Hydrolevel 270SV User Manual

Model 270SV

High Water Limit

120 VAC Operating Voltage

utomatically interrupts pump or feeder when water contacts probe

A

rovides contacts for optional alarm

P

deal for boilers, receiver tanks and process applications.

I

ow maintenance — no moving parts to wear, stick or hang-up

L

Heavy-duty electro-mechanical design for long life

WARNING: To prevent

electrical shock or equip-

ment damage, power must

be off during installation or servicing

of the control. To prevent serious

burns, the boiler should be thoroughly cooled before installing or servicing control. Only qualified personnel

may install or service the control in

accordance with local codes and

ordinances. Read instructions completely before proceeding.

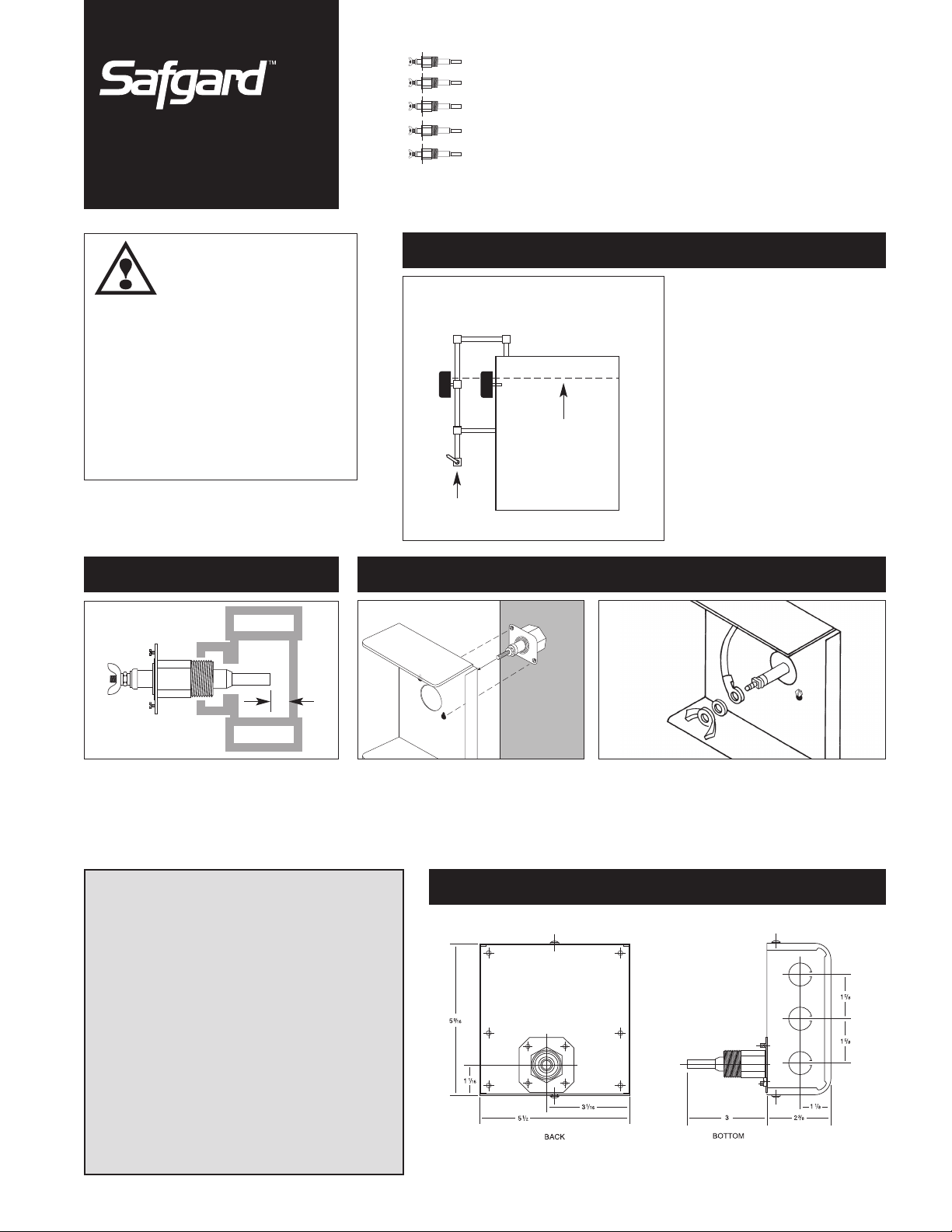

2. Probe Installation

1/4"

