Page 1

MODEL 3250

INSTALLATION INSTRUCTIONS

and OPERATING MANUAL

Temp Limit / LWCO Control

with Thermal Targeting

™

for Water Boilers

120 VAC Operating Voltage

PATENT NO. 7,891,572

• Saves Fuel – Features Thermal Targeting™ technology and

• Universal Design – Replaces common cold-start and triple-action

• Easy to Install – Industry standard wiring, dial-type settings,

• Operating Indicators – LEDs, Dynamic Display and Test Button provide

• Prioritizes Domestic Hot Water – Gives priority to low limit setting or to

• Reduces Condensation – Holds circulator off until boiler reaches 120°F

•

Three Function

Design

Temperature Limit Control

Designed for cold start and tankless

coil boilers.

Low Water Cut-Off

Provides protection against potentially

dangerous low water conditions

when installed with the Hydrolevel

Electro-Well™ (see page 2 for details).

hermal Pre-Purge capability

T

quastats*

A

o external sensors necessary

n

continual and on-demand status checks

calls from indirect water heater

*Aquastat is a registered trademark of Honeywell International, Inc.

Boiler Reset Control

Utilizes

technology to conserve fuel by

monitoring heating demand and

establishing target boiler temperatures

below the high limit setting (see page 7

for details).

WARNING

installing or servicing control. Only qualified personnel may install or service this control in

accordance with local codes and ordinances. Read instructions completely before proceeding.

Thermal Targeting

Electrical shock hazard. To prevent electrical shock, death or

equipment damage, disconnect power supply before

83 Water Street • New Haven, CT 06511 • Phone (203) 776-0473 • FAX (203) 773-1019 • www.hydrolevel.com

™

CAUTION

should be thoroughly cooled before installing or

servicing control.

To prevent serious

burns, boiler

1

Page 2

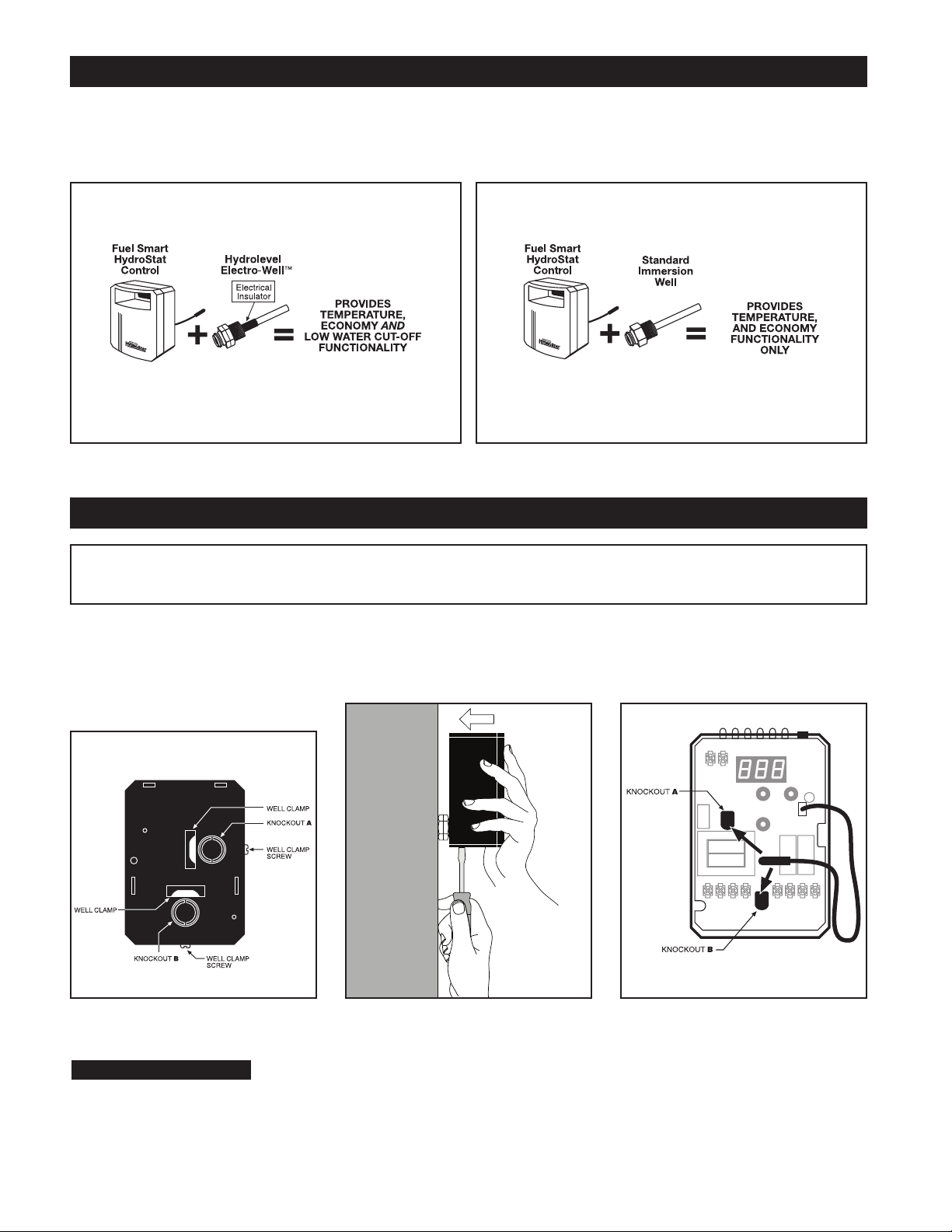

IMMERSION WELLS

Fuel Smart HydroStat can be installed on an existing immersion well already in the boiler or on a Hydrolevel Electro-Well™

(sold separately). The low water cut-off function is automatically activated when installed on an Electro-Well™.

IMPORTANT: The control will not provide low water cut-off protection when installed on a standard immersion well.

NOTE: Do not use heat-conducting grease.

Fuel Smart HydroStat installed

with Hydrolevel Electro-Well™

IMPORTANT: For proper operation of the low water cut-off function, there

must be a minimum of ½" clearance between the copper well tube and any

surface within the boiler.

See Electro-Well models on page 12.

NOTE: When installed on a standard immersion well, the “LWCO Active”

LED will not illuminate.

Fuel Smart HydroStat installed

with standard immersion well

MOUNTING THE CONTROL

IMPORTANT Make sure that the immersion well or Electro-Well™ is installed in the boiler manufacturer’s designated

temperature limit control tapping.

NNOOTTEE::

If installing an Electro-Well, pipe sealing compound should be used. Teflon tape is not recommended.

STEP 1

are available on the back of the control

(Fig. 1). Select which of the two positions

(2 knockouts) is best for the location of

the control. Remove the knockout.

Two mounting positions

STEP 2 Place control on the well.

While holding box against well nut,

tighten well clamp screw. (Fig. 2)

STEP 3 Insert sensor ALL THE

WAY into well through the knockout (A

or B) you have chosen. (Fig. 3)

BACK OF

FUEL SMART HYDROSTAT BOX

FIG. 1 FIG. 3FIG. 2

NOTE: In the case of space restrictions, the Fuel Smart HydroStat control may be mounted in a horizontal orientation without any

loss of function. Hydrolevel recommends vertical mounting, when possible, for proper orientation of LED display.

