HydroLogic W-MFI1665GET Operation & Maintenance Manual

Manual for Operation & Maintenance

Of Manganese Greensand

Iron Filter

Model pictured on right is shown with optional Stainless Steel Tank Jacket

for Model:

W-MFI1665GET

Installation and Service Manual – Manganese Greensand Iron Filter

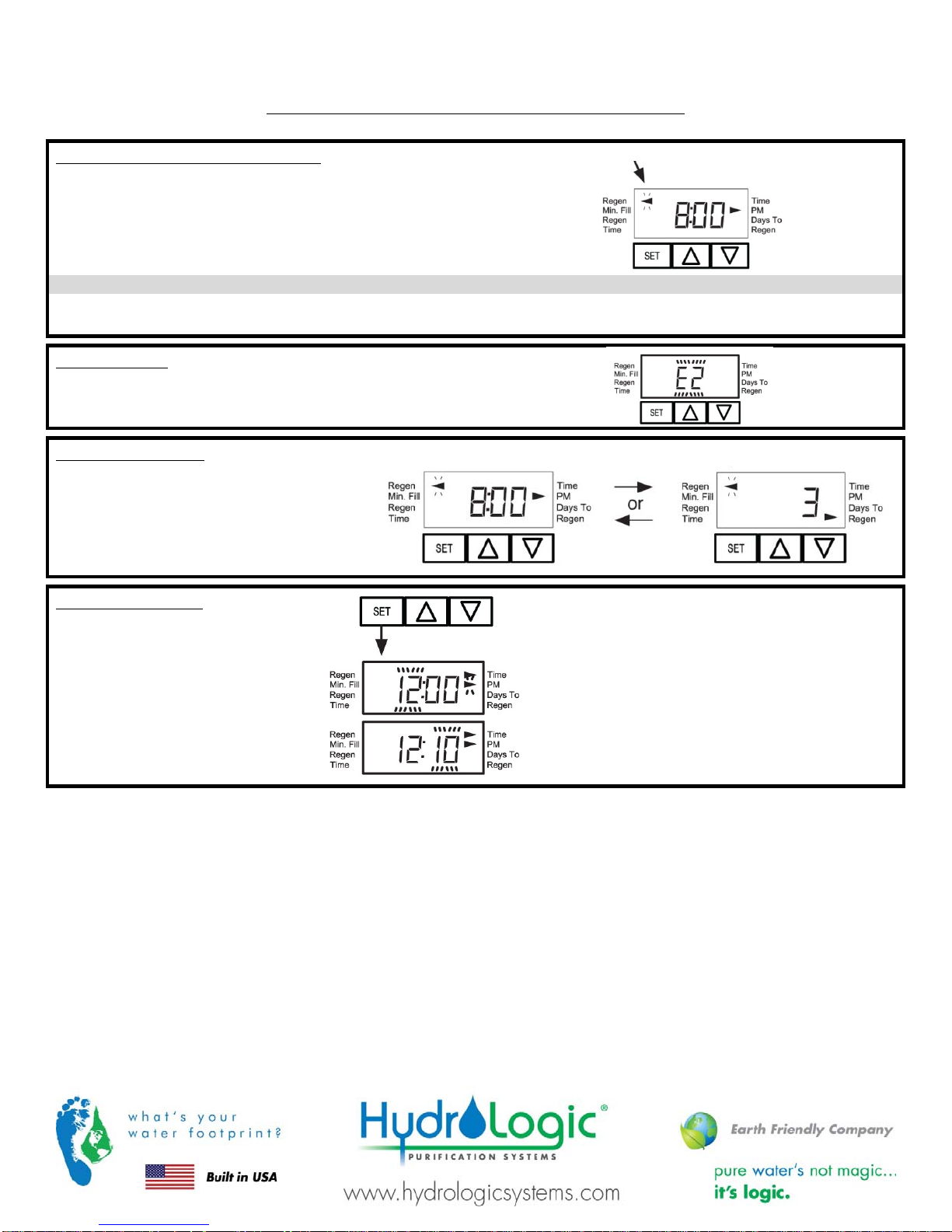

Panel Operation Quick Reference Guide

Manual Regeneration (Backwash)

Note: . If you need to initiate a manual regeneration, either

immediately, or tonight at the preprogrammed time (typically 2

a.m.), complete the following steps.

For Immediate Regeneration: For Regeneration Tonight:

Press and hold and simultaneously until valve

motor starts (typically 3 seconds).

Error Message

If the display shows „E1‰, „E2‰, „E3‰, or „E4‰ (for error), check

the trouble shooting section to identify the error.

General Operation

Arrow will point to Regen if a regeneration is expected „Tonight‰.

When the system is operating one of two

displays will be shown: time of day or days

until the next regeneration.

Pressing or button will toggle between the

two choices.

To Set Time of Day

In the event of a prolonged power

outage, time of day flashes,

indicating that it needs to be reset. All

other information will be stored in

memory no matter how long the

power outage. Please complete the

steps as shown to the right. To access

this mode, press „SET‰.

Arrow will point to Regen if a regeneration is expected „Tonight‰.

Press and release and simultaneously

(notice that arrow points to Regen).

1. Accessed by pressing SET for approximately 3

seconds.

2. Adjust hour with or . With 60 Hz line frequency

detection on power-up, timekeeping is 12 hour with

PM indicator. With 50 Hz line frequency detection

on power-up, timekeeping is 24 hour without the PM

indicator. Press SET to go to the next step.

