Page 1

Page 2

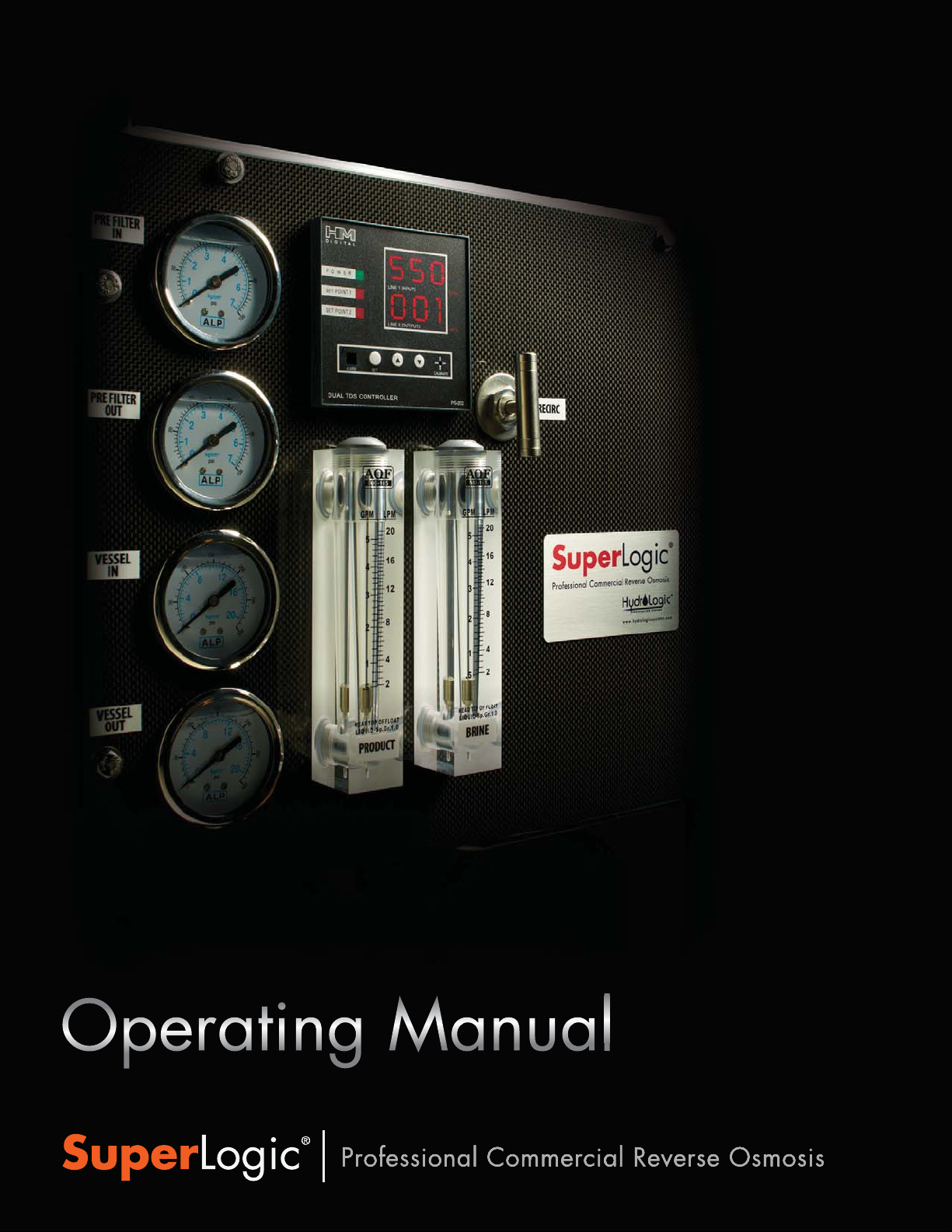

SuperLogic 1500

Installation and Operation Manual

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 3

SuperLogic 1500 Manual

- 1,500 gpd system.

- High flow, low energy membrane

- Automated TDS controller and moni-

tor with simultaneous feed and product

readout

- Carbon fiber face plate

- Rinsable sediment and

Eco-Green Carbon block prefiltration

- Anti-scalant cartridge for use in hard wa-

ter applications

- Brine and product flowmeters

- Prefilter In/Out gauges

- Membrane In/Out gauges

- Stainless steel waste water recirculation

valve

- Stainless steel heavy duty commercial

pump

- Low pressure cut-off switch

- Non-petroleum bioplastic fittings

- Manufactured in the USA

- All systems QC tested and verified

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 4

SuperLogic 1500 Manual

IntroducƟ on

Congratula ons on the purchase of your SuperLogic commercial reverse osmosis system. This is professional water purifi ca on

equipment which, with proper care and maintenance can last you for many years.

Feed water condi ons can vary dras cally as well as fl uctuate at your specifi c site. In order retain your warranty, the provided

opera ng log must be maintained and available for our review.

Prior to star ng up the SuperLogic reverse osmosis systems this user manual must be fully read and understood. Keep this

manual in a safe place for future reference. A copy of this manual can be found at www.hydrologicsystems.com.

