Page 1

Low maintenance. No moving parts to wear stick or hang up,

as in float devices.

400 Series

Solid state circuitry. Designed for the highest level of performance and reliability.

Automatically shuts off burner, after delay, in a low water

Low Water Cut-Offs

For Steam Boilers

24 VAC Operating Voltage

Max. Pressure 15 psi

condition to prevent dry firing.

Time delay allows water to feed above the probe to a safe

operating level.

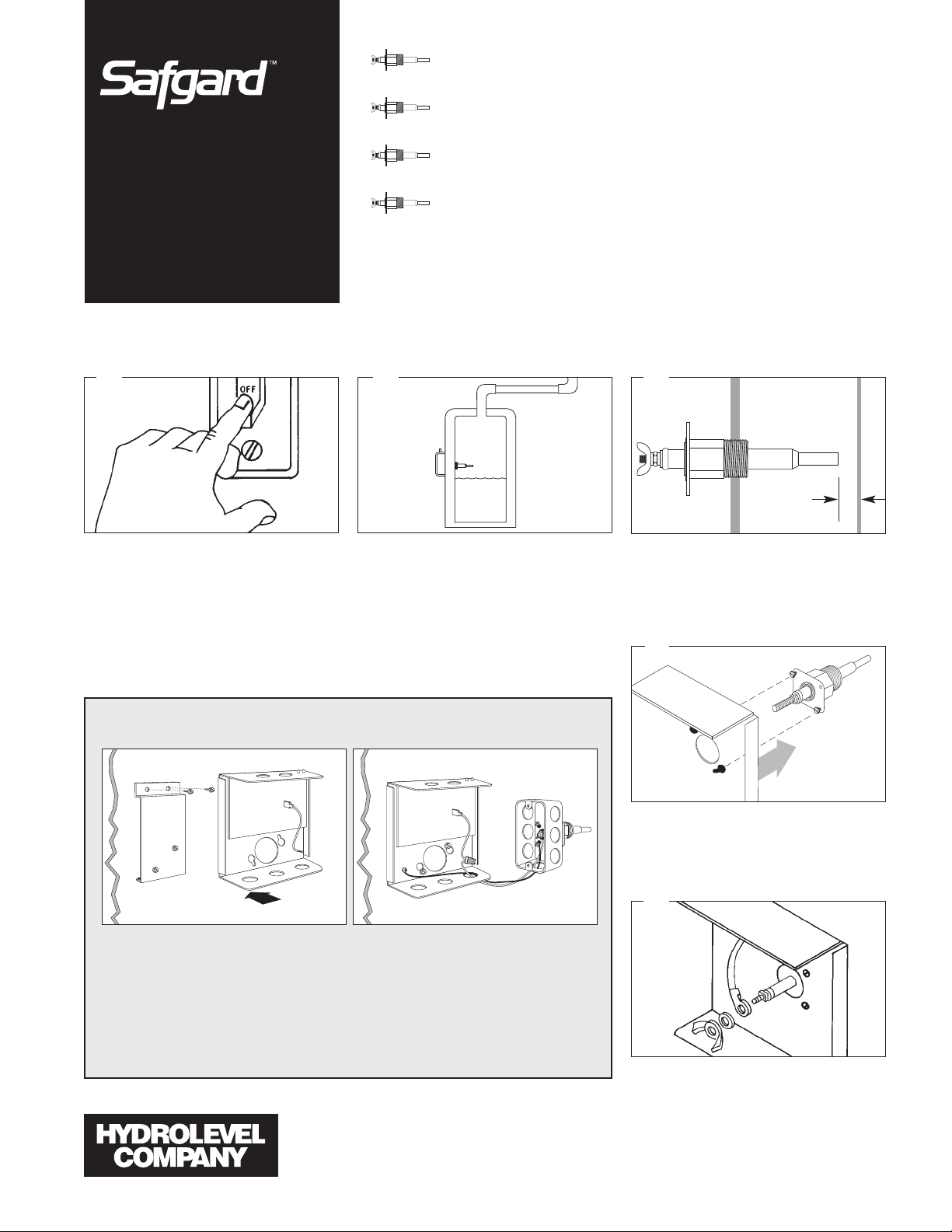

HOW TO INSTALL

1 2 3

SAFE

WATER

LINE

WARNING – To prevent electrical shock or

equipment damage, power must be off during

installation or servicing of the control. To prevent serious burns, the boiler should be thoroughly cooled before installing or servicing control. Only qualified personnel may install or service the control in accordance with local codes

