Page 1

Model VXT-120

Programmable

Water Feeder for

Steam Boilers

120 VAC Operating Voltage

Patent Pending

SPECIFICATIONS

MAXIMUM FLUID

TEMPERATURE: 150°F

AMBIENT TEMPERATURE: 100°F

FLOW RATE: 1 GPM

MAXIMUM FEED: 10 Gallons (2 Cycles)

ELECTRICAL: 120 VAC, 60 HZ

• UNIVERSAL COMPATIBILITY: The VXT feeder can be used with virtually

any probe or float-type low water cut-off.

• FEED COUNTER: Brightly illuminated feed cycle counter displays the

amount of water added to the boiler – essential in diagnosing water loss

problems that can severely shorten the life of a steam boiler. Built-in memory prevents power interruptions from clearing the counter.

• PROGRAMMABLE FEED DELAY SETTINGS: Helps prevent flooded boilers.

Allows time for condensate to return to the boiler before starting feed

cycle – ensuring that additional water is needed.

• PROGRAMMABLE FEED AMOUNT SETTINGS: Six settings provide two

ways to feed: 1-5 gallon settings feed

above

the Low Water Cut-Off to

restore boiler’s normal operating level. Or, select LWCO setting to end the

feed cycle when the Low Water Cut-Off re-energizes the burner.

• UNDERFEED PROTECTION: If one feed cycle is not sufficient to restore

boiler operation, the VXT will delay and feed one additional cycle.

• LOCKOUT FLOOD PROTECTION: The VXT locks-out to prevent steam sys-

tem flooding and costly water damage if burner operation does not

resume after two

consecutive feed cycles.

INSTALLATION

Step ➊– Warning Step ➋– Plumbing

WARNING – To

prevent electrical

shock or equipment

damage, power

must be off during

installation or servicing of the con-

serious burns, the boiler should be thoroughly cooled

before installing or servicing control. Only qualified

personnel may install or service the control in accordance with local codes and ordinances. Read instructions completely before proceeding.

We warrant products manufactured by Hydrolevel Company to

be free from defects in material and workmanship for a period

of two years from the date of manufacture or one year from

the date of installation, whichever occurs first. In the event of

any claim under this warranty or otherwise with respect to our

products which is made within such period, we will, at our

option, repair or replace such products or refund the purchase

price paid to us by you for such products. In no event shall

trol. To prevent

Feeder must be installed with a manual by-pass. Use isolation valves and

unions to allow easy removal for service or replacement.

Note: Arrow on VXT valve indicates direction of water flow.

LIMITED MANUFACTURER’S WARRANTY

Hydrolevel Company be liable for any other loss or damage,

whether direct, indirect, incidental or consequential. This warranty is your EXCLUSIVE remedy and shall be IN PLACE OF

any other warranty or guarantee, express or implied, including, without limitation, any warranty of MERCHANTABILITY or

fitness for a particular purpose. This warranty may not be

assigned or transferred and any unauthorized transfer or

assignment thereof shall be void and of no force or effect.

P.O. Box 1847 • New Haven, CT 06508 • Phone: (203) 776-0473 • FAX: (203) 773-1019 • www.hydrolevel.com

