SpaDepot.com

CS/ES9700Y SERIES

Operation Manual

Covers the following CS & ES series:

9700Y, 9704Y, 9707Y, 9708Y, 9709Y

GECKO

By

Y SERIES

TM

Introduction

This manual covers electrical and installation details on the following

product series. Some photos and instructions may not apply to the

product you have purchased.

-U Series "Fixed" Heater configuration: This series is designed to fit

the most common heater position. Depending upon the actual control

being replaced, you may still need to modify the plumbing to achieve

proper alignment.

-US Series "Slide" Heater configuration: This series is designed to

allow the heater to be positioned within 20" of the control to provide an

installation with a minimum of plumbing modifications. Depending upon

the actual control being replaced, you may still need to modify the

plumbing to achieve proper alignment.

-VH Series "Versi-Heat" Heater configuration: This series is designed

to allow the heater to be positioned within 60" of the control to provide an

installation where there may not be enough room in the immediate

equipment area and to minimize plumbing modifications. Depending

upon the actual control being replaced, you may still need to modify the

plumbing to achieve proper alignment.

-LH Series "Less Heater" configuration: This series allows the use of

customer supplied custom heater configurations which may not have

been available from Hydro-Quip. Please refer to the "LH" wiring diagram

enclosed with the "LH" wiring harness for specific wiring connections and

details NOT covered within this manual.

-LF Series "Lo-Flo” heater configuration: This series allows the use of

Lo-Flo style heater assemblies.

Table of Contents

Important Safety Instructions.............................3-4

Electrical Installation..........................................5-7

GFCI Wiring Detail................................................7

Heater Installation.................................................8

Versi-Heat / Optional Heaters...............................8

Power Connection................................................9

Circuit Board Configurations...............................10

Pump Cord Connections.....................................10

WiFi Module Installation Kit.................................11

Spaside Control Installation................................12

Spaside Functions/Features..........................13-15

Power Up & Breaker Settings.............................16

Changing Low-Level Configuration.....................16

Spaside Messages.........................................17-18

Operation Considerations....................................19

Trouble Shooting............................................20-21

System Data Label..............................................22

Warranty Information...........................................22

IMPORTANT SAFETY INSTRUCTIONS

!

DANGER To reduce the risk of injury, do not permit children to use this product

unless they are closely supervised at all times.

!

WARNING - RISK OF CHILD DROWNING. Extreme caution must be exercised to

prevent unauthorized access by children. To avoid accidents, ensure that children

cannot use a spa or hot tub unless they are supervised at all times.

!

DANGER To reduce the risk of injury to persons, do not remove suction fittings.

Spa location must accommodate sufficient drainage of water around the base of the

structure, as well as the power source compartment.

Prolonged immersion in water that is warmer than normal body temperature can result

in a dangerous condition known as HYPERTHERMIA. The causes, symptoms,

and effects of hyperthermia may be described as follows: Hyperthermia occurs

when the internal temperature of the body reaches a level several degrees above

the normal body temperature of 98.6BF. The symptoms of hyperthermia include

dizziness, fainting, drowsiness, lethargy, and an increase in the internal

temperature of the body. The effects of hyperthermia include (1) unawareness of

impending hazard, (2) failure to perceive heat, (3) failure to recognize the need to

exit spa, (4) physical inability to exit spa, (5) fetal damage in pregnant women, (6)

unconsciousness resulting in danger of drowning. WARNING The use of alcohol,

drugs or medication can greatly increase the risk of fatal hyperthermia in hot tubs

and spas.

!

DANGER - RISK OF ELECTRICAL SHOCK.

A spa may be installed within 5 feet of metal surfaces if each

permanently connected by a solid copper conductor attached to the wire connector

on the terminal box . Refer to NEC and local codes

installation.)

A bonding lug is provided on the control box to permit connection of a

solid copper bonding conductor between this point and any equipment, metal

enclosures of electrical equipment, metal water pipe, or conduit within 5 feet

(1.5m) of the unit as needed to comply with local requirements.

Bond accessible metal to the dedicated connector on the equipment grounding bus,

bond the equipment ground bus to the local common bonding grid as part of the

installation in the form of (1) a reinforced concrete slab for support, (2) a ground

plate provided beneath the hot tub or spa, or (3) a permanent ground connection

that is acceptable to the local inspection authority.

!

DANGER RISK OF ELECTRICAL SHOCK. Do not permit any electrical appliance,

such as a light, telephone, radio, or television, within 5 feet (1.5m) of a spa or hot

tub.

To reduce the risk of injury:

The water in a spa or hot tub should never exceed 104BF (40BC). Water temperatures

between 100BF (38BC) and 104BF (40BC) are considered safe for a healthy adult.

Lower water temperatures are recommended for extended use (exceeding 10-15

minutes) and for young children.

Excessive water temperatures have a high potential for causing fetal damage during

the early months of pregnancy, pregnant or possibly pregnant women should limit

spa or hot tub water temperatures to 100BF(38BC).

Before entering the spa or hot tub, the user should measure the water temperature

with an accurate thermometer.

The use of alcohol, drugs, or medication before or during spa or hot tub use may lead

to unconsciousness with the possibility of drowning.

Persons suffering from obesity or with a medical history of heart disease, low or high

blood pressure, circulatory system problems, or diabetes should consult a

physician before using a spa or hot tub.

in effect at the time of

metal surface is

3

IMPORTANT SAFETY INSTRUCTIONS

Persons using medication should consult a physician before using a spa or hot tub

since some medication may affect heart rate, blood pressure, and circulation.

For Cord and Plug Connected Units

Must be connected to a grounded, grounding type receptacle only. NEVER connect

the spa to an extension cord.

Do not bury the cord.

For Permanently Installed Units

A terminal marked “G” or “ground” is provided in the wiring box located inside the

equipment compartment. To reduce the risk of electric shock, connect the

terminal or connector to the grounding terminal of your electrical service or supply

panel with a continuous green insulated copper wire in accordance with National

Electric Code Table 250-95 and any other local codes in effect at the time of the

installation.

