Outdoor Series

INSTALLATION

& OPERATIONS

MANUAL

Covers the following CS & ES Models:

ES8848A, ES8848B, ES8848C, ES8848D, ES8848E,

ES8848J, ES8848H, ES8848J, ES8850A, ES8850B,

ES8850C, ES8850D, ES8850E, ES8850F, ES8850G,

ES8850H, ES8850J, CS8800A, CS8800B, CS8800C

JL

To ensure that the system is installed

properly, provide your electrician with

these instructions.

8800 BP Series

TABLE OF CONTENTS

Getting Started 1

Terms / Glossary 2-3

System Requirements & Considerations 4-5

NEC Guidelines & Gas/Electric Combination Systems 6-7

Electrical System Sizing 8

GFCI Breaker Wiring 9

Connecting Power to the System 10-14

Wiring Individual Components 15

Gas Heater Options 16

Pump Cord Connections 17

Air Blower Installation & System Configuration 18

Spa Light Wiring 19

Plus Ozone™ / Ozonator / Installation 20-21

Spaside Control Installation 22

Wi-Fi Module Installation 23

System Configuration Options 24-25

Your Spaside Control / Menu Navigation 26-27

System Start Up 28

System Functions, Features & Programming 29-32

Locking and Unlocking Spaside 33

Spaside Messages, Error Codes & Troubleshooting 34-41

System Data Label 42

Warranty Information 43

GETTING STARTED

For the best installation possible, review all the provided instruction materials, and share

with your electrician/installer for advanced planning. A complete understanding of what's

needed before starting work will make things go smoothly, and at the lowest possible

cost.

This manual includes complete instructions for electrical and plumbing connections,

including the addition of pumps, gas heaters, lights, system startup, troubleshooting,

and your warranty guidelines.

First identify the Equipment System (ES) or Control System (CS) from your product

label. Refer to this code when using the GFCI breaker sizing matrix, and wiring diagrams

in this manual

ES series controls include a plastic mounting base, and main system pump. The

separate quick –start sheet #85-0115-4 has detailed instructions for pack assembly, and

pump cord installation

CS series controls are designed for a wall mount application. Your electrician must follow

all local codes and restriction pertaining to placement of an accessible electrical service.

* Copies of this manual are available online at www.hydroquip.com

Your Hydro-Quip 8000 series control has a factory pre set program. Details for changing

system behavior and/or adding new components will be found in this manual.

ATTENTION!

This manual includes instructions for all options available on the ES/CS systems.

Depending on how your system is equipped, some options like Plus Ozone™, Wi,

blowers, gas heaters etc may not apply to your installation.

Warning! Make no attempt to modify, disconnect, damage or adjust the safety devices

contained in this equipment system. Alteration of safety devices can cause serious

component damage, and/or result in unsafe operation leading to personal injury or death

Save a copy of this manual

1

TERMS / GLOSSARY

AC Connection

Additional Panel Button

Amperage Requirement

AUX PCB

Auxiliary Pump

Blower

Bonding Wire

™

BWA APP

Copper Conductors

Dedicated Circuit

Default Programming

Dip Switch

Dip Switch Banks

Discharge

Alternating Current connection point (typically high voltage)

Refers to HQ PT# 34-0224. Required for 3rd pump operation

The accumulated total amperage of all items to be placed on a

single breaker

Smaller daughter board connected to main PCB

A pump that has been added to the original equipment system (ie Aux

pump #2 & #3)

Appliance providing compressed air for the purpose of massage therapy

Continuous bare copper wire connecting all metallic object and electrical

components to the equipment & ground rod

Downloadable Balboa Water Application for wireless system control

Electrical wires made from copper alloy materials

An electrical supply to a remote location, having breaker protection and

no additional branch or service connections

The standard position or programming in which the system is tested

and leaves the factory

Movable programming switch located within a switch-bank (on PCB)

Set of switches used to change operational logic and system behavior

(on PCB)

Pump exit side (piping placed on pressure side of pump)

Dual Source Wiring

Gas Heater Control Circuit

GFCI Breaker

GFCI breaker #1

GFCI breaker #2

Heater Input Leads

Jumper Pins

Electrical power supplied by two individual wiring sources (two breakers)

Wiring provided inside gas heaters, that can be connected to 8000

systems for operational control. Commonly called a fireman circuit

Ground Fault Circuit Interrupter. Specialty breaker with a detection and

reaction device to interrupt power when current leaking is detected to

ground

Main 8000 system breaker, required 4 wires with incorporated “Neutral”

Optional breaker for independent heater operation. Required 3-wire

connection, without “Neutral”

Provided wires for connection of heaters in the dual source

configuration

Circuit board electrical posts for logic changes.

2

TERMS / GLOSSARY

KW

Line of Sight

Logic Jumper

Liquid Tight Conduit

Main Control

Main Pump or Pump #1

NEC

PCB

Persistent Memory

Plus Ozone™/Ozonator

Priming

Pump Amperage

Pump Pot/Basket

Single Source Wiring

Kilowatt. Heater resistance rating used for identifying energy consumption.

A clear and unobstructed path, in which an object or item can be spotted from

or near the spas edge.

Movable coupling located on the jumper pins for changing operational

behavior

Tubing that resists water and debris penetration, made specifically for

wiring

In reference to the 8000 series control box, with factory provided components

System provided pump used for heating and filtration

National Electrical Code. Regulations for design and materials on electrical

installation.

Printed Circuit Board (refers to main board)

Programming that remains unchanged, until the power is turned off and back

on

Appliance designed for spa water sanitation

Initial pump operation until the air is evacuated from the pump and supply

lines

The highest amperage measured, when the pump is under full load

condition

Reservoir mounted to the pump with removable lid and strainer basket

Electrical power supplied by a single wiring source and breaker

(one breaker)

Sub Panel

Suction

System Data Label

System Disconnect

Terminal Strip

Total System Amps

Wi-Fi Enabled

An electrical service box mounted remotely from the main house power panel

Pump front inlet side (piping between spa suctions and pump pot)

Label placed on control box providing serial identification, and vital data

An easy and safe means of 100% electrical disconnection, without

obstruction or the need for tools. See NEC and UL qualifications for approved

devices.

Electrical connection point for components within the PCB cabinet

Highest amperage measured when all components are operating

simultaneously

Having the capacity to control using a wireless connection

3

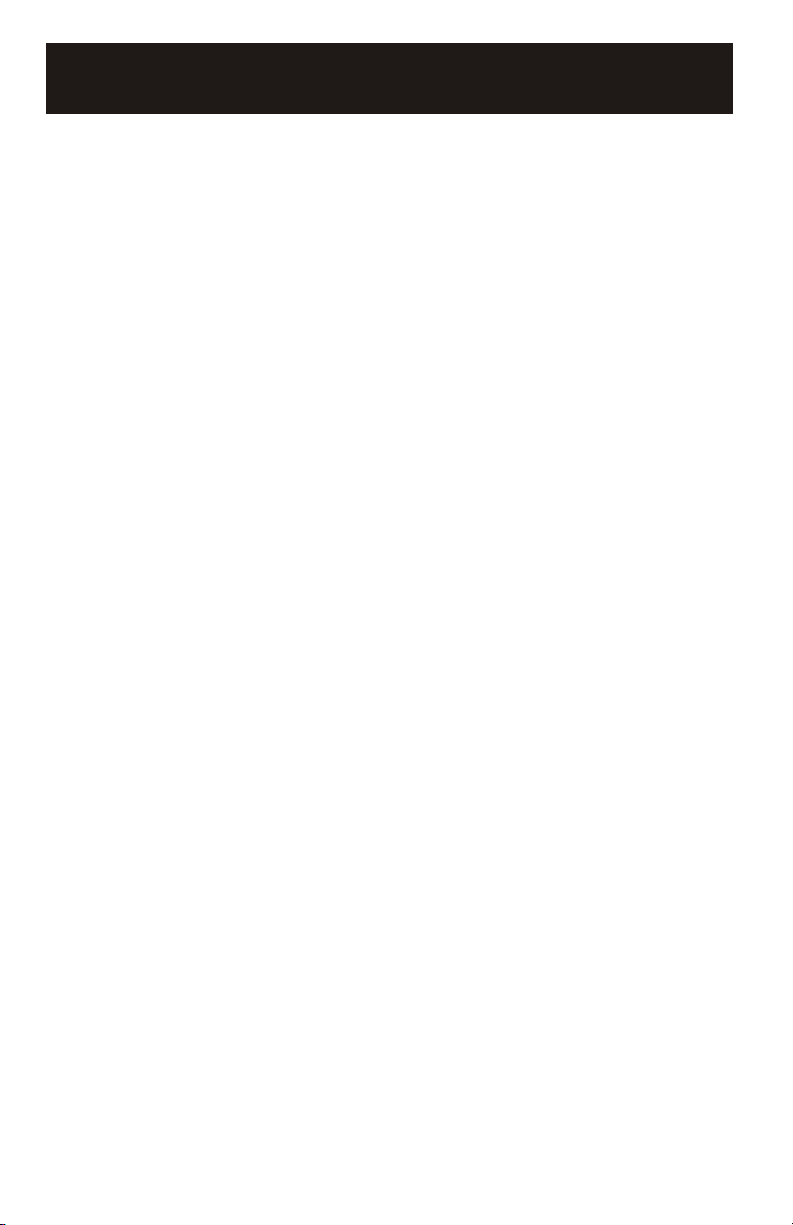

SYSTEM INSTALLATION REQUIREMENTS

The Hydro-Quip 8000 Series Solid-State Systems were designed for indoor or outdoor installations.

This equipment may be used for both inground and above ground spas/hot tubs.

The Equipment System must be installed on a firm, level

surface (ie: concrete or plastic base)

The area where the system is installed must have adequate

Above Water Level

drainage to prevent flooding of the equipment under all

circumstances.

For performance reasons locate the system as close to the

spa/hot tub as practical. (Consult local codes for minimum

REMOTE HEATER SYSTEM

8000

RHS SERIES

distance between equipment and spa)

Provide adequate access around and above the System for

service and maintenance. Three (3’) of clearance around the

equipment is recommended.

The pump(s) provided with the system may or may not be

self-priming. Pumps that are NOT self priming must be

installed BELOW water level or they will not prime.

The Spaside control has a 50’ cord length. Plan routing

distance between the equipment and vessel to be less than

44ft.