REMOTE MOUNTING KITS are available separately for mounting the Fuel Smart HydroStat control box in a remote location.

Each kit includes mounting hardware and a remote sensor. See page 12 for kit options.

2

Page 3

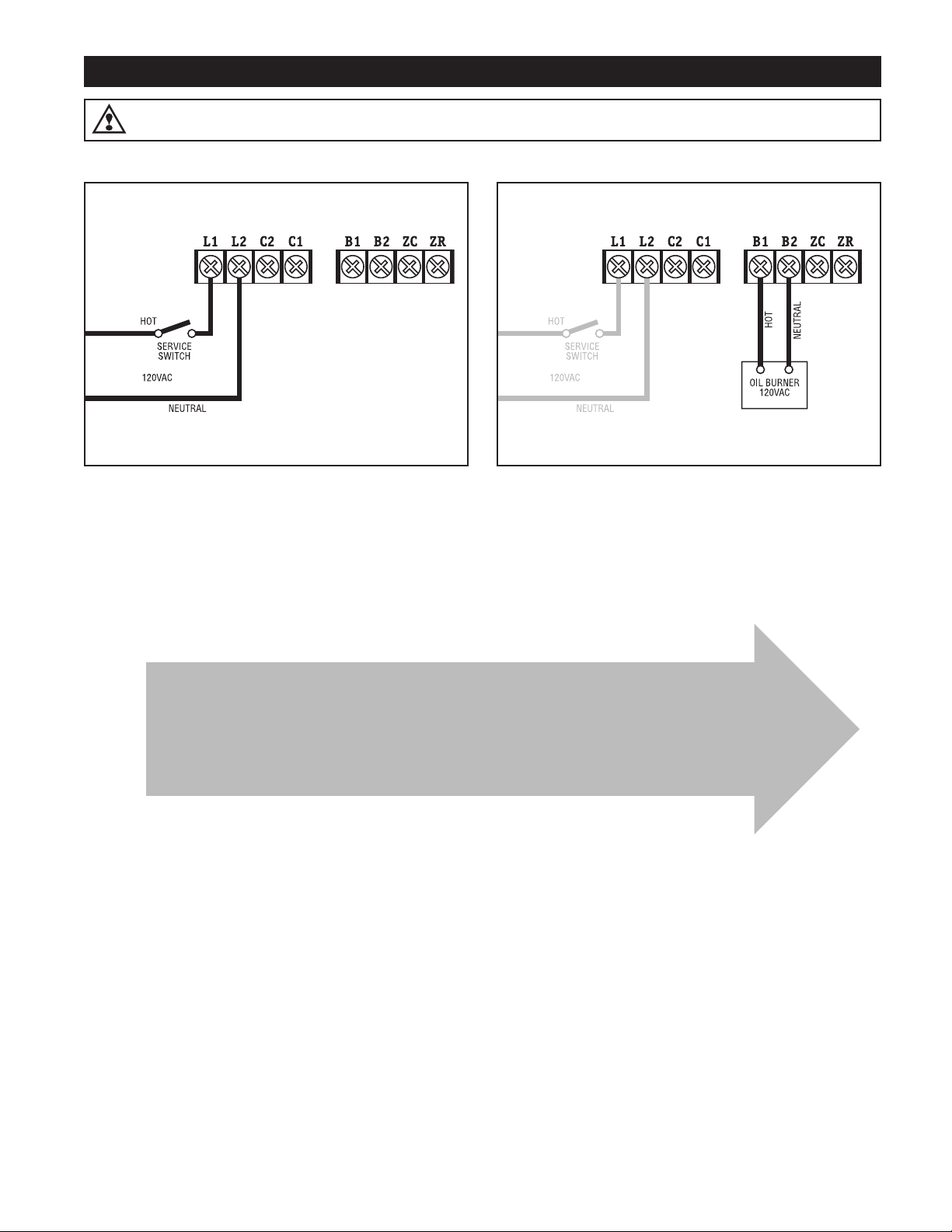

WIRING

WARNING

STEP 1 Connect 120 VAC Hot to terminal L1. Connect

120 VAC Neutral to terminal L2. Disconnect means and

overload protection as required (provided by others).

Electrical shock hazard. To prevent electrical shock, death or equipment damage, disconnect power supply before

installing or servicing this control.

STEP 2 Connect the burner circuit to B1-B2.

(B2 is neutral.)