For Permanently Installed Units not Provided with an Internal Disconnecting Method

The electrical supply for this product must include a suitably rated switch or circuit

breaker to open all ungrounded supply conductors to comply with Section 422-30

of the National Electric Code, ANSI/NFPA 70 1987. The disconnecting means

must be readily accessible to the tub occupant but installed at least 5 feet (1.5m)

from the tub water.

For Units with Gas Heaters

WARNING - Do not install indoors. This unit uses a gas heater that requires proper

ventilation and is intended for outdoor use only.

High Voltage Warning

HIGH VOLTAGE CAN SERIOUSLY INJURE OR KILL!

ONLY EXPERIENCED TECHNICIANS SHOULD SERVICE THIS EQUIPMENT.

DO NOT remove the protective covers from any electrical enclosure, or

attempt to service any related electrical device, unless you are a qualified

electrician or service professional.

DANGER

Risk of electric shock. Before working with any electrical connections,

make certain that the Main Power breaker from the house breaker box has

been turned off.

WARNING

All electrical work must be performed by a qualified electrician and must

conform to all local codes.

IMPORTANT

Due to the danger of severe electrical shock, locate all power disconnects

before servicing a spa. Precautions must be taken whenever working with

breaker boxes, G.F.C.I.’s, or service disconnects.

4

Electrical Installation

A licensed electrician must accomplish the electrical installation in accordance with

the National Electric Code(NEC) Article 680, and any local codes in effect at the

time of installation.

Refer to the System Data Label for equipment voltage and maximum amperage

draws.

The GFCI (Ground Fault Circuit Interrupter) is a mandatory electrical safety device

required for all portable spas and hot tubs as specified in the National Electrical

Code Article 680-42. The GFCI in your particular installation may be installed at the

electrical service panel or a separate sub-panel.

Use copper conductors ONLY. The ground must be sized following the National

Electric Code, Table 250-122. For Power conductor size, refer to the National

Electric Code Table 310-16.

A bonding lug has been provided on the control box to allow connection to local

ground points. To reduce the risk of electrical shock, a solid copper bonding wire

should be connected from this lug to any metal objects within 5 feet of the spa.

The NEC and most local codes require that a “disconnect” be installed within

“line-of-site” of the spa.

Circuit & Breaker

Rating

Maximum Amps

Minimum Wire

Size

The above table is a wiring chart representation.

IMPORTANT- If your electrician is not absolutely sure how to connect

your system correctly, call your local dealer. Any mistake may be costly

and void your equipment warranty.

CAUTION: Do not connect or disconnect any components while the power is on.

All connections must be done with the power off as it may cause damage to the

system.

**Any resulting damages are not covered under manufacturer’s warranty**

CAUTION: Damage may occur to the circuit board and spaside if the spaside

plug is not properly aligned to the receptacle on the circuit board or if the

spaside plug is connected or disconnected while the power is on.

**Any resulting damages are not covered under manufacturer’s warranty**

15A 20A 30A 40A 50A 60A

12A

16A 24A

14 12 10

32A 40A 48A

8

6 4

5

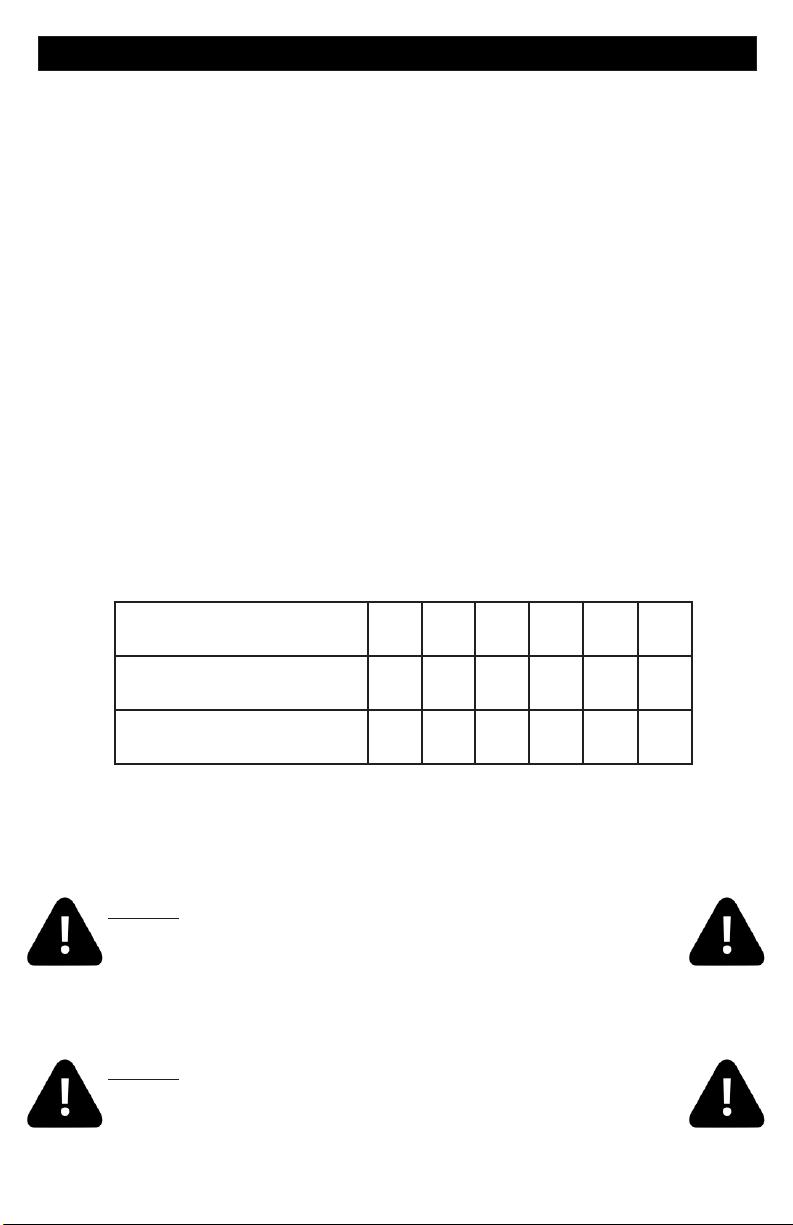

Electrical Installation

ELECTRICAL CONNECTIONS

OPTION 1

20-60AMP HARDWIRED

MAIN BREAKER PANEL

LINE 1

N

LINE 2

Option 1 shows the power from GFCI breaker installed into main service panel to a

service disconnect within line-of-site of the spa. If the manufacturer of your homes main

breaker panel makes a GFCI breaker, you may be able to add it to an open slot in the

panel.