Water Level

REMOTE HEATER SYSTEM

8000

RHS SERIES

Below Water Level

(Flooded Suction)

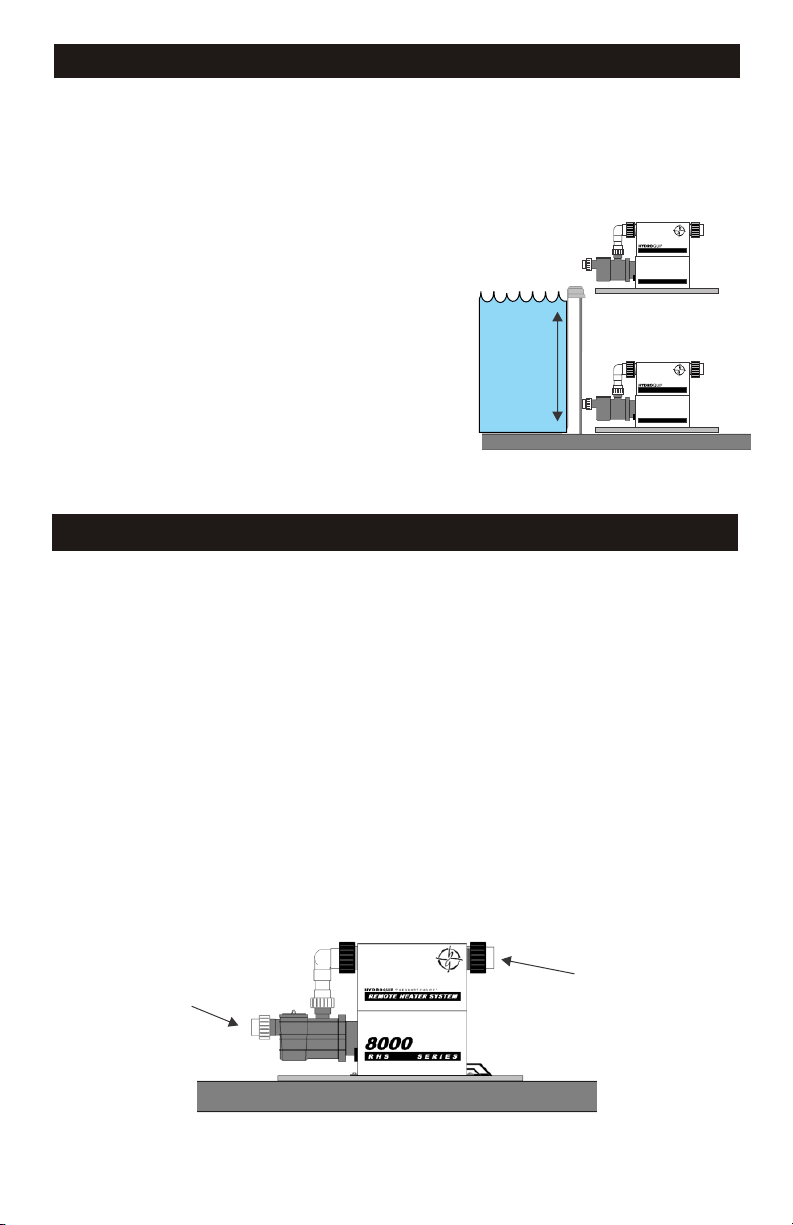

PLUMBING INSTALLATION INSTRUCTIONS

To assure adequate performance, the use of 2” piping is recommended.

There may be 3 or 4 separate plumbing systems in the spa. Verify the function of each pipe.

1) Suction System Plumbing - this plumbing will connect to the spa’s skimmer, main drain and

suction fittings. This plumbing connects to the front end of each pump.

2) Discharge System Plumbing - this plumbing will go to the spa’s hydrotherapy jet and massage

fittings. This plumbing connects to the open end of the heater on your Equipment System.

3) Air Blower Plumbing - this plumbing will go to an air channel under the floor, or to an air distribution

manifold of the spa. This plumbing connects only to an air blower.

4) Aux Pump Plumbing - When more pumps are added, this piping will not interconnect with the

heater control system. Follow the spa/hot tub manufactures instruction for connection, and safety

suction requirement

5) Understand in advance the spa manufactures plumbing design for ozone delivery and make

accommodation in your plumbing plan.

To allow for safe operation of the spa/hot tub, the suction fittings must be agency approved and rated

Max Flow capacity.

After plumbing is complete, secure the Hydro-Quip Equipment System with the appropriate

hardware.

Suction

Discharge

Refer to plumbing schematic Fig.1 on page 15

4

INSTALLATION CONSIDERATIONS

The Hydro-Quip 8000 series incorporates the most advanced controls in the industry, and

are designed for years of trouble free operation. However, for year round success, review

these design recommendations for extreme weather areas.

*For best results, review this manual completely before starting your project.

Hot weather conditions

Water temperatures can be elevated from high outside “ambient” temperatures. If this

occurs, remove the insulating cover and add cool water until the heat has dissipated to a

safe level

Hot temperatures and/or direct sunlight to the equipment system can cause temporary

operational problems.

Pumps are equipped with special overload devises to self protect when encountering

extreme heat conditions. All motors are equipt with an automatic reset device, and will

resume operation when they become cool. Pumps can be enclosed, but require adequate

ventilation

Direct sunlight on equipment can bring temperatures beyond the allowable point for

circuits to function correctly. The system will shut off into a protection mode (see

troubleshooting guide.) To prevent this condition, plan an equipment cover that

incorporates shade, access and ventilation

Freezing weather conditions

If you wish to utilize/operate your system during seasons that may experience freezing

temperatures, please incorporate pipe insulation, draining capabilities and incorporate

an equipment cover that protects from snow and freezing rain. In all cases standing water,

and snow should not be allowed to accumulate in or around the equipment.

If you wish to winterize your spa/hot tub, please contact your spa/hot tub manufacturer or

local area pool/spa/hot tub professional for details.

In all cases make a plan for system draining in case of a power loss. Where possible,

design plumbing drains and disconnects to evacuate water before it becomes frozen and

does system damage.

Note the 8000 systems incorporate a freeze sensing technology, that will automatically

operate the pumps when temperatures drop below 43F. Moving the water will not allow

pipes and equipment to form ice.

5

ELECTRICAL INSTALLATION

NOTICE! Before attempting installation of this equipment system, read all the

information contained in this manual, and confirm the installing electrician understands

and follows all national and local codes and safety instructions.

All connections must be made by a qualified and licensed electrician in accordance with

the National Electrical Code (NEC article 680 Canadian Electric Code, and with any local

codes in effect at the time of installation.

All connections must be made according to the electrical installation label on the outside

of the system box (see page 33) Follow all instructions provided in this manual, and at

labeled connections. If your electrician in unclear on how to correctly connect this

equipment, call your system supplier. Note that damage caused by mistakes can be

costly, and invalidate your warranty.

A GFCI (Ground fault circuit interrupter) breaker is a mandatory electrical device required

for installation on all pool/spa applications as specified in the National Electrical Code

Article 680-42.

The GFCI must be properly sized, and be connected with the appropriate sized wire per

NEC Code Table 310-16. All ground wires must be connected per NEC Table 250-122

Follow the instructions provided in this manual (see pages 7-9) for proper location and

connection of this safety device

This equipment requires a dedicated electrical supply circuit, with no other appliances or

lights connected.

IMPORTANT – The NEC and most local codes require that an electrical “disconnect” be

installed within “line of site” of the spa

Use copper conductors only, with grounding wire properly sized per the National Electric

Code table 250-95.

A bonding lug has been provided on the control box, allowing connection to local ground

points. To reduce the risk of electrical shock, use only a properly sized copper bonding

wire from this lug to all metal ladders, water pipes and other metallic objects within 5 feet

of the spa/hot tubs edge.

CAUTION: Do not connect or disconnect any components while the power is on.

All connections must be done with the power off as it may cause damage to the

system.

**Any resulting damages are not covered under manufacturer’s warranty**

CAUTION: Damage may occur to the circuit board and spaside if the spaside

plug is not properly aligned to the receptacle on the circuit board or if the

spaside plug is connected or disconnected while the power is on.

**Any resulting damages are not covered under manufacturer’s warranty**

6

ELECTRICAL INSTALLATION

This equipment system has been100% factory tested for quality and reliability prior to

shipping. Care should be taken on all electrical connections to avoid damage to the system

circuit board, and added components. Damage caused by accidents, improper wiring

configurations and/or abuse voids your warranty.

Start by having your electrician select a wiring configuration that best fits your total system

needs. (see the GFCI breaker sizing matrix on page 8)

Due to the availability of GFCI breaker sizes, and your electrical supply requirement, some

systems require a second independent or “dual” power source, to supply the electric heater

separately. Diagrams for independent heater wiring are provided in this manual.

Note; 5.5kw systems using a single source power supply will not allow electric heater

operation when pumps are in high speed. See system programming to change operation if

available.

System Type Heater size Connection type

Gas heat none Single source power supply

Electrical heat 5.5kw Single source power supply

Electrical heat 5.5kw Dual source power supply

Electrical heat 11.0kw Dual source power supply

Gas/Electric Combo 5.5 or 11kw/Gas Single Source power supply

All Hydro-Quip 8000 series control systems require a 4 wire electrical supply, incorporating

a “Neutral” wire for operation. Electric heaters being powered independently in the “dual”

circuit configuration do not require a neutral wire supply. This is clearly explained in the

wiring diagrams.

For gas heaters electrical connection, consult your gas heaters supplier manual, and note

in this manual contains important wiring instructions for control and operation of the gas

heaters fireman circuit.

Gas and electric heater combination

When faster heat recovery is desired, or a redundant heat source is a priority, it’s possible

to install both a gas and electric heater on the same 8000 series system.

Default programming allows both the gas heater control circuit (page 15) and electric

heater circuit to operate simultaneously. Input from both heat sources will speed up heating

times, and also provide an operating alternate if one source becomes disabled. You must

follow all installation instructions for both the gas heater, and electric heater plumbing and

wiring requirements to successfully connect. No PCB programming change is required.

7

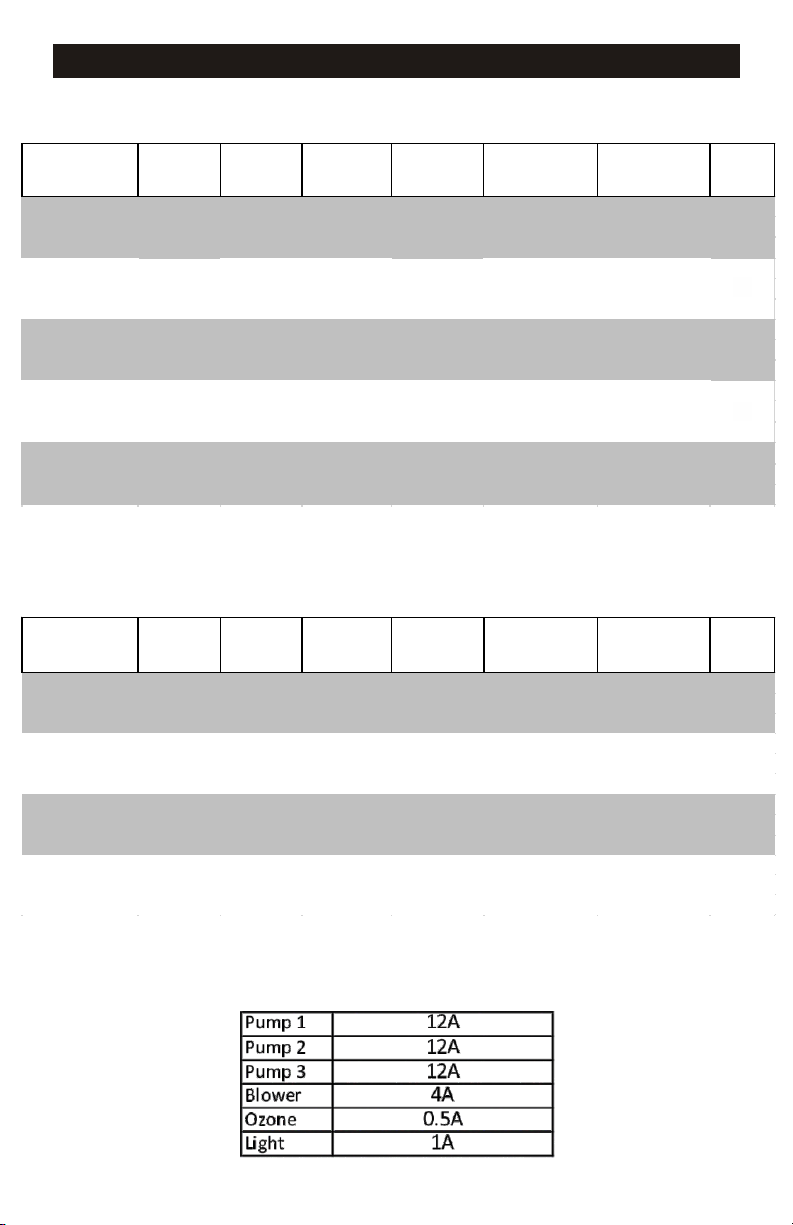

GFCI BREAKER SIZING MATRIX

240V Single source wiring (One breaker required)