3. Adjust minutes with or .

4. Press SET to complete and return to normal operation.

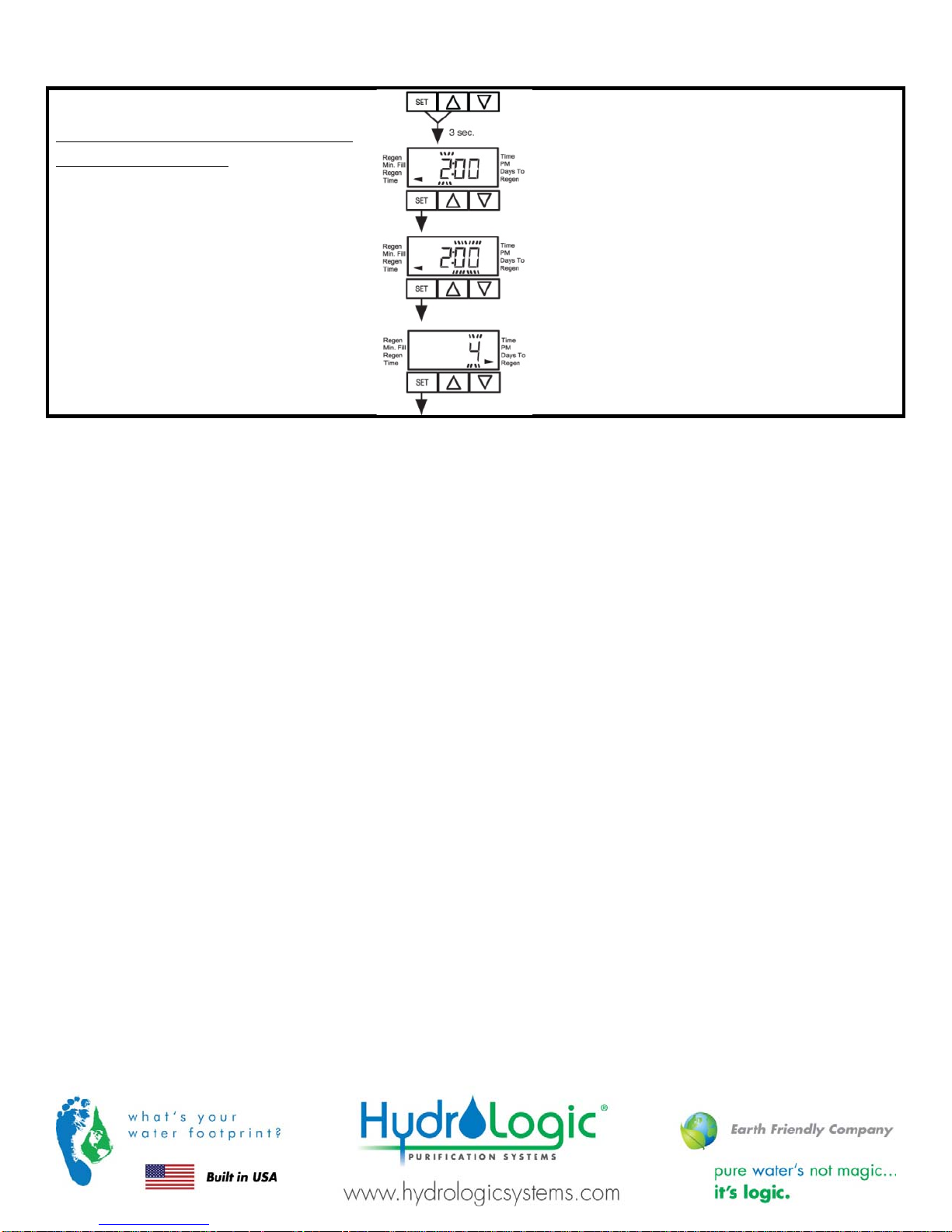

To Set Time of Regeneration and Days

Between Regeneration

For initial set-up or to make adjustments,

please complete the steps as shown.

Access this mode by pressing SET and for

approximately 3 seconds. The number of days

between regenerations may need to be varied

based on usage and water conditions.

(This step will not appear if the 7-day clock

option is selected.)

Installation and Service Manual – Manganese Greensand Iron Filter

1. Accessed by pressing SET and simultaneously for

about 3 seconds.

2. Set Regeneration Time Hour. Set the time for

regeneration to start. Press SET to go to the next step.

3. Set Regeneration Time Minutes. Press SET to go to the

next step.

4. Set number of Days between regeneration cycles.

5. Press SET to complete and return to normal operation.

Page 3

Installation and Service Manual – Manganese Greensand Iron Filter

Table of Contents

Design Basis & Specifications ................................................................................................................................. 6

Table 1 Design Basis Specifications ..................................................................................................................... 6

General Information and Safety ............................................................................................................................. 6

Installation .......................................................................................................................................................... 6

Location ............................................................................................................................................................ 6

Loading the Media ............................................................................................................................................. 7

Media Quantity per Model ................................................................................................................................... 8

Plumbing ........................................................................................................................................................... 9

Initial Start-Up ................................................................................................................................................... 10

System Monitoring and Record Keeping ................................................................................................................. 12

Operating Conditions ......................................................................................................................................... 12

Operating DoÊs and DonÊts .................................................................................................................................. 12

Maintenance .................................................................................................................................................... 13

Control Valve Operation & Service ........................................................................................................................ 14

Control Valve Specifications ................................................................................................................................ 14

Panel Operation Quick Reference Guide ............................................................................................................... 15

General Warnings ............................................................................................................................................ 17

Control Valve General Features and Information ...................................................................................................... 17

Programming Control Valve Options ...................................................................................................................... 18

System Setup: Regeneration (Backwash) Cycle Programs ........................................................................................ 18

Installer Displays and Settings for Control Valve Options ........................................................................................... 22

User Displays ................................................................................................................................................... 26

Set Time of Day ................................................................................................................................................ 27

Power Loss ...................................................................................................................................................... 27

Error Messages ................................................................................................................................................ 27

Control Valve Drawings and Components ............................................................................................................... 28

Front Cover & Drive Assembly ............................................................................................................................. 28

CV1TC Drive Cap Assembly, Downflow Piston, Regenerate Piston & Spacer Stack Assembly .......................................... 29

Injector Cap, Injector Screen, Injector, Plug and O-Ring ............................................................................................ 31

Refill Flow Control Assembly and Refill Port Plug ...................................................................................................... 32

Drain Line Flow Controls 1‰ .............................................................................................................................. 33

CV1 with 1.050‰ Distributor Tube Opening Identification ......................................................................................... 35

Installation Fitting Assembly ................................................................................................................................. 35

Flow Diagram, Service....................................................................................................................................... 36

Flow Diagram, Backwash ................................................................................................................................... 37

Flow Diagram, Rinse ......................................................................................................................................... 38

CV1 Service Spanner Wrench ............................................................................................................................ 38

Control Valve Components Description ................................................................................................................... 40

Drive Assembly ................................................................................................................................................. 40

Drive Cap Assembly, Main Piston ........................................................................................................................ 40

Spacer Stack Assembly ...................................................................................................................................... 40

Injector Plug and Refill Flow Plug .......................................................................................................................... 41

Drain Line Flow Control and Fitting Assembly .......................................................................................................... 41

Installation and Service Manual – Manganese Greensand Iron Filter

Installation Fitting Assemblies ............................................................................................................................... 41

Control Valve Service Instructions .......................................................................................................................... 41

Drive Assembly ................................................................................................................................................. 41

Drive Cap Assembly, Main Piston and Regenerant Piston .......................................................................................... 44

Spacer Stack Assembly ...................................................................................................................................... 45

Drain Line Flow Control ...................................................................................................................................... 45

Troubleshooting ................................................................................................................................................. 46

Product Warranty .............................................................................................................................................. 52

