Page 1

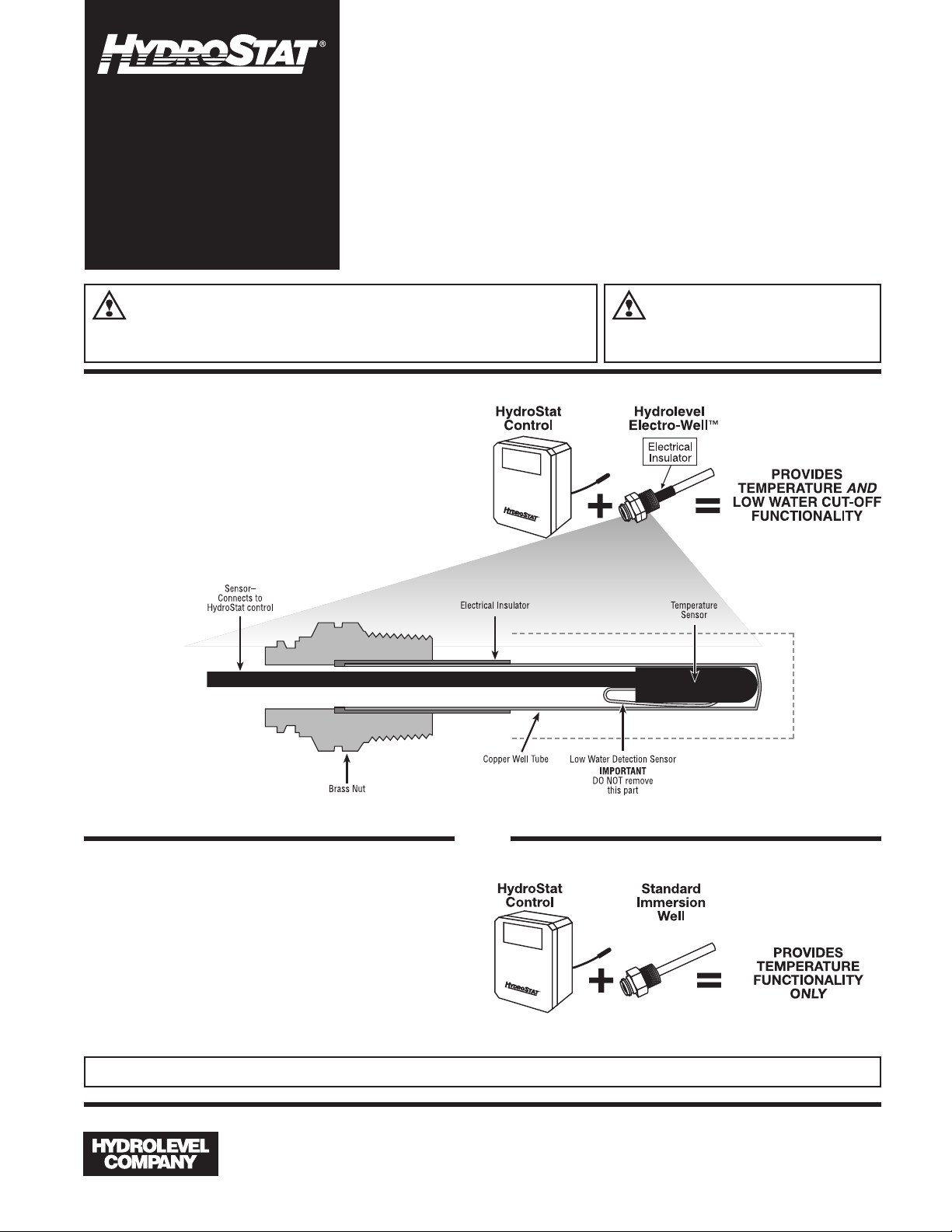

MODEL 3100

Combination Low Water

Cut-Off & Universal

Temperature Limit Control

for Gas Boilers

PATENTS PENDING

• Dual Function Design – HydroStat performs both high temperature limit and low

water cut-off functions when installed with a Hydrolevel Electro-Well™.

Replaces Common Aquastat

•

wells to replace both cold-start and triple-action Aquastats

*

odels – Can be installed on existing immersion

M

®

. Industry standard

wiring designations make change-outs quick and easy.