GFCI Installed in Main Service Panel

INLINE SPA DISCONNECT

PORTABLE SPA

REFER TO GFCI WIRING DETAIL ON PAGE 8

OPTION 2

20-60AMP HARDWIRED

MAIN BREAKER PANEL

Subpanel GFCI Installed

GFCI DISCONNECT

INLINE SPA DISCONNECT

TO PORTABLE SPA

LINE 1NLINE 2

REFER TO GFCI WIRING DETAIL ON PAGE 8

Option 2 shows the power from main service panel to a GFCI subpanel within line-of-site

of the spa. (Note: Most local codes will allow a GFCI subpanel to be a disconnect. If this is

not the case in your installation, a disconnect must be provided.)

6

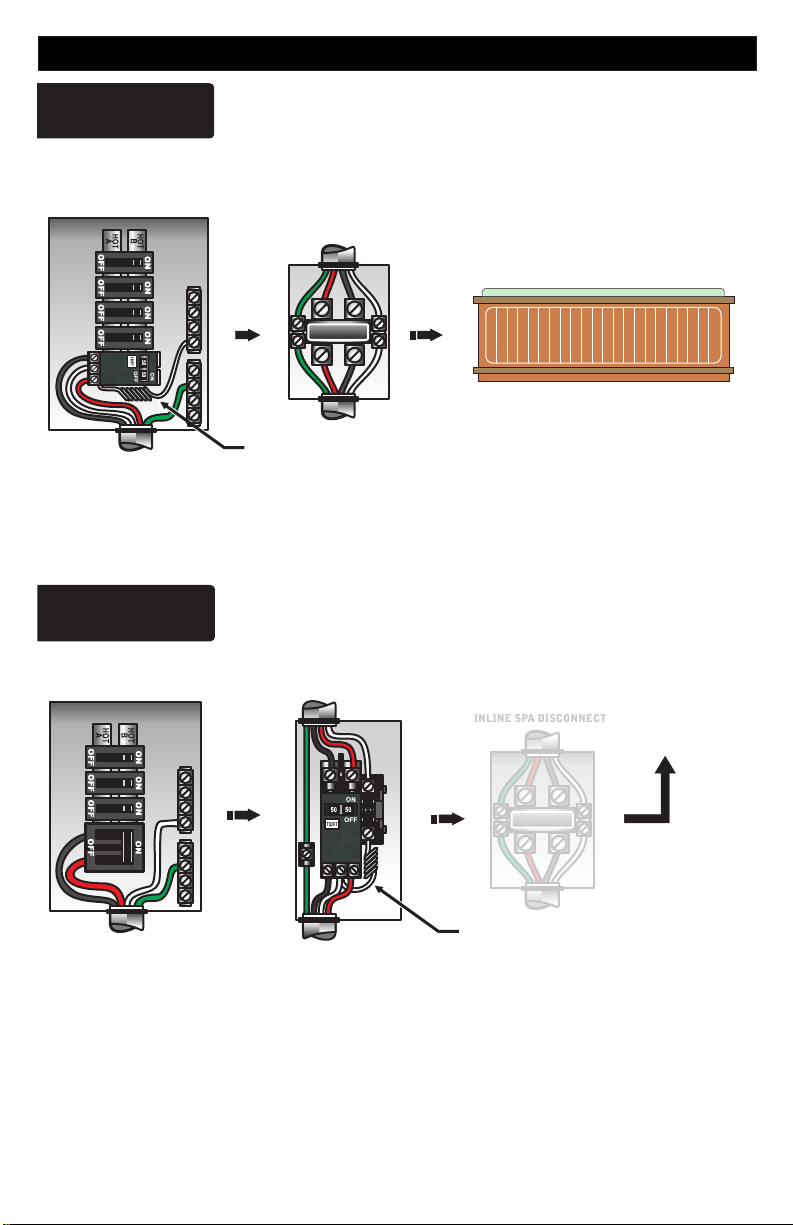

Electrical Installation

If your system was configured to include a 120VAC power cord, ensure that the proper

receptacle has been installed (a dedicated circuit is required). DO NOT under any

circumstances modify a 20 Amp plug to fit into a 15 Amp receptacle or use an extension

cord. Doing so will create hazardous conditions and/or invalidate the warranty.

OPTION 3

15/20AMP CORD END GFCI

MAIN BREAKER PANEL

Units with 15A / 20A GFCI Plug Connection

DEDICATED

15A / 120V OUTLET

PORTABLE SPA

This illustration depicts a typical 15 AMP, cord-end GFCI installation.

(The spa must be installed on a dedicated circuit.)