Page 5

Installation and Service Manual – Manganese Greensand Iron Filter

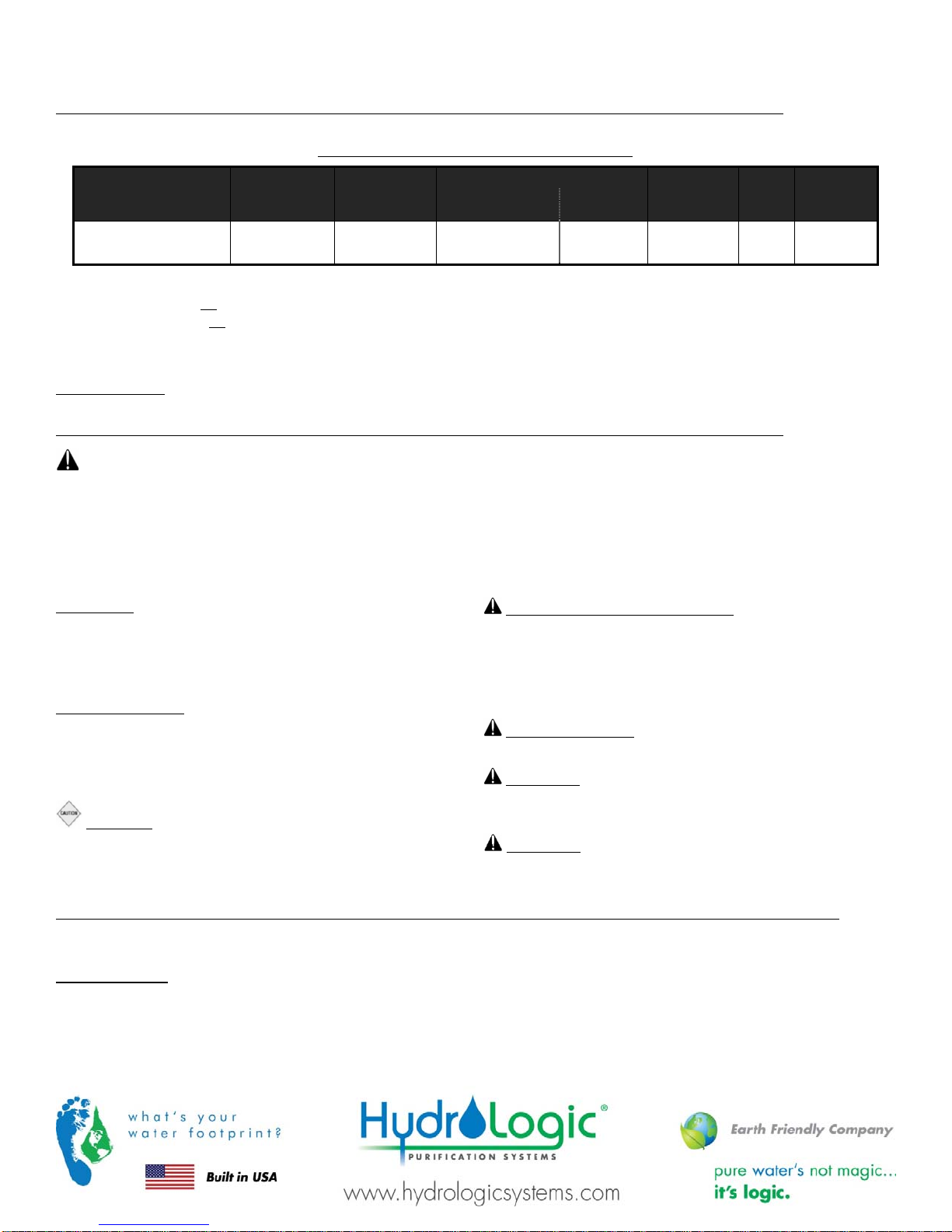

Design Basis & Specifications

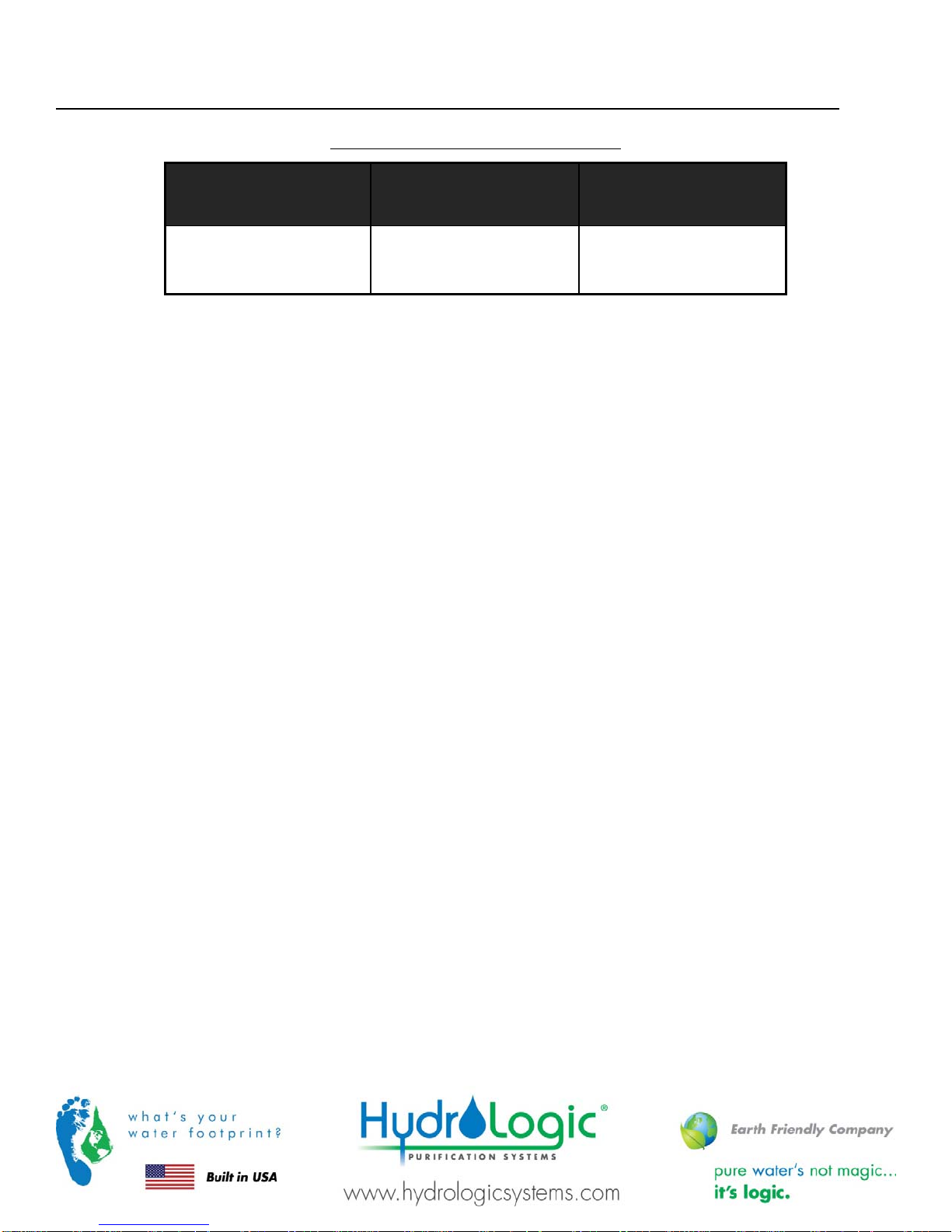

Table 1 Design Basis Specifications

Model No.*

Flow Rate**

(GPM)

Backwash

Flow**

(GPM)

Volume of Media

Manganese

Greensand

(Only)

(ft3)

Total

(Incl.