• Digital Display – Easy to read LED continually displays boiler temperature. Also

isplays temperature limit and differential settings during adjustment.

d

• Easy to Set – Dials for setting temperature limits and differentials eliminate

complicated programming.

Advanced Micro-Controller Design – Utilizes dual thermistor technology for

•

better accuracy, response and reliability.

*Aquastat is a registered trademark of Honeywell International, Inc.

•

Electrical shock hazard. To prevent electrical shock, death or

WARNING

installing or servicing control. Only qualified personnel may install or service this control in

accordance with local codes and ordinances. Read instructions completely before proceeding.

quipment damage, disconnect power supply before

e

HydroStat installed

with Electro-Well™

When installed with the Hydrolevel Electro-Well,

HydroStat will provide

cut-off functionality. If the control was supplied by the

boiler manufacturer, it was installed with an ElectroWell. The Electro-Well is available separately for field

installations. See Electro-Well models on page 8.

both

temperature and low water

/2" CLEARANCE

1

/2" CLEARANCE

1

To prevent serious

CAUTION

should be thoroughly cooled before installing or

servicing control.

urns, boiler

b

IIMMPPOORRTTAANNTT::

For proper operation of the low

water cut-off function, there must

be a minimum of

½" clearance

between the cop-

1/2" CLEARANCE

per well tube and

any surface within

the boiler.

OR

HydroStat installed with

a standard immersion well

For field replacement of common Aquastat®models,

HydroStat can be installed with the immersion well

already on the boiler. In this configuration, HydroStat

will provide the temperature functionality of the control

being replaced, but will not provide low water cut-off

functionality. The “LWCO Active” LED will not illuminate.

IMPORTANT When installed on a standard immersion well, HydroStat will not provide low water cut-off functionality.