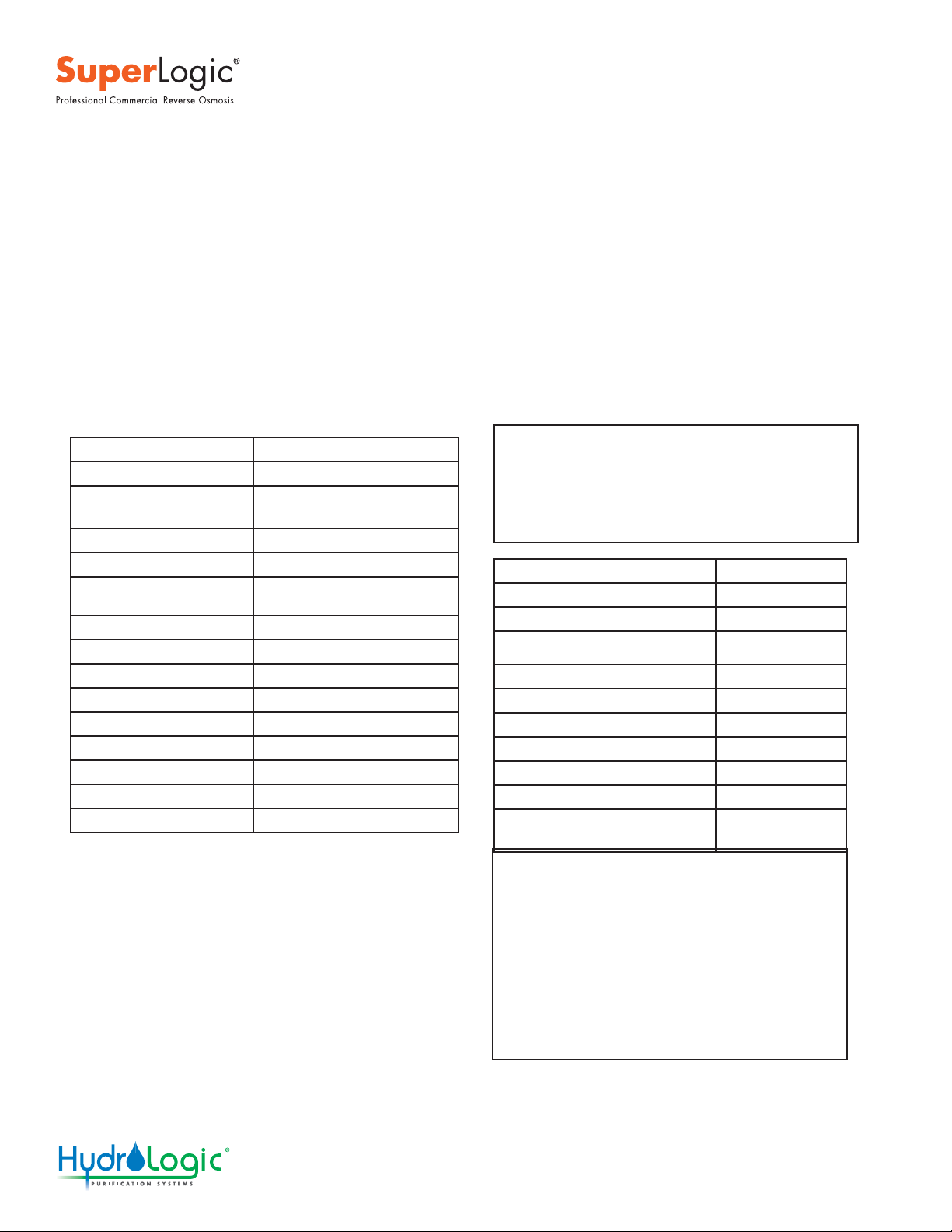

System Specifi caƟ ons

HL Model Number 31043

Capacity (gpd)

Membrane Type

Number of Membranes 1

Membrane TDS RejecƟ on

Prefi lters

Pretreatment An -scalant cartridge

Pump 325 gph

Motor 3/4 Hp

Minimum Feed (GPM) 4 GPM

Feed ConnecƟ on Female garden hose

Brine ConnecƟ on 3/8” tube

Product ConnecƟ on 3/8” tube

Dimensions 18”W x 26”D x 30”H

Weight 100 lbs

1

Based on membrane performance aŌ er 24 hours, 77°F (25°C), 500

ppm TDS, 120 psi and 66% recovery. Membrane performance may

vary ±15%.

1

1,500

4” x 21” high fl ow,

low energy, thin-fi lm

1

10” rinsable sediment (5 micron)

10” Green Carbon block (10 micron)

96%+

Feed Water and OperaƟ ng Specifi caƟ ons

Important Note: Feed water quality has a great eff ect on

the performance of your reverse osmosis. It is very important to meet the minimum feed water requirements.

Failure to do so will cause the membranes to foul and

void the warranty.

Feed Pressure 40-80 psi

Max OperaƟ ng Pressure 150 psi

Temperature 40° - 100°F

Max Chlorine (conƟ nuous) <0.3 ppm

Max Total Dissolved Solids 5,000 ppm

Hardness <15 grains

Silt Density Index <5 SDI

Turbidity <1 NTU

pH Range 2-11

Silica < 1 ppm

Iron, Hydrogen Sulfi de or

Manganese

Please Note:

Higher TDS and/or lower temperatures will reduce the

systems performance

0 ppm

Detailed water analysis available. All levels of pre and

post fi ltra on available to match source water.

