Page 1

USER’S GUIDE

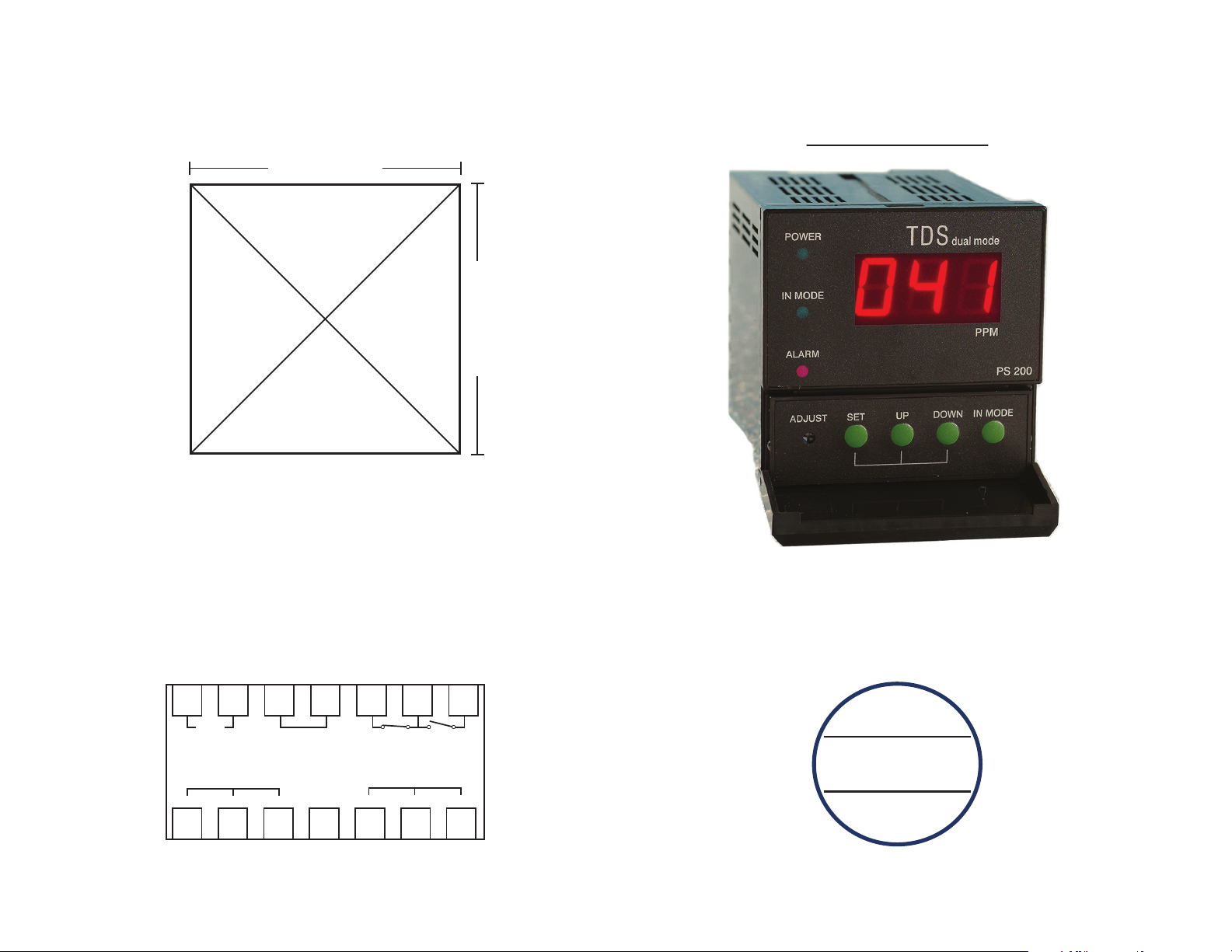

PANEL CUT-OUT DIAGRAM

M

H

D I G I T A L

®

PS-200

PANEL MOUNT DUAL TDS

CONTROLLER/MONITOR

1. Using a knife, cut the diagram out (cut on the outer part of the line).

2. Align the cut-out to your panel and draw cut marks.

3. Cut the hole in the panel to the precise dimensions of the cut-out:

2-11/16 in. x 2-11/16 in. (68 mm x 68 mm)

--> See the installation section for complete instructions.