Underbed)

Resin Tank

(Dia‰H‰)

Valve

Size

In/Out

Conn.

W-MFI1665GET 7 15 3.5 4.0 1665 1‰ 1‰

Filters are available with USA or European style plugs and voltages. The voltage code is added to the end of the model.

*

W-MFI1665GET-US = 120V AC/60Hz with USA cord & plug.

W-MFI16665GET-EU = 220V AC with European cord & plug

5 gpm per sq. ft. of media is the best design condition for filtration. Backwash flow rate based on 25 psi pressure drop.

**

(EU plug is removable to convert into universal 220v cord)

Operating Limits: Vessel rated at 150 psi max. operating pressure, 120F max. operating temperature.

General Information and Safety

ADDITIONAL EQUIPMENT REQUIRED FOR PROPER OPERATION: Manganese greensand filters require KMn04 (Potassium

Permanganate) to be injected into the feed water stream in order to regenerate the media bed. This is usually done with the use

of a chemical injection system including a chemical tank, mixer and metering pump. This equipment is sold separately and should

be designed and sized for each specific installation. The injection method and concentration of potassium permanganate

required depends on the concentration of iron and manganese in the water as well as other factors. Please contact Applied

Membranes, Inc. for assistance in sizing and purchasing the appropriate chemical injection system.

DISCLAIMER: The information contained in this document is subject to

change without notice. Applied Membranes, Inc. shall not be liable

for technical or editorial omissions made herein; nor for incidental or

consequential damages resulting from the furnishing, performance, or

use of this material.

READ THIS MANUAL: Prior to operating or servicing this unit, this

manual must be read and understood. If anything is not clear, call for

assistance before proceeding. Keep this and other associated

manuals for future reference and for new operators or qualified service

personnel.

CAUTION: Never let the filter freeze. Freezing can damage the

media tank.

USE PROPER POWER CONNECTION methods to satisfy local

electrical codes. SHOCK HAZARD: Connect this unit to a properly

grounded connection in accordance with the National Electrical

Code. DO NOT, under any circumstances, remove the ground wire

or ground prong from any power plug. Do not use extension cords or

an adapter without proper consideration.

SERVICE WARNING: To prevent electrical shock, disconnect

power to the system prior to servicing.

WARNING: Do not make any alteration or modification in the

wiring or plumbing of the system. This can result in damage to the

system and cause injury to operators or users.

WARNING: Flush the system for at least 30 minutes before use to

remove all chemicals present.

Installation

Unpack the filter. Inspect assemblies for damage (cracked couplings, broken or split pipes, loose straps, etc.).

Location

Select a location for the filter with adequate clearance from walls and other equipment to allow access on all sides of the tank.

The unit must be located near a drain able to accommodate the backwash flow rate of your unit (see the table on page 4). This is

in addition to any other equipment sharing the drain.

A grounded power supply of the appropriate voltage and a local disconnect switch is required.

Installation and Service Manual – Manganese Greensand Iron Filter

Situate downstream from the potassium permanganate injection system (see note in general information and safety).

Caution: The unit must not be located near any corrosive chemicals, or in an area where the temperature may

exceed 113F (45C).

Warning: The power supply must be properly grounded to avoid injury from electrical shock.

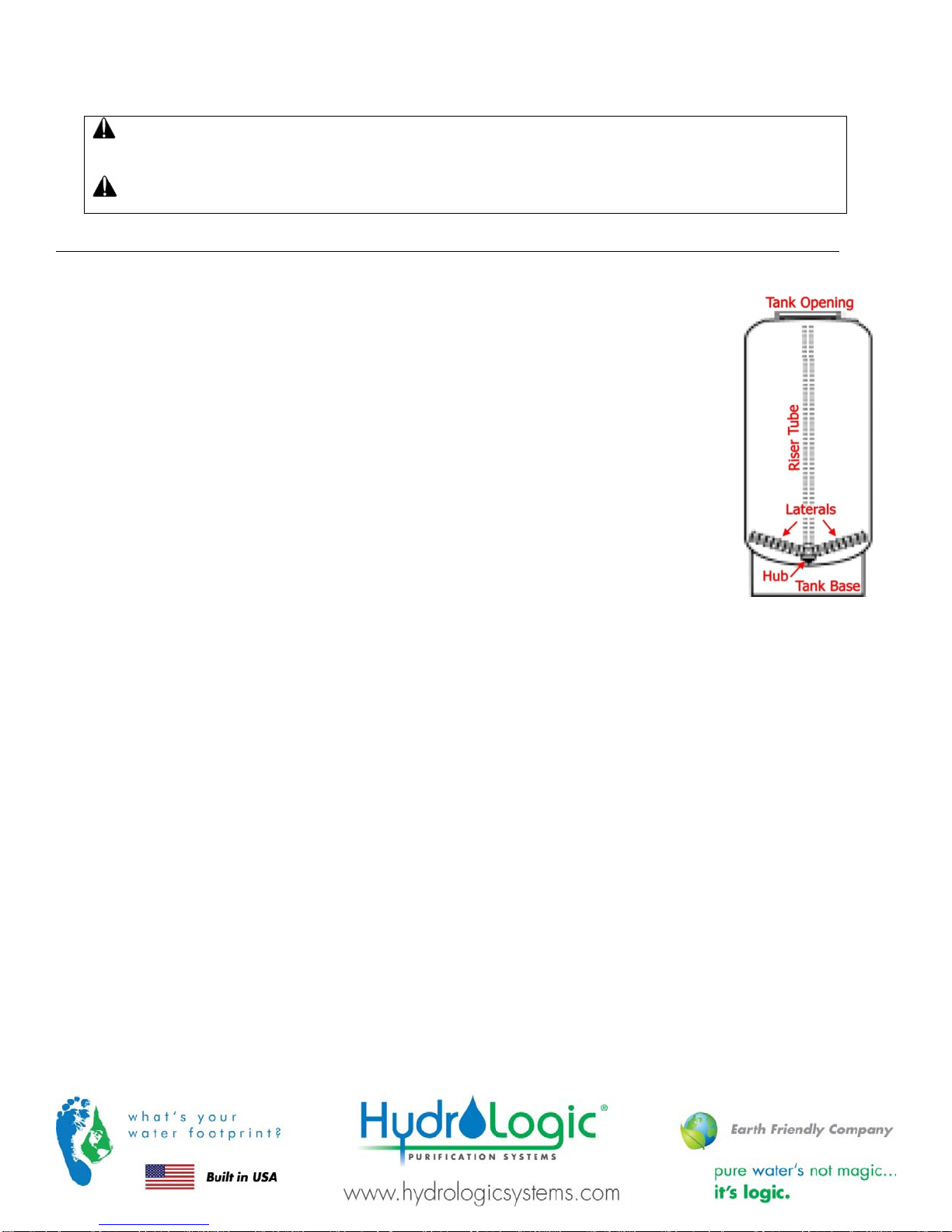

Loading the Media

If media shipped unloaded (packaged separately outside of the tank) then continue with the loading instructions. If the filter was

shipped loaded, please skip to plumbing.