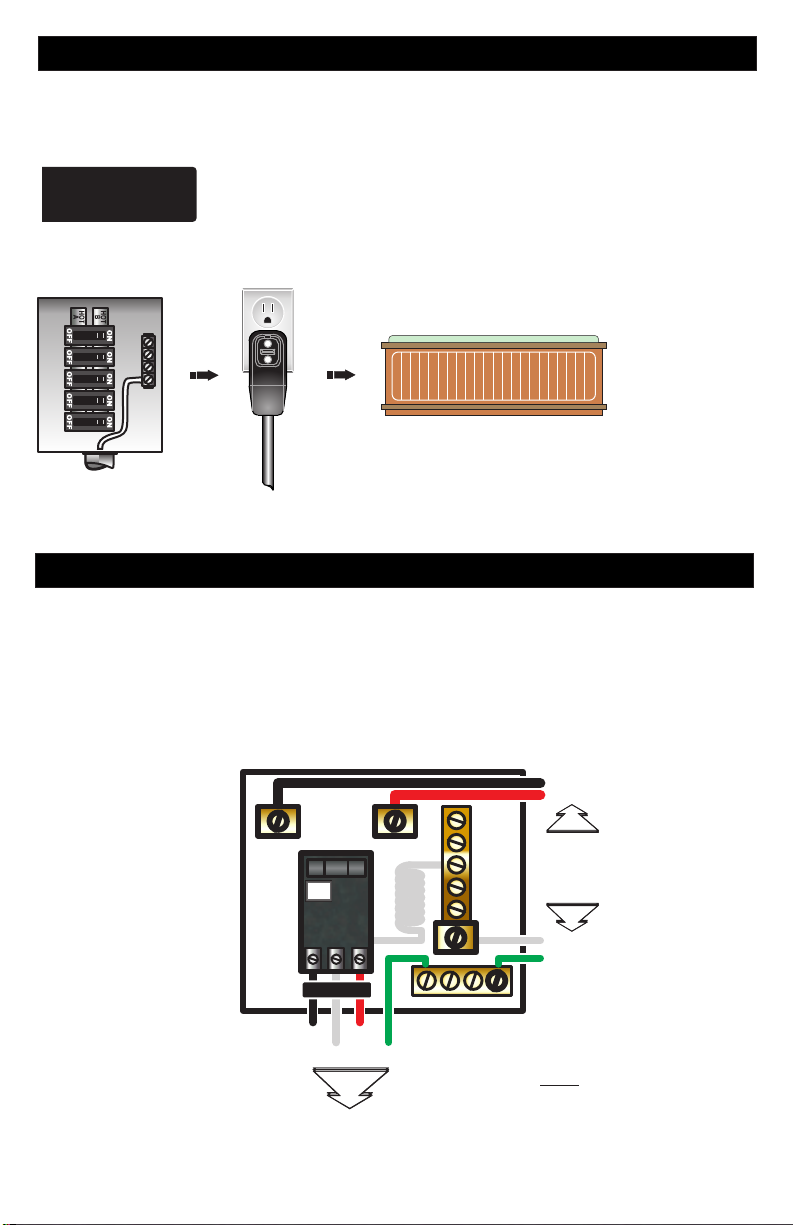

GFCI Wiring Detail

It is important that the GFCI circuit breaker is installed correctly. Often this

component has been improperly installed causing the breaker to instantly trip

when the system is turned on. Below is an illustration of a typical GFCI breaker

installation.

WARNING: Refer to the circuit breaker manufacturers installation

instructions. This illustration is meant to be a guide for Field Technicians

and is not intended to override or substitute the instructions supplied with

the circuit breaker.

LINE 1

LINE 2

LINE LUG #1

TEST

GFCI

(Ground Fault Circuit Interrupter)

CIRCUIT BREAKER

LOAD

LINE 1

NEUTRAL

TO SPA CONTROL SYSTEM

LINE LUG #2

LINE 2

GROUND

INCOMING

SERVICE

CONDUCTORS

FROM

MAIN

NEUTRAL PIGTAIL

GROUND BUS BAR

NEUTRAL BUS BAR

LOAD NEUTRAL MUST BE CONNECTED

DIRECTLY TO GFCI AS SHOWN

PANEL

NEUTRAL

GROUND

7

Heater Installation

The "U" Series Fixed Heater and "US" Series Slide Heater systems will arrive from the factory with the

heater mounted in the bottom location as pictured in Step 1. The "US" Series Slide Heater can be used in

this configuration or you can move the Slide Heater to the back of the control as shown below to align

easily with your particular plumbing arrangement.

Slide heaters are using the Gecko in.flo technology so it may be installed on either the

pressure or vacuum side of the pump.

Step 1

Remove the control system from the carton and

verify contents for completeness. If the

application is a bottom mount installation then

you are ready to go directly to step 6.

Step 3

Adjustable

Clamp

Adjustable

Clamp

When the adjustable clamps are mounted to the

heater, adjust the stud locations to align with the

slide brackets on one end. Do not tighten nuts

yet.

Step 5 Step 6

Step 2

EZ-Access

Heater Retainer

If you n eed to r elocate the heate r for your

installation, simply remove the EZ-Access Heater

Retainers and remove the heater from under the

box. To utilize the slide brackets, install adjustable

stud clamps that are provided in the installation kit to

the heater assembly.

Step 4

Align the other studded clamp and attach to the

other slide bracket. Now determine the proper

alignment for the heater and tighten the nuts and

clamps

Adjustable

Clamp

Ground/Bond the heater directly to the control

box using #8 solid bonding wire. (not included)

Connect the power control cords from the heater

to the matching receptacles on the control box.

Versi-Heat / Optional Heaters

The Versi-Heat series heaters are supplied with a 60” cord which allows for versatile installations and

locations. BE SURE HEATER IS INSTALLED HORIZONTALLY.

Versi-Heat heaters are pressure switch controlled. They must be installed on the

pressure side of the pump.

IMPORTANT - Heater pump must provide a minimum flow of 18 GPM through the heater.

8

Power Connection

IMPORTANT: Always refer to the product data label (located on top of the

control box) for specific electrical information.

Ÿ Use copper conductors only as required by the NEC.

Ÿ Secure wires as defined by the NEC and in compliance with any local

codes in effect at the time of installation.