Call HydroLogic directly for assistance (888) 426.5644

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 5

SuperLogic 1500 Manual

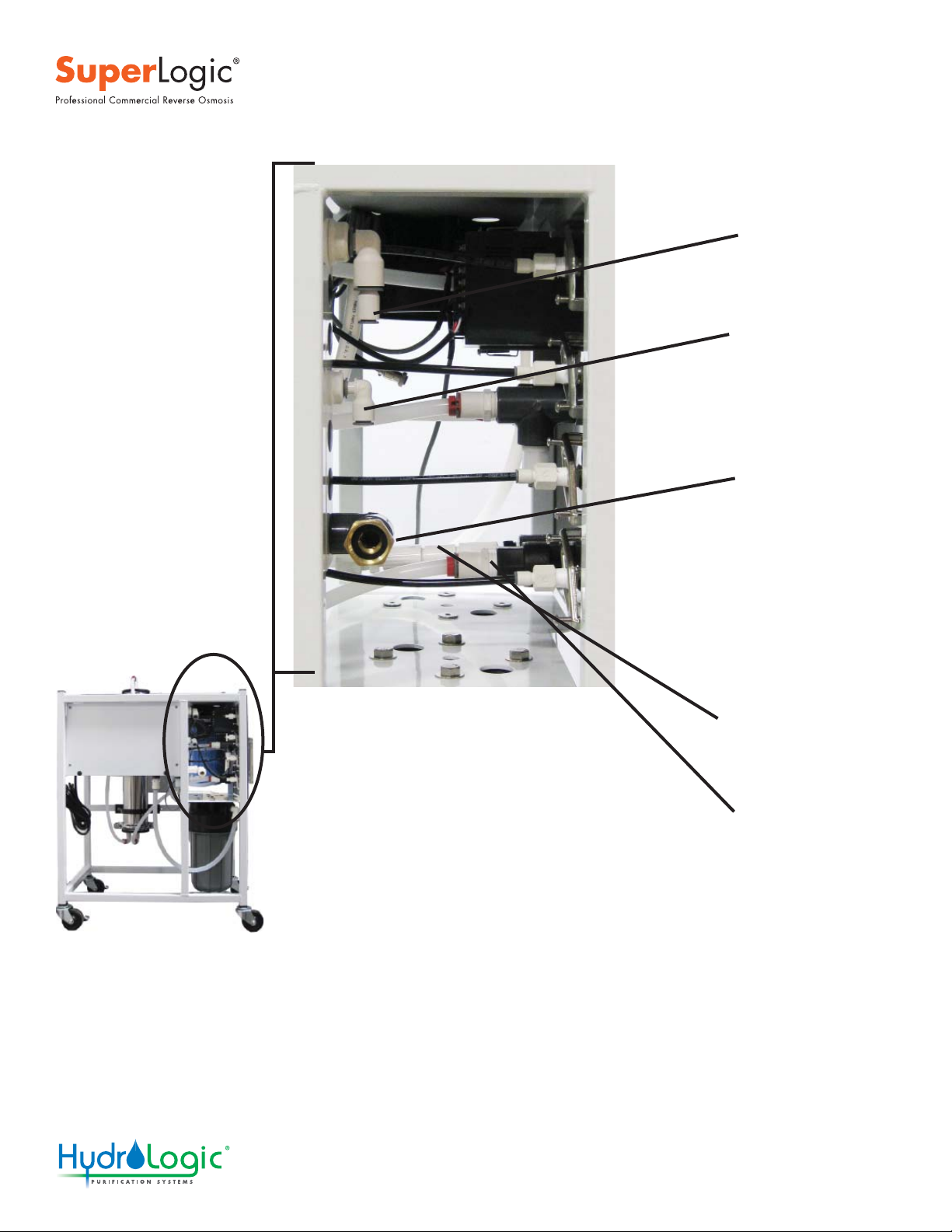

Prefilter IN Gauge

Prefilter OUT Gauge

Vessel IN Gauge

Vessel Out Gauge

Sediment Prefilter

TDS Monitor

Brine/Concentrate

Recircula

Product Flowmeter

Brine Flowmeter

An

on Valve

-Scalant

Solenoid Valve

Carbon Prefilter

Pump/Motor

Low Pressure Switch

Membrane/Vessel

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 6

SuperLogic 1500 Manual

Product Connec on

3/8”

Brine Connec on

3/8”

Feed Connec on

Garden Hose Thread

Flow Control

Product Water

Check Valve

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 7

SuperLogic 1500 Manual

An -Scalant Cartridge: Allows the system to be operated at a 2:1 product to brine recovery ra o by preven ng membrane fouling

due to hardness in the feed water. The system can also be specifi ed for a 4:1 product to brine ra o if a proper water so ener or

an scalant system is installed prior to the SuperLogic. Contact us for details @ (888) 426-5644.

Brine/Concentrate Recircula on Valve: A needle valve that controls the amount of brine from the membrane to be recirculated

back into the feed stream. This feature allows for higher recovery rates (lower waste water ra os). Addi onally, adjustment of

this valve regulates the pump discharge pressure.

Filter IN/OUT Pressure Gauges: Gauges that display the water pressure before and a er the sediment prefi lter. Used to observe

the pressure drop through the sediment prefi lter (a means of detec ng fi lter clogging or loading).

Flow Control: A fi xed orifi ce that controls the amount of water fl owing across the membrane to drain. This controls the ra o for

product water to waste water and either comes at a 4:1 or 2:1 ra o depending on how the system was specifi ed.

Low Pressure Switch: An electrical switch that shuts off the unit in the event of low feed water pressure. This is used as a pump

protec on device. This is factory set to cut off at 12 psi (0.8 bar).