1. Place tank on a level, solid surface in the correct position for installation. Lift the riser tube from

the tank, keeping the attached hub within the opening of the tank. Within the tank, assemble the

laterals onto the hub, twisting each lateral into the hub to lock securely. Gently lower the

assembly to the bottom of the tank. The top of the riser tube should be about level with the top of

the tank.

2. The „riser tube‰ inside the media/resin tank delivers treated water to your control valve. It will

need to be temporarily covered with tape on the top end to prevent anything from falling down

inside the tube during loading.

3. Step back and look at the tank to make sure it is standing straight, and not tilted. The black base

on the bottom of the tank should also be straightened before filling the tank. If your tank is tilted,

simply pick up the tank 2-3 inches off the floor and drop it gently (but firmly) down, favoring the

side of the base that needs to be adjusted.

4. Before loading the media, fill the tank with 2-3 feet of water (or 1/3 full, depending on the tank

size), to soften the fall of the rocks and prevent damage to the distributor. To load the media, use

a funnel in the top of the media tank with the riser tube still inside. Make sure the riser tube is

covered with tape to keep media out.

5. Scoop the media into the funnel, slowly letting it fall down inside the media tank around the riser tube. Fill the tank with the

w

media provided, pouring the media in the following order (1st

of the tank, etc.).

Note: The tank will be approximately - ⅔ full after loading is complete.

ill end up on the bottom of the tank, last will end up at the top

Refer to „Table 2 Resin Quantities per Model‰ for the proper quantities of each component.

I. Gravel YMGRVL11618 0.5 CF (50 lbs) per bag

II. Manganese Greensand YMMNGS 1 CF (85 lbs) per bag

6. Remove the funnel from the top of the tank, and the tape from the end of the riser tube. Brush any loose media off the top

opening of the tank.

7. The bottom of the control valve has an opening with O-rings inside; lubricate the O-ring with a non-petroleum based lubricant.

Position the valve over the top of the media tank, making sure the top of the riser tube inserts inside the opening in the bottom

of the valve.

8. Screw the valve down into the media tank. Another person should hold the tank as the valve is being snugly tightened onto the

tank. Do not over-tighten. Tighten until snug, tighten a bit more, then STOP. The large o-ring will seal itself.

Page 7

Installation and Service Manual – Manganese Greensand Iron Filter

Media Quantity per Model

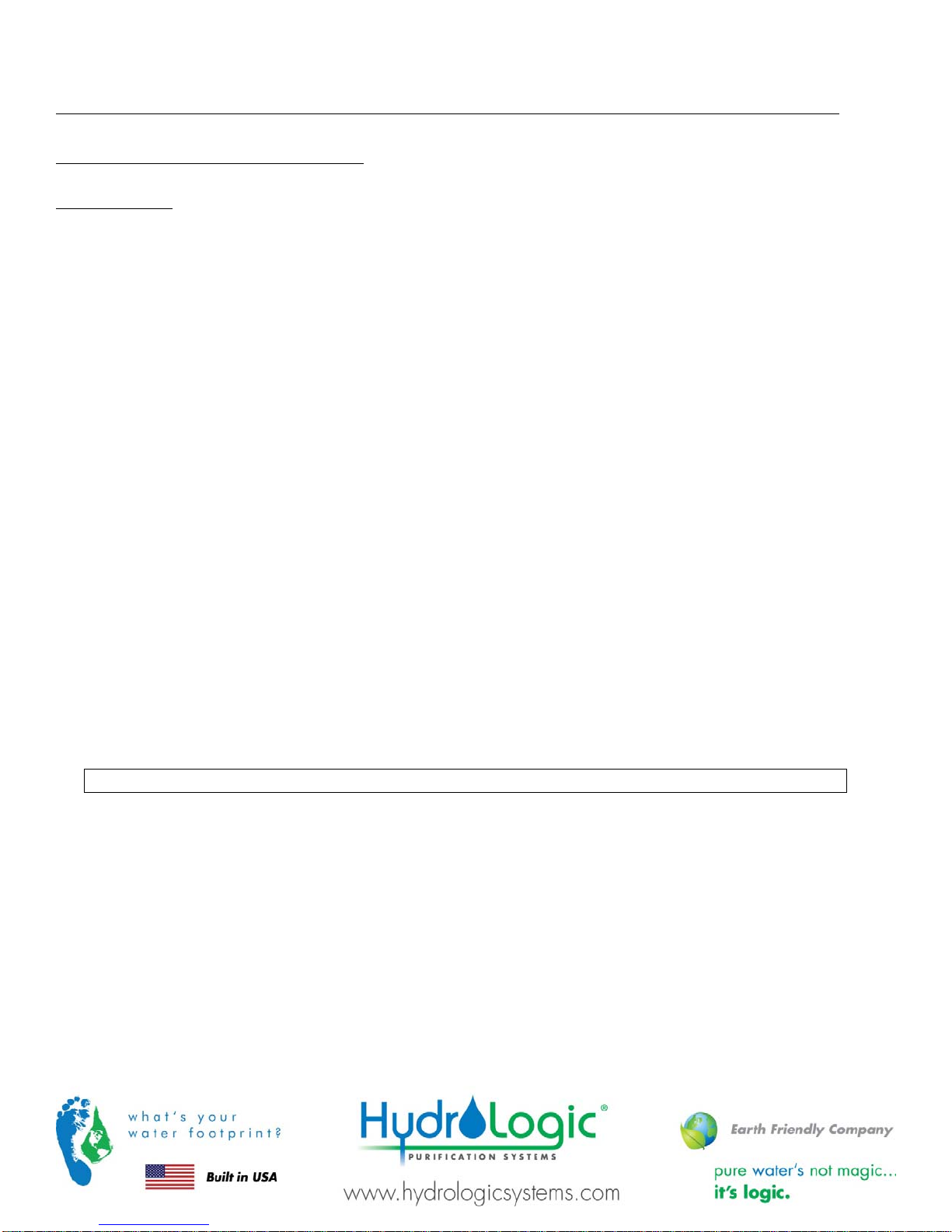

Table 2 Media Quantity per Model

Model No.*

(-US or EU)

Gravel

1

/16 x ⅛

I

Manganese

Greensand

II

W-MFI1665GET 0.5 CF (50 lbs) 3.5 CF (298 lbs)

Installation and Service Manual – Manganese Greensand Iron Filter

Plumbing

Note:

Caution:

All plumbing is to be done in accordance with state and local codes.

Before placing wall anchors to support piping ensure that no electrical conduit or wiring is located behind the

intended mounting location.