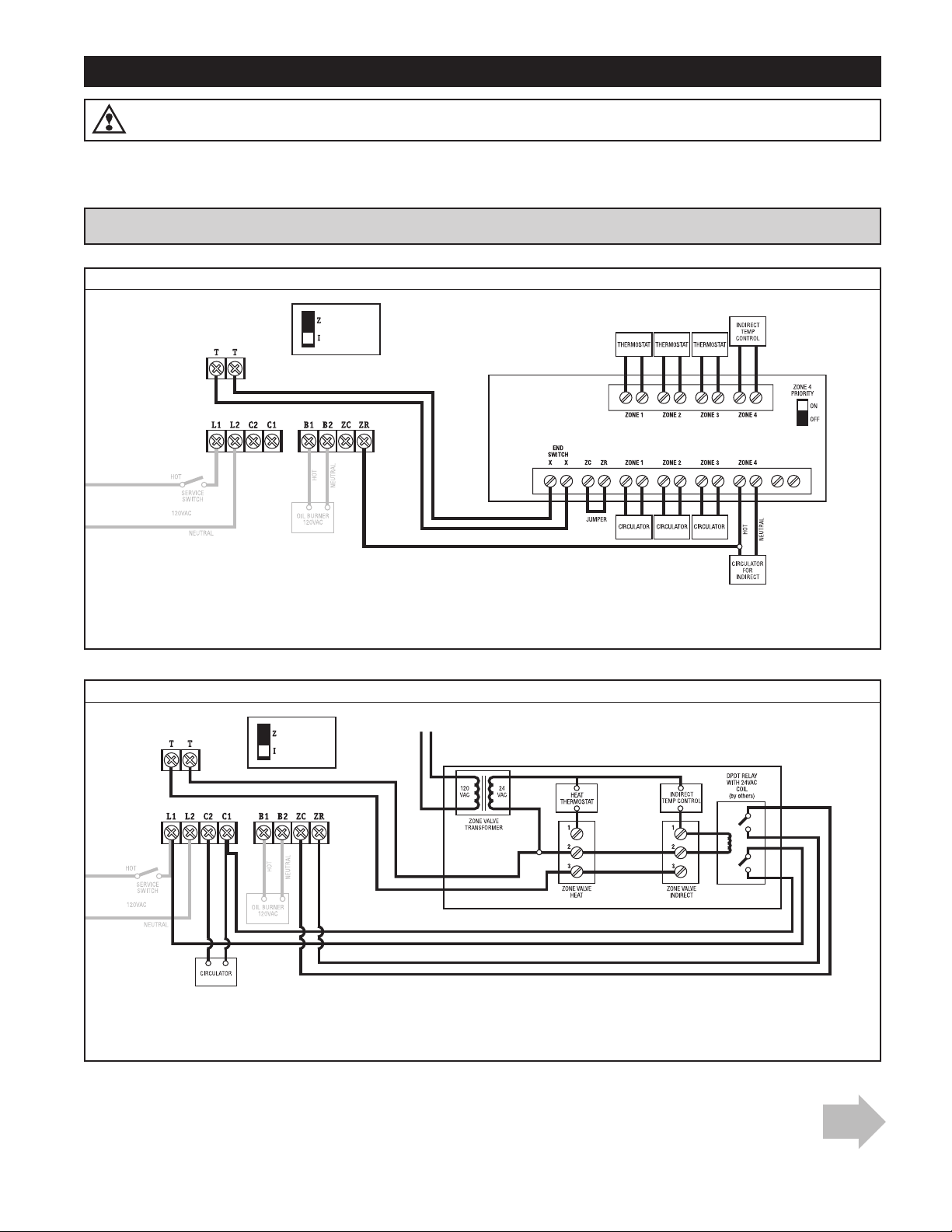

Select the Diagram that

Matches your System Configuration

on Pages 4, 5 or 6

3

Page 4

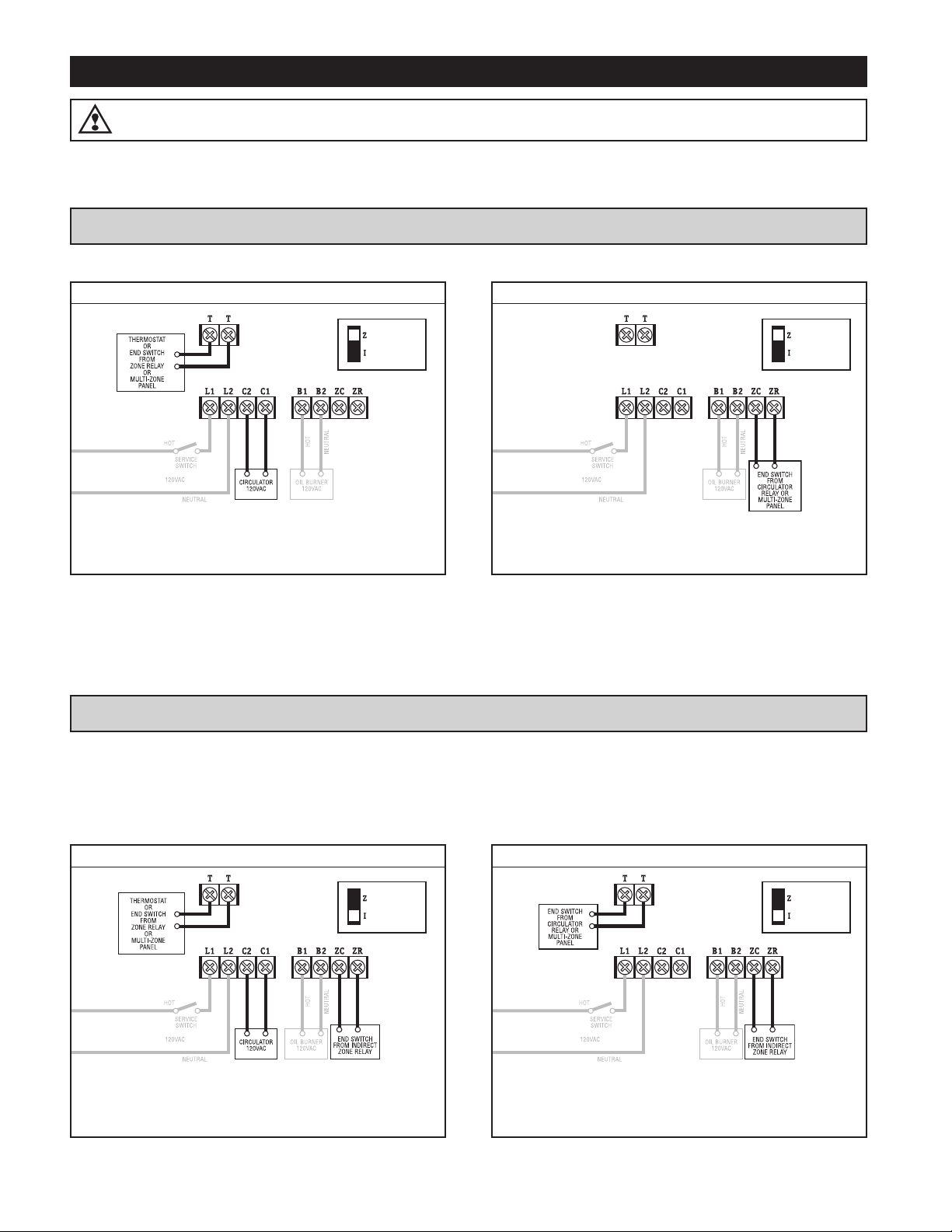

WIRING

WARNING

NOTE: For proper operation of the boiler reset function, all heating thermostats must input to T-T or ZC-ZR terminals as indicated below.

installing or servicing this control.

Jumping the T-T terminals and wiring the thermostat to the primary will override the economy feature.

STEP 3A: HEATING ONLY – No Indirect Water Heater

CHOOSEORBELOW

SINGLE CIRCULATOR MULTIPLE CIRCULATORS

Electrical shock hazard. To prevent electrical shock, death or equipment damage, disconnect power supply before

Connect thermostat or end switch from zone relay or multizone panel to T-T. Connect circulator to C2-C1. Move

Zone/Indirect Switch up to Z.

ONE/

Z

INDIRECT

SWITCH

OSITION

P

ONE/

Z

INDIRECT

SWITCH

OSITION

P

Connect end switch from circulator relay or multi-zone panel to

ZC-ZR. Move Zone/Indirect Switch up to Z.

STEP 3B: HEATING and Indirect Water Heater

IMPORTANT:

bypass the Thermal Targeting feature and allow the boiler to fire to the high limit setting to heat the indirect tank. The indirect signal must be separate from all

heating zone signals. If you choose not to separate the indirect signal from the heating zones, the Economy Feature should be turned OFF to ensure that the

boiler supplies adequate temperature to heat the indirect tank (see page 7).

Connect thermostat or end switch from zone relay or multi-zone

panel to T-T. Connect circulator to C2-C1. Connect end switch

from indirect zone relay to ZC-ZR. Move

down to I.

When installing with an indirect water heater, the Zone/Indirect Switch must be set in the I position. When set in the I position, calls to ZC-ZR will

CHOOSE FROMTHROUGHBELOW OR ON PAGE 5 OR 6

SINGLE CIRCULATOR MULTIPLE CIRCULATORS

Zone/Indirect

ZONE/

INDIRECT

SWITCH

POSITION

Switch

Connect end switch from heating circulator relays or multi-zone

panel to T-T. Connect end switch from indirect circulator relay to

ZC-ZR. Move Zone/Indirect Switch to I.

ZONE/

INDIRECT

SWITCH

POSITION

4

Page 5

WIRING

WARNING

NOTE: For proper operation of the boiler reset function, all heating thermostats must input to T-T or ZC-ZR terminals as indicated below.