CONTACT DIAGRAM

2 11/16 in. (68 mm)

2

11

/16 in. (68 mm)

8 9 10 11 12 13 14

1 2 3 4 5 6 7

AC

N.C. N.O.

WHITE RED BLACK

ALARM

(BUZZ)

SENSOR OUT

110-220V

RELAY (SWITCH)

WHITE RED BLACK

SENSOR IN

Page 2

2 7

Thank you for purchasing HM Digital’s PS-200. The PS-200 is a panel mount total dissolved solids (TDS)

controller that monitors and controls levels of TDS in water. The controller has a maximum set point to

help maintain a limit of TDS allowed in the product water, as well as a second sensor to monitor the TDS

level of the feed water. If the TDS level rises to the set point, the controller will activate a warning light,

sound an alarm (optional) and switch the dry contact position from the normal position (to operate a

valve, pump, etc.). Once the TDS level drops below the set point, this will deactivate the light and alarm

and switch the contacts back to the normal position (normally open or closed). NOTE: The IN mode &

sensor does not have an alarm nor control set point. It is a monitor only.

CONTACT INFO

BOX CONTENTS

SPECIFICATIONS

If you have any problems or questions regarding your controller, please contact HM Digital, Inc.

HM Digital, Inc. info@hmdigital.com

5819 Uplander Way www.tdsmeter.com

Culver City, CA 90230 1-800-383-2777

U.S.A

1. Controller 3. Two sensor cables (grey) 5. Mounting brackets

2. Two sensors (SP-1) 4. Power cord (black) 6. U.S. plug adapter

TDS Range: 0 - 999 ppm (mg/L)

Resolution: 1 ppm

Accuracy: ±2% (of the reading)

Temperature Compensation: Automatic (ATC) (1-60

o

C)

Calibration: Manual by trimmer pot calibration screw

Set-Point: Single point, controlled by on-screen up/down buttons (to any point within the range)

Set-Point Relay: single, isolated, 2A, Max. 220V, resistive load 100,000 strokes

Relay Control (out sensor only): The unit will open or close a circuit via dry contacts when the

ppm level of the OUT sensor (aka product water) reaches or exceeds the control setting (simple

switch). It can be used to control a pump, solenoid valve or other device.

Relay Voltage: 5V (the connected device needs its own power source)

Alarm: Optional steady beep (set by user)

Probe: ½” NPTF bushing

Cable Length: 3 meter (9.8 ft) shielded cable

Display: Bright tri-color L.E.D.

Power Supply: 110V/230V, ±10% Vac; 50/60Hz

Enclosure: Front and back with ABS

Environment: -10 to 50

o

C (4 to 122oF); RH max 95% non-condensing

Dimensions: 7.2 x 7.2 x 10.2 cm (2.8 x 2.8 x 4 in.)

Monitor Weight: 476 grams (1 lb 0.8 oz)

THIS PAGE INTENTIONALLY LEFT BLANK

Page 3

6

3

INSTALLATION INSTRUCTIONS

USAGE INSTRUCTIONS

1. Remove the contents from the box.

2. Insert the controller into the panel. A square hole must be cut into the panel with dimensions

of 2-11/16 in. x 2-11/16 in. (68 mm x 68 mm). Page 8 includes a cut-out diagram.

3. Mount the controller to the panel by inserting the mounting brackets into the grooves on the

bottom and top of the controller. Fasten the brackets with the included screws.