Note:

The control valve, fittings and/or bypass are designed to accommodate minor plumbing misalignments but are not

designed to support the weight of a system or the plumbing.

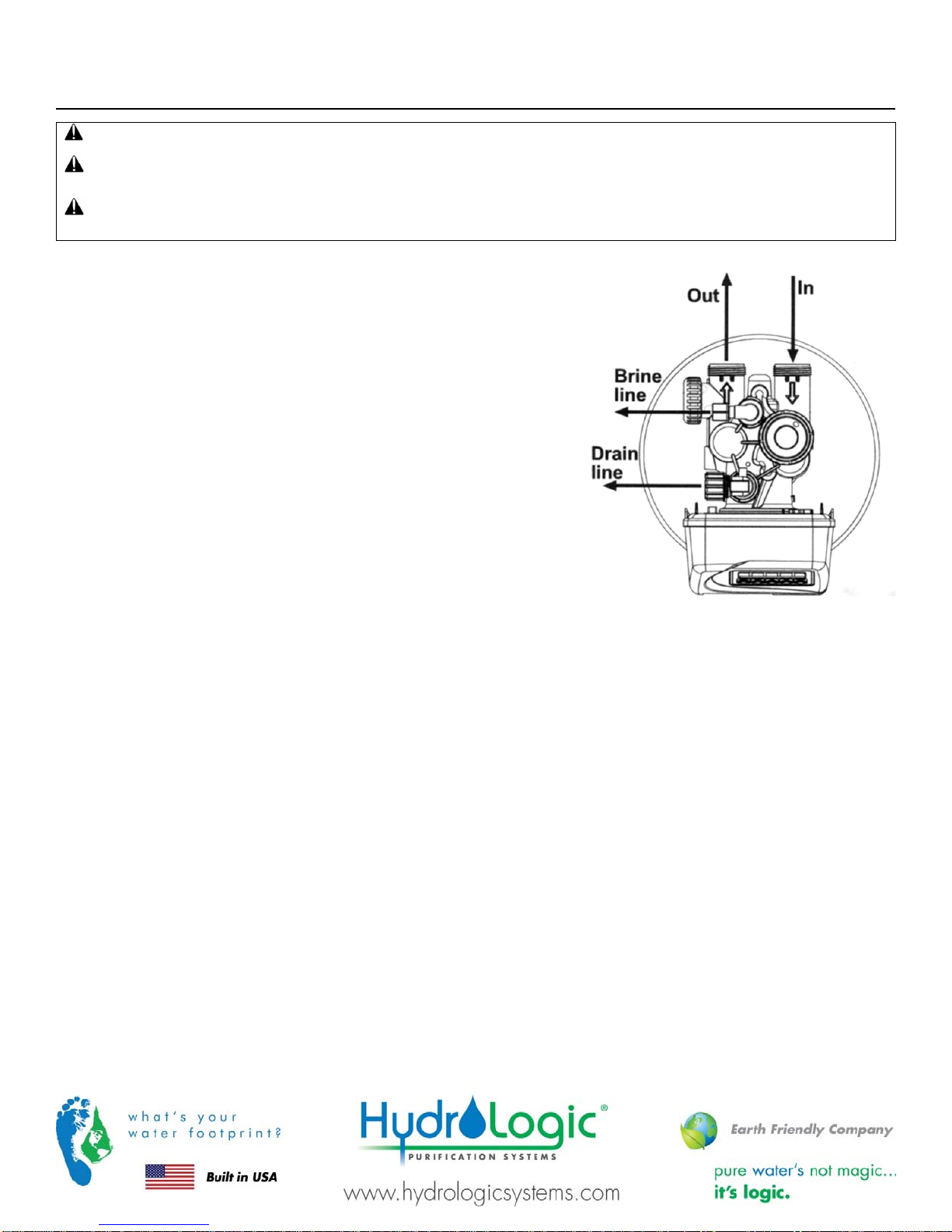

1. Install connecting piping between raw water source and input pipe on

control valve.

The installation fittings connect to the control valve or the bypass valve

using nuts that only require hand tightening. Do not use a pipe wrench to

tighten nuts on installation fittings. The split ring design, incorporated into

the installation fittings allows approximately 2 degrees off axis alignment

to the plumbing system. The installation fittings are designed to

accommodate minor plumbing misalignments but are not designed to

support the weight of a system or the plumbing.

When assembling the installation fitting package, connect the fitting to

the plumbing system first and then attach the nut, split ring and o-ring.

Heat from soldering or solvent cements may damage the nut, split ring or

o-ring. Solder joints should be cool and solvent cements should be set

before installing the nut, split ring and o-ring. Avoid getting primer and

solvent cement on any part of the orings, split rings, bypass valve or

control valve. Solvent cements and primers should be used in accordance

with the manufacturerÊs instructions.

Slip the nut onto the fitting first, then the split ring second and the o-ring last. Hand tighten the nut. If the fitting is leaking

tightening the nut will not stop the leak. Remove the nut, remove the fitting, and check for damage or misalignment of the oring.

Do not use pipe dope or other sealant on threads. Use teflon tape on threaded inlet, outlet and drain fittings. Teflon tape is

not necessary on the nut connection or caps because of o-ring seals.

2. Install drain line from control valve to a free flowing drain.

If the drain line is a ⅝‰ flexible polytube, slide the nut onto the polytube, then place the polytube insert into the end of the

polytube and tighten the nut on to the ‰ drain line fitting. The nut is only designed for use with fexible polytube. Use other

nuts if attaching different materials. (To access the drain line flow control, remove the locking clip by pulling it straight out.

Pull fitting out and replace the locking clip so that it is not misplaced. The drain line fitting is pressed in and has an o-ring

seal.)

3.

4. Install piping between valve output and point of use. The installation fittings connect to the control valve or the bypass valve

using nuts that only require hand tightening.

See step 1 for handling details.

Page 9

Installation and Service Manual – Manganese Greensand Iron Filter

Initial Start-Up

For detailed programming and operating information, please refer to the control valve section of this manual.

1. Check all piping connections and make sure feed valves are open. Inspect plumbing for leaks.

2. Check that control valve is connected to electrical source.

3. Open Raw Water source valve.

Note:

4. Fully open a cold water faucet downstream of the system. Allow water to run until clear. Close the cold water faucet.

5. Turn off the supply water.

6. Initiate manual regeneration of the control valve to regenerate: simultaneously press and for three seconds. Press the

button to advance the unit into the backwash cycle. Wait until the motor stops and the backwash time begins to count

down.

7. Open the inlet water supply valve very slowly, allowing the water to fill the tank in order to expel air.

Check for leaks throughout system as pressure is applied.

Note:

For detailed information on the control valve operation, see the valve manual enclosed.

Caution:

8. When water is flowing steadily to the drain without the presence of air, press the button again to advance the When

water is flowing steadily to the drain without the presence of air, fully open the water supply inlet valve.

Press the REGEN button again to advance to the rinse position and allow the water to run to drain for 2-3 minutes or until

the drain runs clear.