1. Where To Install

BOILER OR TANK

INSTALLATION

R

O

HIGHEST

PERMISSABLE

WATER LEVEL

LOWDOWN

B

VALVE

3. Control Mounting

The 3/4" NPTprobe must be installed

at a location just below the highest

permissable water level. The probe may

be installed in any metal tank, boiler, or

equalizing line. When installed in an

equalizing line, a proper blowdown

valve should be installed for regular

maintenance.

IMPORTANT: To assure proper

drainage, pipe diameter should be no

less than 1" on installations in vertical

piping.

Check to insure 1/4" clearance from the probe to

any surface inside the boiler, tank or tee. Apply

pipe sealing compound to threads.

Note: Use of Teflon tape is not recommended.

LIMITED

MANUFACTURERʼS WARRANTY

We wa rra nt pro duc ts man ufa ctu red by Hy dro lev el

Company to be free from defects in material and workmanship for a period of two years from the date of manufacture or one year from the date of installation, whichever occurs first. In the event of any claim under this warranty or otherwise with respect to our products which is

made within such period, we will, at our option, repair or

replace such products or refund the purchase price paid

to us by yo u for s uch prod u cts. In no ev ent shal l

Hydrolevel Company be liable for any other loss or damage, whether direct, indirect, incidental or consequential.

This warranty is your EXCLUSIVE remedy and shall be IN

PLACE OF any other warranty or guarantee, express or

implied, including, without limitation, any warranty of

MERCHANTABILITY or fitness for a particular purpose.

This warranty may not be assigned or transferred and any

unauthorized transfer or assignment thereof shall be void

and of no force or effect.

Remove the control cover and slide keyhole slots over probe mounting screws

and tighten screws (with either a 1/4" hex

head driver or flat screwdriver).

Dimensions

Connect the ring terminal wire lead to the probe terminal stud and secure with the lock washer and wing nut

provided. With the power removed, proceed with

installation and wiring described on next page.