83 Water Street • New Haven, CT 06511 • Phone (203) 776-0473 • FAX (203) 773-1019 • www.hydrolevel.com

1

Page 2

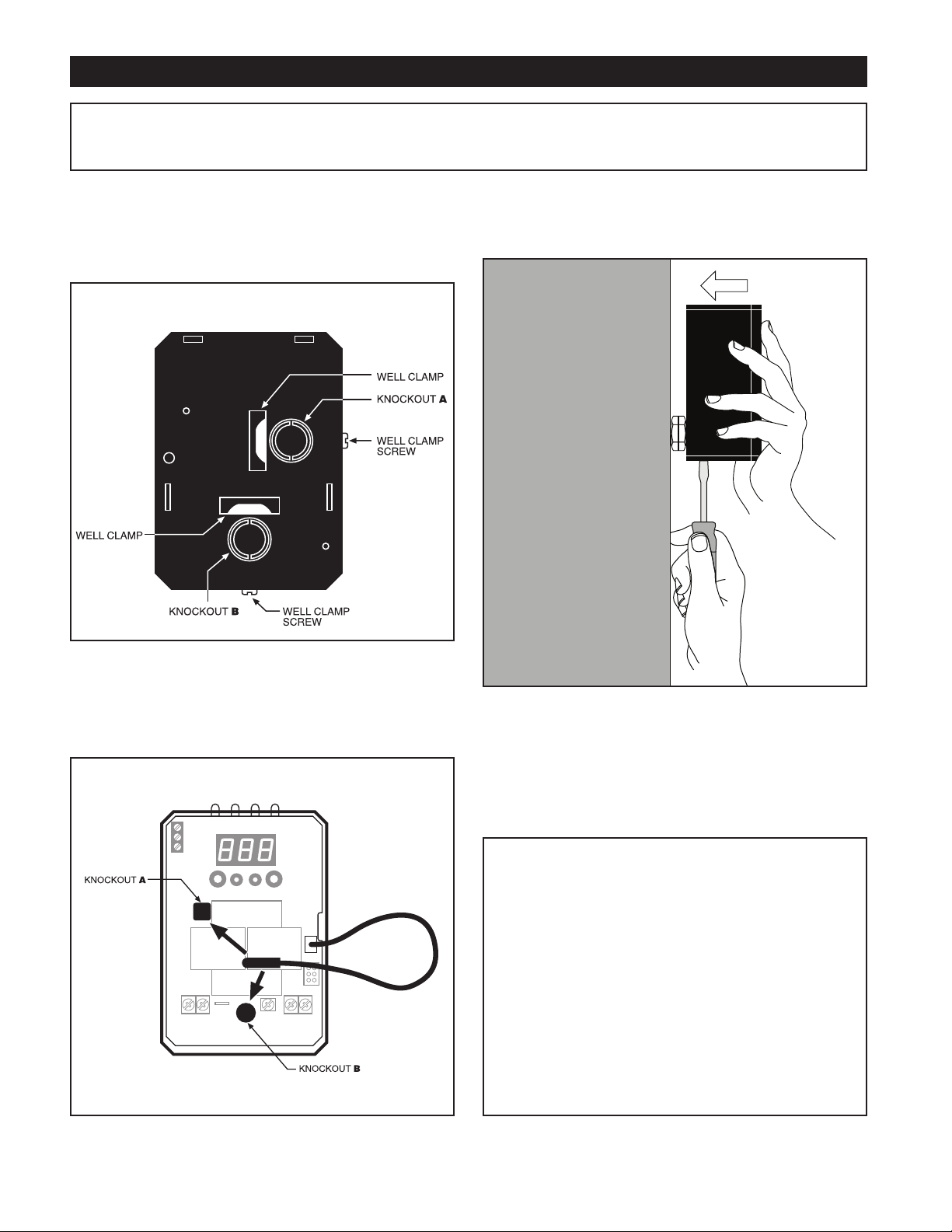

MOUNTING THE CONTROL

IMPORTANT Make sure that the immersion well or Electro-Well™ is installed on the boiler manufacturerʼs

designated temperature limit control tapping. Note: If installing an Electro-Well, pipe sealing compound should be

used. Teflon tape is not recommended.

STEP 1

back of the control (Fig. 1). Select which of the two positions

(2 knockouts) is best for the location of the control. Remove

he knockout.

t

FIG. 1

Two mounting positions are available on the

BACK OF HYDROSTAT BOX

STEP 2 Place control on the well. While holding box

against well nut, tighten well clamp screw. (Fig. 2)

STEP 3 Insert sensor ALL THE WAY into well through

the knockout (A or B) you have chosen. (Fig. 3)

FIG. 3

FIG. 2

NOTE: In the case of space restrictions, the HydroStat control may be mounted in a horizontal orientation without any

loss of function. Hydrolevel recommends vertical mounting,

when possible, for proper orientation of LED display.

REMOTE MOUNTING

The following kits are available separately for mounting

the HydroStat control box in a remote location. Each kit

includes mounting hardware and a remote sensor.