9. Press the REGEN button to advance to the service position.

10. Review the control valve operations section of this manual and ensure settings are properly programmed before placing

the filter in service.

11. Review the potassium permanganate feed injection system (supplied separately) to ensure proper configuration and

dosing. *

*

ADDITIONAL EQUIPMENT REQUIRED FOR PROPER OPERATION: Manganese greensand filters require KMn04

(Potassium Permanganate) to be injected into the feed water stream in order to regenerate the media bed. This is usually

done with the use of a chemical injection system including a chemical tank, mixer and metering pump. This equipment is

sold separately and should be designed and sized for each specific installation. The injection method and concentration of

potassium permanganate required depends on the concentration of iron and manganese in the water as well as other

factors. Please contact Applied Membranes, Inc. for assistance in sizing and purchasing the appropriate chemical injection

system.

If water flows too rapidly, there will be a loss of media out the drain.

Installation and Service Manual – Manganese Greensand Iron Filter

Page 11

Installation and Service Manual – Manganese Greensand Iron Filter

System Monitoring and Record Keeping

Monitor the filter daily and record all pertinent data. This data is needed to determine operating efficiency and for performing

system maintenance.

Note:

The latter includes changing of the media, pressure drop across the mineral tank and control valve.

Warranty Claims cannot be processed without adequate operating data and the filter history.

Operating Conditions

For optimum filter performance, observe the following:

Maintain a minimum of 25 psi during backwash cycle.

Water pressure should not exceed 120 psi across mineral tank.

Water temperature should not exceed 110 F.

CAUTION:

rings or plastic components. Exposure to such hydrocarbons may cause the products to leak. Do not use the

product(s) contained in this document on water supplies that contain hydrocarbons such as kerosene, benzene,

gasoline, etc.

Hydrocarbons such as kerosene, benzene, gasoline, etc., may damage products that contain o-

Operating DoÊs and DonÊts

DO:

Monitor system and keep a daily log.

Maintain proper water pressure for backwashing.

DONÊT:

Permit oils or fats in feed water.

Shut down system for extended periods.

Exceed operating pressures or temperatures.

Backwash filter with insufficient water flow.

Installation and Service Manual – Manganese Greensand Iron Filter

Maintenance

Removal & Replacement of Media

Tools Needed:

Wrench (to removing piping)

Screwdriver wide blade

1. Turn off water to filter.

2. Relieve pressure in tank by either opening a downstream valve or cycling the control valve into the back wash position.

3. If a by-pass valve is installed, place it in the by-pass position.

4. Disconnect drain line.

5. Turn off electrical source and disconnect control valve. Remove any wiring connected to control valve.

6. Loosen plumbing from control valve.

7. Carefully move the filter forward until it clears plumbing.

8. Move the filter to an area where access is available to all sides.

Buckets (for materials)

Wet and Dry Vacuum Cleaner or Tarp

9. Carefully loosen control valve on mineral tank top. Slowly unscrew valve being careful not to damage threads in top of

tank.

10. When valve is loose from top of tank, slowly twist it back and forth to remove it from top of distributor tube inside tank.

11. To remove the filter from mineral tank choose one of the recommended methods below:

a. Vacuum Removal: Vacuum all material out of tank and then wash inside with clean water.

b. Manual Removal: Place a canvas on floor to catch media and other materials dumped from mineral tank. Lay

tank on its side and tip it up to dump media and other materials out of tank. Slowly rotate tank as it is being

dumped. When all material is out of tank wash it with clean water.

Note:

Dispose of the media & underbedding by local procedures or laws.

12. Replace media as per media loading instructions.

13. Perform start-up procedure.

Page 13

Installation and Service Manual – Manganese Greensand Iron Filter

Control Valve Operation & Service

CV1 Control Valves

Control Valve Specifications

Minimum/Maximum Operating Pressures: 20 psi (138 kPa, 1.4 bar) to 125 psi (862 kPa, 8.6 bar)

Minimum/Maximum Operating Temperatures: 40F (4C) to 110F (43C)

No user serviceable parts are on the PC board, the motor, or the power adapter. The means of disconnection from the main

power supply is by unplugging the power adapter from the wall.