240-VOLT ELECTRICAL SERVICE REQUIREMENTS

P9 (240V)

INPUT

VOLTAGE

240V

RED

WHITE

BLACK

L2

N

L2

L1

4

3

N

2

1

L1

GREEN

GR

Heater Voltage (P12) Brown Wire:

Moves to P9 for 240V (Default)

120-VOLT ELECTRICAL SERVICE REQUIREMENTS

INPUT

VOLTAGE

120V

---

WHITE

BLACK

GREEN

N

L1

---

L1

4

3

N

2

1

GR

P5 P7

P79

P2

P5 P7

P79

P2

P9

P10

P14

P15

F1

P11

P13

P6

P78

P12

P12

P10 (120V)

P9

P10

P14

P15

F1

P11

P13

P6

P78

P12

P25

FUSE 30A

P18

P19

P25

FUSE 30A

P18

P19

P17

P17

P21

P21

Heater Voltage* (P12) Brown Wire:

Moves to P10 for 120V

*Heater wattage is rated at 240V. When running 120V to heater, output is approximately 25%.

IMPORTANT- All equipment must be rated for 120VAC.

9

Circuit Board Configurations

Component Volts Amps Wire End Color Code From To

P1 2-SPD 240V 12A Red

N L2

Pump 2 240V 12A Violet / Blue

N L2

Pump 3 240V 10A Violet

N L2

Blower 240V 8A Violet

N L2

Ozone 240V 1A Yellow

N L2

Circ Pump 240V 2A Blue

N L2

All component outputs are pre-configured for 120V. If 240V output is required, please

utilize the illustration below and the wiring diagram that was included with your unit for

the correct component location to properly convert to 240V.

Neutral & L2

Sections

K2

K4

K6

G N

P47

P48P49P50P51P52

P53

P56

P57

P58

P59

P60

P61

P62

P55

L2

P67P68P69P70P71P72

P73

P77

120V

Neutral Section

N

240V

L2 Section

L2

Voltage Selection Chart for 240V Conversion

2-SPEED PUMP CORD CONFIGURATION

The following wiring configuration is for two-speed pump circuits.

System

Pump Cord Connections

Black = High Speed

Red = Low Speed

White = Common

Green = Ground

SINGLE SPEED PUMP / ACCESSORY CORD CONFIGURATION

The following wiring configuration is for single-speed pump circuits, circulation

pumps, ozones, blowers and accessories.

Black = Hot/Line

System

White = Common

Green = Ground

Pump

Single Speed

Device / Acc

10

Wi-Fi Module Installation Kit (Optional)

Your new system has the capability to connect with the internet by using a Wi-Fi

Module Kit (sold separately).

If using this option with your system, please make sure to install the module kit

following these few steps:

Step 1 - Insert the wi-fi module cable connector (MODULE “CO”) into the empty

connection on the system circuit board marked “CO” (Fig.1)

Step 2 - Connect the other module (MODULE “EN”) directly to a wi-fi router

utilizing the included network cable and power adapter. (Fig.2)

Wi-Fi Module Kit

PT# 34-0216G

INTERNET

Fig.1

K6

P45

CO Port (Wi-Fi)

P46

P55

P77

CO C1CO

MODULE “CO” MODULE “EN”

Status

Indicator

Fig.2

WI-FI ROUTER

NETWORK CABLE

Circuit Board

Step 3 - Please follow the detailed instructions provided with the wi-fi module kit

to properly install your Gecko (in.Touch 2) App and control the spa.

Note: If you experience poor connection performance it may be necessary to

relocate the modules closer together.

Status Light Indicator

Spa Transmitter (CO)

Pairing mode Yellow (Blinking)

Spa controller not detected Red

in.touch 2 server detected

Module is fully functional

Blue

Home Transmitter (EN)

Pairing mode Yellow (Blinking)

Router not detected Red

Router detected Green

in.touch 2 server detected

Module is fully functional

* When the LED status is blinking (blue, green or red) this

indicates communication between the modules has not

been established

Blue

11

Spaside Control Installation

A optional placard has been provided with each control to eliminate problems

encountered when the spaside access hole is too large. Use the illustrations and

instructions below to install the spaside control provided with your system.

TAB LOCK

ADHESIVE

GASKET

IN IN

EXISTING HOLE

Step 1 - (If control cutout already exists,

determine if placard must be used. If existing

cutout is sufficient, disregard step 1.) Choose

a location for the spaside control. Using the

template provided, cut out a 2 5/8” X 6 3/8”

hole. Clean area and insert spaside control

making sure tab locks are rotated inward. (If

placard is required, position and secure using

the provided adhesive gasket.)

Step 3 - Remove protective film from display

window then clean the face of the spaside.

Now carefully align and apply the label. (Fig.3)

Overlay may vary

Fig. 3

PLACARD

OUT OUT

Step 2 - Rotate lock tab screws on face of

control clockwise to engage locks and secure

control into place.

Step 4 - Connect spaside to PCB

connection marked C1. (Fig.4)

K6

P45

MAIN KEYPAD

P46

P55

P77

CO C1CO

Fig. 4

12

Power

CS970XY Spaside Functions / Features

Pump 1 Pump 2 Blower Light

Program Temp Up Temp Dwn

Pump 1 - Press o nce to turn

Pump 1

Indicator

on low speed. Press a second time to turn pump to high

Pump 2

Indicator

Blower

Indicator

Filtration

Light

Indicator

Indicator

Heater

Indicator

speed

(with a dual-speed pump). A third time turns pump off.

A built-in timer automatically turns the pump off after 20 minutes unless manually deactivated

first.

The “Pump 1” indicator lights

up when Pump 1 is on. With

will fl ash when Pump 1 is on at

low speed.

dual-speed pump, indicator

Pump2 - Press once to turn on pump on, press a second will turn the pump off unless

Two speed pump. Two speed pump functions as Low, High, Off

A built-in timer automatically turns the accessory off after 20 minutes unless manually deactivated

first.

The “Pump 2” indicator lights

ey

Blower k

-

Press Blower key to turn blower on. Press Blower Key again

up when Pump 2

is on.

to turn

off.