Syste m or de r

code on labe l

ES8848G, H, J

ES8850G, H, J

CS8800C

ES8848G, H, J

ES8850G, H, J

CS8800C

ES8848G, H, J

ES8850G, H, J

CS8800C

ES8848D, E

ES8850D, E

CS8800B

ES8848D, E

ES8850D, E

CS8800B

Syste m

heater type

Gas x _ _ 17

{

Gas x

{

Gas x x x

{

5.5kw x _ _

{

5.5kw x x _

{

240V Dual source wiring with separate heater electrical supply

(Two breakers required)

System orde r

code on labe l

ES8848D, E x x x 43amp s yste m 50 am p #1

ES8850D, E, F 5.5k w _ _ _ 24amp h e ate r 30 am p #2

CS8800B

ES8848A, B, C x _ _ 17amp s yste m 20 am p #1

ES8850A, B, C 11kw _ _ 46am p he ater 60 am p #2

CS8800A

ES8848A, B, C x x _ 30amp sys tem 40 amp #1

ES8850A, B, C 11kw _ _ _ 46amp he ate r 60 am p #2

CS8800A

ES8848A, B, C x x x 43amp sys tem 50 am p #1

ES8850A, B, C 11kw _ _ _ 46amp he ate r 60 am p #2

CS8800A

System

he ate r type

{

{

{

{

Pump 1 &

Syste m

17A Max

Pum p 1 &

System

17A Max

Aux. pum p- 2

12A max

Aux. pu m p- 2

12A m ax

Aux. pum p- 3

12A max

x _ 30

Aux. pu m p- 3

12A m ax

Total s yste m

Am ps

43 50 amp #1 13

41 50 amp #1 12

54 60 amp #1 12

Total sys tem

Am ps

GFCI Break e r Page

20 amp #1

30 amp #1 13

GFCI Bre ak e r Page

13

14

14

14

13

13

11

12

10

10

10

**IMPORTANT NOTE**

Max Amp Per Circuits

8

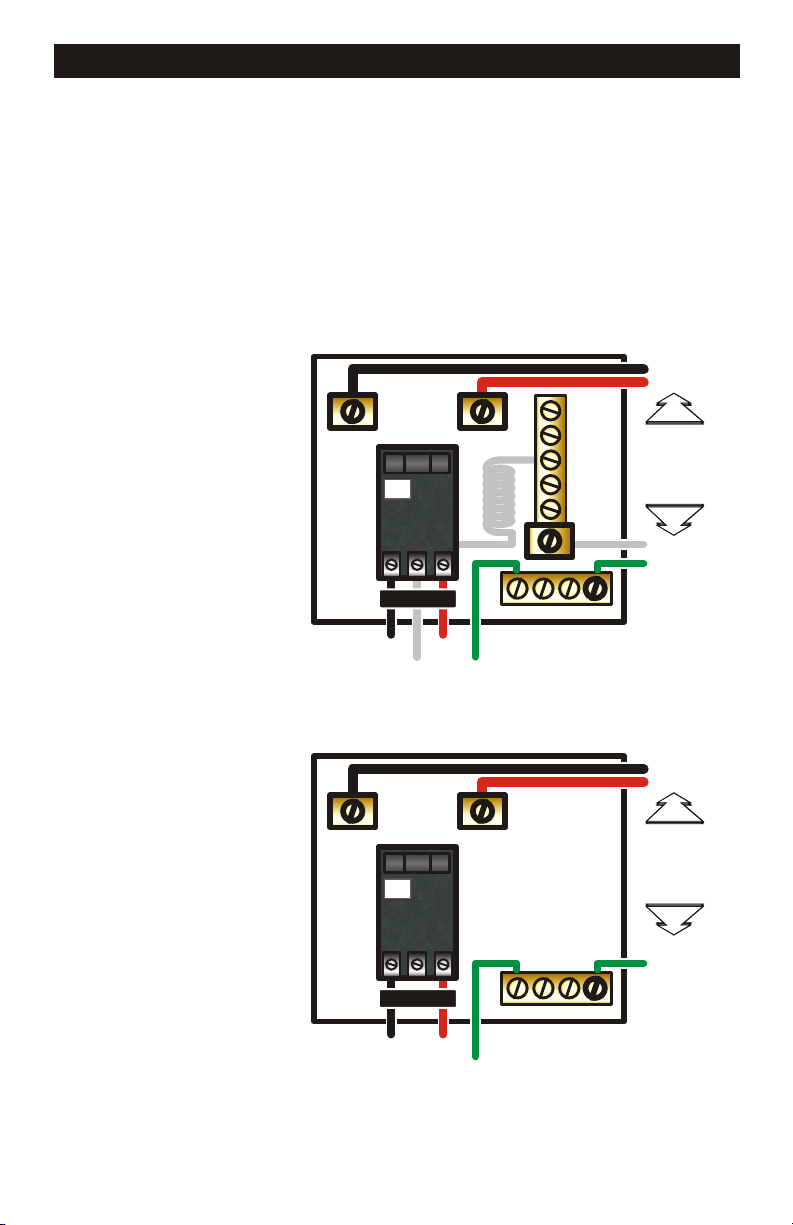

GFCI BREAKER WIRING DETAIL

Improperly wired GFCI breakers are the leading cause of immediate GFCI tripping. It

is important that your system be wired properly, reference the illustrations below for

guidelines.

WARNING: Refer to the circuit breaker manufacturer’s installation instructions. This

illustration is meant to be a guideline, and not meant to override or substitute the

instructions supplied by the breaker manufacturer

LINE 1

LINE 2

GFCI BREAKER #1

(240v 4-wire with neutral)

GFCI BREAKER #2

(240v 3-Wire)

For Independent Heater

LINE LUG #1

LINE LUG #1

LINE LUG #2

TEST

GFCI

(Ground Fault Circuit Interrupter)

CIRCUIT BREAKER

LO A D

LOAD

LOAD

NEUTRAL

GROUND

TO SPA EQUIPMENT

LINE LUG #2

TEST

GFCI

(Ground Fault Circuit Interrupter)

CIRCUIT BREAKER

LO A D

NEUTRAL PIGTAIL

GROUND BUS BAR

GROUND BUS BAR

CONDUCTORS

NEUTRAL BUS BAR

CONDUCTORS

INCOMING

SERVICE

FROM

MAIN

PANEL

NEUTRAL

GROUND

LINE 1

LINE 2

INCOMING

SERVICE

FROM

MAIN

PANEL

GROUND

LOAD LOAD

GROUND

TO SPA EQUIPMENT

9

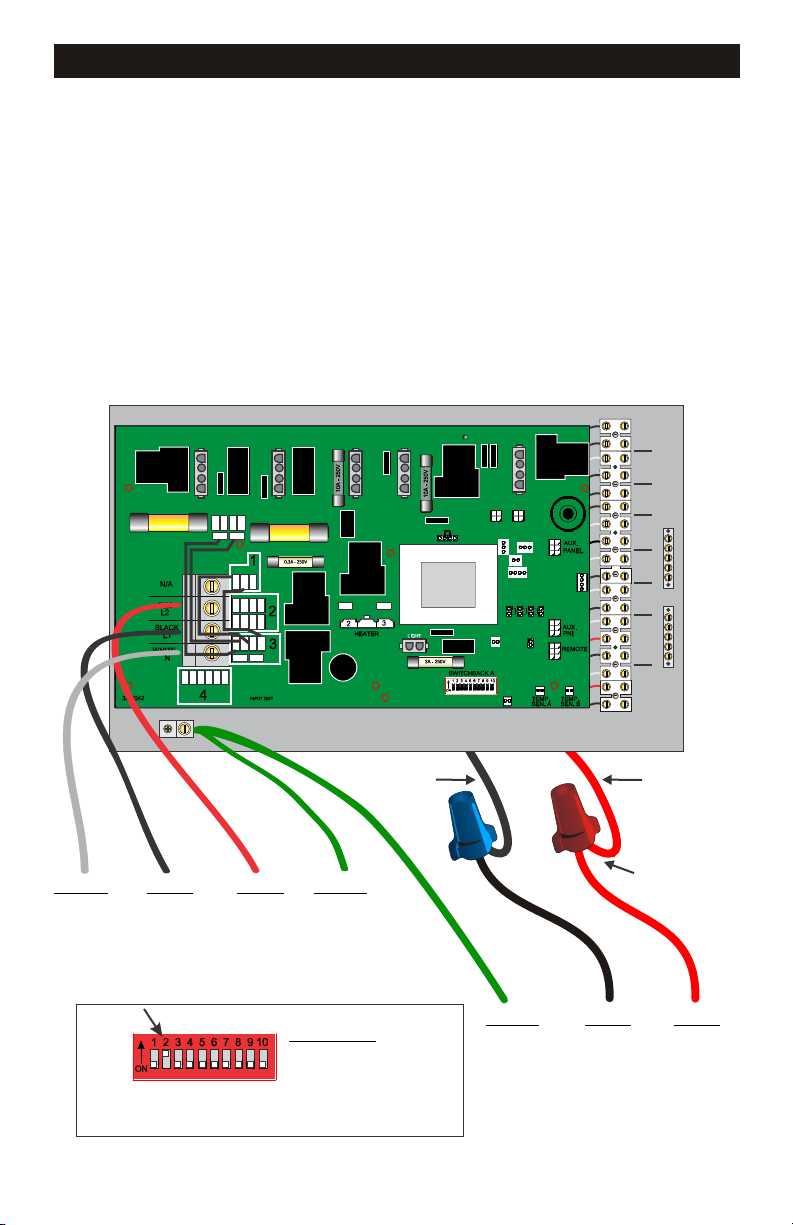

208V ELECTRICAL CONNECTIONS CONSIDERATIONS

IMPORTANT 208V INFORMATION

The system has the capability to operate on 208V provided certain changes are made

to the circuit board transformer and input wiring. When operating on 208V a compatible

pump must be used. A compatible pump would be either 120V or marked specically

for use with 208V.

**240V pumps provided by Hydro-Quip are NOT 208V compatible**

Below is an illustration of the system wiring as shipped from Hydro-Quip. Follow the

instructions on page #X and the illustration on page #X to make the system compatible

with 208V incoming power.