Membrane/Vessel (Desalinator): Separates dissolved solids from the feed water. This assembly consists of a stainless steel pressure vessel that houses the thin-fi lm, reverse osmosis (RO) membrane.

Prefi lter, Carbon: A 10 micron Eco-Green carbon block prefi lter that removes chlorine prior to entering the membrane.

Prefi lter, Sediment: A pleated fi lter that prevents undissolved par cles larger than 5 micron, from entering the system.

Product Water Check Valve: A one-way valve that prevents pressurized product water from fl owing back into the desalinator

(and possibly damaging the membrane) when the system is off .

Pump/Motor: The rotary posi ve displacement pump boosts water pressure in the desalinator up to 150 psi (10.3 bar) for low

energy membranes to ensure high solids rejec on and high fl ow rates.

Solenoid Valve: Electrically operated valve that prevents water from fl owing through the system when it is not in opera on.

Vessel Pressure IN/OUT Gauges: Gauges that display the opera ng pressure before and a er the RO membrane (used to observe

drop in membrane pressure indica ng fouling or clogging).

TDS Monitor: Simultaneously reports the feed and product water TDS in ppm. Includes op onal alarm func on. A low PPM limit

can be programmed so the system shuts down if PPM’s go above set point.

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 8

SuperLogic 1500 Manual

Pre-InstallaƟ on Procedures

PLEASE READ CAREFULLY. FAILURE TO FOLLOW THESE PROCEDURES CAN RESULT IN DAMAGE TO YOUR SYSTEM AND VOID YOUR

WARRANTY.

Packaging

Upon delivery, inspect packaging and report any damage to your carrier immediately. A er unpacking the system,

inspect it carefully for signs of damage. All damage claims should be made to the delivery carrier.

OperaƟ ng Parameters

The SuperLogic 1500 system may only be used on potable water. The user must be sure that water to be treated is both microbiologically safe and non-toxic. Ensure that the opera ng parameters outlined on page 3 are met at the installa on site. Items of most

importance are TDS, feed water pressure, fl ow rate, chlorine level and temperature range. A water analysis is helpful in determining

if any pre-treatment is needed. If your water analysis shows levels of substances in excess of the maximums, contact HydroLogic for

pre-treatment recommenda ons. Contact HydroLogic to inquire about a detailed water analysis.

InstallaƟ on/Start up Procedure

PLEASE READ CAREFULLY. FAILURE TO FOLLOW THESE PROCEDURES CAN RESULT IN DAMAGE TO YOUR SYSTEM AND VOID YOUR

WARRANTY.

LocaƟ on

Locate the system where it will be protected from harsh condi ons such as rain, snow, direct sunlight and extreme temperatures

(both hot and cold). The SuperLogic 1500 system can be located just about anywhere there is a water supply and electrical outlet.

This system is equipped with casters and may be rolled to diff erent loca ons for opera on. Keep in mind, however, that the system

should be out of normal traffi c pa erns yet accessible for daily monitoring and service.

Plumbing

(Figure 1 - Flow Diagram)

Always abide by local plumbing codes when installing the system.

Water Supply ConnecƟ on

Connect feed water supply line to the female garden hose connector. Many other inlet fi ng op ons are available through Hydro-

Logic. If the supply water is being drawn from a non-pressurized source (gravity feed), contact Hydrologic for addi onal informa on.

Minimum inlet pressure is 40 psi. If your inlet psi is below 40 contact HydroLogic for further informa on.

Drain ConnecƟ on

Connect a 3/8” line from the quick connect elbow marked DRAIN to an appropriate drain point. A quick connect drain saddle is available as an op on from HydroLogic and can be plumbed directly into the main train of a sink. Be sure to check your local plumbing

codes to see if an air gap between the system and the drain is required.

Product ConnecƟ on

The product water connec on to the storage tank should not be made un l the system is fl ushed and tested as outlined below.

Tank ConnecƟ on (For Non-Pressurized Tanks Only)

When using a non-pressurized storage tank, connect the 3/8” tubing marked PRODUCT to the tank. Use an op onal electronic fl oat

switch to shut down the system when the tank is full and start the system when water level is low. Quick connect bulk head fi ngs

are available to connect the product line to your tank. Contact HydroLogic for this and other op ons available.

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

7

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 9

Figure 1 - Flow Diagram

SuperLogic 1500 Manual

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 10

SuperLogic 1500 Manual

Electrical

(Figure 2 - Electrical Diagram)

WARNING! THE SYSTEM CAN START AT ANY TIME WHEN POWER IS CONNECTED. DO NOT CONNECT POWER UNTIL THE SYSTEM IS

COMPLETELY INSTALLED AND READY TO RUN.

The SuperLogic 1500 system is built with a standard 115v three-prong plug. Be sure the receptacle you use is on a circuit that

has a Ground Fault Interrupter (GFCI) and has suffi cient capacity for the opera ng current as listed in the system specifi ca ons. It is

recommended that the system be installed on a dedicated circuit to prevent overloading on system start-up.

Op onal External Float Switch Wiring (For non-pressurized tanks only)

A piggy-back connector is supplied with the system. Please see addi onal installa on informa on included with the fl oat switch.

Figure 2 - Electrical Diagram

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 11

SuperLogic 1500 Manual

System Flush and Performance Verifi caƟ on

Although SuperLogic 1500 systems are fully tested at the factory prior to shipping, it is recommended to fl ush and verify your

system’s performance on-site.

