Page 1

Universal Design – Replaces

2.5

3.56

2.2

3.56

2.2

3.34

•

switches by McDonnell & Miller,

Model FS204

General Purpose

Liquid

Taco, Penn and others

Suitable for 1" to 6" Pipe Diameters

•

Adjustable Sensitivity

•

Includes Four Heavy Duty

•

Stainless Steel Paddles

Flow Switch

Indoor/Outdoor

The Safgard FS204 Flow Switch is used to start or stop electrically

operated equipment such as burners, pumps or alarms by detecting

liquid flow through piping. It is designed for use in water media

applications and is not intended for use in hazardous or corrosive fluids.

The FS204 is suitable for wet locations.

WARNING

death or equipment damage, disconnect power supply

before installing or servicing control. Only qualified personnel may install or service this control in accordance with

local codes and ordinances. Read instructions completely

before proceeding.

Electrical shock hazard.

To prevent electrical shock,

CAUTION

• The FS204 is designed as an operating control. It is the responsibility of the

installer to provide safety or limit control on installations where an operating

control failure would result in personal injury and/or property loss.

• The FS204 is not intended for use in explosive environments.

• To prevent serious burns, boiler should be

thoroughly cooled before installing or servicing

control.

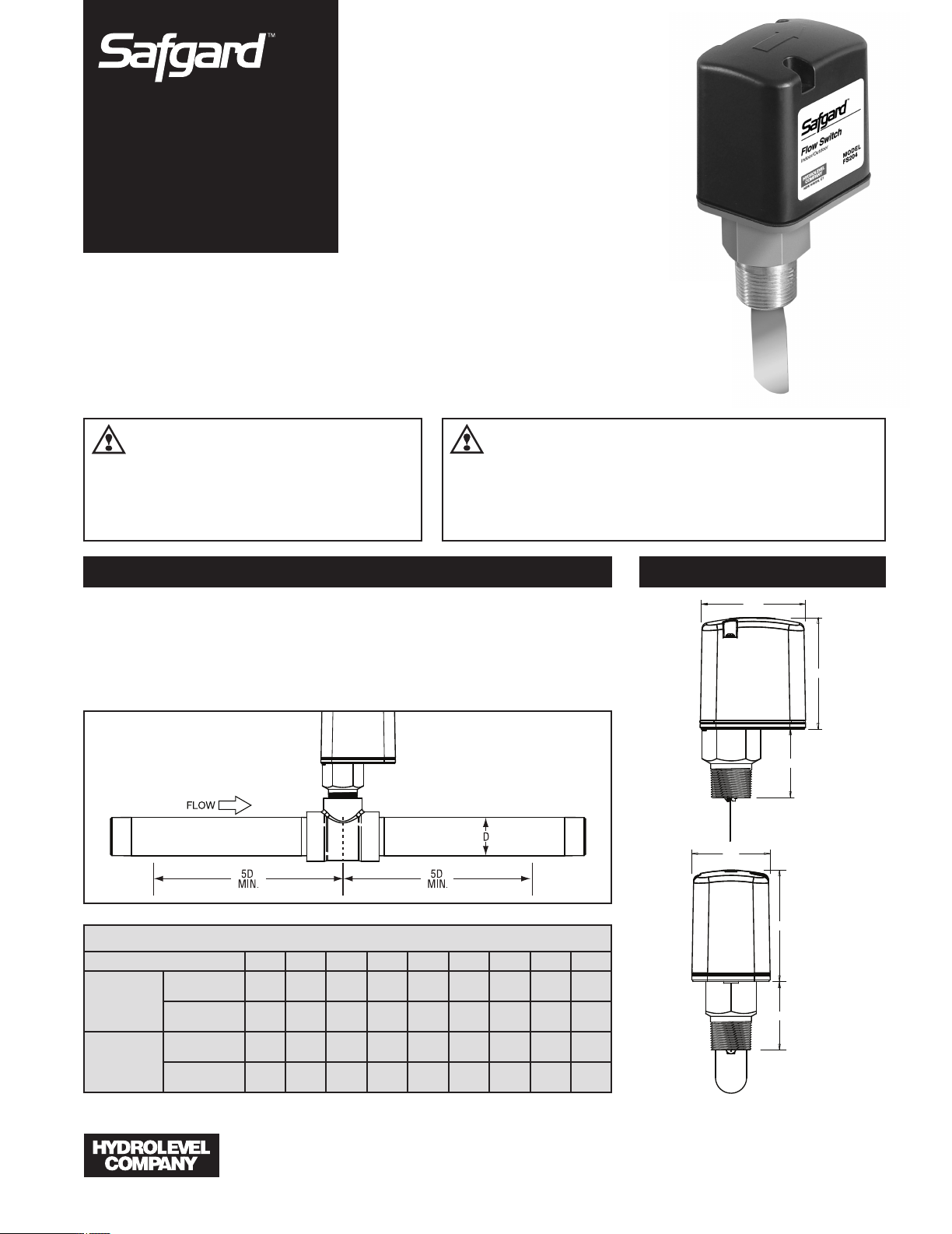

FLOW SWITCH LOCATION DIMENSIONS

The preferred installation of the FS204 is in a horizontal pipe with a straight run of