Page 2

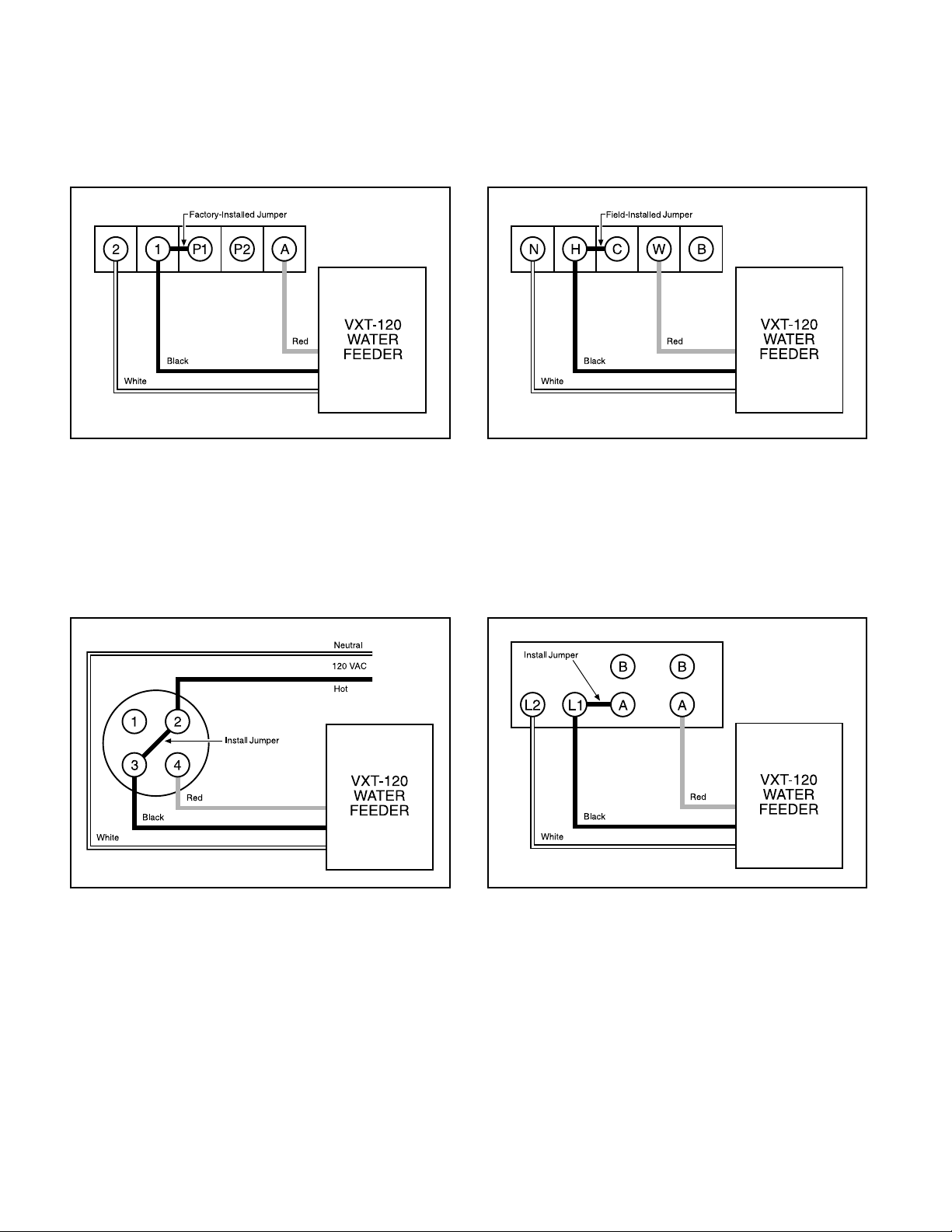

Step ➌– Wiring

Select the wiring diagram below that corresponds to the low water cut-off installed on the boiler. Consult boiler manufacturer’s

instructions for proper burner terminal connections.

Hydrolevel

Safgard Model 450 / CycleGard CG450

STANDARD WIRING STANDARD WIRING

ALTERNATE WIRING: If the power source for the low water

cut-off is separate from the burner circuit, remove the

jumper between 1 and P1, connect the red wire to A, connect the black wire to the burner circuit hot and the white

wire to the burner circuit common.

McDonnell & Miller

PS-800 Series

ALTERNATE WIRING: If the power source for the low water

cut-off is separate from the burner circuit, do not install

jumper between H and C. Connect the red wire to W, connect the black wire to the burner circuit hot and the white

wire to the burner circuit common.

Honeywell

Float Style Control

Model RW-700 Guard Ring

STANDARD WIRING STANDARD WIRING

ALTERNATE WIRING: If you choose to wire the feeder to a

separate power source from the burner circuit, do not install

jumper between 2 and 3. Connect the red wire to 4, the

black wire to the hot side of power source and the white

wire to common.

ALTERNATE WIRING: If you choose to wire the feeder to a

separate power source from the burner circuit, do not install

jumper between L1 and A. Connect the red wire to A, the

black wire to the hot side of power source and the white

wire to common.

Page 3

Step ➍– Set the Feed Delay

30-Second 2-Minute

(Factory Setting)

4-Minute 6-Minute 8-Minute 10-Minute

NOTE: SELECT ONLY ONE DIPSWITCH CORRESPONDING TO THE DESIRED FEED DELAY.

The feed delay feature is designed to prevent boiler flooding by allowing time for condensate to return to the boiler prior to

feeding. If the returns and vents are in good condition, the 2-minute factory setting is usually sufficient. If for any reason condensate takes longer to return to the boiler (such as old return lines or long horizontal runs), a longer delay setting should be

selected.

Step

– Set the Feed Amount

➎

LWCO

(Factory Setting)

1-Gallon 2-Gallon 3-Gallon 4-Gallon 5-Gallon

NOTE: SELECT ONLY ONE DIPSWITCH CORRESPONDING TO THE DESIRED FEED AMOUNT.

CAUTION: BOILER FLOODING CAN OCCUR IF THE FEEDER IS NOT SET PROPERLY.

UNLIKE OTHER FEEDERS, THE 1-GALLON TO 5-GALLON SETTINGS WILL FEED THE FULL

CYCLE REGARDLESS OF WHEN THE WATER REACHES THE LOW WATER CUT-OFF.