Installation and Service Manual – Manganese Greensand Iron Filter

Panel Operation Quick Reference Guide

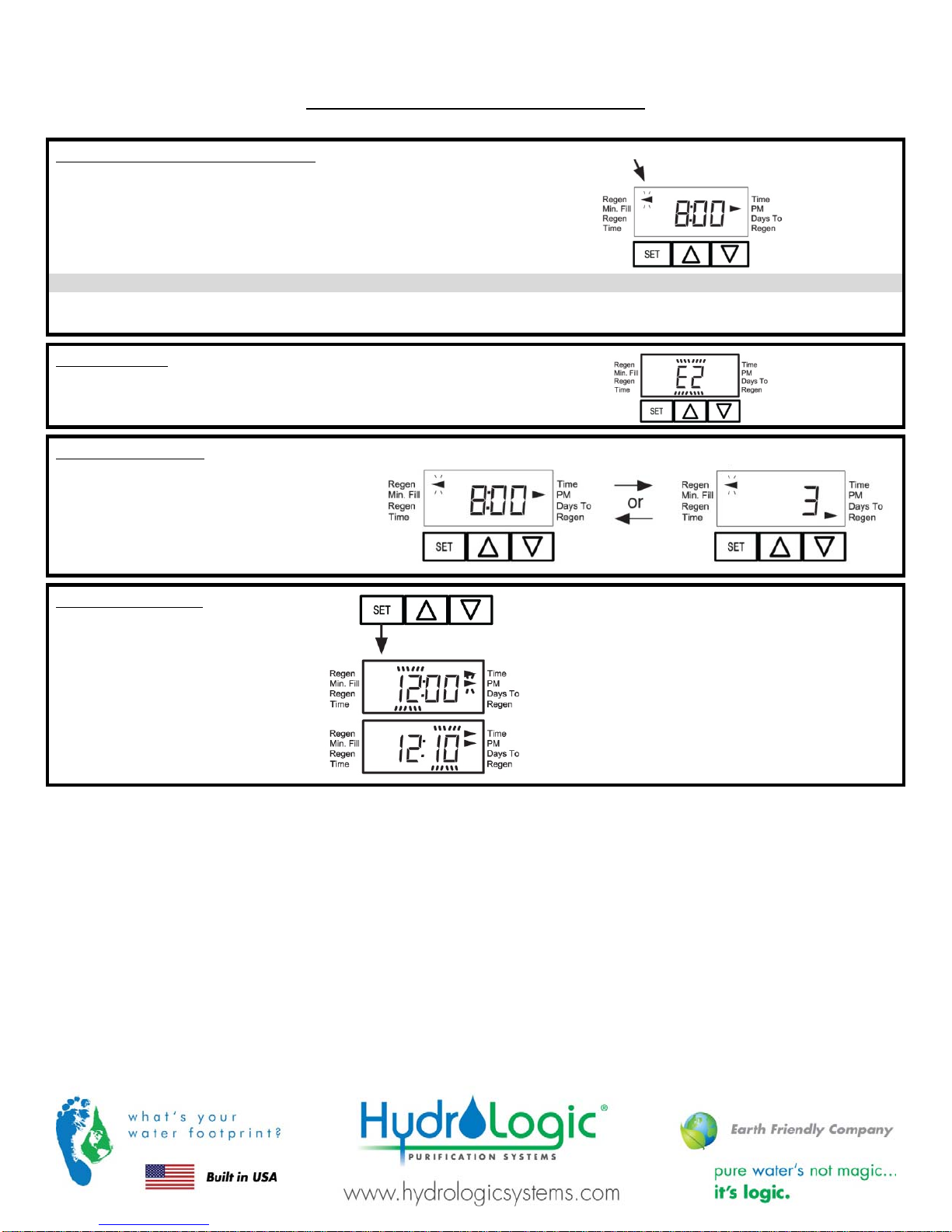

Manual Regeneration (Backwash)

Note: If you need to initiate a manual regeneration, either

immediately, or tonight at the preprogrammed time (typically 2

a.m.), complete the following steps.

For Immediate Regeneration: For Regeneration Tonight:

Press and hold and simultaneously until valve

motor starts (typically 3 seconds).

Error Message

If the display shows „E1‰, „E2‰, „E3‰, or „E4‰ (for error), check

the trouble shooting section to identify the error.

General Operation

Arrow will point to Regen if a regeneration is expected „Tonight‰.

When the system is operating one of two

displays will be shown: time of day or days

until the next regeneration.

Pressing or button will toggle between the

two choices.

To Set Time of Day

In the event of a prolonged power

outage, time of day flashes,

indicating that it needs to be reset. All

other information will be stored in

memory no matter how long the

power outage. Please complete the

steps as shown to the right. To access

this mode, press „SET‰.

Arrow will point to Regen if a regeneration is expected „Tonight‰.

Press and release and simultaneously

(notice that arrow points to Regen).

5. Accessed by pressing SET for approximately 3

seconds.

6. Adjust hour with or . With 60 Hz line frequency

detection on power-up, timekeeping is 12 hour with

PM indicator. With 50 Hz line frequency detection

on power-up, timekeeping is 24 hour without the PM

indicator. Press SET to go to the next step.

7. Adjust minutes with or .

8. Press SET to complete and return to normal operation.

Page 15

Installation and Service Manual – Manganese Greensand Iron Filter

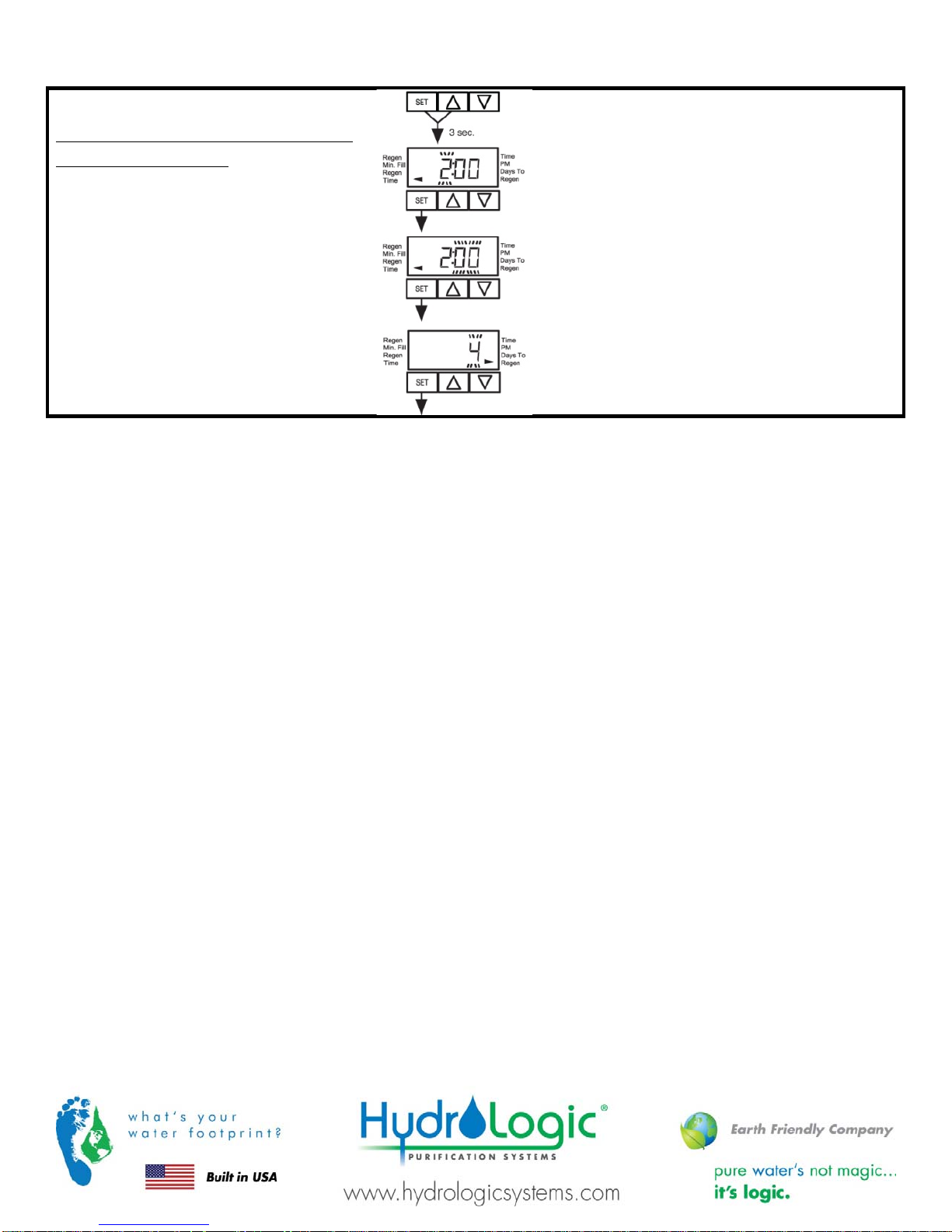

To Set Time of Regeneration and Days

Between Regeneration

For initial set-up or to make adjustments,

please complete the steps as shown.

Access this mode by pressing SET and for

approximately 3 seconds. The number of days

between regenerations may need to be varied

based on usage and water conditions.

(This step will not appear if the 7-day clock

option is selected.)

6. Accessed by pressing SET and simultaneously for

about 3 seconds.

7. Set Regeneration Time Hour. Set the time for

regeneration to start. Press SET to go to the next step.

8. Set Regeneration Time Minutes. Press SET to go to the

next step.

9. Set number of Days between regeneration cycles.

10. Press SET to complete and return to normal operation.

Loading...

Loading...