Flushing

New membranes are shipped with a preserva ve that needs to be fl ushed out before use. Run the product line to drain while fl ush-

ing the system.

• Fully open the brine/concentrate recircula on valve by turning the knob counterclockwise.

• Turn on water supply to the unit and check for leaks at the pre fi lter housings and the feed connec ons.

• Plug the system into a compa ble electrical outlet. CAUTION! THE SYSTEM WILL START and rapidly cycle, star ng and stop-

ping un l the membrane vessels are full of water and water starts fl owing out of the product and brine ports.

• A er the system has run for a few minutes to clear any air, turn the brine/concentrate recircula on valve clockwise

un l the “vessel in” pressure gauge reads 120 psi (8.3 bar).

• Allow the system to fl ush for one hour with all water discharged to drain. Periodically check for leaks and

check the “vessel in” pressure gauge. It is likely that the vessel pressure will dri from 120 psi (8.3 bar) during the fl ushing.

If it does, turn brine/concentrate recircula on valve clockwise to increase pressure and counterclockwise to decrease

pressure.

• The recircula on valve will need to be adjusted when membranes are replaced or if there are seasonal changes in water

temperature that cause the pump pressure to dri by 10 psi or more.

• The 120 psi pressure provides the best compromise of membrane performance and life me while maintaining pump and

motor longevity. The system can operate above 120 psi and up to a maximum of 150 psi. Inlet water temperature and TDS

can eff ect the fl ow rate of purifi ed water and in situa ons with low water temperatures and/or high TDS increased pressure

may be necessary to achieve desired fl ow rates of purifi ed water.

*** DO NOT LET SYSTEM PRESSURE RISE ABOVE 150 PSI (10.3 BAR) AS DAMAGE TO THE SYSTEM CAN OCCUR***

Performance Verifi caƟ on

Factory test data is supplied with the system. To ensure op mal performance, on-site data should be taken and compared to the fac-

tory test data. This data should be taken a er the system has been fl ushed for one hour. Some devia ons may be seen due to

diff erences in feed water TDS and temperature between the site and factory. If you have already connected the product line to the

tank, you will need to disconnect it to take product samples.

Flow Tests

Determine the fl ow rates for both product and brine. Put the product line into a container and measure the volume of water that

fl ows into it in one minute. Repeat the process with the brine (drain) line. These values should be in either gallons per minute or

milliliters per minute. Product fl ow rates (at 77°F, 25°C) should be within 15% of the produc on rates given in the system specifi ca-

ons.

Product to Brine/Concentrate RaƟ o

Compute the product to brine ra o by dividing the brine fl ow rate by the product fl ow rate. This ra o should be either 4:1 or 2:1

± 30%. The 30% varia on can be due to inlet water temperature being above or below 77 degrees ferenheit as well as inlet TDS be-

ing above or below 500 PPM.

Total Dissolved Solids (TDS) rejecƟ on

Using the TDS monitor, note the TDS in both the feed water and the product water.

Calculate percent rejec on using the formula: (Feed TDS-Product TDS) ÷ (Feed TDS) × 100 = % Rejec on

Rejec on should be 85% or be er. For example, where the feed TDS is 600 and the product TDS is 24, the

percent rejec on is: (600-24) ÷ 600 × 100 = 96%

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 12

SuperLogic 1500 Manual

Low Pressure Switch Test

While the system is running, shut off the water supply to the system. The system should shut off . If the system does not shut off a er

ten seconds, either unplug the system or restore the water supply to the system. Call HydroLogic to diagnose problem.

DO NOT LET THE SYSTEM RUN WITHOUT THE WATER SUPPLY TURNED ON. PUMP DAMAGE WILL OCCUR.

Tank ConnecƟ on

Make the tank connec on as outlined on page 8.

OpƟ onal Float Switch Test (for non-pressurized tanks)

The system should run when the fl oat is hanging down by the power cord. Tilt fl oat up so the power cord is at the bo om of the

fl oat. The unit should shut off . If unit does not shut off , re-check installa on procedure.

OperaƟ on and Maintenance

SuperLogic 1500 systems are designed for simple opera on with li le user interven on. We recommend keeping accurate

performance records and following a regular preventa ve maintenance schedule to maximize the life of your system.

Daily System Checks

Your water supply pressure can vary from me to me. This can also aff ect your system opera ng pressure. Check

and adjust your vessel pressure daily to ensure maximum water produc on rates and quality. Check both the prefi lter in pressure

gauge and pre fi lter out pressure gauge. Under normal condi ons, there should be a 3-5 psi diff erence

between the two gauges. When the diff erence reaches 10 psi it is recommended to change your pre-fi lters.

Monthly System Checks

In addi on to the daily checks, it is recommended to repeat the procedure in the sec on on Performance Verifi ca on

and record all data on a performance record sheet.

Semi-Annual Service

It is recommended to change both sediment and carbon fi lter cartridges at least every six months. Carbon cartridges

should be changed more o en if bad taste and/or odor becomes evident. Sediment cartridge should be changed more o en if water

supply pressure and fi lter pressure gauges diff er by 10 psi or more.

Peripheral Equipment

Peripheral equipment such as tanks also have periodic maintenance requirements. It is essen al to maintain these as they can have a

drama c eff ect on the performance of your system. Refer to their specifi c manuals for proper maintenance procedures.