Part No. Description

48-101 Wall/Jacket Mounting Kit with 2' sensor cord

48-102 Wall/Jacket Mounting Kit with 4' sensor cord

48-103 Wall/Jacket Mounting Kit with 10' sensor cord

48-104 Wall/Jacket Mounting Kit with 20' sensor cord

48-121 Pipe Mounting Kit with 4' sensor cord

2

Page 3

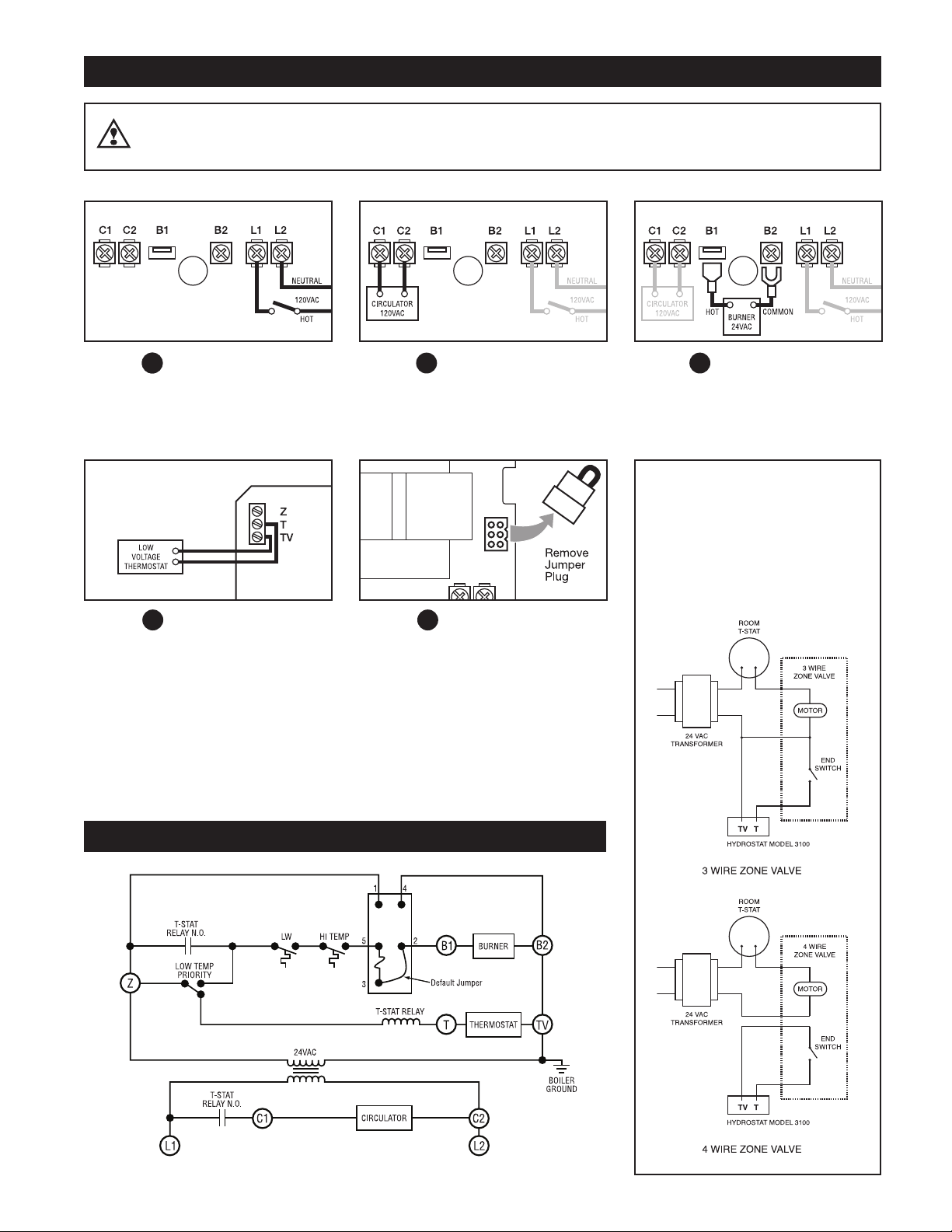

WIRING

WARNING

STEP 1

to terminal L1. Connect 120 VAC

Neutral to terminal L2. Disconnect

means and overload protection as

required (provided by others).

Connect 120 VAC Hot

Electrical shock hazard. To prevent electrical shock, death or equipment damage, disconnect power supply before

installing or servicing this control.

STEP 4 Connect wires from Low

Voltage Thermostat to T and TV.

STEP 2 Connect the circulator to

C1 and C2 (C2 is neutral).

STEP 5 If the boiler is equipped

with a plug-in style vent damper,

unplug the factory installed jumper

from the receptacle on the circuit board

and replace it with the vent damper

plug. NOTE: Once a vent damper plug

is connected to the HydroStat, the control is permanently altered and will no

longer function when the vent damper

plug is disconnected.

STEP 3 Connect wire from 24

VAC Burner Circuit to B1(quick connect). Connect wire from 24 VAC

Burner Circuit common to B2 (fork).

ZONE VALVE WIRING

MPORTANT: Use a separate transformer to

I

power zone valves. Connecting zone valves to

Z-TV may overload the HydroStat and cause a

lock-out condition (see

for more information). The total load, including the

burner circuit, vent damper, and Z-TV connections

must not exceed 1.2 amps (30 VA). Connect zone

valve end-switch to T-TV as shown below.

Troubleshooting

on page 6

SCHEMATIC/LADDER DIAGRAM

3

Page 4

SETTING THE CONTROL

WARM START

(maintains temperature for domestic hot water)

Low Limit Switch = ON

COLD START

Low Limit Switch = OFF

Example

High Limit = 180°

Differential = 10°

On a call for heat, the burner will

shut off at 180° and restart at

170° (180°-10°). The circulator

will run as long as there is a call

for heat.