A built-in timer automatically turns the accessory off after 20 minutes unless manually deactivated

first.

blower

The “

Light -

” indicator lights up

when Blower is on.

Press once to turn light on. Press Light key a second time to

turn light off.

A built-in timer automatically turns the light off after 2 hours unless manually deactivated first.

The “Light” indicator lights up

when light is on.

Temp Up - Use Up key to raise the temperature Set Point. The temperature setting will

be displayed for 5 seconds to confirm your new selection.

The "Set Point" icon indicates that the display shows the

desired temperature,

NOT the current water temperature!

Temp Down - Use Up key to lower the temperature Set Point. The temperature setting

will be displayed for 5 seconds to confirm your new selection.

The "Set Point" icon indicates that the display shows the

desired temperature,

NOT the current water temperature!

13

Spaside Functions / Features (Cont.)

Power Key - This key provides access to:

Manual Economy Mode - When active this mode forces the system to maintain a

temperature 20F° less than the set temperature. The display will toggle between “E ”

the clock and the water temperature. Press the power button again to disable economy

mode.

E = Economy mode active

E = Economy mode not active

FILTER/PROGRAM Key: A quick press of the Filter key will allow you to display the

clock. A long press of 5 seconds will allow you to enter the program menu. In the

program menu, the following parameters can be set: the clock, the filter cycles or the

purge cycles, the economy mode and the temperature units. While you are in the

program menu, use the up or down keys to adjust the parameters and use the Filter key

jump to the next parameter.

Note: Changes will be saved after the confirmation of the last parameter only. If

there is no key press for 10 seconds, the system will exit the program menu

without saving the changes.

Setting the Clock: Enter the programming menu by pressing and

holding the FILTER key for 5 seconds. The current time will be

displayed with the hours flashing.

Press the UP or DOWN key to adjust the hours accordingly making

sure the PM indicator is set properly.

* PM indicator

Press the PROGRAM key to advance to changing the minutes

Press the UP or DOWN key to adjust the hours accordingly making

sure the PM indicator is set properly.

Setting the Filter Cycle: Enter the programming menu by pressing

and holding the FILTER key for 5 seconds. The current time will be

displayed with the hours flashing. If adjusting the clock is necessary

do it now, otherwise press the FILTER key repeatedly until FS## is

displayed. “FS” represents FILTER START “##” represents the

start time hour.

Press the UP or DOWN key to adjust the hours accordingly making

sure the PM indicator is set properly.

Press the FILTER key until F ## is displayed. “F ” represents

FILTER DURATION “##” represents the run time for the filter cycle

in hours.

0 = No Filtration

24 = Continuous Filtration

P

P

14

Spaside Functions / Features (Cont.)

Setting the Filter Cycle Frequency: - Enter the programming menu

by pressing and holding the FILTER key for 5 seconds. The current

time will be displayed with the hours flashing. If adjusting the clock is

necessary do it now, otherwise press the FILTER key repeatedly until

FF## is displayed. “FF” represents FILTER FREQUENCY “##”

represents the number of cycles per day, 1 - 4 cycles per day.

Press the UP or DOWN key to adjust the cycles as required.

Setting the Economy Mode: Enter the programming menu by

pressing and holding the FILTER key for 5 seconds. The current time

will be displayed with the hours flashing. If adjusting the clock is

necessary do it now, otherwise press the FILTER key repeatedly until

EP## is displayed. “EP” represents ECONOMY PROGRAM

“##” represents cycle enabled or not

1 = On / Cycle Enabled

0 = OFF / Cycle Disabled

Press the UP or DOWN key to adjust the setting as required.

Setting the Economy Start Time: Enter the programming menu by

pressing and holding the FILTER key for 5 seconds. The current time

will be displayed with the hours flashing. If adjusting the clock is

necessary do it now, otherwise press the FILTER key repeatedly until

ES## is displayed. “ES” represents ECONOMY START, “##”

represents hour the cycle starts

Press the UP or DOWN key to adjust the setting as required paying

close PM indicator.

Setting the Economy Duration: Enter the programming menu by

pressing and holding the FILTER key for 5 seconds. The current time

will be displayed with the hours flashing. If adjusting the clock is

necessary do it now, otherwise press the FILTER key repeatedly until

PP

e ## is displayed. “e ” represents ECONOMY DURATION,

“##” represents the active time in hours.

Press the UP or DOWN key to adjust the hours as required

0 = No Economy

24 = Continuous Economy

Changing the Temperature Readout: Enter the programming menu

by pressing and holding the FILTER key for 5 seconds. The current

time will be displayed with the hours flashing. If adjusting the clock is

necessary do it now, otherwise press the FILTER key repeatedly until

F or C is displayed.

Press the UP or DOWN key to adjust as required

F = Farenheit

C = Celcius

15

Power Up & Breaker Setting

Power-up & breaker setting

Boot up display sequence (Each parameter is displayed for 2 seconds)

8.8.8

Lamp test

All the segments and

LEDs light up.

260

Software number

Software Part Number Revision of the Software

2

Software Revision

Low-level selection

Low-level selected

from Low-level menu

It’s important to specify the current rating of the GFCI used to ensure safe and efficient

current management (and reduce nuisance GFCI trippings).

98

Thevalues displayed by the system

correspond

amperage capacity of

Use

desired value.

modified typically from10to 48

AMP.

to 0.8 of the maximum

Down button to select the

Up /

the GFCI.

The valuecan be

safe

the

and

It'simportant to specify

current rating of the GFCI

usedto ensure

efficient

(and reduce nuisanceGFCI

trippings)

Press and hold Filter button

until you access the breaker

setting menu.

NOTE: If all installed components do not operate or only one

component can be operated at a time it may be caused by this

setting. Set breaker size accordingly to allow components to run.

current management

.