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 13

SuperLogic 1500 Manual

Filter/Membrane Replacement Schedule

Sediment pre-fi lter - The 5 micron sediment fi lter is pleated and can be rinsed with a garden hose. You can rinse as o en as needed

but it is recommended to replace this fi lter every 6 months. If you observe a 10 psi drop in the pre-fi lter out gauge from the psi in the

pre-fi lter in gauge this indicates a clog in the sediment fi lter and you should either rinse it or replace it.

Carbon Pre-Filter - The 10 micron carbon fi lter is rated at 2 PPM chlorine removal and should be changed according to the schedule

below:

@ 4:1 ra o replace every 25,000 gallons of product water

@ 2:1 ra o replace every 15,000 gallons of product water

An -Scale Pre-Filter - Should be replace every me the carbon fi lter is replaced

Membrane - Upon startup the vessel in gauge should read 120 while the vessel out gauge will always read approximately 10 psi less

or 110 psi. When the vessel out gauge reads 20 psi lower than the vessel in gauge, or 100 psi, this indicates when to change your

membrane.

370 Encinal Street, Suite 150, Santa Cruz, CA 95060

(888) 426-5644, Fax (831) 336-9840

www.hydrologicsystems.com

Page 14

Limited Warranty

This Limited Warranty extends to the original purchaser of the unit. This warranty covers all parts and factory labor needed to repair any manufacturer supplied item that proves to be defec ve material, workmanship or factory prepara on. The above-men oned warranty applies for the

fi rst full calendar year from the date of purchase. These defec ve items are subject to the following exclusions: membranes, fi lters, O-rings, and

all other parts or components that require regular replacement as a result of ordinary usage.

Disclaimers: This Warranty applies only if the unit is installed and used in compliance with the instruc ons enclosed with the unit.

The Warranty does not cover any unauthorized parts or parts not included on the original unit. This Warranty does not cover the costs of repairs

or adjustments to the unit that may be needed because of the use of improper parts, equipment or materials. This Warranty does not cover

repairs required due to use of unauthorized parts, unauthorized altera ons of the unit, failure of a unit caused by such altera ons or by unau-

thorized repairs.

The Warranty does not cover malfunc ons of the unit due to tampering, misuse, altera on, lack of regular maintenance, misapplica on, fouling

due to hydrogen sulfi de or iron, scaling from excessive hardness, or excessive membrane hydrolysis due to chlorine levels in excess of 1.0 mg/L,

or opera ng at too high a recovery. In addi on, damage to the unit due to fi re, accident, negligence, act of god, or events beyond the control of

the manufacturer are not covered by this warranty.

The manufacturer warran es the membranes per the original manufacturers warranty. These warran es generally cover faulty material and

workmanship for anywhere from one to three years. Membrane fouling is not covered.

The manufacturer warran es all items supplied by outside vendors, per the manufacturers warran es. These warran es generally cover faulty

material and workmanship for one year.

Incidental and ConsequenƟ al Damages: The manufacturer does not assume responsibility for payment of incidental damages as a result of the

failure of this unit to comply with express or implied warran es, such as lost me, inconvenience, damage to personal property, loss of revenue,

commercial losses, postage, travel, telephone expenditures, or other losses of this nature. Some states do not allow the exclusion or limita on of

incidental or consequen al damages, so this exclusion may not apply to you.

Owner’s Warranty ResponsibiliƟ es: Under the provisions of this Warranty, the owner is expected to perform mely maintenance, as described

in this Manual. Neglect, improper maintenance, abuse, or unapproved modifi ca ons may invalidate the Warranty. Should your unit develop a

defect or otherwise fail to perform in accordance with this warranty, you should contact HydroLogic.

Implied WarranƟ es: Implied at-law warran es of merchantability and fi tness for a par cular purpose shall terminate on the date one year a er

the date of purchase. Note: some states do not allow limita ons on how an implied warranty lasts, so the above limita ons may not apply to you.

Other Rights This Warranty gives you specifi c legal rights and you may also have other rights that vary from state to state.

Returned Goods AuthorizaƟ on In order to process a return, a Returned Goods Authoriza on (RGA) number will be assigned. Include the RGA

number with an explana on of the defect with the item being returned. Items returned under the RGA process will be reviewed and/or for-

warded to the original manufacturer for evalua on. Items returned must be sent prepaid.

.

Page 15

T

°

T

Rejection Comments

GPM Recovery

F/°C GPM PPM PSIIN PSIOU

PPM

Filter Feed Product Vessel Brine

PSIIN PSIOU

Date

Page 16

Page 17

USER’S GUIDE

PANEL CUT-OUT DIAGRAM

M

H

D I G I T A L

®

PS-200

PANEL MOUNT DUAL TDS

CONTROLLER/MONITOR

1. Using a knife, cut the diagram out (cut on the outer part of the line).

2. Align the cut-out to your panel and draw cut marks.

3. Cut the hole in the panel to the precise dimensions of the cut-out:

2-11/16 in. x 2-11/16 in. (68 mm x 68 mm)

--> See the installation section for complete instructions.

CONTACT DIAGRAM

2 11/16 in. (68 mm)

2

11

/16 in. (68 mm)

8 9 10 11 12 13 14

1 2 3 4 5 6 7

AC

N.C. N.O.