SWITCH

FIREMANS

L L

120V

LIGHT

J35

FUSE 30A

J34

J56

J57

J55

J59

FUSE 30A

J41J60

J51

J52

J98

J72

J42J3J61

J37J4J1

J47

J36

J12

J88

J62

J58J53

J45

J79

J54

J77

J75

J78

J49 J48

MAINMAIN

L C

L C

H L C

H L C L C L L L C

LIGHT

OZONE 12V

GROUNDGROUND

BLOWER

PUMP 3

PUMP 1 PUMP 2

GROUND

Neutral Line 1 Line 2 Ground

GFCI BREAKER #1

(240v 4-Wire only)

see page 8 for breaker sizing

Fig. A

SwtichBank ON:

A2: Add 1 HS Pump with heat

A3: Add 2 HS pumps with heat

A4: Add 4 HS pumps with heat

Move dip switch #2 - #4 to the ON position

to allow high speed pump(s) and heater to

function simultaneously

10

Black

Red

Heater main wires

electric heater models

only

Ground Line 1 Line 2

GFCI BREAKER #2

(240v 3-Wire only)

see page 8 for breaker sizing

Instruction

Wiring Instruction from 220-240v. to 208v. power supply

Ÿ Information provided for Balboa BP-2000 system board only

Ÿ 1 logic jumper P/N 34-20564 is included with this instruction

Ÿ Terminal Block wiring label

Ÿ New diagram# 5195-5197

WARNING! System power must be off when removing or installing logic jumpers

Logic jumper(s) must be programmed to match incoming power supply voltage.

Use these steps if a programming change is required

Step #1 Disconnect power

Step #2 Locate transformer programing bank at position J24 on PCB

Step #3 Conrm system supply voltage with your electrician.

Step #4 Use diagrams below to correctly place logic jumper(s) to match system supply voltage

(Dia #1 = 220-240V. ) (Dia #2 = 208V)

Step #5 Remove and Discard the jumper wire connecting J41 to J12

Step #6 Remove and Discard the jumper wire connecting J51 to J88

Step #7 The wire currently connected to J36 must be relocated to J51

Step #8 The wire currently connected to J52 must be relocated to J75

Step #9 The wire currently connected to J58 must be relocated to J52

Step #10 The wire currently connected to J49 must be relocated to J98

BEFORE AFTER

...connued from previous page

Step #11 New Incoming Power label provided must be applied to circuit board (illustraon below)

Step #12 This instrucon sheet and new diagram must be inserted in the faceplate slip if one is not

currently present

Below is an illustration of the system transformer and wiring converted and ready

for 208V use.

SWITCH

SWITCH

FIREMANS

FIREMANS

L L

L L

120V

120V

LIGHT

LIGHT

J35

J34

J35

FUSE 30A

FUSE 30A

J56

J57

J55

J59

J56

J57

J55

J59

FUSE 30A

FUSE 30A

J41J60

J41J60

J51

J52

J98

J51

J52

J98

J49 J48

J72

J42J3J61

J72

J42J3J61

J37J4J1

J47

J37J4J1

J47

J36

J12

J88

J62

J36

J12

J88

J62

J58J53

J58J53

J45

J45

J79

J54

J77

J75

J78

J79

J54

J77

J75

J78

J49 J48

J34

MAINMAIN

MAINMAIN

L C

L C

L C

L C

H L C

H L C

H L C L C L L L C

H L C L C L L L C

LIGHT

LIGHT

OZONE 12V

OZONE 12V

GROUNDGROUND

GROUNDGROUND

BLOWER

BLOWER

PUMP 3

PUMP 3

PUMP 1 PUMP 2

PUMP 1 PUMP 2

GROUND

GROUND

Neutral Line 1 Line 2 Ground

GFCI BREAKER #1

(208v-240v 4-Wire only)

see page 8 for breaker sizing

10

Black

Ground Line 1 Line 2

GFCI BREAKER #2

(208v-240v 3-Wire only)

see page 8 for breaker sizing

Red

Heater main wires

Heater main wires

electric heater models

electric heater models

only

only

208V ELECTRICAL CONNECTIONS CONSIDERATIONS

Below is an illustration of the system transformer and wiring converted and ready for

Below is an illustration of the system transformer and wiring converted and ready for

208V use.

208V use.

Note wiring changes at the input terminal block and at the voltage conversion jumper(s)

Note wiring changes at the input terminal block and at the voltage conversion jumper(s)

above the transformer.

above the transformer.

SWITCH

SWITCH

FIREMANS

FIREMANS

L L

L L

120V

120V

LIGHT

LIGHT

J35

J34

J35

FUSE 30A

FUSE 30A

J34

MAINMAIN

J56

J57

J55

J59

J56

J57

J55

J59

FUSE 30A

FUSE 30A

J41J60

J41J60

J51

J52

J98

J51

J52

J98

J49 J48

J72

J42J3J61

J72

J42J3J61

J37J4J1

J47

J37J4J1

J47

J36

J12

J88

J62

J36

J12

J88

J62

J58J53

J58J53

J45

J45

J79

J54

J77

J75

J78

J79

J54

J77

J75

J78

J49 J48

MAINMAIN

L C

L C

L C

L C

H L C

H L C

H L C L C L L L C

H L C L C L L L C

LIGHT

LIGHT

OZONE 12V

OZONE 12V

GROUNDGROUND

GROUNDGROUND

BLOWER

BLOWER

PUMP 3

PUMP 3

PUMP 1 PUMP 2

PUMP 1 PUMP 2

GROUND

GROUND

Neutral Line 1 Line 2 Ground

Neutral Line 1 Line 2 Ground

GFCI BREAKER #1

GFCI BREAKER #1

(208v-240v 4-Wire only)

(208v-240v 4-Wire only)

see page 8 for breaker sizing

see page 8 for breaker sizing

Fig. A

SwtichBank ON:

A2: Add 1 HS Pump with heat

A3: Add 2 HS pumps with heat

A4: Add 4 HS pumps with heat

Move dip switch #2 - #4 to the ON position

to allow high speed pump(s) and heater to

function simultaneously

10

Black

Black

Red

Red

Heater main wires

Heater main wires

electric heater models

electric heater models

only

only

Ground Line 1 Line 2

Ground Line 1 Line 2

GFCI BREAKER #2

GFCI BREAKER #2

(208v-240v 3-Wire only)

(208v-240v 3-Wire only)

see page 8 for breaker sizing

see page 8 for breaker sizing

11KW ELECTRICAL CONNECTIONS

11KW electric heat “Main” control system wiring diagram

SINGLE SOURCE WIRE CONNECTION

For correct wire and GFCI breaker sizing, Reference the GFCI breaker sizing matrix

page in this manual

Factory programming will prevent the heater and high speed pump from operating

simultaneously.

FOR SYSTEM MODEL CODES (Label located on outside of box)

ES8848A ES8848B ES8848C CS8800A

ES8850A ES8850B ES8850C

SWITCH

FIREMANS

L L

120V

LIGHT

J35

FUSE 30A

FUSE 30A

J34

MAINMAIN

L C

L C

H L C

LIGHT

OZONE 12V

GROUNDGROUND

BLOWER

PUMP 3

GROUND

Black

Red

HEATER MAIN WIRES

Neutral Line 1 Line 2 Ground

GFCI BREAKER #1

(240v 4-Wire only)

see page 8 for breaker sizing

11

H L C L C L L L C

PUMP 1 PUMP 2

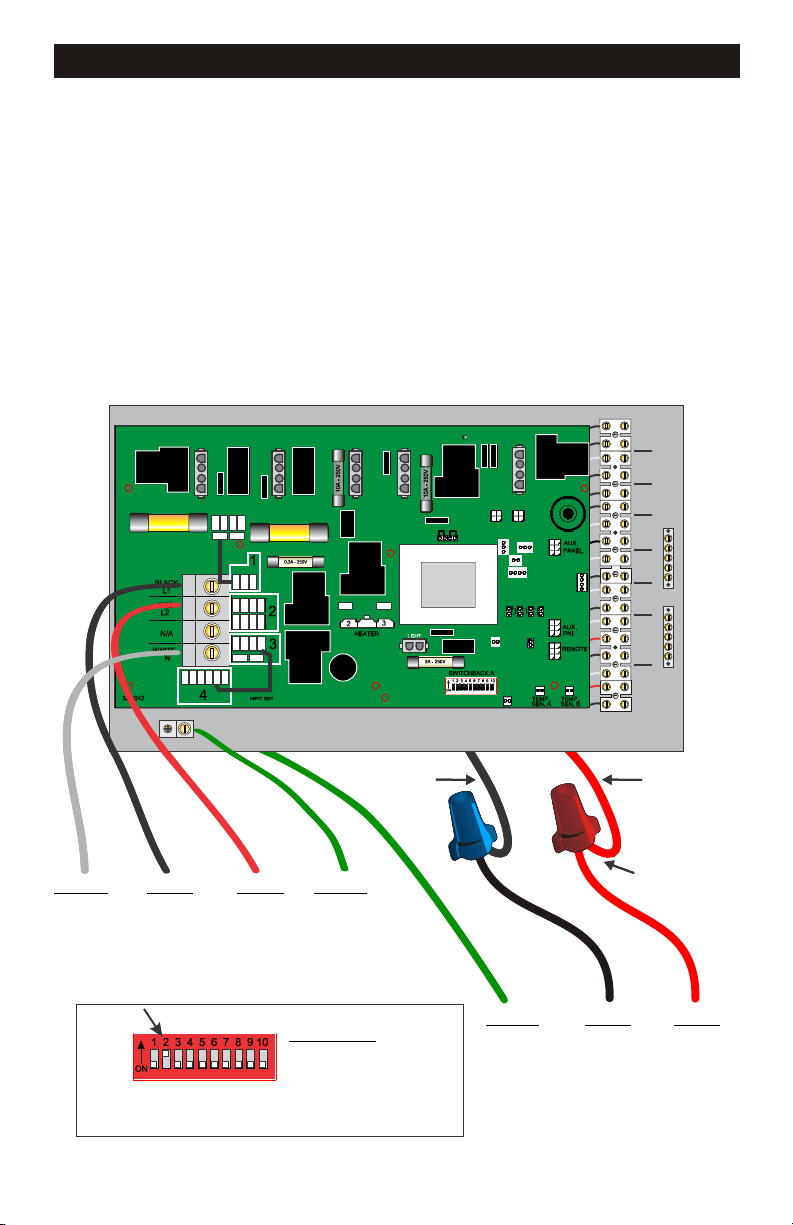

5.5KW ELECTRICAL CONNECTIONS

5.5KW electric heat “Main” control with independent heater wiring

DUAL SOURCE WIRE CONNECTION

For correct GFCI breaker sizing, Reference the GFCI breaker sizing matrix page in

this manual

Programming allowing heater and high speed pump operation simultaneously

requires “dip switch” change on board (see figure below)

FOR SYSTEM MODEL CODES (Label located on outside of box)

ES8848D ES8848E ES8850F

ES8850D ES8850E CS8800B

SWITCH

FIREMANS

L L

120V

LIGHT

J35

FUSE 30A

FUSE 30A

J34

MAINMAIN

L C

L C

LIGHT

OZONE 12V

GROUNDGROUND

BLOWER

PUMP 3

GROUND

Neutral Line 1 Line 2 Ground

GFCI BREAKER #1

(240v 4-Wire only)

see page 8 for breaker sizing

Fig. A

SwtichBank ON:

