Hydrolevel Company AcuTemp, AcuTemp 2000, AcuTemp 2000-135 Installation Instructions And Operating Manual

Installation Instructions

3-17/32"

and Operating Manual

The AcuTemp utilizes a microcontroller-based

Temperature

Control

NOTICE - Read these instructions completely before proceeding

with the installation. Retain these instructions for future reference.

design to control water temperature. An advanced

software algorithm closely monitors the rate of

tank temperature changes and controls the heating

source to minimize fluctuations in tank temperature

while optimizing fuel efficiency. The control features

adjustable temperature settings for both residential

and commercial temperature operating ranges.

Electrical shock

WARNING

electrical shock, death, or equipment damage, disconnect power supply before installing or servicing control.

hazard. To prevent

RATINGS

Input 24 VAC, 60 Hz

Power 2.4 VA

Output Dry contacts, 50 VA

@ 24 VAC, 60 Hz

Ambient temp 30°F - 140°F

Operating temp (user selected)

Differential Automatically controlled 5°F - 10°F

DIMENSIONS

All work must be

WARNING

qualified and licensed professional in accordance with

all applicable codes and ordinances.

Model 2000 (Residential Setting): 60°F - 160°F default

Model 2000 (Commercial Setting): 60°F - 180°F

Other Models: 60°F to the number specified in the suffix of the

model number. (ex Model 2000-135 has an operating temp

range of 60°F - 135°F)

performed by a

2-3/4"

1

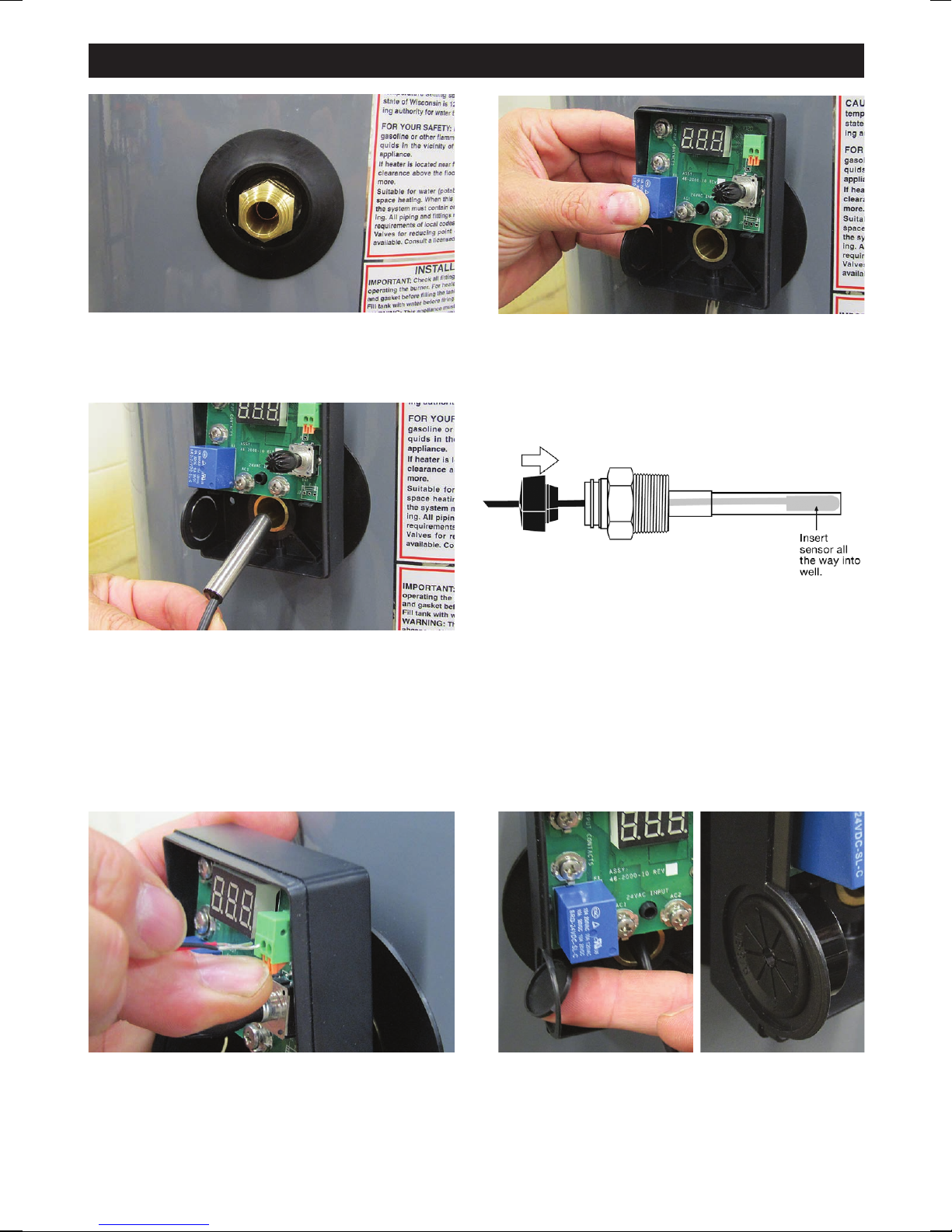

INSTALLING THE CONTROL

1 Locate the immersion well in the tank that is

designed for the temperature control.

2 Hold the AcuTemp control onto the well and

tighten the screw at the base of the control.

3A Sensor and Well

(remote mounted control)

3 Slide the sensor into the well. NOTE: two

sensor diameters (3/8" & 1/4") are available to

accommodate different well sizes.

WARNING: The sensor must be fully inserted and fit snugly in the well for proper operation.

If a smaller sensor is used or the sensor is not fully inserted overheating and scalding could result.

1. Insert the sensor all the way into the well.

2. Install the rubber well cap onto the sensor wire

and slide to cover the end of the well

4 Trim the sensor wire to the required length (if

needed). Plug the sensor wire into the sensor

input. The terminals are not polarity sensitive.

NOTE: Be sure the wires are fully inserted into the

sensor input.

5 Remove the knockout and replace it with the

plastic bushing.

NOTE: For line voltage applications replace the

knockout with proper conduit in accordance with

all applicable codes and ordinances.

2

Loading...

Loading...