WHITE RED BLACK

ALARM

(BUZZ)

SENSOR OUT

110-220V

RELAY (SWITCH)

WHITE RED BLACK

SENSOR IN

Page 18

2 7

Thank you for purchasing HM Digital’s PS-200. The PS-200 is a panel mount total dissolved solids (TDS)

controller that monitors and controls levels of TDS in water. The controller has a maximum set point to

help maintain a limit of TDS allowed in the product water, as well as a second sensor to monitor the TDS

level of the feed water. If the TDS level rises to the set point, the controller will activate a warning light,

sound an alarm (optional) and switch the dry contact position from the normal position (to operate a

valve, pump, etc.). Once the TDS level drops below the set point, this will deactivate the light and alarm

and switch the contacts back to the normal position (normally open or closed). NOTE: The IN mode &

sensor does not have an alarm nor control set point. It is a monitor only.

CONTACT INFO

BOX CONTENTS

SPECIFICATIONS

If you have any problems or questions regarding your controller, please contact HM Digital, Inc.

HM Digital, Inc. info@hmdigital.com

5819 Uplander Way www.tdsmeter.com

Culver City, CA 90230 1-800-383-2777

U.S.A

1. Controller 3. Two sensor cables (grey) 5. Mounting brackets

2. Two sensors (SP-1) 4. Power cord (black) 6. U.S. plug adapter

TDS Range: 0 - 999 ppm (mg/L)

Resolution: 1 ppm

Accuracy: ±2% (of the reading)

Temperature Compensation: Automatic (ATC) (1-60

o

C)

Calibration: Manual by trimmer pot calibration screw

Set-Point: Single point, controlled by on-screen up/down buttons (to any point within the range)

Set-Point Relay: single, isolated, 2A, Max. 220V, resistive load 100,000 strokes

Relay Control (out sensor only): The unit will open or close a circuit via dry contacts when the

ppm level of the OUT sensor (aka product water) reaches or exceeds the control setting (simple

switch). It can be used to control a pump, solenoid valve or other device.

Relay Voltage: 5V (the connected device needs its own power source)

Alarm: Optional steady beep (set by user)

Probe: ½” NPTF bushing

Cable Length: 3 meter (9.8 ft) shielded cable

Display: Bright tri-color L.E.D.

Power Supply: 110V/230V, ±10% Vac; 50/60Hz

Enclosure: Front and back with ABS

Environment: -10 to 50

o

C (4 to 122oF); RH max 95% non-condensing

Dimensions: 7.2 x 7.2 x 10.2 cm (2.8 x 2.8 x 4 in.)

Monitor Weight: 476 grams (1 lb 0.8 oz)

THIS PAGE INTENTIONALLY LEFT BLANK

Page 19

6

3

INSTALLATION INSTRUCTIONS

USAGE INSTRUCTIONS

1. Remove the contents from the box.

2. Insert the controller into the panel. A square hole must be cut into the panel with dimensions

of 2-11/16 in. x 2-11/16 in. (68 mm x 68 mm). Page 8 includes a cut-out diagram.

3. Mount the controller to the panel by inserting the mounting brackets into the grooves on the

bottom and top of the controller. Fasten the brackets with the included screws.

4. View the contact diagram on the side of the controller (also on page 8).

5. Do NOT connect to a power source yet! Connect the black power cord to the contacts

#8 & #9 (110 V - 230V). It does not matter which color wire is connected to the

contacts. Screw in tight with a Phillips head screwdriver. (Note – If in the U.S. (or a country

that uses Type A or B plugs/sockets), connect the included plug adapter to the power cord).

6. If using a pump, valve, etc., connect a relay wire (not included) to contacts #13 and #14 for a

normally open (N.O.) position OR to contacts #12 and #13 for a normally closed (N.C.) position.

7. Connect a gray sensor cable by attaching the white wire to contact #1, the red to #2, and the

black to #3.

8. Connect the second sensor cable by attaching the white wire to contact #5, the red to #6, and

the black to #7. The cables are identical and can be swapped.

9. Align the pins of each sensor to each cable and attach. Screw the tightening ring closed. The

sensors are identical and can be swapped. Note which sensor is now the IN sensor and which is

the OUT sensor.

10. Insert each sensor electrode into a female ½” NPTF threaded tting.

11. Attach the tting connected to the OUT sensor to the product water.

12. Attach the tting connected to the IN sensor to the feed water.

13. Ensure the orientation of the sensor is perpendicular to the ow of the water. Water

should ow equally over both pins. (If using a T, if you look through the top of the T, you

should see both pins equally side-by-side. If using the sensor in a tank, ensure that there are

no air bubbles trapped between the pins or in a tting.)

14. To DISCONNECT the audible alarm, disconnect the blue wire from contacts #10 and #11.

15. Plug the power cord into an electrical outlet. The controller does not have a power switch

and will automatically power on when the power is connected.

WARRANTY

ONE YEAR LIMITED WARRANTY

The PS-200, including the controller and both sensors, is warranted by HM Digital, Inc.

("the Company") to the purchaser against defective materials and workmanship for

one (1) year from the date of purchase.

What is covered: Repair parts and labor, or replacement at the Company's option.

Transportation charges for repaired of new product to be returned to the purchaser.

What is not covered: Transportation charges for the defective product to be sent to

the Company. Any consequential damages, incidental damages, or incidental

expenses, including damages to property. This includes damages from abuse or

improper maintenance such as tampering, wear and tear, water damage, or any other

physical damage. The Company's products are not waterproof and should not be fully

submerged in water. Products with any evidence of such damage will not be repaired

or replaced. See additional note below.