Changing System Low-Level Program Configuration

Although every system has been factory set, in certain cases when servicing or replacing a

unit in the field, it may be necessary to set a new pre-determined low-level program

configuration. Follow these simple steps to re-enter the low-level programming using the

spaside control.

Then press Filter button to set breaker

rating. This table shows typicalsettings

for different

of b

one that matches your breaker.

GFCI b

60 Amp 48 Amp

50 Amp 40 Amp

40Amp 32Amp

30Amp 24

20Amp

GFCI ratings. Select the

Amp

Amp

16

98

Pressand hold the Pump 1

key for 30 seconds

The spaside display will show L xx

configuration number

Use the

Temp Up/Down

number and press the

the configuration selectionchart below).

If the Filter key is not pressed within 25 seconds, the unit will exit this menu

without changing any settings.

registered in the system.

keytochoose the new desired

Filter key to confirm the selectedconfiguration (referto

where "xx" representsthe previous

low-level configuration

Low-Level Configuration Number Chart

If at power-up of the system and spaside display shows the following message: , it

means that all low-level configurations have been downloaded, but no configuration

number has been chosen.

L __

16

Smart Winter Mode

Smart Winter Mode (SWM) protects the spa and equipment by monitoring the

temperature within the equipment bay. When a freezing condition is detected SWM

becomes active for the next 24 hours. During this period the system will start the Pump(s)

and Blower for a minimum of 1 minute at preset intervals becoming more frequent the more

severe the freezing condition becomes.

The Filtration Icon “Blinks” when

“Smart Winter Mode” is active

Spaside Messages

An internal hardware error has been detected in the spapack

Temperature sensor malfunction

This error will occur when a problem with the temperature sensor exists.

Contact your local spa dealer

Water has exceeded 108F at the temperature sensor.

The heater, pump and accessory will be deactivated until the water

cools. Be sure to check the actual water temperature with an accurate

thermometer.

DO NOT ENTER SPA WATER!!

The spa water has exceeded 119F at the high-limit sensor.

The heater will deactivate while the pump and accessory will still

operate. The blower (if equipped) can be activated to help cool the

water. Water must be below 119F and power must be reset to clear the

“HL” error

DO NOT ENTER SPA WATER!!

1. A dirty spa filter can also cause a restricted flow of water, be sure the

filter is cleaned regularly and ensure all water shutoff valves are open.

2. If the system has been operating normally until now, the pump may

be overheating the spa. Refer to “Programing Filtration” on page 18 and

reduce the duration and/or number of cycles per day.

3. If you’ve eliminated items 1 & 2 as problems, the high-limit sensor

may have malfunctioned.

Contact your local spa dealer

The system did not detect any water flow while the heater pump was

running.

Make sure that the low-level programming has been properly set, with

or without circulation pump (depending on your system configuration)

Make sure water valves are open and proper water level

Check and remove anything obstructing the filter

17

Spaside Messages Cont’d

The system detected water flow when the heater main pump was

or is off.

Make sure that the low-level programming has been properly set, with

or without circulation pump (depending on your system configuration)

If present while heater pump is off pressure/flow switch may be stuck

shut or need replacement and/or adjustment.

Ground

RED:

Pump 1 / 2-Speed

PINK:

Pump 2 or 3 / 1-Speed

Ground

Brown:

Pump 2 / 2-Speed

No low-level

configuration software

has been downloaded

intothe system.

Temperature inside the spa skirt istoo high, causing the

internal temperature in the spa pack to go above normal

limits .

System Plug Pinouts

High Speed / Black

Low Speed / Red

Common / White

Hot / Black

Ground

Common / White

Low Speed / Red

High Speed / Black

Common / White

PURPLE:

Air Blower / 1-Speed

YELLOW:

Ozone

BLUE:

Circ. Pump

Note flat sides in connector

Low Speed / Red

High Speed / Black

Common / White

Ground / Green

Ground

Hot / Black

Common / White

Common / White

Ground

Hot / Black

Ground

Hot / Black

Common / White

Testing / Replacing the Sensor Set

18

Operation Considerations

The following describes situations you may encounter and situations to be

aware of.

Warm Weather Conditions

Since your spa will normally be expected to maintain warm to hot water ready for use, a great deal of

attention has been directed to the energy conservation detail of insulation to keep electrical cost down.

Energy conservation efficiency may be achieved by extensive insulation of the spa cabinet, plumbing,

spa shell and in some climates full foam insulation may have been provided. This energy conservation

feature may cause an inconvenience during warmer times of the year. During warm periods of the year,

the temperature within the equipment compartment can elevate to a point that the pump will automatically

turn off for a short amount of time (15-30 minutes) to allow the pump to cool down before automatically

restarting. This cool down feature will not harm your spa, but serves only to protect the pump from

damage ad as and indicator that it is too hot. To minimize this occurrence, refrain from using your

Hydrotherapy Jets for prolonged periods of time during warm seasons. The jet pump chosen for your spa

has been specifically sized for maximum performance and your Hydrotherapy enjoyment.

Filtration System

Please refer to your Spa Manufactures Owner’s Manual regarding the operation, maintenance and

cleaning of your filtration system.

IMPORTANT - Heater pump must provide a minimum flow of 23 GPM through heater.

Winterizing

When freezing weather and/or power losses are expected, contact your local spa dealer for freeze

protection or winterizing recommendations for both the spa and the equipment system. Freeze

related damage is not covered by the warranty.

Chemical Water Treatment

Your dealer is familiar with local water conditions and which chemicals are compatible with and designed

specifically for your spa. This is the best person to advise you on proper water quality management. The

one thing you can do to insure years of trouble free equipment operations is to maintain proper water

chemistry.

Two basic goals of the chemical water treatment are sanitizing and balancing the water. Sanitizing simply

means keeping the water free from microorganisms including algae, bacteria and viruses. The current

most popular chemicals for sanitizing include chlorine, bromine and ozone.