A2: Add 1 HS Pump with heat

A3: Add 2 HS pumps with heat

A4: Add 4 HS pumps with heat

Move dip switch #2 - #4 to the ON position

to allow high speed pump(s) and heater to

function simultaneously

12

Black

H L C

PUMP 1 PUMP 2

H L C L C L L L C

Blue

Heater main wires

Ground Line 1 Line 2

GFCI BREAKER #2

(240v 3-Wire only)

see page 8 for breaker sizing

5.5KW ELECTRICAL CONNECTIONS

5.5KW electric heat “Main” control system wiring diagram

SINGLE SOURCE WIRE CONNECTION

For correct wire and GFCI breaker sizing, Reference the GFCI breaker sizing matrix

page in this manual

Factory programming will prevent the heater and high speed pump from operating

simultaneously

FOR SYSTEM MODEL CODES (Label located on outside of box)

ES8848D ES8848E ES8850F

ES8850D ES8850E CS8800B

SWITCH

FIREMANS

L L

120V

LIGHT

J35

FUSE 30A

FUSE 30A

J34

MAINMAIN

L C

L C

H L C

LIGHT

OZONE 12V

GROUNDGROUND

BLOWER

PUMP 3

GROUND

Black

Blue

HEATER MAIN WIRES

Neutral Line 1 Line 2 Ground

GFCI BREAKER #1

(240v 4-Wire only)

see page 8 for breaker sizing

13

H L C L C L L L C

PUMP 1 PUMP 2

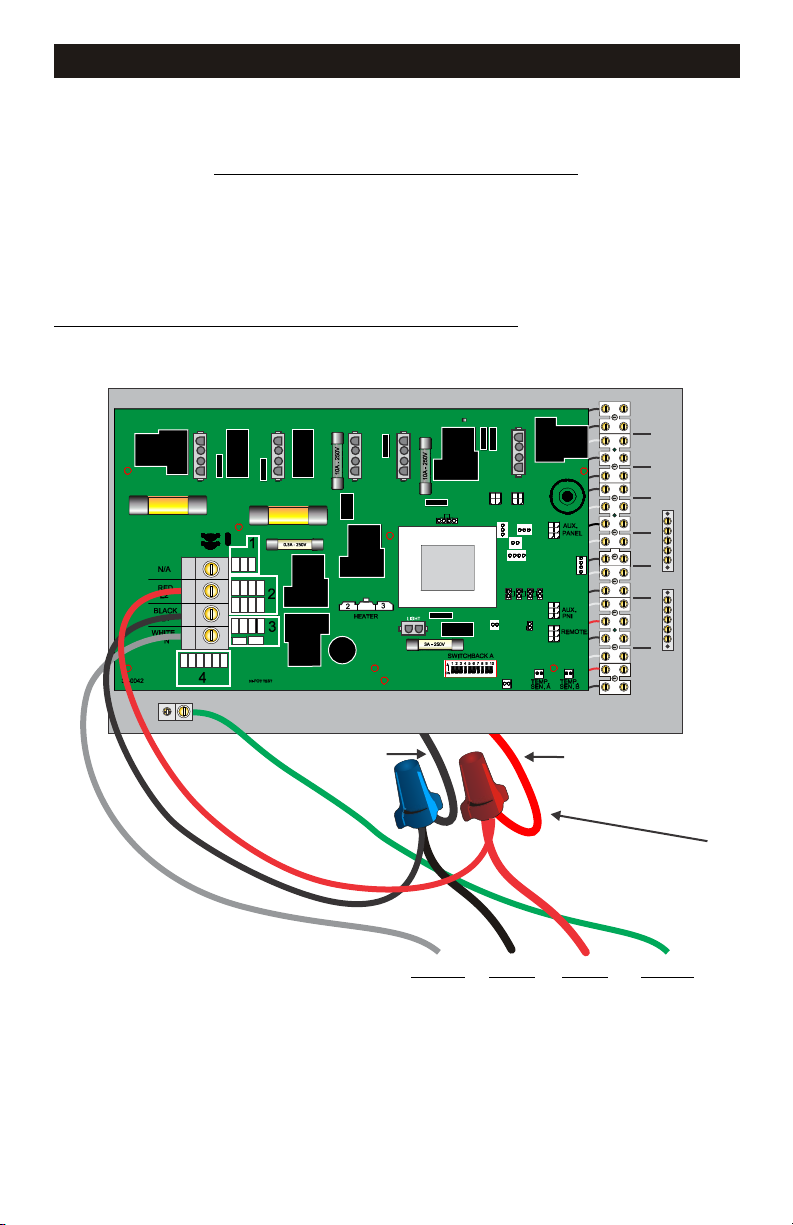

GAS ELECTRICAL CONNECTIONS

Remote gas heat “Main” control system wiring diagram

SINGLE SOURCE WIRE CONNECTION

For correct wire and GFCI breaker sizing, Reference the GFCI breaker sizing matrix

page in this manual

FOR SYSTEM MODEL CODES (Label located on outside of box)

ES8848G ES8848H ES8848J CS8800C

ES8850G ES8850H ES8850J

FUSE 30A

FUSE 30A

J35

J34

MAINMAIN

Gas heater

internal control

see page 15

SWITCH

FIREMANS

L L

120V

LIGHT

LIGHT

OZONE 12V

GROUNDGROUND

L C

BLOWER

L C

PUMP 3

GROUND

Neutral Line 1 Line 2 Ground

GFCI BREAKER #1

(240v 4-Wire only)

see page 8 for breaker sizing

14

Fig. A

Move dip switch #7 to the ON position to

allow 5 minute gas heater cool down

H L C

H L C L C L L L C

PUMP 1 PUMP 2

COMPONENT CONNECTION

The system is set up to have components hardwired to a terminal strip inside the upper enclosure.

Liquid tight conduit must be used on all externally added field connections exposed to the weather.

Route and connect the conduit to the knock-outs in the back of the lower box. The wires will then

enter the bottom of the upper box through another set of knock-outs. Connect the component(s)

accordingly to the corresponding position on the terminal strip and tighten securely. Refer to the

included wiring diagram as needed. All components not included with the system are set at the

factory for 120V. Verify the voltage of the additional component(s) and adjust supply voltage if

necessary by referring to System Configuration on page 10.

*Systems equipped with blowers and Plus Ozone options come pre connected to the terminal strip™

SWITCH

FIREMANS

FUSE 30A

FUSE 30A

L L

J35

J34

MAINMAIN

L C

L C

H L C

H L C L C L L L C

120V

LIGHT

LIGHT

OZONE 12V

GROUNDGROUND

BLOWER

PUMP 3

PUMP 1 PUMP 2

Lighting

Lighting

Sanitation

Air Blower

Aux. Pump

Aux. Pump

Primary Pump

GROUND

BLOWER

UPPER BOX

15

LOWER BOX

LIQUID-TIGHT

CONDUIT

TO EXTERNAL

COMPONENT

GAS HEATER CONNECTION

Warning: Do not install a spa that utilizes a natural gas or propane heater without proper

venting. These heaters require adequate ventilation and must be installed according to the

heater manufacturers instructions and to local building codes.

Warning: Gas heaters MUST be installed in the plumbing AFTER the control system as

shown below. Fig.1

Note: Many gas heaters require a separate electrical service for proper

operation, the Hydro-Quip “Gas Heater Control Circuit” does NOT

provide voltage to any gas heater circuits. Always refer to the manual

included with your gas heater for proper installation.

Flow

Spa/Hot Tub

Flow

Jets

Pump 2 Pump 3 Blower

Flow

Jets

Flow

Flow

Equipment System

ANALU & TATA

REMOTE HEATER SYSTEM

8000

RHS SERIES

Pressure Filter

Flow

TYPICAL PLUMBING LAYOUT

Gas Heater Control Circuit

Your control system contains a Gas Heater Control Circuit Fig.2. This circuit is a passive

or “dry contact” circuit, do not apply line voltage to this circuit. Connect this circuit to the

gas heater’s Fireman Switch or Fireman Circuit. Refer to the instructions provided with

your gas heater to identify the circuit / switch and correct wiring connection. Additional

programming may be required to the gas heater to utilize an auxiliary control system.

Gas Heater

Fig.1

Flow

SWITCH

FIREMANS

L L

H L C L C

12V

LIGHT

OZONE

PUMP 1

GROUND

To Gas Heater

Fireman Switch*

or

Fireman Circuit*

Inside control box

Terminal connection.

Fig.2

IMPORTANT: Applying line voltage to Gas Heater Control Circuit voids all

warranty.

16

PUMP CORD INSTALLATION

The equipment system has been provided with a pump power cord and liquid-tight

conduit assembly. This is to be used on the main 2-speed pump supplied with the

system. Any other components or accessories attached to the equipment system

should be attached in a similar manner.

Follow the simple instructions below to quickly attach the cord assy to the pump:

Cord Assy included for Pump 1

1) Remove the terminal cover off the

back off the pump

3) Route the power wires through the conduit hole and pull

toward you to allow for the cord assy to be rotated for tightening.

4) While holding the wires as shown

thread the liquid-tight connector into the

pump until secure then connect the

power wires to the pump per the label

on the pump.

WIRING NOTE:

RED = LOW

BLACK = HIGH

WHITE = COMMON

GREEN = GROUND

17

2) Remove the conduit hole cover

5) Route the other end of the conduit

through the empty knock-out and secure

with lock-nut. The cord inside will route

up to the terminal strip inside the upper

portion of the enclosure.

AIR BLOWER INSTALLATION (Optional)

PUMP 1 RED

PUMP 2 VIOLET

BLOWER BLUE

OZONE YELLOW

CAUTION: The air blower must be connected ONLY to the

spa’s air distribution plumbing. Connecting the air blower to the

air piping associated with the hydrotherapy jets will create a

hazzard by providing a path for high-pressure water to be

forced into the blower motor. This will result in damage to the air

blower, and create an electrical shock hazzard.

18” Above

Maximum Water

Level

Check Valve*

Above

Water

Level

ANALU D.

JASON LUGO

Ÿ The air blower must be installed to ensure that water

cann ot e nte r the air blo we r mot or. Thi s ca n be

accomplished by installing a single or double air loop that

incorporates a check valve.