at least 5 pipe diameters on each side of the paddle (Figure 1). There should be no

restrictions from elbows, valves, orifices, etc. Refer to Table 1 below for flow rates.

The Flow Switch can be installed in a vertical pipe

liquid is upward.

FIGURE 1

Table 1 does not apply to vertical installations.

only if the flow direction of the

Table 1 FLOW SPECIFICATIONS

Pipe Size 1" 11⁄4" 11⁄2" 2" 21⁄2" 3" 4" 5" 6"

Minimum

Adjustment

Maximum

Adjustment

*Calculated for various pipe sizes. Flow rates may vary ±10% from values above.

Flow

Increases

Flow

Decreases

Flow

Increases

Flow

Decreases

4.5 8.1 11.8 16.5 25 33 51 85* 120*

2.2 6.8 7.6 9.3 19 22 38 75* 100*

14.8 22.1 25.7 32.3 75 90* 110* 170* 240*

13.8 20.1 23.7 30.5 72 85* 100* 155* 220*

83 Water Street • New Haven, CT 06511 • Phone (203) 776-0473 • FAX (203) 773-1019 • www.hydrolevel.com

Page 2

INSTALLATION

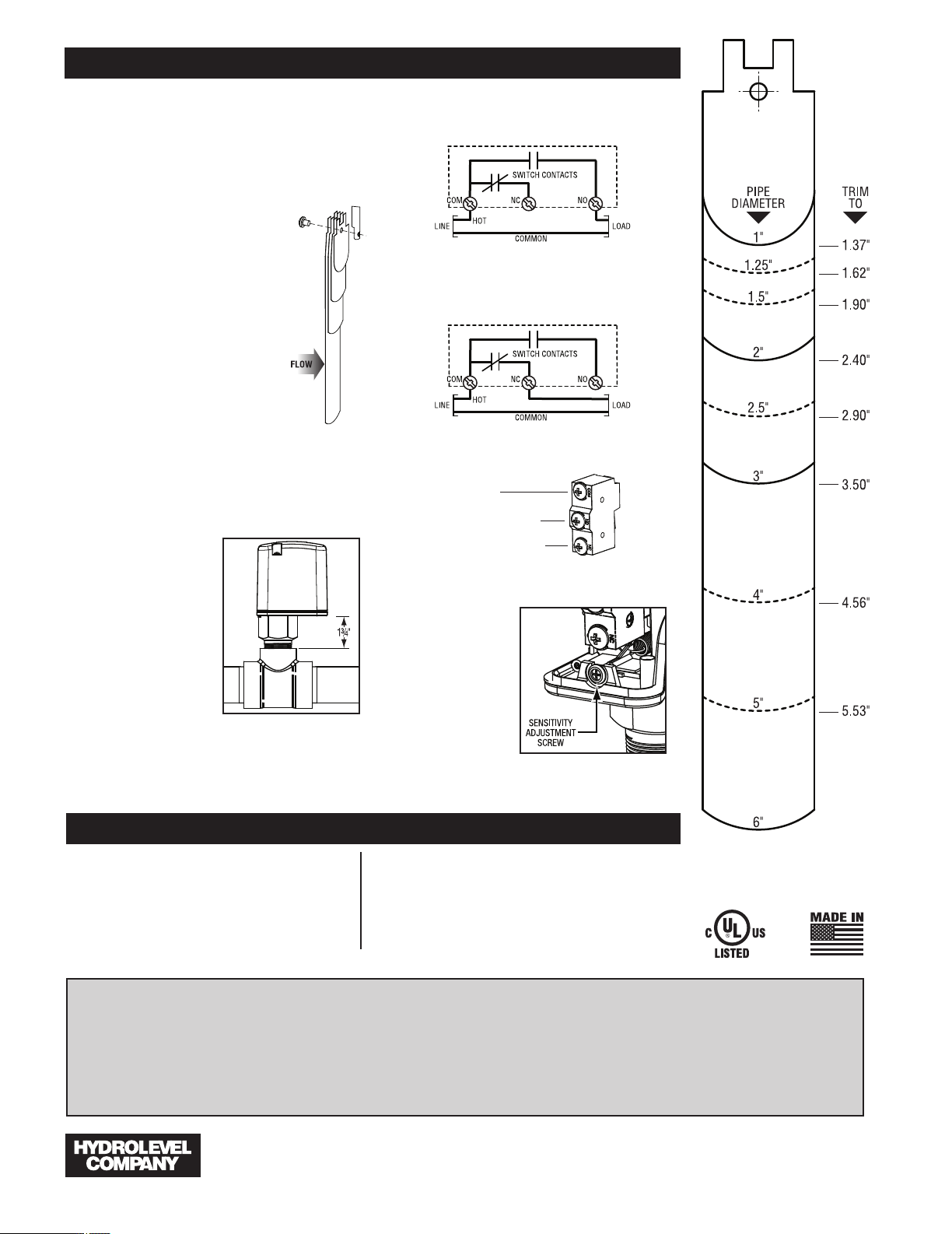

Step 1 Trimming the Paddles

The stainless steel paddles (set of 4 supplied)

must be trimmed to the appropriate length for the

pipe diameter being used. Use the template at the

right of this page as a cutting guide. Follow the

curve indicated as closely as possible. Standard

shears or tin snips can be used.

Step 2 Stacking the

Paddles

After trimming, the paddles must be

stacked as shown in Figure 2 and

then screwed onto the stem of the

flow switch. IMPORTANT: The correct orientation of the paddles to

the flow of the fluid is essential.

FIGURE 2

Step 3 Installing in Tee

The Flow Switch must be installed in a 1" NPT

threaded pipe fitting. If a reducing bushing or

welded fitting is required, the length must be kept

to a minimum to insure that the paddle can move

freely in the run of the pipe without coming in contact with the bushing or fitting. Tighten the Flow

Switch with a 1

wrench or adjustable

wrench applied to the

brass nut only.

tighten by grasping the

enclosure.

space from the bottom of

the enclosure to the top

of the tee (Figure 3) and

be sure that the arrow

on the side of the enclosure is in the direction of

the flow.

IMPORTANT:

The paddle must not touch the inside wall of the

opposite side of the pipe. If there is any contact,

additional trimming is required.

5