Electrical shock hazard. To prevent electrical shock, death or equipment damage, disconnect power supply before

installing or servicing this control.

Jumping the T-T terminals and wiring the thermostat to the primary will override the economy feature.

STEP 3B: HEATING and Indirect Water Heater – continued

MULTIPLE CIRCULATORS — Typical Zone Panel with Priority Zone

ZONE/

INDIRECT

WITCH

S

POSITION

NOTE: The wire from ZR to the hot terminal of the indirect circulator will ensure

that indirect calls will fire to limit and receive priority over heating calls.

SINGLE CIRCULATOR — Multiple Zone Valves including Indirect, No Zone Control Panel

NOTE: When using zone valves for both heat and indirect, the calls must be separated in order to prioritize indirect calls. This can

be accomplished by using a general purpose relay as shown above. However, for ease of installation, a zone control panel is recommended (see wiring diagram 7 on next page).

ZONE/

INDIRECT

SWITCH

POSITION

MORE

5

Page 6

WIRING

WARNING

NOTE: For proper operation of the boiler reset function, all heating thermostats must input to T-T or ZC-ZR terminals as indicated below.

Electrical shock hazard. To prevent electrical shock, death or equipment damage, disconnect power supply before

installing or servicing this control.

Jumping the T-T terminals and wiring the thermostat to the primary will override the economy feature.

STEP 3B: HEATING and Indirect Water Heater – continued

SINGLE CIRCULATOR — Typical Multiple Zone Valve Panel with Indirect

ONE/

Z

INDIRECT

SWITCH

OSITION

P

NOTE – If a Zone Valve Control Panel has no priority zone: To ensure adequate boiler temperature to satisfy the domestic hot water tank, it may be necessary to turn the Economy Feature off.

MULTIPLE CIRCULATORS — Typical Three Zone Switch Relay

NOTE: The wire from ZR to the hot terminal of the indirect circulator will ensure

that indirect calls will fire to limit and receive priority over heating calls.

Tacoʼs SR503 combines ZR amd X2.

ZONE/

INDIRECT

SWITCH

POSITION

6

Page 7

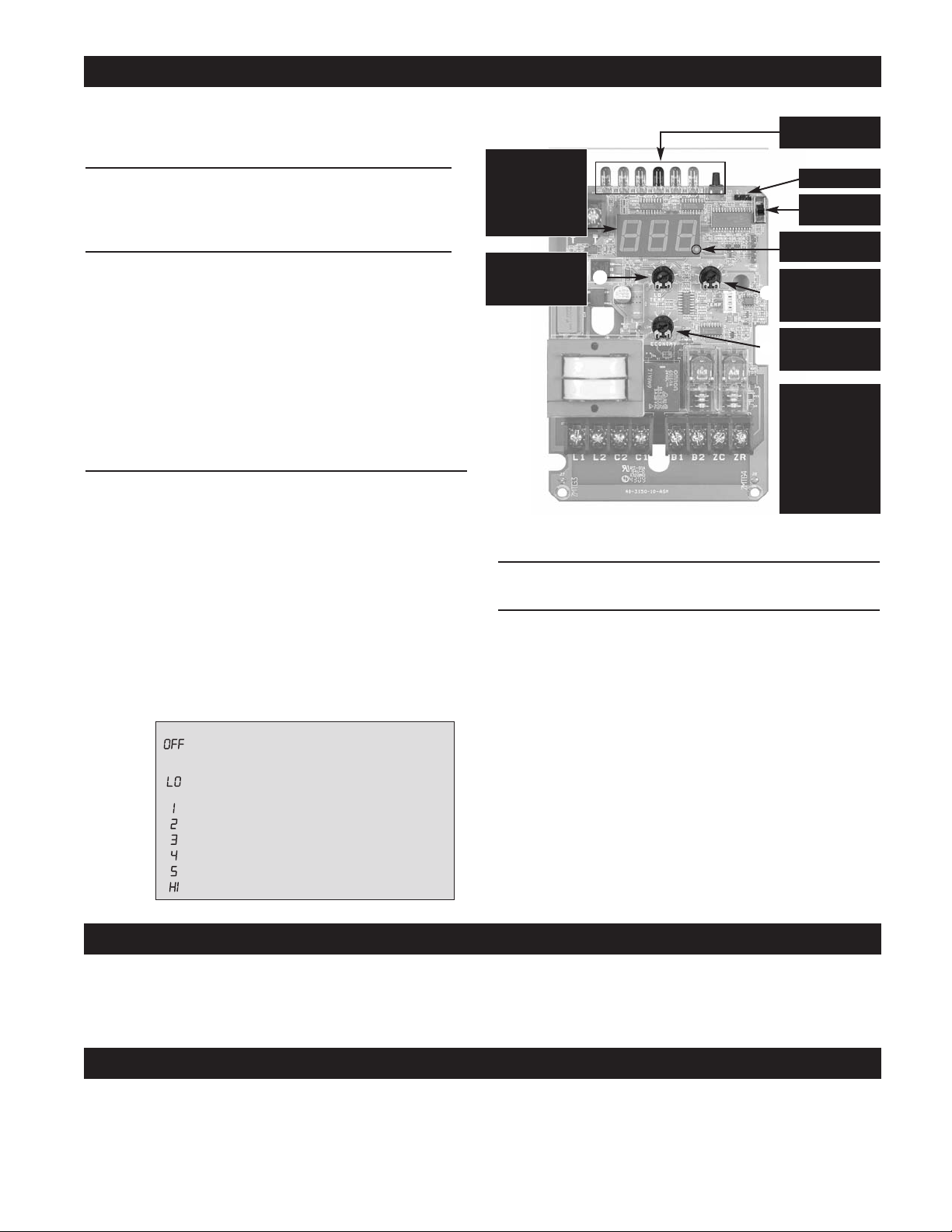

SETTING THE CONTROL

NOTE: Settings can be checked using the

TEST/SETTINGS Button. See page 8 for details.

Setting the High Limit

The high limit is factory set at 190°F. To adjust, turn the HI

TEMP Dial

until the desired setting is displayed.

(Setting range: 100°-220°F)

Setting the Low Limit

The low limit is designed to maintain temperature in boilers equipped with tankless coils used for domestic hot

water. The low limit is factory set to OFF. Prior to adjusting, remove the jumper (not equipped on all units)

Then turn the LO TEMP Dial

clockwise until the

.

desired temperature is displayed. For proper operation,

the low temperature limit setting should be at least 10°

below the high limit setting. NOTE: For cold start operation, the low limit must be turned OFF. IMPORTANT: If low

limit temperature cannot be set above 140°F, remove

jumper

. (Setting range: OFF or 110°-200°F).

Setting the Economy Feature

The Economy Feature is factory set for a 1 zone heating system. To adjust, turn the ECONOMY Dial

displayed equals the number of heating zones. Do not

include indirect water heaters in the number of heating

zones. The Economy Feature conserves fuel by reducing

boiler temperature (see “How Thermal Targeting Works”

below). If the heating system is unable to supply needed heat

to the house, the ECONOMY Dial should be turned to a lower

setting (example: In a three zone house, turn the dial to 2 or

1). Conversely, if the boiler provides adequate heat, added

fuel savings can be achieved by selecting a higher setting

(example: 4 or 5). If the heating and indirect water heater

signals were not separated when wiring the control, the

Economy Feature should be turned OFF to ensure the boiler

supplies

adequate

temperature to

heat the

indirect

tank.