High Temperature Limit

(Adjustable 100° to 220°F)

De-energizes burner at HIGH

LIMIT setting

High Temperature Limit

(Adjustable 100° to 220°F)

De-energizes burner at HIGH

LIMIT setting

High Temperature

Differential

(Adjustable 10° to 30°F)

Re-energizes burner when

temperature falls to the HIGH

LIMIT DIFFERENTIAL set point

High Temperature

Differential

(Adjustable 10° to 30°F)

Re-energizes burner when

temperature falls to the HIGH

LIMIT DIFFERENTIAL set point

Low Temperature Limit

(Adjustable 110° to 200°F)

De-energizes burner at LOW

LIMIT setting

Low Temperature

Differential

(Adjustable 10° to 30°F)

Re-energizes burner when

temperature falls to the LOW

LIMIT DIFFERENTIAL set point

Example

High Limit = 180°

Differential = 10°

On a call for heat, the burner will

shut off at 180° and restart at

170° (180°-10°). The circulator

will run as long as there is a call

for heat.

Example

Low Limit = 150°

Differential = 10°

When there is no call for heat,

the burner fires at 140°

(150°-10°) to maintain boiler

temperature. Burner shuts off

at 150°.

NOTE: To prioritize domestic hot

water the HydroStat control will

not allow the c irculator to

operate at any time the

temperature is below the low

limit setting.

Dynamic

Display

ater Temperature

W

and Real Time

Verification of

etting Adjustments.

S

All Settings are

Displayed Every

ime Control is

T

Powered Up

Low Temperature

Limit Setting

OFF or 110°-200°F)

(

actory OFF

F

ow Temperature

L

Differential Setting

(10°-30°F)

Factory 10°F

iagnostic LEDs

D

High Temperature

Limit Setting

100°-220°F)

(

actory 190°F

F

igh Temperature

H

Differential Setting

(10°-30°F)

Factory 10°F

NOTE: Be careful not to select overlapping temperature settings.

For example: If the HIGH TEMPERATURE LIMIT is set at

190°F with a HIGH TEMPERATURE DIFFERENTIAL set at 20°F,

then the LOW TEMPERATURE LIMIT needs to be set at 170°F

(190°F - 20°F = 170°F) or below.

IMPORTANT: To prevent flue gas condensation and reduce fatigue

caused by thermal cycling on conventional (non-condensing) boilers,

both HIGH and LOW LIMIT set points should be 150°F or above

(Limit Setting - Differential Setting ≥ 150°F). Boiler manufacturerʼs

temperature requirements supercede these recommendations.

To set COLD START operation

Operates on call for heat only.

Low Temperature Limit

Make sure Low Temperature Limit is turned fully counterclockwise (OFF position).

Low Temperature Differential

No change is required.

High Temperature Limit

factory setting = 190°F)

(

Adjust setting until desired temperature is displayed.

High Temperature Differential

factory setting = 10°F)

(

Using a small screwdriver, adjust setting until desired differential is displayed.

To set WARM START operation

Maintains temperature for domestic hot water.

Low Temperature Limit

Adjust setting until desired temperature is displayed.

Low Temperature Differential

Using a small screwdriver, adjust setting until desired differential is displayed.

High Temperature Limit

(factory setting = 190°F)

Adjust setting until desired temperature is displayed.

High Temperature Differential

(factory setting = 10°F)

Using a small screwdriver, adjust setting until desired differential is displayed.

OPERATION

4

Page 5

LED LEGEND

remain lit until the water temperature

falls below the high limit setting less

the differential setting. The HydroStat

control will prevent burner operation

while this LED is on.

NOTE: This LED illuminates regularly

during normal boiler operation.

LWCO ACTIVE Indicates that

the low water cut-off (LWCO) function

TEMP ACTIVE Indicates that

he HydroStat control is powered and

t

that the temperature function is active.

TEMP HIGH TEMP Illuminates

when the boiler water temperature

reaches the high limit setting. It will

of the HydroStat control is active.

When the control is installed with a

ydrolevel Electro-Well, this LED will

H

be on at all times when the control is

powered.

NOTE: If the control was installed with

a well other than the Electro-Well, this

TROUBLESHOOTING

Burner Will Not Fire See Flow Chart 1, page 6

Burner Will Not Shut Down See Flow Chart 2, page 7

Temperature Display Exceeds

High Limit Setting

Under normal operation, boiler temperature will continue to rise after the control shuts off

the burner. This condition, known as “thermal stacking”, results from hot boiler surfaces

continuing to release heat into the boiler water.