How to obtain warranty performance: Attach to the product your name, address,

description of problem, phone number, and proof of date of purchase, package and

return to:

HM Digital, Inc.

ATTN: Returns

5819 Uplander Way

Culver City, CA 90230

U.S.A.

Implied Warranties: Any implied warranties, including implied warranties of

merchantability and tness for a particular purpose, are limited in duration to ve

years from date of purchase. Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not apply to you. To the extent any

provision of this warranty is prohibited by federal and state law and cannot be

preempted, it shall not be applicable. This warranty gives you specic legal rights, and

you may also have other rights, which vary from state to state.

NOTE: Warranties are product-specic. Third-party products and products deemed by

HM Digital as "accessories" are not covered under warranty. Third-party products and

accessories include, but are not limited to, batteries, fuses, mounting brackets, plug

adaptors and ttings.

IMPORTANT: Double-check your contacts prior to connecting the controller to a

power source. Incorrect connections could result in shorting out the unit.

1. The controller will turn on when the power cord is plugged into an electrical outlet.

2. Open the cover on the front of the controller by gently pulling down.

3. There is only one display for both the IN mode (feed water) and OUT mode (product water).

The OUT mode is the default. To view the TDS level of the feed water, press the “IN MODE”

button. The display will switch to the feed water. NOTE: The display will automatically switch

back to the product water TDS after ve seconds. To view the feed water display for longer,

press and hold the “IN MODE” button.

4. To turn o the controller, unplug it from the electrical outlet.

Page 20

Setting the Control Set Point

1. To set the control set point (to activate a device via the relay), press the SET button once.

The EC reading will switch to a ashing number (the current set point).

2. Press the UP or DOWN buttons until the desired set point is reached. Pressing once will ad vance the reading by a single digit. Press and hold the button to advance the reading quickly.

3. Press the SET button again. This will save the set point to memory.

4. If the EC level reaches the saved set point, the controller will switch the contacts from the

normal position (either normally open or normally closed), thereby operating the pump,

solenoid valve, or other device attached to contacts #12 & 13 or #13 & 14.

5. Once the EC level falls below the set point, the contacts will switch back to the normal

position.

6. The alarm (if connected) will sound continuously while the EC level is over the set point.

The only way to turn it o is by lowering the EC level below the set point or disconnect ing the blue wire from contacts #5 and #11.

Problem Potential Solution(s)

The controller will not power on.

Incorrect readings.

The relay control does not work.

TROUBLESHOOTING

1. Check to ensure the connections are correct (doublecheck 110V vs. 220V).

2. Check to ensure the power cable is plugged in.

1. Try to recalibrate the controller. Note that the calibration should be done with a tting on (if using a tting).

2. Check for interference caused by other machinery or

electronics (near the controller or cables).

1. Double-check the connections for contacts #12, 13 & 14.

2. Make sure that the set point is properly set.

Calibration

Your controller was factory calibrated to 342 ppm (NaCl). This level is suitable for most tap

water/ltered water applications, so it is ready to use out of the box. However, you may need

to re-calibrate based on your needs, as well as from time-to-time to ensure best results.

To calibrate:

1. Obtain a certied calibration solution that is correct for your needs. The calibration

solution should be NaCl. HM Digital’s 342 ppm NaCl is recommended.

2. Calibrate to the OUT sensor. This will calibrate both sensors simultaneously.

3. Check the controller against the calibration solution. Prior to inserting the sensor into the

calibration solution, be sure the sensor is dry and free of any TDS residue. If the reading

on the controller does not match the calibration value, you will need to re-calibrate. If

using a tting, calibrate with the tting on the sensor. (See step 5 for additional informa tion regarding the calibration value.)

4. For better accuracy, calibrate to a owing solution. If this is not possible, you can

calibrate to a still solution. Ensure the tting is completely lled with solution and there

are no air bubbles. This step is critical for proper calibration.

5. If the reading on the controller does not match the solution, adjust the reading up or

down by gently turning the trimmer pot calibration screw on the face of the unit (marked

as “ADJUST”) clockwise or counterclockwise to raise or lower the reading.

6. If calibrating to a still (not owing) solution, calibrate to 3% above the level of the calibra tion solution. This will accomodate for the lack of owing water, which the controller is

programmed for. For example, if the calibration solution is 342 ppm, adjust the screw

until it reads 352 ppm. If you are calibrating to a owing solution, calibrate to the level of

the solution.

7. Gently release the screwdriver from the trimmer pot.

8. Your controller is now calibrated. There is no need to do anything else.

The display shows “Err”.

1. The TDS level of the water is out of the controller’s range.

2. The sensor is not connected.

3. The sensor is dirty or damaged.

The display shows the feed water

TDS level, instead of the product.

1. The sensors are reversed. Connect the sensor for the

feed water to the IN sensor contacts, and the sensor for

the product water water to the IN sensor contacts.

If troubleshooting does not solve the problem, please contact HM Digital for assistance. If your controller

is still under warranty, please return the controller to HM Digital for repair or replacement (see page 6).

Sensor Replacement

If your sensor has been damaged, you can purchase a new one (model SP-1) without the need

to purchase a new controller.

Contact your authorized HM Digital distributor for a replacement sensor. If you cannot locate

an HM Digital distributor, contact HM Digital at info@hmdigital.com

Loading...

Loading...