4. View the contact diagram on the side of the controller (also on page 8).

5. Do NOT connect to a power source yet! Connect the black power cord to the contacts

#8 & #9 (110 V - 230V). It does not matter which color wire is connected to the

contacts. Screw in tight with a Phillips head screwdriver. (Note – If in the U.S. (or a country

that uses Type A or B plugs/sockets), connect the included plug adapter to the power cord).

6. If using a pump, valve, etc., connect a relay wire (not included) to contacts #13 and #14 for a

normally open (N.O.) position OR to contacts #12 and #13 for a normally closed (N.C.) position.

7. Connect a gray sensor cable by attaching the white wire to contact #1, the red to #2, and the

black to #3.

8. Connect the second sensor cable by attaching the white wire to contact #5, the red to #6, and

the black to #7. The cables are identical and can be swapped.

9. Align the pins of each sensor to each cable and attach. Screw the tightening ring closed. The

sensors are identical and can be swapped. Note which sensor is now the IN sensor and which is

the OUT sensor.

10. Insert each sensor electrode into a female ½” NPTF threaded tting.

11. Attach the tting connected to the OUT sensor to the product water.

12. Attach the tting connected to the IN sensor to the feed water.

13. Ensure the orientation of the sensor is perpendicular to the ow of the water. Water

should ow equally over both pins. (If using a T, if you look through the top of the T, you

should see both pins equally side-by-side. If using the sensor in a tank, ensure that there are

no air bubbles trapped between the pins or in a tting.)

14. To DISCONNECT the audible alarm, disconnect the blue wire from contacts #10 and #11.

15. Plug the power cord into an electrical outlet. The controller does not have a power switch

and will automatically power on when the power is connected.

WARRANTY

ONE YEAR LIMITED WARRANTY

The PS-200, including the controller and both sensors, is warranted by HM Digital, Inc.

("the Company") to the purchaser against defective materials and workmanship for

one (1) year from the date of purchase.

What is covered: Repair parts and labor, or replacement at the Company's option.

Transportation charges for repaired of new product to be returned to the purchaser.

What is not covered: Transportation charges for the defective product to be sent to

the Company. Any consequential damages, incidental damages, or incidental

expenses, including damages to property. This includes damages from abuse or

improper maintenance such as tampering, wear and tear, water damage, or any other

physical damage. The Company's products are not waterproof and should not be fully

submerged in water. Products with any evidence of such damage will not be repaired

or replaced. See additional note below.

How to obtain warranty performance: Attach to the product your name, address,

description of problem, phone number, and proof of date of purchase, package and

return to:

HM Digital, Inc.

ATTN: Returns

5819 Uplander Way

Culver City, CA 90230

U.S.A.

Implied Warranties: Any implied warranties, including implied warranties of

merchantability and tness for a particular purpose, are limited in duration to ve

years from date of purchase. Some states do not allow limitations on how long an

implied warranty lasts, so the above limitation may not apply to you. To the extent any

provision of this warranty is prohibited by federal and state law and cannot be

preempted, it shall not be applicable. This warranty gives you specic legal rights, and

you may also have other rights, which vary from state to state.

NOTE: Warranties are product-specic. Third-party products and products deemed by

HM Digital as "accessories" are not covered under warranty. Third-party products and

accessories include, but are not limited to, batteries, fuses, mounting brackets, plug

adaptors and ttings.

IMPORTANT: Double-check your contacts prior to connecting the controller to a

power source. Incorrect connections could result in shorting out the unit.

1. The controller will turn on when the power cord is plugged into an electrical outlet.

2. Open the cover on the front of the controller by gently pulling down.

3. There is only one display for both the IN mode (feed water) and OUT mode (product water).

The OUT mode is the default. To view the TDS level of the feed water, press the “IN MODE”

button. The display will switch to the feed water. NOTE: The display will automatically switch

back to the product water TDS after ve seconds. To view the feed water display for longer,

press and hold the “IN MODE” button.