LED will not illuminate. This indicates

that the control is providing

temperature function only.

LWCO LOW WATER Indicates

that the boiler is in a low water

condition. The HydroStat control will

revent burner operation during this

p

condition.

IMPORTANT:

The system must be checked by a

qualified heating professional prior to

esuming operation.

r

WARNING: ALLOW THE BOILER TO

FULLY COOL BEFORE ADDING

WATER.

Red Light on Circuit Board

is Flashing

No Domestic Hot Water

Boiler Will Not Maintain

Low Limit Temperature

Temperature Display

Differs from Boiler

T&P Gauge Temperature

Reading

LWCO “Active” Light

(Green LED) Is Not On

Low Water Light

(Red LED) Is On

The red light to the left of the temperature display will flash if the transformer has been

overloaded. (See top portion of troubleshooting flow chart on page 6.)

If the boiler is equipped with a tankless coil, make sure the low limit setting on the

HydroStat is set properly. NOTE: If the low limit setting is dialed fully counter clockwise, it

will shut off the low temperature maintenance feature.

Check for overlapping high temperature setting. If the high limit setting is set below the

low limit setting, the control will default to the high limit setting and the corresponding

high limit differential setting.

Temperature variances can result from differing water temperatures within the boiler or

different reaction times of the two devices. If the HydroStat temperature is significantly

below the T&P gauge temperature, make sure the thermistor is inserted all the way to

the end of the well. If installed in an existing conventional well, check that hardened heat

conducting grease has not impeded the insertion of the thermistor. Clean or replace the

well to ensure proper insertion of the sensor.

When Installed on Standard Immersion Well: This is a normal condition. The control

will provide temperature functionality only. The HydroStat must be installed on a

Hydrolevel Electro-Well for low water cut-off functionality.

When Installed on a Hydrolevel Electro-Well: The control is detecting unusually high

conductivity. Check for minimum ½" clearance between the copper well tube and any

surface within the boiler.

WARNING: A low water condition is a serious and potentially dangerous condition. Do

not attempt to add water to a hot boiler. Allow the boiler to fully cool before adding water.

1. If the heating system is filled with water, pull the sensor out of the well and inspect it.

Make sure that the metal clip on the sensor is intact. This metal clip must be in contact

with the inside of the copper well in order for the control to sense the presence of

water. Check that the well does not have excessive build-up of heat transfer grease

that may interfere with clip contacting the well.

2. Remove well and examine for excessive residue build-up. Clean and re-install.

5

Page 6

Troubleshooting Flow Chart 1 – Burner Will Not Fire

The burner will not fire until overload condition is corrected.

Is the

Red LED on

the Circuit Board

lashing?

f

NO

YES

The Load on

he Transformer

t

Exceeds 30 VA.

Recheck wiring – Terminal TV is electrically connected to boiler

ground. If wiring to TV & Z is reversed, there could be a short

across the transformer.

Make sure that the total load, including the burner circuit, vent

damper and Z & TV connections does not exceed 30 VA.

Is the

reen LED

G

(TEMP ACTIVE)

On?

YES

Is the

Red LED

On?

NO

Is the

Yellow LED

On?

N

O

Is the

Thermostat

(T-TV) Calling

for Heat?

YES

NO

YES

YES

NO

The Control is

Not Powered.

The Control is

Sensing

Low Water.

The Control is

Sensing High

Temperature.

Is the

Low Limit Dial

Set to OFF?

NO

he Temp Active LED will be on at all times when the control is

T

powered.

Check for 120 VAC on terminals L1 and L2.

CAUTION – ALWAYS ALLOW A BOILER TO COOL BEFORE ADDING WATER

The burner will not fire until the low water condition is satisfied.

Check that the system is filled with water.

Check that the sensor is inserted correctly into well.

Note: The use of heat-conductive grease may interfere with the

contact between the spring clip and the copper well tube.

Check that the control is tightly clamped to the well.

The burner will not fire until the boiler water has dropped to the

high limit differential set-point. See HydroStat Settings chart.

Check that the high temperature setting is correct.

When the low temperature

setting is set to OFF, the

HydroStat will act as a cold

YES

start control. The burner will

not fire unless there is a call

from the thermostat (T-TV).