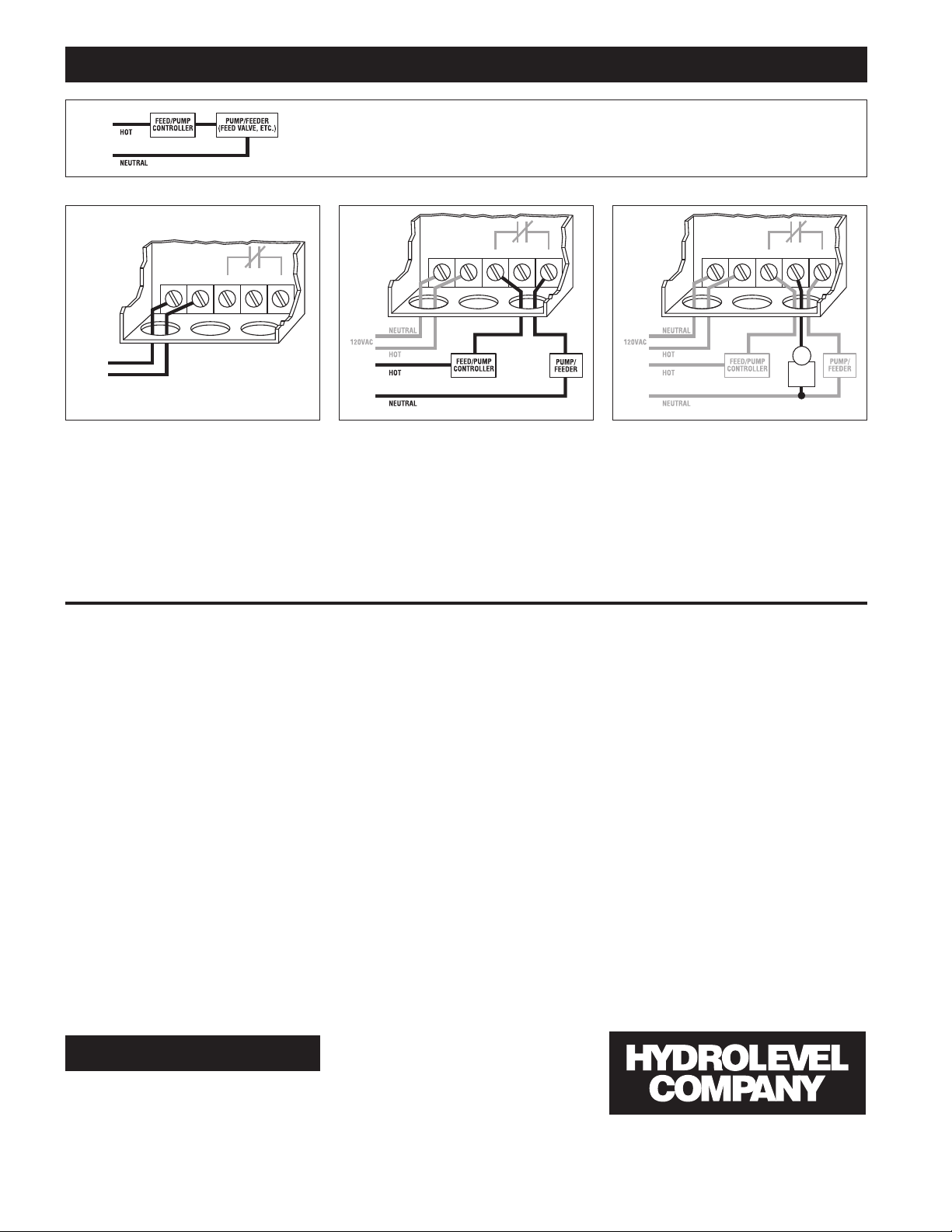

4. Wiring

TYPICAL WATER FEED CONTROL CIRCUIT

he Safgard 270SV High Limit wires in series with the system’s water

T

feed circuit.

STEP 1

Connect the hot lead of input voltage

(120 VAC, 60 Hz) to terminal H and the

neutral lead to terminal GN.

STEP 2

Connect the Feed/Pump Controller to

terminal C. Connect the Pump/Feeder to

terminal NC. When water reaches the

High Limit, contacts C-NC will open,

interrupting power to the Pump/Feeder.

Important: If the current of the Pump/

Feeder exceeds 15 amps, a suitable

relay/starter should be installed.

STEP 3

Optional High Water Alarm

Select an alarm with the same operating

voltage as the Pump/Feeder. Connect the

hot lead of the alarm to terminal NO.

Connect the neutral lead to the Feed circuit neutral. When water reaches the

High Limit, contact C-NO will close,

powering the alarm.

MAINTENANCE

Remove and inspect probe annually. Clean any sediment or scale from the probe using a scouring pad or steel wool.

TROUBLE SHOOTING

IF THE PUMP DOES NOT OPERATE

1. Using a voltage meter, isolate the problem to determine if the 270SV High Limit Control is breaking the circuit.

2. Check to insure that the water level is below the probe and that the tee is not collecting water which could be sensed

by the probe.

3. Remove power and recheck wiring.

4. Remove power and check for adequate clearance from the probe to any surface inside the boiler or tee.

IF THE PUMP DOES NOT SHUT DOWN WHEN WATER REACHES THE HIGH LIMIT

1. Make sure that the high water level is in contact with the probe.

2. Ensure that the probe lead wire is fastened securely.

3. Check for proper ground between the probe and the boiler shell or tee. Excessive use of Teflon tape or sealing compound may

insulate the probe from ground.

4. Recheck wiring and test for correct incoming voltage.

Specifications

MAXIMUM PRESSURE: 250 PSI

INPUT VOLTAGE: 120 VAC, 60 HZ

SWITCH RATINGS: .25 hp @ 120 VAC

RESISTIVE LOAD: 20 A

SWITCH CONTACTS: SPDT

P.O. Box 1847

New Haven, CT 06508

Phone: (203) 776-0473

FAX: (203) 773-1019

45-2700

Loading...

Loading...