and ordinances. Read instructions completely

before proceeding.

The probe may be installed in the boiler above

the lowest safe water level established by the

boiler manufacturer. Most manufacturers provide a suitable opening in the side of the boiler.

1/4"

Allow 1/4" clearance from the probe to any boiler

surface, tube or baffle. NOTE: Excessive use of

Teflon tape to seal probe piping threads may

insulate the control from boiler ground. This

could result in the control not operating.

4

R E M O T E M O U N T E D M O D E L S O N L Y

BA

A. To secure mounting plate to boiler jacket,* pre-drill two 3/32" pilot holes using the mounting plate as a template. Secure plate with sheet metal screws provided. Attach control to

mounting plate by slipping keyholes in back of chassis over pre-mounted screws on plate.

Tighten screws.

B. Using a wire nut, attach a wire (min 90°C) to the pigtail lead in the control box. Attach the

other end to the probe terminal in the remote probe housing. Attach a second wire between

the ground screw on the control chassis and one of the four screws in the remote probe

housing. Note: Wires and wire nuts not provided.

*Or other suitable surface

P.O. Box 1847

New Haven, CT 06508

Phone: (203) 776-0473

FAX: (203) 773-1019

Loosen the two control cover binding head

screws and remove the cover. Assemble the

chassis to the probe flange and secure with the

screws provided with the probe.

5

Connect the ring terminal wire lead to the probe

terminal stud and secure with the lock washer

and wing nut provided. With the power

removed, proceed with installation and wiring

according to the instructions on page 2. Upon

completion of wiring replace control cover.