Balancing water means establishing a balance among pH, total alkalinity and total hardness. Water that is

unbalanced can corrode the spa and it’s support equipment or leave deposits of minerals. Properly

balanced water is essential to allow the sanitizing chemical to work effectively. There are numerous

chemical additives to help you in controlling pH, total hardness and alkalinity. Never use softened water

when filling you spa. Softened water is extremely corrosive to the metal parts of the spa equipment and

may lead to an unforeseen failure. Sometimes, despite your most diligent efforts, your water may become

to far out of balance to be managed chemically. At this point it is probably better to drain and clean the spa

and start over with fresh water. Equipment failure caused be improper water chemistry will not be covered

under warranty. Saltwater purification systems can potentially damage your equipment. Any related

failures will not be covered under warranty.

19

Troubleshooting

The following describes situations and possible solutions to common problems you may

encounter as a spa owner.

Nothing Operates

Main Breaker is OFF - Set to On.

Sub-Panel Breaker Off - Set to On.

Equipment GFCI Off - Set to On.

Power switch in Off position - Set to On.

Components not plugged in - Plug in components.

Power cord not plugged in - Plug in power cord.

Over or High Temperature Protection On - Refer to Spa Side Messages.

No, Low or Surging Water Flow

Air Lock in Plumbing System - “Bleed” the system.

Restricted Flow - Insure that the water shut-off valves are open and that suction

fittings are not blocked by debris.

Dirty Filter - Clean or replace filter.

Low Water Level - Increase water level to recommended level.

Low Speed Pump Not Operational

Circuit board configuration is Incorrect - Contact your local dealer.

Pump Not Plugged-In - Plug in the Pump.

Blown Fuse - Contact your local dealer.

Jets or Blower Not Operational

Blower or Pump Not Plugged-In - Plug in the Blower or Pump.

Blown Fuse - Contact your local dealer.

Over or High Temperature Protection On - Refer to Spa Side Messages.

TroubleShooting

20

Troubleshooting

Therapy Jet Not Operational

Water Shut-Off Valves are Closed - Open Shut-Off valves.

Dirty Filter - Clean or replace filter.

Jets Not Properly Adjusted - Adjust Jets properly.

Diverter Valve Not Properly Adjusted - Adjust diverter valve properly.

Thermal Overload Tripping - Check for restricted flow of water.

Water Leaks

Spa Overfilled - Adjust water level.

Too Many People in the Spa - Adjust water level.

Drain-Valve Left Open - Close drain valve.

Couplings or Unions Loose - Tighten or contact your local dealer.

Pump Seal Leaking - Contact your local dealer.

Plumbing / Connections Leaking - Contact your local dealer.

Water Leaking from Spaside Control - Contact your local dealer.

Water in Air Blower Plumbing - Contact your local dealer.

No Heat

Temperature Not Set Correctly - Adjust Set Point.

Over or High Temperature Protection On - Refer to Spa Side Messages

Current Limiting On - 120V Systems will not heat if High Speed or Blower is on.

Contact your local dealer.

No Power - Reset breaker at service panel.

Low Water Flow - Clean or Replace filter.

System is in Rest Mode - Refer to Modes on page 19.

Light Not Operation

Light Bulb Defective - Replace bulb or contact your local dealer.

Reflector has Fallen Off - Replace deflector or contact your local dealer.

Light Not Plugged-In - Plug in the Light.

High Heat

Filter Cycles Running Too Long - Adjust filter cycles down.

Temperature Set Too High - Adjust Set Point.

High Ambient Temperature - Remove spa cover.

GFCI Breaker Trips Occasionally

Lightning / Electrical Storm or Power Surge

NOTE: The GFCI breaker must be properly installed by a licensed electrician.

GFCI Breaker Trips Immediately

Defective Component or Improper GFCI Breaker Installation - Contact a qualified

service technician or the factory for assistance.

Temp/Hi-Limit sensor not connected - Connect Temp/Hi-Limit to P38 on PCB

- Reset GFCI Breaker.

21

System Data Label

Note: This information will be necessary if you should ever have to request warranty or

any other type of service.

The system data label is located on the control box. This label is very important and

contains information you will need to establish your electrical service. The voltage and

amperage ratings are shown on the bottom of the label. Product, Model, Serial and Code

numbers are also shown on the label.

Corona, CA 92880 | www.hydroquip.com

SAMPLE

E99812

Warranty Information

Hydro-Quip warrants its products to the original purchaser to be free from defects in

material and workmanship for a period of 1 year (12 months) from the original date of

purchase, except as noted below.

Products which become defective within the warranty period will be repaired or replaced (at

the option of Hydro-Quip) except for damage due to freezing, water chemistry, negligence,

abuse, misuse, misapplication, unauthorized modification, improper installation, normal wear

and tear or chemical attack.

This warranty extends only to normal, personal (non-commercial) usage by the original

purchaser. Pump seals, o-rings, gaskets, air blower brushes are only covered for 90 days

from original date of purchase.

Hydro-Quip will not be responsible for labor incurred in removing, inspecting or reinstalling of

warrantable products. Hydro-Quip will not be responsible for any travel related charges or

labor costs attributable to disassembly and reassembly of the spa, skirt, decking or any other

materials enclosing the product, or attributable to difficulties in gaining access to the product.

Hydro-Quip will not be responsible for labor incurred for routine maintenance, adjustments or

alterations to the calibration of electrical devices.

Any products which are claimed to be defective must be shipped freight prepaid to HydroQuip and the repaired or replaced product will be returned to the sender freight collect. When

sent to Hydro-Quip, the product must be accompanied by the sales receipt or other proof of

the purchase date as well as the sender's name, mailing address, daytime phone number and

a detailed description of the defect as well as any other information relating to this claim.

Unless state law expressly provides otherwise, Hydro-Quip will only be responsible for repair

or replacement of any of its products that are found to be defective as provided above, and will

not bear the cost of any consequential damages. This warranty gives you specific legal rights

but you may have other rights which vary from state to state.

22

85-

0127B

Rev.03.1 07/19

Loading...

Loading...