Set thermostat to call for

heat. Burner should fire.

If the boiler has a tank-

less coil, set the Low

Temperature Limit to

maintain temperature.

Is There

24 VAC

Between B1

and B2?

NO

Replace

Control

YES

The Control

is Operating

Properly.

HydroStat is supplying 24 VAC to the burner circuit.

Recheck wiring and operation of burner and other limit controls.

If both the red and yellow LEDs are off and

there is a call to fire the burner, there will be

24 VAC on terminals B1 and B2.

If 24 VAC is not present, the control should

be replaced.

6

Page 7

Troubleshooting Flow Chart 2 – Burner Will Not Shut Down

s the

I

Red LED

n?

O

NO

Is the

Yellow LED

On?

NO

Is the

hermostat

T

(T-TV) Calling

for Heat?

NO

Is the

Low Limit Dial

Set to OFF?

YES

YES

Y

N

he Control is

T

Sensing

ow Water.

L

The Control is

Sensing High

Temperature.

The Control is

ES

Operating

Normally.

Check temperature display. When the Low Limit is

O

set, the HydroStat will fire the burner until the

temperature reaches the Low Limit Setting.

WARNING!

URN OFF POWER TO BURNER IMMEDIATELY!

T

CAUTION – ALWAYS ALLOW A BOILER TO FULLY COOL

BEFORE ADDING WATER.

Recheck wiring. Make sure that burner is wired to

1. Burner should never fire when red or yellow

B

LED is lit.

The burner will continue to fire when there is a call

from the thermostat.

YES

Is there

24 VAC between

B1 and B2?

YES

Replace

Control.

NO

Recheck

Wiring.

When there is no call to fire the burner, the voltage

should be 0 volts between B1 and B2.

Make sure the burner is wired to B1.

If there is no call for heat (from T-TV or Low Limit),

there should be 0 VAC between B1-B2.

If there is voltage between B1-B2, the control

should be replaced.

7

Page 8

LOW WATER CUT-OFF TEST PROCEDURE

HydroStatʼs low water cut-off function is active when the control is installed on a Hydrolevel Electro-Well. To test the low water

cut-off function:

to simulate a low water condition.

should not fire.

ACTIVE light should illuminate and the burner should

NOTE: Do not remove the sensor from the well while the control is powered.

Turn OFF power to the control.Set the thermostat to call for heat.Gently slide the sensor out of the well

Turn ON power to the control. The red LOW WATER light should come on and the burner

Turn OFF power again and reinstall the sensor in the well.Turn ON power to the control. The green LWCO

fire.

MAINTENANCE

Remove the Electro-Well from the heating system every five years and clean any scale or sediment deposits from all parts that

are exposed to the boiler water. After cleaning, reinstall the well using pipe sealing compound. Teflon tape is not recommended.

ELECTRO-WELLS

DIMENSIONS

SPECIFICATIONS

Input voltage 120 VAC, 60 HZ

Burner contacts 30 VA@24 VAC

Circulator contacts 5.8 FLA, 34.8 LRA@120 VAC

Operating range – low limit Off or 110°F - 200°F

Operating range – high limit 100°F - 220°F

Operating range – differential 10°F - 30°F

HYDROSTAT MODEL 3100

LIMITED MANUFACTURERʼS WARRANTY

We warrant products manufactured by Hydrolevel Company to be free from defects in

material and workmanship for a period of two years from the date of manufacture or

one year from the date of installation, whichever occurs first. In the event of any claim

under this warranty or otherwise with respect to our products which is made within

such period, we will, at our option, repair or replace such products or refund the purchase price paid to us by you for such products. In no event shall Hydrolevel Company

83 Water Street • New Haven, CT 06511 • Phone (203) 776-0473 • FAX (203) 773-1019 • www.hydrolevel.com

be liable for any other loss or damage, whether direct, indirect, incidental or consequential. This warranty is your EXCLUSIVE remedy and shall be IN PLACE OF any other

warranty or guarantee, express or implied, including, without limitation, any warranty

of MERCHANTABILITY or fitness for a particular purpose. This warranty may not be

assigned or transferred and any unauthorized transfer or assignment thereof shall be

void and of no force or effect.

8

Loading...

Loading...