SETTING

Disables economy function. Will allow boiler to fire until

hi-limit temp is reached and re-fire with a 10° subtractive

differential.

Provides lowest level of fuel savings. Use this setting only

if the house does not stay warm at higher settings.

Recommended setting for single zone systems

Recommended setting for Two zone systems

Recommended setting for Three zone systems

Recommended setting for Four zone systems

Recommended setting for Five zone systems

Provides highest level of fuel savings

until the number

D

iagnostic LEDs

and Test Button

Dynamic

Display

Water Temperature

and Real Time

Verification of

etting Adjustments.

S

Low Temperature

Limit Setting

(OFF or 110°-200°F)

Factory OFF

Jumper

Zone/Indirect

S

witch

Indicator Light

(announces heat

High Temperature

imit Setting

L

(100°-220°F)

actory 190°F

F

Economy Dial

(OFF or LO, 1, 2, 3,

4, 5, HI)

Differentials

are automatic

and will vary

based on

control settings

and boiler temperature.

Setting the Zone/Indirect Switch

See WIRING on page 4-6.

Activating Thermal Pre-Purge (optional)

NOTE: Activation of this feature is not

recommended for boilers with tankless coils.

Fuel Smart HydroStat has a Thermal Pre-Purge feature to

maximize efficiency. When activated, the control will purge

higher boiler temperatures down to 135° at the start of any

thermostat call and supply the latent energy in the boiler to the

heating zone that is calling. During the purge cycle, the display will indicate Pur. If the heat is not sufficient to satisfy the

thermostat, the control will energize the burner. This feature

works with single- and multi-zone heating systems utilizing circulators or zone valves. No change in wiring is needed.

To Activate Thermal Pre-Purge

Push and hold the TEST/SETTINGS button for 20 seconds.

The display will read Pur On. To deactivate the feature, push

and hold the button a second time for

20 seconds. The display will read Pur OFF.

call)

SYSTEM START-UP

At initial start up, with the Economy Feature active, the control establishes a 145°F target temperature. To test the high limit

shut-off function, the Economy Dial must be turned to OFF. Once tested, restore the Economy setting. If the heating demand is

high, the target will increase over time to satisfy the heat load. NOTE: To reduce the potential for condensing, the control

will allow the boiler to heat to 120°F prior to energizing the circulator.

HOW THERMAL TARGETING WORKS

Thermal Targeting technology analyzes thermostat activity and continually evaluate how much heat the house requires. When it

is very cold outside, the heat demand is high and the Fuel Smart HydroStat will raise the boilerʼs Target temperature to provide

needed heat to the home. When the outside temperature is milder, the heat demand is lower. During these periods, the Fuel

Smart HydroStat will lower the boilerʼs Target temperature – saving fuel – while continuing to provide comfort to the house.

7

Page 8

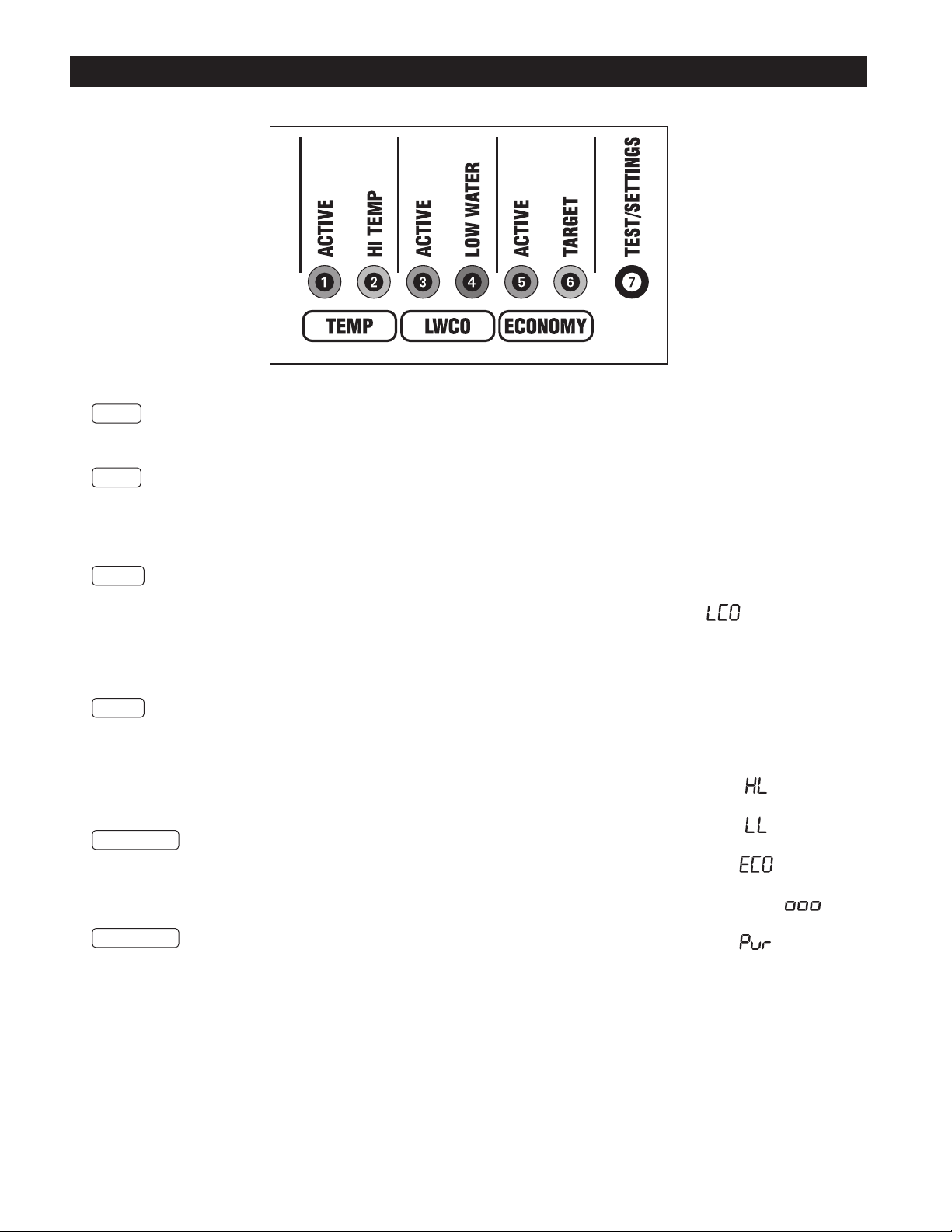

LED LEGEND and TEST/SETTINGS BUTTON

TEMP ACTIVE Indicates that the Fuel Smart

HydroStat control is powered and that the temperature

function is active.

TEMP HI TEMP Illuminates when the boiler water

temperature reaches the high limit setting. It will remain lit

until the water temperature falls 10°. The Fuel Smart

HydroStat prevents burner operation while this LED is on.

See Differential explanation on page 7.