Below

Water

Level

Check*

Valve

To

Blower

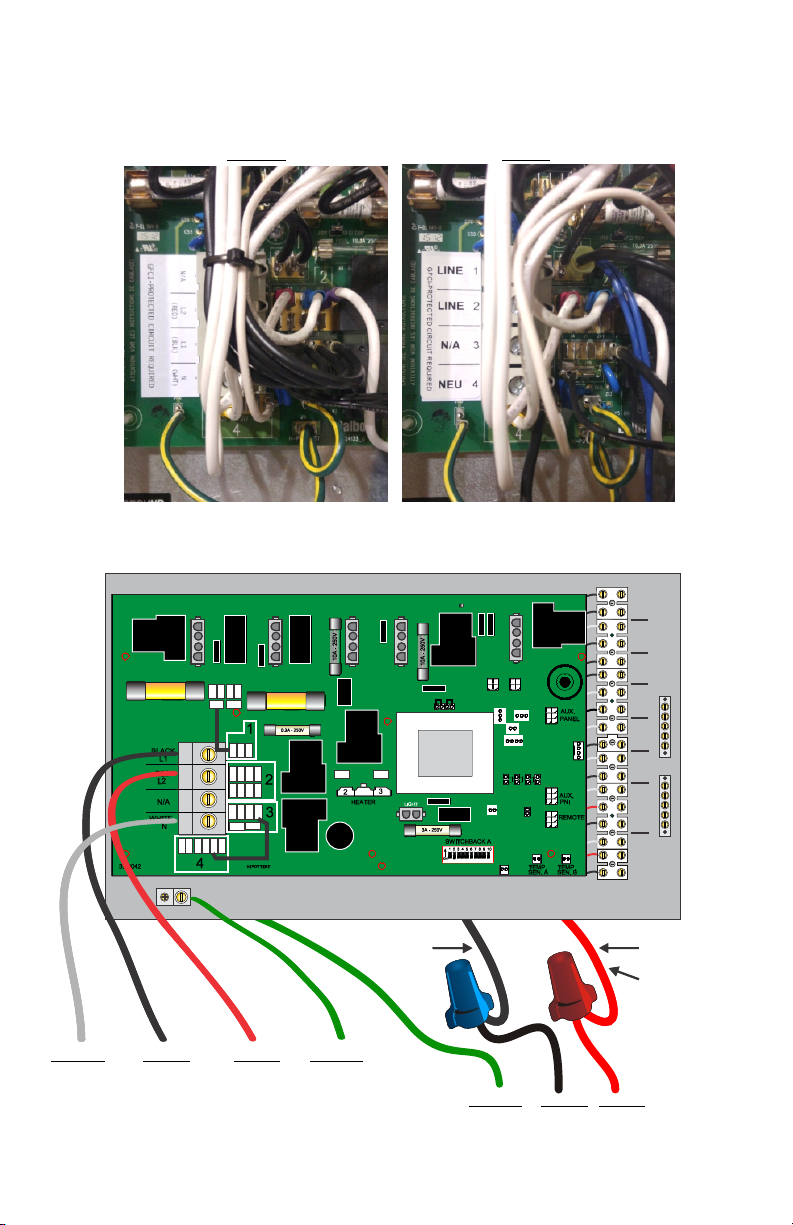

SYSTEM CONFIGURATION

This System was pre-configured by the manufacturer as follows:

Pump 1: 240V Pump 3: 240V Ozone: 120V

Pump 2: 240V Blower: 240V

CHANGING CONFIGURATIONS

Below are illustrations and instructions for converting the universal circuits of your control.

Hydro-Quip utilizes color coded connectors to help identify each circuit. Simply locate the

colored connector on the Neutral (white) wire from each component receptacle on the PCB.

Using the wiring diagram provided with each control (located inside of cover), remove the Neutral

connector from its Block 4 / Neutral position and reconnect to an empty position at the Block 2 /

Line 2 connection block. Once accomplished the conversion is complete, repeat these steps for

each component that operates on 240V.

COMPONENT COLOR CODE

(1) Remove connector from Block 4 connection

(2) Reinstall connector onto Block 2 connection

240V

Block 2

120V

RED AC

Block 4

WHT AC

18

SPA LIGHT INSTALLATION

To offer the most flexibility, Hydro-Quip configures each 8000 Series system so that it can

accept a 120-Volt light and/or 12-Volt light. A terminal block has been provided for connection

purposes.

Connect your light using the

illustration below.

GR-L1-N

120-Volt Light

Connection

19

L1-N

12-Volt Light

Connection

Plus Ozone Option

Systems equipped with the factory installed Plus Ozone™ option are identied with both a visible

green label on the front access door “A” and a generator connection barb extending from the

cabinet bottom. Follow these instructions and diagram to properly connect or disable the Plus

Ozone™ feature

*Refer to diagram #1 below for all locations for this section

8000 ES/CS Series outdoor control

ELECTRICAL CONNECTION:

The Plus Ozone™ generator comes prewired to the 8000 control system, there is no additional

electrical connection required

PLUMBING CONNECTION:

Locate the provided Ozone Check Valve Kit #48-0200 and follow the assembly diagram and

requirements for connecting check valve to tubing and ozone barb

ES SYSTEM WITH LOWER BASE CABINET

1. Select and remove ½” electrical knockout in lower cabinet for ozone tubing exit.

2. Install rubber grommet (provided) into hole for edge protection and insect block

3. Cut rubber grommet center skin open and feed tubing through hole

Your spa manufacturer will provide instructions for connecting the check valve to the spas ozone

vacuum plumbing. NOTE: This Check valve can only be connected to an air vacuum plumbing

DO NOT connect to pressurized water pipes

20

Plus Ozone Option

▲ IMPORTANT! Plus Ozone™ generators operate at high voltage and must never come in

contact with water at any time. The #42-0200 kit includes a one-way check valve that must be installed

correctly to prevent the backow of water into the ozone generator. Failure to install the valve or

installing the valve backwards may cause permanent damage and will void the product warranty.

▲ WARNING! Ozonators exposed to water may cause system electrical problems and

potential harm to the user. DO NOT connect tubing to the ozone generator barb, unless the

check valve has been installed correctly per the instructions

DISABLE PLUS OZONE™ OPTION:

If your spa does not have an ozone vacuum system connection, if you are unsure how to connect

plumbing, or if you choose not to use the Plus Ozone™ it's important to disconnect the electrical

power. To disconnect power, simply disconnect male and female plug connectors as shown in Dia #1,

then coil and store plugs out of the way in the cabinet

OPERATION:

The Plus Ozone™ system is only activated when the main lter pump (pump #1) is operating in low

speed. Reference “Filtration Settings” in this manual to adjust lter cycle duration that will directly

effect the length of time the Plus Ozone™ operates

ABOUT:

Plus Ozone™ is a Corona Discharge (CD) ozone generator that is self- operating, self-regulating and

contains no serviceable parts. Do not attempt to alter, adjust or repair this device. The Plus Ozone™

generator is automatically activated by system programing, to insure there is no operation without a

means of vacuum delivery.

It is normal to encounter a purication smell at the water surface, conrming ozone is being generated

and delivered. Potency has been regulated on this device, and remains non-adjustable for your safety

and convenience. Ozone gas applies an instant sanitation effect to the water, however is does not

build or maintain a lasting residual. Therefore, ozone becomes ineffective shortly after the generator is

turned off

Ozone generated by this device is solely intended for the sanitation of water and the inner walls of the

delivery piping system by means of direct exposure, the effectiveness and expected benet is strictly

limited to the time during operation. IMPORTANT! Consult with your spa manufacturer and/or local

pool and spa professional to establish an additional chemical regiment for water care

SERVICE:

1. The Plus Ozone™ barb has a removable intake lter that must be cleaned annually. Remove the

lter (ref lter on Dia #1) and wash with clean water, allow to dry and re-install.

2. The one way check valve should be visually inspected and tested annually to conrm water is

not getting back to the Plus Ozone™ generator.

WARNING! Disconnect tubing from the generator and electrical connection as described in

“Disable Plus Ozone™ option” immediately if found to have water present in tubing. Contact

your Hydro Quip supplier for replacement valve and tubing.

3. Plus Ozone™ CD generators have a rated life cycle of 9000 hours, after which the output of the

generator is greatly diminished and requires replacement. Calculate your annual operational hours by

multiplying your accumulated daily lter cycle time by 365. This will give you an idea when the

generator will need replacement. Contact you're your Hydro Quip system provider for instructions for

replacement

21

SPASIDE CONTROL INSTALLATION

If required, you may have to cut out a hole in the spa shell to install spaside control.

Ÿ The mounting area must be above the maximum water level of the spa and in an area with

good drainage to prevent any standing water on or around the spaside.

Ÿ The spaside should never be submerged.

Ÿ The spaside should be protected from extended periods of exposure to sunlight.

Ÿ Do not step or stand on the spaside

Step 1 - Clean area and insert spaside

control. (Fig.1)

Step 2 - Remove the double sided adhesive

from the back of the spaside. Make certain

the spaside is straight and adhere to the spa

shell. (Fig.2)

Fig.1

Step 3 - Remove protective film from display

window then clean the face of the spaside.

Now carefully align and apply the label. (Fig.3)

Overlay & Spaside may vary

Fig.3

CONNECTING SPASIDE & EXTENSION

*Must align Locking Clip on spaside plug

with Locking Tab on circuit board for proper

function.

When utilizing a

spaside extension

cord, the clip and

tab must also be

aligned at all

connections. Fig.5

Fig.5

Cord plugs are labeled to insure proper

plug alignment as shown in Fig.6

Fig.2

Step 4 - Connect spaside to an empty

connection marked MAIN. (Fig.4)

Locking Clip*Locking Tab*

Circuit

Board

J23

SERIAL

J108

EXPANDER

MAIN

MAIN

J28 AUX FRZ

Front side

VAC

J22

J29

J16 J17

TEMP SENSORS

HTR

DISBL

Spaside

Back side

Plug

Fig.4

Fig.6

CAUTION: Damage may occur to the circuit board and spaside if the spaside

plug is not properly aligned to the receptacle on the circuit board or if the

spaside plug is connected or disconnected while the power is on.

**Any resulting damages are not covered under manufacturer’s warranty**

ATTENTION! The plug connectors must be placed in a protected area so moisture,

dirt or chemicals are not allowed to infect this link.

22

WIFI MODULE INSTALLATION KIT (OPTIONAL)

You may control your 8000 ES or CS spa system remotely using your smart phone, and/or other

connected mobile device by installing the optional wifi antenna kit #34-0126E.

A yard friendly connection can be established directly from peer to peer, or an intranet

connection can be made through a localized router for premier global control. Review the BWG

information provided with the wifi antenna kit to explain the capabilities and options

Follow these steps for installing the wifi antenna kit

Step 1 - Disconnect power to the control system before performing work

Step 2 - Route the antenna cable through one of the knockouts in the 8000 cabinet. Reference

component connection page in this manual for a diagram showing the knockout locations

Step 3 - Insert the wifi cable plug into any empty connection port on PCB marked “Main” if a

receptacle is unavailable, use the provided “Y” cable splitter for connecting 2 devices to a single

“Main” port

Overlay and

Spaside

may vary

MAIN

J L

MAIN

LUGO

Step 4 - selecting a location for the antenna

Do not mount the wifi antenna inside or attached to the 8000 cabinet or other metal enclosure, as

this will cause a reduction in reception capability. Follow the kit instructions and locate the

antenna as high as possible, away from metal objects, and towards the home router.

The wifi antenna is indoor/outdoor weather resistant and therefore must be located under a visor

that provides shade and/or protection from extreme weather conditions.

Mount the antenna with the arrow facing up, and make sure the cable is protected from objects

and materials that may cause damage

Step 5 – Follow kit instructions for setup and connection of your Smart phone or other wireless

device using the BWA™ APP

Step 6 - testing

Before permanently mounting antenna with the provided screws, confirm the wifi connection is

satisfactory. If you're experiencing problems, it may be necessary to relocate the antenna closer

to the home router (or an improved line of site with a peer to peer only connection)

*A wifi antenna cable extension is available from your Hydro Quip system provider

23

SYSTEM CONFIGURATION (Optional)

Set Up Reference Table

HQ Set Up Set Up #

Default 18

Opt 1 3

Opt 2 2

Opt 3* 5

Pump 1 Pump 2 Pump 3 Blower

2-Speed 1-Speed None 1-Speed

2-Speed 2-Speed None 1-Speed

2-Speed 2-Speed 1-Speed None

2-Speed 1-Speed 1-Speed 1-Speed

Y Splitter Req.