Page 2

24VAC

HOT

COMMON

+

0

LIMIT

CONTROLS

AP2P112

BURNER

CIRCUIT

WATER

FEEDER

BURNER

POWER

SOURCE

24VAC

HOT

COMMON

BURNER

CIRCUIT

AP2P112

BURNER

POWER

SOURCE

BURNER

POWER

SOURCE

24

V

AC

+

0

LIMIT

CONTROLS

AP2P112

HOT

COMMON

BURNER

CIRCUIT

BURNER

POWER

SOURCE

24

V

AC

AP2P112

FACTORY

INSTALLED

JUMPER

COMMON

HOT

BURNER

POWER

SOURCE

24

V

AC

+

0

LIMIT

CONTROLS

AP2P112

BURNER

CIRCUIT

WATER

FEEDER

24VAC

AP2P112

REMOVE

JUMPER

24VAC

+

0

LIMIT

CONTROLS

AP2P112

BURNER

CIRCUIT

HOT

COMMON

BURNER

POWER

SOURCE

P2

2

1

AP2P112

AP2P112

WATER

FEEDER

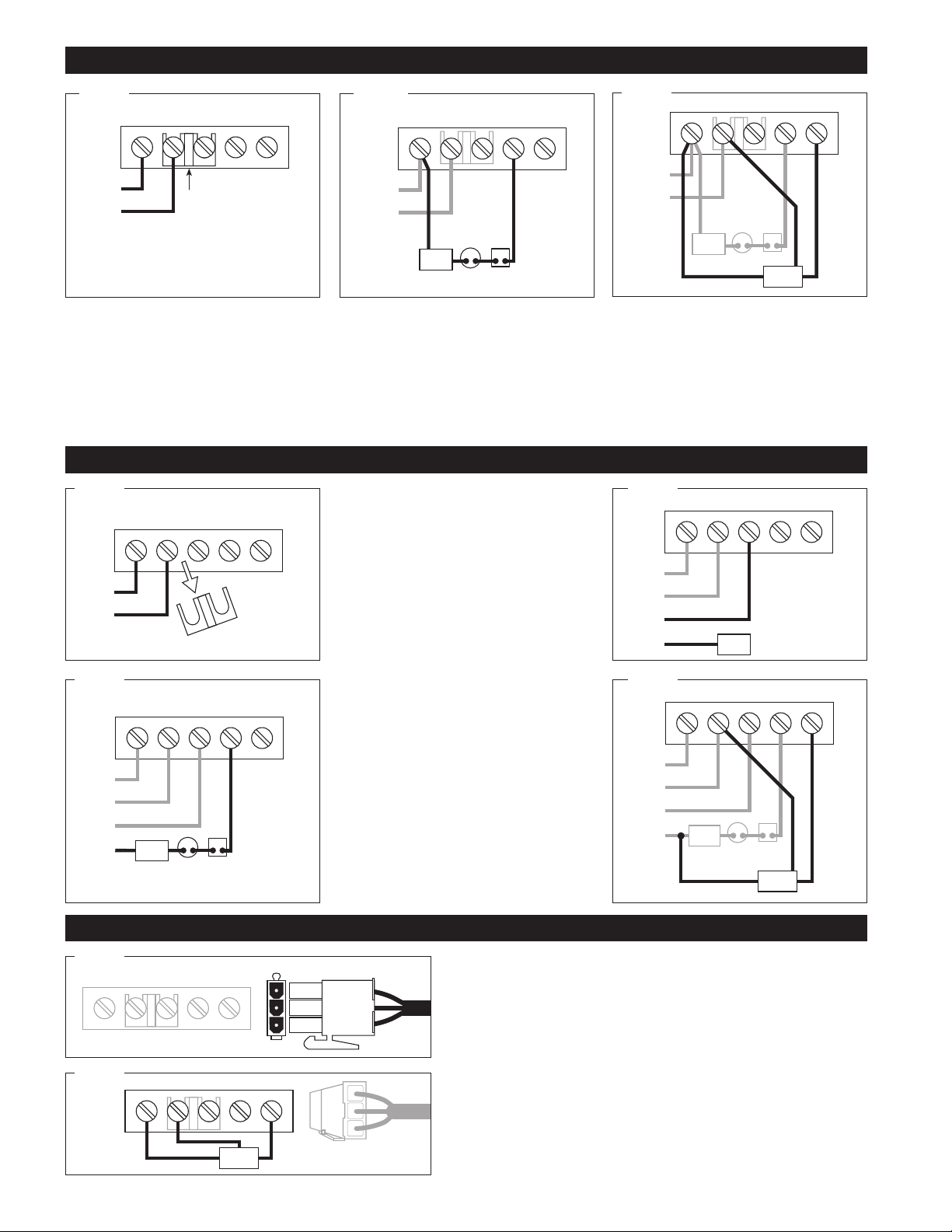

WIRING METHOD A: SAME POWER SOURCE FOR CONTROL AND BURNER CIRCUIT.

A1 A2

A1 Connect input voltage (24 VAC, 60 HZ) to

terminals 1 and 2. 24 VAC, 60 HZ must be supplied

to terminals 1 and 2 for internal operation of the

control.

WIRING METHOD B: SEPARATE POWER SOURCE FOR CONTROL AND BURNER CIRCUIT.

B1

B3

A2 Connect terminal 2 to burner circuit com-

mon. Connect terminal P2 to burner Circuit in

series with other limit controls. Consult boiler

manufacturer instructions for proper terminal connections. Control should be wired in series with

and before other limit controls.

䊴

B1Remove jumper between terminals 1

and P1. Connect input voltage (24 VAC, 60 HZ) to

terminals 1 and 2. 24 VAC 60 HZ must be supplied

to terminals 1 and 2 for internal operation of the

control.