LWCO ACTIVE Indicates that the low water cut-off

(LWCO) function of the Fuel Smart HydroStat is active. When

the control is installed with a Hydrolevel Electro-Well, this

LED will be on at all times when the control is powered.

IMPORTANT: If the control is installed with a well other than

the Electro-Well, this LED will not illuminate indicating that

the control is not providing low water cut-off functionality.

LWCO LOW WATER Illuminates if the boiler is in a

low water condition. The Fuel Smart HydroStat will prevent

burner operation during this condition. IMPORTANT: The

system must be checked by a qualified heating professional

prior to resuming operation.

WARNING: DO NOT ADD WATER UNTIL THE BOILER

HAS FULLY COOLED.

ECONOMY ACTIVE Indicates that the Thermal

Targeting function is active and the Fuel Smart HydroStat will

reduce boiler temperature to conserve fuel. The Economy

feature is activated using the ECONOMY dial. (See “How

Thermal Targeting Works” on page 7 for more information).

ECONOMY TARGET When the Economy feature is

active, the Fuel Smart HydroStat continually sets target

temperatures below the high limit setting to maximize fuel

efficiency. When the boiler water reaches the target

temperature, the LED illuminates and the burner will shut

down. The boiler water will continue to circulate and heat the

house as long as the thermostat call continues. The LED will

stay lit until the boiler temperature drops below the

differential set point at which point the boiler will be allowed

to fire again. See Differential explanation on page 7.

NOTE: This LED illuminates regularly during normal boiler

operation.

TEST/SETTINGS Button

To Test Low Water Cut-Off: Press and hold the Test/

Settings button for 5 seconds. The display will read LCO.

LWCO TEST

The red Low Water light should illuminate and the burner

circuit (B1 and B2) should de-energize. NOTE: The control

must be installed with a Hydrolevel Electro-Well for low water

cut-off functionality (see page 2 for more details).

To View Current Settings: Press and release the

Test/Settings Button in short intervals to sequentially display

the following settings:

HIGH LIMIT SETTING

00

00

LOW LIMIT SETTING

00

ECONOMY SETTING

000

CURRENT TARGET TEMPERATURE

PRE-PURGE SETTING

The display will return to boiler temperature (default) if

Test/Settings Button in not pressed for 5 seconds.

000

8

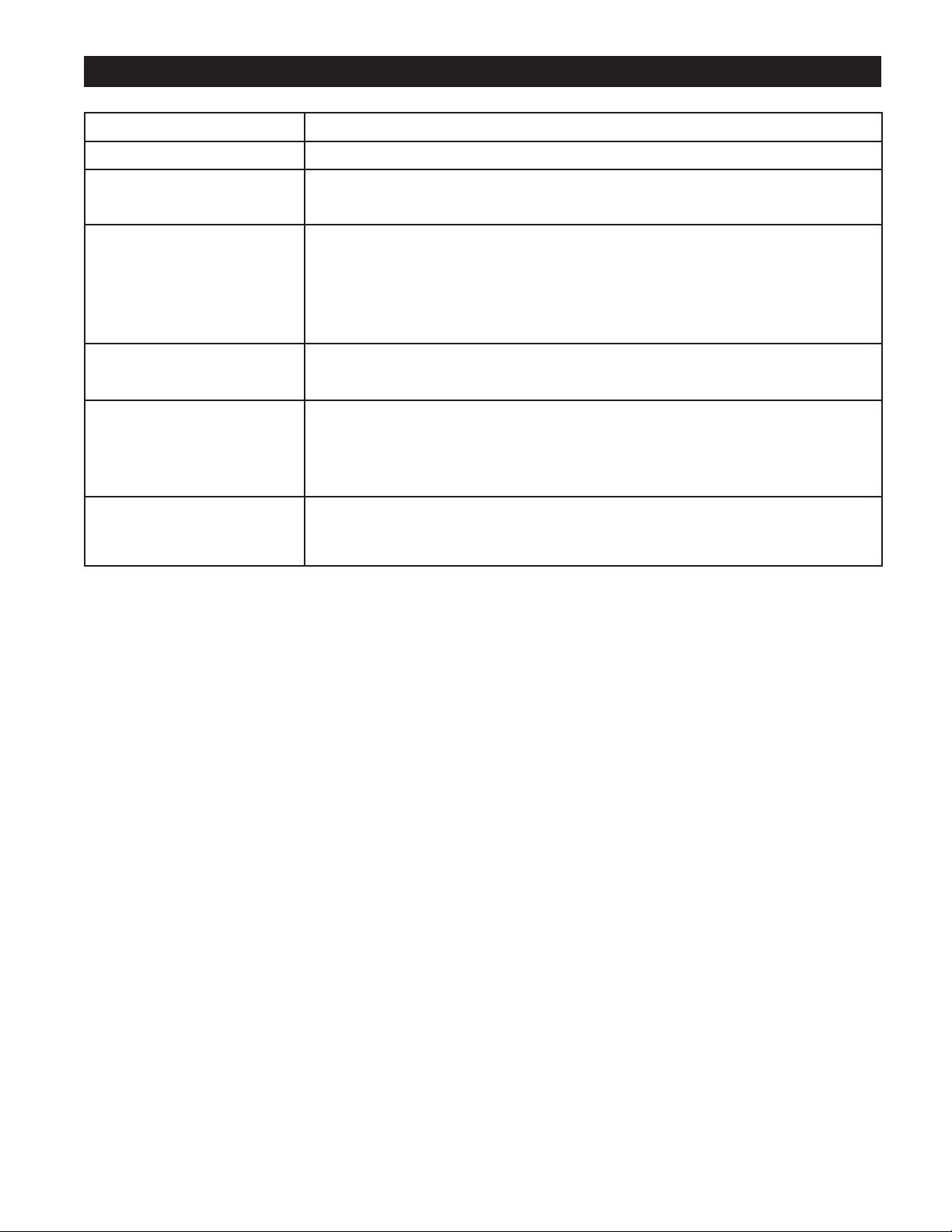

Page 9

TROUBLESHOOTING

Burner Will Not Fire See Flow Chart 1, page 10

Burner Will Not Shut Down See Flow Chart 2, page 11

nder normal operation, boiler temperature will continue to rise after the control shuts off

Temperature Display Exceeds

High Limit Setting

No or Insufficient

Domestic Hot Water

Boiler Will Not Maintain

Low Limit Temperature

House Will Not Get

or Stay Warm

U

the burner. This condition, known as “thermal stacking”, results from hot boiler surfaces

continuing to release heat into the boiler water.

or boilers equipped with a tankless coil, make sure the low limit setting on the HydroStat

F

is set properly. NOTE: If the low limit setting is dialed fully counter clockwise, it will shut

off the low temperature maintenance feature and will function as a cold start control. If

installed with an indirect water heater, check that the Zone/Indirect Switch is set in the

Indirect (I) position. Verify that the end switch in the relay box controlling the indirect water

heater is connected to the ZC-ZR terminals. This will ensure that the domestic water calls

are prioritized. (see “Heating and Indirect Water Heater” on page 4-6).

Check for overlapping high temperature setting. If the high limit setting is set below the

low limit setting, the control will default to the high limit setting and the corresponding

high limit differential setting.