LWCO Setting: The VXT feeder is shipped in the LWCO feed setting. When operating in this setting, the VXT will feed only

until the low water cut-off re-energizes the burner circuit (or a maximum of 5 gallons). This will restore boiler operation, but on

some applications may only be enough water to satisfy the

boiler’s

complete, regardless of when the low water cut-off is satisfied. These settings should be used only when the LWCO setting

does not provide adequate water to restore the boiler to a

these settings:

Boilers with probe-type cut-offs:

1. With power to the system on and the thermostat off, lower

2. Press the FEED button on the water feeder and, using a

3. Round the time to the nearest minute and set the feeder

Example:

rise from 1/2" below the probe to the normal operating level,

round to 1 minute and set the feeder for 1-Gallon.

normal

1 Gallon to 5 Gallon Settings: When the 1 to 5 Gallon settings are used, the feeder will continue to feed until the cycle is

the water level to approximately 1/2" below the probe.

watch with a second hand, time how long it takes boiler

water to reach the

middle of the gauge glass unless otherwise specified by

the boiler manufacturer).

for the corresponding number of gallons.

operating level, the 1-Gallon to 5-Gallon settings should be selected using the instructions below.

normal

If it takes 1 minute and 15 seconds for water to

operating level (Usually the

minimum

normal

requirements. If additional water is needed to reach the

operating level. Use the following instructions when choosing

Boilers with float-type cut-offs:

1. With power to the system on and the thermostat off, lower

the water level until 1/4" is visible in the gauge glass.

2. Press the FEED button on the water feeder and, using a

watch with a second hand, time how long it takes boiler

water to reach the

middle of the gauge glass unless otherwise specified by

the boiler manufacturer).

3. Round the time to the nearest minute and set the feeder

for the corresponding number of gallons.

Example:

rise from 1/4" in the gauge glass to the normal operating

level, round to 2 minutes and set the feeder for 2-Gallons.

If it takes 2 minutes and 10 seconds for water to

normal

operating level (Usually the

Page 4

Step ➏– Attach Service Tag

Complete the information at the top of the service tag provided and attach tag near the VXT Water Feeder.

Feed Counter

The VXT’s built-in feed counter records the number of gallons that enter the boiler during automatic feed cycles

FEED button is pressed.* To determine how much water has been added to the boiler since the last service, the counter should

be checked, recorded, and reset each time the boiler is serviced. The counter reset (DISPLAY RST) button is located in the

bottom right corner of the circuit board.

The addition of water to a boiler raises the oxygen level and accumulates lime and other mineral deposits over time. Excessive

feed cycles, resulting from leaks in the system, can cause cast iron boilers to oxidize (rust) internally, significantly reducing the

life of the boiler. Lime and sediment build-up can impede heat transfer causing damage and/or premature failure of the boiler.

Recommended Limits on Make-Up Water

Many factors, such as the water capacity of the boiler, feed water conditions and boiler design can impact the amount of water that can safely be added to a steam boiler. As a general guideline for late model

boilers, Hydrolevel recommends the monthly limits in the table at the

right for boiler operation during the heating season. If feed amounts

significantly exceed these levels, the system should be checked for

leaks by a qualified technician. Note: Any feed limits provided by the

boiler manufacturer supercede Hydrolevel recommendations. Please

check the boiler manufacturer’s instructions carefully.

*The VXT Feeder is equipped with an orifice to regulate flow rates over a wide range of

water pressures. The Feed Counter readings are designed to be accurate to ±15% with

water pressures between 20 to 90 PSI.

Recommended Make-Up Water Limits

Net IBR Rating Gal/month

MBH Limit

Up to 90,000 6

91,000 - 120,000 8

121,000 - 150,000 10

151,000 - 185,000 12

185,000 & Higher 15

Note: The above limits are based on normal boiler operation during the heating season. They do not include water added as a result of boiler and/or low

water cut-off maintenance.

or

when the

Service / Maintenance

Check Feeder Operation: Feeder operation should be checked annually during boiler servicing to ensure proper operation

and feed amount.

Record and Reset Feed Counter: The feed counter should be checked annually. If the feed amount falls within the recommendations provided in the table above, record this amount on the card provided and press the reset button (DISPLAYRST)

on the bottom right corner of the circuit board. Note: If the feed amount significantly exceeds the recommendations above, the

system should be checked for leaks by a qualified technician.

Trouble Shooting

If LOC appears in the digital counter, this indicates that the safety lockout feature is activated. This feature

gized the burner. The feeder can be reset by briefly interrupting power to the heating system. Important: The following trouble

shooting steps should be taken to determine the cause of the lockout condition before restoring normal operation.

1. If the boiler is overfilled, the low water cut-off is not functioning properly. Using the manufacturer’s instructions, check the

low water cut-off operation.

2. If the boiler is in low water:

a. Check boiler and return piping for leaks.

b. If no leaks are detected, check to determine if the flow of the feeder is restricted. Check isolation valves around feeder

c. Check the feeder setting to ensure that it is set to feed adequate water in the event of a low water condition.

engages only when the feeder completes two consecutive feed cycles and the low water cut-off does not re-ener-

to ensure they are fully opened.

If ERR appears in the digital counter, this indicates that more than one or no delay or feed button has been selected. See Step 4 and Step 5 for DELAY and FEED setting instructions.

P.O. Box 1847 • New Haven, CT 06508 • Phone: (203) 776-0473 • FAX: (203) 773-1019 • www.hydrolevel.com

Loading...

Loading...