⁄8" box

Do not

Allow a 13⁄4"

FIGURE 3

Step 4 Wiring

ENERGIZE CIRCUIT UPON FLOW

Flow Switch will activate load (alarm, light,

relay, motor starter, etc.) when flow occurs.

ENERGIZE CIRCUIT UPON NO FLOW

Flow Switch will activate load (alarm, light,

relay, motor starter, etc.) when no flow occurs.

COMMON (COM)

FLOW OPENS CIRCUIT (NC)

FLOW CLOSES CIRCUIT (NO)

Step 5 Adjusting Sensitivity

To INCREASE

sensitivity (switch

activates at a lower

flow rate), turn the

adjustment screw

counter-clockwise.

To DECREASE

sensitivity (switch

activates at a higher

flow rate), turn the

adjustment screw

clockwise.

FIGURE 4

SPECIFICATIONS – FLOW SWITCH MODEL FS204

Maximum Service Pressure: 160 psi

Maximum Temperature: 250°F

Enclosure: NEMA type 4 (for wet locations).

Contacts: SPDT switch

7.4 FLA, 44.4 LRA@120VAC Motor Duty

Pilot Duty Rating: 125VA@120/240VAC

LIMITED MANUFACTURERʼS WARRANTY

We warrant products manufactured by Hydrolevel Company to be free from defects in

material and workmanship for a period of two years from the date of manufacture or

one year from the date of installation, whichever occurs first. In the event of any claim

under this warranty or otherwise with respect to our products which is made within

such period, we will, at our option, repair or replace such products or refund the purchase price paid to us by you for such products. In no event shall Hydrolevel

83 Water Street • New Haven, CT 06511 • Phone (203) 776-0473 • FAX (203) 773-1019 • www.hydrolevel.com

Ambient Temperature Range: 32°F-176°F (0°C-80°C)

Media Temperature Range: 32°F-250°F (0°C-121°C)

Pipe Connection: 1"NPT - Brass

Conduit Access: 2 openings for 1/2" conduit

Usage: 1" to 6" pipe sizes (see Flow Chart - Table 1)

Company be liable for any other loss or damage, whether direct, indirect, incidental or

consequential. This warranty is your EXCLUSIVE remedy and shall be IN PLACE OF

any other warranty or guarantee, express or implied, including, without limitation, any

warranty of MERCHANTABILITY or fitness for a particular purpose. This warranty

may not be assigned or transferred and any unauthorized transfer or assignment

thereof shall be void and of no force or effect.

FS204-0712

Loading...

Loading...