 13-07268-06 Power Switch Cover

* 13-07122-00 Mounting Bracket Kit

13-07725-00

Logic Circuit Board

*Denotes items not shown.

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 12

Page 13

Maintenance and Specifications

Routine maintenance includes keeping the dispenser wiped clean with a damp cloth and periodic

Pump Tube replacement.

NOTE: In the event of pump tube failure, always clean all pump part surfaces with a damp cloth to prevent

possible damage from chemical attack.

Dimensions

Size: 8" (20.3 cm) wide X 9" (22.2 cm) high X 6" (150.4 cm) deep

Weight: 5.5 lbs. (2.47 kilos)

Temperature: 120° F Maximum

Power Requirements

Total amperage draw during operation is: 90 to 249 VAC, 50/60 Hz. 1.0 amps (max).

General Specifications

Pump Flow Rate 6.0 oz/minute (177 mls/minute)

NOTE: All specifications subject to change without notice.

Limited Warranty

SELLER warrants solely to BUYER the Products will be free from defects in material and workmanship

under normal use and service for a period of one year from the date of completion of manufacture. This

limited warranty does not apply to (a) hoses; (b) and products that have a normal life shorter than one year; or

(c) failure in performance or damage caused by chemicals, abrasive materials, corrosion, lightening, improper

voltage supply, physical abuse, mishandling or misapplication. In the event the Products are altered or

repaired by BUYER without SELLER’S prior written approval, all warranties will be void.

NO OTHER WARRANTY, ORAL, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE, IS MADE FOR THESE PRODUCTS,

AND ALL OTHER WARRANTIES ARE HEREBY EXPRESSLY EXCLUDED.

SELLER’S sole obligation under this warranty will be, at SELLER’S option, to repair or replace F.O.B.

SELLER’S facility in Cincinnati, Ohio any Products found to be other than as warranted.

Limitation of Liability

SELLER’S WARRANTY OBLIGATIONS AND BUYERS REMEDIES ARE SOLELY AND EXCLUSIVELY AS

STATED HEREIN. SELLER SHALL HAVE NO OTHER LIABILITY, DIRECT OR INDIRECT, OF ANY KIND,

INCLUDING LIABILITY FOR SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES OR FOR ANY OTHER

CLAIMS FOR DAMAGE OR LOSS RESULTING FROM ANY CAUSE WHATSOEVER, WHETHER BASED ON

NEGLIGENCE, STRICT LIABILITY, BREACH OF CONTRACT OR BREACH OF WARRANTY.

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 13

Page 14

Index

A

Auto Formula Select Wiring ...................... 5

Automatic Mode ................................... 3, 6

C

Clear Load Counter “CLr” ...................... 10

Counting Loads ........................................ 3

D

Delay Time “D1A” ..................................... 9

E

Electrical Installation ................................. 5

Exit Program Mode “End” ...................... 10

F

Filter Duration ........................................... 3

Filter Duration “Fd” ................................. 10

Finish Program “Fin” ................................ 9

Formula Program “F-1” ............................ 9

H

Hoses ....................................................... 4

K

Keypad ..................................................... 8

L

Loads

counting .............................................. 3

Lockout

functions .............................................. 3

operation .......................................... 6-7

programming ....................................... 9

Lockout Timer

resetting .............................................. 3

M

Main Power ........................................ 5, 11

Mechanical Installation ............................. 4

Mounting Bracket ..................................... 4

N

Numerical Displays Explained. See also

Programming; User Mode Operation

O

Occurrence Mode .................... 3, 5-6, 9-10

Operating Modes .................................. 3, 9

Operating Parameters “oP” ...................... 9

P

Password

access to program mode ........... 7-8, 10

edit “Pin” ........................................... 10

Password Edit “Pin” ............................... 10

Power Failure ............................................ 6

Prevent false activation of pumps ............ 3

Prime Pump “P-1” .................................... 9

Product levels ........................................... 3

Program Mode Screens ......................... 10

Programming ....................................... 8-10

Pump

delays .................................................. 3

numbers .......................................... 5, 9

product levels A & B ............................ 3

run time, setting .............................. 6, 9

Pump Amount “P1A ................................. 9

Push Button Mode .................... 3-4, 6, 8-9

R

Relay Mode ................................. 4-6, 9-10

formula programming not available .... 9

Restart Loads ........................................... 3

S

Signal Wiring

instructions .......................................... 5

Supply and Discharge Hoses ................... 4

T

Trigger Signal Input Number..................... 3

Trigger Signal Wiring ................................ 5

U

User Mode Operation ............................ 6-7

User Prime “uPr” .................................... 10

W

Wall Mounting Unit ................................... 4

Wash Formula

early termination .............................. 3, 6

programming ................................... 3, 6

Wiring

instructions .......................................... 5

P/N 20-07665-00 Rev L © Hydro Systems Company, Inc. 2018

HydroSystemsCo.com Toll Free: 1.800.543.7184 14

Loading...

Loading...