No

No

No

Yes

*See page 23 for Option 3 considerations.

Changing Software Setups

Under the TEST Menu, the Setup screen will allow changing the Setup from 1 to any number established by the

Manufacturer.

When the panel displays RUN PMPS PURG AIR, press any Temperature button ONCE to exit Priming Mode.

You should see “---T” where the T indicates the system is in Test Mode.

You will have 1 minute to complete the setup change after you manually exit Priming Mode.

Immediately after exiting Priming Mode, press this sequence of buttons: Warm, Light, Warm, Warm, Warm, Warm.

Continue to press Warm until the diplay

When the correct setup number is showing, press Light once, and the system will reset,

using the newly-selected Setup from that point on.

Move DIP Switch 1 to the OFF position to take the spa out of Test Mode. °F or °C will replace °T.

NOTE: Changing the Setup may require wiring changes as well - refer to the wiring diagram.

SET

While the system is running, move DIP Switch 1 (on S1 on the Main circuit board) to ON.

shows the Setup Number (S-01, S-02, etc.) you want to switch to.

Main Screen

READ

While the Set Temperature is

R

ANGE

SE

R

ANGE

Y

T

FL

TR

1

still flashing, press Light

TEST will now appear in

the LCD first.

SET

The System will reset and go into Priming Mode if the Light Button

is pressed while anything other than the current setup is flashing.

If there is no change to the Setup Number (S-01, S-02, etc.),

the display returns to the SETP screen.

SE

T

SET

SET

When set to ON, Panel will display

alternate readings from

Senor A and Sensor B

on Main Screen

Several Setups can

exist in in this string

A dash (--) indicates

the current Setup.

Displays Fault Log

or

Approx.

SE

T

SE

T

SE

T

SE

T

SE

T

SE

T

SE

T

SET

SE

T

5 sec.

Approx.

5 sec.

or

Main Screen

READY

R

ANGE

F

L

TR

1

24

OPTION 3 SETUP CONSIDERATIONS

The Y-Splitter (included) is required when choosing Option #3 on the setup menu (see

Pg. #24). You must have a topside control compatible with 3-pumps and a blower.

PUMP 3

VOLTAGE

CONVERSION

SEE PAGE 10

Y - SPLITTER

PUMP 2

Y-SPLITTER

REQUIRED

FOR

OPTION

#3

ONLY

PUMP 3

Please diagram for proper configurations.

25

YOUR SPASIDE CONTROL

Overlay and spaside may vary

JET 1 WARM/UP

JET 2

AUX COOL/DOWN

JET 1

INDICATOR

JET 2

INDICATOR

LIGHT

INDICATOR

HEATER

INDICATOR

Jets 1 Key: Pressing this key when the pump is OFF will turn it ON to Low

Speed, a second press switches the pump to High speed, a third press turns

the pump OFF. If the pump is ON from manual activation, an automatic timer

will turn the pump OFF after 15 minutes of operation. Jet 1 indicator will

illuminate when it is active. If the pump cannot be turned OFF a filter cycle is

active.

Jets 2 Key: Press this key to turn Pump 2 ON and OFF. An automatic timer

will turn the pump off after 15 minutes of operation. Jet 2 indicator will

illuminate when it is active.

Blower / AUX Key: Press this key to turn the blower ON and OFF. An

automatic timer will turn the blower off after 15 minutes of operation.

LIGHT

Light Key: Press this key to turn the light ON and OFF. An automatic timer

will turn the light off after 4 hours of operation. The Light indicator will

illuminate when it is active.

Temperature Set Keys: Press the “Cool/Down” button or “Warm/Up”

button to display the current set water temperature. Pressing either

button while the set temperature is displayed will increase or decrease

the set temperature by 1°F. The temperature is adjustable between 80°F

- 104°F / 26°C - 40°C or 50°F - 99°F / 10°C - 37°C (See Temp Range

Settings Pg.8)

26

MAIN MENU NAVIGATION

Navigation

Navigating the entire menu structure is done with 2 or 3 buttons on the control panel.

Some panels have separate WARM (Up) and COOL (Down) buttons, while

others have a single Temperature button. In the navigation diagrams

Temperature buttons are indicated by a single button icon.

Panels that have two Temperature buttons (Warm and Cool) can

use both of them to simplify navigation and programming where

a single Temperature icon is shown.

The LIGHT Button is also used to

choose the various menus and navigate each section.

Typical use of the Temperature button(s) allows changing the

Set Temperature while the numbers are ashing in the LCD.

Pressing the LIGHT button while the numbers are ashing will

enter the menus.

The menus can be exited with certain button presses. Simply waiting for

Power-up Screens

Each time the System powers up, a series of numbers is displayed.

After the startup sequence of numbers, the system will enter Priming Mode (See Page 4).

Main Screen

several seconds will return the panel operation to normal.

READY

RANGE

SETRANGE

SET

READY

SET

F

LTR

1

If Time of Day is not set

SE

T

“SET TIME” will

appear in this menu.

P

R

ANGE

Main Screen

READY

RANGE

F

LT

R

1

Waiting Several Seconds in the Main Menu

will allow the display to revert to the Main Screen.

Most changes are not saved unless Light is pressed.

Refer to Key above.

While the Temperature is

still ashing, press Light.

SET

1

2

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

*****

ignores any change to that menu item.

Indicates a Menu Item that

Depends on a Manufacturer

Conguration and

may or may not appear.

Light Cycle if enabled

27

SYSTEM START-UP

Preparation and Filling

Fill the spa to its correct operating level. Be sure to open all valves and jets in the plumbing system before lling to allow

as much air as possible to escape from the plumbing and the control system during the lling process.

After turning the power on at the main power panel, the top-side panel display will go through specic sequences. These

sequences are normal and display a variety of information regarding the conguration of the hot tub control.

Priming Mode

Regardless of whether the priming mode ends automatically or you manually exit the priming mode, the system will automatically return to normal heating and ltering at the end of the priming mode. During the priming mode, the heater is

disabled to allow the priming process to be completed without the possibility of energizing the heater under low-ow or

no-ow conditions. Nothing comes on automatically, but the pump(s) can be energized by pushing the “Jet” buttons.

If the spa has a Circ Pump, it can be activated by pressing the “Light” button during Priming Mode.

Priming the Pumps

As soon as the above display appears on the panel, push the “Jet” button once to start Pump 1 in low-speed and then

again to switch to high-speed. Also, push the Pump 2 or “Aux” button, if you have a 2nd pump, to turn it on. The pumps

will now be running in high-speed to facilitate priming. If the pumps have not primed after 2 minutes, and water is not

owing from the jets in the spa, do not allow the pumps to continue to run. Turn off the pumps and repeat the process.

Note: Turning the power off and back on again will initiate a new pump priming session. Sometimes momentarily turning

the pump off and on will help it to prime. Do not do this more than 5 times. If the pump(s) will not prime, shut off the

power to the spa and call for service.

Important: A pump should not be allowed to run without priming for more than 2 minutes.

a pump be allowed to run without priming beyond the end of the 4-5 minute priming mode. Doing so may cause damage to

the pump and cause the system to energize the heater and go into an overheat condition.

Under NO circumstances should

Exiting Priming Mode

You can manually exit Priming Mode by pressing a “Temp” button (Up or Down). Note that if you do not manually exit the

priming mode as described above, the priming mode will be automatically terminated after 4-5 minutes. Be sure that the

pump(s) have been primed by this time.

Once the system has exited Priming Mode, the top-side panel will momentarily display the set temperature but the display

will not show the temperature yet, as shown below. This is because the system requires approximately 1 minute of water

owing through the heater to determine the water temperature and display it.

READ

or

R

ANGE

Y

READ

R

ANGE

Y

28

SYSTEM FUNCTIONS / FEATURES

Pumps

Press the “Jets 1” button once to turn pump 1 on or off, and to shift between low- and high-speeds if equipped.

If left running, the pump will turn off after a time-out period. The pump 1 low-speed will time out after 30 minutes. The

high-speed will time out after 15 minutes.

the low-speed of pump 1 runs when the blower or any other pump is on. If the spa is in Ready Mode

(See page 7), Pump 1 low may also activate for at least 1 minute every 30 minutes to detect the spa temperature (polling)

and then to heat to the set temperature if needed. When the low-speed turns on automatically, it cannot be deactivated

from the panel, however the high speed may be started.

Filtration and Ozone

Pump 1 low and the ozone generator will run during ltration.

The system is factory-programmed with one lter cycle that will run in the evening (assuming the time-of-day is properly

set) when energy rates are often lower. The lter time and duration are programmable.

A second lter cycle can be enabled as needed.

At the start of each lter cycle, the blower (if there is one) or Pump 2 (if there is one) will run briey to purge its plumbing to maintain good water quality.

Freeze Protection

If the temperature sensors within the heater detect a low enough temperature (44°F) , then the pump(s) and the blower

automatically activate to provide freeze protection. The pump(s) and blower will run either continuously or periodically

depending on conditions.

SETTING THE TIME-OF-DAY

Setting the time-of-day can be important for determining ltration times and other background features.

When in the TIME menu, SET TIME will ash on the display if no time-of-day is set in the memory.

Main Screen

READY

To next item in

Main Menu

While the Temperature is

still ashing, press Light

P

P

repeatedly until TIME

appears in the LCD.

Several Seconds

SET

Main Screen

READY

F

L

TR

R

ANGE

1

SET

P

If Time of Day is not actually programmed due to a power cycle,

P

SET TIME will appear in the menu instead of just TIME.

R

ANGE

R

ANGE

SE

T

F

L

TR1

SET

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

*****

ignores any change to that menu item.

To Set

SET

P

*****

P

Waiting

Several Seconds

Reverts to Original Setting

Main Screen

READ

Y

R

ANGE

F

LTR1

Note:

If power is interrupted to the system, Time-of-Day is not stored. The system will still operate and all other user settings

will be stored. If lter cycles are required to run at a particular time of day, resetting the clock will return the lter times

to the actual programmed periods.

When the system starts up, it defaults to 12:00 Noon, so another way to get lter times back to normal is to start up the

spa at noon on any given day. SET TIME will still ash in the TIME Menu until the time is actually set, but since the spa

started at noon, the lter cycles will run as programmed.

29

TEMPERATURE SETTINGS

Adjusting the Set Temperature

When using a panel with Up and Down buttons (Temperature buttons), pressing Up or Down will cause the temperature to

ash. Pressing a temperature button again will adjust the set temperature in the direction indicated on the button. When

the LCD stops ashing, the spa will heat to the new set temperature when required.

If the panel has a single temperature button, pressing the button will cause the temperature to ash. Pressing the button

again will cause the temperature to change in one direction (e.g. UP). After allowing the display to stop ashing, pressing

the Temperature Button will cause the temperature to ash and the next press will change the temperature in the opposite

direction (e.g. DOWN).