1. Check for air-bound radiators. 2. Check thermostat settings including heat anticipator

settings (common on non-digital thermostats). 3. Check the Economy setting. The

Economy feature, much like outdoor reset controls, lowers average boiler temperature

and can slow or, in some cases, prevent the house from coming up to temperature.

Move to a lower setting (see “Setting the Economy Feature” on page 7).

Circulator Contacts

C1 and C2 Not Energized

on Call for Heat

Check to see that boiler water is at or above 120°F. On a call for heat, the control will not

permit the circulator to operate if the boiler water temperature is below 120°F.

9

Page 10

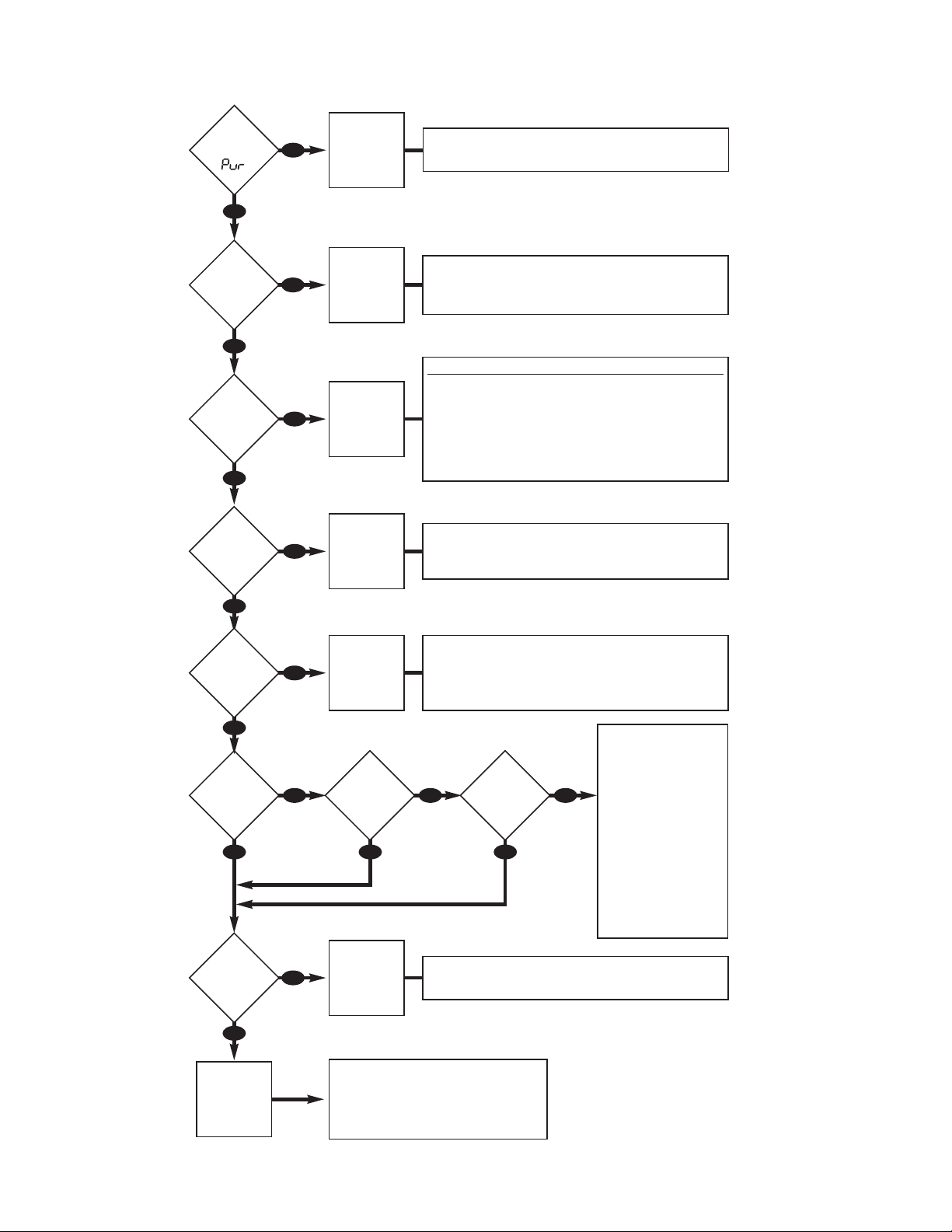

Troubleshooting Flow Chart 1 – Burner Will Not Fire

Does the

Display Read

?

O

N

Is the

Green LED

(TEMP ACTIVE)

O

n?

YES

I

s the

Red LED

(

LOW WATER)

On?

NO

Is the

Yellow LED

(HI TEMP)

On?

The Control is

Y

Heat from the

Purging Latent

ES

The Thermal Pre-Purge feature holds off the burner until the

c

irculator has purged the boiler temperature down to 135°F.

Boiler.

T

NO

The Control is

Not Powered.

he Temp Active LED will be on at all times when the control is

powered.

Check for 120 VAC on terminals L1 and L2.

CAUTION – ALWAYS ALLOW A BOILER TO COOL BEFORE ADDING WATER

The burner will not fire until the low water condition is satisfied.

The Control is

S

ES

Y

ensing

L

ow Water.

Check that the system is filled with water.

Check that the sensor is inserted correctly into well.

: The use of heat-conductive grease may interfere with the

NNoottee

contact between the spring clip and the copper well tube.

Check that the control is tightly clamped to the well.

The Control is

Sensing High

ES

Y

Temperature.

The burner will not fire until the boiler water has dropped to the

high limit differential set-point (10° below high limit setting).

Check that the high temperature setting is correct.

O

N

Is the

Yellow LED

(TARGET)

On?

O

N

Is the

Thermostat

(T-T) Calling

for Heat?

YES

Is There

120 VAC

Between B1

and B2?

NO

YES

YES

NO

The Boiler has

Reached the

Target

Temperature.

When the ECONOMY function is active, the control monitors heating

demand and establishes Target boiler temperatures below the high

limit setting to conserve fuel (see “How Thermal Targeting Works”

on page 7). The burner will not fire until the boiler temperature

drops to the automatically calculated Target Temp Differential.

Is the

External Zone

(ZC-ZR) Calling

NO

for Heat?

YES NO

The Control

is Operating

Properly.

HydroStat is supplying 120 VAC to the burner circuit.

Recheck wiring and operation of burner and other limit controls.

Is the

Low Limit Dial

Set to OFF?

When the low temperature

setting is set to OFF, the

HydroStat will act as a cold

start control. The burner

will not fire unless there is

YES

a call from the thermostat

(T-T) or an external zone

(ZC-ZR).

Set thermostat to call

for heat. Burner should

fire.

If the boiler has a tank-

less coil, set the Low

Temperature Limit to

maintain temperature.

Replace

Control

If both the red and yellow LEDs are off and

there is a call to fire the burner, there will be

120 VAC on terminals B1 and B2.

If 120 VAC is not present, the control should

be replaced.