Connect hot lead from the burner B2

control circuit to terminal P1. This terminal supplies power to terminal P2 in normal operating

conditions when water is at the probe. Connect

common to burner circuit. Note: Consult boiler

manufacturer instructions for proper terminal connections.

䊴

B3 Connect terminal P2 to burner circuit in

series with and before other limit controls.

Optional water feeder connection. B4

Connect feeder H to terminal 1. Connect feeder

“FEED” or “W” to terminal A. Connect terminal N to

common of the burner circuit supply. For feeders

with two leads, connect feeder hot to terminal A

and connect feeder common to common of the

burner circuit supply. Note: Use of solenoid valve

or McDonnell & Miller model 101A water feeder

may cause flooding and is not recommended for

use with this low water cut-off.

䊳䊳

䊳䊳

A3

A3 Optional water feeder connection. Connect

feeder N to terminal 2. Connect Feeder H to terminal 1. Connect feeder “FEED” or “W” to terminal A.

For water feeders with 2 leads, connect feeder

common to terminal 2 and feeder hot to terminal A.

Note: Use of a solenoid valve or McDonnell &

Miller Model 101A water feeder may cause flooding and is not recommended for use with this low

water cut-off.

B2

B4

WIRING METHOD C: PLUG CONNECTOR.

C1

C2

䊴

C1Plug wire harness connector into matching end on circuit board. IMPOR-

TANT: Factory installed jumper must be in place between

terminals 1 and P1.

䊴

C2 Optional water feeder connection. Connect feeder N to terminal 2.

Connect Feeder H to terminal 1. Connect feeder “FEED” or “W” to terminal A.

For water feeders with 2 leads, connect feeder common to terminal 2 and feeder hot

to terminal A. Note: Use of a solenoid valve or McDonnell & Miller Model 101A

water feeder may cause flooding and is not recommended for use with this low

water cut-off.

Page 3

CYCLEGARD

LOW-WATER

CUT-OFF

CYCLEGARD

LOW-WATER

CUT-OFF

Principle of Operation

P1

BURNER

POWER

P2

P1

BURNER

POWER

P2

Hydrolevel controls are electrically operated. A probe is installed in the boiler shell and connected to the control unit. Water is used as a conductor to

complete a circuit from the probe to the control unit. The control unit provides switching contacts to complete the burner control circuit and to operate an

optional alarm or water feeder.

NORMAL OPERATION

With water present at the probe, the control circuit is complete.

Contact between terminals P1 and P2 completes the burner circuit,

allowing for normal operation of the burner.

Operating Instructions

LOW WATER CONDITION

Whenever the water falls below the probe, a time delay is activated

in the control. After 15 seconds of a low water condition, the control

interrupts the burner circuit and shuts down the boiler. This time

delay feature prevents short cycling of the burner circuit during temporary low water levels common in turbulent steam boiler environments.

NOTE

For proper low water cut-off operation, the boiler should be cleaned at

initial installation and periodically thereafter. Refer to the boiler manufacturer’s instructions for cleaning procedures.

OPERATING TEST PROCEDURE

1. After installation, bring the boiler water to a safe operating level, turn

on power and set the thermostat to call for heat. The amber LED

lamp should be off. The boiler will fire after a 30 second delay.

2. Slowly

lower the boiler water to a point below the probe. The amber

LED lamp on the control will light. The lamp may begin to flicker

with the bouncing water level. Stop draining the boiler when the

lamp glows steadily. NOTE: The water should not be lowered

beyond a visible point in the gauge glass.

3. The boiler will shut down within 15 seconds.

IF BURNER DOES NOT SHUT DOWN IN LOW WATER

1. Check terminal block wiring to insure that all connections are

correct.

Maintenance

2. Check the probe installation to insure that there is 1/4" clearance

from any surface within the boiler or pipe. (Refer to Step 3 on page

1 of this instruction sheet.