Press-and-Hold

If a Temperature button is pressed and held when the temperature is ashing, the temperature will continue to change

until the button is released. If only one temperature button is available and the limit of the Temperature Range is reached

when the button is being held, the progression will reverse direction.

Dual Temperature Ranges

This system incorporates two temperature range settings with independent set temperatures. The High Range designated in

the display by an “up” arrow, and the Low Range designated in the display by a “down” arrow.

These ranges can be used for various reasons, with a common use being a “ready to use” setting vs. a “vacation” setting.

The Ranges are chosen using the menu structure below. Each range maintains its own set temperature as programmed by

the user. This way, when a range is chosen, the spa will heat to the set temperature associated with that range.

For example:

High Range might be set between 80°F and 104°F.

Low Range might be set between 50°F and 99°F.

Freeze Protection is active in either range.

See Mode Setting on Page 29

for additional heating control information.

Main Screen

Set Temp will Show & Flash

Press a Temp Button repeatedly to change the temperature.

Main Screen

READ

High-Range vs

Low-Range Temp Choice

F

R

LTR

ANGE

Y

1

While

temperature

is ashing...

Toggle the Range arrows in the LCD.

SET

R

ANGE

To next item in Main Menu

Main Screen

READ

Y

R

ANGE

Set Temp will Show & Flash

F

LT

R

1

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

*****

ignores any change to that menu item.

SE

T

R

ANGE

SE

T

R

ANGE

SE

T

R

ANGE

OR

Several Seconds

READY

R

ANGE

F

LTR

1

Pressing and holding a Temp Button will also change the temperature.

Main Screen

To Set

SET

R

ANGE

R

ANGE

SE

T

*****

Waiting

Several Seconds

Reverts to Original Setting

READ

R

FL

ANGE

TR1

Y

Press a Temp Button repeatedly to change the temperature.

R

F

LT

R

1

SE

T

ANGE

F

LT

R

1

R

ANGE

SE

T

F

LT

R

1

OR

Several Seconds

Main Screen

READY

R

F

LT

ANGE

R

1

Pressing and holding a Temp Button will also change the temperature.

30

MODE SETTINGS

Setting Modes

In order for the spa to heat, a pump needs to circulate water through the heater. The pump that performs this function is

referred to as the heater pump or main pump as the “heater pump.”

The heater pump can be either a 1 or 2 speed pump.

READY Mode - If the heater pump is a 2-Speed Pump 1, will circulate water every 1/2 hour, using Pump 1 Low, in order to

maintain a constant water temperature, heat as needed, and refresh the temperature display. This is known as “polling.”

REST Mode - Will only allow heating during programmed lter cycles. Since polling does not occur, the temperature display

may not show a current temperature until the heater pump has been running for a minute or two.

Main Screen

While the Temperature is

READY

R

ANGE

SE

T

READ

Y

To next item in

Main Menu

If not toggled

still ashing, press Light

SETRANGE

F

L

TR

1

SE

REST

T

Toggle between READY and REST

Pressing Light when the display is toggled will go to Main Screen.

repeatedly until MODE

appears in the LCD.

To Set

*****

Waiting

Several Seconds

Reverts to Original Setting

Main Screen

REST

R

FL

ANGE

TR1

Key

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

*****

ignores any change to that menu item.

Main Screen

1 Hour

R

F

LTR1

ANGE

RE

ST

R

ANGE

REST

The Main Screen will display RUN PUMP FOR TEMP if the ltration pump has not run for over 1 hour.

The Main Screen will display normally during Filter Cycles or when the spa is in use.

If the ltration pump has been off for an hour or more, when any function button, EXCEPT Light, is pressed on the panel,

the pump used in conjuncton with the heater will run so that temperature can be sensed and displayed.

REST

R

ANGE

REST

R

ANGE

REST

RANGE

REST

R

ANGE

Ready-in-Rest Mode

READY/REST appears in the display if the spa is in Rest Mode and Jet 1 is pressed. It is assumed that the spa is being used

and will heat to set temperature. While Pump 1 High can be turned on and off, Pump 1 Low will run until set temperature

is reached, or 1 hour has passed. After 1 hour, the System will revert to Rest Mode. This mode can also be reset by entering

the Mode Menu and changing the Mode.

31

FILTER SETTINGS

Main Filtration

Filter cycles are set using a start time and a duration. Start time is indicated by an “A” (AM) or “P” (PM) in the bottom right

corner of the display. Duration has no “A” or “P” indication. Each setting can be adjusted in 15-minute increments. The

panel calculates the end time and displays it automatically.

Main Screen

READ

R

ANGE

Y

To next item in

Main Menu

While the Temperature is

still ashing, press Light

R

ANGE

SE

F

LTR1

T

1

2

SET

repeatedly until FLTR 1

appears in the LCD.

FLTR1

to show RUN HRS

FLTR

1

to show F1 ENDS xx:xx

To Set

To Set

2

F

LTR

2

F

LTR

to show RUN HRS

2

FL

TR

to show F1 ENDS xx:xx

To Set

Shows/ashes start time

F

LTR1

SET

FLTR

1

2

F

LTR

SET

Shows/ashes start time

2

FLTR

SET

2

FL

TR

Sets start hour

F

LTR

SE

P

Sets Filter 1 length in hours

SET

1PSE

T

FLTR

1

To Set

*****

A

Waiting several seconds

will lose any new Filter 1

Start Time and Run Hours and

revert to the previous Filter 1 settings.

Waiting

Several Seconds

Reverts to Original Setting

To Set

Sets start hour Selects minutes

P

SET

Sets Filter 1 length in hours

SET

2

FLTR

2

F

LTR

P

Selects part of an hour

To Set

*****

Waiting several seconds

A

will lose any new Filter 2 On/OFF,

Start Time and Run Hours and

revert to any previous Filter 2 settings.

Selects minutes

F

T

Selects part of an hour

FLTR

SET

Main Screen

READY

R

FL

ANGE

FLTR

SET

F

LTR

SET

Sets 15-minute increments

LTR1

SE

T

P

Sets 15-minute increments

1

SET

TR1

Sets 15-minute increments

2 P

SET

Sets 15-minute increments

2

SET

Main Screen

READ

R

ANGE

Y

Main Screen

READ

Y

*****

F

LTR

1

P

Wait to

Revert

*****

FLTR1

FLTR1

Waiting

Reverts to Original Setting

*****

2 P

FLTR

Wait to

Revert

*****

2

F

LTR

F

L

R

ANGE

TR

Waiting

Several Seconds

Reverts to Original Setting

Several Seconds

1

Filter Cycle 2 - Optional Filtration

Filter Cycle 2 is OFF by default.

It is possible to overlap Filter Cycle 1 and Filter Cycle 2, which will shorten

overall ltration by the overlap amount.

Purge Cycles

In order to maintain sanitary conditions, secondary Pumps and/or a Blower will

purge water from their respective plumbing by running briey at the

beginning of each lter cycle.

If Filter Cycle 1 is set for 24 hours, enabling Filter Cycle 2 will initiate a purge

when Filter Cycle 2 is programmed to begin.

The Meaning of Filter Cycles

1. The heating pump always runs during the lter cycle*

2. In Rest Mode, heating only occurs during the lter cycle

3. Purges happen at the start of each lter cycle

* For example, if your spa is set up for 24/hour circulation except for shutting

off when the water temperature is 3˚F/1.3˚C above the set temperature, that

shutoff does not occur during lter cycles.

32

LOCKING AND UNLOCKING SPASIDE

The control can be restricted to prevent unwanted use or temperature adjustments.

Locking the panel prevents the controller from being used, but all automatic functions are still active.

Locking the Temperature allows Jets and other features to be used, but the Set Temperature and other programmed

settings cannot be adjusted.

Temperature Lock allows access to a reduced selection of menu items.

These include Set Temperature, FLIP, LOCK, UTIL, INFO and FALT LOG.

Main Screen

READY

F

L

R

TR1

ANGE

SET

To next item in

Main Menu

Panel Locked

Main Screen

READY

FLTR1

R

ANGE

Temperature Locked

Main Screen

READY

LTR1

F

R

ANGE

While the Temperature is

R

SE

ANGE

T

still ashing, press Light

repeatedly until LOCK

appears in the LCD.

Locks all function buttons.Locks Temp. and Settings.

SET

SET

Several Seconds

Any

Button

Press

When the Temperature is locked, the panel will display the Set Temperature

by pressing a Temperature Button, as ususal.

LOCK will appear if an attempt to reset the temperature is made with a subsequent button press.

Adjustable settings in the menus are also locked.

Other function buttons will operate normally.

READ

LTR

F

R

ANGE

1

Y

R

ANGE

Several

Seconds

READY

Main Screen

READY

R

ANGE

Several

Seconds

F

L

TR

R

ANGE

1

Key

Indicates Flashing or Changing Segment

Indicates Alternating or Progressive Message - every 1/2 second

A temperature button, used for “Action”

Light or dedicated “Choose” button, depending on control panel conguration

Waiting time that keeps the last change to a menu item.

Waiting time (depends on menu item) that reverts to original setting and

*****

ignores any change to that menu item.

SET

FLTR1

LOCK will remain on the display

for 3 seconds and then revert to the normal display.

Main Screen

READY

LTR1

F

R

ANGE

To Set

Main Screen

SE

T

*****

Waiting

Several Seconds

Reverts to Original Setting

READ

R

F

LTR

ANGE

1

Y

Unlocking Spaside

This Unlock sequence may be used from any screen that may be displayed on a restricted panel.

While pressing and holding the Temperature Button (or UP button, if available),

Slowly press and release the Light Button two times.

A Few

Seconds

Main Screen

READY

LTR

R

ANGE

F

1

NOTE: If the panel has both an UP and a Down button, the ONLY button that will work in the Unlock Sequence is

the UP button.

33

SPASIDE MESSAGES

General Messages

Priming Mode

pump and manually verify that the pumps are primed (air is purged) and water is owing. This typically requires observing

the output of each pump separately, and is generally not possible in normal operation. Priming Mode lasts 4 minutes, but

you can exit it earlier by pressing any Temp button. The heater is not allowed to run during Priming Mode.

NOTE: If your spa has a Circ Pump, it will turn on with Jets 1 in Priming Mode. The Circ Pump will run by itself when Priming Mode is exited.

READ

Y

or

R

ANGE

READ

R

ANGE

Y

Water Temperature is Unknown

After the pump has been running for 1 minute, the temperature will be displayed.

READ

R

FLTR

ANGE

1

Y

Too Cold - Freeze Protection

A potential freeze condition has been detected, or the Aux Freeze Switch has closed, and all pumps and blower are acti-

vated. All pumps and blower are ON for at least 4 minutes after the potential freeze condition has ended, or when the aux

freeze switch opens.

In some cases, pumps may turn on and off and the heater may operate during Freeze Protection.

This is an operational message, not an error indication.

Water is too Hot (OHS)

auto reset when the spa water temp is below 108°F (42.2°C). Check for extended pump operation or

high ambient temp.

Safety Trip - Pump Suction Blockage*

problem or a possible entrapment situation avoided. (Note: not all spas have this feature.)

* This message can be reset from the topside panel with any button press.

34

SPASIDE MESSAGES

Heater-Related Messages

Heater Flow is Reduced (HFL) – M016