4. To turn o the controller, unplug it from the electrical outlet.

Page 4

Setting the Control Set Point

1. To set the control set point (to activate a device via the relay), press the SET button once.

The EC reading will switch to a ashing number (the current set point).

2. Press the UP or DOWN buttons until the desired set point is reached. Pressing once will ad vance the reading by a single digit. Press and hold the button to advance the reading quickly.

3. Press the SET button again. This will save the set point to memory.

4. If the EC level reaches the saved set point, the controller will switch the contacts from the

normal position (either normally open or normally closed), thereby operating the pump,

solenoid valve, or other device attached to contacts #12 & 13 or #13 & 14.

5. Once the EC level falls below the set point, the contacts will switch back to the normal

position.

6. The alarm (if connected) will sound continuously while the EC level is over the set point.

The only way to turn it o is by lowering the EC level below the set point or disconnect ing the blue wire from contacts #5 and #11.

Problem Potential Solution(s)

The controller will not power on.

Incorrect readings.

The relay control does not work.

TROUBLESHOOTING

1. Check to ensure the connections are correct (doublecheck 110V vs. 220V).

2. Check to ensure the power cable is plugged in.

1. Try to recalibrate the controller. Note that the calibration should be done with a tting on (if using a tting).

2. Check for interference caused by other machinery or

electronics (near the controller or cables).

1. Double-check the connections for contacts #12, 13 & 14.

2. Make sure that the set point is properly set.

Calibration

Your controller was factory calibrated to 342 ppm (NaCl). This level is suitable for most tap

water/ltered water applications, so it is ready to use out of the box. However, you may need

to re-calibrate based on your needs, as well as from time-to-time to ensure best results.

To calibrate:

1. Obtain a certied calibration solution that is correct for your needs. The calibration

solution should be NaCl. HM Digital’s 342 ppm NaCl is recommended.

2. Calibrate to the OUT sensor. This will calibrate both sensors simultaneously.

3. Check the controller against the calibration solution. Prior to inserting the sensor into the

calibration solution, be sure the sensor is dry and free of any TDS residue. If the reading

on the controller does not match the calibration value, you will need to re-calibrate. If

using a tting, calibrate with the tting on the sensor. (See step 5 for additional informa tion regarding the calibration value.)

4. For better accuracy, calibrate to a owing solution. If this is not possible, you can

calibrate to a still solution. Ensure the tting is completely lled with solution and there

are no air bubbles. This step is critical for proper calibration.

5. If the reading on the controller does not match the solution, adjust the reading up or

down by gently turning the trimmer pot calibration screw on the face of the unit (marked

as “ADJUST”) clockwise or counterclockwise to raise or lower the reading.

6. If calibrating to a still (not owing) solution, calibrate to 3% above the level of the calibra tion solution. This will accomodate for the lack of owing water, which the controller is

programmed for. For example, if the calibration solution is 342 ppm, adjust the screw

until it reads 352 ppm. If you are calibrating to a owing solution, calibrate to the level of

the solution.

7. Gently release the screwdriver from the trimmer pot.

8. Your controller is now calibrated. There is no need to do anything else.

The display shows “Err ”.

1. The TDS level of the water is out of the controller’s range.

2. The sensor is not connected.

3. The sensor is dirty or damaged.

The display shows the feed water

TDS level, instead of the product.

1. The sensors are reversed. Connect the sensor for the

feed water to the IN sensor contacts, and the sensor for

the product water water to the IN sensor contacts.

If troubleshooting does not solve the problem, please contact HM Digital for assistance. If your controller

is still under warranty, please return the controller to HM Digital for repair or replacement (see page 6).

Sensor Replacement

If your sensor has been damaged, you can purchase a new one (model SP-1) without the need

to purchase a new controller.

Contact your authorized HM Digital distributor for a replacement sensor. If you cannot locate

an HM Digital distributor, contact HM Digital at info@hmdigital.com

Loading...

Loading...