10

Page 11

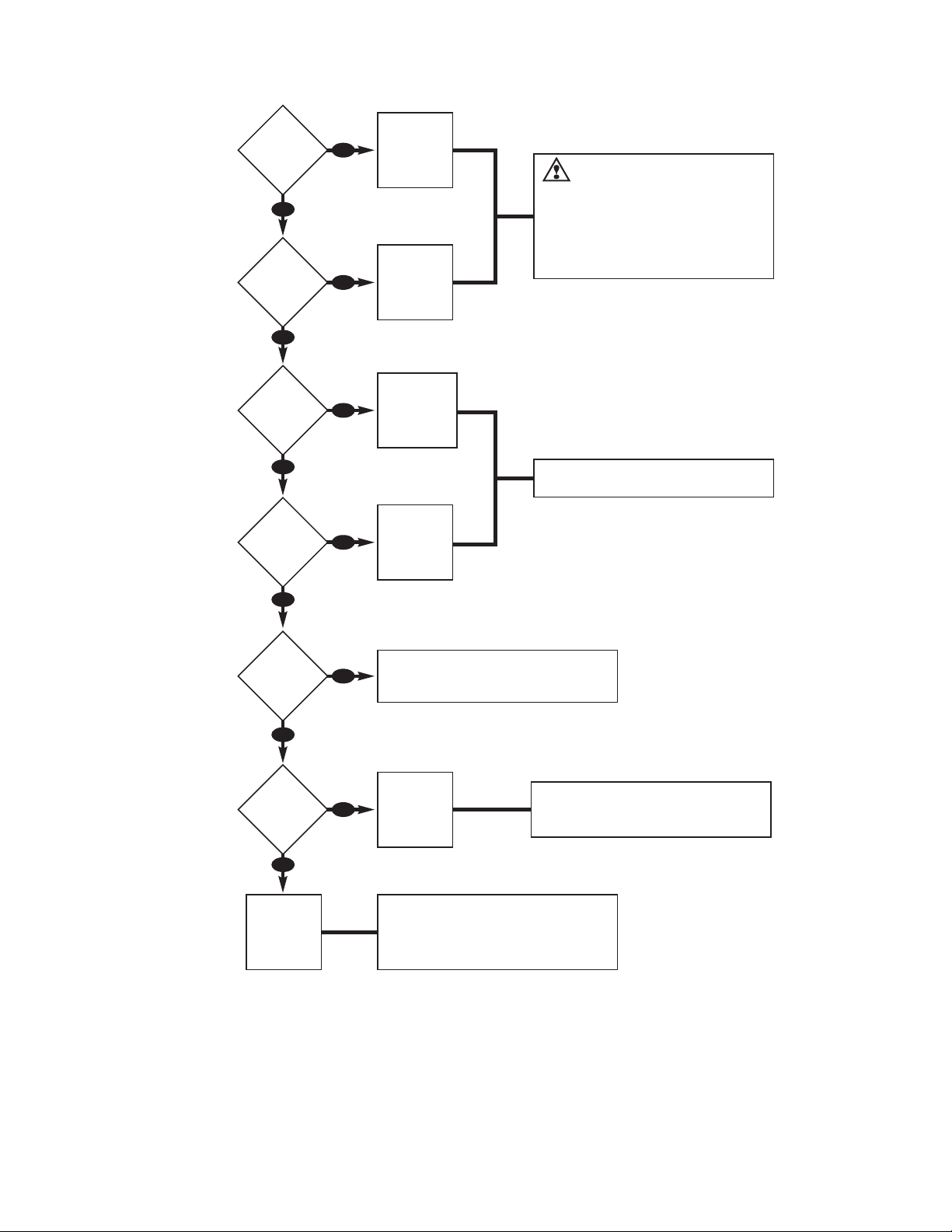

Troubleshooting Flow Chart 2 – Burner Will Not Shut Down

I

s the

Red LED

(LOW WATER)

On?

NO

Is either

Y

ellow LED

On?

O

N

Y

YES

ES

The Control is

S

ensing

Low Water.

T

he Control has

Reached Target

o

r High Limit

Temperature.

WARNING!

T

URN OFF POWER TO BURNER IMMEDIATELY!

C

AUTION – ALWAYS ALLOW A BOILER TO FULLY COOL

BEFORE ADDING WATER.

Recheck wiring. Make sure that burner is wired to

B1. Burner should never fire when red or yellow

LED is lit.

Is the

T

hermostat

(T-T) Calling

f

or Heat?

NO

Is the

External Zone

(ZC-ZR) Calling

for Heat?

NO

Is the

Low Limit Dial

Set to OFF?

YES

Is there

120 VAC between

B1 and B2?

YES

Y

NO

NO

The Control is

Operating

Normally.

The Control is

ES

Operating

Normally.

Check temperature display. When the Low Limit is

set, the HydroStat will fire the burner until the

temperature reaches the Low Limit Setting.

Recheck

Wiring.

The burner will continue to fire when there is a call

f

rom the thermostat or external zone.

When there is no call to fire the burner, the voltage

should be 0 volts between B1 and B2.

Make sure the burner is wired to B1.

YES

Replace

Control.

If there is no call for heat (from T-T, ZC-ZR or Low

Limit), there should be 0 VAC between B1-B2.

If there is voltage between B1-B2, the control

should be replaced.

11

Page 12

MAINTENANCE

Remove the Electro-Well from the heating system every five years and clean any scale or sediment deposits from all parts that are

exposed to the boiler water. After cleaning, reinstall the well using pipe sealing compound. Teflon tape is not recommended.

REMOTE MOUNTING KITS

Part No. Description

48-101 HydroStat Remote Mount Kit with 24" sensor

48-102 HydroStat Remote Mount Kit with 48" sensor

DIMENSIONSELECTRO-WELLS

Part No. Description

48-103 HydroStat Remote Mount Kit with 10' sensor

48-104 HydroStat Remote Mount Kit with 20' sensor

48-121 HydroStat Pipe Mounting Kit with 48" sensor

SPECIFICATIONS

Input voltage 120 VAC, 60 HZ

Burner contacts 7.4 FLA, 44.4 LRA@120 VAC

Circulator contacts 5.8 FLA, 34.8 LRA@120 VAC

Operating range – low limit Off or 110°F - 200°F (43°C - 93°C)

Operating range – high limit 100°F - 220°F (38°C - 104°C)

LIMITED MANUFACTURERʼS WARRANTY

We warrant products manufactured by Hydrolevel Company to be free from defects in

material and workmanship for a period of two years from the date of manufacture or

one year from the date of installation, whichever occurs first. In the event of any claim

under this warranty or otherwise with respect to our products which is made within

such period, we will, at our option, repair or replace such products or refund the purchase price paid to us by you for such products. In no event shall Hydrolevel Company

83 Water Street • New Haven, CT 06511 • Phone (203) 776-0473 • FAX (203) 773-1019 • www.hydrolevel.com

FUEL SMART HYDROSTAT MODEL 3250

be liable for any other loss or damage, whether direct, indirect, incidental or consequential. This warranty is your EXCLUSIVE remedy and shall be IN PLACE OF any other

warranty or guarantee, express or implied, including, without limitation, any warranty

of MERCHANTABILITY or fitness for a particular purpose. This warranty may not be

assigned or transferred and any unauthorized transfer or assignment thereof shall be

void and of no force or effect.

12

Loading...

Loading...