3. Clean the boiler in accordance to the manufacturer’s instructions.

Machining oils, grease, rust and other contaminants in the boiler

water can cause foaming or surging and make a low water condition

difficult to detect during burner operation.

IF THE AMBER LED LAMP IS ON

The amber LED lamp indicates that the water is below the probe. If the

gauge glass shows that the water is at the correct operating level and

the amber LED is lit check the following:

1. Check for plugged gauge glass.

2. Make sure probe lead wire is properly secured to the terminal.

3. Check for proper ground between probe and boiler shell. Excessive

use of Teflon tape or sealing compound may isolate the probe from

the boiler shell.

4. Remove probe and examine for oily residue. Clean probe with steel

wool and skim boiler.

To ensure optimum performance remove and inspect probe annually. Clean any sediment or scale from the probe using a scouring pad or steel

wool. Re-install the probe and perform the Operating Test Procedure described above.

Page 4

2"

SQUARE

17/8"

313/16"

15

/16"

1"

3

/4" NPT

5

/16"

2"

SQUARE

17/8"

49/16"

1"

3

/4" NPT

5

/16"

111/16"

225/32

37/8

15/8

11/8

15/8

23/8

BOTTOM

59/16

51/2

1.00

BACK

11/8

23/8

15/8

TOP

VXT WATER FEEDER

PROBES

Test Pressure: 1000 PSI, All Models

EL1214 – STANDARD MODEL – 3/4" NPT

For 1/2”, order Model No. EL-1220

The VXT Water Feeder (available separately) can be installed with Hydrolevel or

other low water cut-offs to automatically

replenish boiler water in the event of a low

water condition. The VXT offers programmable

feed amount

and

feed delay

settings. These can easily be set to ensure

the proper feed amount and to provide

adequate time for condensate to return to

EL1214-P – 3/4" NPT

the boiler before starting a feed cycle. The

VXT Feederʼs

Digital Feed Counter

tracks

the amount of water added to the boiler

exposing system leaks, which can significantly shorten the life of a cast iron boiler.

Additional features including a manual feed

button, underfeed and flood protection

make the VXT an ideal choice for safety

and convenience.

EL1214-R

REMOTE PROBE

THE PROBE MAKES THE DIFFERENCE

The probe used in all Hydrolevel controls offers

you distinctive advantages. Unlike float devices,

there are no moving parts to wear stick, or

“hang-up” the in harsh boiler environment .

LIMITED MANUFACTURERʼS WARRANTY

We wa rran t pr oduc ts manu f act u red b y

Hydrolevel Company to be free from defects in

material and workmanship for a period of two

years from the date of manufacture or one year

from the date of installation, whichever occurs

first. In the event of any claim under this warranty or otherwise with respect to our products

which is made within such period, we will, at our

option, repair or replace such products or refund

the purchase price paid to us by you for such

products. In no event shall Hydrolevel Company

A stuck or “hung-up” float can cause dangerous

low water conditions. And if suddenly released, a

float can feed cold water into overheated tubes

or plates and cause explosive results.

be liable for any other loss or damage, whether

direct, indirect, incidental or consequential. This

warranty is your EXCLUSIVE remedy and shall be

IN PLACE OF any other warranty or guarantee,

express or implied, including, without limitation,

any warranty of MERCHANTABILITY or fitness

for a particular purpose. This warranty may not

be assigned or transferred and any unauthorized

transfer or assignment thereof shall be void and

of no force or effect.

The Hydrolevel control has no float bowl so sediment cannot collect. The reliable solid state circuitry and low maintenance probe are designed

to provide years of troublefree operation.

MAXIMUM PRESSURE: 15 PSI

INPUT VOLTAGE: 24 VAC, 60 HZ

SWITCH CONTACTS: SPDT

SWITCH RATINGS

AND ALARM CIRCUIT: 50 VA @ 24 VAC

Pilot Duty

P.O. Box 1847

New Haven, CT 06508

Phone: (203) 776-0473

FAX: (203) 773-1019

Loading...

Loading...